Transmission SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 715 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-71

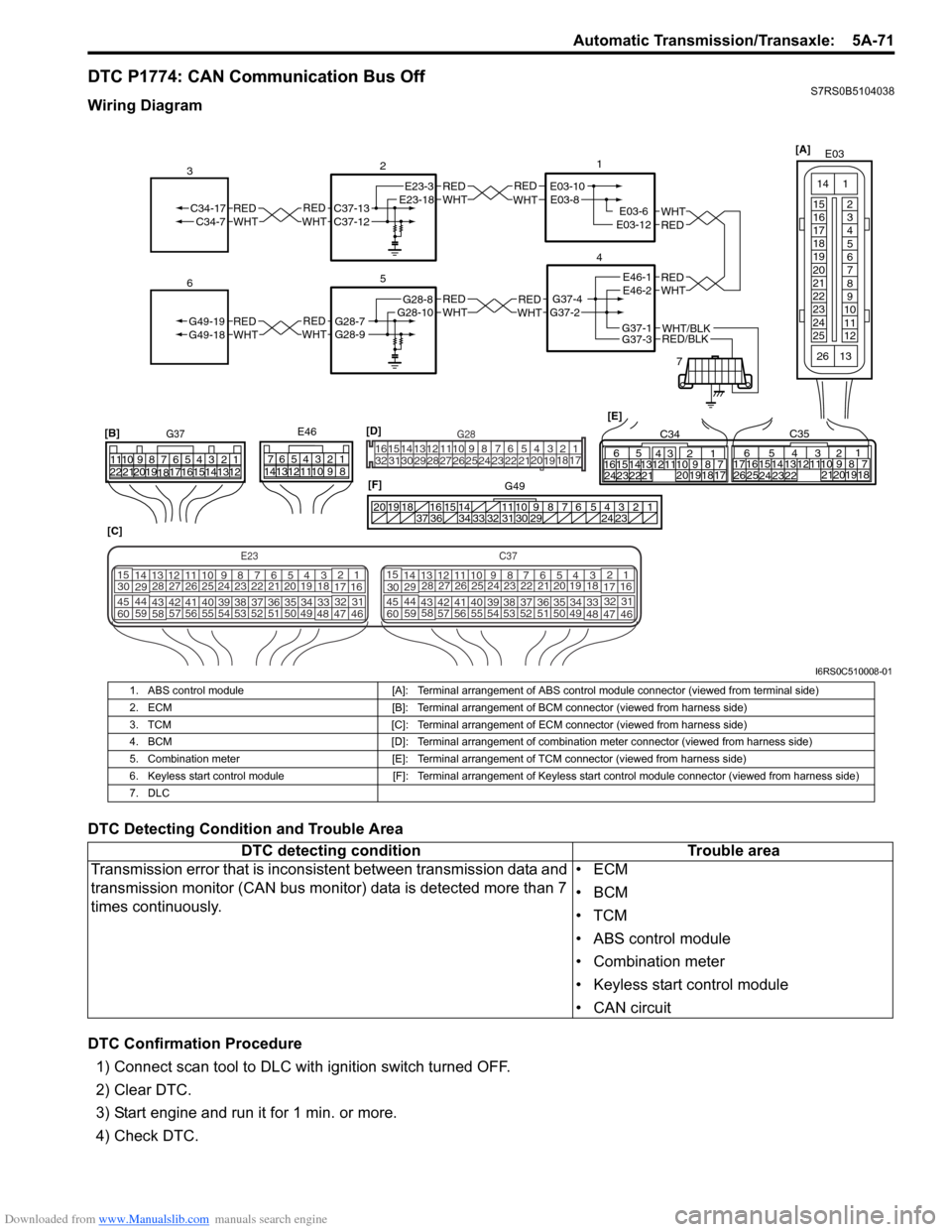

DTC P1774: CAN Communication Bus OffS7RS0B5104038

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

REDWHTE03-6E03-12

1

4

7

REDWHT

2

[C]

[B]

G37E46

1234567

1234567

891011

891011

121314 121314

151617

18

19202122 [E]65

1615 14131211 43

2423 2122 10 9 8 7

21

1920 1817

C3417 16

26 2515 14

65 3

42

13 12

23 2224 1110 9

212019 87

18

1

C35

[F]

REDWHTC37-13C37-12REDWHTC34-17C34-7

3

1234567891011

141516

36 34 33 32 31 30 29 24 23

37

181920

[D] [A]

G49

E23-3E23-18

5

REDWHTG28-7G28-9REDWHTG49-19G49-18

6

REDWHTE03-10E03-8

G37-4G37-2

REDWHTE46-1E46-2REDWHTREDWHTG28-8G28-10

RED/BLKWHT/BLKG37-3G37-1

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

G281234567

8

910111213141516

1718

19

20

212223242526272829303132

I6RS0C510008-01

1. ABS control module [A]: Terminal arrangement of ABS control module connector (viewed from terminal side)

2. ECM [B]: Terminal arrangement of BCM connector (viewed from harness side)

3. TCM [C]: Terminal arrangement of ECM connector (viewed from harness side)

4. BCM [D]: Terminal arrangement of combination meter connector (viewed from harness side)

5. Combination meter [E]: Terminal arrangement of TCM connector (viewed from harness side)

6. Keyless start control module [F]: Terminal arrangement of Keyless start control module connector (viewed from harness side)

7. DLC

DTC detecting condition Trouble area

Transmission error that is incons istent between transmission data and

transmission monitor (CAN bus monitor) data is detected more than 7

times continuously. •ECM

•BCM

•TCM

• ABS control module

• Combination meter

• Keyless start control module

• CAN circuit

Page 716 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-72 Automatic Transmission/Transaxle:

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1774? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4.

Repair circuit.

4 DTC check

1) Turn ignition switch to OFF position.

2) Connect connectors of disconnected control modules

communicating by means of CAN.

3) Disconnect connector from any one of control modules other than BCM and TCM.

4) Recheck TCM for DTC.

Is DTC P1774 detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 3)

one by one and check

that DTC P1774 is

detected by TCM each

time connector is

disconnected. When

DTC P1774 is not

detected by TCM while

checking in this way, go

to description under

“NO” below. If DTC

P1774 is detected by

TCM, go to Step 5.Check power and

ground circuit of control

module disconnect in

Step 3). If circuit is OK,

substitute a known-

good control module

disconnected in Step 3)

and recheck.

5 DTC check of BCM

1) Turn ignition switch to OFF position.

2) Disconnect connector from all control modules other

than BCM.

3) Check BCM for DTC referring to “DTC Check in Section 10B”

Is DTC U1073 (No. 1073) detected? Substitute a known

good BCM and recheck.

Substitute a known

good TCM and recheck.

Page 717 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-73

DTC P1777: TCM Lost Communication with ECM (Reception Error)S7RS0B5104040

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” and confirm

that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r ECM is detected more than specified

time continuously. •ECM

•TCM

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means of CAN.

2) Recheck DTC.

Is there DTC P1777? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error) in

Section 1A”.

Check ECM power and

ground circuit. If circuit

is OK, CAN

communication circuit

between ECM and ABS

hydraulic unit / control

module is open circuit.

4 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

Page 718 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

DTC P1778: TCM Lost Communication with BCM (Reception Error)S7RS0B5104041

Wiring Diagram

Refer to “DTC P1774: CAN Communication Bus Off”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform “DTC Confirmation Procedure:” “DTC

Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data fo r BCM is detected more than specified

time continuously. •ECM

•TCM

•BCM

• ABS control module

• CAN circuit

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Control module connector check

1) Check connection of connectors of all control modules

communicating by means by means of CAN.

2) Recheck DTC.

Is there DTC P1778? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 DTC check in BCM (bus off)

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is there DTC U1073? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.

Go to Step 4.

4 DTC check in ABS control module

1) Check ABS control module for DTC referring to “DTC

Check in Section 4E”.

Is there DTC U1100? Go to “DTC U1100: Lost

Communication with

ECM (Reception Error)

in Section 4E”.

Go to Step 5.

5 DTC check in ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there DTC P1678? Check BCM power and

ground circuit. If circuit

is OK, substitute a

known-good BCM and

recheck.Go to Step 6.

6 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check CAN communication circuit between control modules for open, short and high resistance.

Is each CAN communication circuit in good condition? Check TCM power and

ground circuit. If circuit

is OK, substitute a

known-good TCM and

recheck.

Repair circuit.

Page 719 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-75

DTC P1878: Torque Converter Clutch ShudderS7RS0B5104042

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle with 3rd or 4th gear in “D” range and slip c ontrolled lock-up ON for 20 seconds or longer referring to

“Automatic Gear Shift Table”.

5) Stop vehicle.

6) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting DTC detecting condition

Trouble area

The acceleration slip control function stops when the variation in the output

revolution speed of the specified amp litude and specified cycle is detected

within a specified period of time. When t he specified variation is not detected

after the acceleration slip control stops. • Mismatching ATF

• Torque converter clutch malfunction

• Valve body

•TCM

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Change A/T fluid referring to “A/T Fluid Change”. Check DTC after performing “DTC Confirmation Procedure”.

Is DTC P1878 still indicated? Faulty torque converter

clutch.

Replace torque

converter.System is in good

condition.

Page 720 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-76 Automatic Transmission/Transaxle:

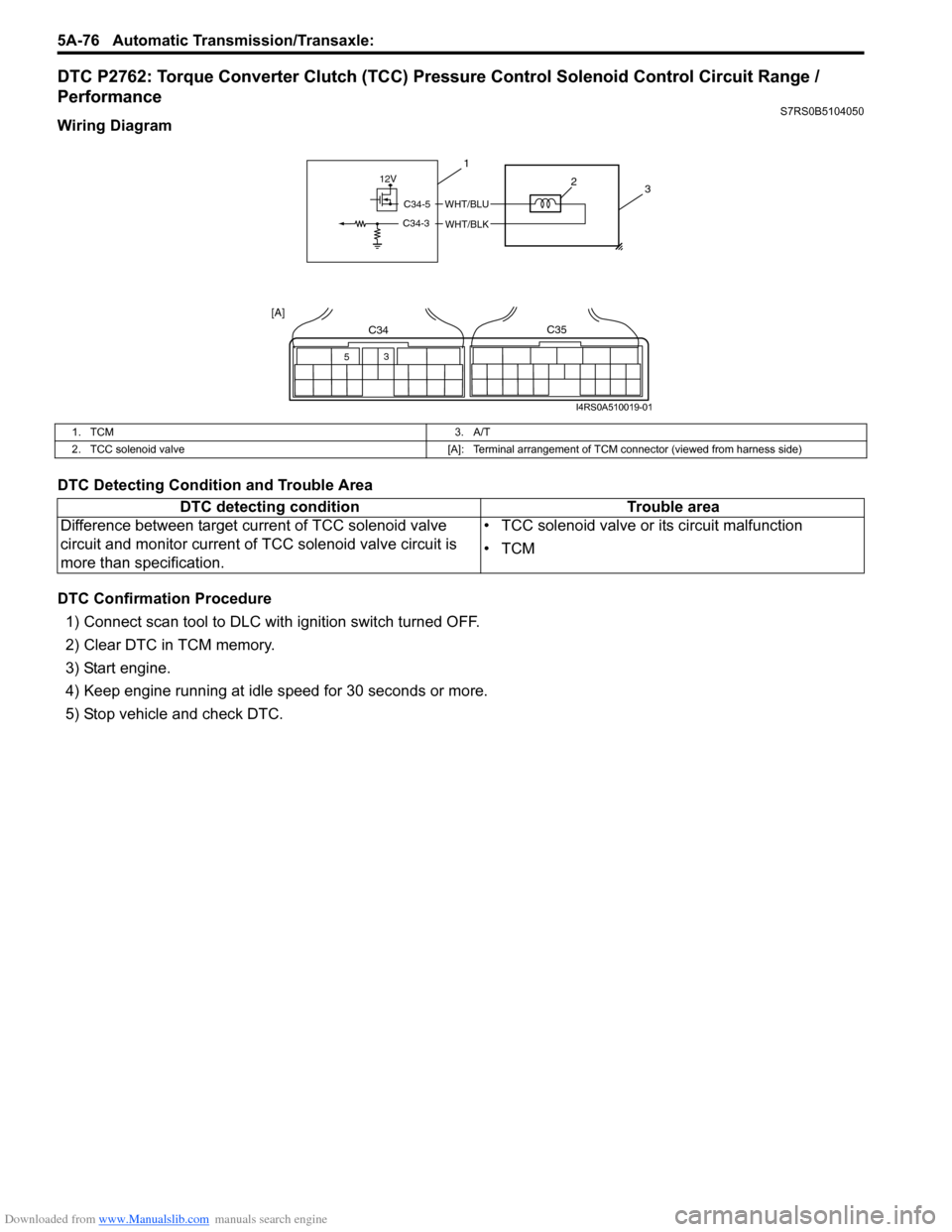

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit Range /

Performance

S7RS0B5104050

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

1. TCM

3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Difference between target current of TCC solenoid valve

circuit and monitor current of TCC solenoid valve circuit is

more than specification. • TCC solenoid valve or its circuit malfunction

•TCM

Page 721 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-77

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

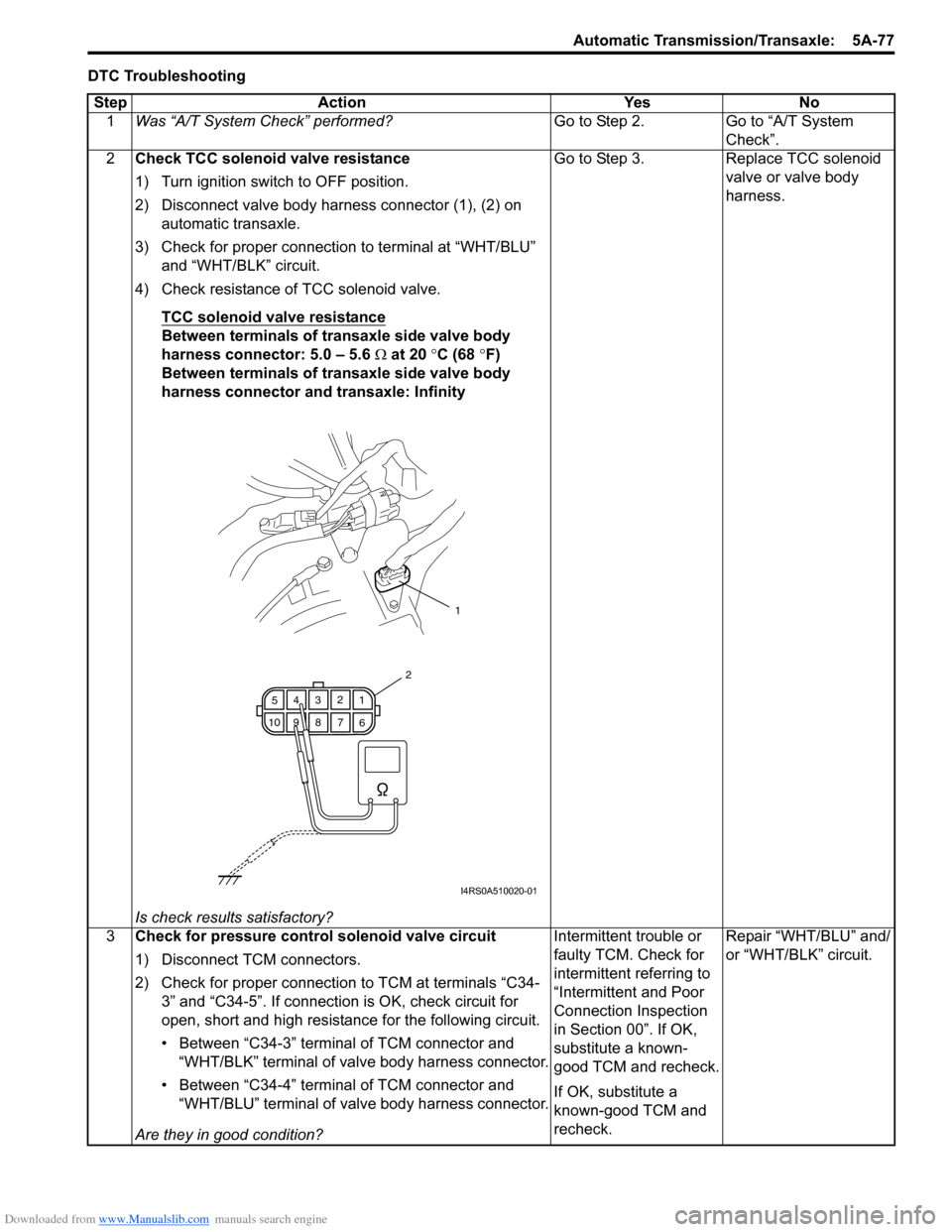

2 Check TCC solenoid valve resistance

1) Turn ignition switch to OFF position.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to terminal at “WHT/BLU” and “WHT/BLK” circuit.

4) Check resistance of TCC solenoid valve.

TCC solenoid valve resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Go to Step 3. Replace TCC solenoid

valve or valve body

harness.

3 Check for pressure control solenoid valve circuit

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C34-

3” and “C34-5”. If connection is OK, check circuit for

open, short and high resistance for the following circuit.

• Between “C34-3” terminal of TCM connector and “WHT/BLK” terminal of valve body harness connector.

• Between “C34-4” terminal of TCM connector and “WHT/BLU” terminal of valve body harness connector.

Are they in good condition? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.

If OK, substitute a

known-good TCM and

recheck.

Repair “WHT/BLU” and/

or “WHT/BLK” circuit.

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 722 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-78 Automatic Transmission/Transaxle:

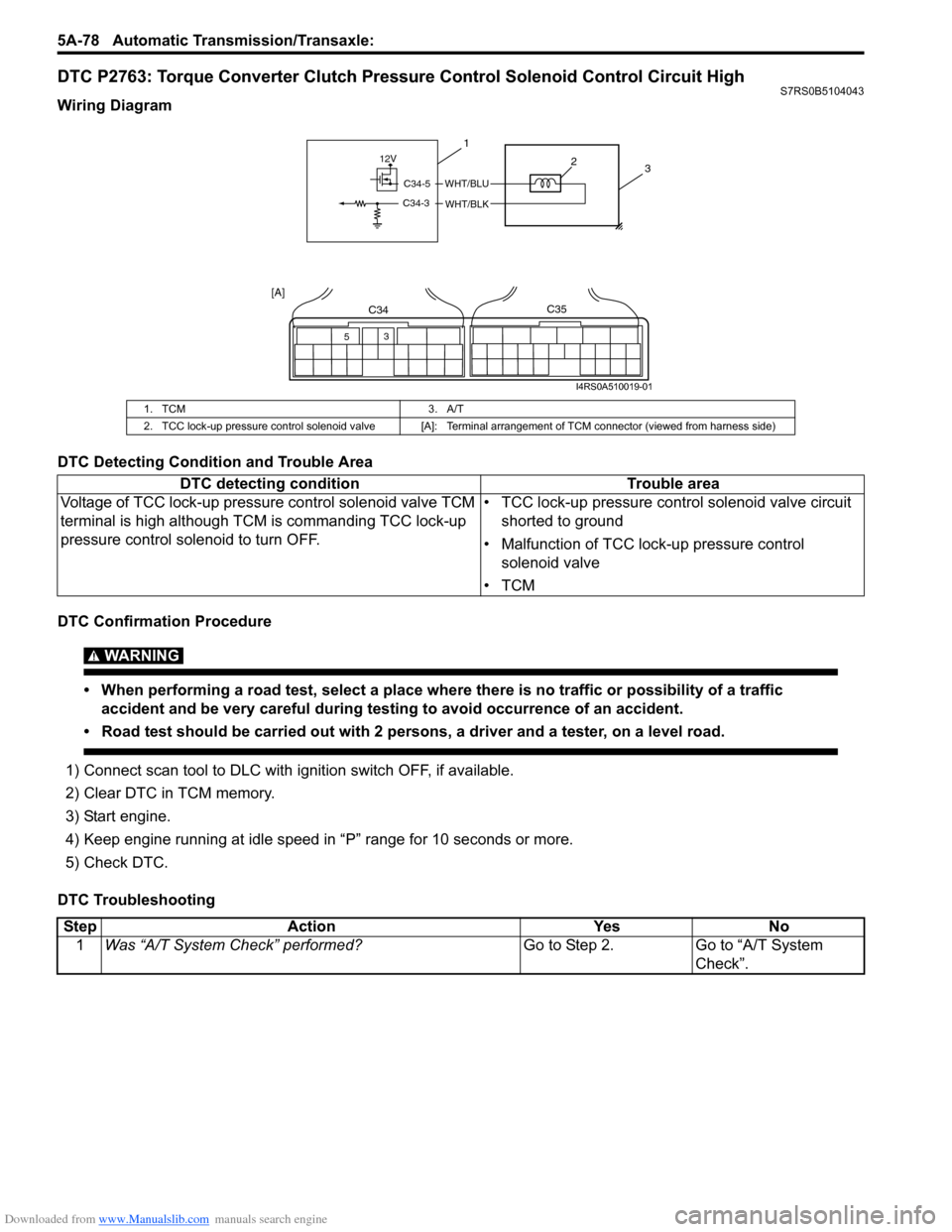

DTC P2763: Torque Converter Clutch Pressure Control Solenoid Control Circuit HighS7RS0B5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC lock-up pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is high although TCM is commanding TCC lock-up

pressure control sole noid to turn OFF. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

Page 723 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-79

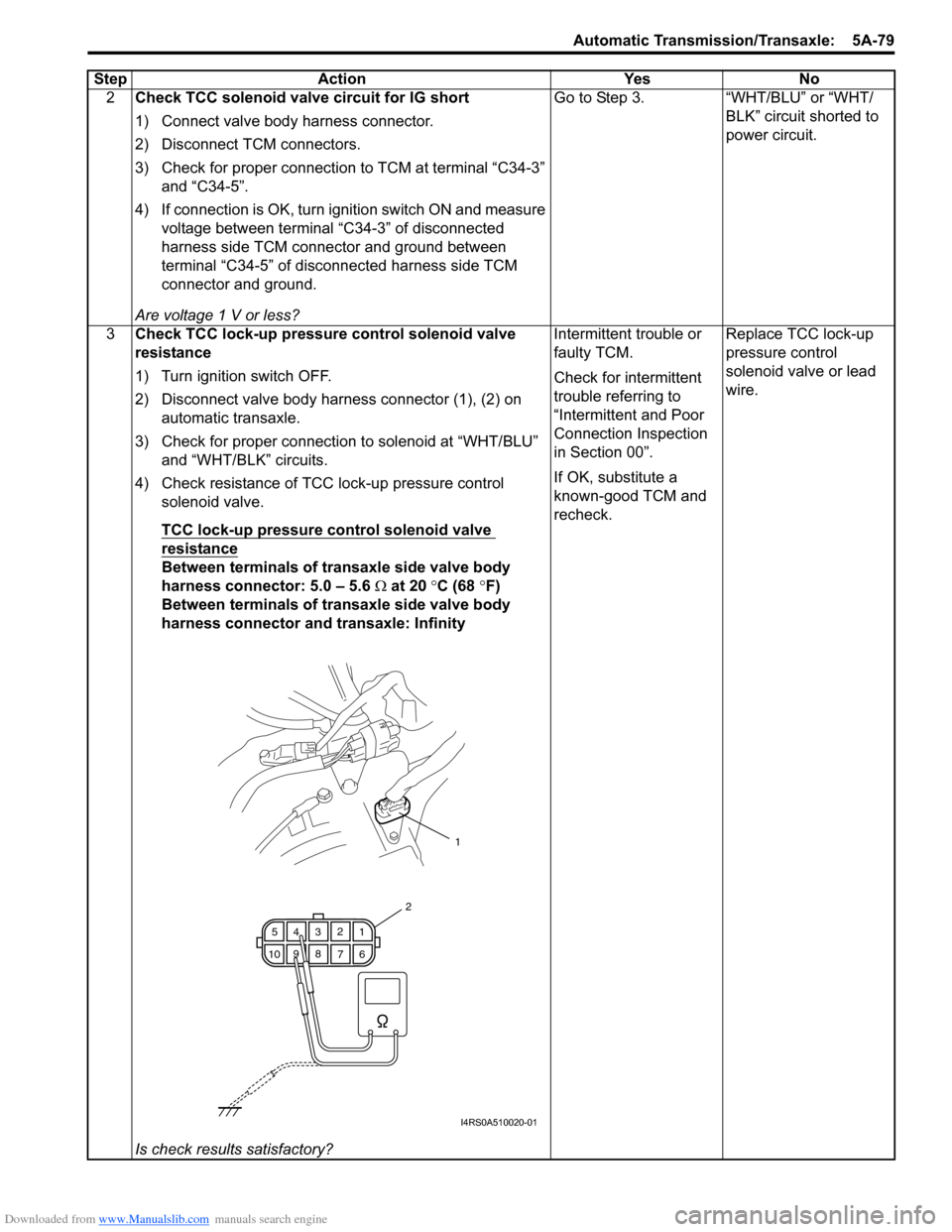

2Check TCC solenoid valve circuit for IG short

1) Connect valve body harness connector.

2) Disconnect TCM connectors.

3) Check for proper connection to TCM at terminal “C34-3”

and “C34-5”.

4) If connection is OK, turn ignition switch ON and measure voltage between terminal “C34-3” of disconnected

harness side TCM connector and ground between

terminal “C34-5” of disconnected harness side TCM

connector and ground.

Are voltage 1 V or less? Go to Step 3. “WHT/BLU” or “WHT/

BLK” circuit shorted to

power circuit.

3 Check TCC lock-up pressure control solenoid valve

resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “WHT/BLU” and “WHT/BLK” circuits.

4) Check resistance of TCC lock-up pressure control

solenoid valve.

TCC lock-up pressure control solenoid valve

resistance

Between terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory? Intermittent trouble or

faulty TCM.

Check for intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

If OK, substitute a

known-good TCM and

recheck.

Replace TCC lock-up

pressure control

solenoid valve or lead

wire.

Step Action Yes No

1

6

7

89

10 5

43 2

1

2

I4RS0A510020-01

Page 724 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

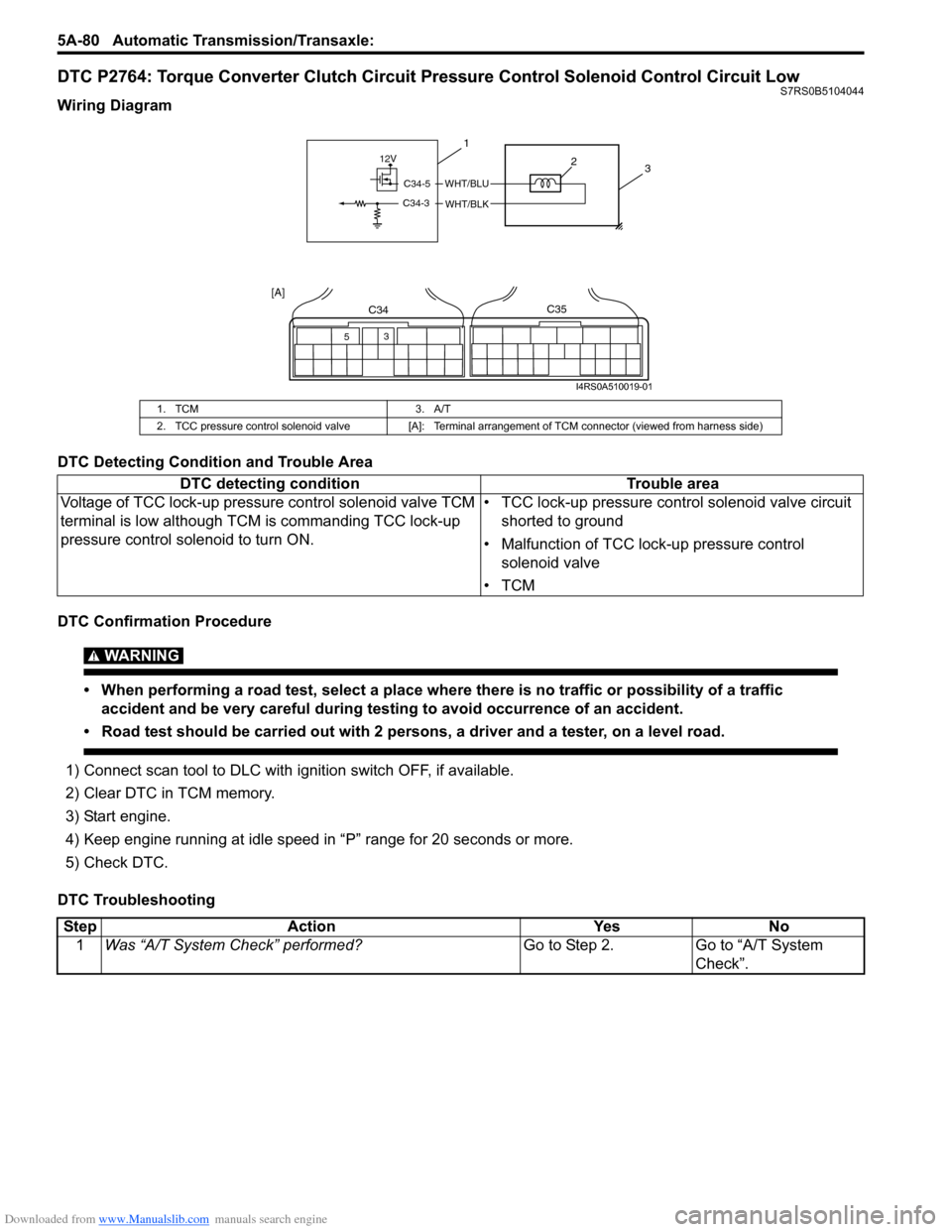

DTC P2764: Torque Converter Clutch Circuit Pressure Control Solenoid Control Circuit LowS7RS0B5104044

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. TCC pressure control solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC lock-up pressure control solenoid valve TCM

terminal is low although TCM is commanding TCC lock-up

pressure control sole noid to turn ON. • TCC lock-up pressure contro

l solenoid valve circuit

shorted to ground

• Malfunction of TCC lock-up pressure control solenoid valve

•TCM

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.