Signal SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 952 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

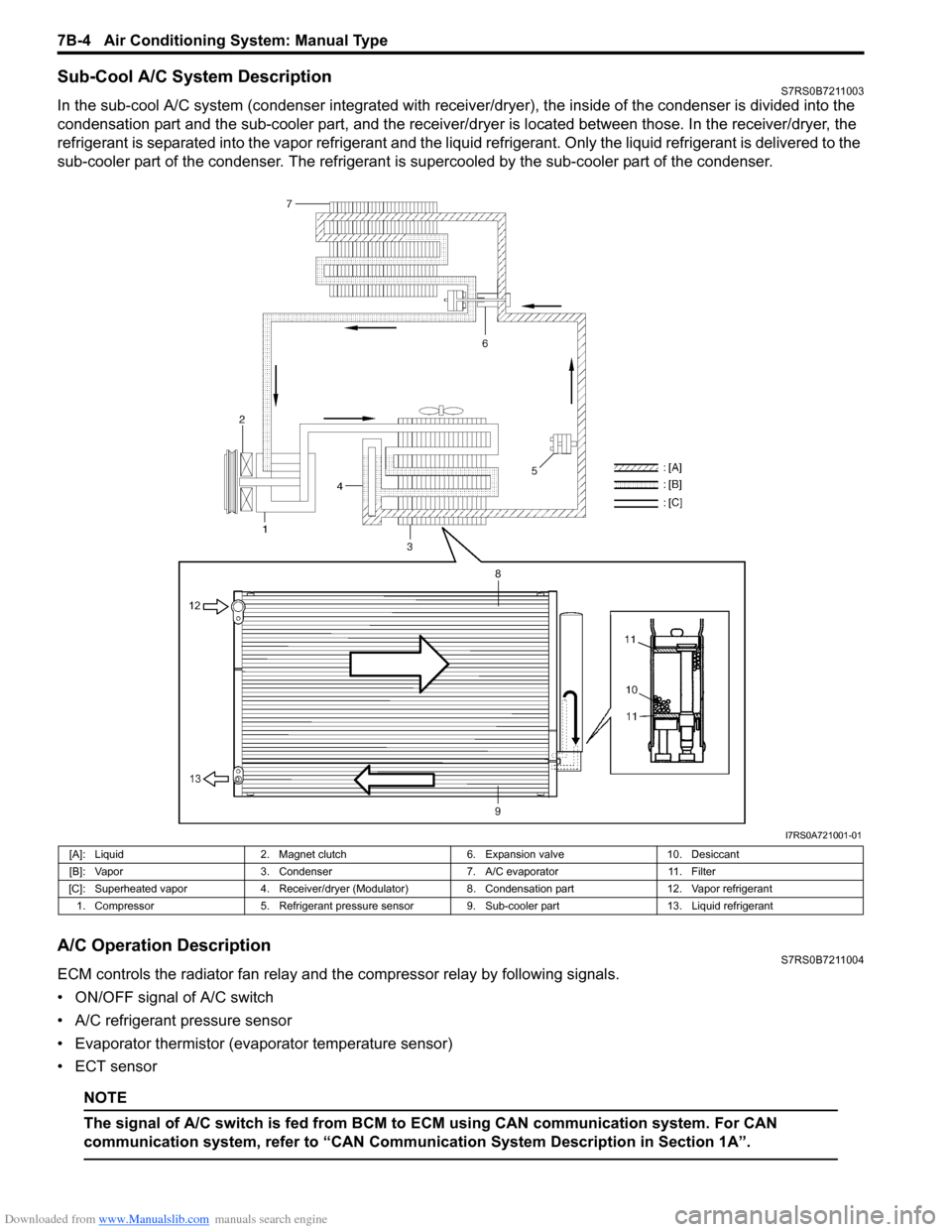

Sub-Cool A/C System DescriptionS7RS0B7211003

In the sub-cool A/C system (condenser integrated with receiver/dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver/dryer is located between those. In the receiver/dryer, the

refrigerant is separated into the vapor refrigerant and the liqui d refrigerant. Only the liquid refrigerant is delivered to the

sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

A/C Operation DescriptionS7RS0B7211004

ECM controls the radiator fan relay and the compressor relay by following signals.

• ON/OFF signal of A/C switch

• A/C refrigerant pressure sensor

• Evaporator thermistor (evaporator temperature sensor)

• ECT sensor

NOTE

The signal of A/C swit ch is fed from BCM to ECM usin g CAN communication system. For CAN

communication system, refer to “CAN Communication System Description in Section 1A”.

I7RS0A721001-01

[A]: Liquid 2. Magnet clutch 6. Expansion valve10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator11. Filter

[C]: Superheated vapor 4. Receiver/dryer (Modulator) 8. Condensation part12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 984 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-36 Air Conditioning System: Automatic Type

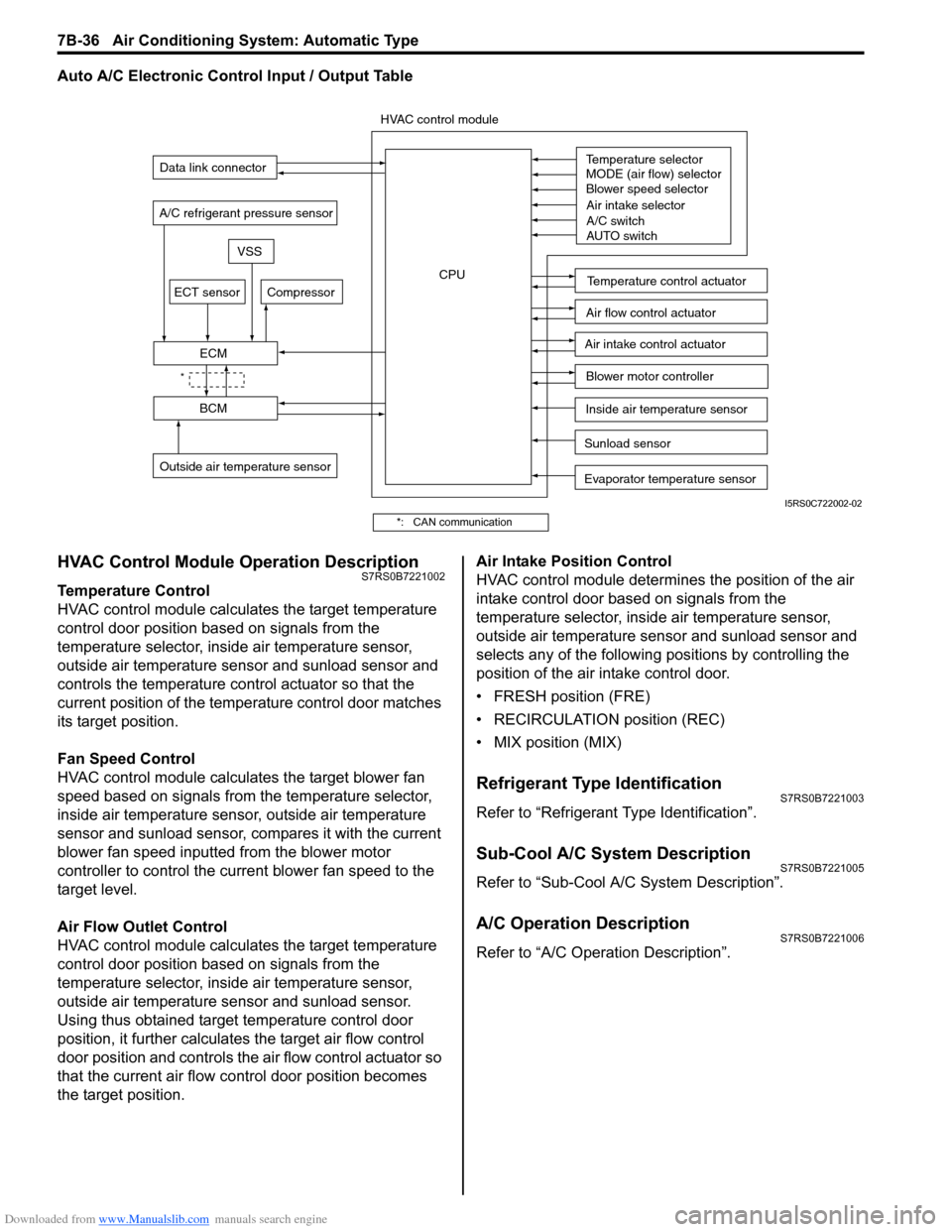

Auto A/C Electronic Control Input / Output Table

HVAC Control Module Operation DescriptionS7RS0B7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor and sunload sensor, compares it with the current

blower fan speed inputted from the blower motor

controller to control the current blower fan speed to the

target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor.

Using thus obtained target temperature control door

position, it further calculates the target air flow control

door position and controls the ai r flow control actuator so

that the current air flow c ontrol door position becomes

the target position. Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)

Refrigerant Type IdentificationS7RS0B7221003

Refer to “Refrigerant Type Identification”.

Sub-Cool A/C System DescriptionS7RS0B7221005

Refer to “Sub-Cool A/C System Description”.

A/C Operation DescriptionS7RS0B7221006

Refer to “A/C Operation Description”.

Sunload sensor

Outside air temperature sensor Evaporator temperature sensor

A/C refrigerant pressure sensor

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch

A/C switch

Compressor

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Inside air temperature sensor

VSS

*

I5RS0C722002-02

*: CAN communication

Page 992 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-44 Air Conditioning System: Automatic Type

3) Light over sunload sensor vertically with an incandescent lamp approximately 100 W apart from

about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

4) Turn ignition switch to ON position.

5) Erase DTC according to instructions displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the clearance, turn ignition switch to OFF position, and then di sconnect SUZUKI scan

tool from DLC.

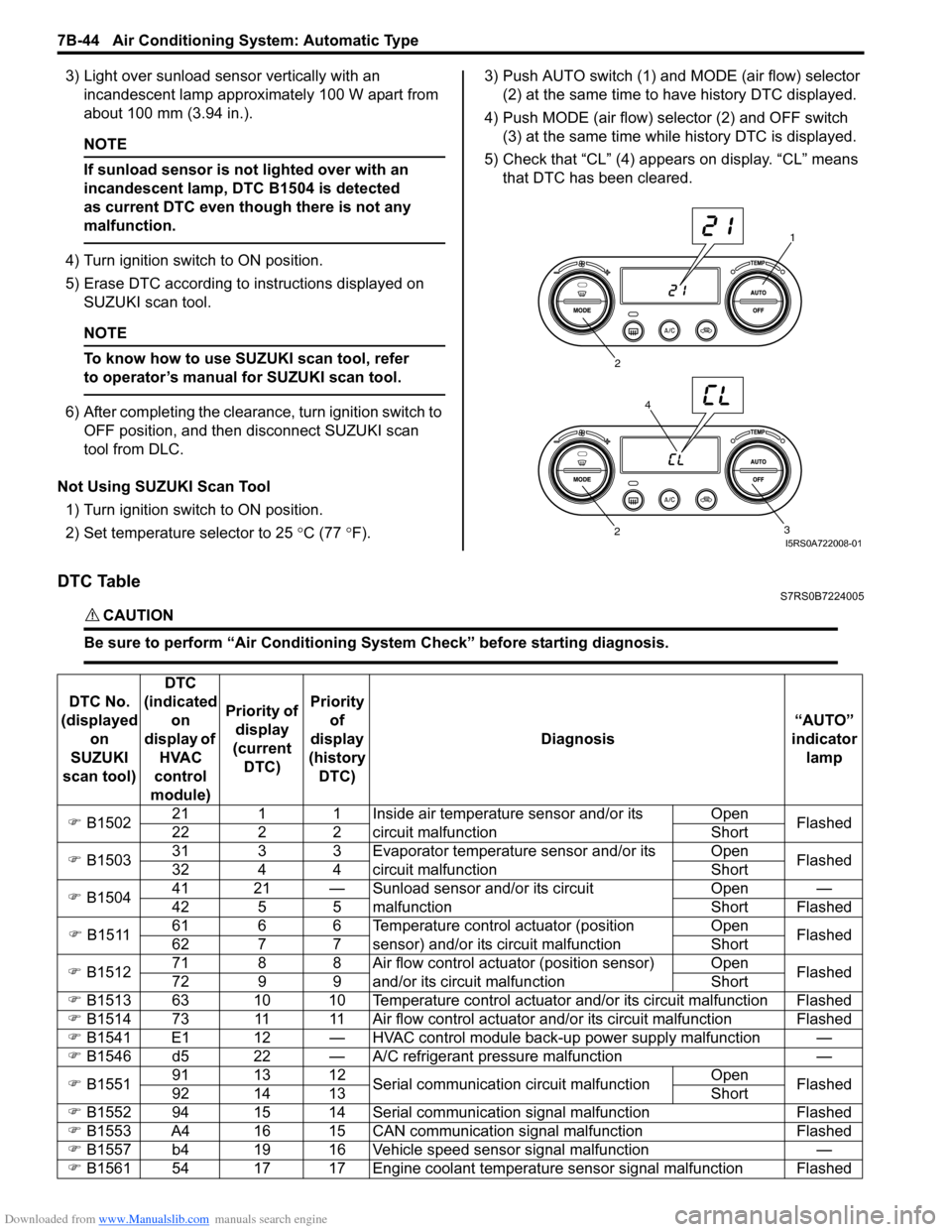

Not Using SUZUKI Scan Tool 1) Turn ignition switch to ON position.

2) Set temperature selector to 25 °C (77 °F). 3) Push AUTO switch (1) and

MODE (air flow) selector

(2) at the same time to have history DTC displayed.

4) Push MODE (air flow) selector (2) and OFF switch (3) at the same time while history DTC is displayed.

5) Check that “CL” (4) appears on display. “CL” means that DTC has been cleared.

DTC TableS7RS0B7224005

CAUTION!

Be sure to perform “Air Conditioning Sy stem Check” before starting diagnosis.

1

2

3

2

4

I5RS0A722008-01

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

�) B1502 21 1 1 Inside air temperature sensor and/or its

circuit malfunction Open

Flashed

22 2 2 Short

�) B1503 31 3 3 Evaporator temperature sensor and/or its

circuit malfunction Open

Flashed

32 4 4 Short

�) B1504 41 21 — Sunload sensor and/or its circuit

malfunction Open —

42 5 5 Short Flashed

�) B1511 61 6 6 Temperature control actuator (position

sensor) and/or its circuit malfunction Open

Flashed

62 7 7 Short

�) B1512 71 8 8 Air flow control actuator (position sensor)

and/or its circuit malfunction Open

Flashed

72 9 9 Short

�) B1513 63 10 10 Temperature control actuator and/or its circuit malfunction Flashed

�) B1514 73 11 11 Air flow control actuator and/or its circuit malfunction Flashed

�) B1541 E1 12 — HVAC control module back-up power supply malfunction —

�) B1546 d5 22 — A/C refrigerant pressure malfunction —

�) B1551 91 13 12

Serial communication circuit malfunction Open

Flashed

92 14 13 Short

�) B1552 94 15 14 Serial communication signal malfunction Flashed

�) B1553 A4 16 15 CAN communication signal malfunction Flashed

�) B1557 b4 19 16 Vehicle speed sensor signal malfunction —

�) B1561 54 17 17 Engine coolant temperature sensor signal malfunction Flashed

Page 993 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-45

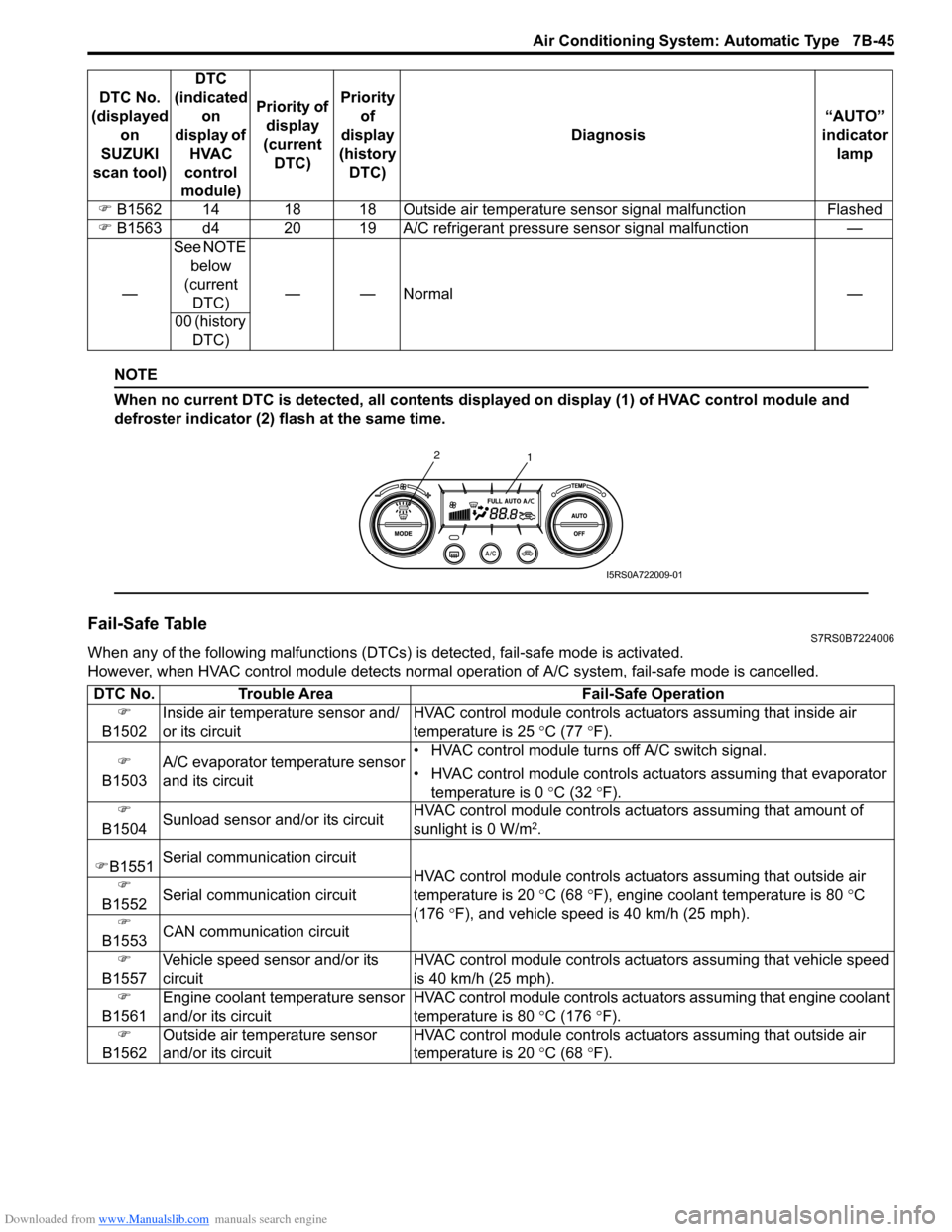

NOTE

When no current DTC is detected, all contents displayed on display (1) of HVAC control module and

defroster indicator (2) flash at the same time.

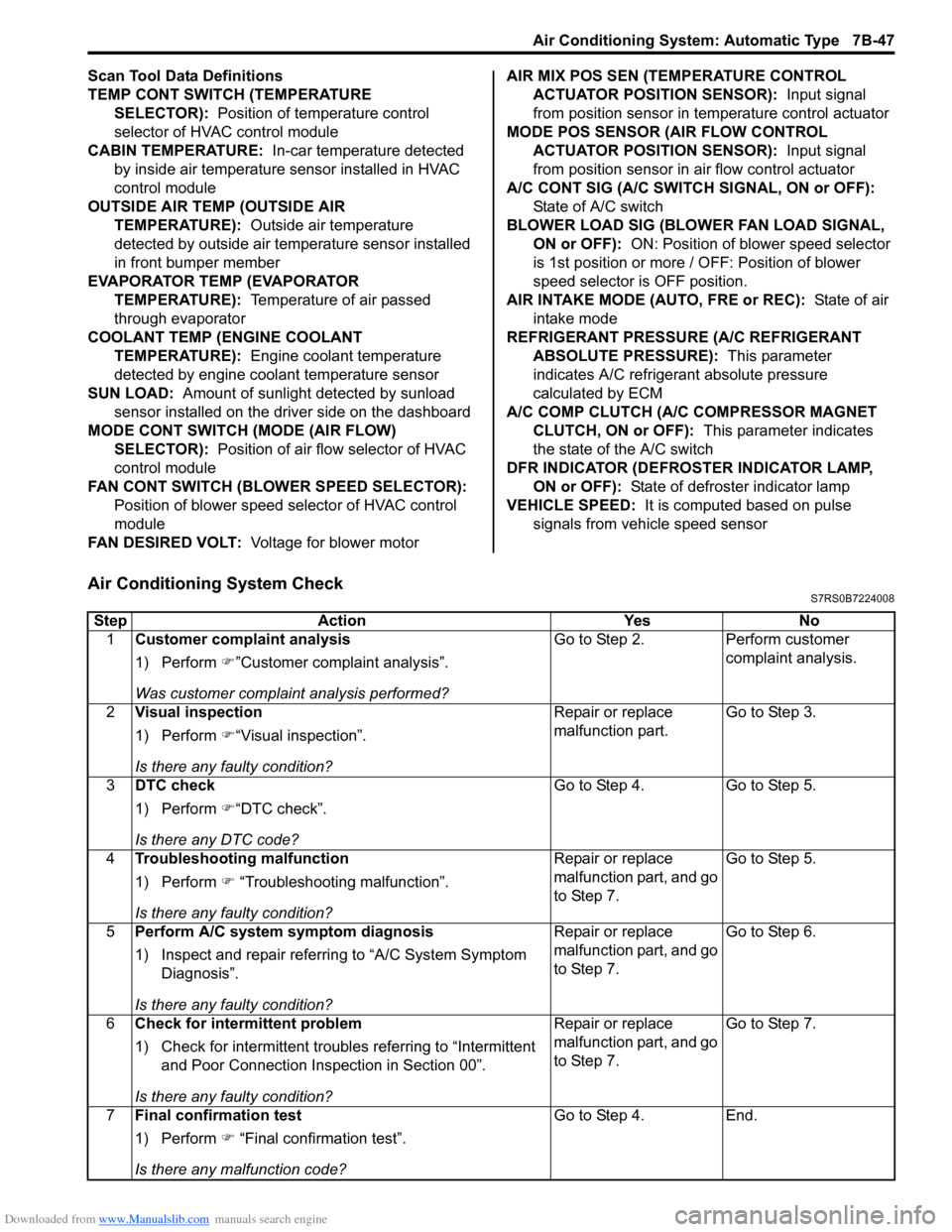

Fail-Safe TableS7RS0B7224006

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal ope ration of A/C system, fail-safe mode is cancelled.

�)

B1562 14 18 18 Outside air temperatur e sensor signal malfunction Flashed

�) B1563 d4 20 19 A/C refrigerant pressure sensor signal malfunction —

— See NOTE

below

(current DTC) ——Normal —

00 (history DTC)

DTC No.

(displayed on

SUZUKI

scan tool) DTC

(indicated on

display of HVAC

control

module) Priority of

display

(current DTC) Priority

of

display

(history DTC) Diagnosis

“AUTO”

indicator lamp

1

2

I5RS0A722009-01

DTC No.

Trouble Area Fail-Safe Operation

�)

B1502 Inside air temperature sensor and/

or its circuit HVAC control module controls actu

ators assuming that inside air

temperature is 25 ° C (77 °F).

�)

B1503 A/C evaporator temperature sensor

and its circuit • HVAC control module turn

s off A/C switch signal.

• HVAC control module controls actu ators assuming that evaporator

temperature is 0 ° C (32 °F).

�)

B1504 Sunload sensor and/or its circuit HVAC control module controls actu

ators assuming that amount of

sunlight is 0 W/m

2.

�) B1551 Serial communication circuit

HVAC control module controls actuators assuming that outside air

temperature is 20 ° C (68 °F), engine coolant temperature is 80 °C

(176 °F), and vehicle speed is 40 km/h (25 mph).

�)

B1552 Serial communication circuit

�)

B1553 CAN communication circuit

�)

B1557 Vehicle speed sensor and/or its

circuit HVAC control module controls act

uators assuming that vehicle speed

is 40 km/h (25 mph).

�)

B1561 Engine coolant temperature sensor

and/or its circuit HVAC control module controls act

uators assuming that engine coolant

temperature is 80 ° C (176 °F).

�)

B1562 Outside air temperature sensor

and/or its circuit HVAC control module controls actu

ators assuming that outside air

temperature is 20 ° C (68 °F).

Page 995 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

Scan Tool Data Definitions

TEMP CONT SWITCH (TEMPERATURE SELECTOR): Position of temperature control

selector of HVAC control module

CABIN TEMPERATURE: In-car temperature detected

by inside air temperature sensor installed in HVAC

control module

OUTSIDE AIR TEMP (OUTSIDE AIR TEMPERATURE): Outside air temperature

detected by outside air temperature sensor installed

in front bumper member

EVAPORATOR TEMP (EVAPORATOR TEMPERATURE): Temperature of air passed

through evaporator

COOLANT TEMP (ENGINE COOLANT TEMPERATURE): Engine coolant temperature

detected by engine coolant temperature sensor

SUN LOAD: Amount of sunlight detected by sunload

sensor installed on the driver side on the dashboard

MODE CONT SWITCH (MODE (AIR FLOW) SELECTOR): Position of air flow selector of HVAC

control module

FAN CONT SWITCH (BLOWER SPEED SELECTOR): Position of blower speed selector of HVAC control

module

FAN DESIRED VOLT: Voltage for blower motor AIR MIX POS SEN (TEMPERATURE CONTROL

ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in temperature control actuator

MODE POS SENSOR (AIR FLOW CONTROL ACTUATOR POSITI ON SENSOR): Input signal

from position sensor in air flow control actuator

A/C CONT SIG (A/C SWITCH SIGNAL, ON or OFF): State of A/C switch

BLOWER LOAD SIG (BLO WER FAN LOAD SIGNAL,

ON or OFF): ON: Position of blower speed selector

is 1st position or more / OFF: Position of blower

speed selector is OFF position.

AIR INTAKE MODE (AUTO, FRE or REC): State of air

intake mode

REFRIGERANT PRESSURE (A/C REFRIGERANT ABSOLUTE PRESSURE): This parameter

indicates A/C refrigerant absolute pressure

calculated by ECM

A/C COMP CLUTCH (A/C COMPRESSOR MAGNET CLUTCH, ON or OFF): This parameter indicates

the state of the A/C switch

DFR INDICATOR (DEFROSTER INDICATOR LAMP, ON or OFF): State of defroster indicator lamp

VEHICLE SPEED: It is computed based on pulse

signals from vehicle speed sensor

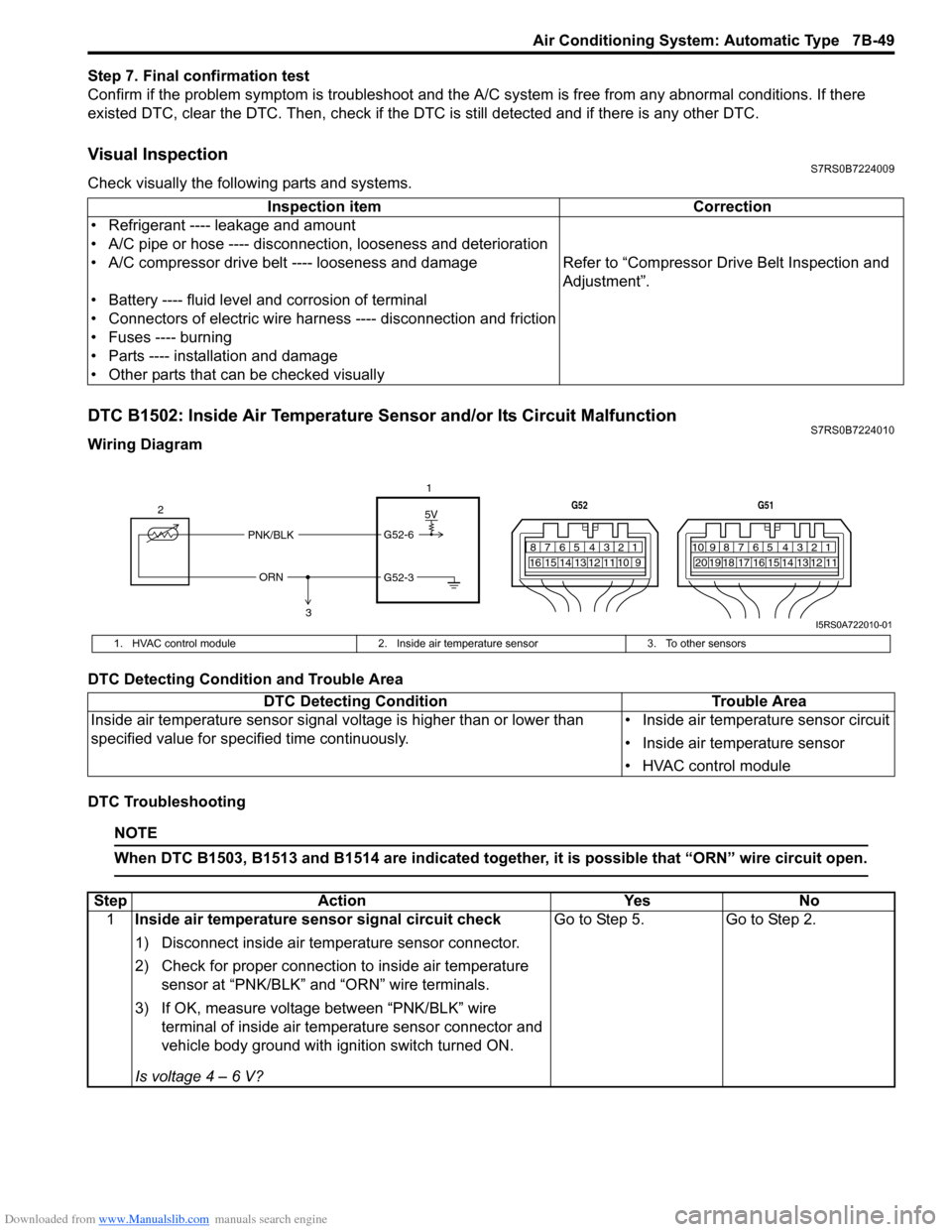

Air Conditioning System CheckS7RS0B7224008

Step Action YesNo

1 Customer complaint analysis

1) Perform �)”Customer complaint analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 Visual inspection

1) Perform �)“Visual inspection”.

Is there any faulty condition? Repair or replace

malfunction part.

Go to Step 3.

3 DTC check

1) Perform �)“DTC check”.

Is there any DTC code? Go to Step 4.

Go to Step 5.

4 Troubleshooting malfunction

1) Perform �) “Troubleshooting malfunction”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 5.

5 Perform A/C system symptom diagnosis

1) Inspect and repair referri ng to “A/C System Symptom

Diagnosis”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 6.

6 Check for intermittent problem

1) Check for intermittent troubles referring to “Intermittent

and Poor Connection Inspection in Section 00”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 7.

Go to Step 7.

7 Final confirmation test

1) Perform �) “Final confirmation test”.

Is there any malfunction code? Go to Step 4.

End.

Page 997 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-49

Step 7. Final confirmation test

Confirm if the problem symptom is troubleshoot and the A/C system is free from any abnormal conditions. If there

existed DTC, clear the DTC. Then , check if the DTC is still detected and if there is any other DTC.

Visual InspectionS7RS0B7224009

Check visually the following parts and systems.

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224010

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1503, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

Inspection item Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and deterioration

• A/C compressor drive belt ---- looseness and damage Refer to “Compressor Drive Belt Inspection and

Adjustment”.

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harn ess ---- disconnection and friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

5V

PNK/BLK

ORN G52-6

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722010-01

1. HVAC control module

2. Inside air temperature sensor 3. To other sensors

DTC Detecting Condition Trouble Area

Inside air temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Inside air temperature sensor circuit

• Inside air temperature sensor

• HVAC control module

Step

Action YesNo

1 Inside air temperature sensor signal circuit check

1) Disconnect inside air temperature sensor connector.

2) Check for proper connection to inside air temperature

sensor at “PNK/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

Page 998 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-50 Air Conditioning System: Automatic Type

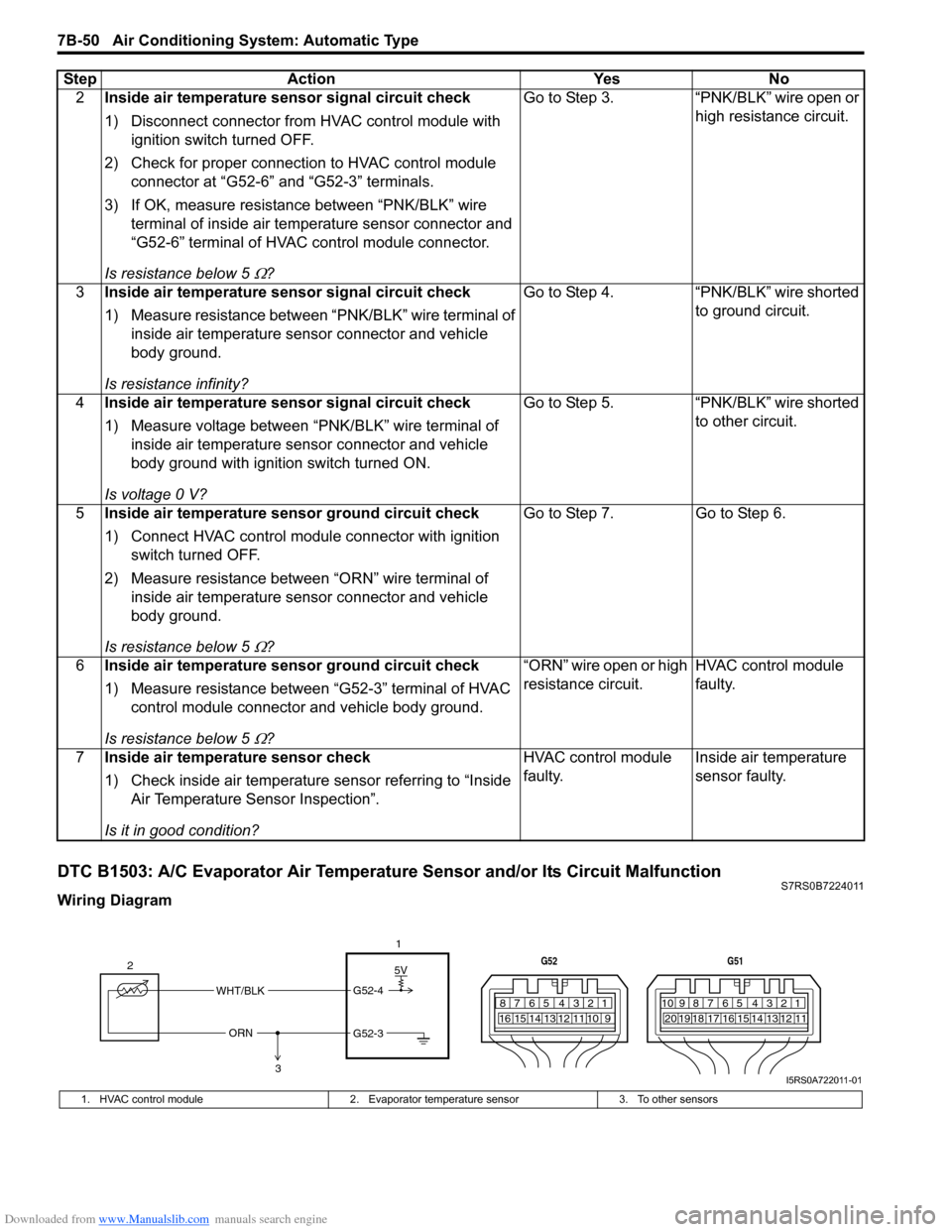

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit MalfunctionS7RS0B7224011

Wiring Diagram2

Inside air temperature sensor signal circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-6” and “G52-3” terminals.

3) If OK, measure resistance between “PNK/BLK” wire terminal of inside air temp erature sensor connector and

“G52-6” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “PNK/BLK” wire open or

high resistance circuit.

3 Inside air temperature sensor signal circuit check

1) Measure resistance between “PNK/BLK” wire terminal of

inside air temperature sensor connector and vehicle

body ground.

Is resistance infinity? Go to Step 4.

“PNK/BLK” wire shorted

to ground circuit.

4 Inside air temperature sensor signal circuit check

1) Measure voltage between “PNK/BLK” wire terminal of

inside air temperature sensor connector and vehicle

body ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 5.

“PNK/BLK” wire shorted

to other circuit.

5 Inside air temperature sensor ground circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure resistance between “ORN” wire terminal of inside air temperature sensor connector and vehicle

body ground.

Is resistance below 5

Ω? Go to Step 7. Go to Step 6.

6 Inside air temperature sensor ground circuit check

1) Measure resistance between “G52-3” terminal of HVAC

control module connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire open or high

resistance circuit.

HVAC control module

faulty.

7 Inside air temperature sensor check

1) Check inside air temperature sensor referring to “Inside

Air Temperature Sensor Inspection”.

Is it in good condition? HVAC control module

faulty.

Inside air temperature

sensor faulty.

Step Action Yes No

5V

WHT/BLK

ORN G52-4

G52-3

2

1

3

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722011-01

1. HVAC control module

2. Evaporator temperature sensor 3. To other sensors

Page 999 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-51

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

When DTC B1502, B1513 and B1514 are indicated together, it is possible that “ORN” wire circuit open.

DTC Detecting ConditionTrouble Area

Evaporator temperature sensor signal voltage is higher than or lower than

specified value for specified time continuously. • Evaporator temperature sensor

circuit

• Evaporator temperature sensor

• HVAC control module

Step Action YesNo

1 Evaporator temperature sensor signal circuit check

1) Disconnect evaporator temperature sensor connector.

2) Check for proper connection to evaporator temperature

sensor at “WHT/BLK” and “ORN” wire terminals.

3) If OK, measure voltage between “WHT/BLK” wire terminal of evaporator te mperature sensor connector

and vehicle body ground with ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

2 Evaporator temperature sensor signal circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-4” and “G52-3” terminals.

3) If OK, measure resistance between “WHT/BLK” wire terminal of evaporator te mperature sensor connector

and “G52-4” terminal of HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “WHT/BLK” wire open

or high resistance

circuit.

3 Evaporator temperature sensor signal circuit check

1) Measure resistance between “WHT/BLK” wire terminal

of evaporator temperature sensor connector and vehicle

body ground.

Is resistance infinity? Go to Step 4. “WHT/BLK” wire

shorted to ground

circuit.

4 Evaporator temperature sensor signal circuit check

1) Measure voltage between “WHT/BLK” wire terminal of

evaporator temperature sens or connector and vehicle

body ground with ignition switch turned ON.

Is voltage 0 V? Go to Step 5. “WHT/BLK” wire

shorted to other circuit.

5 Evaporator temperature sensor ground circuit check

1) Connect HVAC control module connector with ignition

switch turned OFF.

2) Measure resistance between “ORN” wire terminal of evaporator temperature sens or connector and vehicle

body ground.

Is resistance below 5

Ω? Go to Step 7. Go to Step 6.

6 Evaporator temperature sensor ground circuit check

1) Measure resistance between “G52-3” terminal of HVAC

control module connector and vehicle body ground.

Is resistance below 5

Ω? “ORN” wire open or high

resistance circuit.

HVAC control module

faulty.

Page 1000 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-52 Air Conditioning System: Automatic Type

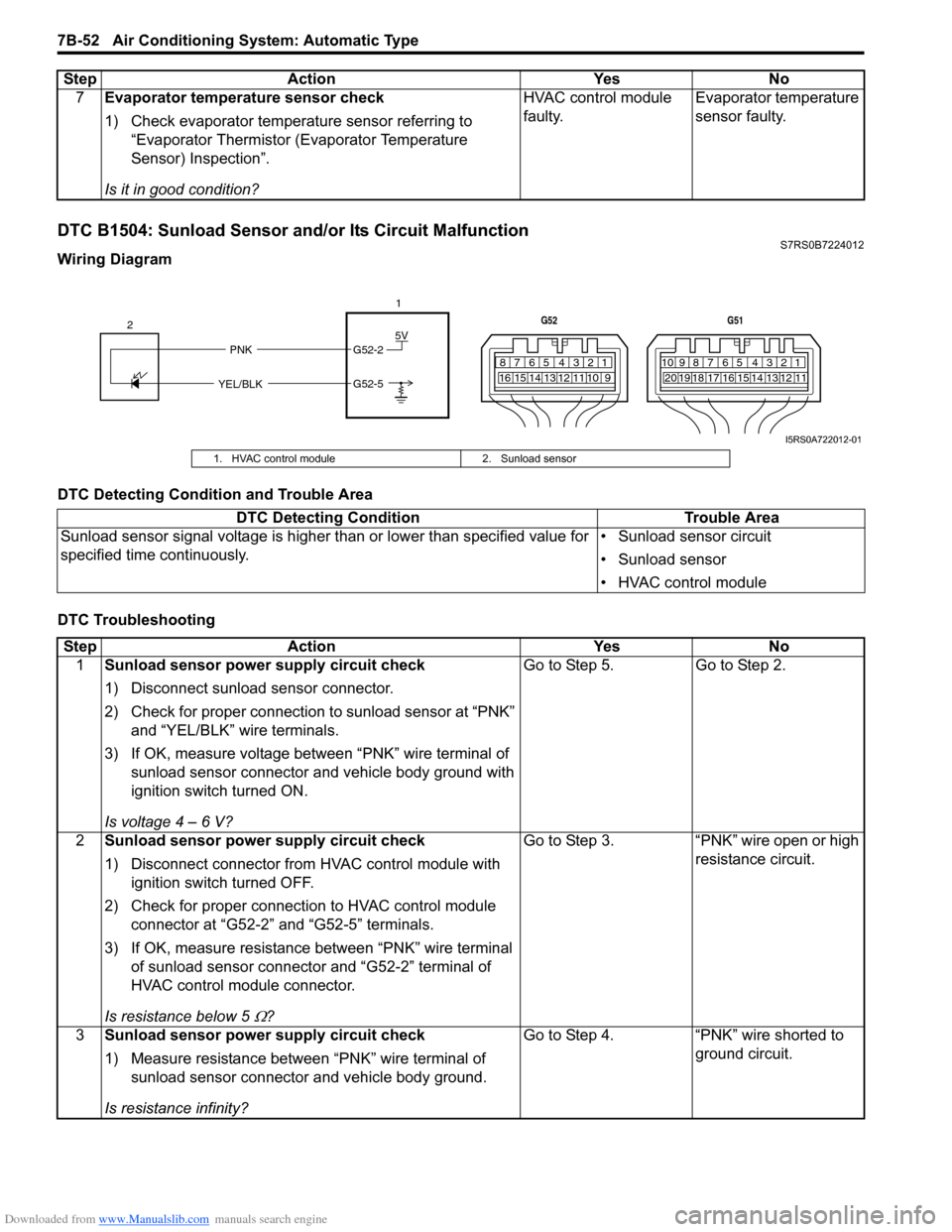

DTC B1504: Sunload Sensor and/or Its Circuit MalfunctionS7RS0B7224012

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting7

Evaporator temperature sensor check

1) Check evaporator temperature sensor referring to

“Evaporator Thermistor (Evaporator Temperature

Sensor) Inspection”.

Is it in good condition? HVAC control module

faulty.

Evaporator temperature

sensor faulty.

Step Action Yes No

5V

PNK G52-2

G52-5

YEL/BLK

2

1

7812910

65 431516 14 13 12 11

G52

789101920121112

65 431718 16 15 14 13

G51

I5RS0A722012-01

1. HVAC control module

2. Sunload sensor

DTC Detecting Condition Trouble Area

Sunload sensor signal voltage is higher than or lower than specified value for

specified time continuously. • Sunload sensor circuit

• Sunload sensor

• HVAC control module

Step

Action YesNo

1 Sunload sensor power supply circuit check

1) Disconnect sunload sensor connector.

2) Check for proper connection to sunload sensor at “PNK”

and “YEL/BLK” wire terminals.

3) If OK, measure voltage between “PNK” wire terminal of sunload sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 5.

Go to Step 2.

2 Sunload sensor power supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to HVAC control module connector at “G52-2” and “G52-5” terminals.

3) If OK, measure resistance between “PNK” wire terminal of sunload sensor connector and “G52-2” terminal of

HVAC control module connector.

Is resistance below 5

Ω? Go to Step 3. “PNK” wire open or high

resistance circuit.

3 Sunload sensor power supply circuit check

1) Measure resistance between “PNK” wire terminal of

sunload sensor connector and vehicle body ground.

Is resistance infinity? Go to Step 4. “PNK” wire shorted to

ground circuit.