12 volt SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 632 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-58 Electronic Stability Program:

6) Measure voltage at resistance without wheel rotation.

If voltage is out of specification, check sensor,

mating encoder and their installation conditions.

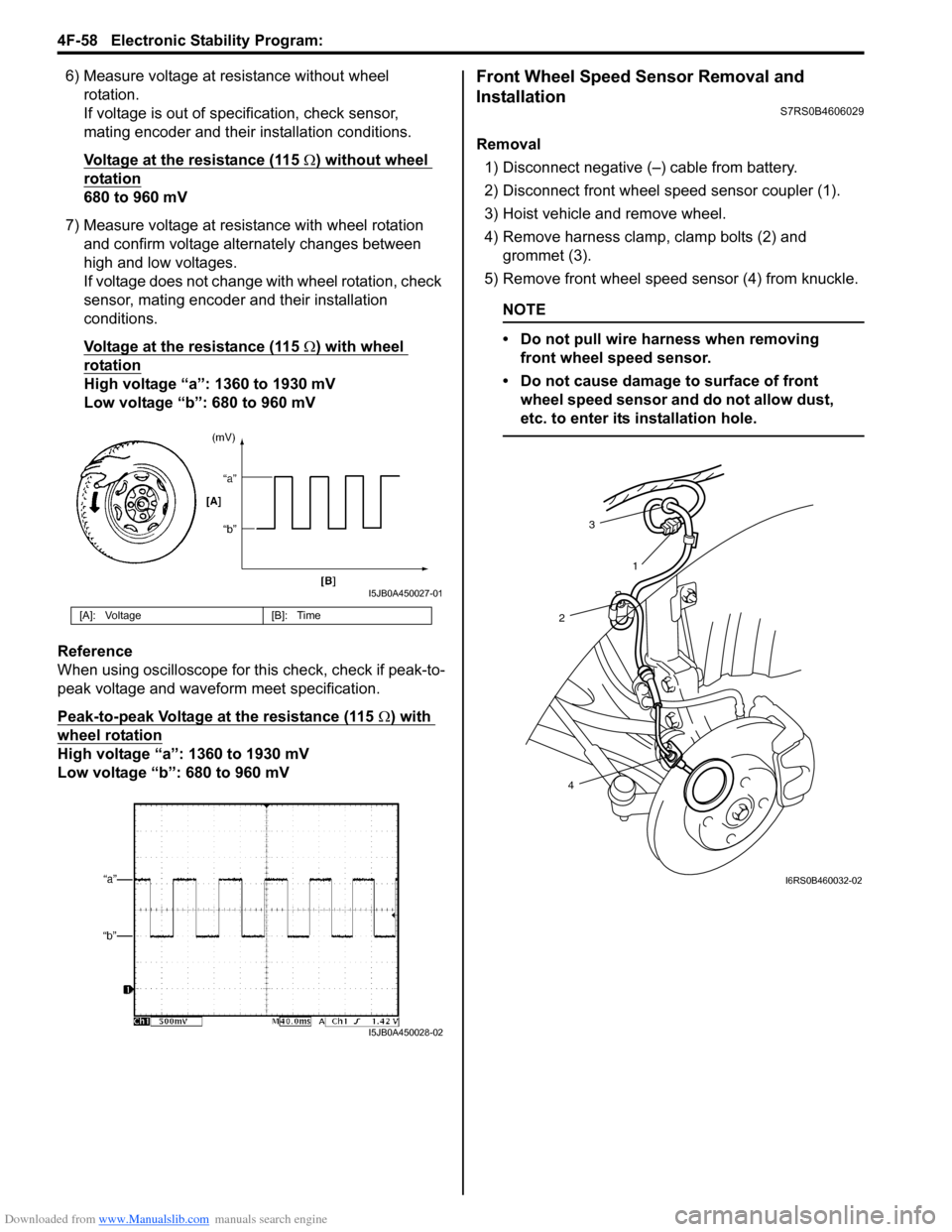

Voltage at the resistance (115

Ω) without wheel

rotation

680 to 960 mV

7) Measure voltage at resistance with wheel rotation and confirm voltage alternately changes between

high and low voltages.

If voltage does not change with wheel rotation, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak Voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

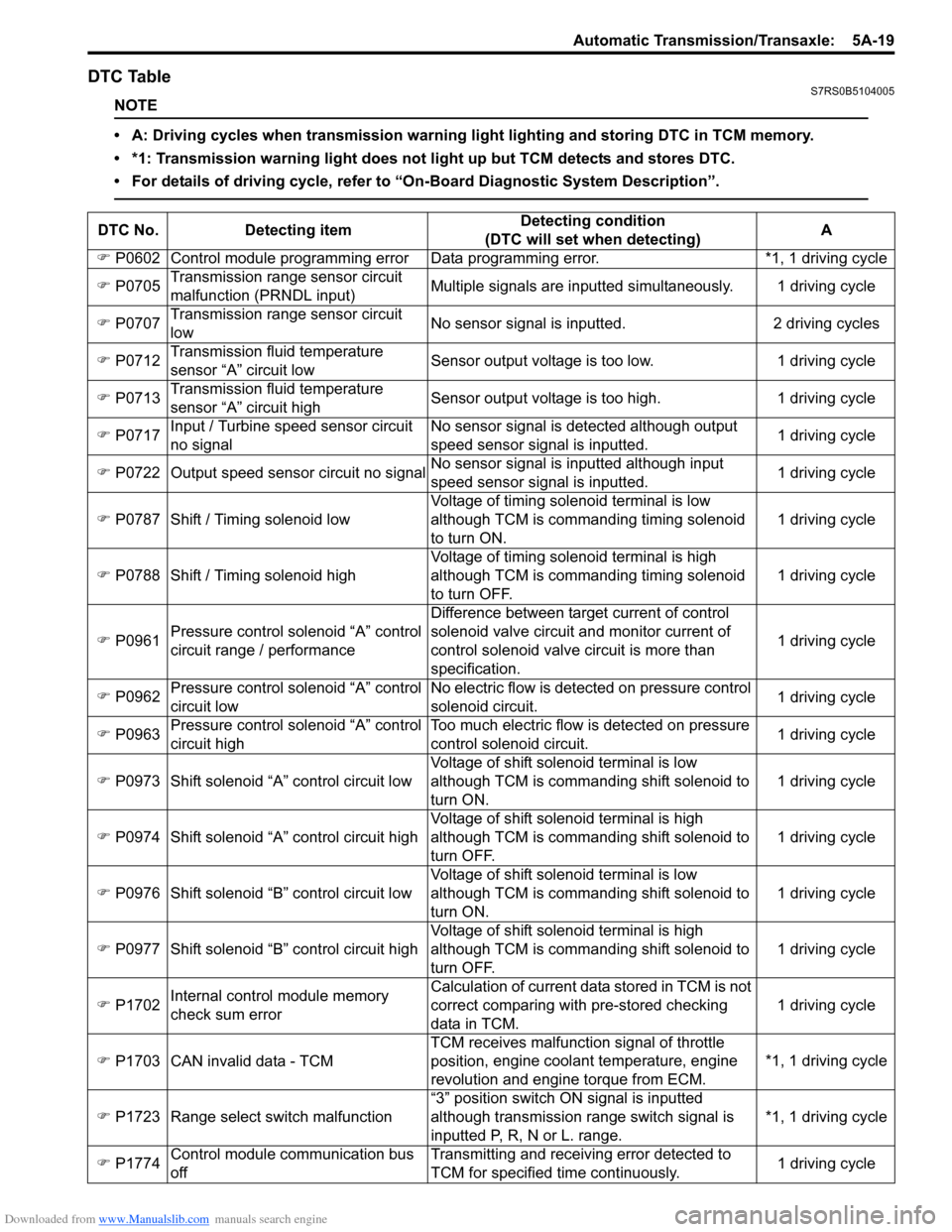

Front Wheel Speed Sensor Removal and

Installation

S7RS0B4606029

Removal

1) Disconnect negative (–) cable from battery.

2) Disconnect front wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolts (2) and grommet (3).

5) Remove front wheel speed sensor (4) from knuckle.

NOTE

• Do not pull wire harness when removing front wheel speed sensor.

• Do not cause damage to surface of front wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

3

2

4 1

I6RS0B460032-02

Page 663 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-19

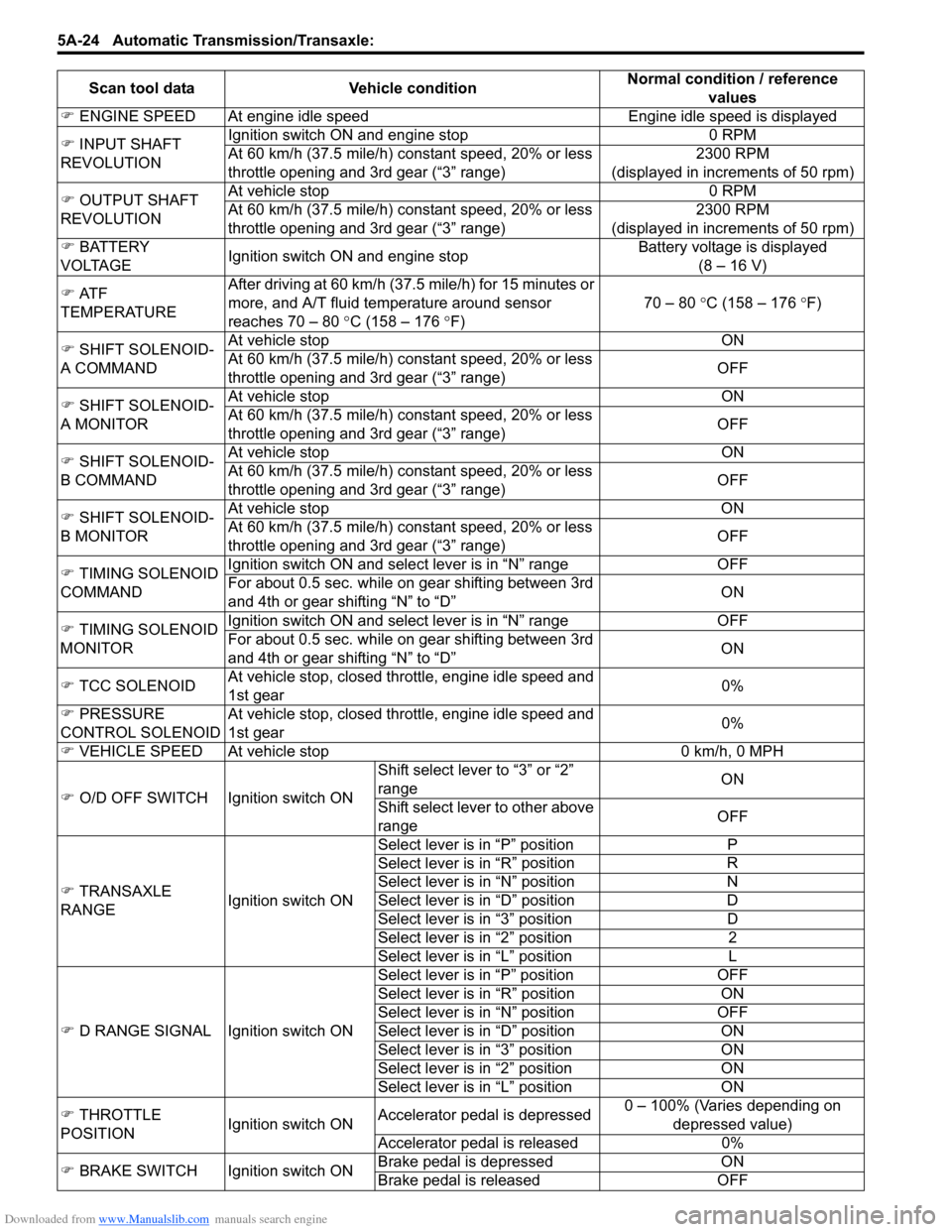

DTC TableS7RS0B5104005

NOTE

• A: Driving cycles when transmission warning light lighting and storing DTC in TCM memory.

• *1: Transmission warning light does not light up but TCM detects and stores DTC.

• For details of driving cycle, refer to “On-Board Diagnostic System Description”.

DTC No.Detecting item Detecting condition

(DTC will set when detecting) A

�) P0602 Control module programming error D ata programming error. *1, 1 driving cycle

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) Multiple signals are inputted

simultaneously. 1 driving cycle

�) P0707 Transmission range sensor circuit

low No sensor signal is inputted.

2 driving cycles

�) P0712 Transmission fluid temperature

sensor “A” circuit low Sensor output voltage is too low.

1 driving cycle

�) P0713 Transmission fluid temperature

sensor “A” circuit high Sensor output voltage is too high.

1 driving cycle

�) P0717 Input / Turbine speed sensor circuit

no signal No sensor signal is detected although output

speed sensor signal is inputted.

1 driving cycle

�) P0722 Output speed sensor circuit no signal No sensor signal is inputted although input

speed sensor signal is inputted. 1 driving cycle

�) P0787 Shift / Timing solenoid low Voltage of timing solenoid terminal is low

although TCM is commanding timing solenoid

to turn ON. 1 driving cycle

�) P0788 Shift / Timing solenoid high Voltage of timing solenoid terminal is high

although TCM is commanding timing solenoid

to turn OFF. 1 driving cycle

�) P0961 Pressure control solenoid “A” control

circuit range / performance Difference between target current of control

solenoid valve circuit and monitor current of

control solenoid valve circuit is more than

specification.

1 driving cycle

�) P0962 Pressure control solenoid “A” control

circuit low No electric flow is detected on pressure control

solenoid circuit.

1 driving cycle

�) P0963 Pressure control solenoid “A” control

circuit high Too much electric flow is detected on pressure

control solenoid circuit.

1 driving cycle

�) P0973 Shift solenoid “A” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0974 Shift solenoid “A” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P0976 Shift solenoid “B” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0977 Shift solenoid “B” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P1702 Internal control module memory

check sum error Calculation of current data stored in TCM is not

correct comparing with pre-stored checking

data in TCM.

1 driving cycle

�) P1703 CAN invalid data - TCM TCM receives malfunction signal of throttle

position

, engine coolan t temperature, engine

revolution and engine torque from ECM. *1, 1 driving cycle

�) P1723 Range select switch malfunction “3” position switch ON signal is inputted

although transmission range switch signal is

inputted P, R, N or L. range. *1, 1 driving cycle

�) P1774 Control module communication bus

off Transmitting and receiving error detected to

TCM for specified time continuously.

1 driving cycle

Page 668 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-24 Automatic Transmission/Transaxle:

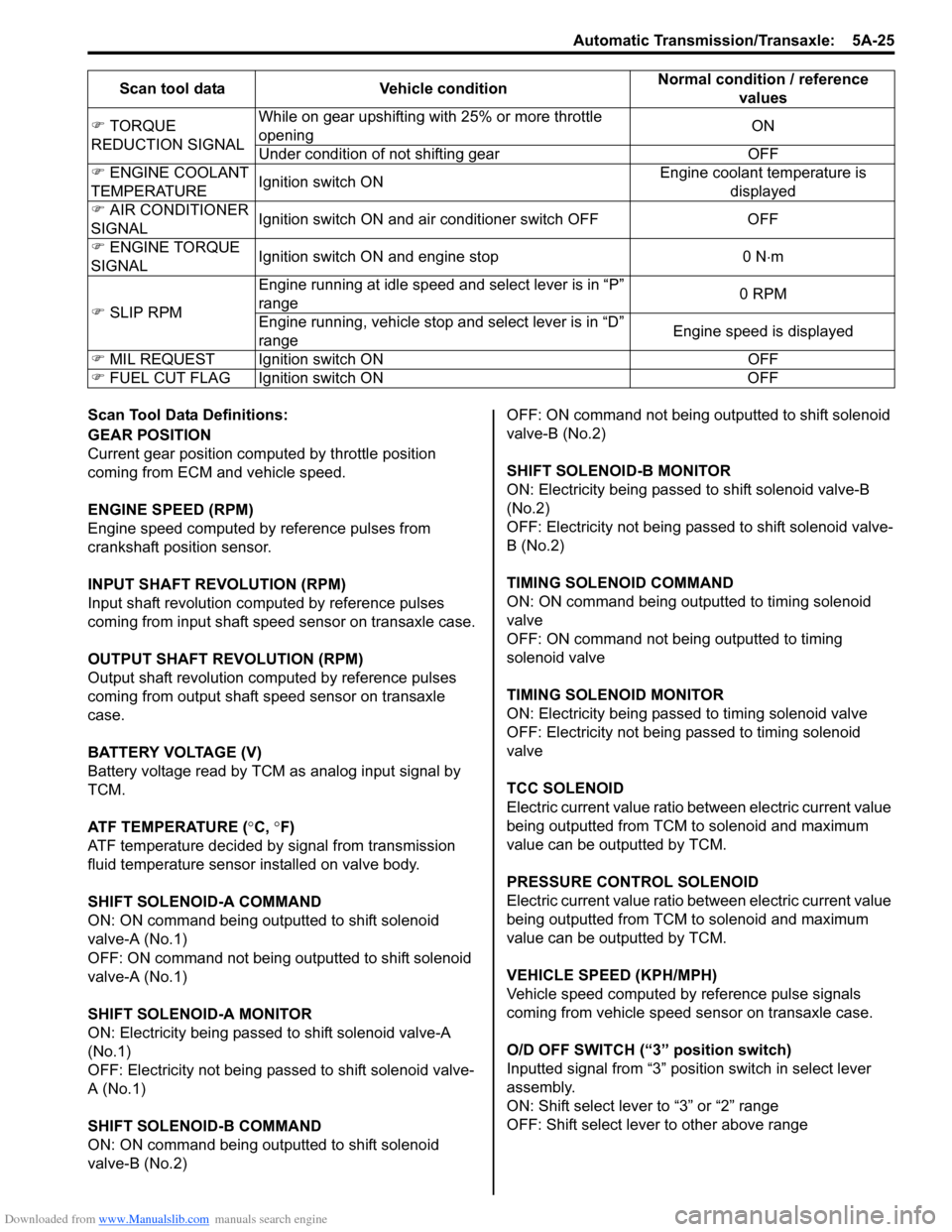

�) ENGINE SPEED At engine idle spee d Engine idle speed is displayed

�) INPUT SHAFT

REVOLUTION Ignition switch ON and engine stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

�) OUTPUT SHAFT

REVOLUTION At vehicle stop 0 RPM

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

2300 RPM

(displayed in increments of 50 rpm)

�) BATTERY

VOLTAGE Ignition switch ON and engine stop Battery voltage is displayed

(8 – 16 V)

�) AT F

TEMPERATURE After driving at 60 km/h (37.5 mile/h) for 15 minutes or

more, and A/T fluid temperature around sensor

reaches 70 – 80

°C (158 – 176 °F) 70 – 80

°C (158 – 176 °F)

�) SHIFT SOLENOID-

A COMMAND At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

A MONITOR At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

B COMMAND At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) SHIFT SOLENOID-

B MONITOR At vehicle stop ON

At 60 km/h (37.5 mile/h) constant speed, 20% or less

throttle opening and 3rd gear (“3” range)

OFF

�) TIMING SOLENOID

COMMAND Ignition switch ON and sele

ct lever is in “N” range OFF

For about 0.5 sec. while on gear shifting between 3rd

and 4th or gear shifting “N” to “D” ON

�) TIMING SOLENOID

MONITOR Ignition switch ON and sele

ct lever is in “N” range OFF

For about 0.5 sec. while on gear shifting between 3rd

and 4th or gear shifting “N” to “D” ON

�) TCC SOLENOID At vehicle stop, closed throttle, engine idle speed and

1st gear 0%

�) PRESSURE

CONTROL SOLENOID At vehicle stop, closed throttle, engine idle speed and

1st gear

0%

�) VEHICLE SPEED At vehicle stop 0 km/h, 0 MPH

�) O/D OFF SWITCH Ignition switch ON Shift select lever to “3” or “2”

range

ON

Shift select lever to other above

range OFF

�) TRANSAXLE

RANGE Ignition switch ONSelect lever is in “P” position P

Select lever is in “R

” position R

Select lever is in “N” position N

Select lever is in “D” position D

Select lever is in “3” position D

Select lever is in “2” position 2

Select lever is in “L” position L

�) D RANGE SIGNAL Ignition switch ON Select lever is in “P” position

OFF

Select lever is in “R” position ON

Select lever is in “N” position OFF

Select lever is in “D” position ON

Select lever is in “3” position ON

Select lever is in “2” position ON

Select lever is in “L” position ON

�) THROTTLE

POSITION Ignition switch ONAccelerator peda

l is depressed 0 – 100% (Varies depending on

depressed value)

Accelerator peda l is released 0%

�) BRAKE SWITCH Ignition switch ON Brake pedal is depressed

ON

Brake pedal is released OFF

Scan tool data

Vehicle condition Normal condition / reference

values

Page 669 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-25

Scan Tool Data Definitions:

GEAR POSITION

Current gear position computed by throttle position

coming from ECM and vehicle speed.

ENGINE SPEED (RPM)

Engine speed computed by reference pulses from

crankshaft position sensor.

INPUT SHAFT REVOLUTION (RPM)

Input shaft revolution computed by reference pulses

coming from input shaft speed sensor on transaxle case.

OUTPUT SHAFT REVOLUTION (RPM)

Output shaft revolution computed by reference pulses

coming from output shaft speed sensor on transaxle

case.

BATTERY VOLTAGE (V)

Battery voltage read by TCM as analog input signal by

TCM.

ATF TEMPERATURE (°C, °F)

ATF temperature decided by signal from transmission

fluid temperature sensor installed on valve body.

SHIFT SOLENOID-A COMMAND

ON: ON command being outputted to shift solenoid

valve-A (No.1)

OFF: ON command not being outputted to shift solenoid

valve-A (No.1)

SHIFT SOLENOID-A MONITOR

ON: Electricity being passed to shift solenoid valve-A

(No.1)

OFF: Electricity not being passed to shift solenoid valve-

A (No.1)

SHIFT SOLENOID-B COMMAND

ON: ON command being outputted to shift solenoid

valve-B (No.2) OFF: ON command not being outputted to shift solenoid

valve-B (No.2)

SHIFT SOLENOID-B MONITOR

ON: Electricity being passed to shift solenoid valve-B

(No.2)

OFF: Electricity not being passed to shift solenoid valve-

B (No.2)

TIMING SOLENOID COMMAND

ON: ON command being outputted to timing solenoid

valve

OFF: ON command not being outputted to timing

solenoid valve

TIMING SOLENOID MONITOR

ON: Electricity being passed to timing solenoid valve

OFF: Electricity not being passed to timing solenoid

valve

TCC SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

PRESSURE CONTROL SOLENOID

Electric current value ratio between electric current value

being outputted from TCM to solenoid and maximum

value can be outputted by TCM.

VEHICLE SPEED (KPH/MPH)

Vehicle speed computed by reference pulse signals

coming from vehicle speed sensor on transaxle case.

O/D OFF SWITCH (“3” position switch)

Inputted signal from “3” position switch in select lever

assembly.

ON: Shift select lever to “3” or “2” range

OFF: Shift select lever to other above range

�)

TORQUE

REDUCTION SIGNAL While on gear upshifting with 25% or more throttle

opening

ON

Under condition of not shifting gear OFF

�) ENGINE COOLANT

TEMPERATURE Ignition switch ON Engine coolant temperature is

displayed

�) AIR CONDITIONER

SIGNAL Ignition switch ON and air conditioner switch OFF OFF

�) ENGINE TORQUE

SIGNAL Ignition switch ON and engine stop 0 N

⋅m

�) SLIP RPM Engine running at idle speed

and select lever is in “P”

range 0 RPM

Engine running, vehicle stop and select lever is in “D”

range Engine speed is displayed

�) MIL REQUEST Ignition switch ON OFF

�) FUEL CUT FLAG Ignition switch ON OFFScan tool data Vehicle condition

Normal condition / reference

values

Page 686 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-42 Automatic Transmission/Transaxle:

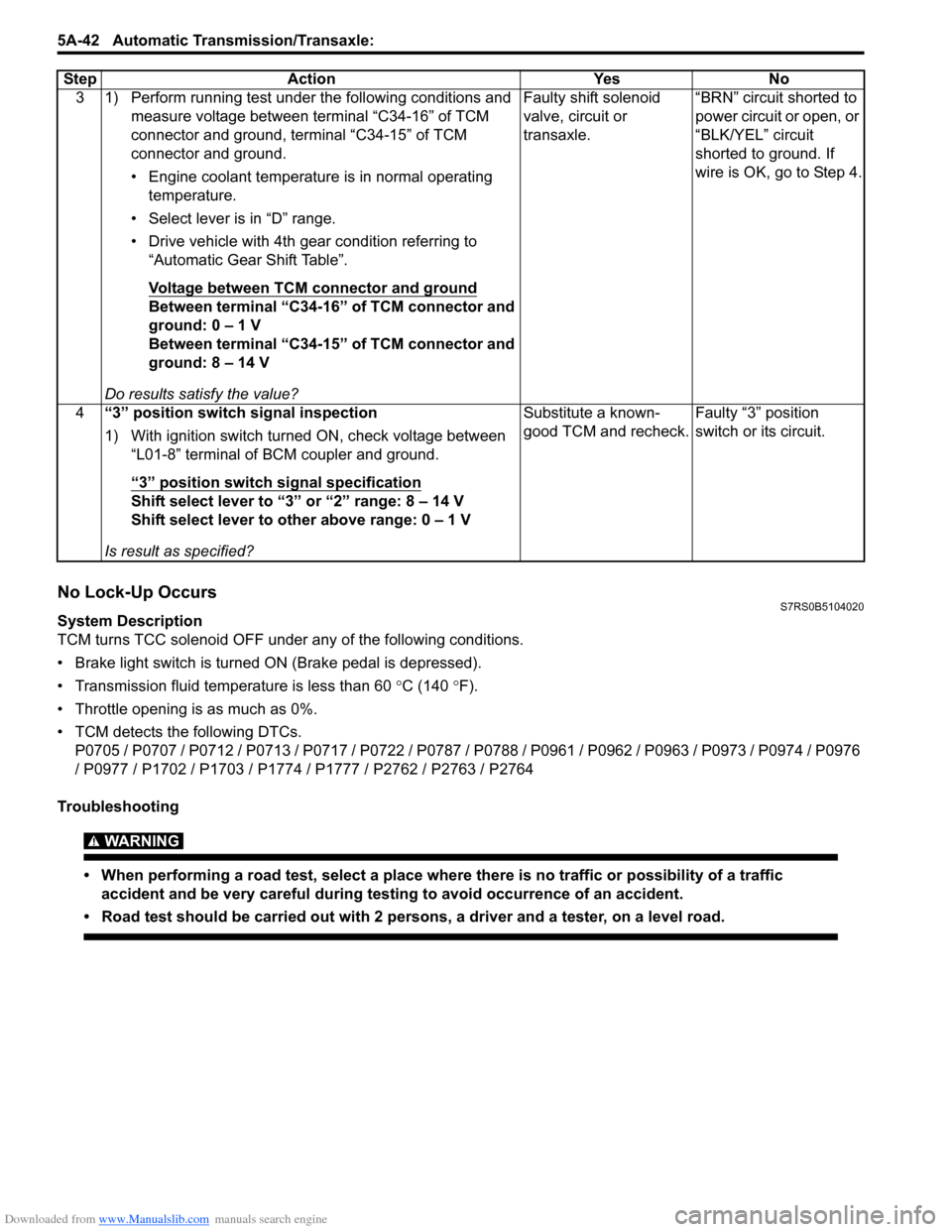

No Lock-Up OccursS7RS0B5104020

System Description

TCM turns TCC solenoid OFF under any of the following conditions.

• Brake light switch is turned ON (Brake pedal is depressed).

• Transmission fluid temperat ure is less than 60 °C (140 °F).

• Throttle opening is as much as 0%.

• TCM detects the following DTCs. P0705 / P0707 / P0712 / P0713 / P0717 / P0722 / P0787 / P0788 / P0961 / P0962 / P0963 / P0973 / P0974 / P0976

/ P0977 / P1702 / P1703 / P1774 / P1777 / P2762 / P2763 / P2764

Troubleshooting

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

3 1) Perform running test under the following conditions and measure voltage between terminal “C34-16” of TCM

connector and ground, terminal “C34-15” of TCM

connector and ground.

• Engine coolant temperature is in normal operating temperature.

• Select lever is in “D” range.

• Drive vehicle with 4th gear condition referring to “Automatic Gear Shift Table”.

Voltage between TCM connector and ground

Between terminal “C34-16” of TCM connector and

ground: 0 – 1 V

Between terminal “C34-15” of TCM connector and

ground: 8 – 14 V

Do results satisfy the value? Faulty shift solenoid

valve, circuit or

transaxle.

“BRN” circuit shorted to

power circuit or open, or

“BLK/YEL” circuit

shorted to ground. If

wire is OK, go to Step 4.

4 “3” position switch signal inspection

1) With ignition switch turned ON, check voltage between

“L01-8” terminal of BCM coupler and ground.

“3” position switch signal specification

Shift select lever to “3” or “2” range: 8 – 14 V

Shift select lever to other above range: 0 – 1 V

Is result as specified? Substitute a known-

good TCM and recheck.

Faulty “3” position

switch or its circuit.

Step Action Yes No

Page 687 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-43

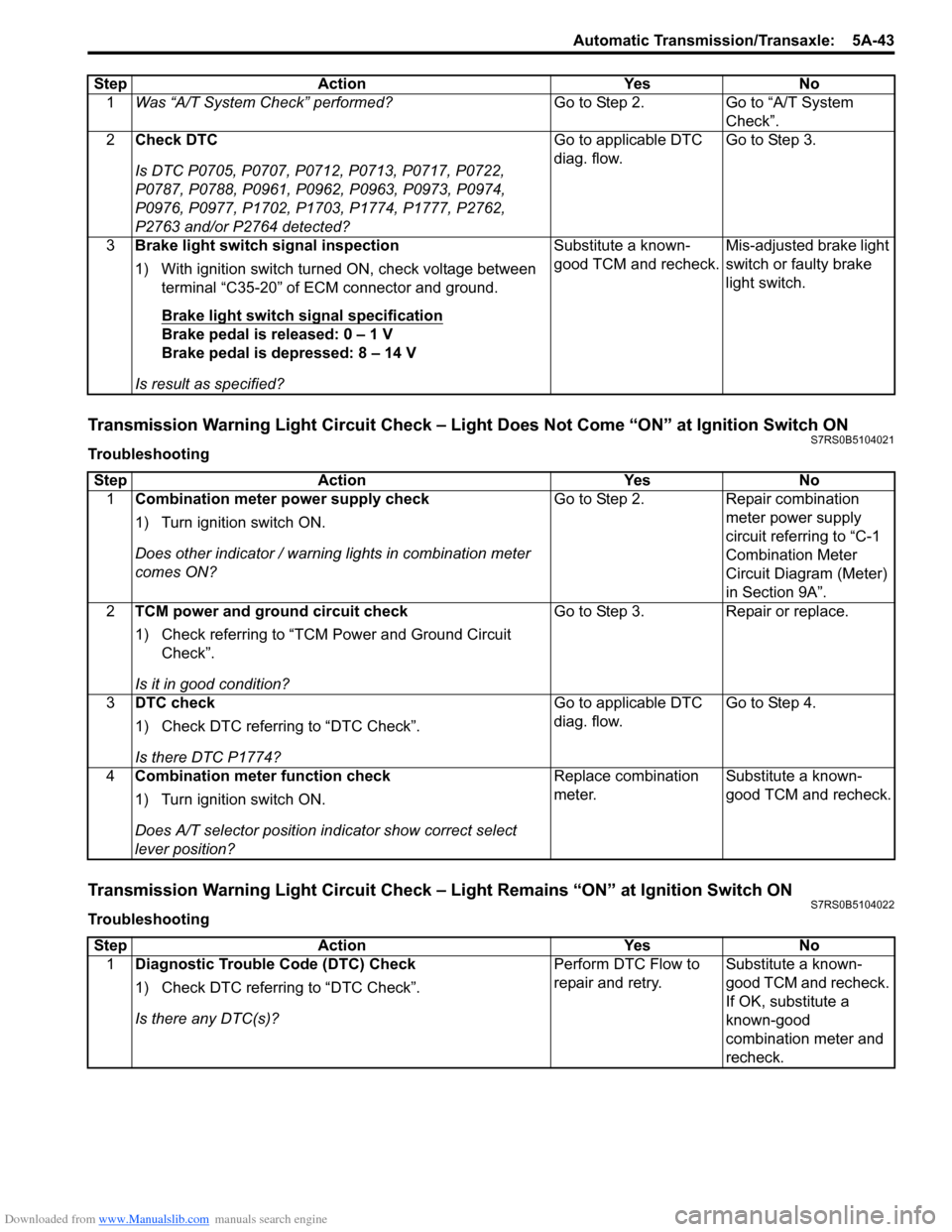

Transmission Warning Light Circuit Check – Light Does Not Come “ON” at Ignition Switch ONS7RS0B5104021

Troubleshooting

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ONS7RS0B5104022

TroubleshootingStep Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check DTC

Is DTC P0705, P0707, P0712, P0713, P0717, P0722,

P0787, P0788, P0961, P0962, P0963, P0973, P0974,

P0976, P0977, P1702, P1703, P1774, P1777, P2762,

P2763 and/or P2764 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Brake light switch signal inspection

1) With ignition switch turned ON, check voltage between

terminal “C35-20” of ECM connector and ground.

Brake light switch signal specification

Brake pedal is released: 0 – 1 V

Brake pedal is depressed: 8 – 14 V

Is result as specified? Substitute a known-

good TCM and recheck.

Mis-adjusted brake light

switch or faulty brake

light switch.

Step

Action YesNo

1 Combination meter power supply check

1) Turn ignition switch ON.

Does other indicator / warnin g lights in combination meter

comes ON? Go to Step 2.

Repair combination

meter power supply

circuit referring to “C-1

Combination Meter

Circuit Diagram (Meter)

in Section 9A”.

2 TCM power and ground circuit check

1) Check referring to “TCM Power and Ground Circuit

Check”.

Is it in good condition? Go to Step 3.

Repair or replace.

3 DTC check

1) Check DTC referring to “DTC Check”.

Is there DTC P1774? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Combination meter function check

1) Turn ignition switch ON.

Does A/T selector position in dicator show correct select

lever position? Replace combination

meter.

Substitute a known-

good TCM and recheck.

Step

Action YesNo

1 Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to “DTC Check”.

Is there any DTC(s)? Perform DTC Flow to

repair and retry.

Substitute a known-

good TCM and recheck.

If OK, substitute a

known-good

combination meter and

recheck.

Page 689 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-45

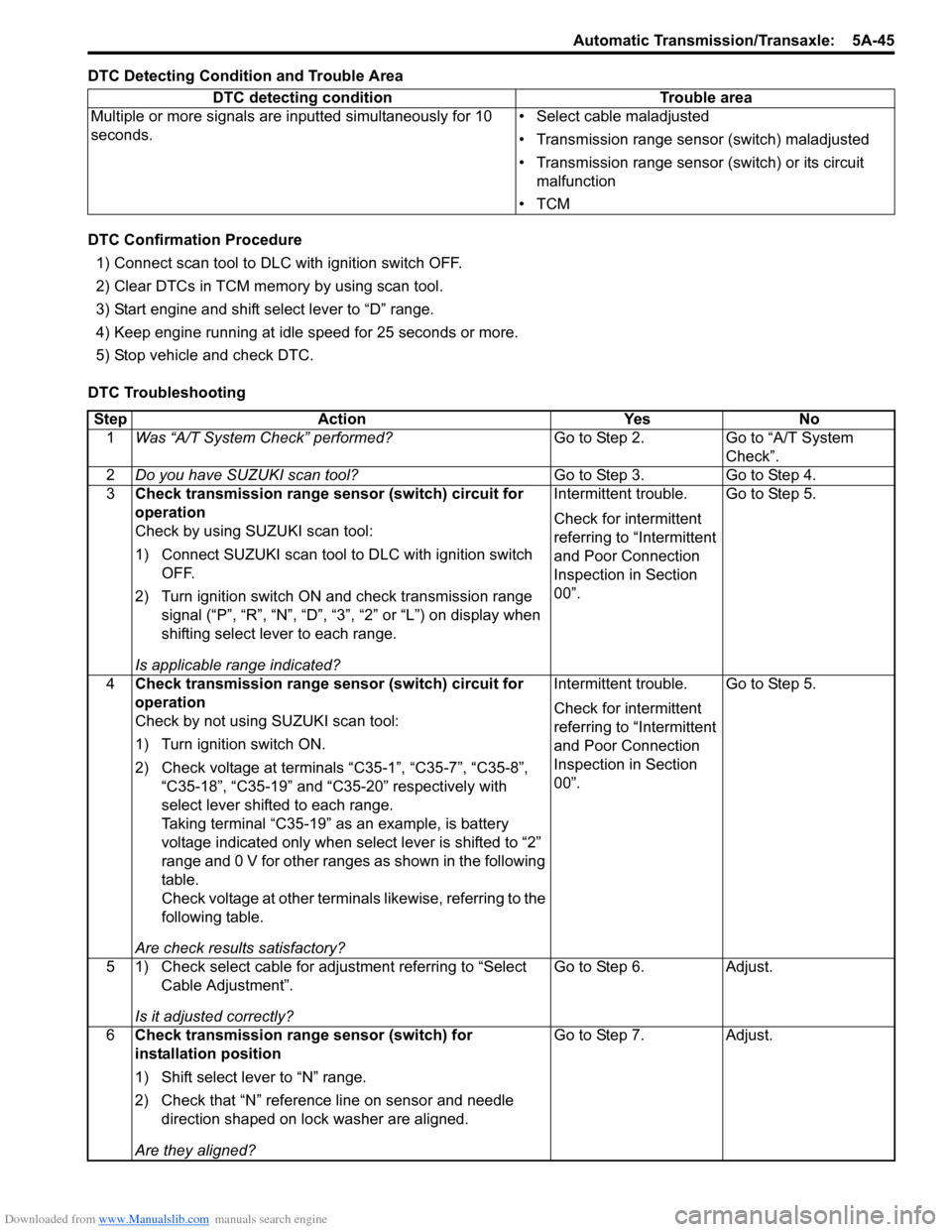

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Keep engine running at idle speed for 25 seconds or more.

5) Stop vehicle and check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Multiple or more signals are inputted simultaneously for 10

seconds. • Select cable maladjusted

• Transmission range sensor (switch) maladjusted

• Transmission range sensor (switch) or its circuit

malfunction

•TCM

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (“P”, “R”, “N”, “D”, “3”, “2” or “L”) on display when

shifting select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 691 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-47

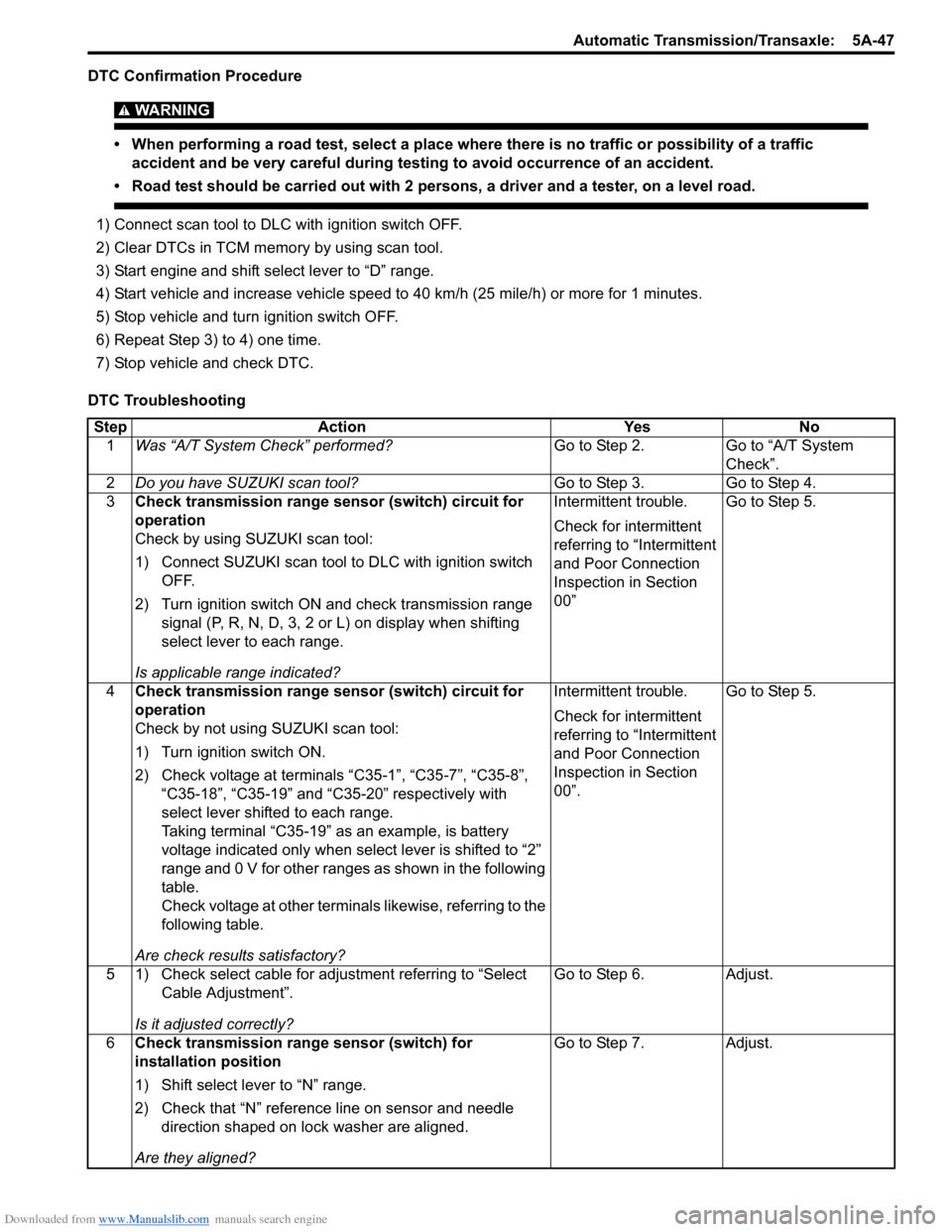

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) or more for 1 minutes.

5) Stop vehicle and turn ignition switch OFF.

6) Repeat Step 3) to 4) one time.

7) Stop vehicle and check DTC.

DTC Troubleshooting Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (P, R, N, D, 3, 2 or L) on display when shifting

select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 692 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-48 Automatic Transmission/Transaxle:

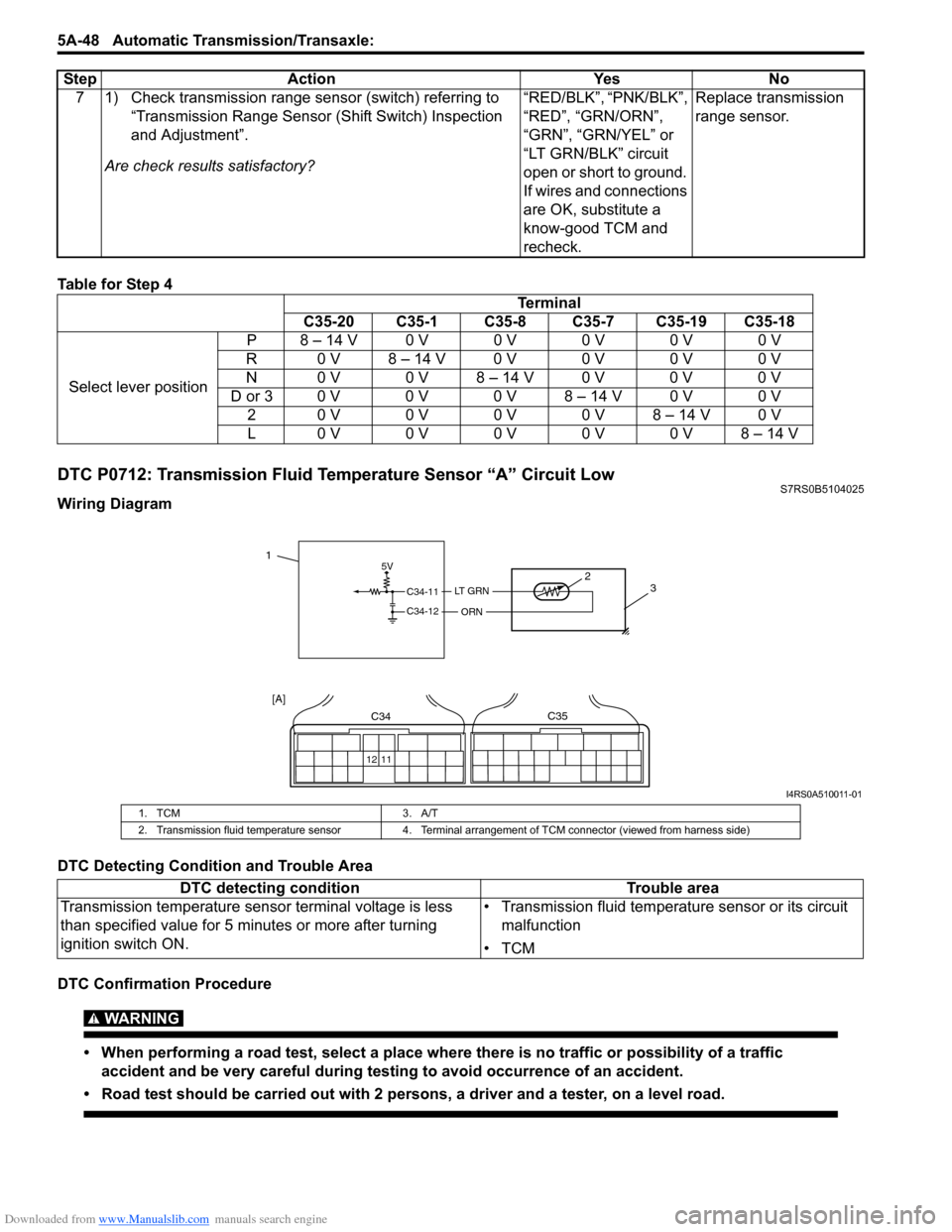

Table for Step 4

DTC P0712: Transmission Fluid Temperature Sensor “A” Circuit LowS7RS0B5104025

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

7 1) Check transmission range sensor (switch) referring to “Transmission Range Sensor (Shift Switch) Inspection

and Adjustment”.

Are check results satisfactory? “RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

open or short to ground.

If wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor.

Step Action Yes No

Terminal

C35-20 C35-1 C35-8 C35-7 C35-19 C35-18

Select lever position P8 – 14 V0 V0 V0 V0 V0 V

R 0 V 8 – 14 V 0 V 0 V 0 V 0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V 20 V0 V0 V0 V8 – 14 V0 V

L0 V0 V0 V0 V0 V8 – 14 V

5V

C34-11

C34-12

LT GRN

ORN

2 3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor 4. Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission temperature sensor terminal voltage is less

than specified value for 5 minutes or more after turning

ignition switch ON. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 693 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Keep engine running at idle speed for 10 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting

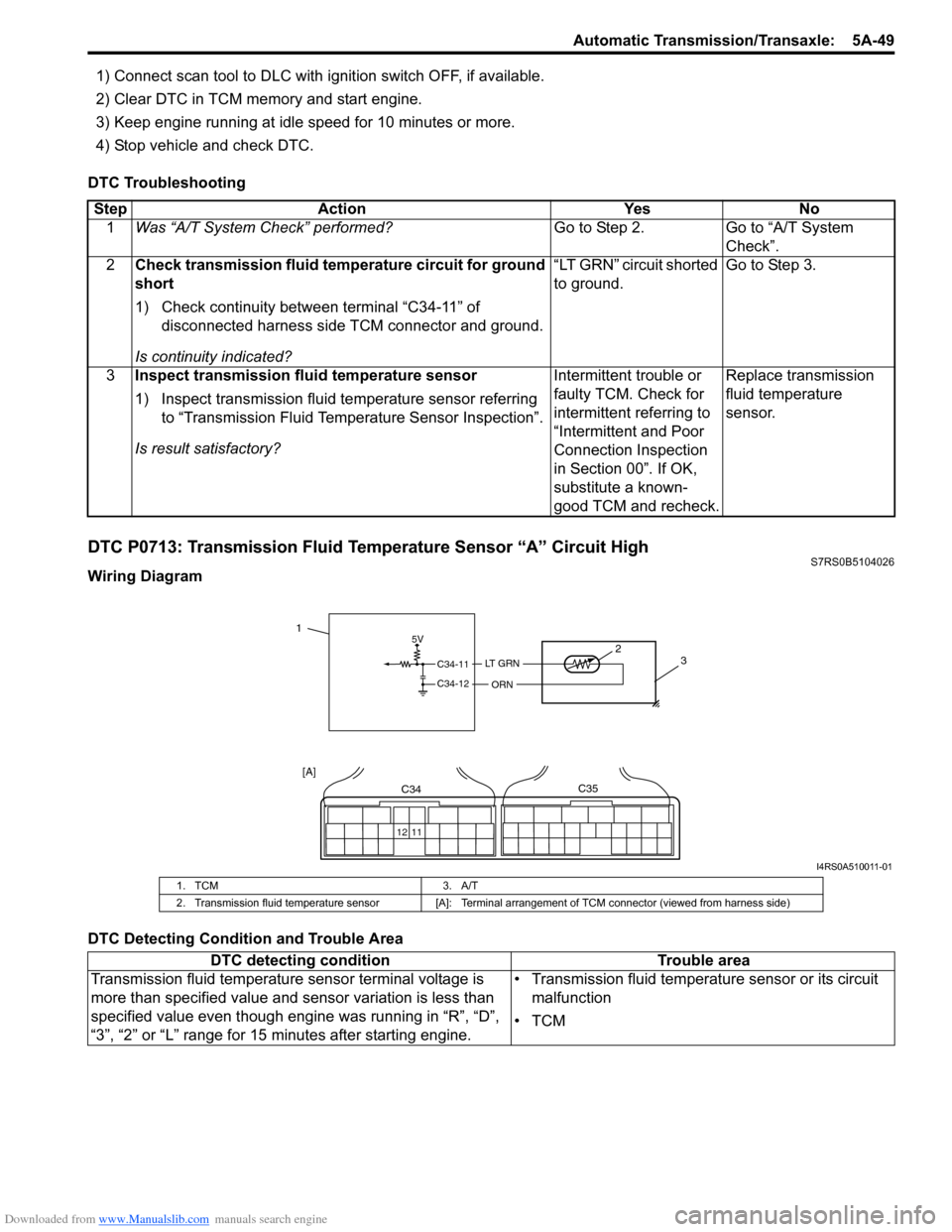

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit HighS7RS0B5104026

Wiring Diagram

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for ground

short

1) Check continuity between terminal “C34-11” of

disconnected harness side TCM connector and ground.

Is continuity indicated? “LT GRN” circuit shorted

to ground.

Go to Step 3.

3 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Replace transmission

fluid temperature

sensor.

5V

C34-11

C34-12

LT G R N

ORN

2

3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission fluid temperature sensor terminal voltage is

more than specified value and sensor variation is less than

specified value even though engine was running in “R”, “D”,

“3”, “2” or “L” range for 15 minutes after starting engine. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM