AT transaxle service SUZUKI SWIFT 2007 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 812 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-168 Automatic Transmission/Transaxle:

Special Tools and Equipment

Recommended Service MaterialS7RS0B5108001

NOTE

Required service material is also described in the following.

“Select Cable Components”

“Automatic Transaxle Unit Components”

“Automatic Transaxle Assembly Components”

“Oil Pump Assembly Components”

“Direct Clutch Assembly Components”

“Forward and Reverse Clutch Assembly Components”

“2nd Brake Piston Assembly Components”

“Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components”

“Countershaft Assembly Components”

“Valve Body Assembly Components”

“Differential Assembly Components”

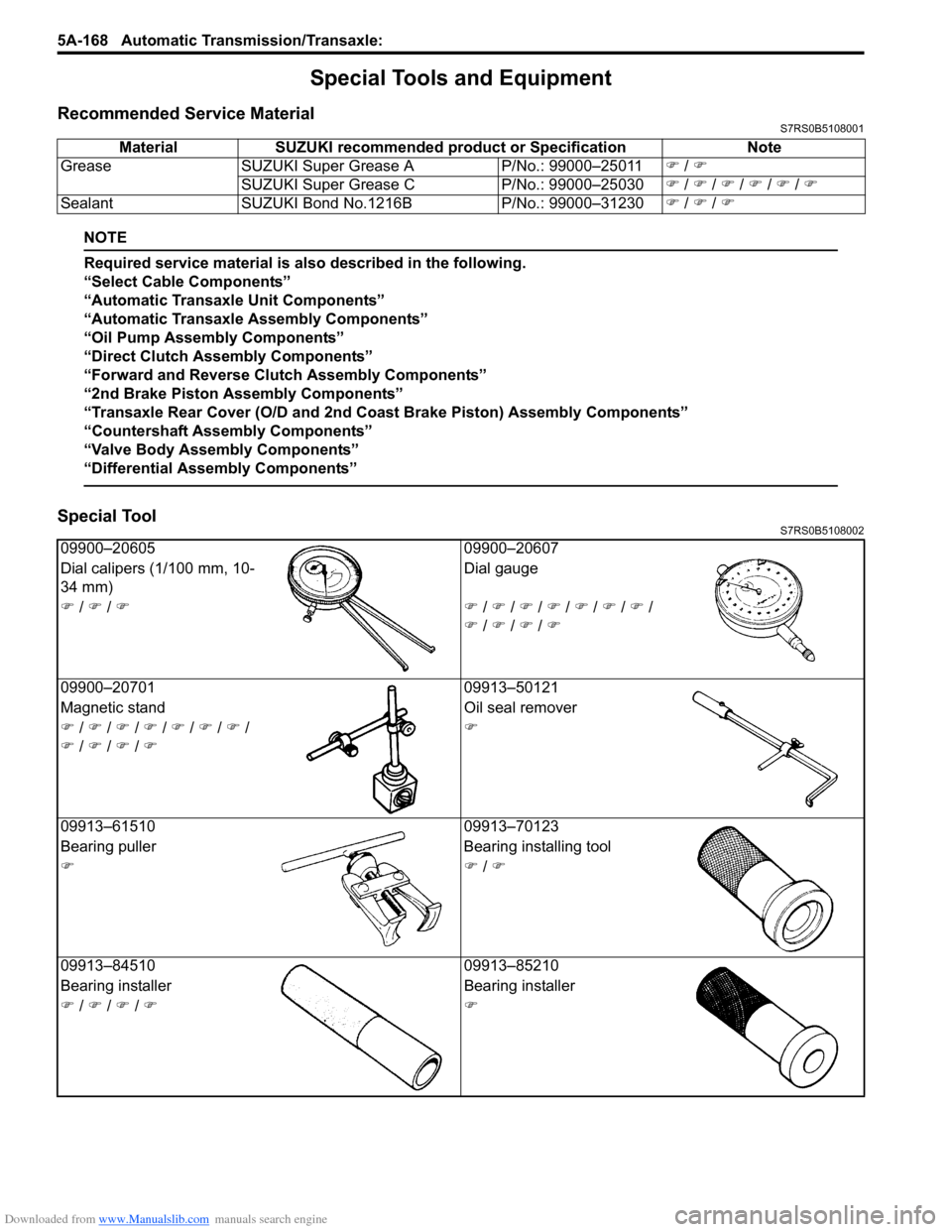

Special ToolS7RS0B5108002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �)

SUZUKI Super Grease C P/No.: 99000–25030�) / �) / �) / �) / �) / �)

Sealant SUZUKI Bond No.1216B P/No.: 99000–31230�) / �) / �)

09900–20605 09900–20607

Dial calipers (1/100 mm, 10-

34 mm) Dial gauge

�) / �) / �)�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �)

09900–20701 09913–50121

Magnetic stand Oil seal remover

�) / �) / �) / �) / �) / �) / �) /

�) / �) / �) / �) �)

09913–61510 09913–70123

Bearing puller Bearing installing tool

�)�) / �)

09913–84510 09913–85210

Bearing installer Bearing installer

�) / �) / �) / �)�)

Page 817 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

Diagnostic Information and Procedures

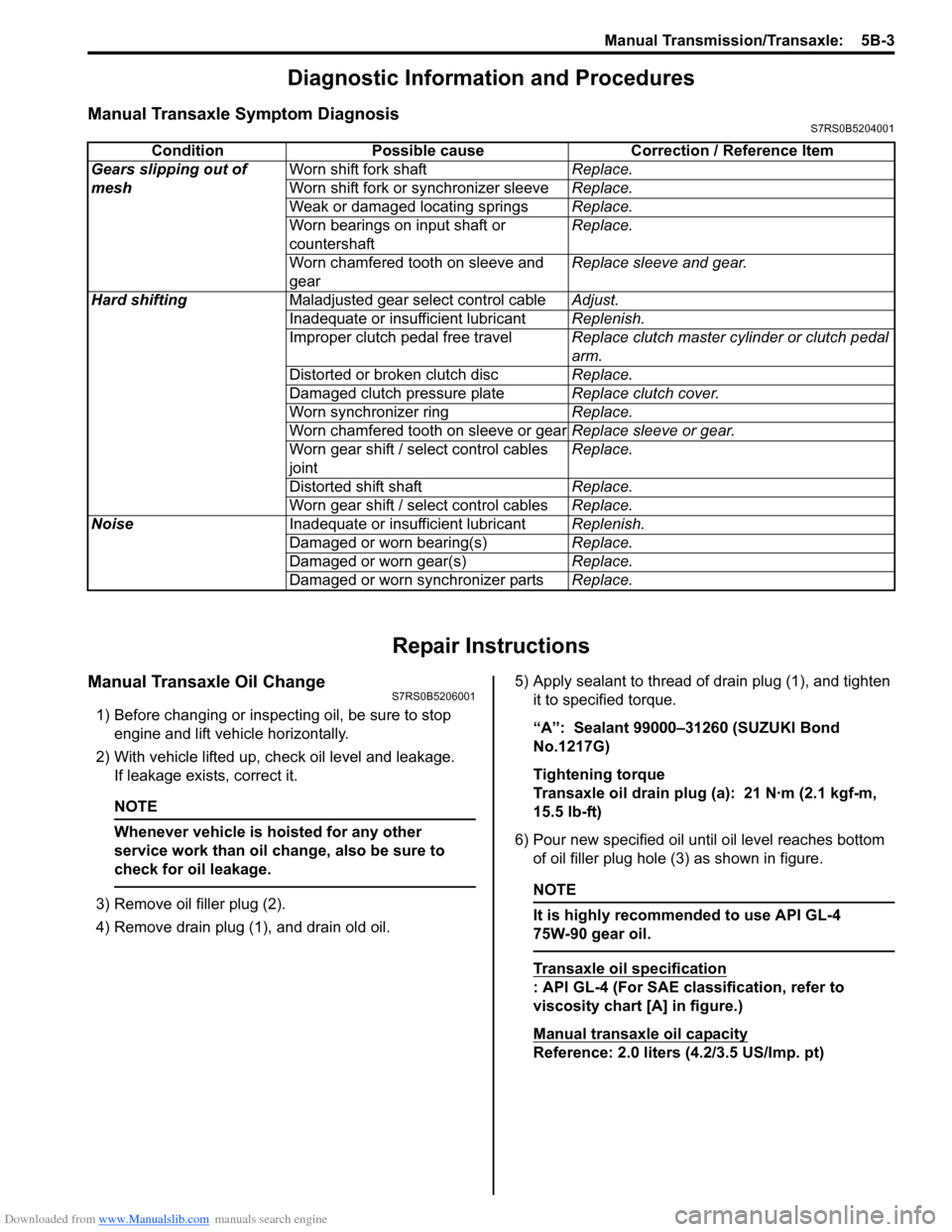

Manual Transaxle Symptom DiagnosisS7RS0B5204001

Repair Instructions

Manual Transaxle Oil ChangeS7RS0B5206001

1) Before changing or inspecting oil, be sure to stop engine and lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil. 5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

6) Pour new specified oil unt il oil level reaches bottom

of oil filler plug hole (3) as shown in figure.NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.0 liters (4.2/3.5 US/Imp. pt)

Condition Possible cause Correction / Reference Item

Gears slipping out of

mesh Worn shift fork shaft

Replace.

Worn shift fork or synchronizer sleeve Replace.

Weak or damaged locating springs Replace.

Worn bearings on input shaft or

countershaft Replace.

Worn chamfered tooth on sleeve and

gear Replace sleeve and gear.

Hard shifting Maladjusted gear select control cable Adjust.

Inadequate or insufficient lubricant Replenish.

Improper clutch pedal free travel Replace clutch master cylinder or clutch pedal

arm.

Distorted or broken clutch disc Replace.

Damaged clutch pressure plate Replace clutch cover.

Worn synchronizer ring Replace.

Worn chamfered tooth on sleeve or gear Replace sleeve or gear.

Worn gear shift / select control cables

joint Replace.

Distorted shift shaft Replace.

Worn gear shift / select control cables Replace.

Noise Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn synchronizer parts Replace.

Page 835 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-21

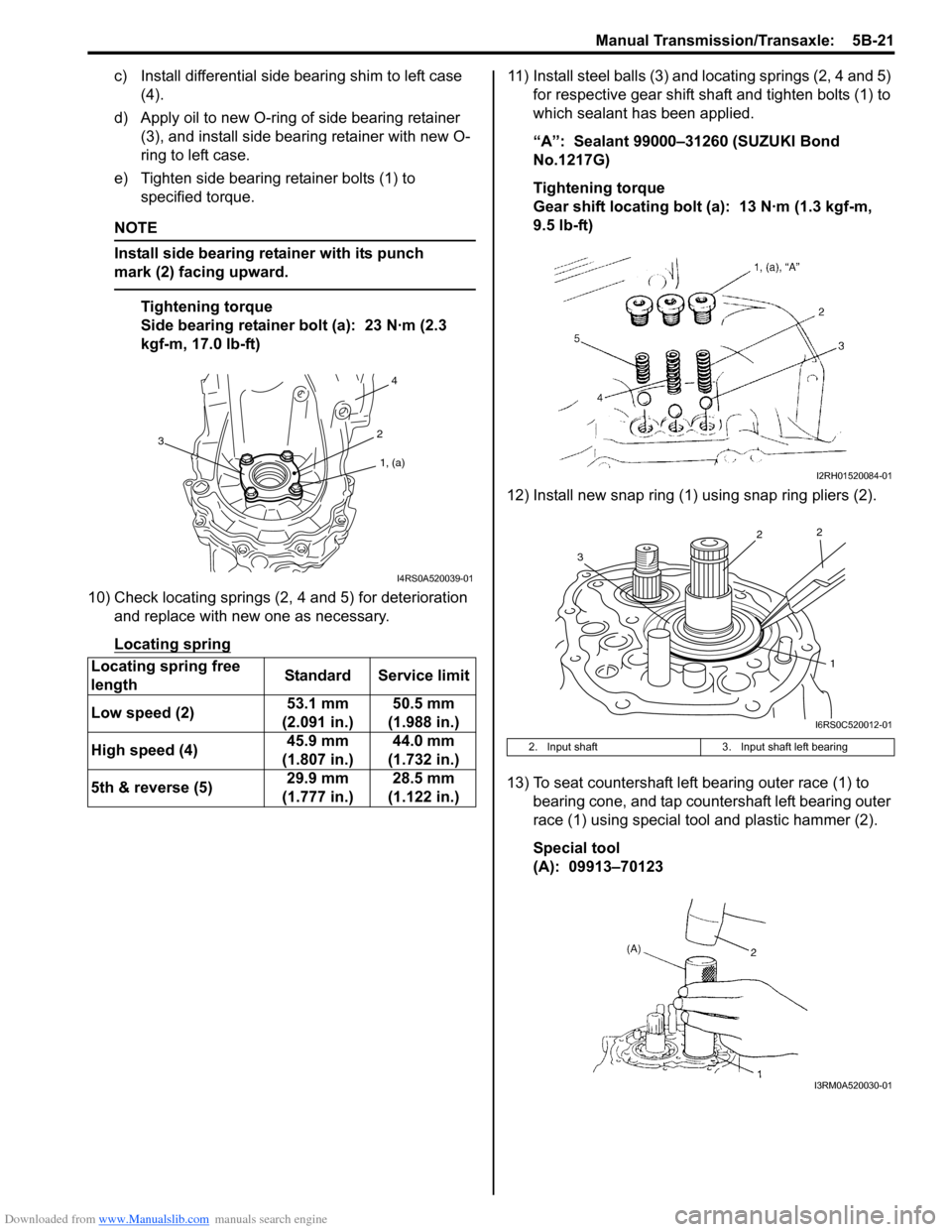

c) Install differential side bearing shim to left case (4).

d) Apply oil to new O-ring of side bearing retainer (3), and install side bea ring retainer with new O-

ring to left case.

e) Tighten side bearing retainer bolts (1) to specified torque.

NOTE

Install side bearing retainer with its punch

mark (2) facing upward.

Tightening torque

Side bearing retainer bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

10) Check locating springs (2, 4 and 5) for deterioration and replace with new one as necessary.

Locating spring

11) Install steel balls (3) and locating springs (2, 4 and 5) for respective gear shift shaft and tighten bolts (1) to

which sealant has been applied.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift locating bolt (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

12) Install new snap ring (1) using snap ring pliers (2).

13) To seat countershaft left bearing outer race (1) to bearing cone, and tap countershaft left bearing outer

race (1) using special tool and plastic hammer (2).

Special tool

(A): 09913–70123

Locating spring free

length

Standard Service limit

Low speed (2) 53.1 mm

(2.091 in.) 50.5 mm

(1.988 in.)

High speed (4) 45.9 mm

(1.807 in.) 44.0 mm

(1.732 in.)

5th & reverse (5) 29.9 mm

(1.777 in.) 28.5 mm

(1.122 in.)

1, (a)

2

4

3

I4RS0A520039-01

2. Input shaft 3. Input shaft left bearing

I2RH01520084-01

1

2

2

3

I6RS0C520012-01

I3RM0A520030-01

Page 845 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-31

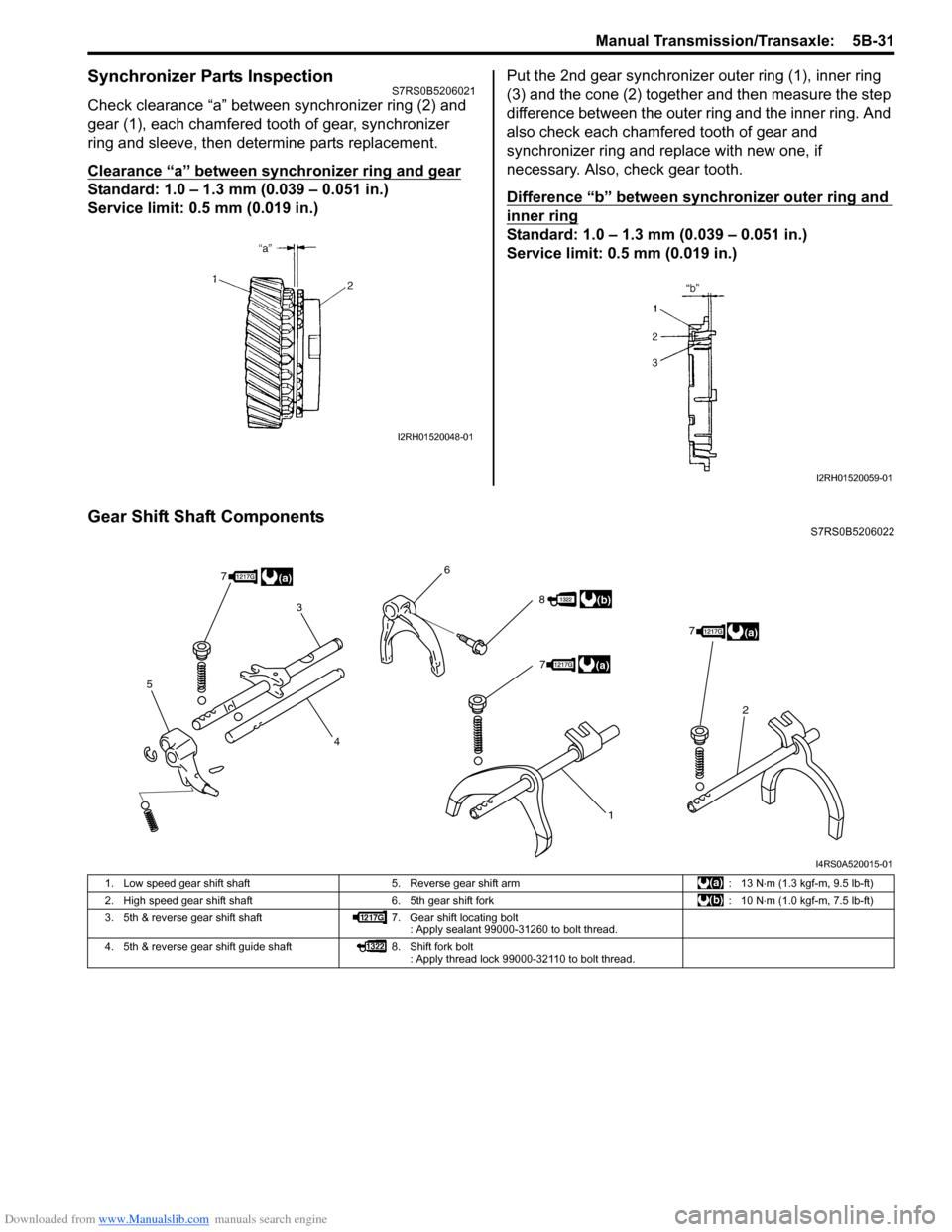

Synchronizer Parts InspectionS7RS0B5206021

Check clearance “a” between synchronizer ring (2) and

gear (1), each chamfered tooth of gear, synchronizer

ring and sleeve, then determine parts replacement.

Clearance “a” between synchronizer ring and gear

Standard: 1.0 – 1.3 mm (0.039 – 0.051 in.)

Service limit: 0.5 mm (0.019 in.)Put the 2nd gear synchronizer outer ring (1), inner ring

(3) and the cone (2) together and then measure the step

difference between the outer ring and the inner ring. And

also check each chamfered tooth of gear and

synchronizer ring and replace with new one, if

necessary. Also, check gear tooth.

Difference “b” between synchronizer outer ring and

inner ring

Standard: 1.0 – 1.3 mm (0.039 – 0.051 in.)

Service limit: 0.5 mm (0.019 in.)

Gear Shift Shaft ComponentsS7RS0B5206022

I2RH01520048-01

I2RH01520059-01

5

3

4 6

1

2

8

7

77

(a)

(b)

(a)

(a)

I4RS0A520015-01

1. Low speed gear shift shaft

5. Reverse gear shift arm : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

2. High speed gear shift shaft 6. 5th gear shift fork : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

3. 5th & reverse gear shift shaft 7. Gear shift locating bolt

: Apply sealant 99000-31260 to bolt thread.

4. 5th & reverse gear shift guide shaft 8. Shift fork bolt

: Apply thread lock 99000-32110 to bolt thread.

Page 846 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-32 Manual Transmission/Transaxle:

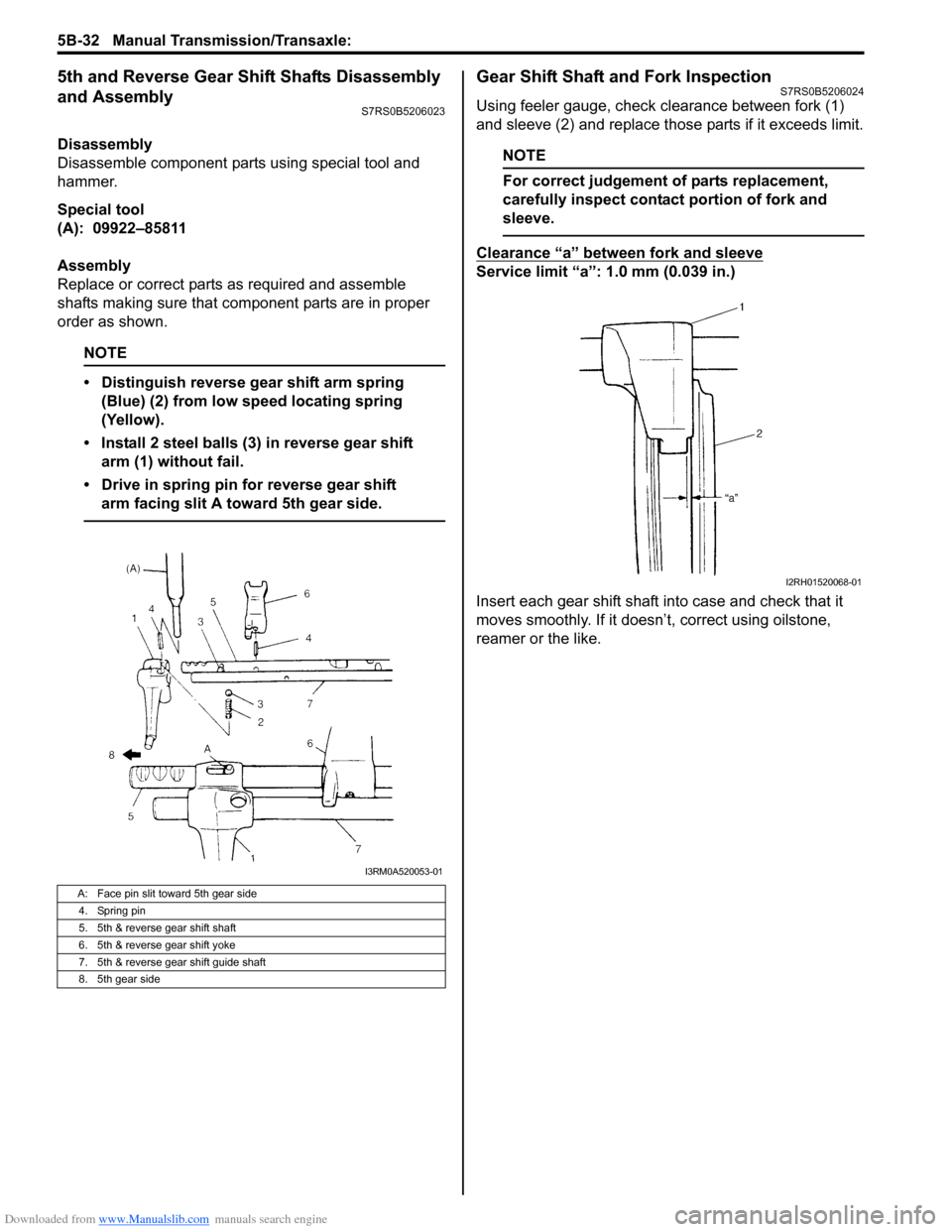

5th and Reverse Gear Shift Shafts Disassembly

and Assembly

S7RS0B5206023

Disassembly

Disassemble component parts using special tool and

hammer.

Special tool

(A): 09922–85811

Assembly

Replace or correct parts as required and assemble

shafts making sure that component parts are in proper

order as shown.

NOTE

• Distinguish reverse gear shift arm spring (Blue) (2) from low speed locating spring

(Yellow).

• Install 2 steel balls (3) in reverse gear shift arm (1) without fail.

• Drive in spring pin for reverse gear shift arm facing slit A toward 5th gear side.

Gear Shift Shaft and Fork InspectionS7RS0B5206024

Using feeler gauge, check clearance between fork (1)

and sleeve (2) and replace those parts if it exceeds limit.

NOTE

For correct judgement of parts replacement,

carefully inspect contact portion of fork and

sleeve.

Clearance “a” between fork and sleeve

Service limit “a”: 1.0 mm (0.039 in.)

Insert each gear shift shaft into case and check that it

moves smoothly. If it doesn’t, correct using oilstone,

reamer or the like.

A: Face pin slit toward 5th gear side

4. Spring pin

5. 5th & reverse gear shift shaft

6. 5th & reverse gear shift yoke

7. 5th & reverse gear shift guide shaft

8. 5th gear side

I3RM0A520053-01

I2RH01520068-01

Page 850 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-36 Manual Transmission/Transaxle:

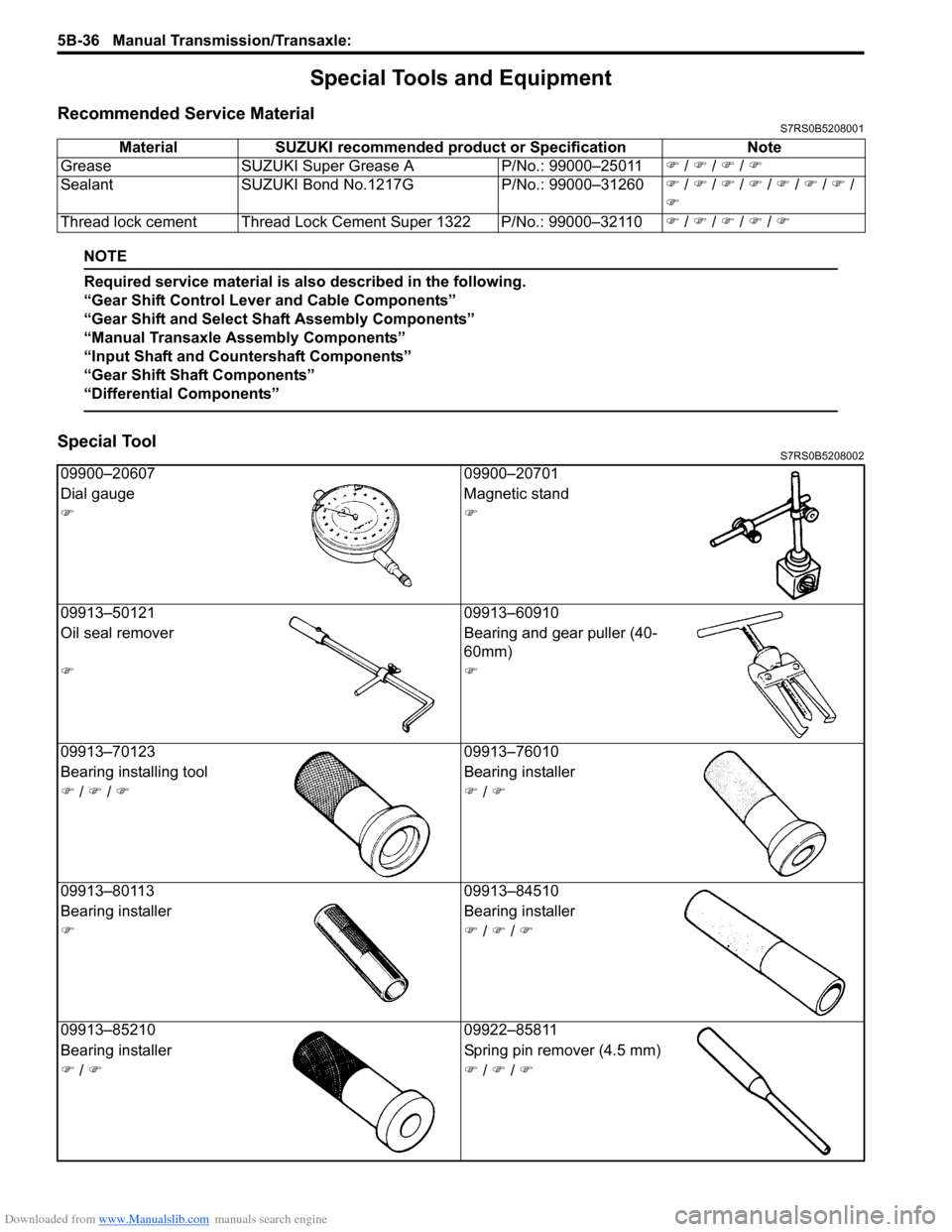

Special Tools and Equipment

Recommended Service MaterialS7RS0B5208001

NOTE

Required service material is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Input Shaft and Countershaft Components”

“Gear Shift Shaft Components”

“Differential Components”

Special ToolS7RS0B5208002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �) / �) / �)

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�) / �) / �) / �) / �) / �) / �) /

�)

Thread lock cement Thread Lock Cement Super 1322 P/No.: 99000–32110 �) / �) / �) / �) / �)

09900–20607 09900–20701

Dial gauge Magnetic stand

�)�)

09913–50121 09913–60910

Oil seal remover Bearing and gear puller (40-

60mm)

�)�)

09913–70123 09913–76010

Bearing installing t ool Bearing installer

�) / �) / �)�) / �)

09913–80113 09913–84510

Bearing installer Bearing installer

�)�) / �) / �)

09913–85210 09922–85811

Bearing installer Spring pin remover (4.5 mm)

�) / �)�) / �) / �)

Page 862 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-10 Clutch:

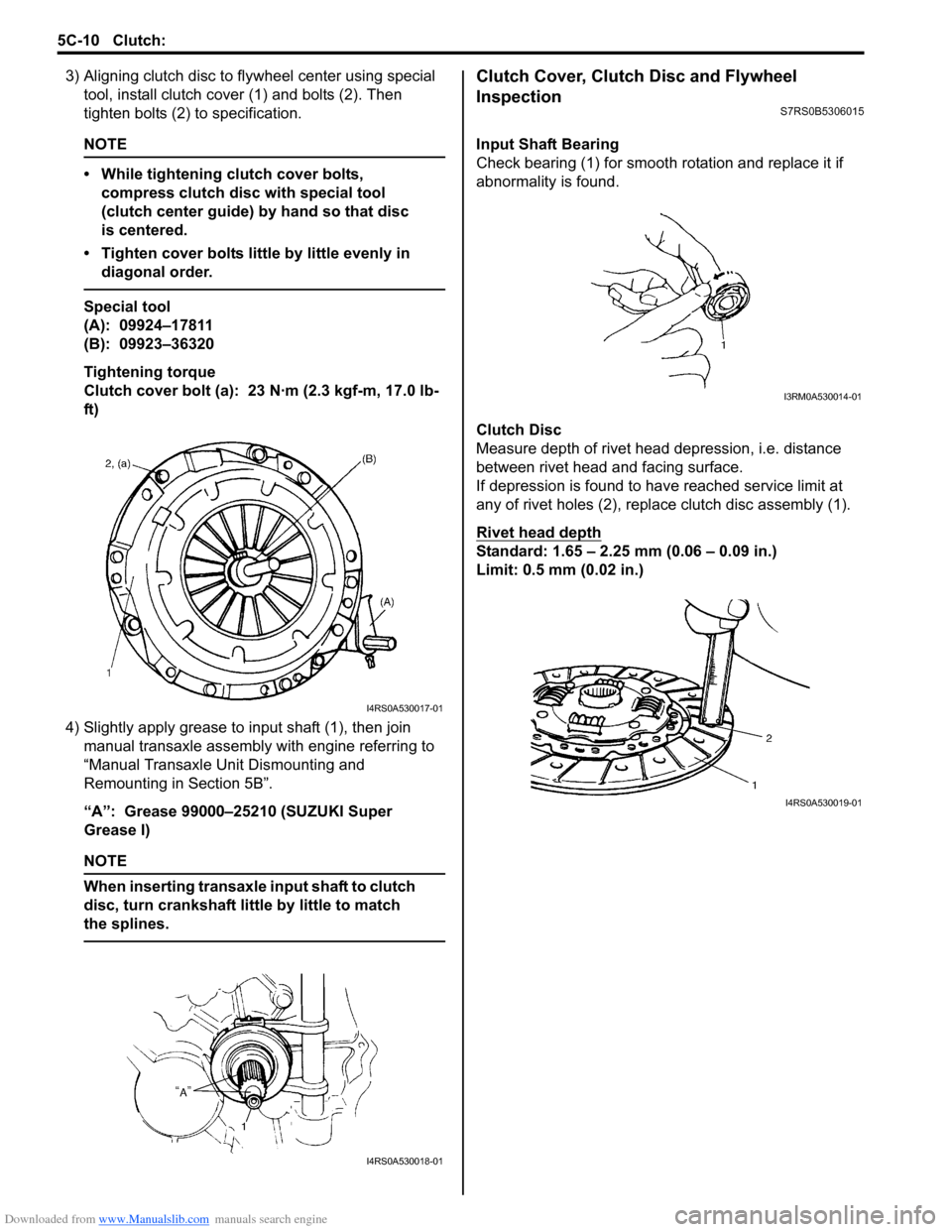

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts, compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

4) Slightly apply grease to input shaft (1), then join manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft li ttle by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S7RS0B5306015

Input Shaft Bearing

Check bearing (1) for smooth ro tation and replace it if

abnormality is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to hav e reached service limit at

any of rivet holes (2), repl ace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)

I4RS0A530017-01

I4RS0A530018-01

I3RM0A530014-01

I4RS0A530019-01