Vehicle speed SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 708 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-64 Automatic Transmission/Transaxle:

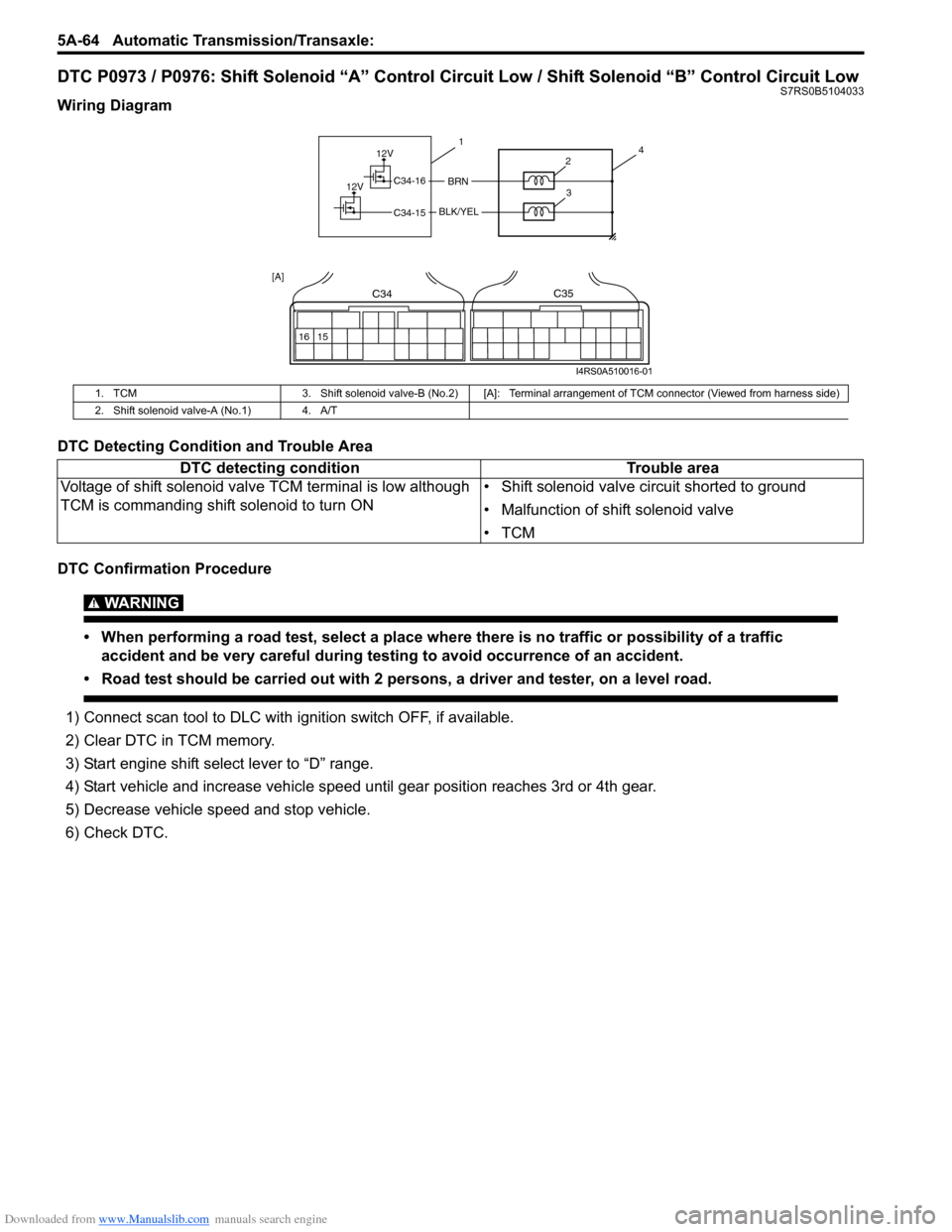

DTC P0973 / P0976: Shift Solenoid “A” Control Circuit Low / Shift Solenoid “B” Control Circuit LowS7RS0B5104033

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine shift select lever to “D” range.

4) Start vehicle and increase vehicle speed until gear position reaches 3rd or 4th gear.

5) Decrease vehicle sp eed and stop vehicle.

6) Check DTC.

1. TCM 3. Shift solenoid valve-B (No.2) [A]: Terminal arr angement of TCM connector (Viewed from harness side)

2. Shift solenoid valve-A (No.1) 4. A/T

DTC detecting condition Trouble area

Voltage of shift solenoid valv e TCM terminal is low although

TCM is commanding shift solenoid to turn ON • Shift solenoid valve circuit shorted to ground

• Malfunction of shift solenoid valve

•TCM

12V

12VBRNC34-16

C34-15BLK/YEL

41

2

3

16 15

C34C35

[A]

I4RS0A510016-01

Page 710 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-66 Automatic Transmission/Transaxle:

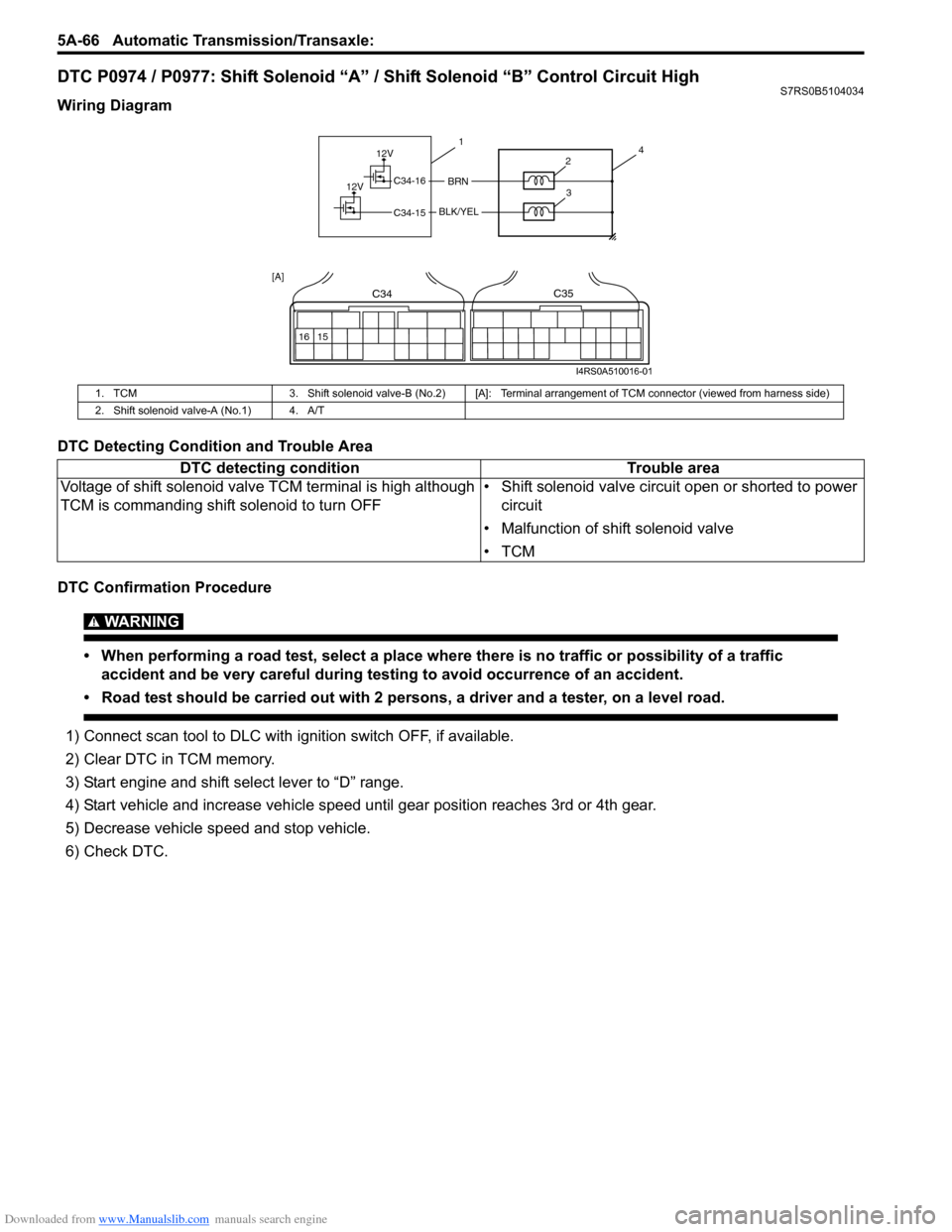

DTC P0974 / P0977: Shift Solenoid “A” / Shift Solenoid “B” Control Circuit HighS7RS0B5104034

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed until gear position reaches 3rd or 4th gear.

5) Decrease vehicle sp eed and stop vehicle.

6) Check DTC.

1. TCM 3. Shift solenoid valve-B (No.2) [A]: Terminal arra ngement of TCM connector (viewed from harness side)

2. Shift solenoid valve-A (No.1) 4. A/T

DTC detecting condition Trouble area

Voltage of shift solenoid valve TCM terminal is high although

TCM is commanding shift solenoid to turn OFF • Shift solenoid valve circuit open or shorted to power

circuit

• Malfunction of shift solenoid valve

•TCM

12V

12VBRNC34-16

C34-15BLK/YEL

41

2

3

16 15

C34C35

[A]

I4RS0A510016-01

Page 719 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-75

DTC P1878: Torque Converter Clutch ShudderS7RS0B5104042

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle with 3rd or 4th gear in “D” range and slip c ontrolled lock-up ON for 20 seconds or longer referring to

“Automatic Gear Shift Table”.

5) Stop vehicle.

6) Check DTC, pending DTC and freeze-frame data.

DTC Troubleshooting DTC detecting condition

Trouble area

The acceleration slip control function stops when the variation in the output

revolution speed of the specified amp litude and specified cycle is detected

within a specified period of time. When t he specified variation is not detected

after the acceleration slip control stops. • Mismatching ATF

• Torque converter clutch malfunction

• Valve body

•TCM

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Change A/T fluid referring to “A/T Fluid Change”. Check DTC after performing “DTC Confirmation Procedure”.

Is DTC P1878 still indicated? Faulty torque converter

clutch.

Replace torque

converter.System is in good

condition.

Page 720 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-76 Automatic Transmission/Transaxle:

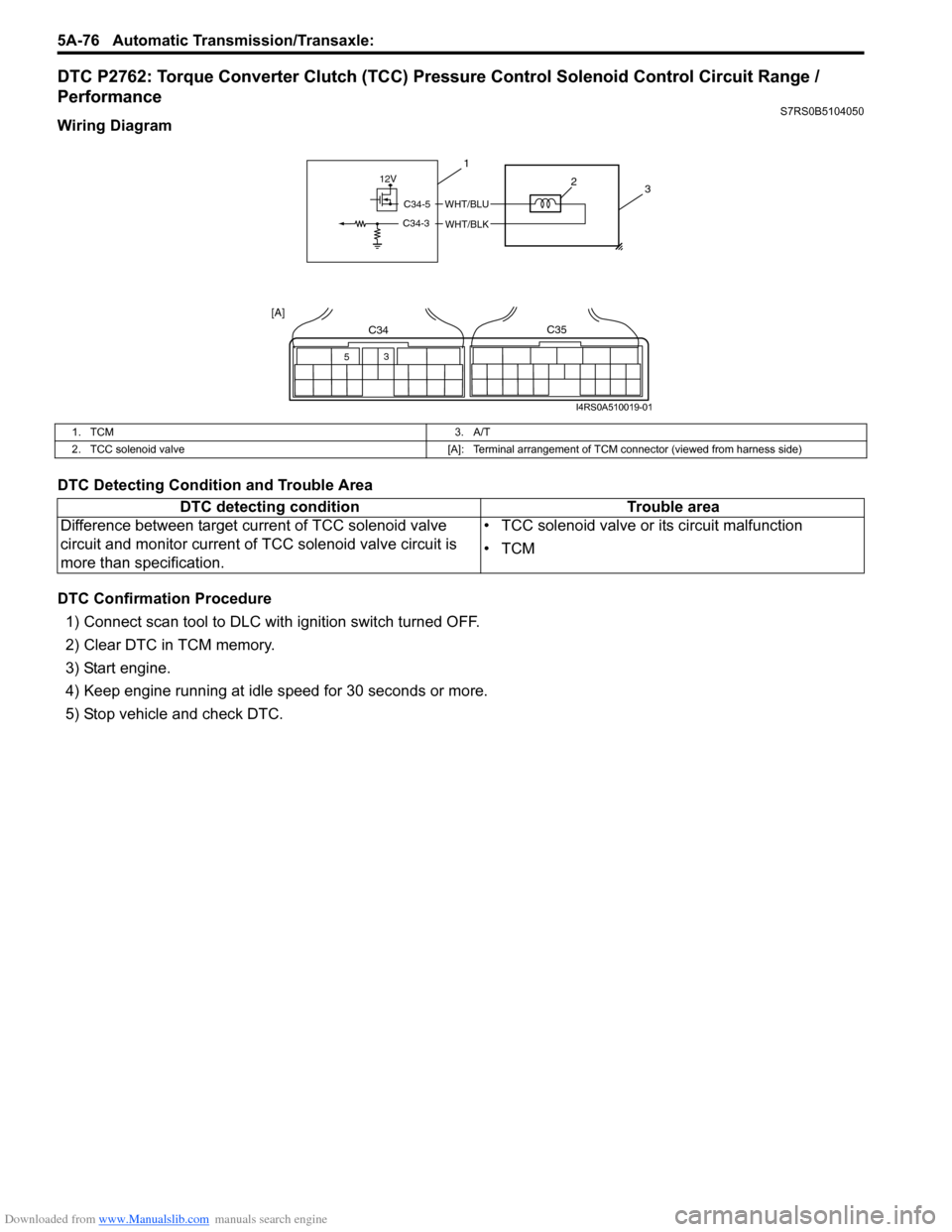

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit Range /

Performance

S7RS0B5104050

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

12V

C34-5

C34-3

WHT/BLU

WHT/BLK

3

1

2

53

C34C35

[A]

I4RS0A510019-01

1. TCM

3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting conditionTrouble area

Difference between target current of TCC solenoid valve

circuit and monitor current of TCC solenoid valve circuit is

more than specification. • TCC solenoid valve or its circuit malfunction

•TCM

Page 728 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-84 Automatic Transmission/Transaxle:

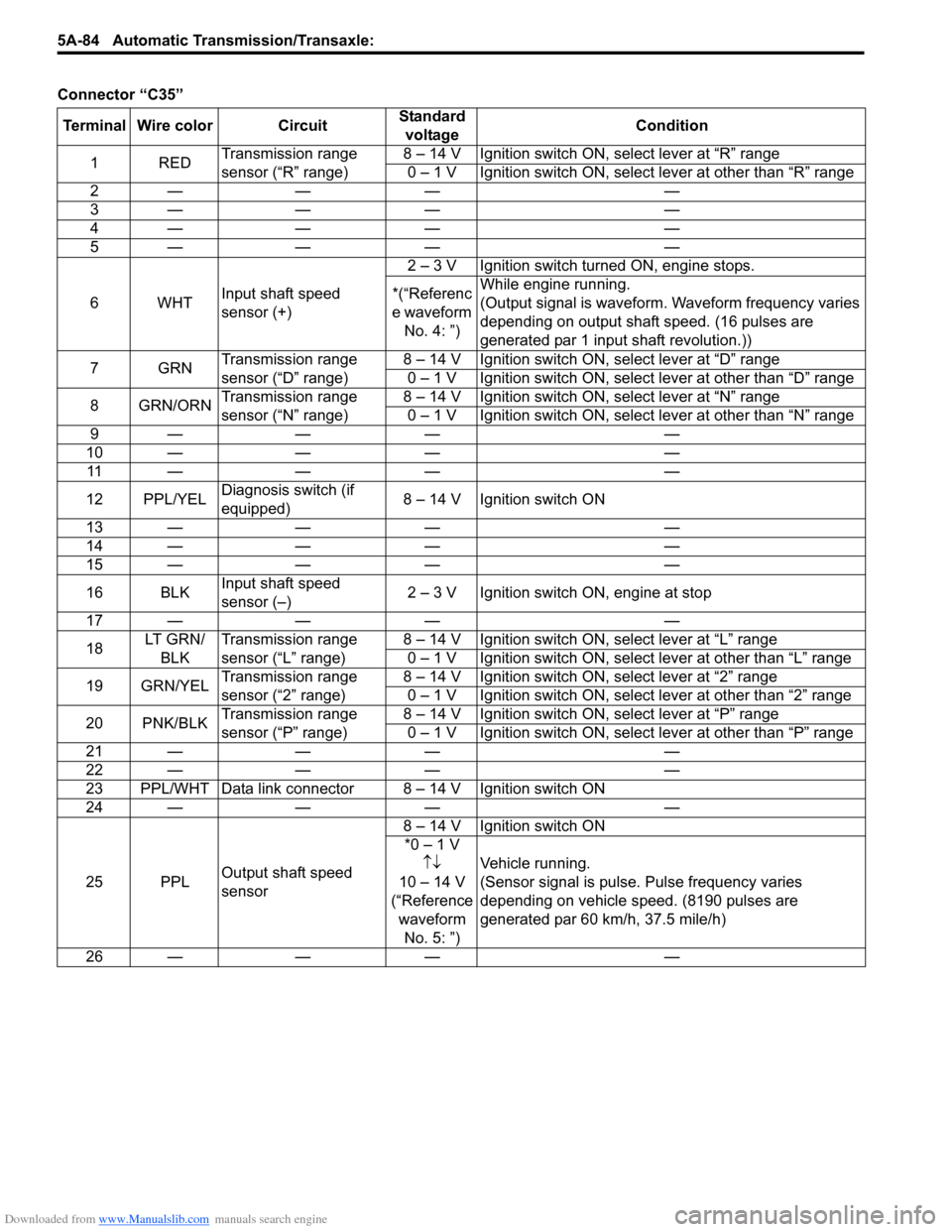

Connector “C35”

Terminal Wire color Circuit Standard

voltage Condition

1RED Transmission range

sensor (“R” range) 8 – 14 V Ignition switch ON, select lever at “R” range

0 – 1 V Ignition switch ON, select lever at other than “R” range

2— — — —

3— — — —

4— — — —

5— — — —

6WHT Input shaft speed

sensor (+) 2 – 3 V Ignition switch turned ON, engine stops.

*(“Referenc

e waveform No. 4: ”) While engine running.

(Output signal is waveform. Waveform frequency varies

depending on output shaft speed. (16 pulses are

generated par 1 input shaft revolution.))

7GRN Transmission range

sensor (“D” range) 8 – 14 V Ignition switch ON, select lever at “D” range

0 – 1 V Ignition switch ON, select lever at other than “D” range

8 GRN/ORN Transmission range

sensor (“N” range) 8 – 14 V Ignition switch ON, select lever at “N” range

0 – 1 V Ignition switch ON, select lever at other than “N” range

9— — — —

10 — — — — 11 — — — —

12 PPL/YEL Diagnosis switch (if

equipped) 8 – 14 V Ignition switch ON

13 — — — —

14 — — — —

15 — — — —

16 BLK Input shaft speed

sensor (–) 2 – 3 V Ignition switch ON, engine at stop

17 — — — —

18 LT G R N /

BLK Transmission range

sensor (“L” range) 8 – 14 V Ignition switch ON, select lever at “L” range

0 – 1 V Ignition switch ON, select lever at other than “L” range

19 GRN/YEL Transmission range

sensor (“2” range) 8 – 14 V Ignition switch ON, select lever at “2” range

0 – 1 V Ignition switch ON, select lever at other than “2” range

20 PNK/BLK Transmission range

sensor (“P” range) 8 – 14 V Ignition switch ON, select lever at “P” range

0 – 1 V Ignition switch ON, select lever at other than “P” range

21 — — — —

22 — — — —

23 PPL/WHT Data link connector 8 – 14 V Ignition switch ON

24 — — — —

25 PPL Output shaft speed

sensor 8 – 14 V Ignition switch ON

*0 – 1 V ↑↓

10 – 14 V

(“Reference waveform No. 5: ”) Vehicle running.

(Sensor signal is pulse. Pulse frequency varies

depending on vehicle speed. (8190 pulses are

generated par 60 km/h, 37.5 mile/h)

26 — — — —

Page 730 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-86 Automatic Transmission/Transaxle:

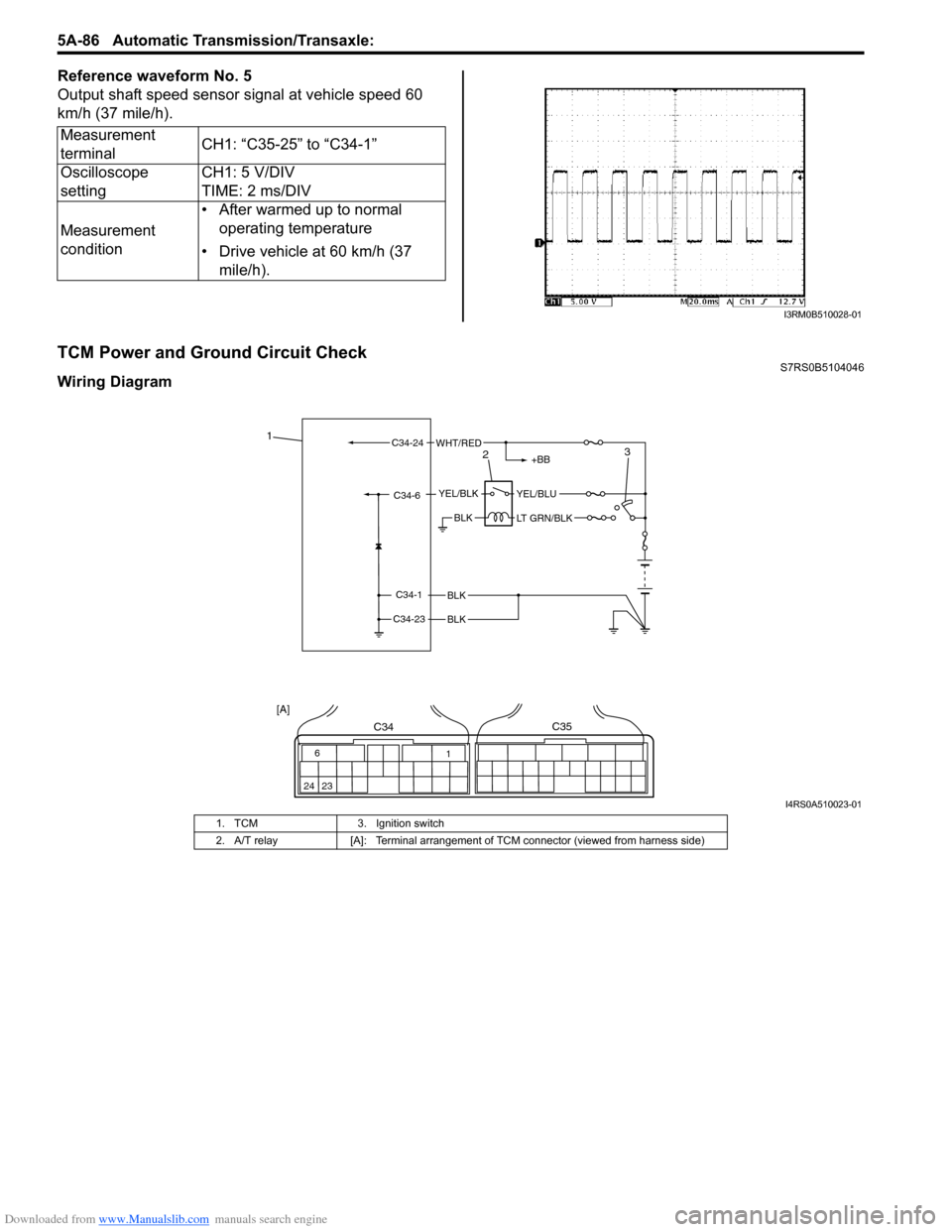

Reference waveform No. 5

Output shaft speed sensor signal at vehicle speed 60

km/h (37 mile/h).

TCM Power and Ground Circuit CheckS7RS0B5104046

Wiring DiagramMeasurement

terminal

CH1: “C35-25” to “C34-1”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 2 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Drive vehicle at 60 km/h (37 mile/h).

I3RM0B510028-01

BLK

BLK

BLK

C34-1

C34-23

C34-6YEL/BLKYEL/BLU

LT GRN/BLK

+BB

C34-24WHT/RED1

23

6

24 23 1

C34C35

[A]

I4RS0A510023-01

1. TCM

3. Ignition switch

2. A/T relay [A]: Terminal arrangement of TCM connector (viewed from harness side)

Page 741 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

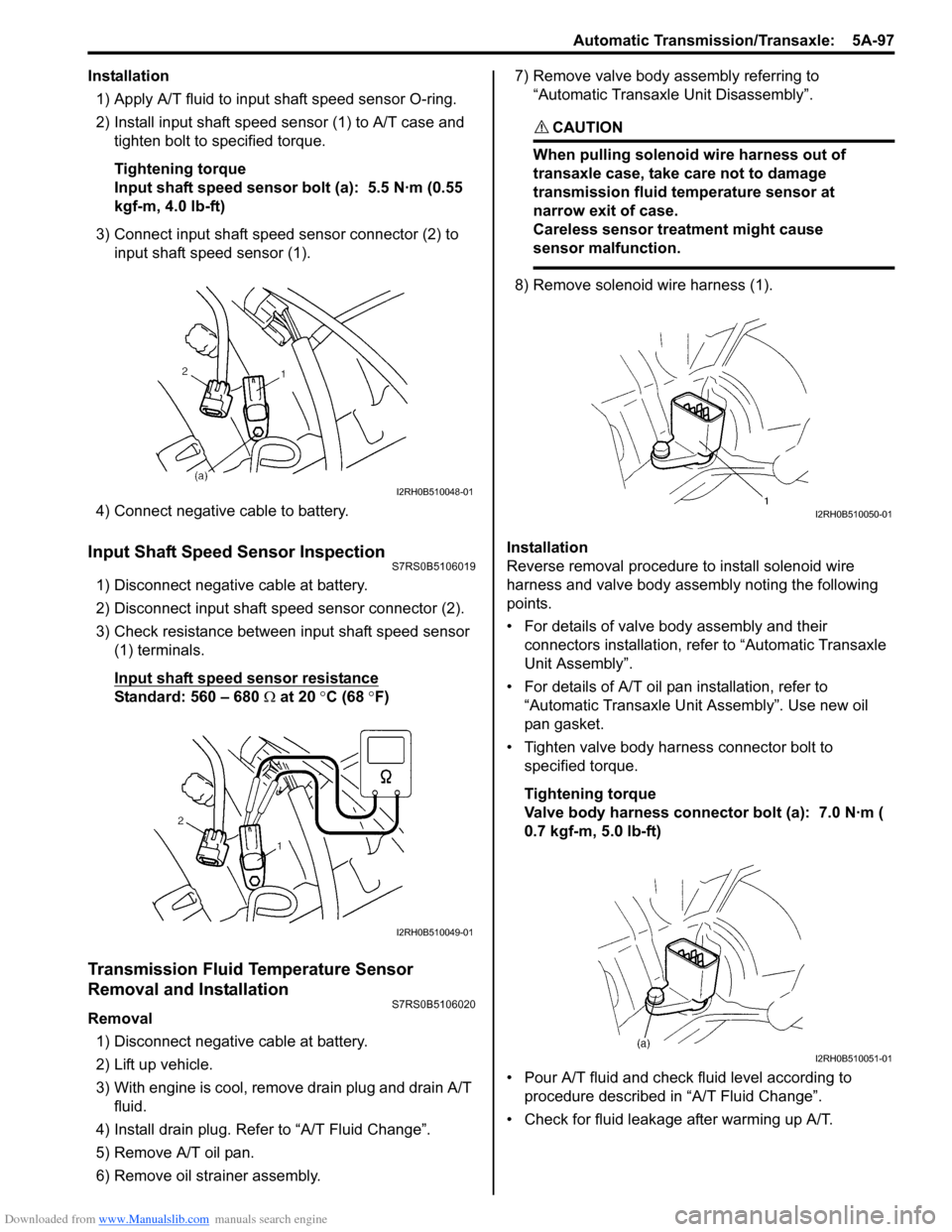

Installation1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed se nsor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to input shaft speed sensor (1).

4) Connect negative cable to battery.

Input Shaft Speed Sensor InspectionS7RS0B5106019

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor (1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S7RS0B5106020

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) With engine is cool, remove drain plug and drain A/T fluid.

4) Install drain plug. Refer to “A/T Fluid Change”.

5) Remove A/T oil pan.

6) Remove oil stra iner assembly. 7) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

CAUTION!

When pulling solenoid wire harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

8) Remove solenoid wire harness (1).

Installation

Reverse removal procedure to install solenoid wire

harness and valve body assembly noting the following

points.

• For details of valve body assembly and their connectors installation, refer to “Automatic Transaxle

Unit Assembly”.

• For details of A/T oil pa n installation, refer to

“Automatic Transaxle Unit Assembly”. Use new oil

pan gasket.

• Tighten valve body harness connector bolt to specified torque.

Tightening torque

Valve body harness connector bolt (a): 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft)

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

I2RH0B510048-01

I2RH0B510049-01

I2RH0B510050-01

I2RH0B510051-01

Page 884 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-2 Power Assisted Steering System:

General Description

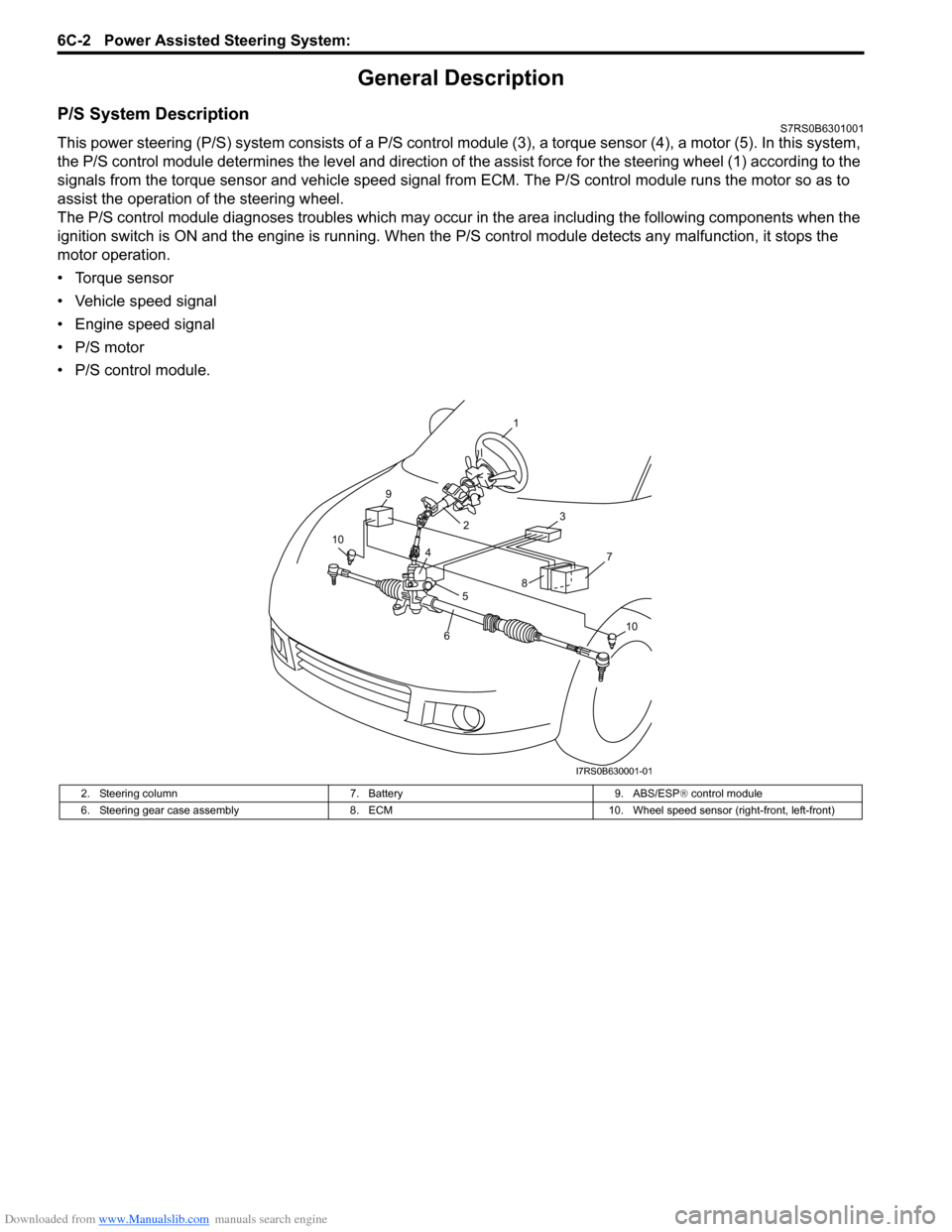

P/S System DescriptionS7RS0B6301001

This power steering (P/S) system consists of a P/S control module (3), a torque sensor (4), a motor (5). In this system,

the P/S control module determines the level and direction of the assist force for the steering wheel (1) according to the

signals from the torque sensor and vehicle speed signal from ECM. The P/S control module runs the motor so as to

assist the operation of the steering wheel.

The P/S control module diagnoses troubles which may occur in the area including the following components when the

ignition switch is ON and the engine is running. When the P/S control module detects any malfunction, it stops the

motor operation.

• Torque sensor

• Vehicle speed signal

• Engine speed signal

• P/S motor

• P/S control module.

2. Steering column 7. Battery9. ABS/ESP® control module

6. Steering gear case assembly 8. ECM10. Wheel speed sensor (right-front, left-front)

7

3

9

10

10

1

2

4

5

6

8

I7RS0B630001-01

Page 887 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-5

Terminal Arrangement of P/S Control Module Coupler (Viewed from Harness Side)

Diagnostic Information and Procedures

EPS System CheckS7RS0B6304001

WARNING!

Carry out test drive in light traffic area to prevent an accident.

Refer to the following items for the details of each step.Terminal Circuit Terminal Circuit

E49-1 Main power supply for internal memory

and EPS motor E52-9 Ground for torque sensors

E49-2 Ground for P/S control module E52-10 —

E51-1 Motor output 1 E52-11 Serial communication for data link

connector

E51-2 Motor output 2 E52-12 Engine speed signal

E52-1 Ignition switch signal for P/S control

module E52-13 —

E52-2 — E52-14 P/S operation signal (idle up signal)

E52-3 — E52-15 —

E52-4 Vehicle speed signal E52-16 Torque sensor internal failure signal

E52-5 “EPS” warning light E52-17 —

E52-6 Torque sensor signal (Sub) E52-18 Torque sensor signal (Main)

E52-7 — E52-19 Ground for shield wire

E52-8 Main power supply for torque sensor E52-20 5 V reference power supply for torque

sensor

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) DTC check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC Check”, Record and Clearance.

Is there any DTC(s)? Print DTC or write them

down and clear them by

referring to “DTC

Clearance” and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

Page 891 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-9

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan tool and the vehicle can not be

established, perform “Serial Data Link

Circuit Check”.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

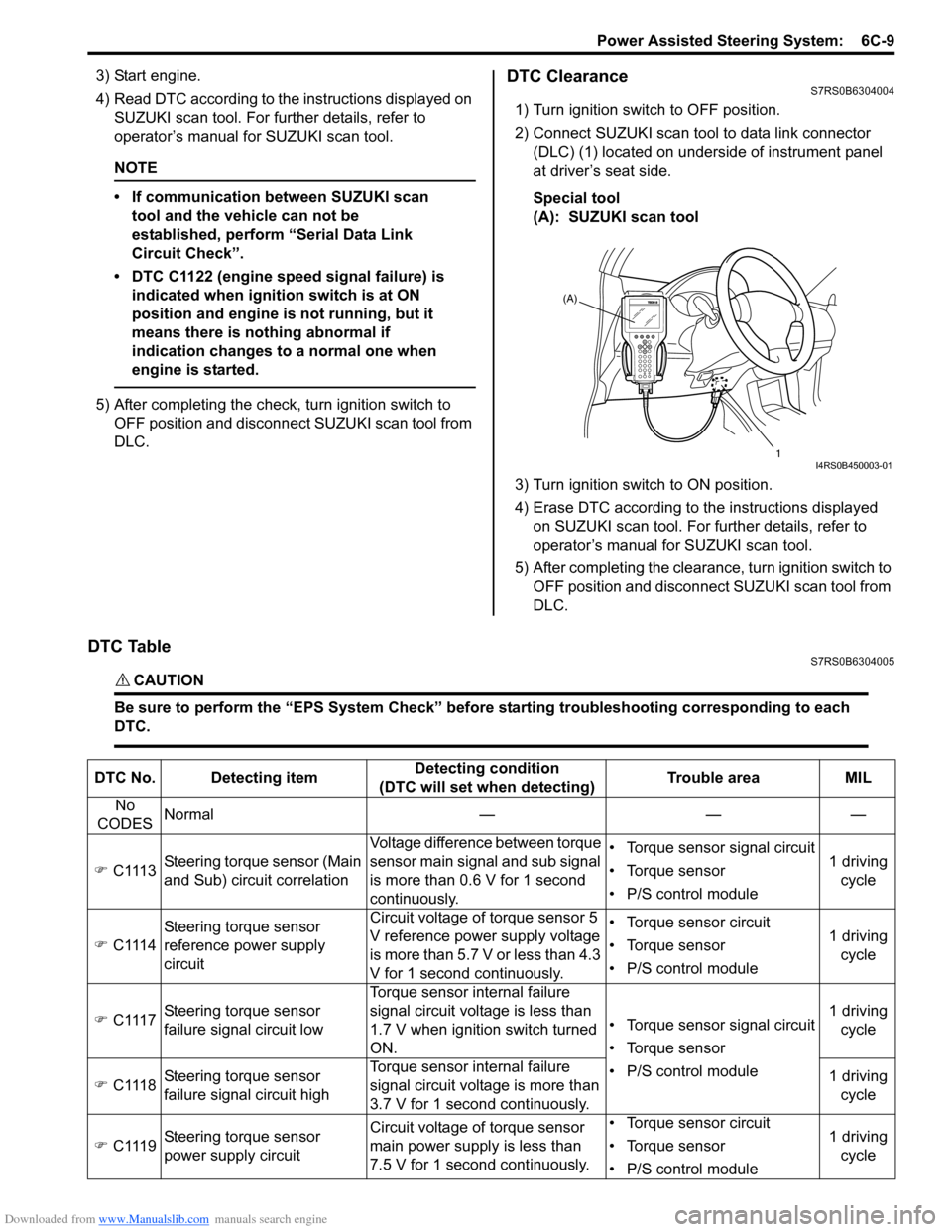

DTC ClearanceS7RS0B6304004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to the instructions displayed on SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

5) After completing the clearance, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

DTC TableS7RS0B6304005

CAUTION!

Be sure to perform the “EPS Syst em Check” before starting troubleshooting corresponding to each

DTC.

(A)

1

I4RS0B450003-01

DTC No. Detecting item Detecting condition

(DTC will set when detecting) Trouble area MIL

No

CODES Normal — — —

�) C1113 Steering torque sensor (Main

and Sub) circuit correlation Voltage difference between torque

sensor main signal and sub signal

is more than 0.6 V for 1 second

continuously. • Torque sensor signal circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1114 Steering torque sensor

reference power supply

circuit Circuit voltage of torque sensor 5

V reference power supply voltage

is more than 5.7 V or less than 4.3

V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle

�) C1117 Steering torque sensor

failure signal circuit low Torque sensor internal failure

signal circuit voltage is less than

1.7 V when ignition switch turned

ON.

• Torque sensor signal circuit

• Torque sensor

• P/S control module1 driving

cycle

�) C1118 Steering torque sensor

failure signal circuit high Torque sensor internal failure

signal circuit voltage is more than

3.7 V for 1 second continuously. 1 driving

cycle

�) C1119 Steering torque sensor

power supply circuit Circuit voltage of torque sensor

main power supply

is less than

7.5 V for 1 second continuously. • Torque sensor circuit

• Torque sensor

• P/S control module

1 driving

cycle