Ignition wire SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

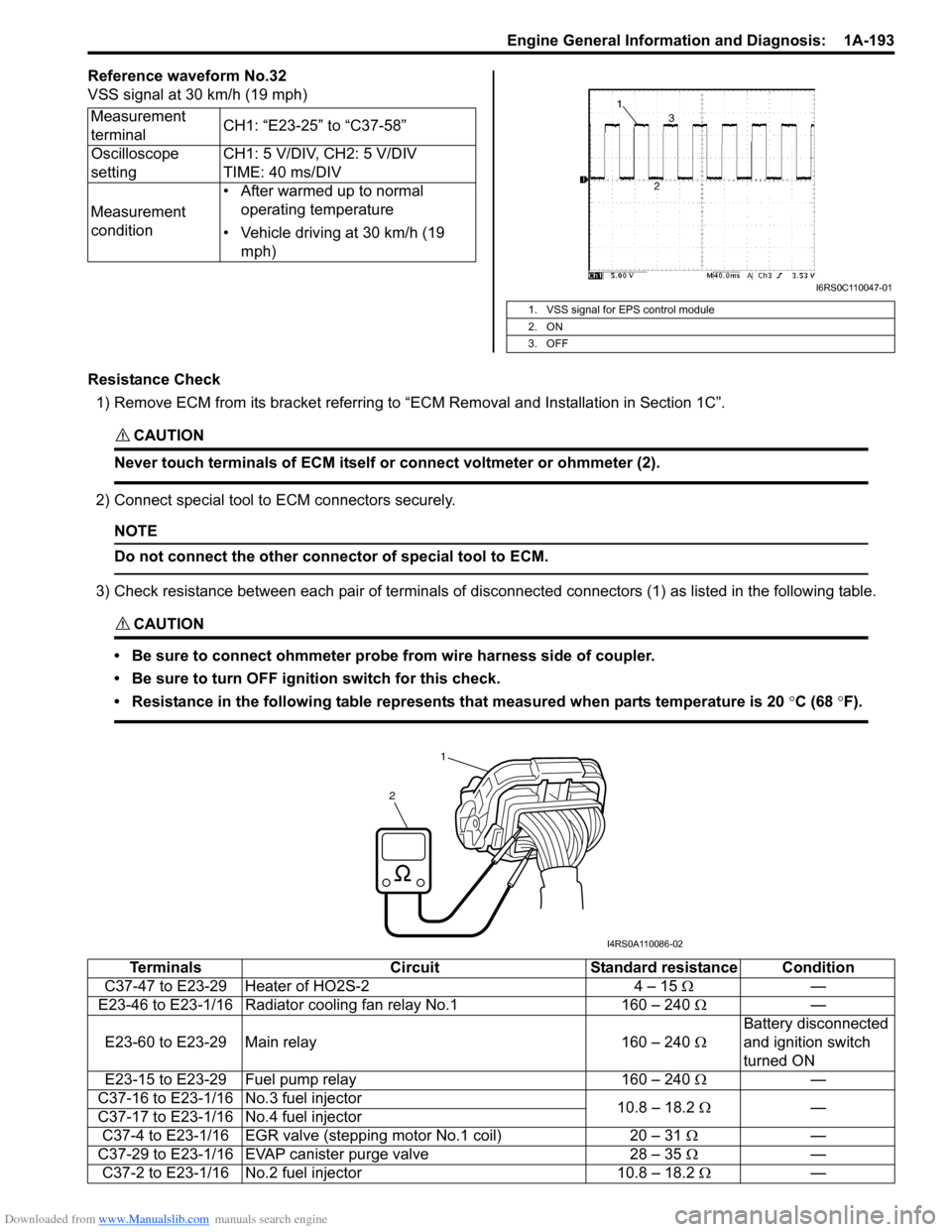

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

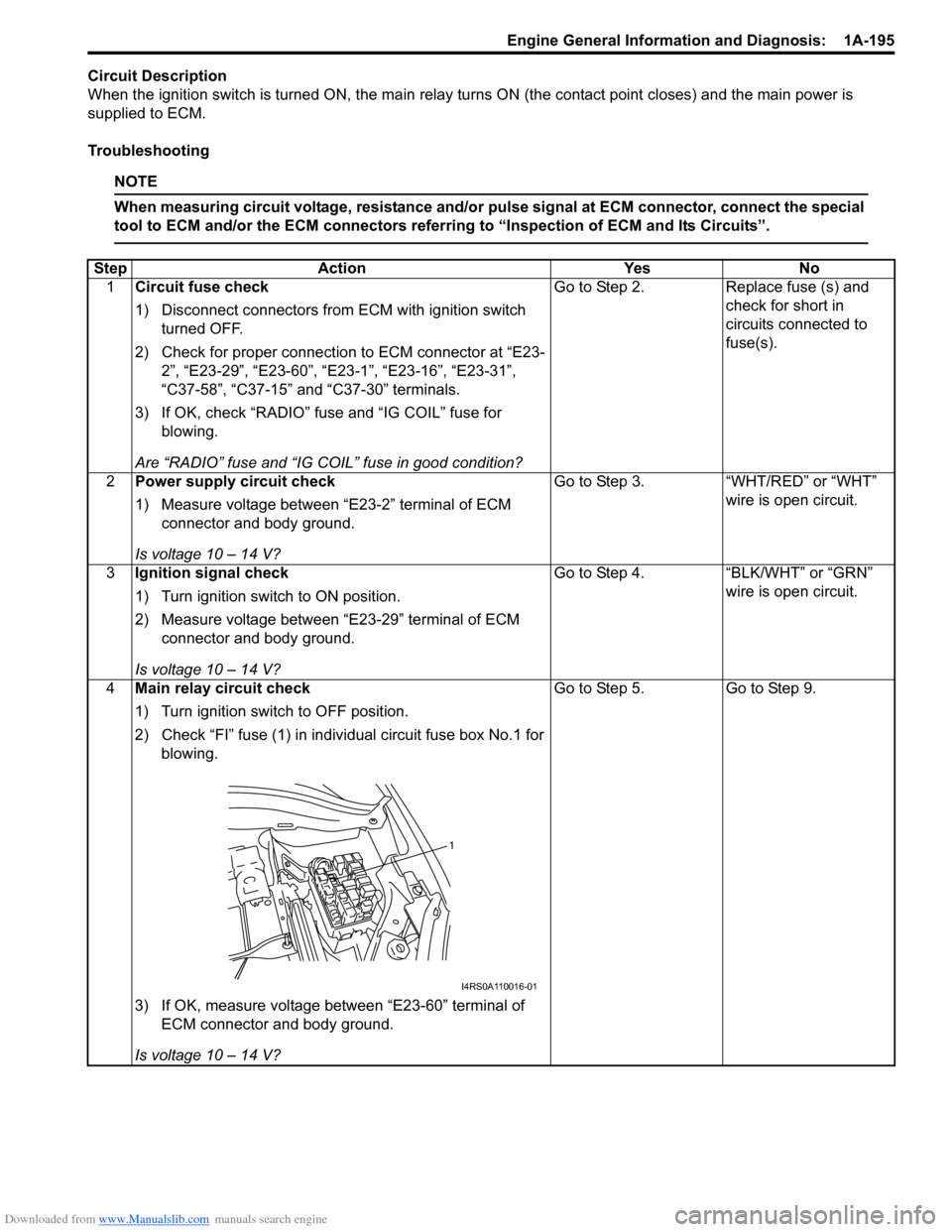

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—

Page 245 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-195

Circuit Description

When the ignition switch is turned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Circuit fuse check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to ECM connector at “E23- 2”, “E23-29”, “E23-60”, “E23-1”, “E23-16”, “E23-31”,

“C37-58”, “C37-15” and “C37-30” terminals.

3) If OK, check “RADIO” fuse and “IG COIL” fuse for blowing.

Are “RADIO” fuse and “IG COIL” fuse in good condition? Go to Step 2.

Replace fuse (s) and

check for short in

circuits connected to

fuse(s).

2 Power supply circuit check

1) Measure voltage between “E23-2” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 3.

“WHT/RED” or “WHT”

wire is open circuit.

3 Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between “E23-29” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/WHT” or “GRN”

wire is open circuit.

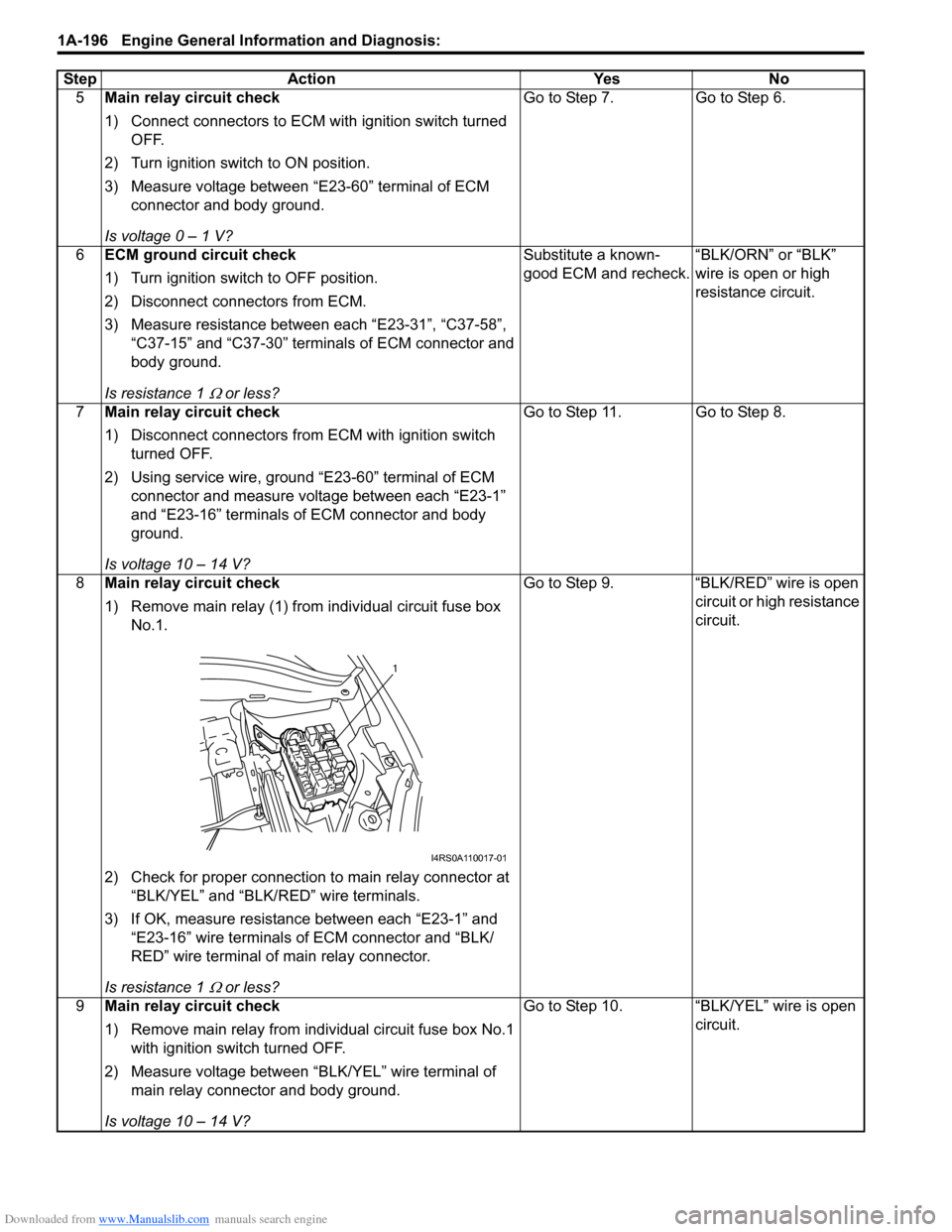

4 Main relay circuit check

1) Turn ignition switch to OFF position.

2) Check “FI” fuse (1) in indivi dual circuit fuse box No.1 for

blowing.

3) If OK, measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 10 – 14 V? Go to Step 5.

Go to Step 9.

1

I4RS0A110016-01

Page 246 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-196 Engine General Information and Diagnosis:

5Main relay circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 0 – 1 V? Go to Step 7. Go to Step 6.

6 ECM ground circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from ECM.

3) Measure resistance between each “E23-31”, “C37-58”,

“C37-15” and “C37-30” terminals of ECM connector and

body ground.

Is resistance 1

Ω or less? Substitute a known-

good ECM and recheck.

“BLK/ORN” or “BLK”

wire is open or high

resistance circuit.

7 Main relay circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Using service wire, ground “E23-60” terminal of ECM connector and measure voltage between each “E23-1”

and “E23-16” terminals of ECM connector and body

ground.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 8.

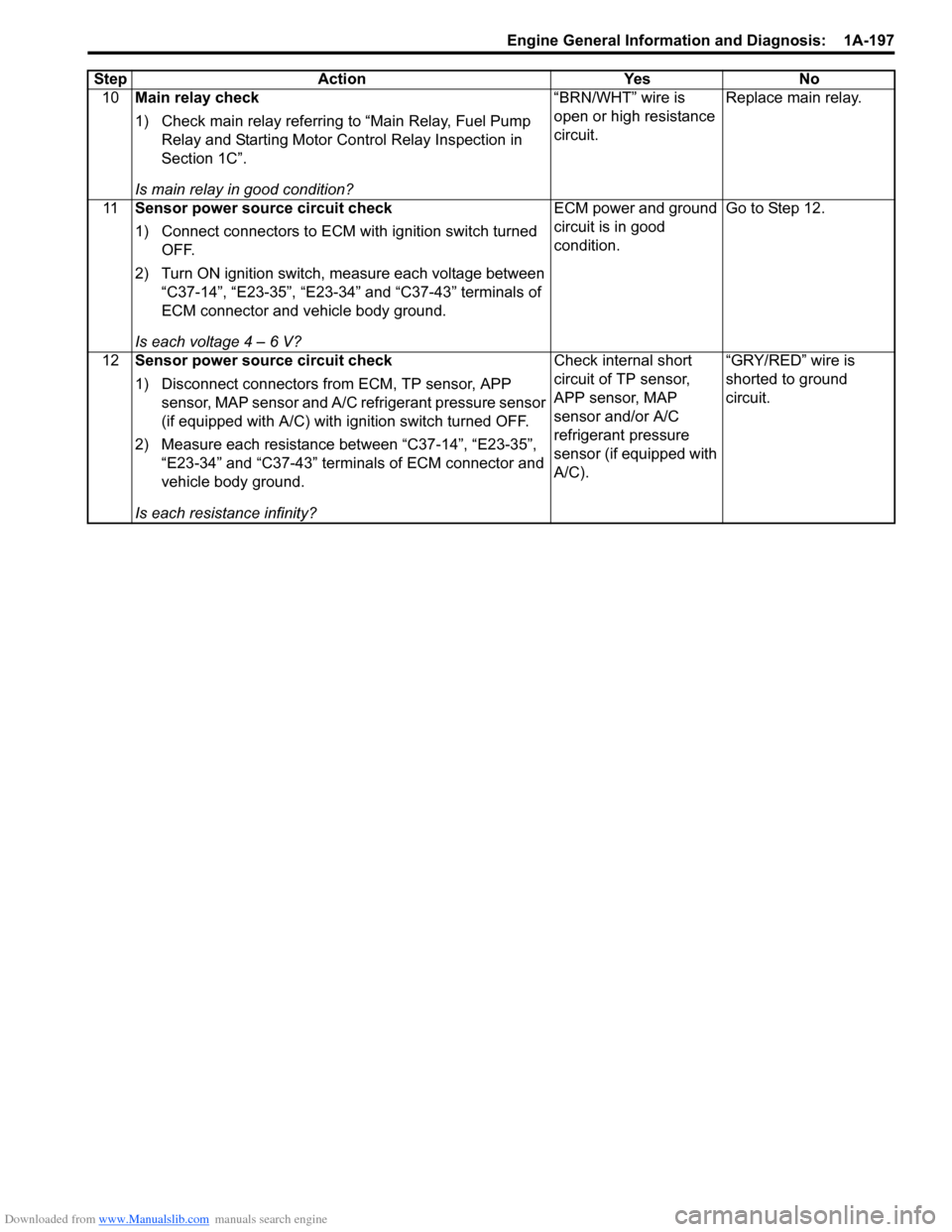

8 Main relay circuit check

1) Remove main relay (1) from individual circuit fuse box

No.1.

2) Check for proper connection to main relay connector at “BLK/YEL” and “BLK/RED” wire terminals.

3) If OK, measure resistance between each “E23-1” and “E23-16” wire terminals of ECM connector and “BLK/

RED” wire terminal of main relay connector.

Is resistance 1

Ω or less? Go to Step 9. “BLK/RED” wire is open

circuit or high resistance

circuit.

9 Main relay circuit check

1) Remove main relay from individual circuit fuse box No.1

with ignition swit ch turned OFF.

2) Measure voltage between “BLK/YEL” wire terminal of main relay connector and body ground.

Is voltage 10 – 14 V? Go to Step 10. “BLK/YEL” wire is open

circuit.

Step Action Yes No

1

I4RS0A110017-01

Page 247 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

10Main relay check

1) Check main relay referring to “Main Relay, Fuel Pump

Relay and Starting Motor Control Relay Inspection in

Section 1C”.

Is main relay in good condition? “BRN/WHT” wire is

open or high resistance

circuit.

Replace main relay.

11 Sensor power source circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ON ignition switch, measure each voltage between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of

ECM connector and vehicle body ground.

Is each voltage 4 – 6 V? ECM power and ground

circuit is in good

condition.

Go to Step 12.

12 Sensor power source circuit check

1) Disconnect connectors from ECM, TP sensor, APP

sensor, MAP sensor and A/C refrigerant pressure sensor

(if equipped with A/C) with i gnition switch turned OFF.

2) Measure each resistance between “C37-14”, “E23-35”, “E23-34” and “C37-43” terminals of ECM connector and

vehicle body ground.

Is each resistance infinity? Check internal short

circuit of TP sensor,

APP sensor, MAP

sensor and/or A/C

refrigerant pressure

sensor (if equipped with

A/C).

“GRY/RED” wire is

shorted to ground

circuit.

Step Action Yes No

Page 249 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector ma ke operating sound? Fuel injectors circuit is

in good condition.

Go to Step 2.

2 Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each terminals.

3) If OK, check all 4 fuel inject ors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition? Go to Step 3.

Faulty fuel injector.

3 Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation? Go to Step 4.

Faulty fuel injector.

4 Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V? Go to Step 5.

“BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5 Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity? Go to Step 6.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6 Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V? Go to Step 7.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7 Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C37-1”, “C37-2”, “C37- 16”, “C37-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V? Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 251 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-201

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON? Fuel pump circuit is in

good condition.

Go to Step 2.

2 Fuel pump relay po wer supply check

1) Disconnect fuel pump relay from individual circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each terminal.

3) If OK, turn ON ignition switch, measure voltage between “BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V? Go to Step 3.

“BLK/WHT” wire is open

or shorted to ground

circuit.

3 Fuel pump relay po wer supply check

1) Turn ON ignition switch, measure voltage between “BLK/ RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/RED” wire is open

circuit.

4 Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay and Starting Moto r Control Relay Inspection

in Section 1C”.

Is relay in good condition? Go to Step 5.

Faulty relay.

5 Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E23-15” terminal of ECM connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned ON.

Is voltage 10 – 14 V? Go to Step 6.

“GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 252 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-202 Engine General Information and Diagnosis:

6Fuel pump relay drive signal check

1) Measure voltage within 2 second after ignition switch is

turned ON.

Is voltage 0 – 1 V? Go to Step 7. Substitute a known-

good ECM and recheck.

7 Wire circuit check

1) Turn OFF ignition switch.

2) Detach fuel tank referring to “Fuel Tank Removal and

Installation in Section 1G”.

3) Disconnect connector from fuel pump.

4) Measure resistance between “PNK” wire terminal of fuel pump connector and vehicle body ground.

Is resistance infinity? Go to Step 8. “PNK” wire is shorted to

ground.

8 Fuel pump circuit check

1) Connect service wire between “E23-15” terminal of ECM

connector and vehicle body ground.

2) Turn ON ignition switch, measure voltage between “PNK” terminal at fuel pump connector and vehicle body

ground.

Is voltage 10 – 14 V? Go to Step 9. “PNK” wire is open

circuit.

9 Fuel pump circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “BLK” wire terminal at fuel

pump connector and vehicle body ground.

Is resistance less than 5

Ω? Faulty fuel pump. “BLK” wire is open

circuit.

Step Action Yes No

Page 257 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-207

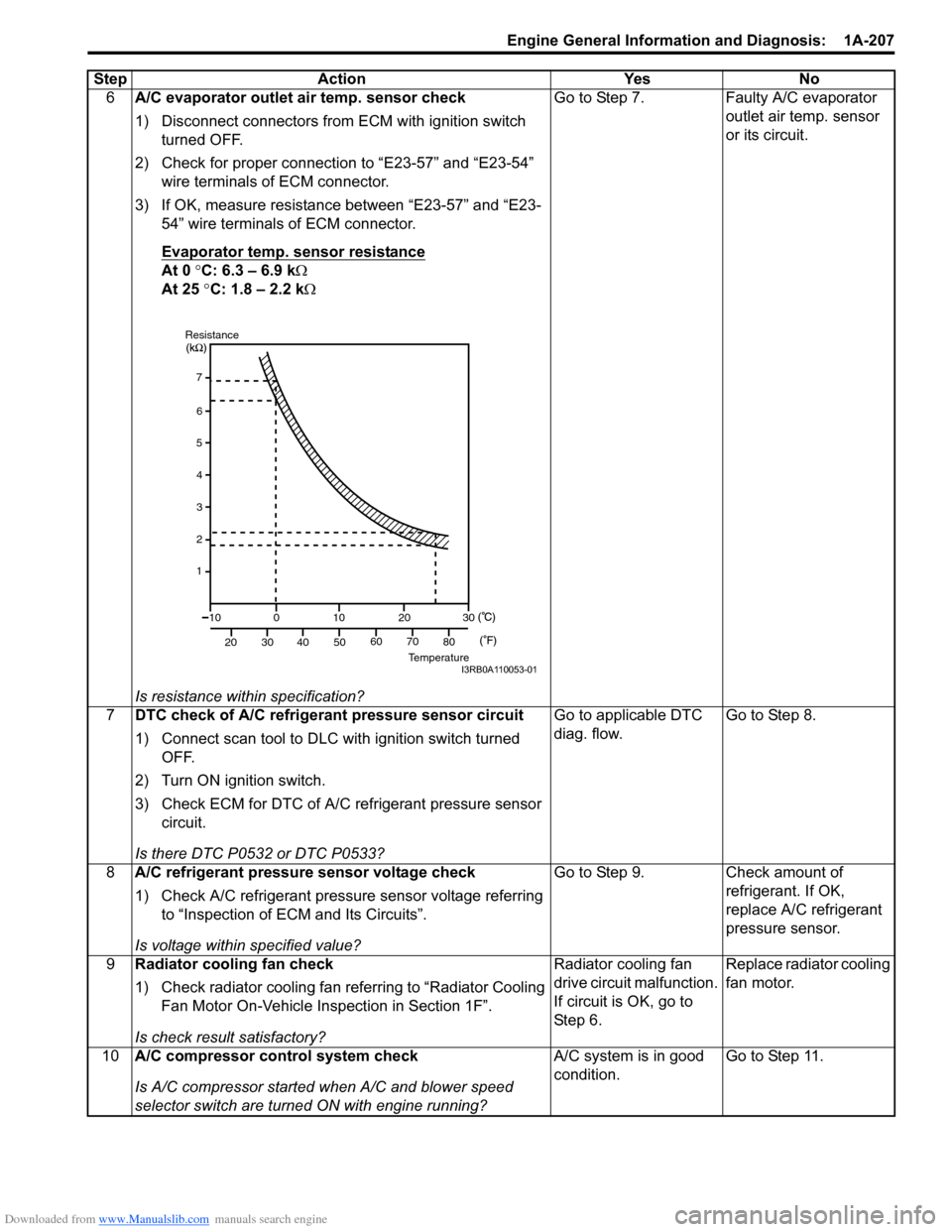

6A/C evaporator outlet air temp. sensor check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to “E23-57” and “E23-54” wire terminals of ECM connector.

3) If OK, measure resistance between “E23-57” and “E23- 54” wire terminals of ECM connector.

Evaporator temp. sensor resistance

At 0 °C: 6.3 – 6.9 k Ω

At 25 °C: 1.8 – 2.2 k Ω

Is resistance within specification? Go to Step 7. Faulty A/C evaporator

outlet air temp. sensor

or its circuit.

7 DTC check of A/C refrigerant pressure sensor circuit

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check ECM for DTC of A/C refrigerant pressure sensor circuit.

Is there DTC P0532 or DTC P0533? Go to applicable DTC

diag. flow.

Go to Step 8.

8 A/C refrigerant pressure sensor voltage check

1) Check A/C refrigerant pressure sensor voltage referring

to “Inspection of ECM and Its Circuits”.

Is voltage within specified value? Go to Step 9. Check amount of

refrigerant. If OK,

replace A/C refrigerant

pressure sensor.

9 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is check result satisfactory? Radiator cooling fan

drive circuit malfunction.

If circuit is OK, go to

St ep 6 .

Replace radiator cooling

fan motor.

10 A/C compressor control system check

Is A/C compressor started when A/C and blower speed

selector switch are turned ON with engine running? A/C system is in good

condition.

Go to Step 11.

Step Action Yes No

7

6

5

4

3

2

1

10

20 30

40 50

0

10

2030

60 70 80

ResistanceTemperatureI3RB0A110053-01

Page 258 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-208 Engine General Information and Diagnosis:

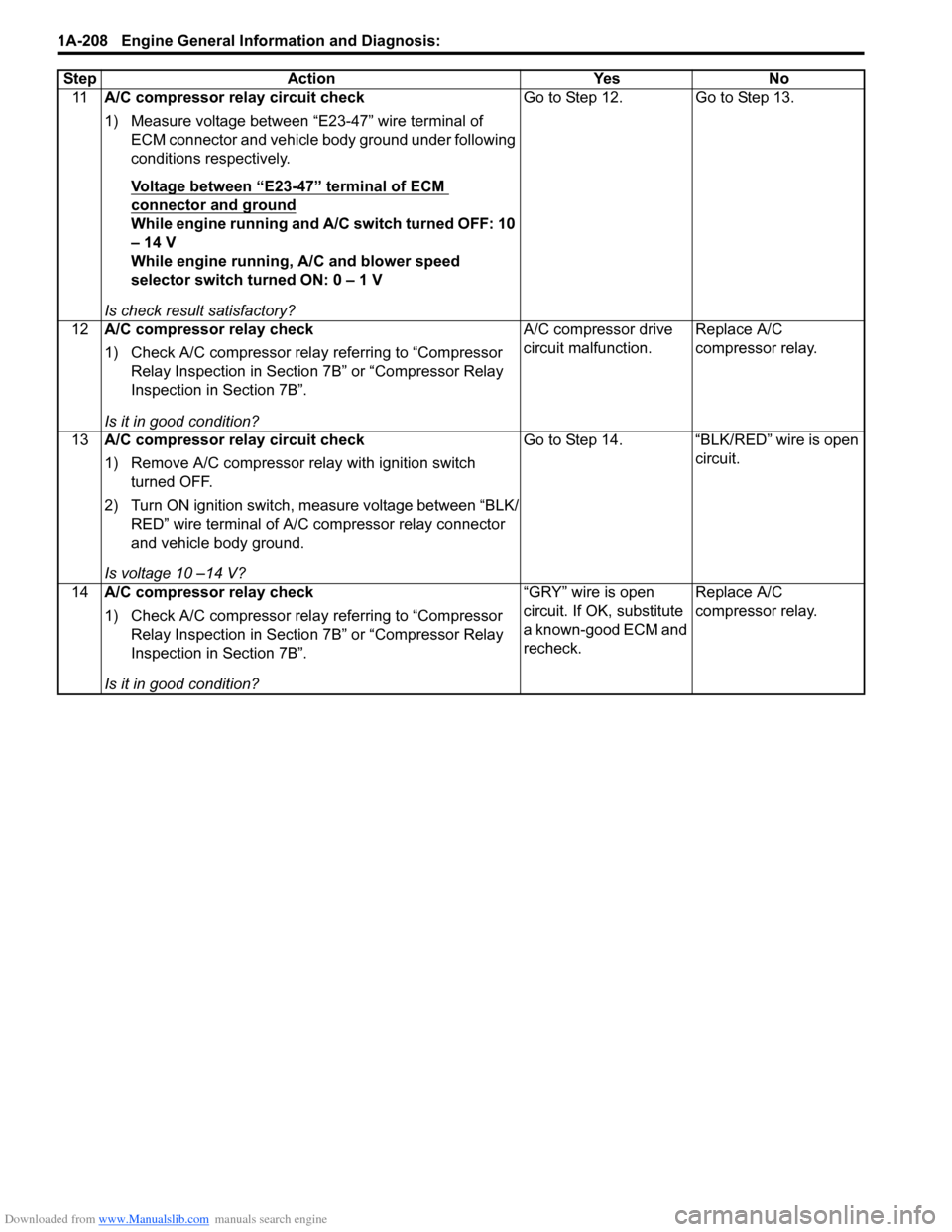

11A/C compressor relay circuit check

1) Measure voltage between “E23-47” wire terminal of

ECM connector and vehicle body ground under following

conditions respectively.

Voltage between “E23-47” terminal of ECM

connector and ground

While engine running and A/C switch turned OFF: 10

– 14 V

While engine running, A/C and blower speed

selector switch turned ON: 0 – 1 V

Is check result satisfactory? Go to Step 12. Go to Step 13.

12 A/C compressor relay check

1) Check A/C compressor rela y referring to “Compressor

Relay Inspection in Sectio n 7B” or “Compressor Relay

Inspection in Section 7B”.

Is it in good condition? A/C compressor drive

circuit malfunction.

Replace A/C

compressor relay.

13 A/C compressor relay circuit check

1) Remove A/C compressor re lay with ignition switch

turned OFF.

2) Turn ON ignition switch, measure voltage between “BLK/ RED” wire terminal of A/C compressor relay connector

and vehicle body ground.

Is voltage 10 –14 V? Go to Step 14. “BLK/RED” wire is open

circuit.

14 A/C compressor relay check

1) Check A/C compressor rela y referring to “Compressor

Relay Inspection in Sectio n 7B” or “Compressor Relay

Inspection in Section 7B”.

Is it in good condition? “GRY” wire is open

circuit. If OK, substitute

a known-good ECM and

recheck.

Replace A/C

compressor relay.

Step Action Yes No

Page 262 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-212 Engine General Information and Diagnosis:

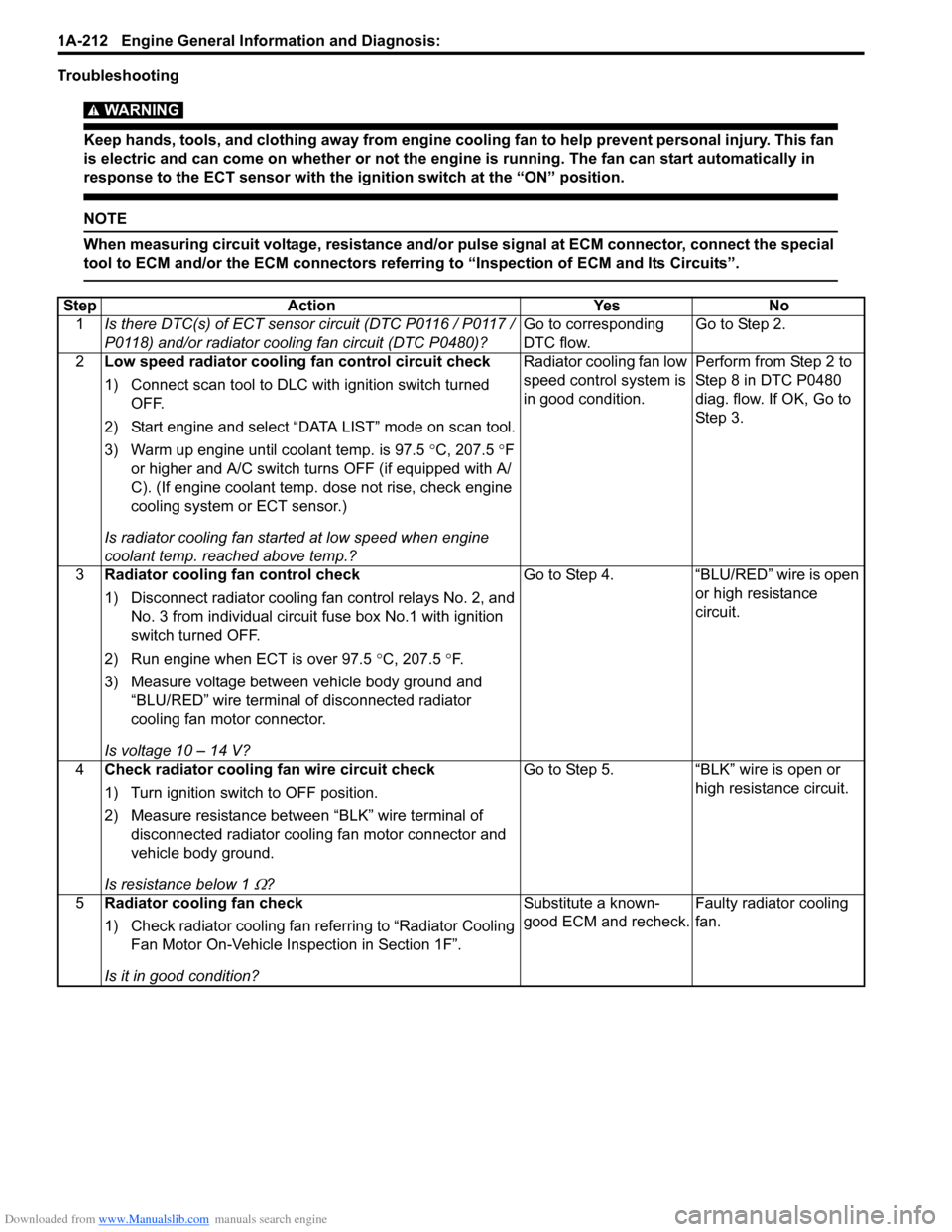

Troubleshooting

WARNING!

Keep hands, tools, and clothing away from engine cooling fan to help prevent personal injury. This fan

is electric and can come on whether or not the engi ne is running. The fan can start automatically in

response to the ECT sensor with the ig nition switch at the “ON” position.

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Is there DTC(s) of ECT sensor circuit (DTC P0116 / P0117 /

P0118) and/or radiator cooling fan circuit (DTC P0480)? Go to corresponding

DTC flow.Go to Step 2.

2 Low speed radiator cooling fan control circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Warm up engine until coolant temp. is 97.5 °C, 207.5 °F

or higher and A/C switch turns OFF (if equipped with A/

C). (If engine coolant temp. dose not rise, check engine

cooling system or ECT sensor.)

Is radiator cooling fan started at low speed when engine

coolant temp. reached above temp.? Radiator cooling fan low

speed control system is

in good condition.

Perform from Step 2 to

Step 8 in DTC P0480

diag. flow. If OK, Go to

Ste p 3.

3 Radiator cooling fan control check

1) Disconnect radiator cooling fan control relays No. 2, and

No. 3 from individual circuit fuse box No.1 with ignition

switch turned OFF.

2) Run engine when ECT is over 97.5 °C, 207.5 °F.

3) Measure voltage between vehicle body ground and “BLU/RED” wire terminal of disconnected radiator

cooling fan motor connector.

Is voltage 10 – 14 V? Go to Step 4.

“BLU/RED” wire is open

or high resistance

circuit.

4 Check radiator cooling fan wire circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK” wire terminal of

disconnected radiator coolin g fan motor connector and

vehicle body ground.

Is resistance below 1

Ω? Go to Step 5. “BLK” wire is open or

high resistance circuit.

5 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty radiator cooling

fan.