Shaft SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 757 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-113

19) Remove transaxle case plug (1).

20) Remove torque converter housing bolts.

21) Remove torque converter housing (1) while tapping

around it lightly with plastic hammer.

22) Remove breather hose (1).

23) Remove breather union (2).

24) Measure input shaft thrust play. Apply dial gauge onto input shaft end (1) and

measure thrust play of input shaft.

When input shaft thrust play is out of specification,

select input shaft front th rust bearing with proper

thickness from among the list below and replace it.

Special tool

(A): 09900–20607

(B): 09900-20701

Input shaft thrust play

0.3 – 0.9 mm (0.012 – 0.035 in.)

Available input shaft front thrust bearing

thickness

: 3.45, 4.05 mm (0.136, 0.159 in.) 25) Remove oil pump assembly (1).

26) Remove direct clutch assembly (1).

27) Remove input shaft front thrust bearing (1).

NOTE

If input shaft front thrust bearing is not

found, it may have been taken out with oil

pump assembly.

I2RH0B510095-01

I3RM0B510060-01

1

2

I2RH0B510097-01

I2RH0B510098-01

I2RH0B510099-01

I2RH0B510100-01

I2RH0B510101-01

Page 758 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-114 Automatic Transmission/Transaxle:

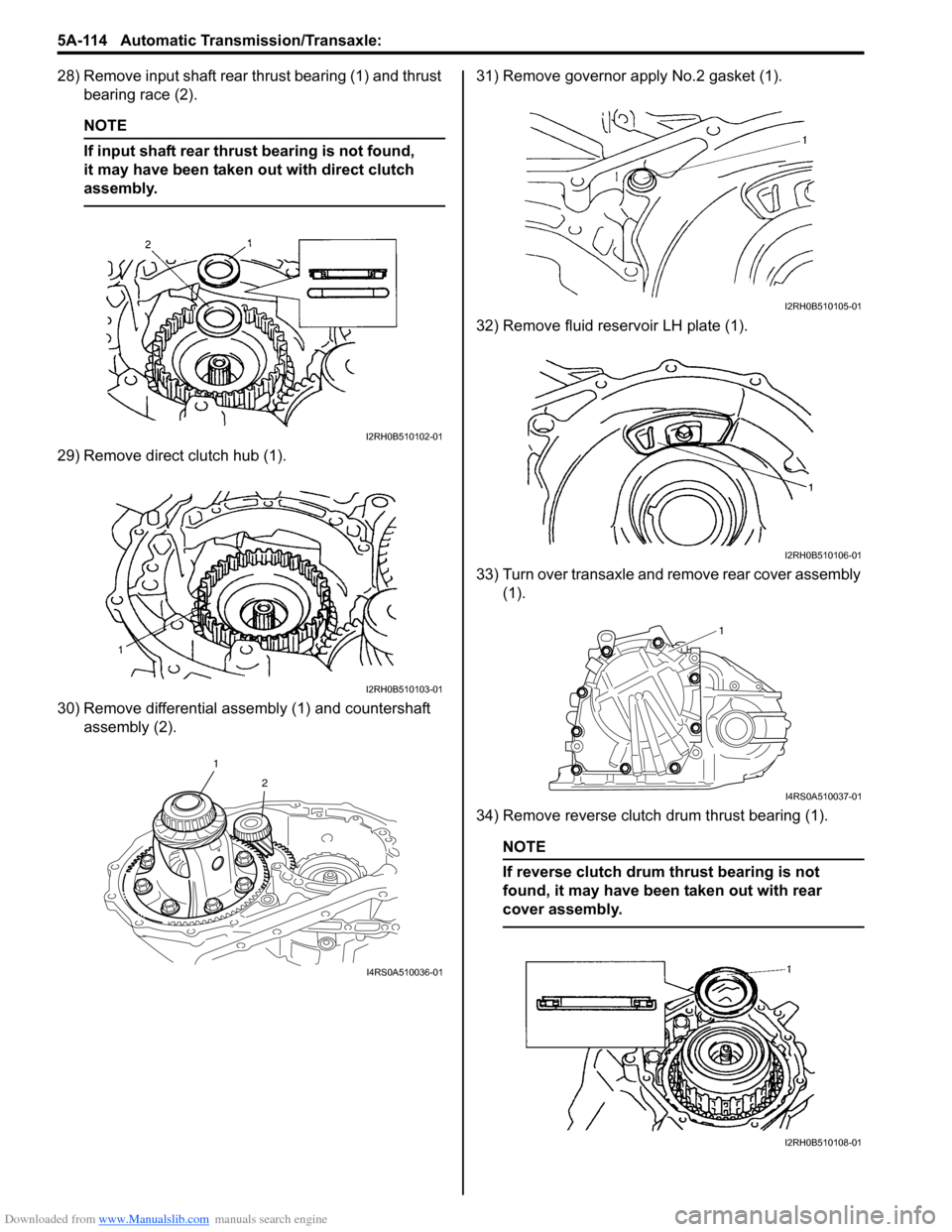

28) Remove input shaft rear thrust bearing (1) and thrust bearing race (2).

NOTE

If input shaft rear thrust bearing is not found,

it may have been taken out with direct clutch

assembly.

29) Remove direct clutch hub (1).

30) Remove differential assembly (1) and countershaft assembly (2). 31) Remove governor apply No.2 gasket (1).

32) Remove fluid reservoir LH plate (1).

33) Turn over transaxle and remove rear cover assembly

(1).

34) Remove reverse clutch drum thrust bearing (1).

NOTE

If reverse clutch drum thrust bearing is not

found, it may have been taken out with rear

cover assembly.

I2RH0B510102-01

I2RH0B510103-01

1 2

I4RS0A510036-01

I2RH0B510105-01

I2RH0B510106-01

1

I4RS0A510037-01

I2RH0B510108-01

Page 759 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-115

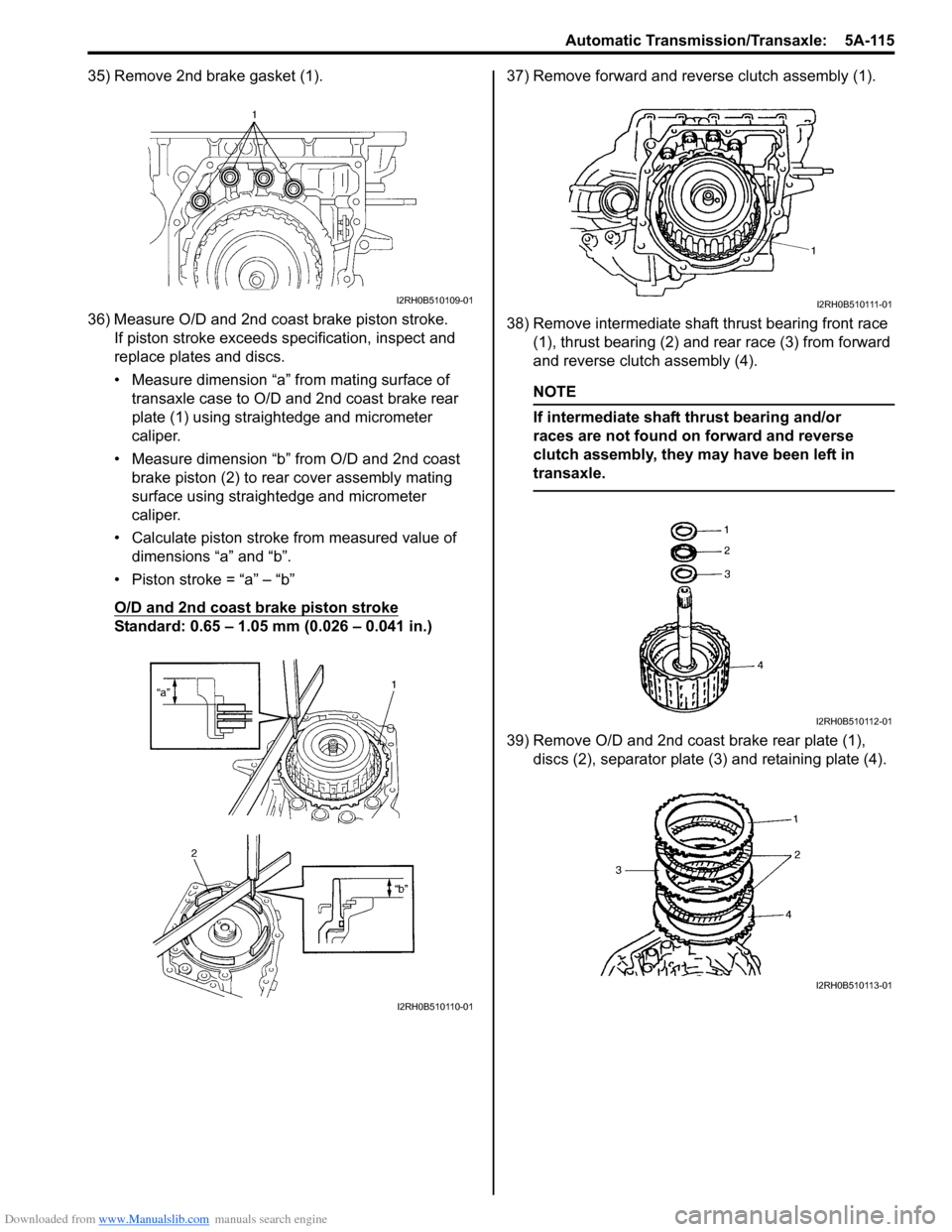

35) Remove 2nd brake gasket (1).

36) Measure O/D and 2nd coast brake piston stroke.If piston stroke exceeds specification, inspect and

replace plates and discs.

• Measure dimension “a” from mating surface of transaxle case to O/D and 2nd coast brake rear

plate (1) using straightedge and micrometer

caliper.

• Measure dimension “b” from O/D and 2nd coast brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.) 37) Remove forward and reverse clutch assembly (1).

38) Remove intermediate shaft thrust bearing front race

(1), thrust bearing (2) and rear race (3) from forward

and reverse clutch assembly (4).

NOTE

If intermediate shaft thrust bearing and/or

races are not found on forward and reverse

clutch assembly, they may have been left in

transaxle.

39) Remove O/D and 2nd coast brake rear plate (1), discs (2), separator plate (3) and retaining plate (4).

I2RH0B510109-01

I2RH0B510110-01

I2RH0B510111-01

I2RH0B510112-01

I2RH0B510113-01

Page 763 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-119

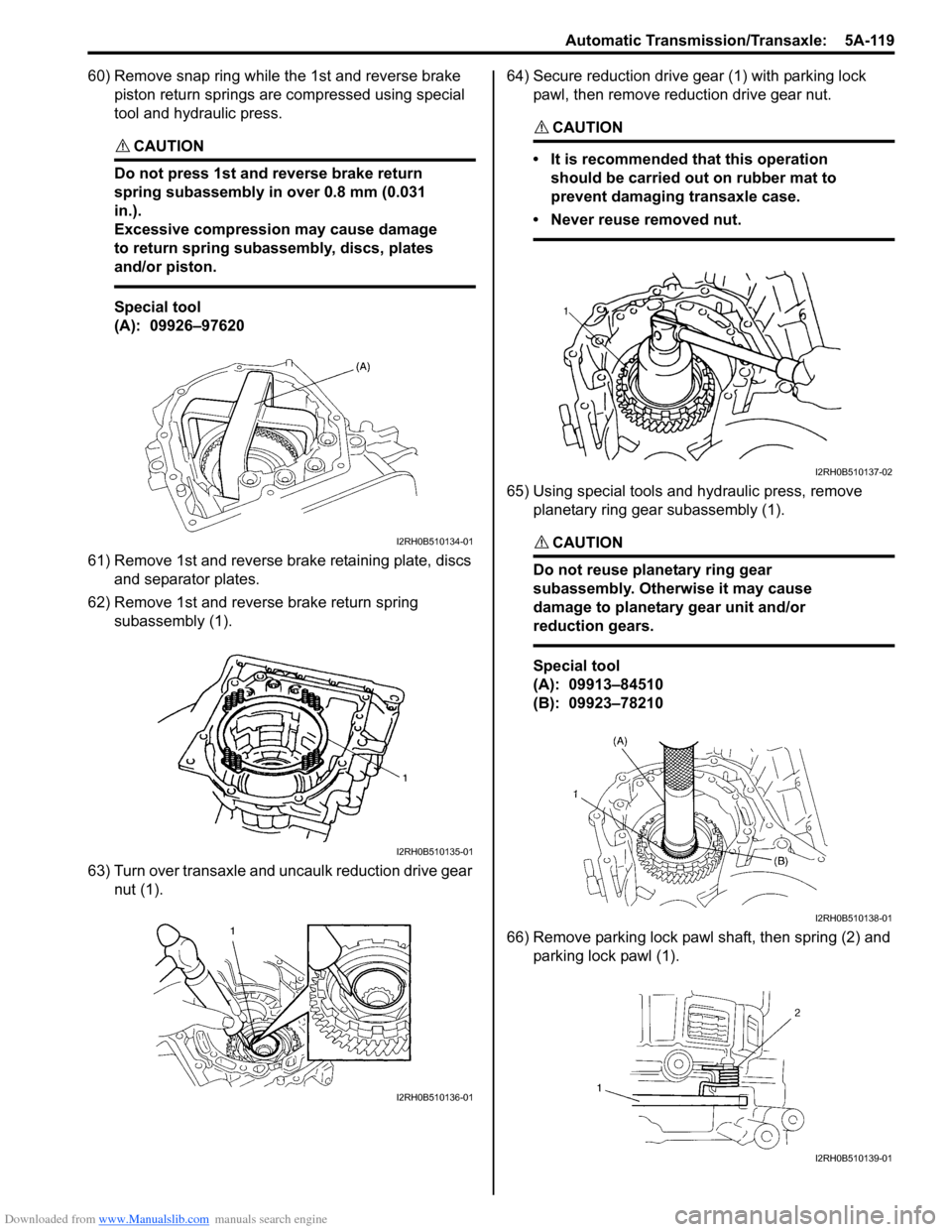

60) Remove snap ring while the 1st and reverse brake piston return springs are compressed using special

tool and hydraulic press.

CAUTION!

Do not press 1st and reverse brake return

spring subassembly in over 0.8 mm (0.031

in.).

Excessive compression may cause damage

to return spring subassembly, discs, plates

and/or piston.

Special tool

(A): 09926–97620

61) Remove 1st and reverse brake retaining plate, discs and separator plates.

62) Remove 1st and reverse brake return spring subassembly (1).

63) Turn over transaxle and uncaulk reduction drive gear nut (1). 64) Secure reduction drive gear (1) with parking lock

pawl, then remove reduction drive gear nut.

CAUTION!

• It is recommended that this operation should be carried out on rubber mat to

prevent damaging transaxle case.

• Never reuse removed nut.

65) Using special tools and hydraulic press, remove planetary ring gear subassembly (1).

CAUTION!

Do not reuse planetary ring gear

subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

Special tool

(A): 09913–84510

(B): 09923–78210

66) Remove parking lock pawl shaft, then spring (2) and parking lock pawl (1).

I2RH0B510134-01

I2RH0B510135-01

I2RH0B510136-01

I2RH0B510137-02

I2RH0B510138-01

I2RH0B510139-01

Page 764 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-120 Automatic Transmission/Transaxle:

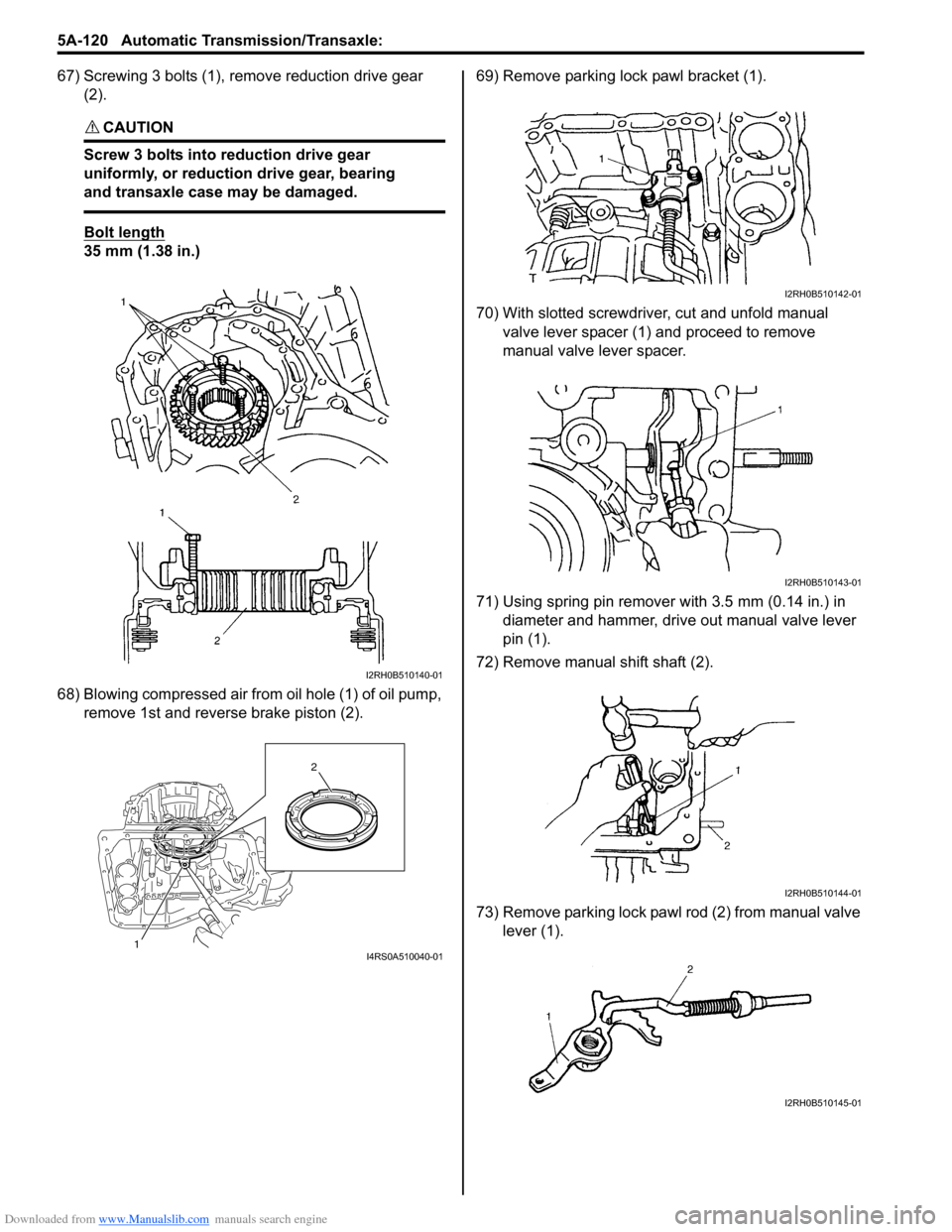

67) Screwing 3 bolts (1), remove reduction drive gear (2).

CAUTION!

Screw 3 bolts into reduction drive gear

uniformly, or reduction drive gear, bearing

and transaxle case may be damaged.

Bolt length

35 mm (1.38 in.)

68) Blowing compressed air from oil hole (1) of oil pump,

remove 1st and reverse brake piston (2). 69) Remove parking lock pawl bracket (1).

70) With slotted screwdriver, cut and unfold manual

valve lever spacer (1) and proceed to remove

manual valve lever spacer.

71) Using spring pin remover with 3.5 mm (0.14 in.) in diameter and hammer, drive out manual valve lever

pin (1).

72) Remove manual shift shaft (2).

73) Remove parking lock pawl rod (2) from manual valve lever (1).

I2RH0B510140-01

1 2I4RS0A510040-01

I2RH0B510142-01

I2RH0B510143-01

I2RH0B510144-01

I2RH0B510145-01

Page 765 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-121

74) Remove manual detent spring (1).75) Remove manual shift shaft oil seal (1).

Oil Pump Assembly ComponentsS7RS0B5106034

I2RH0B510146-01I2RH0B510147-01

I2RH0B510148-01

1. Oil seal

: Apply grease 99000-25030 to oil seal lip. 5. Oil pump drive gear : Apply automatic transaxle fluid.

2. O-ring 6. Stator shaft assembly : Tightening torque

3. Oil pump body 7. Oil pump subassembly bolts : Do not reuse.

4. Oil pump driven gear

Page 766 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-122 Automatic Transmission/Transaxle:

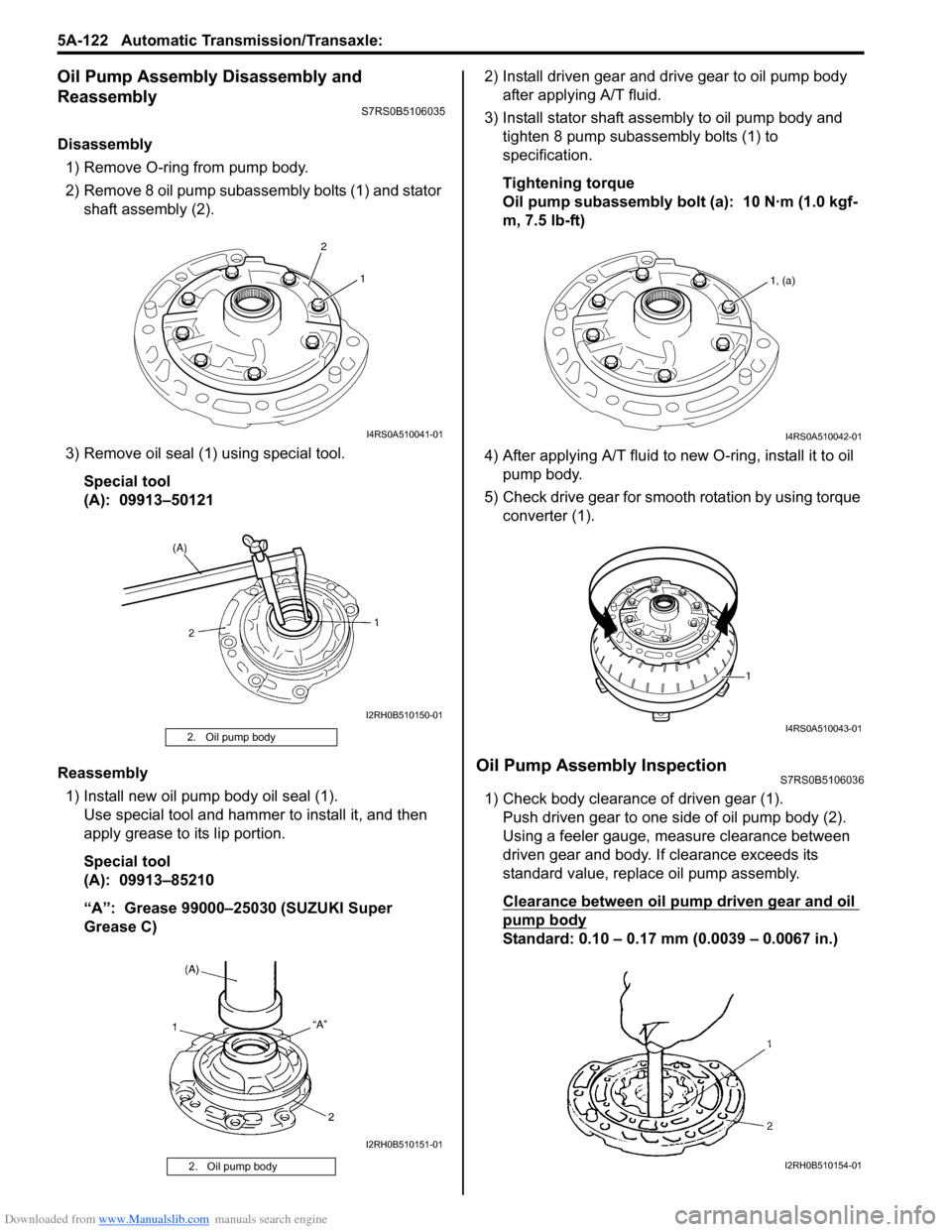

Oil Pump Assembly Disassembly and

Reassembly

S7RS0B5106035

Disassembly1) Remove O-ring from pump body.

2) Remove 8 oil pump subassembly bolts (1) and stator shaft assembly (2).

3) Remove oil seal (1) using special tool. Special tool

(A): 09913–50121

Reassembly 1) Install new oil pump body oil seal (1). Use special tool and hammer to install it, and then

apply grease to its lip portion.

Special tool

(A): 09913–85210

“A”: Grease 99000–25030 (SUZUKI Super

Grease C) 2) Install driven gear and drive gear to oil pump body

after applying A/T fluid.

3) Install stator shaft assembly to oil pump body and tighten 8 pump subassembly bolts (1) to

specification.

Tightening torque

Oil pump subassembly bolt (a): 10 N·m (1.0 kgf-

m, 7.5 lb-ft)

4) After applying A/T fluid to new O-ring, install it to oil pump body.

5) Check drive gear for smooth rotation by using torque converter (1).

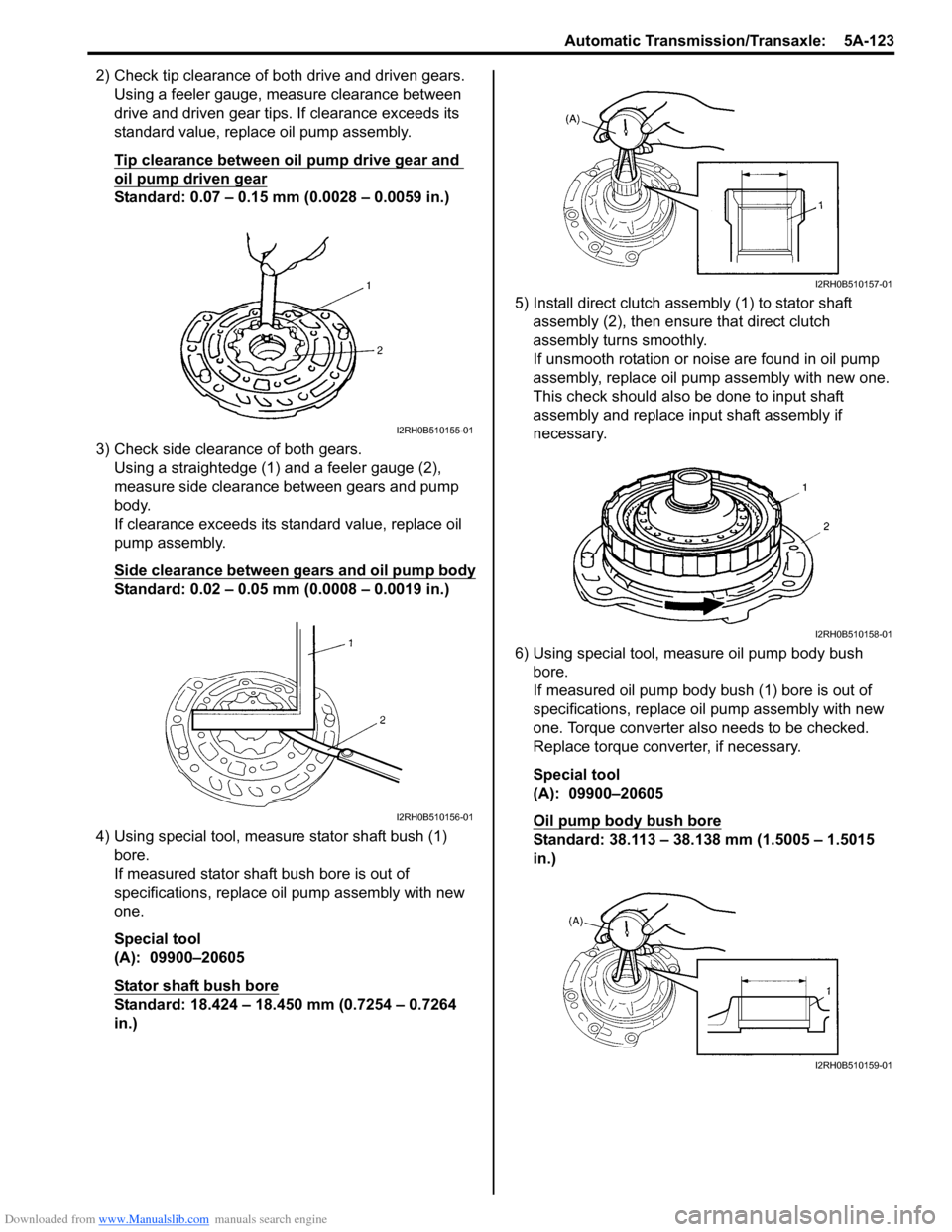

Oil Pump Assembly InspectionS7RS0B5106036

1) Check body clearance of driven gear (1).Push driven gear to one side of oil pump body (2).

Using a feeler gauge, m easure clearance between

driven gear and body. If clearance exceeds its

standard value, replace oil pump assembly.

Clearance between oil pump driven gear and oil

pump body

Standard: 0.10 – 0.17 mm (0.0039 – 0.0067 in.)

2. Oil pump body

2. Oil pump body

2 1

I4RS0A510041-01

I2RH0B510150-01

I2RH0B510151-01

1, (a)

I4RS0A510042-01

1

I4RS0A510043-01

I2RH0B510154-01

Page 767 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-123

2) Check tip clearance of both drive and driven gears.Using a feeler gauge, m easure clearance between

drive and driven gear tips. If clearance exceeds its

standard value, replace oil pump assembly.

Tip clearance between oil pump drive gear and

oil pump driven gear

Standard: 0.07 – 0.15 mm (0.0028 – 0.0059 in.)

3) Check side clearance of both gears. Using a straightedge (1) and a feeler gauge (2),

measure side clearance between gears and pump

body.

If clearance exceeds its standard value, replace oil

pump assembly.

Side clearance between gears and oil pump body

Standard: 0.02 – 0.05 mm (0.0008 – 0.0019 in.)

4) Using special tool, measure stator shaft bush (1) bore.

If measured stator shaft bush bore is out of

specifications, replace oil pump assembly with new

one.

Special tool

(A): 09900–20605

Stator shaft bush bore

Standard: 18.424 – 18.450 mm (0.7254 – 0.7264

in.) 5) Install direct clutch asse

mbly (1) to stator shaft

assembly (2), then ensure that direct clutch

assembly turns smoothly.

If unsmooth rotation or noise are found in oil pump

assembly, replace oil pump assembly with new one.

This check should also be done to input shaft

assembly and replace input shaft assembly if

necessary.

6) Using special tool, measure oil pump body bush bore.

If measured oil pump body bush (1) bore is out of

specifications, replace o il pump assembly with new

one. Torque converter also needs to be checked.

Replace torque converter, if necessary.

Special tool

(A): 09900–20605

Oil pump body bush bore

Standard: 38.113 – 38.138 mm (1.5005 – 1.5015

in.)

I2RH0B510155-01

I2RH0B510156-01

I2RH0B510157-01

I2RH0B510158-01

I2RH0B510159-01

Page 768 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-124 Automatic Transmission/Transaxle:

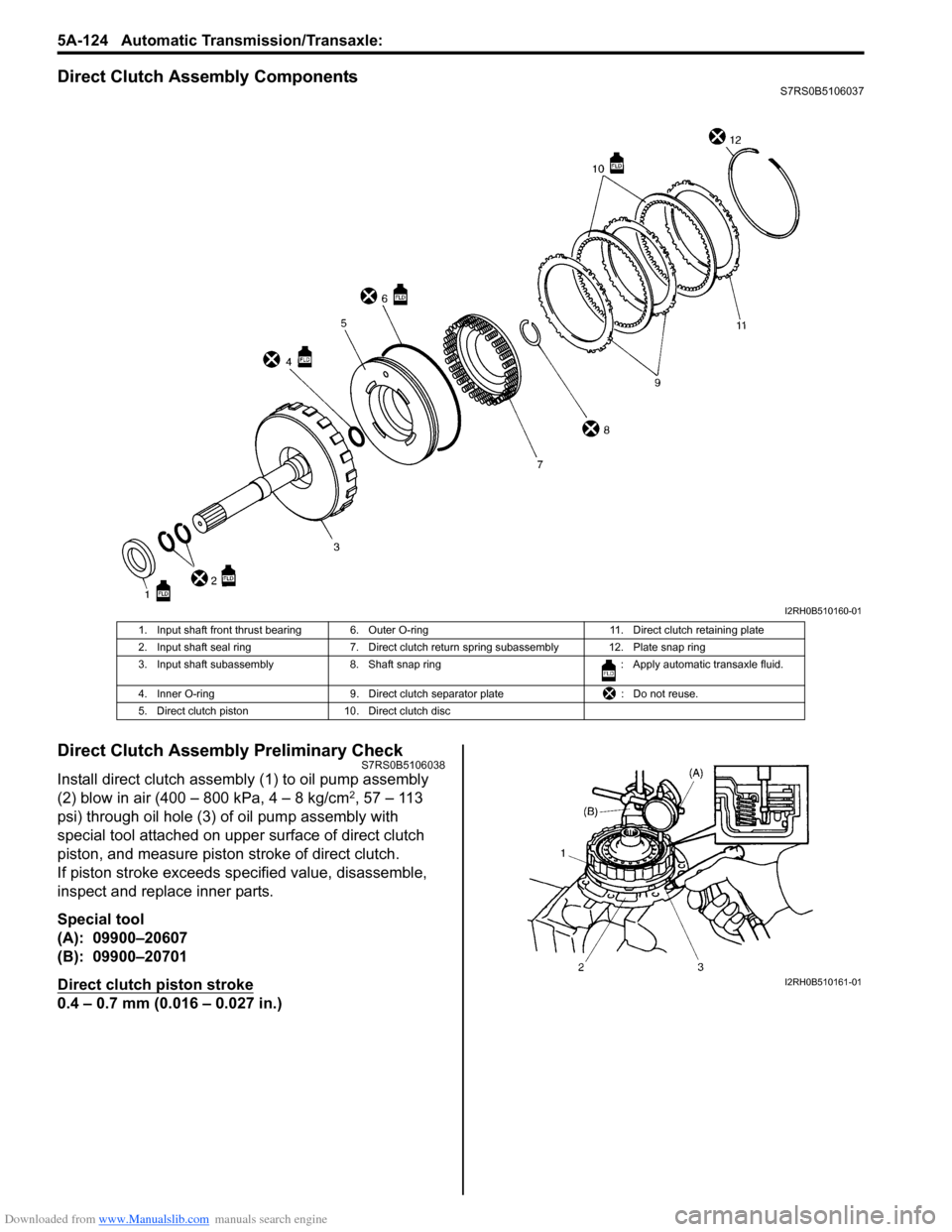

Direct Clutch Assembly ComponentsS7RS0B5106037

Direct Clutch Assembly Preliminary CheckS7RS0B5106038

Install direct clutch assembly (1) to oil pump assembly

(2) blow in air (400 – 800 kPa, 4 – 8 kg/cm2, 57 – 113

psi) through oil hole (3) of oil pump assembly with

special tool attached on uppe r surface of direct clutch

piston, and measure piston stroke of direct clutch.

If piston stroke exceeds sp ecified value, disassemble,

inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

Direct clutch piston stroke

0.4 – 0.7 mm (0.016 – 0.027 in.)

I2RH0B510160-01

1. Input shaft front thrust bearing 6. Outer O-ring 11. Direct clutch retaining plate

2. Input shaft seal ring 7. Direct clutch return spring subassembly 12. Plate snap ring

3. Input shaft subassembly 8. Shaft snap ring : Apply automatic transaxle fluid.

4. Inner O-ring 9. Direct clutch separator plate : Do not reuse.

5. Direct clutch piston 10. Direct clutch disc

I2RH0B510161-01

Page 769 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-125

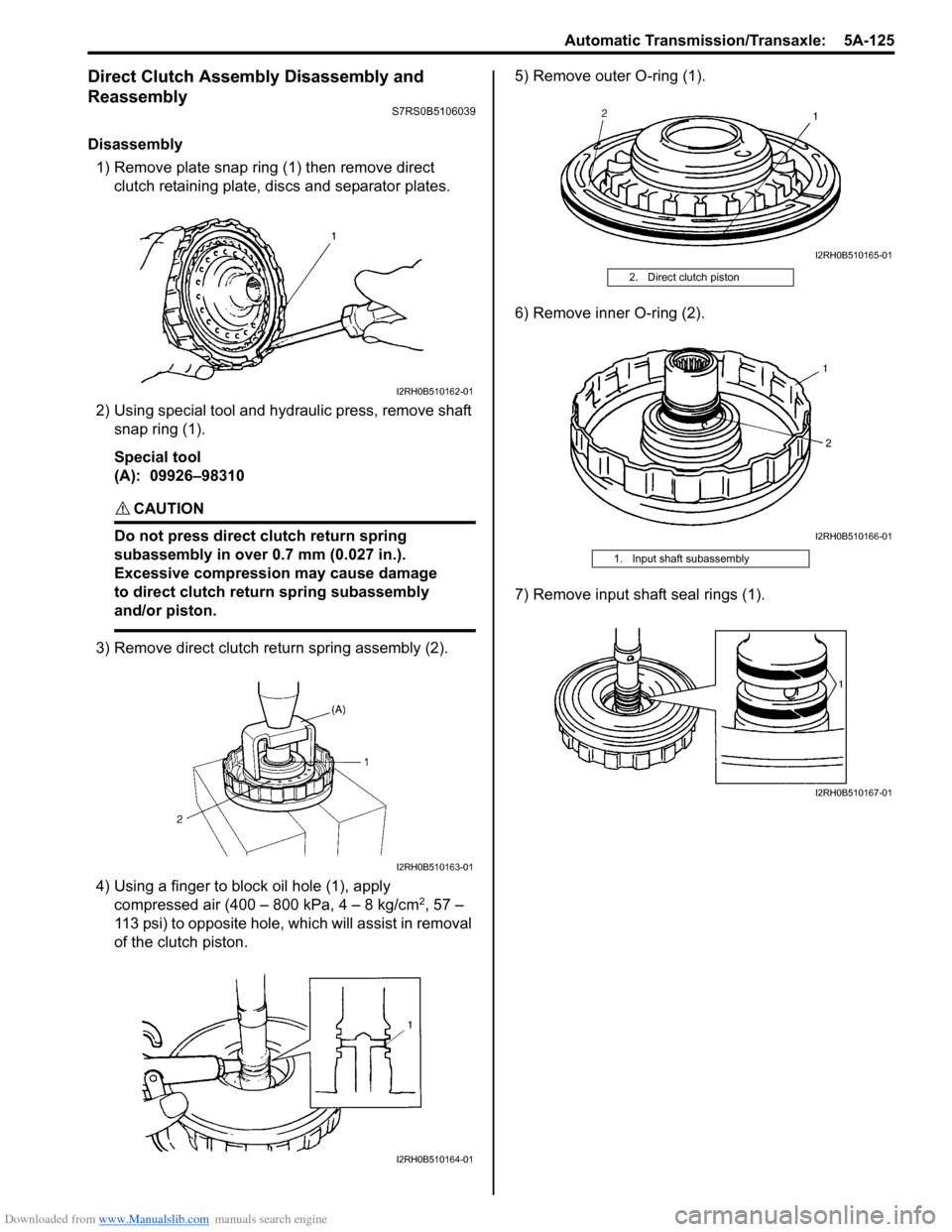

Direct Clutch Assembly Disassembly and

Reassembly

S7RS0B5106039

Disassembly1) Remove plate snap ring (1) then remove direct clutch retaining plate, discs and separator plates.

2) Using special tool and hydraulic press, remove shaft snap ring (1).

Special tool

(A): 09926–98310

CAUTION!

Do not press direct clutch return spring

subassembly in over 0.7 mm (0.027 in.).

Excessive compression may cause damage

to direct clutch return spring subassembly

and/or piston.

3) Remove direct clutch re turn spring assembly (2).

4) Using a finger to block oil hole (1), apply compressed air (400 – 800 kPa, 4 – 8 kg/cm

2, 57 –

113 psi) to opposite hole, which will assist in removal

of the clutch piston. 5) Remove outer O-ring (1).

6) Remove inner O-ring (2).

7) Remove input shaft seal rings (1).

I2RH0B510162-01

I2RH0B510163-01

I2RH0B510164-01

2. Direct clutch piston

1. Input shaft subassembly

I2RH0B510165-01

I2RH0B510166-01

I2RH0B510167-01