Meter SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1048 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-10 Air Bag System:

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS7RS0B8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

The order in which DTCs are diagnosed is

very important. Failure to diagnose the DTCs

in the order specified may result in extended

diagnostic time, incorrect diagnosis and

incorrect parts replacement.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.1) Perform the “Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning right operation

through “AIR BAG” warning right and whether air

bag DTCs exist.)

2) Refer to the proper diagnost ic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow” after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

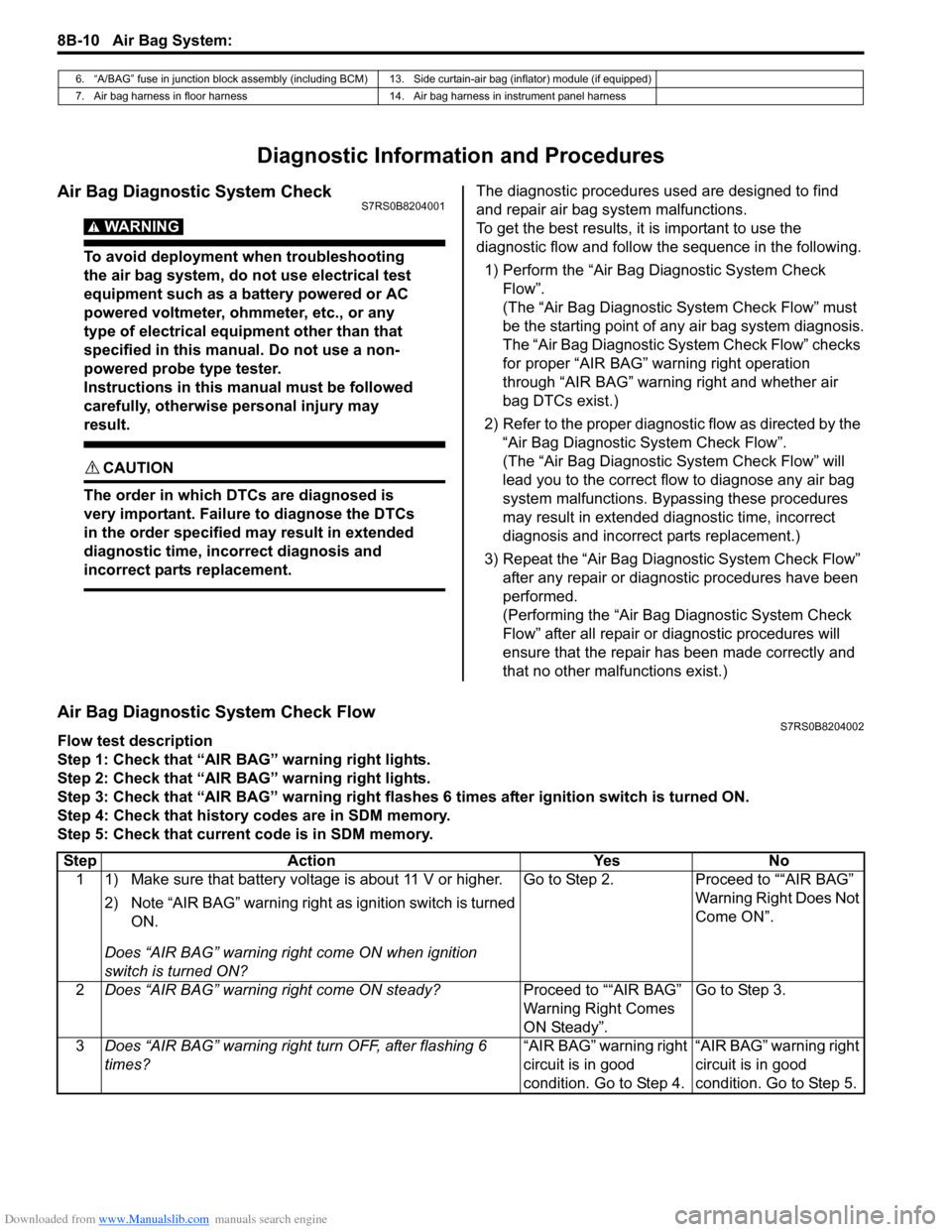

Air Bag Diagnostic System Check FlowS7RS0B8204002

Flow test description

Step 1: Check that “AIR BAG” warning right lights.

Step 2: Check that “AIR BAG” warning right lights.

Step 3: Check that “AIR BAG” warning right flas hes 6 times after ignition switch is turned ON.

Step 4: Check that history codes are in SDM memory.

Step 5: Check that current code is in SDM memory.

6. “A/BAG” fuse in junction block assembly (including BCM) 13. Side curtain-air bag (inflator) module (if equipped)

7. Air bag harness in floor harness 14. Air bag harness in instrument panel harness

Step Action YesNo

1 1) Make sure that battery voltage is about 11 V or higher.

2) Note “AIR BAG” warning right as ignition switch is turned

ON.

Does “AIR BAG” warning ri ght come ON when ignition

switch is turned ON? Go to Step 2.

Proceed to ““AIR BAG”

Warning Right Does Not

Come ON”.

2 Does “AIR BAG” warning right come ON steady? Proceed to ““AIR BAG”

Warning Right Comes

ON Steady”.Go to Step 3.

3 Does “AIR BAG” warning right turn OFF, after flashing 6

times? “AIR BAG” warning right

circuit is in good

condition. Go to Step 4.“AIR BAG” warning right

circuit is in good

condition. Go to Step 5.

Page 1051 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-13

Scan Tool DataS7RS0B8204006

Data list of SDM

Definition

Back Up Volt (V)

This parameter indicates the capacity of the backup

condenser installed to maintain the ignition current (as

much as possible) even when the power supply to SDM

that ignites the inflator is shut off.

Battery Voltage (V)

Battery voltage is an analog input signal read by SDM.

System ID (4ch/8ch)

This parameter indicates the number of initiator circuits.

Driv A/B Ini Res (Driver air bag initiator resistance)

(ohm)

This parameter indicates the resistance of the driver air

bag initiator circuit. Pass A/B Ini Res (Passenger air bag initiator

resistance) (ohm)

This parameter indicates the

resistance of the passenger

air bag initiator circuit.

Driv Preten Ini Res (Dri ver pretensioner initiator

resistance) (ohm)

This parameter indicates the resistance of the driver seat

belt pretensioner initiator circuit.

Pass Preten Ini Res (Passenger pretensioner

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

seat belt pretensioner initiator circuit.

Driv Sidebag Ini Res (Driver side-air bag initiator

resistance) (ohm)

This parameter indicates the resistance of the driver

side-air bag initiator circuit.

Pass Sidebag Ini Res (Passenger side-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the

Passenger side-air bag initiator circuit.

Driv curtain Ini Res (Driver side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the re sistance of the driver side

curtain-air bag initiator circuit.

Pass curtain Ini Res (Passenger side curtain-air bag

initiator resistance) (ohm)

This parameter indicates the resistance of the passenger

side curtain-air bag initiator circuit.

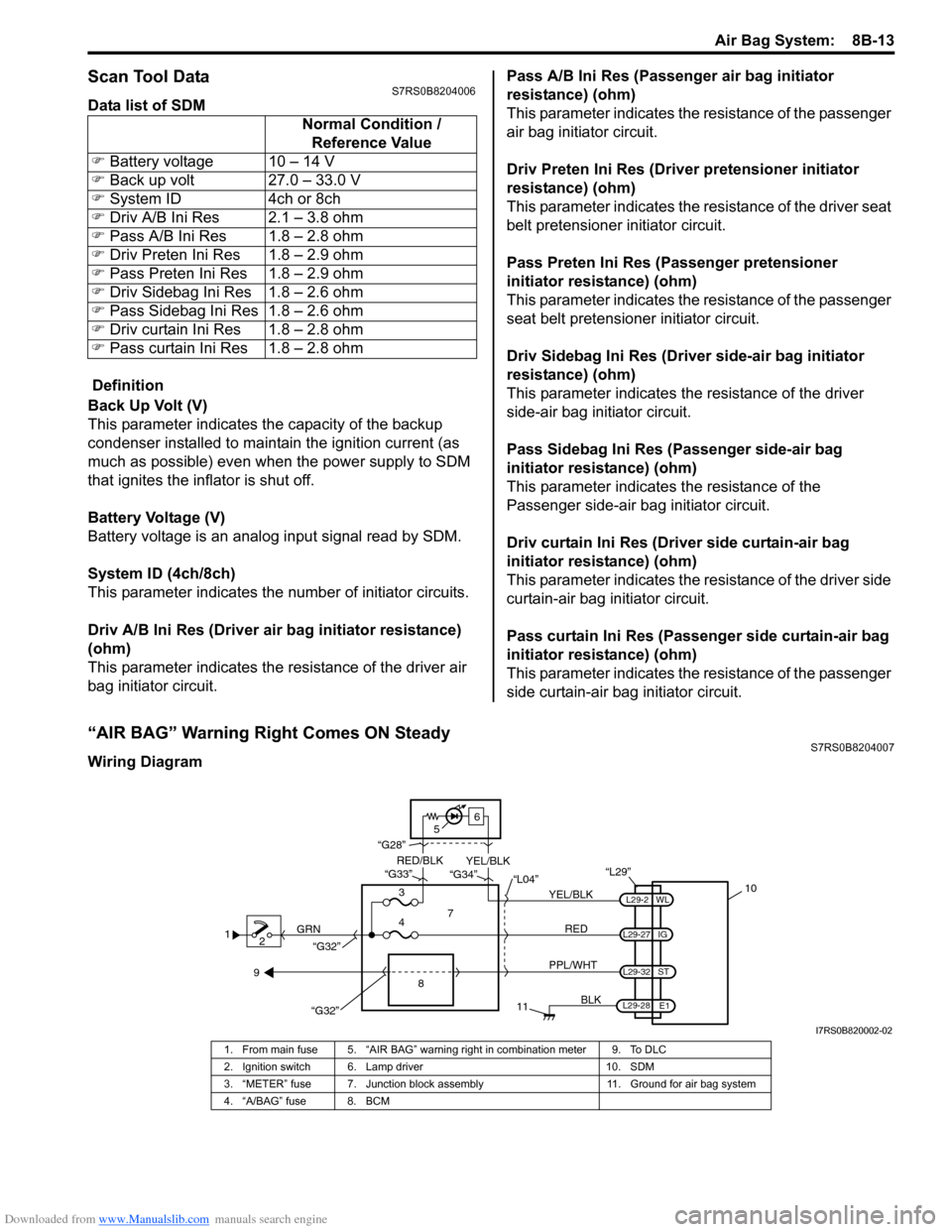

“AIR BAG” Warning Right Comes ON SteadyS7RS0B8204007

Wiring Diagram Normal Condition /

Reference Value

�) Battery voltage 10 – 14 V

�) Back up volt 27.0 – 33.0 V

�) System ID 4ch or 8ch

�) Driv A/B Ini Res 2.1 – 3.8 ohm

�) Pass A/B Ini Res 1.8 – 2.8 ohm

�) Driv Preten Ini Res 1.8 – 2.9 ohm

�) Pass Preten Ini Res 1.8 – 2.9 ohm

�) Driv Sidebag Ini Res 1.8 – 2.6 ohm

�) Pass Sidebag Ini Res 1.8 – 2.6 ohm

�) Driv curtain Ini Res 1.8 – 2.8 ohm

�) Pass curtain Ini Res 1.8 – 2.8 ohm

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1053 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-15

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

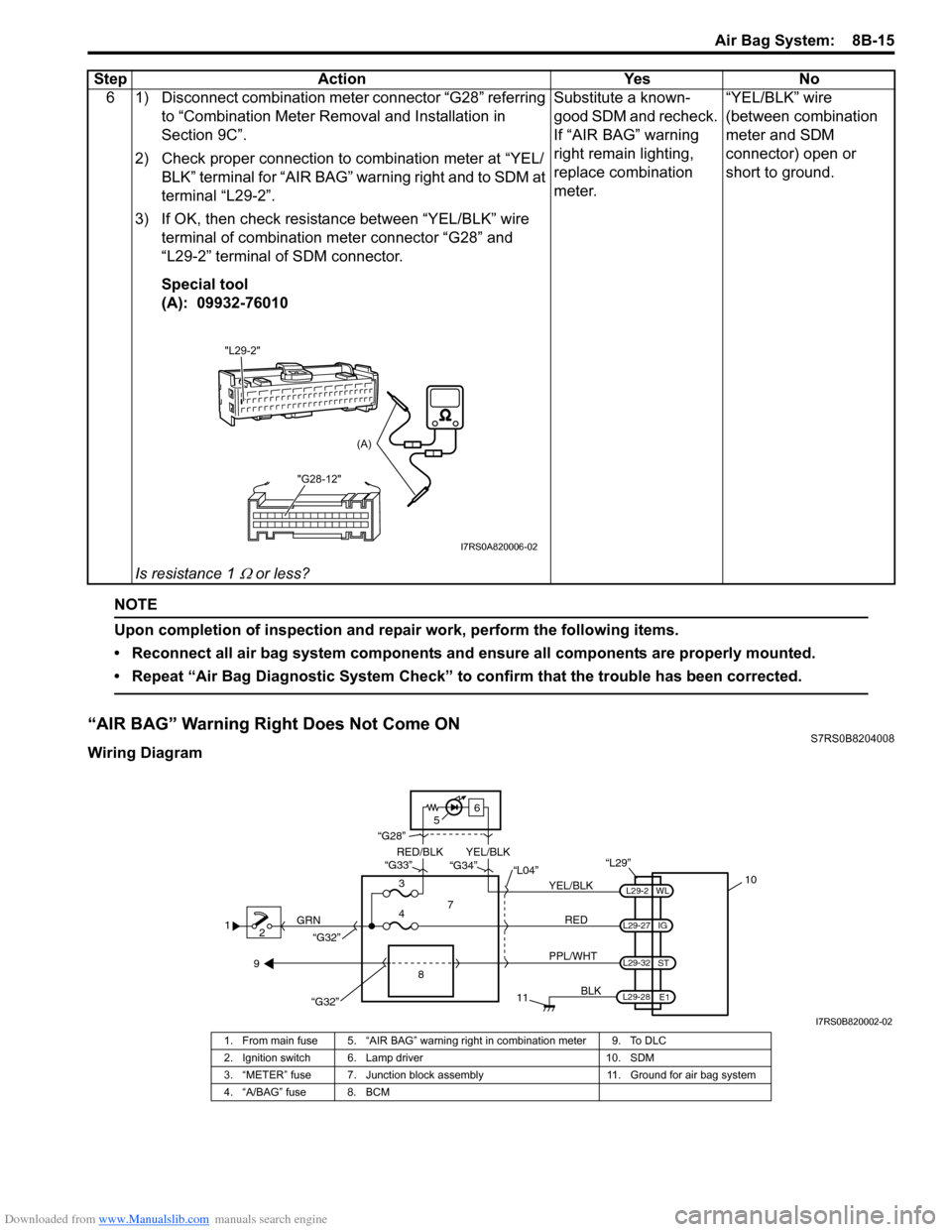

“AIR BAG” Warning Right Does Not Come ONS7RS0B8204008

Wiring Diagram6 1) Disconnect combination meter connector “G28” referring

to “Combination Meter Removal and Installation in

Section 9C”.

2) Check proper connection to combination meter at “YEL/ BLK” terminal for “AIR BAG” warning right and to SDM at

terminal “L29-2”.

3) If OK, then check resistance between “YEL/BLK” wire terminal of combination meter connector “G28” and

“L29-2” terminal of SDM connector.

Special tool

(A): 09932-76010

Is resistance 1

Ω or less? Substitute a known-

good SDM and recheck.

If “AIR BAG” warning

right remain lighting,

replace combination

meter.

“YEL/BLK” wire

(between combination

meter and SDM

connector) open or

short to ground.

Step Action Yes No

"L29-2"

"G28-12"

(A)

I7RS0A820006-02

12 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1054 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-16 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Step 1: Check combination meter power feed circuit.

Step 2: Check “AIR BAG” warning right circuit.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

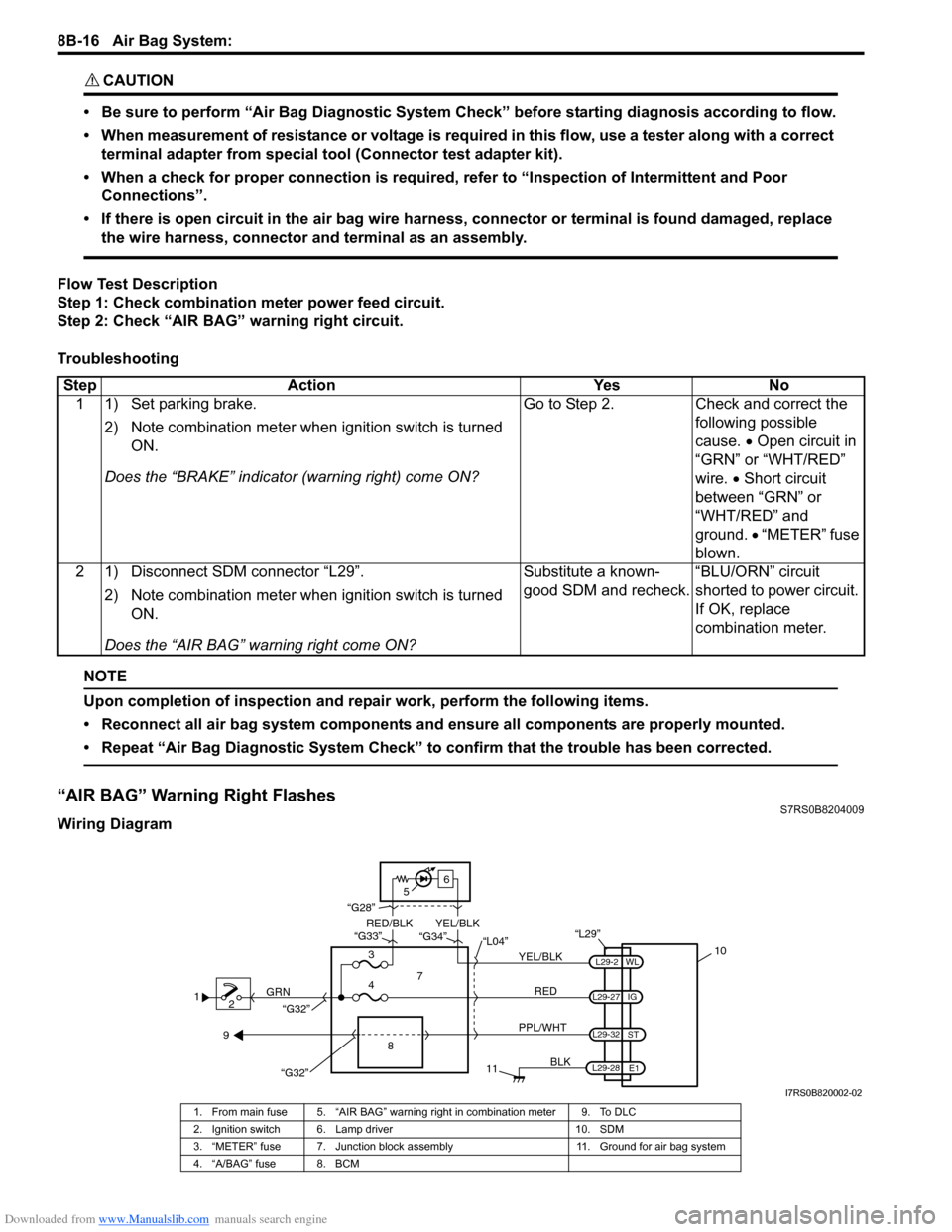

“AIR BAG” Warning Right FlashesS7RS0B8204009

Wiring Diagram Step Action Yes No

1 1) Set parking brake.

2) Note combination me ter when ignition switch is turned

ON.

Does the “BRAKE” in dicator (warning right) come ON? Go to Step 2. Check and correct the

following possible

cause. • Open circuit in

“GRN” or “WHT/RED”

wire. • Short circuit

between “GRN” or

“WHT/RED” and

ground. • “METER” fuse

blown.

2 1) Disconnect SDM connector “L29”.

2) Note combination me ter when ignition switch is turned

ON.

Does the “AIR BAG” warning right come ON? Substitute a known-

good SDM and recheck.

“BLU/ORN” circuit

shorted to power circuit.

If OK, replace

combination meter.

1

2 GRN

11

BLK

L29-27

L29-2

L29-28 WL

E1

IG

L29-32

ST

10

8

“L29”

RED

PPL/WHT

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

“G32”

YEL/BLK

YEL/BLK

RED/BLK

9

I7RS0B820002-02

1. From main fuse 5. “AIR BAG” warning right in combination meter 9. To DLC

2. Ignition switch 6. Lamp driver 10. SDM

3. “METER” fuse 7. Junction block assembly 11. Ground for air bag system

4. “A/BAG” fuse 8. BCM

Page 1055 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-17

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Flow Test Description

Check for short circuit between diag nosis switch circuit and ground.

Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1013: SDM faultS7RS0B8204010

DTC Will Set when

An internal SDM fault is detected by SDM.

NOTE

DTC B1013 can never be cleared once it has been set.

DTC Troubleshooting 1) Turn ignition switch OFF.

2) Replace SDM.

3) Repeat “Air Bag Diagnostic System Check”.

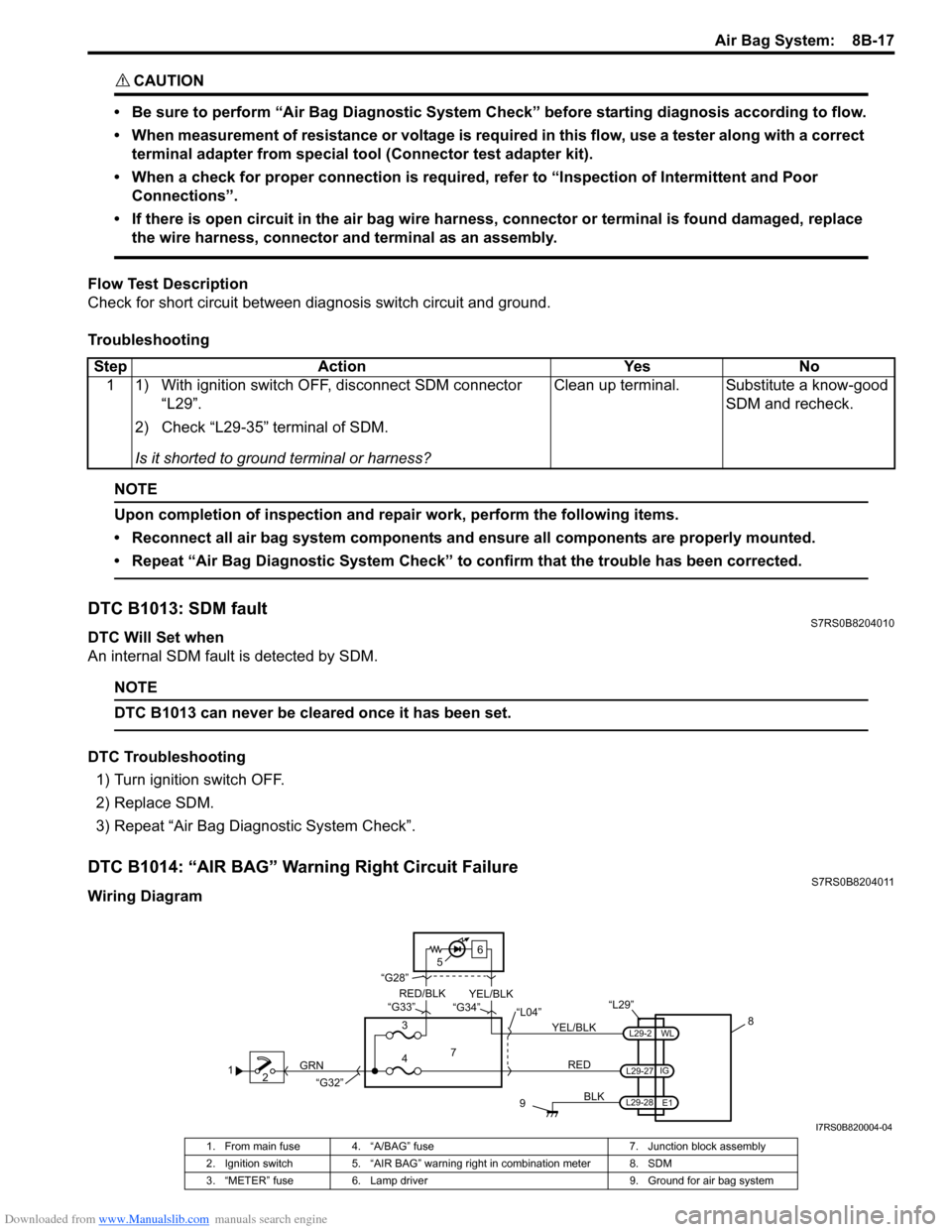

DTC B1014: “AIR BAG” Warning Right Circuit FailureS7RS0B8204011

Wiring DiagramStep Action Yes No

1 1) With ignition switch OFF, disconnect SDM connector “L29”.

2) Check “L29-35” terminal of SDM.

Is it shorted to ground terminal or harness? Clean up terminal. Substitute a know-good

SDM and recheck.

12 GRN

9

BLK

L29-2

L29-27

L29-28 IG

E1

WL

8

“L29”

RED

7

3

4 “L04”

“G34”

“G33”

“G28”

“G32”

5 6

YEL/BLK

YEL/BLK

RED/BLK

I7RS0B820004-04

1. From main fuse 4. “A/BAG” fuse

7. Junction block assembly

2. Ignition switch 5. “AIR BAG” warning right in combination meter 8. SDM

3. “METER” fuse 6. Lamp driver 9. Ground for air bag system

Page 1153 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-115

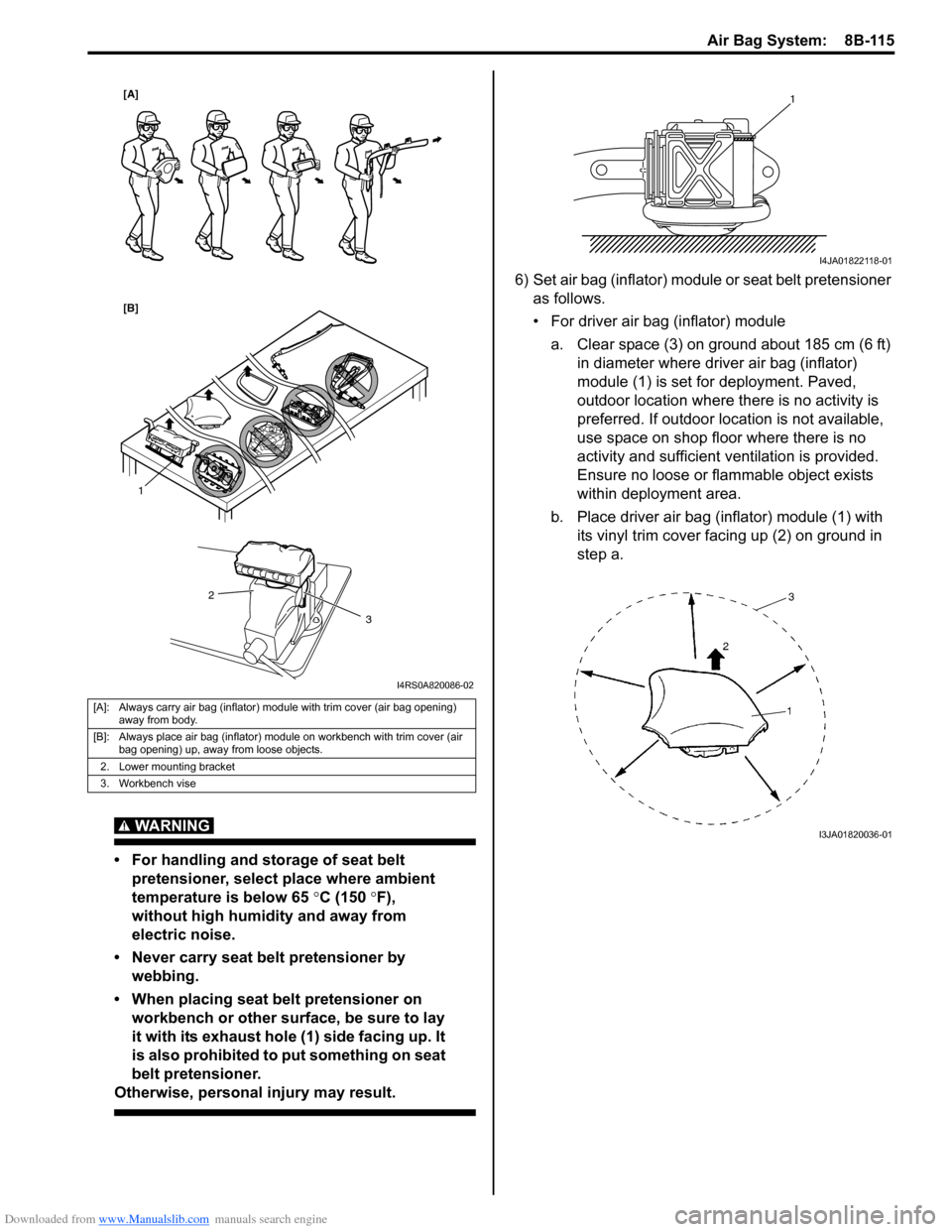

WARNING!

• For handling and storage of seat belt pretensioner, select place where ambient

temperature is below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by webbing.

• When placing seat belt pretensioner on workbench or other surface, be sure to lay

it with its exhaust hole (1) side facing up. It

is also prohibited to put something on seat

belt pretensioner.

Otherwise, personal injury may result.

6) Set air bag (inflator) module or seat belt pretensioner

as follows.

• For driver air bag (inflator) module

a. Clear space (3) on ground about 185 cm (6 ft) in diameter where driver air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place driver air bag (inflator) module (1) with its vinyl trim cover facing up (2) on ground in

step a.

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

2. Lower mounting bracket

3. Workbench vise

1

2

3

[A]

[B]

I4RS0A820086-02

1

I4JA01822118-01

I3JA01820036-01

Page 1154 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-116 Air Bag System:

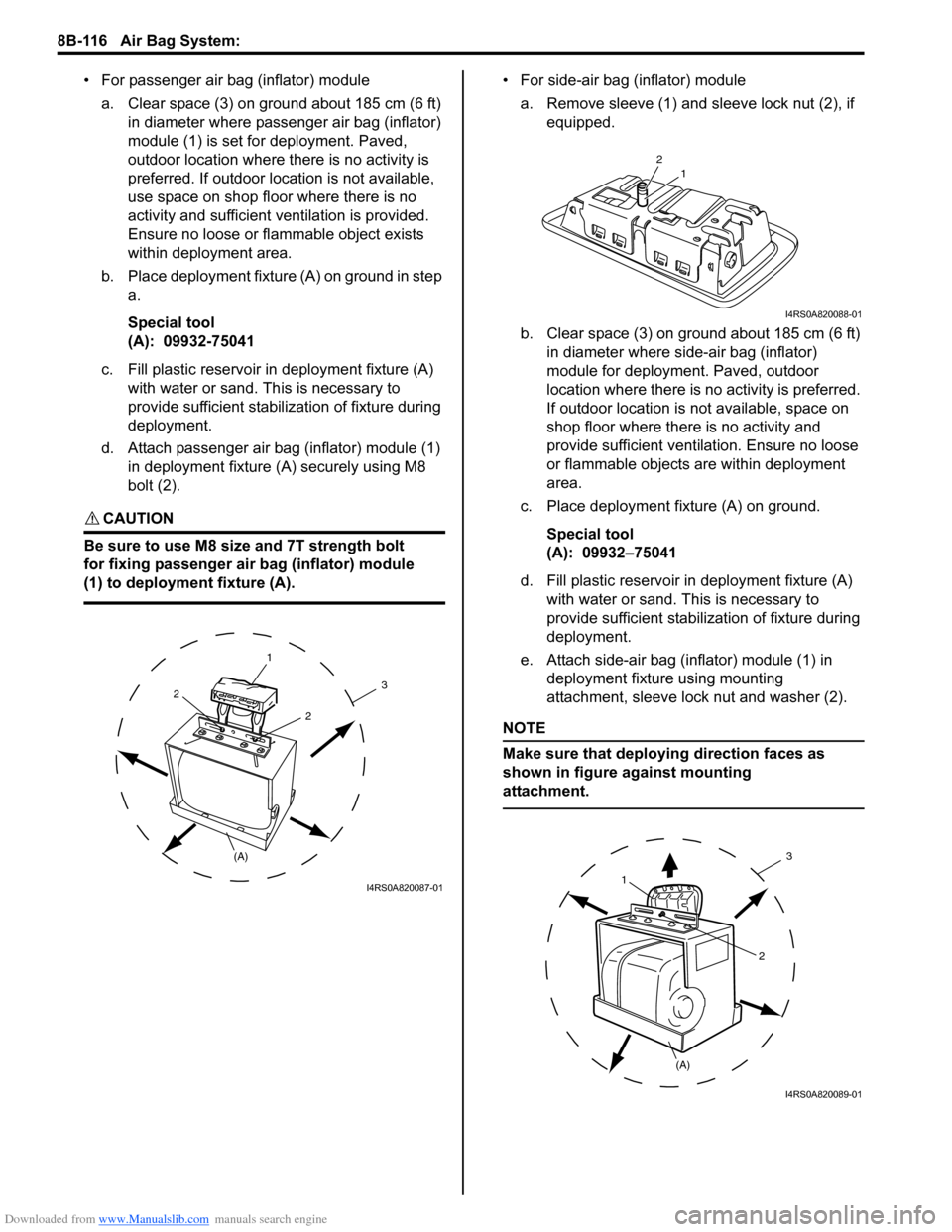

• For passenger air bag (inflator) modulea. Clear space (3) on ground about 185 cm (6 ft) in diameter where passenger air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place deployment fixture (A) on ground in step a.

Special tool

(A): 09932-75041

c. Fill plastic reservoir in deployment fixture (A) with water or sand. Th is is necessary to

provide sufficient stabilization of fixture during

deployment.

d. Attach passenger air bag (inflator) module (1) in deployment fixture (A ) securely using M8

bolt (2).

CAUTION!

Be sure to use M8 size and 7T strength bolt

for fixing passenger air bag (inflator) module

(1) to deployment fixture (A).

• For side-air bag (inflator) module

a. Remove sleeve (1) and sl eeve lock nut (2), if

equipped.

b. Clear space (3) on ground about 185 cm (6 ft) in diameter where side-air bag (inflator)

module for deployment. Paved, outdoor

location where there is no activity is preferred.

If outdoor location is not available, space on

shop floor where there is no activity and

provide sufficient ventilation. Ensure no loose

or flammable objects are within deployment

area.

c. Place deployment fixture (A) on ground.

Special tool

(A): 09932–75041

d. Fill plastic reservoir in deployment fixture (A) with water or sand. Th is is necessary to

provide sufficient stabiliz ation of fixture during

deployment.

e. Attach side-air bag (inflator) module (1) in deployment fixture using mounting

attachment, sleeve lock nut and washer (2).

NOTE

Make sure that deploying direction faces as

shown in figure against mounting

attachment.

1

(A)

2

2

3

I4RS0A820087-01

21

I4RS0A820088-01

1

(A) 2

3

I4RS0A820089-01

Page 1155 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-117

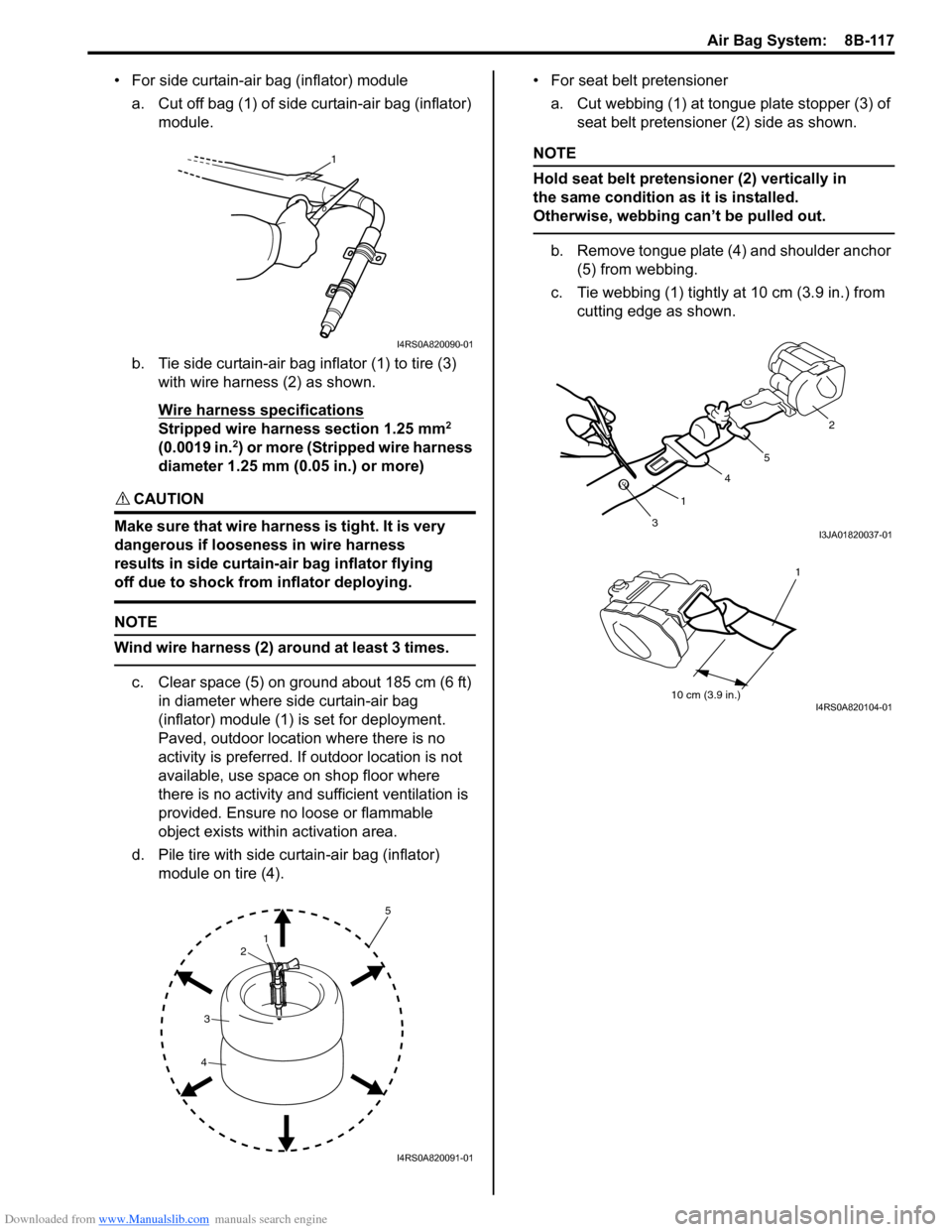

• For side curtain-air bag (inflator) modulea. Cut off bag (1) of side curtain-air bag (inflator) module.

b. Tie side curtain-air bag inflator (1) to tire (3) with wire harness (2) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

CAUTION!

Make sure that wire harness is tight. It is very

dangerous if looseness in wire harness

results in side curtain-air bag inflator flying

off due to shock from inflator deploying.

NOTE

Wind wire harness (2) around at least 3 times.

c. Clear space (5) on ground about 185 cm (6 ft) in diameter where side curtain-air bag

(inflator) module (1) is set for deployment.

Paved, outdoor location where there is no

activity is preferred. If outdoor location is not

available, use space on shop floor where

there is no activity and sufficient ventilation is

provided. Ensure no loose or flammable

object exists within activation area.

d. Pile tire with side curtain-air bag (inflator) module on tire (4). • For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor (5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

1

I4RS0A820090-01

1

2

3

4

5

I4RS0A820091-01

3 1 4

5 2I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01

Page 1156 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-118 Air Bag System:

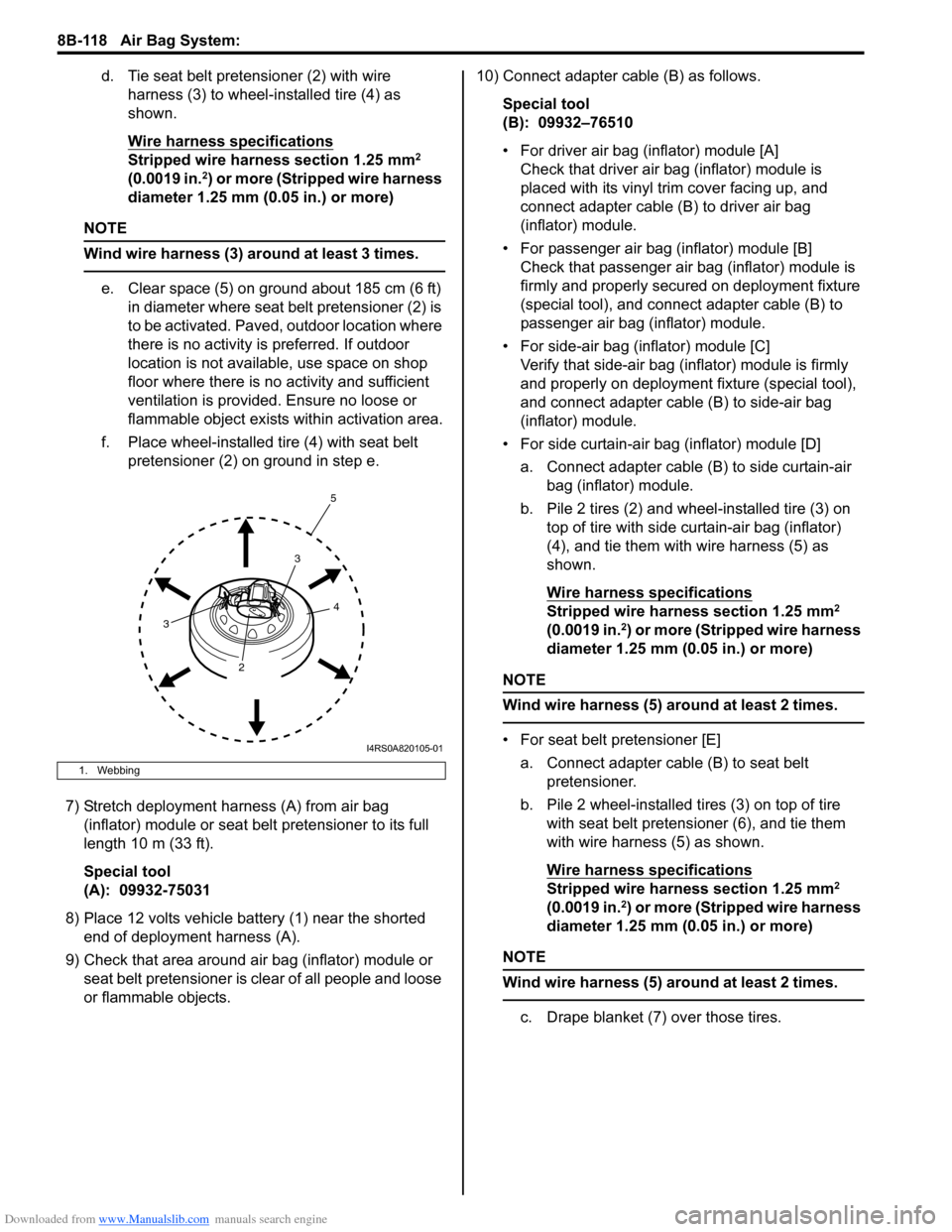

d. Tie seat belt pretensioner (2) with wire harness (3) to wheel-installed tire (4) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (3) around at least 3 times.

e. Clear space (5) on ground about 185 cm (6 ft) in diameter where seat belt pretensioner (2) is

to be activated. Paved, outdoor location where

there is no activity is preferred. If outdoor

location is not available, use space on shop

floor where there is no activity and sufficient

ventilation is provided. Ensure no loose or

flammable object exists within activation area.

f. Place wheel-installed tire (4) with seat belt pretensioner (2) on ground in step e.

7) Stretch deployment harness (A) from air bag (inflator) module or seat belt pretensioner to its full

length 10 m (33 ft).

Special tool

(A): 09932-75031

8) Place 12 volts vehicle battery (1) near the shorted end of deployment harness (A).

9) Check that area around air bag (inflator) module or seat belt pretensioner is clear of all people and loose

or flammable objects. 10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]Check that driver air bag (inflator) module is

placed with its vinyl trim cover facing up, and

connect adapter cable (B) to driver air bag

(inflator) module.

• For passenger air bag (inflator) module [B] Check that passenger air bag (inflator) module is

firmly and properly secured on deployment fixture

(special tool), and connect adapter cable (B) to

passenger air bag (inflator) module.

• For side-air bag (inflator) module [C] Verify that side-air bag (inflator) module is firmly

and properly on deployment fixture (special tool),

and connect adapter cable (B) to side-air bag

(inflator) module.

• For side curtain-air bag (inflator) module [D] a. Connect adapter cable (B) to side curtain-air bag (inflator) module.

b. Pile 2 tires (2) and wheel-installed tire (3) on top of tire with side curtain-air bag (inflator)

(4), and tie them with wire harness (5) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

• For seat belt pretensioner [E]

a. Connect adapter cable (B) to seat belt pretensioner.

b. Pile 2 wheel-installed tires (3) on top of tire with seat belt pretensioner (6), and tie them

with wire harness (5) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

c. Drape blanket (7) over those tires.

1. Webbing

4

3

3 2 5

I4RS0A820105-01

Page 1163 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-125

Specifications

Tightening Torque SpecificationsS7RS0B8207001

NOTE

The specified tightening torque is also described in the following.

“Air Bag System Components, Wiring and Connectors Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Use of Special ToolsS7RS0B8208001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified. Do not use a non-powered probe

type tester.

Instructions must be followed carefully,

otherwise personal injury may result.

You should be familiar with the tools listed under the

heading “Special Tool”. You should be able to measure

voltage and resistance. You should be familiar with

proper use of a scan tool such as Air Bag Driver /

Passenger Load Tool, Connector Test Adapter Kit and

the Digital Multimeter.

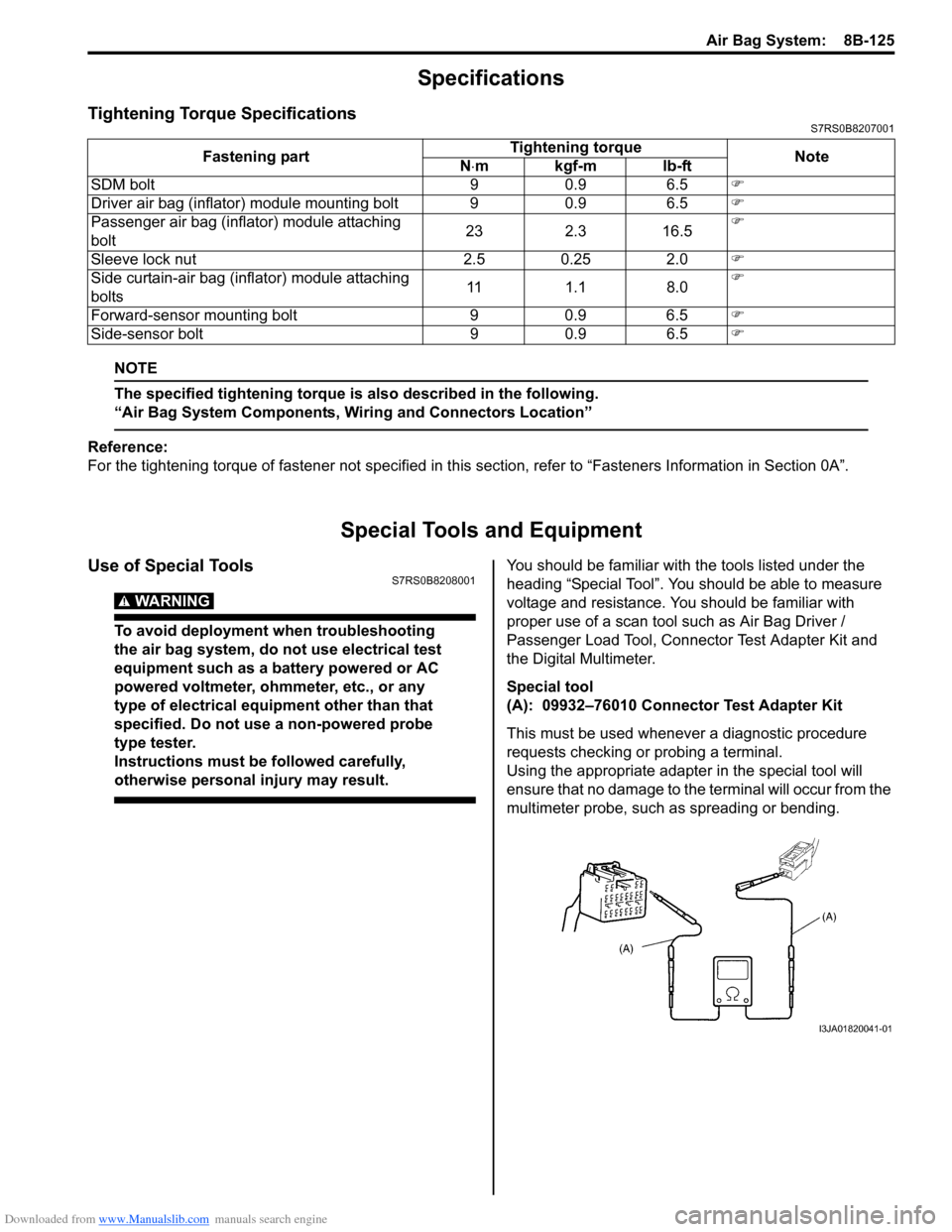

Special tool

(A): 09932–76010 Connector Test Adapter Kit

This must be used whenever a diagnostic procedure

requests checking or probing a terminal.

Using the appropriate adapter in the special tool will

ensure that no damage to the terminal will occur from the

multimeter probe, such as spreading or bending.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

SDM bolt 9 0.9 6.5 �)

Driver air bag (inflator) module mounting bolt 9 0.9 6.5 �)

Passenger air bag (inflator) module attaching

bolt 23 2.3 16.5�)

Sleeve lock nut 2.5 0.25 2.0 �)

Side curtain-air bag (inflator) module attaching

bolts 11 1.1 8.0�)

Forward-sensor mounting bolt 9 0.9 6.5 �)

Side-sensor bolt 9 0.9 6.5 �)

I3JA01820041-01