App SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

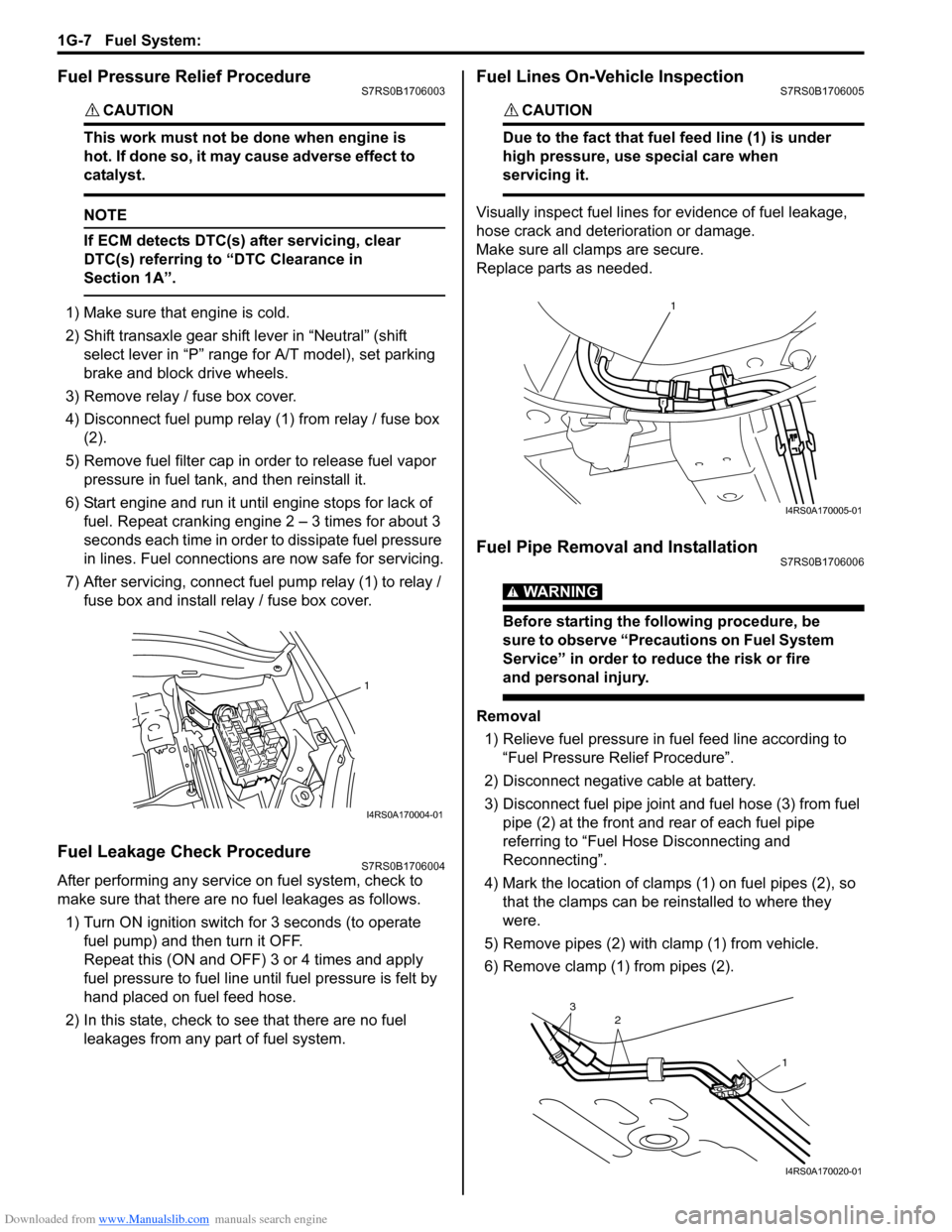

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

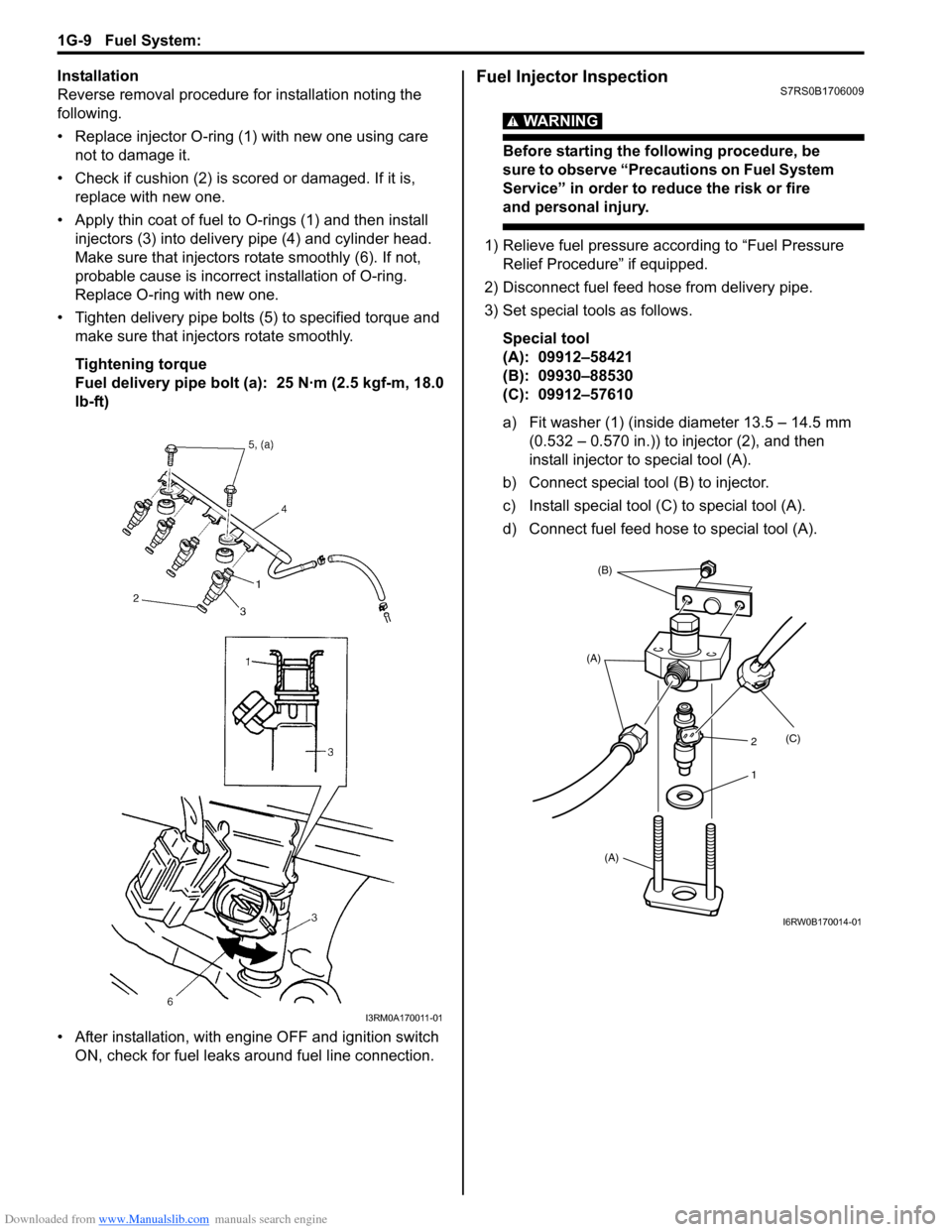

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 384 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-9 Fuel System:

Installation

Reverse removal procedure for installation noting the

following.

• Replace injector O-ring (1) with new one using care not to damage it.

• Check if cushion (2) is scor ed or damaged. If it is,

replace with new one.

• Apply thin coat of fuel to O-rings (1) and then install injectors (3) into delivery pipe (4) and cylinder head.

Make sure that injectors rota te smoothly (6). If not,

probable cause is incorrect installation of O-ring.

Replace O-ring with new one.

• Tighten delivery pipe bolts (5) to specified torque and make sure that inject ors rotate smoothly.

Tightening torque

Fuel delivery pipe bolt (a): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

• After installation, with engine OFF and ignition switch ON, check for fuel leaks around fuel line connection.Fuel Injector InspectionS7RS0B1706009

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure” if equipped.

2) Disconnect fuel feed hose from delivery pipe.

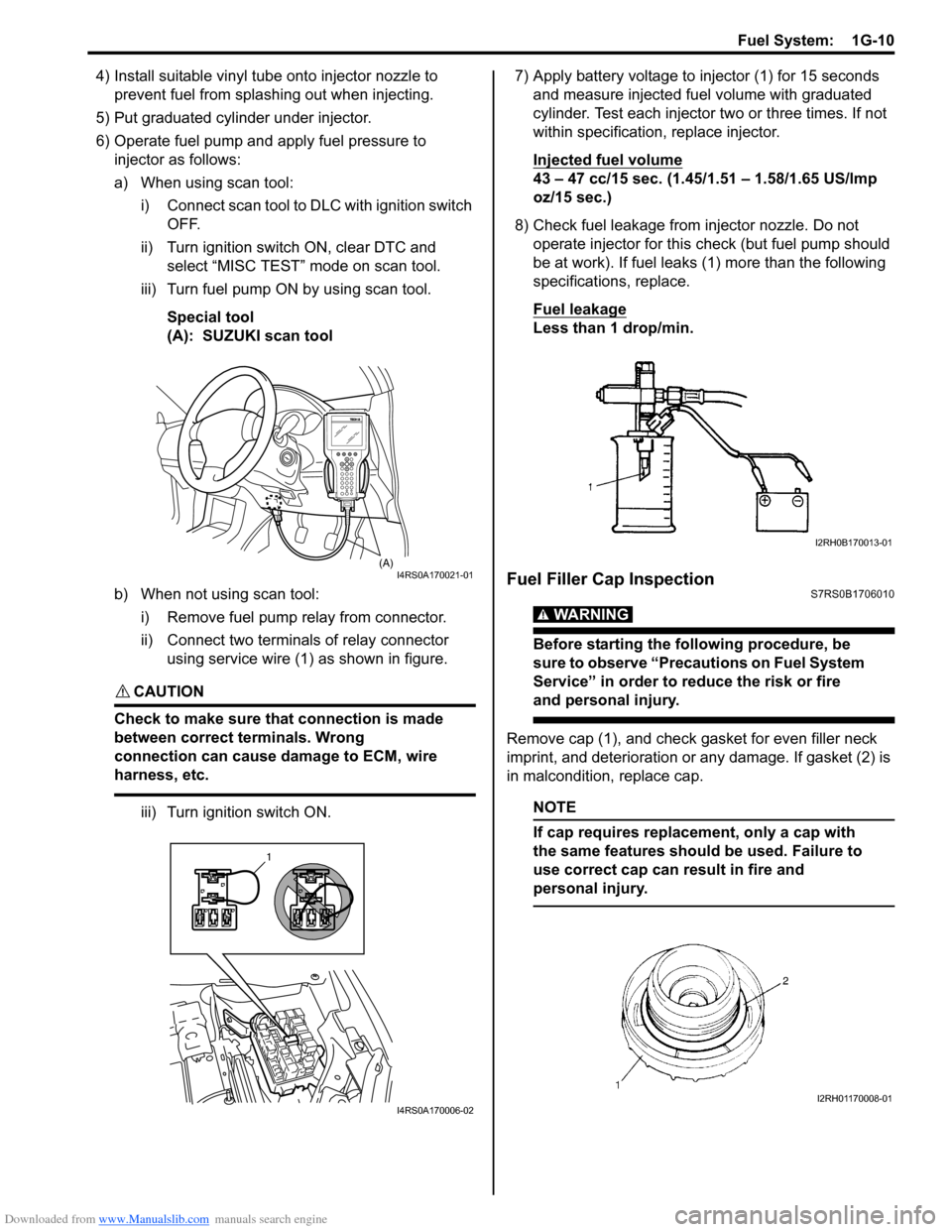

3) Set special tools as follows.

Special tool

(A): 09912–58421

(B): 09930–88530

(C): 09912–57610

a) Fit washer (1) (inside diameter 13.5 – 14.5 mm (0.532 – 0.570 in.)) to injector (2), and then

install injector to special tool (A).

b) Connect special tool (B) to injector.

c) Install special tool (C) to special tool (A).

d) Connect fuel feed hose to special tool (A).

I3RM0A170011-01

(B)

(A)

(A) (C)

2

1

I6RW0B170014-01

Page 385 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-10

4) Install suitable vinyl tube onto injector nozzle to

prevent fuel from splashing out when injecting.

5) Put graduated cylinder under injector.

6) Operate fuel pump and apply fuel pressure to

injector as follows:

a) When using scan tool:

i) Connect scan tool to DLC with ignition switch OFF.

ii) Turn ignition switch ON, clear DTC and select “MISC TEST” mode on scan tool.

iii) Turn fuel pump ON by using scan tool.

Special tool

(A): SUZUKI scan tool

b) When not using scan tool: i) Remove fuel pump relay from connector.

ii) Connect two terminals of relay connector using service wire (1) as shown in figure.

CAUTION!

Check to make sure that connection is made

between correct terminals. Wrong

connection can cause damage to ECM, wire

harness, etc.

iii) Turn ignition switch ON. 7) Apply battery voltage to in

jector (1) for 15 seconds

and measure injected fuel volume with graduated

cylinder. Test each injector two or three times. If not

within specification, replace injector.

Injected fuel volume

43 – 47 cc/15 sec. (1.45/1.51 – 1.58/1.65 US/lmp

oz/15 sec.)

8) Check fuel leakage from injector nozzle. Do not operate injector for this check (but fuel pump should

be at work). If fuel leaks (1) more than the following

specifications, replace.

Fuel leakage

Less than 1 drop/min.

Fuel Filler Cap InspectionS7RS0B1706010

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Remove cap (1), and che ck gasket for even filler neck

imprint, and deterioration or any damage. If gasket (2) is

in malcondition, replace cap.

NOTE

If cap requires replacement, only a cap with

the same features should be used. Failure to

use correct cap can result in fire and

personal injury.

(A)I4RS0A170021-01

1

I4RS0A170006-02

I2RH0B170013-01

I2RH01170008-01

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

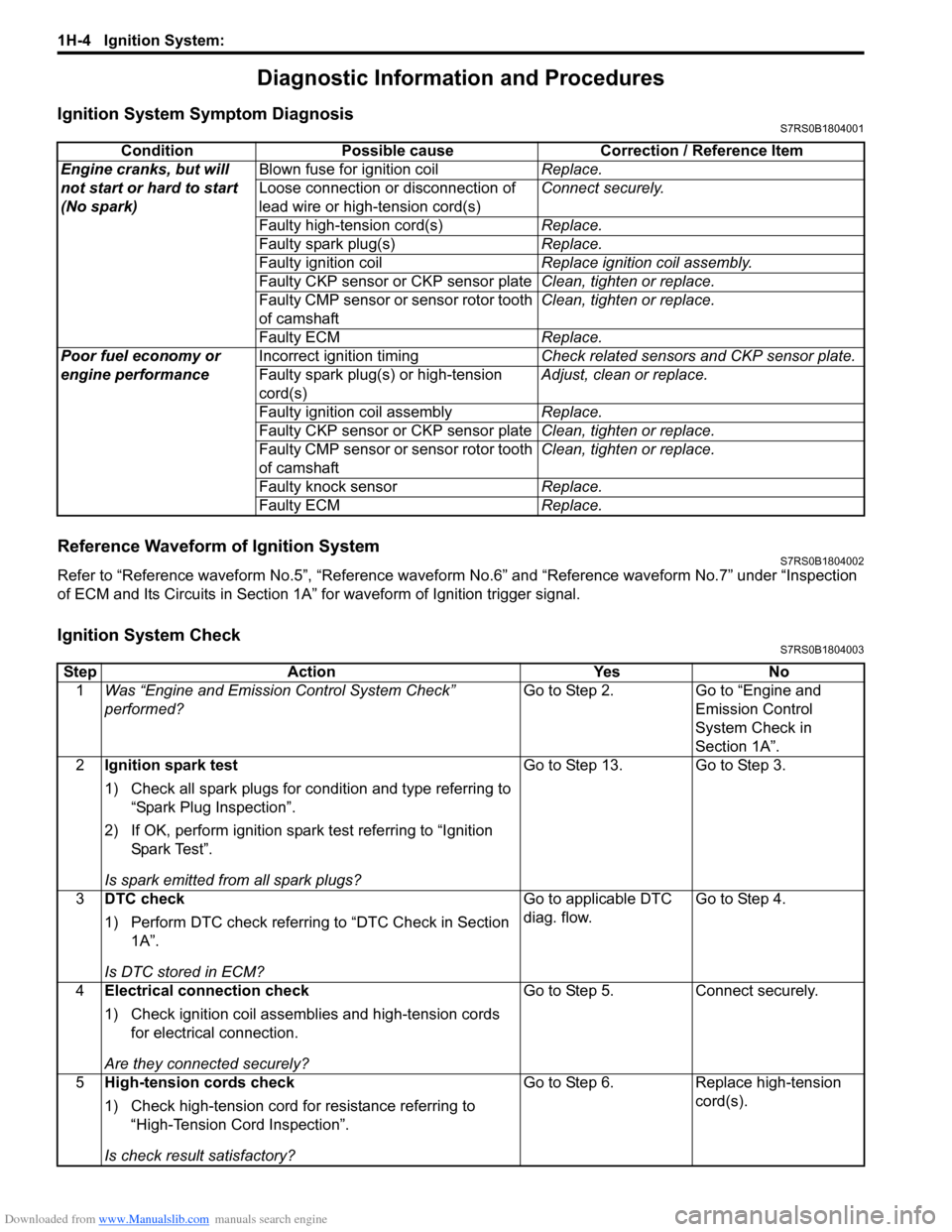

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 406 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-5 Starting System:

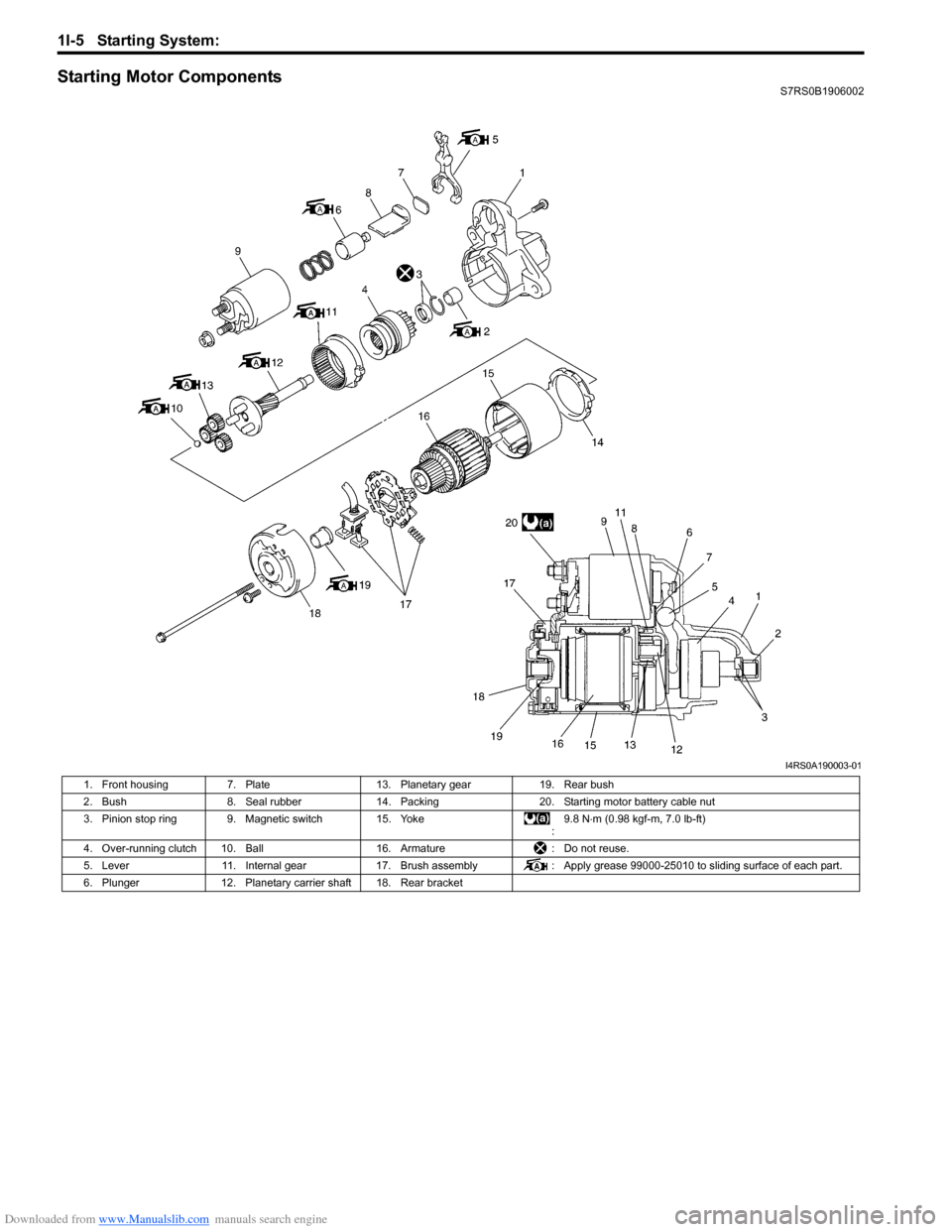

Starting Motor ComponentsS7RS0B1906002

I4RS0A190003-01

1. Front housing 7. Plate 13. Planetary gear 19. Rear bush

2. Bush 8. Seal rubber 14. Packing 20. Starting motor battery cable nut

3. Pinion stop ring 9. Magnetic switch 15. Yoke :9.8 N

⋅m (0.98 kgf-m, 7.0 lb-ft)

4. Over-running clutch 10. Ball 16. Armature: Do not reuse.

5. Lever 11. Internal gear 17. Brush assembly : Apply grease 99000-25010 to sliding surface of each part.

6. Plunger 12. Planetary carrier shaft 18. Rear bracket

Page 413 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

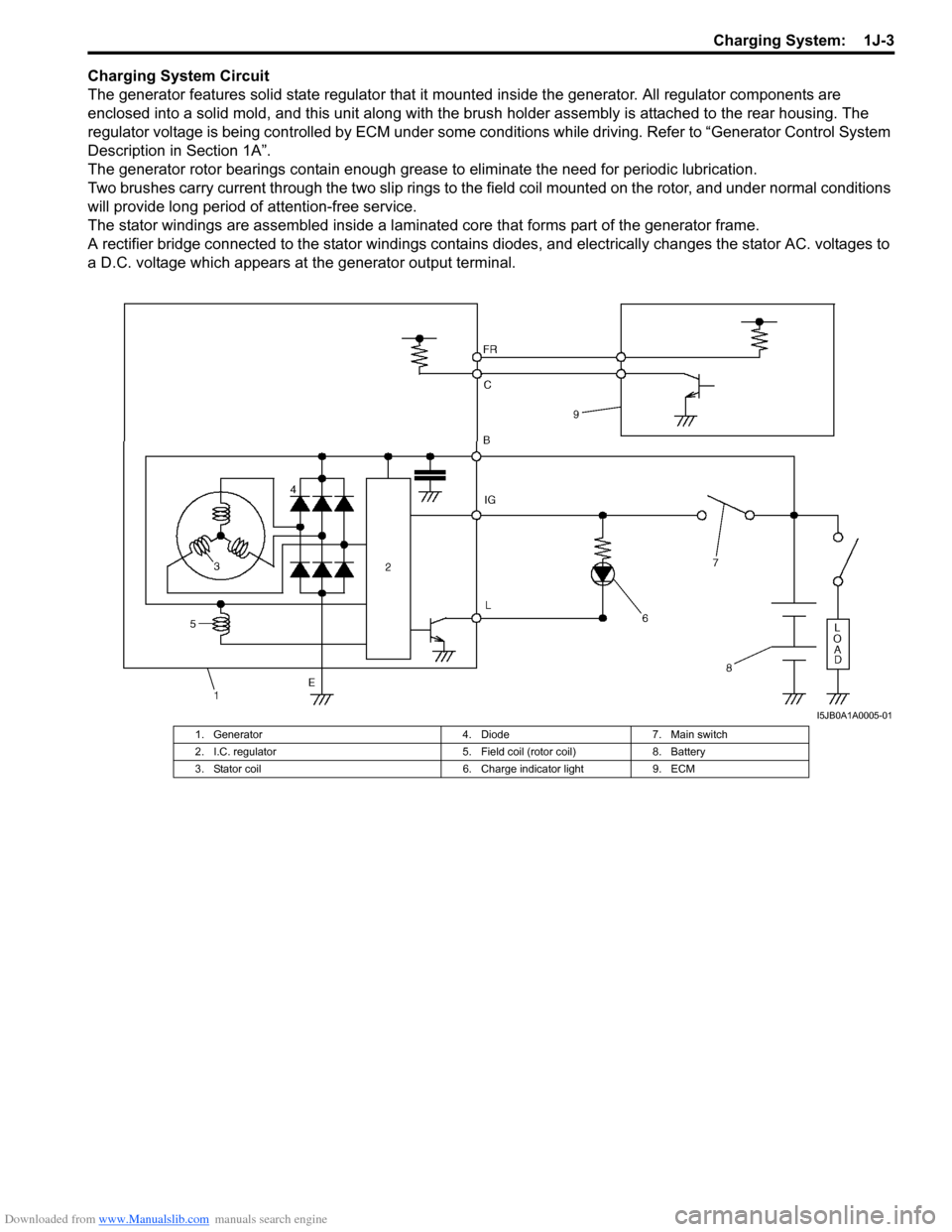

Charging System Circuit

The generator features solid state regulator that it mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brus h holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some cond itions while driving. Refer to “Generator Control System

Description in Section 1A”.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminate d core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes the stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

I5JB0A1A0005-01

1. Generator 4. Diode7. Main switch

2. I.C. regulator 5. Field coil (rotor coil)8. Battery

3. Stator coil 6. Charge indicator light9. ECM

Page 414 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

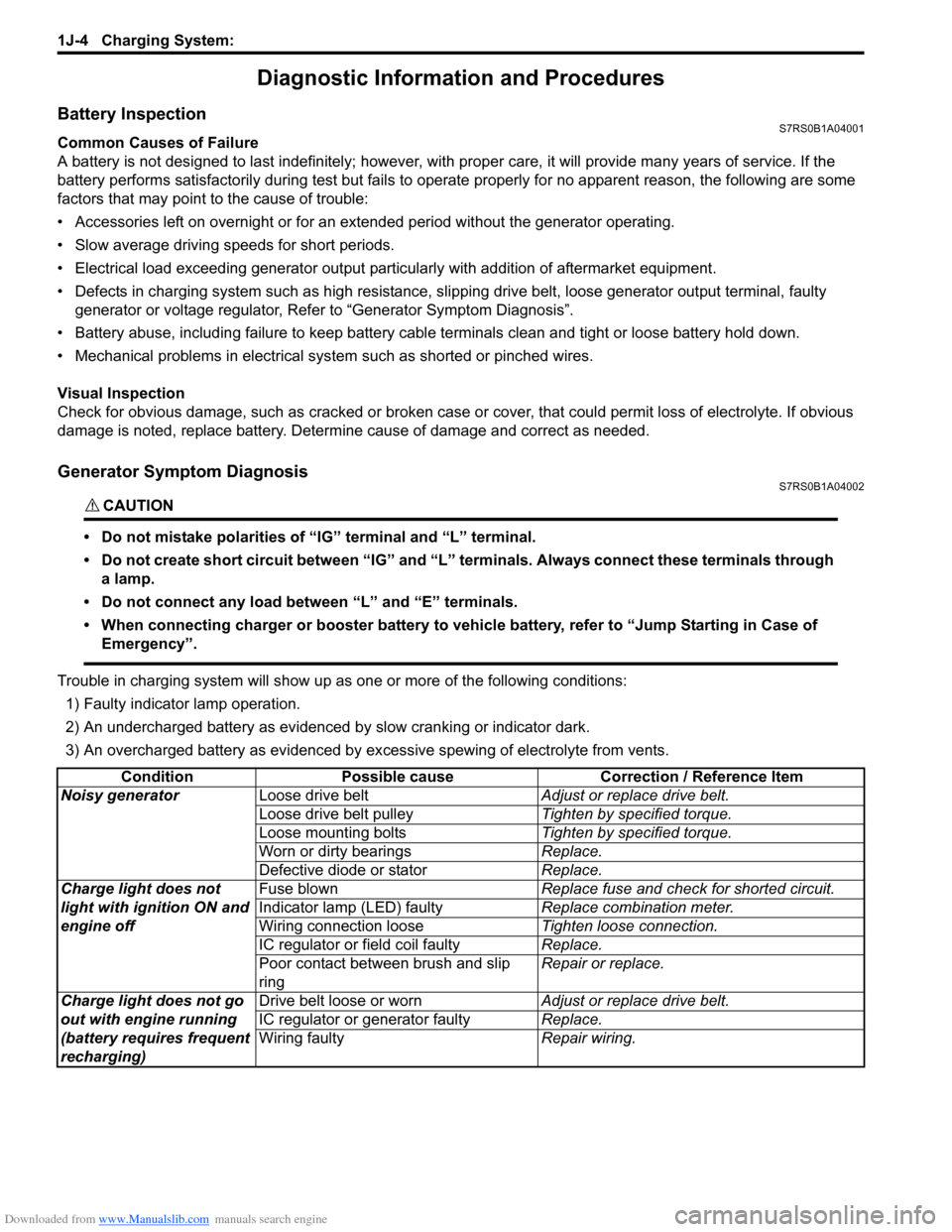

Diagnostic Information and Procedures

Battery InspectionS7RS0B1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however, with proper care, it will provide many years of service. If the

battery performs satisfactorily during te st but fails to operate properly for no apparent reason, the following are some

factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended period without the generator operating.

• Slow average driving speeds for short periods.

• Electrical load exceeding generator output partic ularly with addition of aftermarket equipment.

• Defects in charging system such as high resistance, s lipping drive belt, loose generator output terminal, faulty

generator or voltage regulator, Refer to “Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical sys tem such as shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken case or cover, that could permit loss of electrolyte. If obvious

damage is noted, replace battery. Determine cause of damage and correct as needed.

Generator Symptom DiagnosisS7RS0B1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal and “L” terminal.

• Do not create short circuit between “IG” and “L” terminals. Always connect these terminals through a lamp.

• Do not connect any load between “L” and “E” terminals.

• When connecting charger or booster battery to vehicle battery, refer to “Jump Starting in Case of Emergency”.

Trouble in charging system will show up as one or more of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow cranking or indicator dark.

3) An overcharged battery as evidenced by ex cessive spewing of electrolyte from vents.

Condition Possible cause Correction / Reference Item

Noisy generator Loose drive belt Adjust or replace drive belt.

Loose drive belt pulley Tighten by specified torque.

Loose mounting bolts Tighten by specified torque.

Worn or dirty bearings Replace.

Defective diode or stator Replace.

Charge light does not

light with ignition ON and

engine off Fuse blown

Replace fuse and check for shorted circuit.

Indicator lamp (LED) faulty Replace combination meter.

Wiring connection loose Tighten loose connection.

IC regulator or field coil faulty Replace.

Poor contact between brush and slip

ring Repair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging) Drive belt loose or worn

Adjust or replace drive belt.

IC regulator or generator faulty Replace.

Wiring faulty Repair wiring.

Page 415 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-5

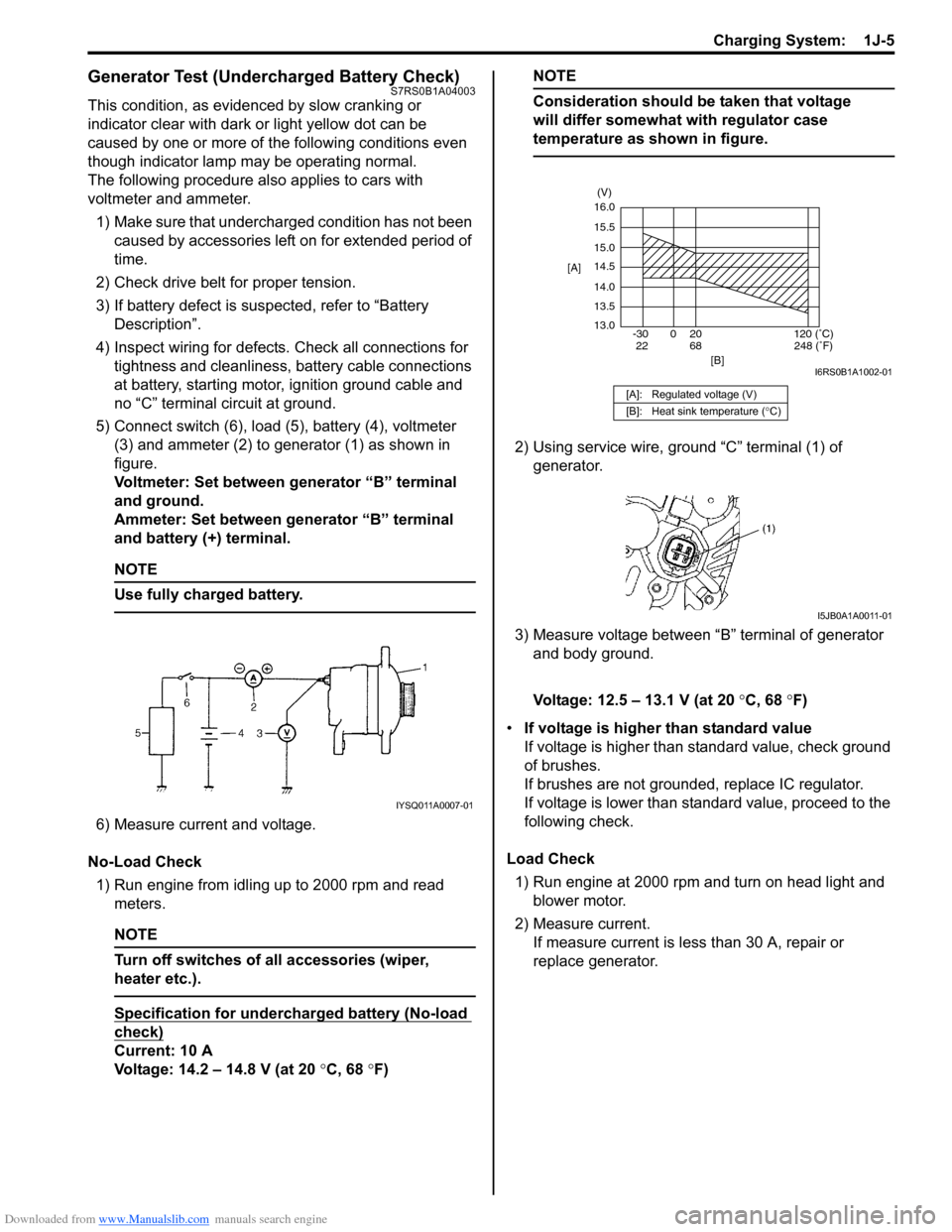

Generator Test (Undercharged Battery Check)S7RS0B1A04003

This condition, as evidenced by slow cranking or

indicator clear with dark or light yellow dot can be

caused by one or more of the following conditions even

though indicator lamp may be operating normal.

The following procedure also applies to cars with

voltmeter and ammeter.1) Make sure that undercharged condition has not been caused by accessories left on for extended period of

time.

2) Check drive belt for proper tension.

3) If battery defect is suspected, refer to “Battery Description”.

4) Inspect wiring for defects. Check all connections for tightness and cleanliness, battery cable connections

at battery, starting motor, ignition ground cable and

no “C” terminal circuit at ground.

5) Connect switch (6), load (5), battery (4), voltmeter (3) and ammeter (2) to generator (1) as shown in

figure.

Voltmeter: Set between generator “B” terminal

and ground.

Ammeter: Set between generator “B” terminal

and battery (+) terminal.

NOTE

Use fully charged battery.

6) Measure current and voltage.

No-Load Check 1) Run engine from idling up to 2000 rpm and read meters.

NOTE

Turn off switches of all accessories (wiper,

heater etc.).

Specification for undercharged battery (No-load

check)

Current: 10 A

Voltage: 14.2 – 14.8 V (at 20 °C, 68 °F)

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in figure.

2) Using service wire, ground “C” terminal (1) of

generator.

3) Measure voltage between “B” terminal of generator and body ground.

Voltage: 12.5 – 13.1 V (at 20 °C, 68 °F)

• If voltage is higher than standard value

If voltage is higher than standard value, check ground

of brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to the

following check.

Load Check 1) Run engine at 2000 rpm and turn on head light and blower motor.

2) Measure current. If measure current is less than 30 A, repair or

replace generator.

IYSQ011A0007-01

[A]: Regulated voltage (V)

[B]: Heat sink temperature ( °C)

16.0

15.5

15.0

14.5

14.0

13.5

13.0

-30 0 20

[A]

[B]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0B1A1002-01

I5JB0A1A0011-01

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

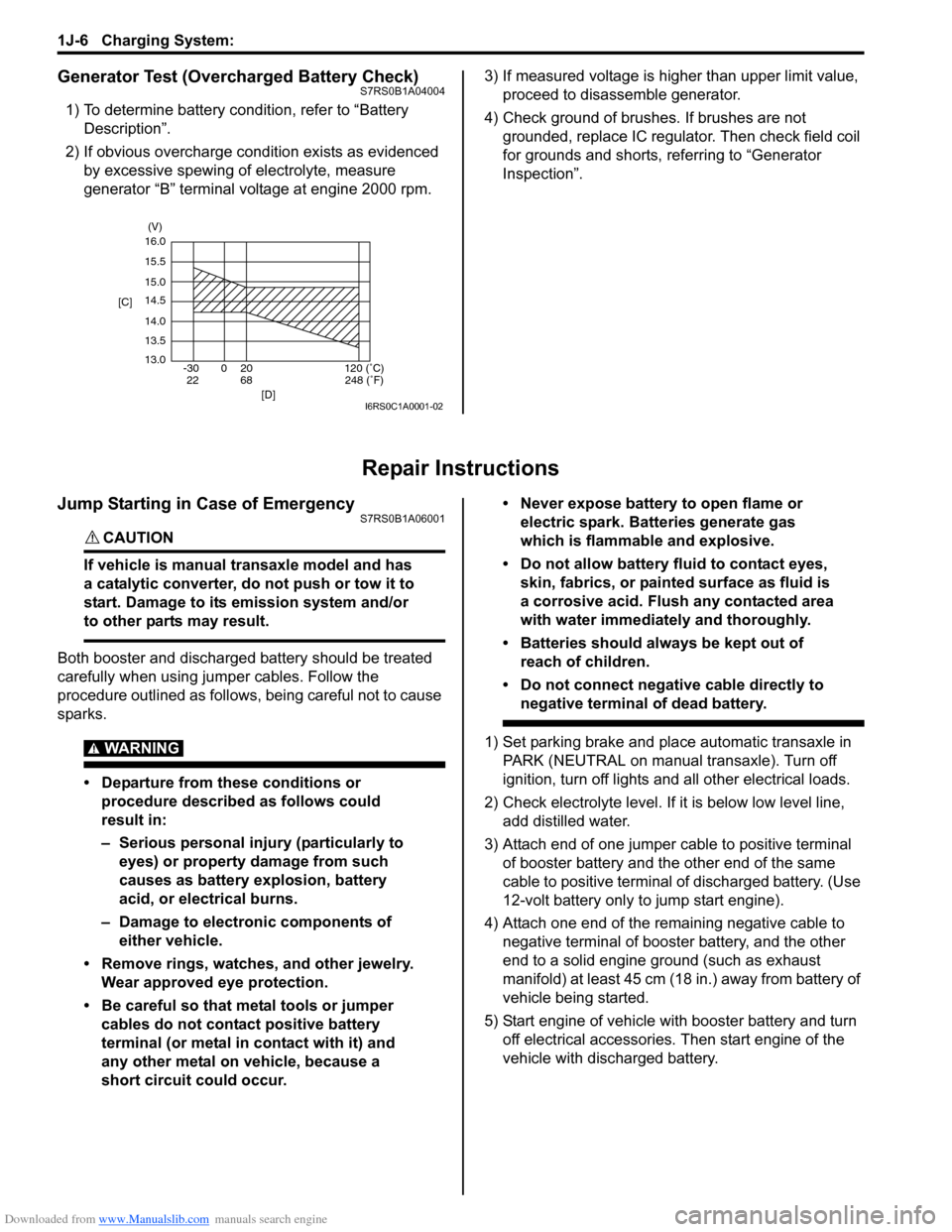

Generator Test (Overcharged Battery Check)S7RS0B1A04004

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 435 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS7RS0B2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:

• Check all tires for proper inflation pressures and approximately the same tread wear. • Check for loose of ball join

ts. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missin g stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check alignment and follow manufa cturer’s instructions.

• Regardless of equipment used to check alignment, vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S7RS0B2206001

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted properly and wheel is free from deflection.

• Check that each suspension part is free from bend, dent, wear or damage in any other form.

• Check that ground clearance at the right and left is just about the same.

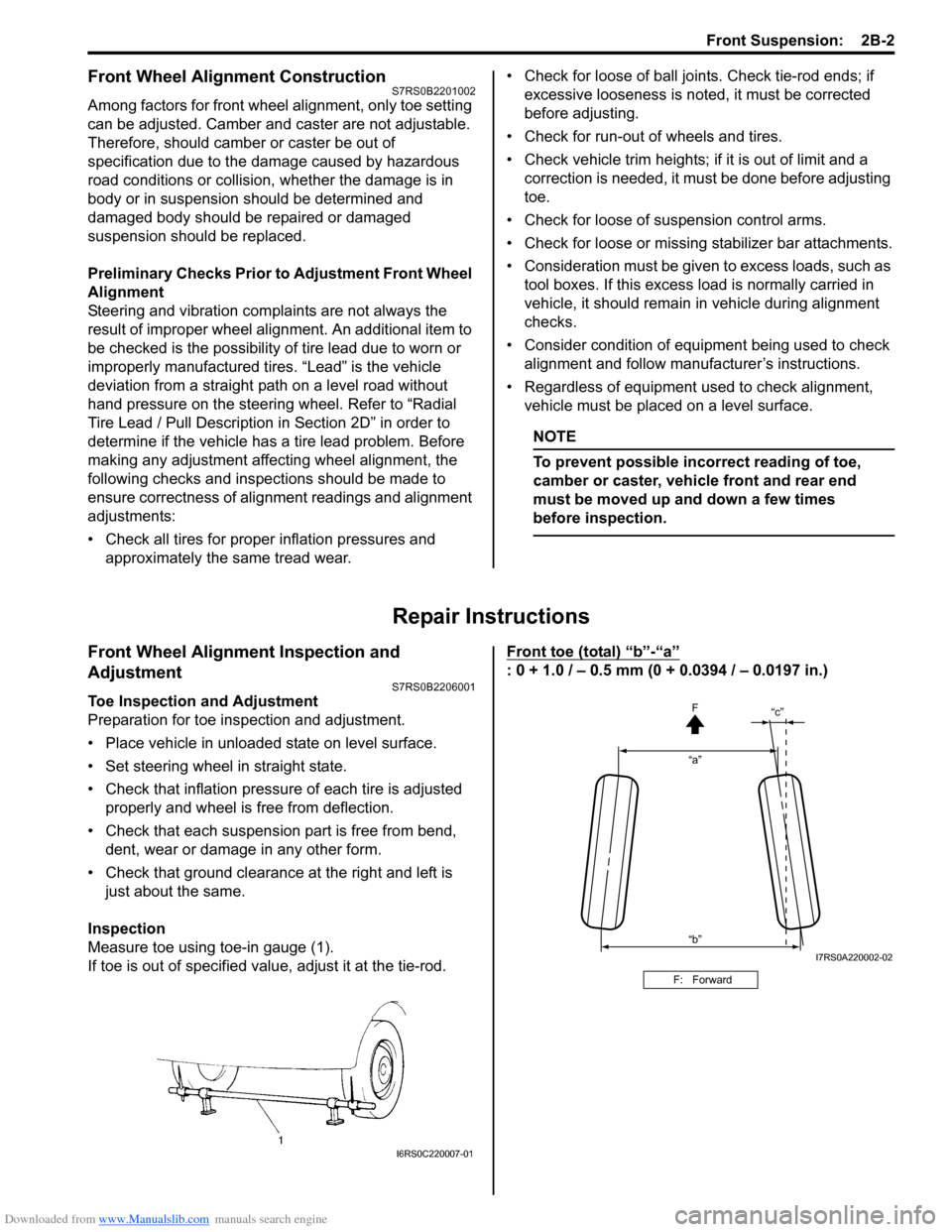

Inspection

Measure toe using toe-in gauge (1).

If toe is out of specified value, adjust it at the tie-rod. Front toe (total) “b”-“a”

: 0 + 1.0 / – 0.5 mm (0 + 0.0394 / – 0.0197 in.)

I6RS0C220007-01

F: Forward

“a”

“c”

“b” F

I7RS0A220002-02