Exhaust valve SUZUKI SWIFT 2007 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 142 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-92 Engine General Information and Diagnosis:

DTC P0134: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor-1)S7RS0B1104033

Wiring Diagram

Refer to “DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-1)”

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine Coolant temperature: 70 °C (158 °F) to 150 °C (302 ° F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Drive vehicle at 40 mph (60 km/h) or higher. (engine speed: 2500 – 3000 r/min.)

5) Keep above vehicle speed for 6 min. or more. (Throt tle valve opening is kept constant in this step.)

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting (with fuel cut for 3 sec. or more)

and then stop vehicle.

7) Check if DTC and pending DTC exist by using scan tool. If not, check if oxygen sensor monitoring test has been

completed by using scan tool. If not in both of above c hecks (i.e., no DTC and pending DTC and oxygen sensor

monitoring test not completed), check vehicle cond ition (environmental) and repeat Step 3) through 6).

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

HO2S voltage is higher than 0.6 V for more than 1 min

continuously after warming up engine or HO2S voltage is lower

than 0.3 V for more than 1 min continuously after warming up

engine.

(2 driving cycle detection logic) •HO2S-1

• HO2S-1 circuit

• Exhaust gas leakage

•ECM

• Air intake system

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

Page 155 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-105

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylinder Misfire Detected / Cylinder 1

/ Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected

S7RS0B1104039

System Description

ECM measures the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC de tecting condition, it determines the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: –10 °C, 14 °F or higher

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

5) Stop vehicle and check DTC and pending DTC. 11

Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0300:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected at 2 or more cylinders. (MIL flashes as lo ng as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 2 or more cylinders. (2 driving cycle detection logic) • Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system

• Abnormal air drawn in

• Engine compression

• Valve lash adjuster

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality

DTC P0301, P0302, P0303, P0304:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 1 cylinder. (2 driving cycle detection logic)

Page 166 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-116 Engine General Information and Diagnosis:

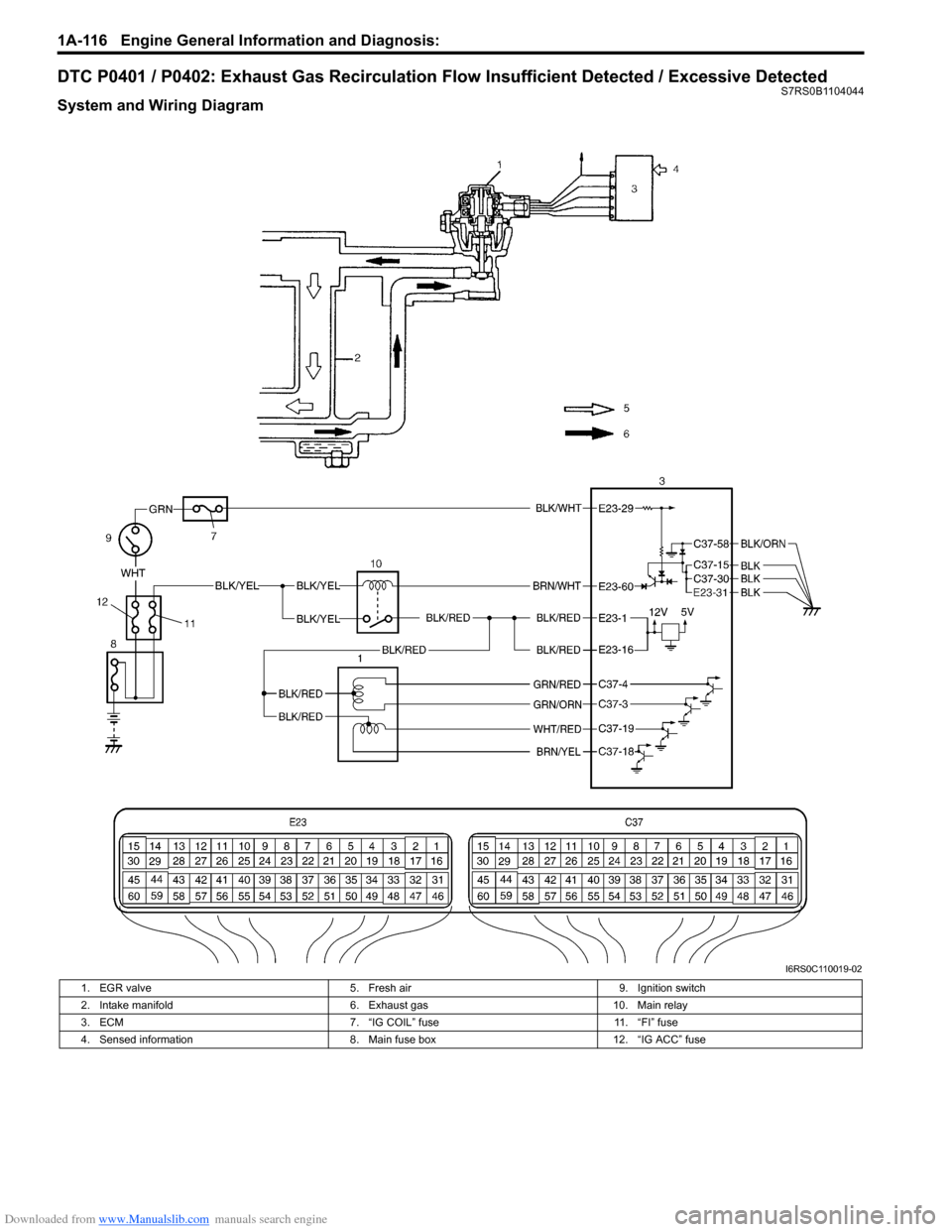

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected / Excessive DetectedS7RS0B1104044

System and Wiring Diagram

I6RS0C110019-02

1. EGR valve5. Fresh air 9. Ignition switch

2. Intake manifold 6. Exhaust gas10. Main relay

3. ECM 7. “IG COIL” fuse11. “FI” fuse

4. Sensed information 8. Main fuse box12. “IG ACC” fuse

Page 168 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-118 Engine General Information and Diagnosis:

DTC P0403: Exhaust Gas Recirculation Control CircuitS7RS0B1104045

Wiring Diagram

Refer to “DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected / Excessive Detected”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and run it for 30 seconds.

4) Check DTC. 3

EGR valve operation check

1) With ignition switch turned OF F, install SUZUKI scan tool

to DTC.

2) Check EGR system referring to “EGR System Inspection

in Section 1B”.

Is it in good condition? Go to Step 4. Go to Step 5.

4 MAP sensor check

1) Check MAP sensor for performance referring to “MAP

Sensor Inspection in Section 1C”.

Is check result satisfactory? Intermittent trouble or

faulty ECM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Replace MAP sensor.

5 EGR valve control circuit check

1) Check that EGR valve control circuits are in good

condition referring to Step 2 to 5 of “DTC P0403:

Exhaust Gas Recirculation Control Circuit”

Are circuits in good condition? Go to Step 6. Repair or replace EGR

valve control circuit(s).

6 EGR valve check

1) Check EGR valve referring to “EGR Valve Inspection in

Section 1B”.

Is check result satisfactory? Go to Step 7. Faulty EGR valve.

7 MAP sensor check

1) Check MAP sensor for performance referring to “MAP

Sensor Inspection in Section 1C”.

Is check result satisfactory? EGR passage clogged.

If OK, substitute a

known-good ECM and

recheck.

Replace MAP sensor.

Step Action Yes No

DTC detecting condition

Trouble area

EGR valve output voltage is differ ent from output command with more

than one pole out of 4 poles.

(1 driving cycle detection logic) • EGR valve circuit open

•EGR valve

•ECM

Page 171 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-121

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: 70 °C, 158 °F to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (500 mmHg, 75 kPa or more)

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Increase vehicle speed to 37 – 62 mph, 60 – 100 km/h. (engine speed: 2500 – 3000 r/min.)

4) Keep above vehicle speed for 10 min. or more (Thr ottle valve opening is kept constant in this step).

5) Stop vehicle and check if DTC / pending DTC exists using sc an tool. If not, check if catalyst monitoring test has

been completed using scan tool. If not in both of above checks (i.e., no DTC / pending DTC and catalyst

monitoring test not completed), check vehicle cond ition (environmental) and repeat Step 3) through 5).

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Response delay of HO2S-2 signal (shifting delay from rich to lean and

from lean to rich with threshold at 0.45 V) compared to switching cycle

(rich-lean) of A/F feed back is less than specified while vehicle is

running at constant speed and except with high engine load after

warmed up.

(*2 driving cycle detection logic, monitoring once per driving cycle) • Exhaust gas leak

• Warm up three way catalytic converter

malfunction

• HO2S-2 malfunction

• HO2S-1 malfunction

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Exhaust system visual check

1) Check exhaust system for leaks, damage and loose

connection.

Is it in good condition? Go to Step 3.

Repair or replace

defective part.

Page 172 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-122 Engine General Information and Diagnosis:

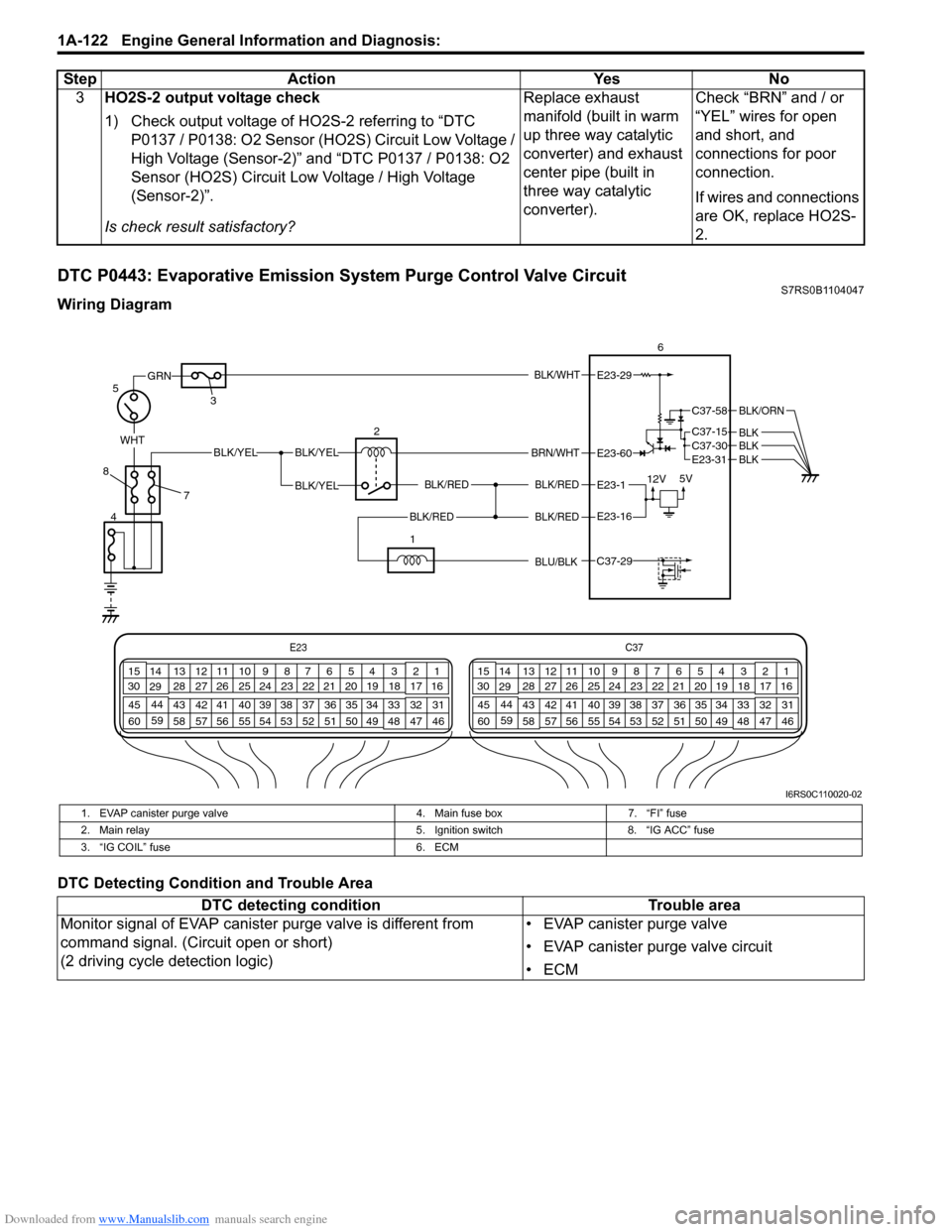

DTC P0443: Evaporative Emission System Purge Control Valve CircuitS7RS0B1104047

Wiring Diagram

DTC Detecting Condition and Trouble Area3

HO2S-2 output voltage check

1) Check output voltage of HO2S-2 referring to “DTC

P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage /

High Voltage (Sensor-2)” and “DTC P0137 / P0138: O2

Sensor (HO2S) Circuit Low Voltage / High Voltage

(Sensor-2)”.

Is check result satisfactory? Replace exhaust

manifold (built in warm

up three way catalytic

converter) and exhaust

center pipe (built in

three way catalytic

converter).

Check “BRN” and / or

“YEL” wires for open

and short, and

connections for poor

connection.

If wires and connections

are OK, replace HO2S-

2.

Step Action Yes No

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 33 1

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/WHT

BLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V 5V

5

4 2

3 6E23-29

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

7

8

BLK/REDBLK/REDE23-16

1

C37-29 BLU/BLK

I6RS0C110020-02

1. EVAP canister purge valve

4. Main fuse box7. “FI” fuse

2. Main relay 5. Ignition switch8. “IG ACC” fuse

3. “IG COIL” fuse 6. ECM

DTC detecting conditionTrouble area

Monitor signal of EVAP canister purge valve is different from

command signal. (Circuit open or short)

(2 driving cycle detection logic) • EVAP canister purge valve

• EVAP canister purge valve circuit

•ECM

Page 280 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

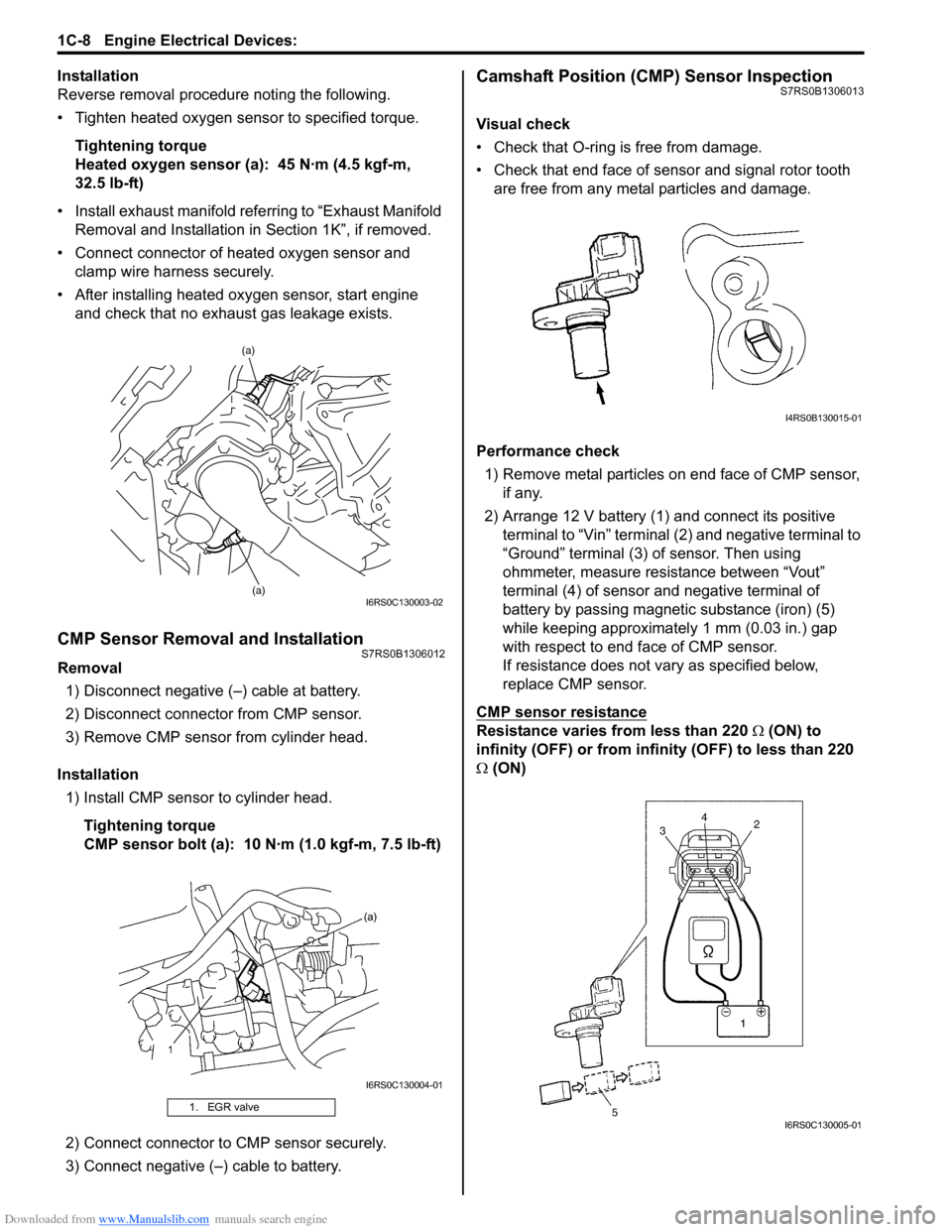

Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor to specified torque.Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor and clamp wire harness securely.

• After installing heated oxygen sensor, start engine and check that no exhaust gas leakage exists.

CMP Sensor Removal and InstallationS7RS0B1306012

Removal

1) Disconnect negative (–) cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove CMP sensor from cylinder head.

Installation 1) Install CMP sensor to cylinder head.

Tightening torque

CMP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative (–) cable to battery.

Camshaft Position (CMP) Sensor InspectionS7RS0B1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CMP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

1. EGR valve

(a)

(a)

I6RS0C130003-02

I6RS0C130004-01

I4RS0B130015-01

I6RS0C130005-01

Page 287 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-2

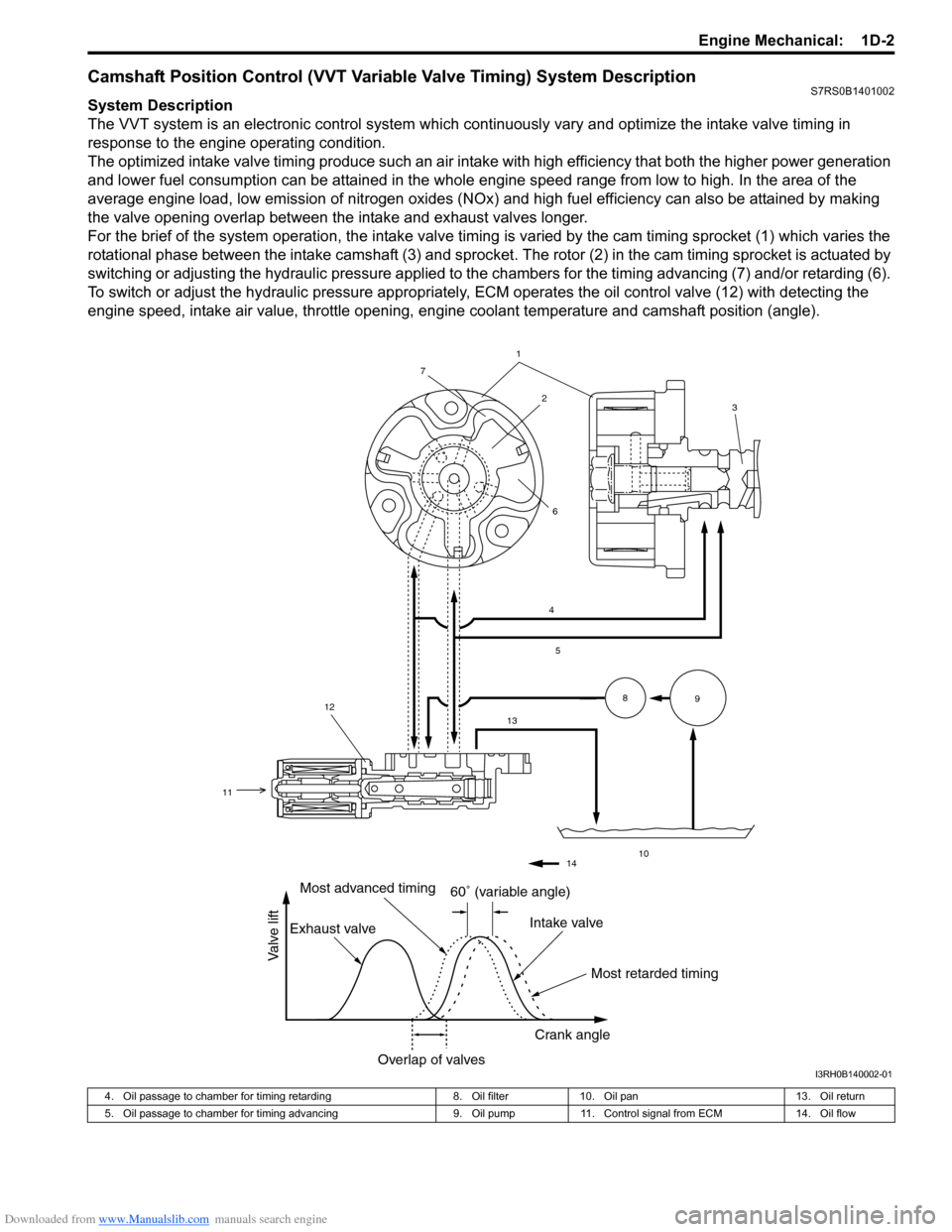

Camshaft Position Control (VVT Variable Valve Timing) System DescriptionS7RS0B1401002

System Description

The VVT system is an electronic control system which continuously vary and optimize the intake valve timing in

response to the engine operating condition.

The optimized intake valve timing produce such an air intake with high efficiency that both the higher power generation

and lower fuel consumption can be attained in the whole engine speed range from low to high. In the area of the

average engine load, low emission of nitrogen oxides (NOx) and high fuel efficiency can also be attained by making

the valve opening overlap between the intake and exhaust valves longer.

For the brief of the system operation, the intake valve timing is varied by the cam timing sprocket (1) which varies the

rotational phase between the intake camshaft (3) and sprocket . The rotor (2) in the cam timing sprocket is actuated by

switching or adjusting the hydraulic pressure applied to the chambers for the timing advancing (7) and/or retarding (6).

To switch or adjust the hydraulic pressure appropriately, ECM operates the oil control valve (12) with detecting the

engine speed, intake air value, throttle opening, engine coolant temperature and camshaft position (angle).

1

4

5

13

10

89

2

7

6

12

11

3

14

60� (variable angle)

Most retarded timing

Most advanced timing

Exhaust valve Intake valve

Crank angle

Overlap of valves

Valve lift

I3RH0B140002-01

4. Oil passage to chamber for timing retarding 8. Oil filter10. Oil pan 13. Oil return

5. Oil passage to chamber for timing advancing 9. Oil pump11. Control signal from ECM 14. Oil flow

Page 289 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-4

Targeted Timing Varying Operation

Diagnostic Information and Procedures

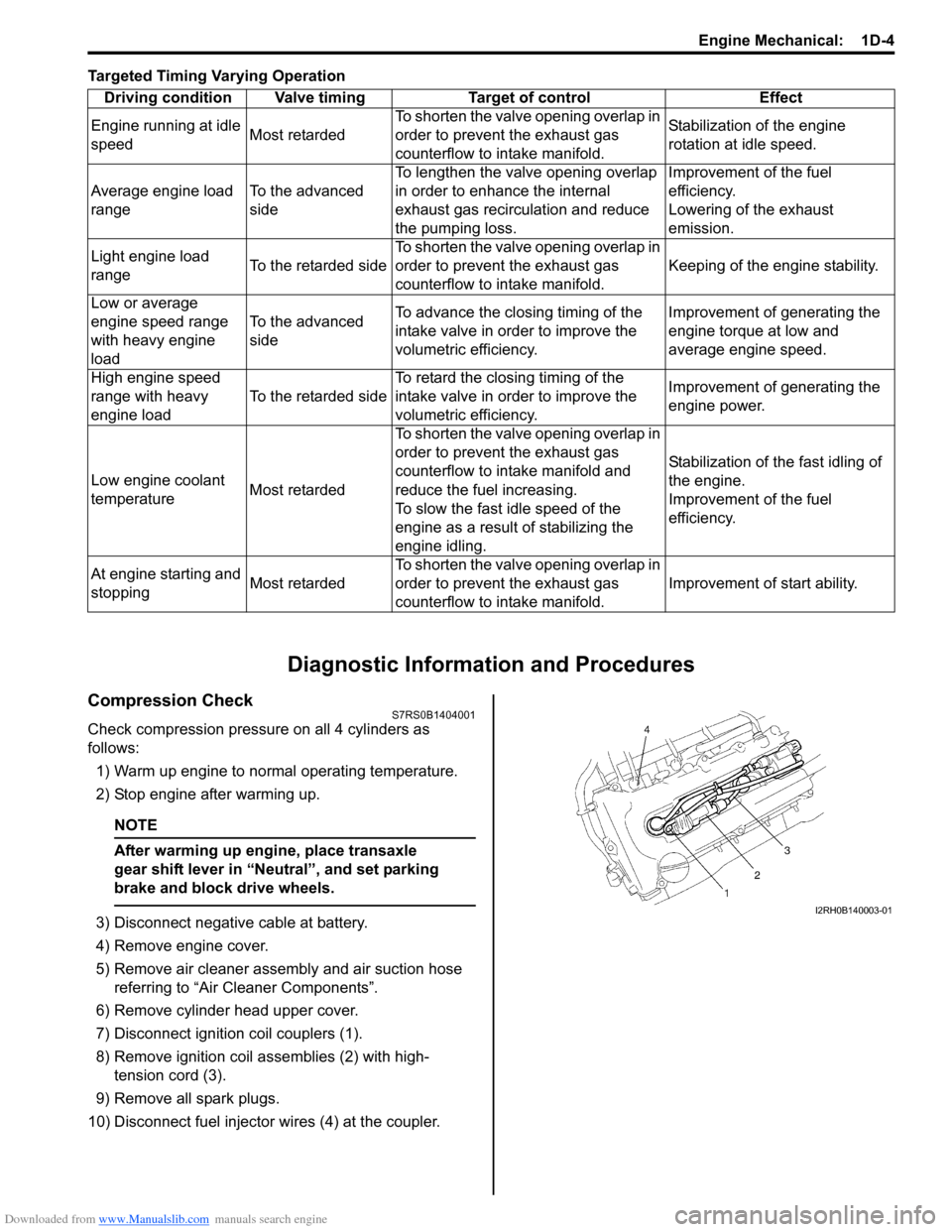

Compression CheckS7RS0B1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

3) Disconnect negative cable at battery.

4) Remove engine cover.

5) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

6) Remove cylinder head upper cover.

7) Disconnect ignition coil couplers (1).

8) Remove ignition coil assemblies (2) with high- tension cord (3).

9) Remove all spark plugs.

10) Disconnect fuel injector wires (4) at the coupler. Driving condition Valve timing Target of control Effect

Engine running at idle

speed Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Stabilization of the engine

rotation at idle speed.

Average engine load

range To the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss. Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range To the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load To the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine power.

Low engine coolant

temperature Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling. Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Improvement of start ability.I2RH0B140003-01

Page 291 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-6

6) Connect special tool (Vacuum gauge) to PCV hose (1).

Special tool

(A): 09915–67311

7) Blind PCV valve (2) using tape (3) or the like.

8) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

9) Run engine at specified idle speed and read vacuum gauge. Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 in.Hg) at

specified idle speed

10) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

11) Disconnect special tool (vacuum gage) from PCV valve.

12) Detach blind cap from PCV valve, and connect PCV hose to PCV valve.

13) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

14) Install engine cover.

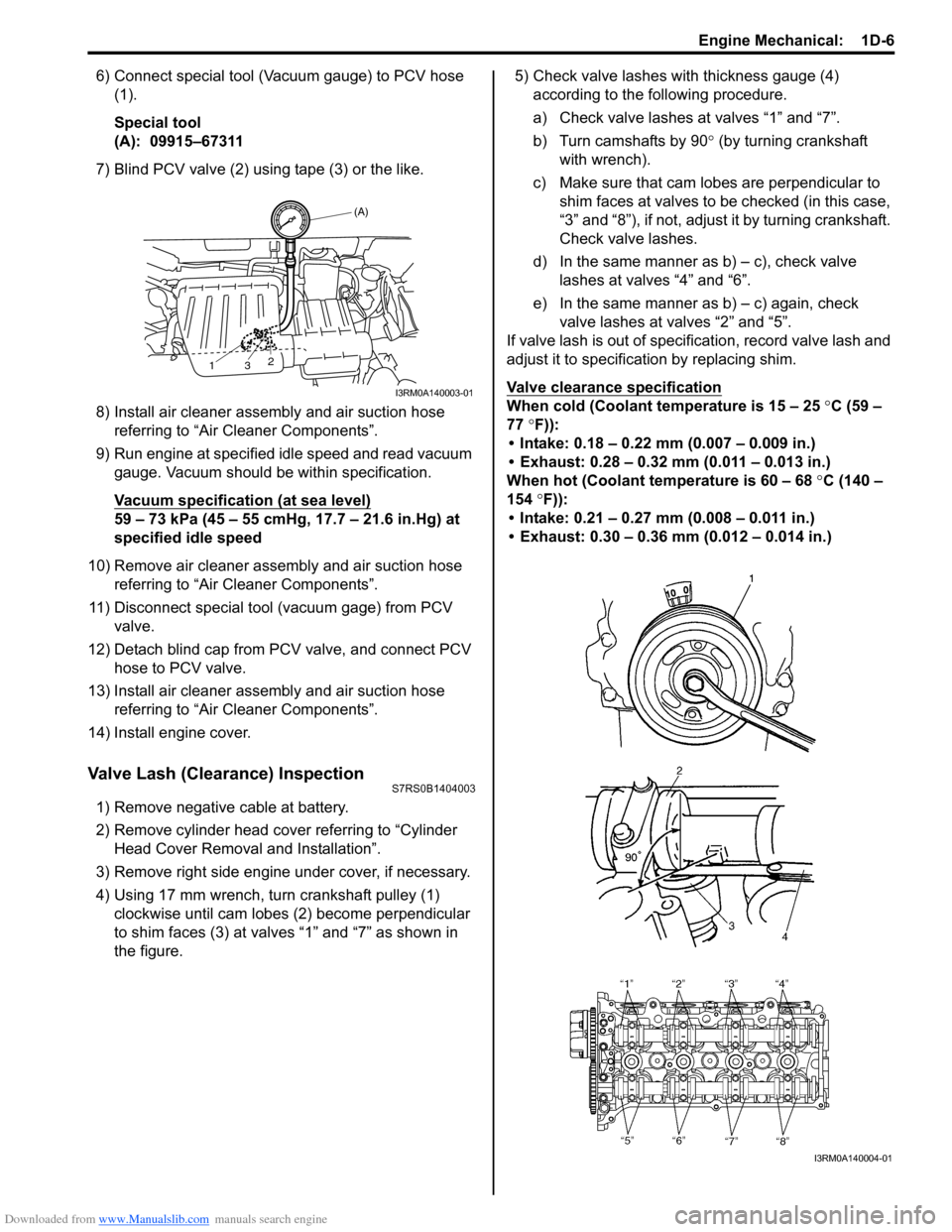

Valve Lash (Clearance) InspectionS7RS0B1404003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

3) Remove right side engine under cover, if necessary.

4) Using 17 mm wrench, turn crankshaft pulley (1) clockwise until cam lobes (2) become perpendicular

to shim faces (3) at valves “1” and “7” as shown in

the figure. 5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90 ° (by turning crankshaft

with wrench).

c) Make sure that cam lobes are perpendicular to shim faces at valves to be checked (in this case,

“3” and “8”), if not, adjust it by turning crankshaft.

Check valve lashes.

d) In the same manner as b) – c), check valve

lashes at valves “4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at valves “2” and “5”.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant te mperature is 15 – 25 °C (59 –

77 °F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68 °C (140 –

154 °F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)

(A)

13 2

I3RM0A140003-01

I3RM0A140004-01