Transmission SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 845 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-31

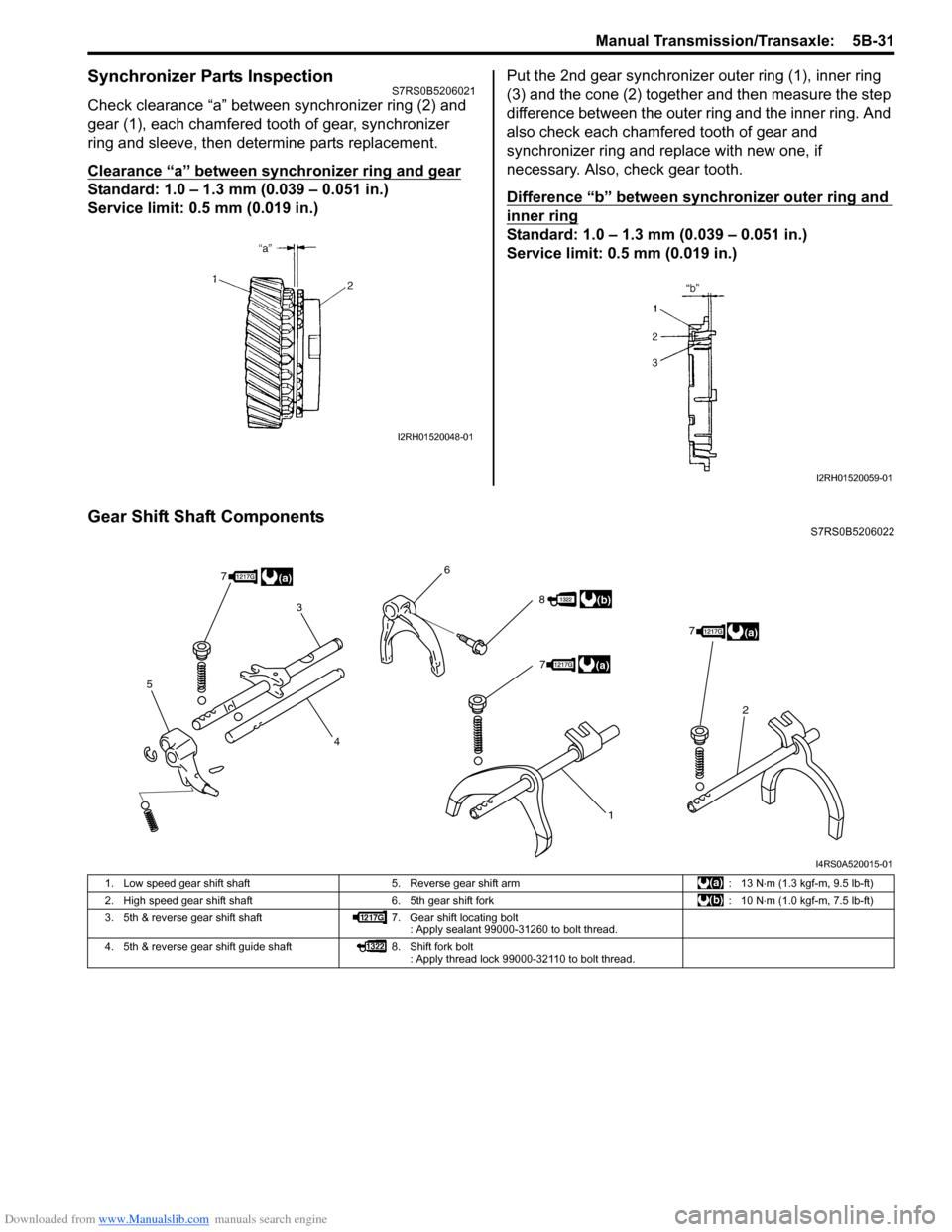

Synchronizer Parts InspectionS7RS0B5206021

Check clearance “a” between synchronizer ring (2) and

gear (1), each chamfered tooth of gear, synchronizer

ring and sleeve, then determine parts replacement.

Clearance “a” between synchronizer ring and gear

Standard: 1.0 – 1.3 mm (0.039 – 0.051 in.)

Service limit: 0.5 mm (0.019 in.)Put the 2nd gear synchronizer outer ring (1), inner ring

(3) and the cone (2) together and then measure the step

difference between the outer ring and the inner ring. And

also check each chamfered tooth of gear and

synchronizer ring and replace with new one, if

necessary. Also, check gear tooth.

Difference “b” between synchronizer outer ring and

inner ring

Standard: 1.0 – 1.3 mm (0.039 – 0.051 in.)

Service limit: 0.5 mm (0.019 in.)

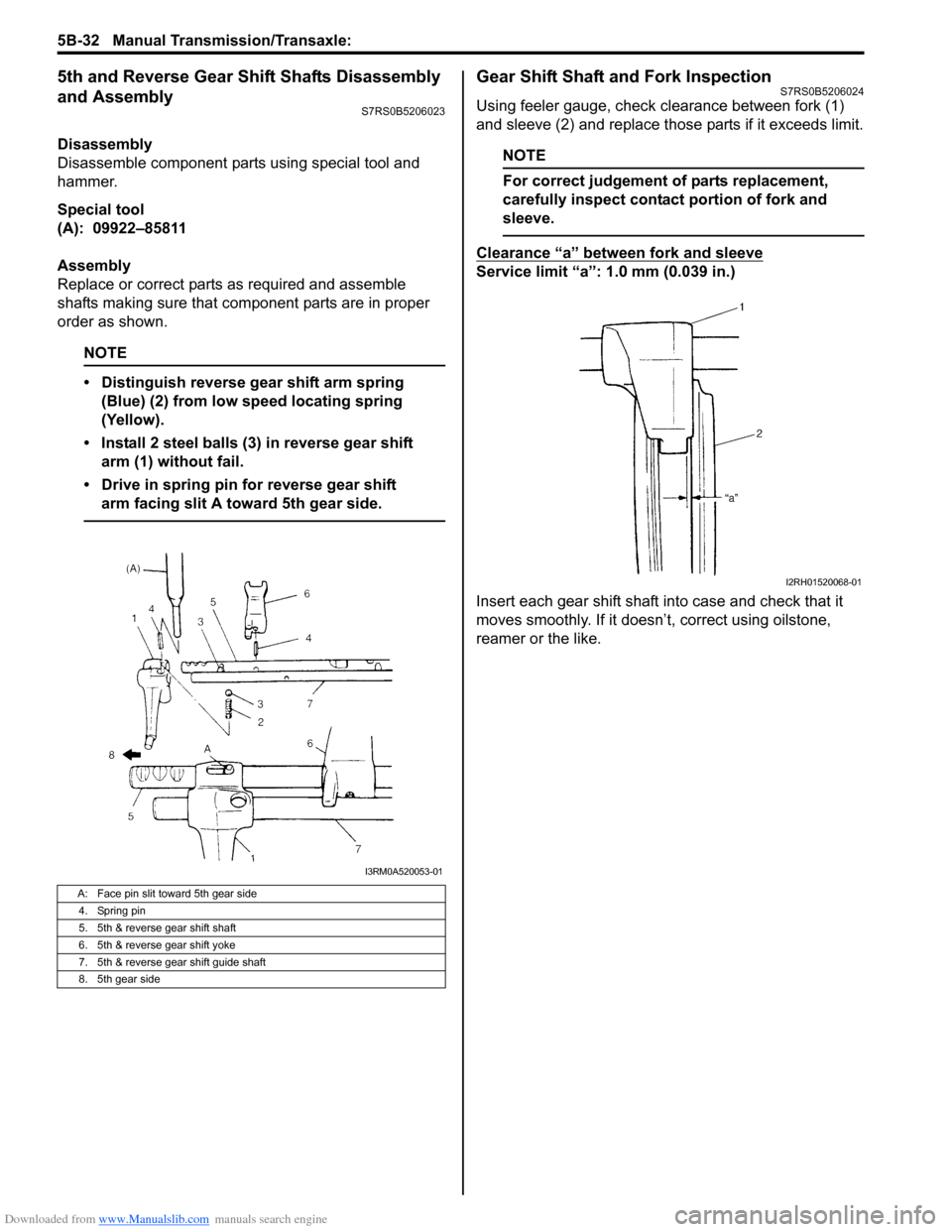

Gear Shift Shaft ComponentsS7RS0B5206022

I2RH01520048-01

I2RH01520059-01

5

3

4 6

1

2

8

7

77

(a)

(b)

(a)

(a)

I4RS0A520015-01

1. Low speed gear shift shaft

5. Reverse gear shift arm : 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

2. High speed gear shift shaft 6. 5th gear shift fork : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

3. 5th & reverse gear shift shaft 7. Gear shift locating bolt

: Apply sealant 99000-31260 to bolt thread.

4. 5th & reverse gear shift guide shaft 8. Shift fork bolt

: Apply thread lock 99000-32110 to bolt thread.

Page 846 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-32 Manual Transmission/Transaxle:

5th and Reverse Gear Shift Shafts Disassembly

and Assembly

S7RS0B5206023

Disassembly

Disassemble component parts using special tool and

hammer.

Special tool

(A): 09922–85811

Assembly

Replace or correct parts as required and assemble

shafts making sure that component parts are in proper

order as shown.

NOTE

• Distinguish reverse gear shift arm spring (Blue) (2) from low speed locating spring

(Yellow).

• Install 2 steel balls (3) in reverse gear shift arm (1) without fail.

• Drive in spring pin for reverse gear shift arm facing slit A toward 5th gear side.

Gear Shift Shaft and Fork InspectionS7RS0B5206024

Using feeler gauge, check clearance between fork (1)

and sleeve (2) and replace those parts if it exceeds limit.

NOTE

For correct judgement of parts replacement,

carefully inspect contact portion of fork and

sleeve.

Clearance “a” between fork and sleeve

Service limit “a”: 1.0 mm (0.039 in.)

Insert each gear shift shaft into case and check that it

moves smoothly. If it doesn’t, correct using oilstone,

reamer or the like.

A: Face pin slit toward 5th gear side

4. Spring pin

5. 5th & reverse gear shift shaft

6. 5th & reverse gear shift yoke

7. 5th & reverse gear shift guide shaft

8. 5th gear side

I3RM0A520053-01

I2RH01520068-01

Page 847 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-33

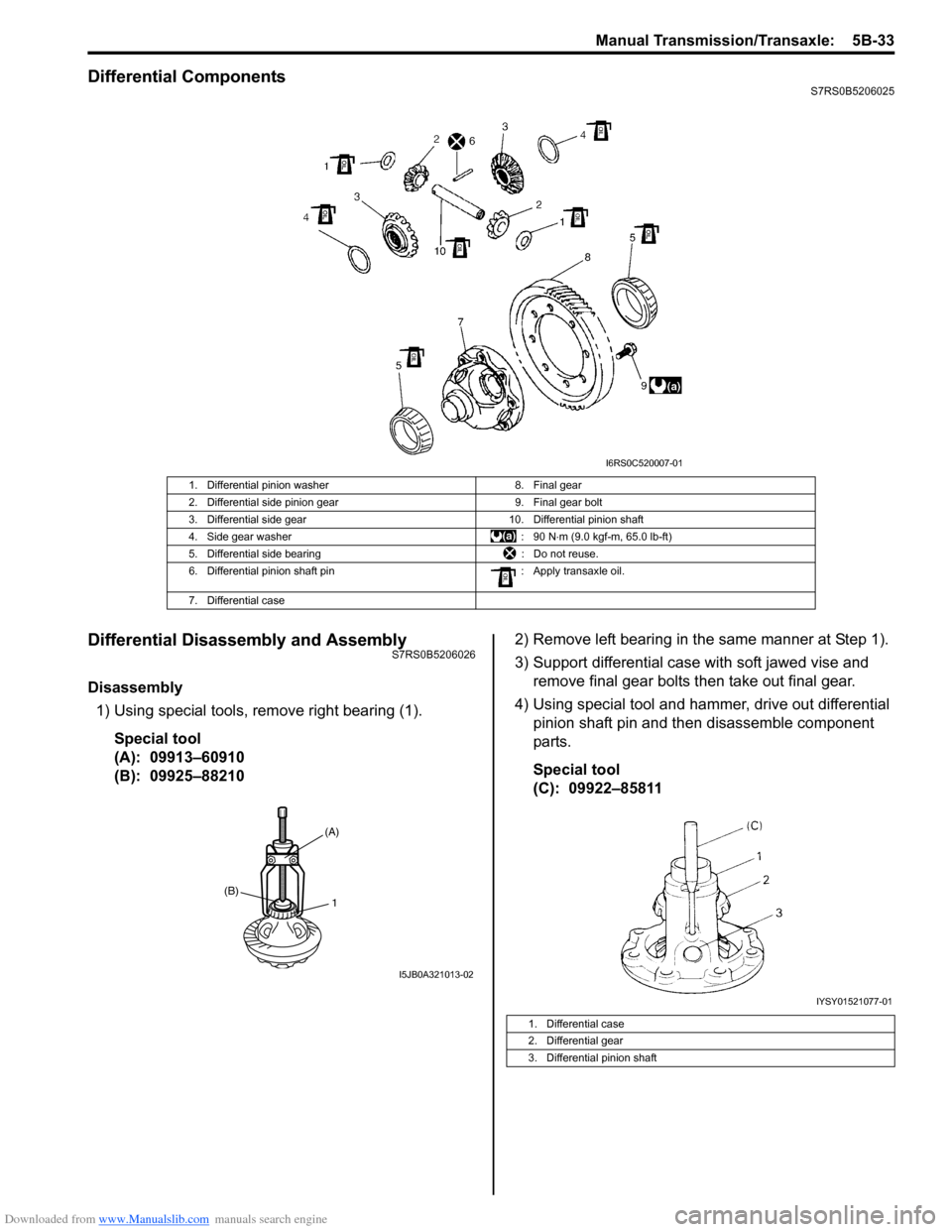

Differential ComponentsS7RS0B5206025

Differential Disassembly and AssemblyS7RS0B5206026

Disassembly1) Using special tools, remove right bearing (1).

Special tool

(A): 09913–60910

(B): 09925–88210 2) Remove left bearing in the same manner at Step 1).

3) Support differential case with soft jawed vise and

remove final gear bolts then take out final gear.

4) Using special tool and hammer, drive out differential pinion shaft pin and then disassemble component

parts.

Special tool

(C): 09922–85811

1. Differential pinion washer 8. Final gear

2. Differential side pinion gear 9. Final gear bolt

3. Differential side gear 10. Differential pinion shaft

4. Side gear washer : 90 N⋅m (9.0 kgf-m, 65.0 lb-ft)

5. Differential side bearing : Do not reuse.

6. Differential pinion shaft pin : Apply transaxle oil.

7. Differential case

I6RS0C520007-01

1(B)

(A)

I5JB0A321013-02

1. Differential case

2. Differential gear

3. Differential pinion shaft

IYSY01521077-01

Page 848 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-34 Manual Transmission/Transaxle:

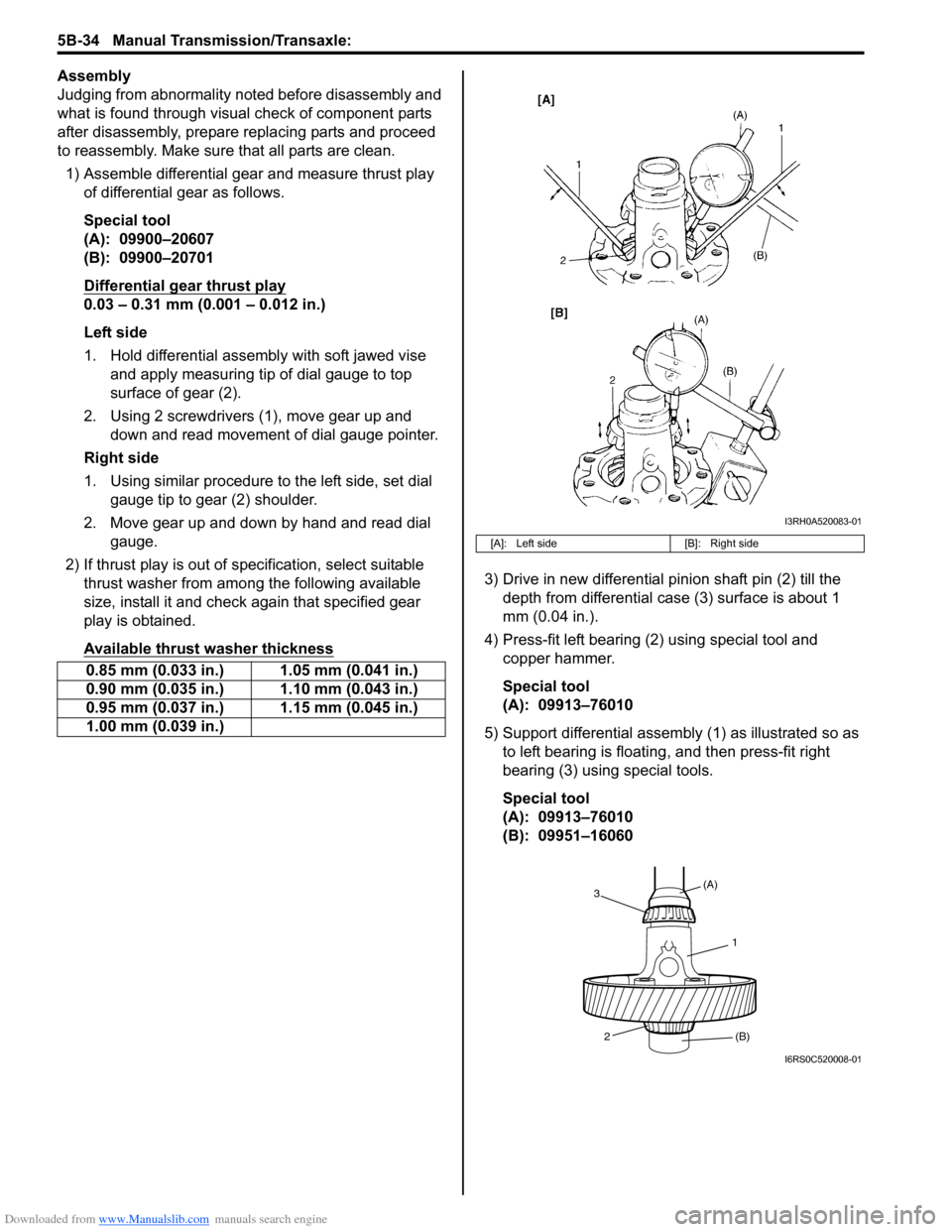

Assembly

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly. Make sure that all parts are clean.

1) Assemble differential gear and measure thrust play

of differential gear as follows.

Special tool

(A): 09900–20607

(B): 09900–20701

Differential gear thrust play

0.03 – 0.31 mm (0.001 – 0.012 in.)

Left side

1. Hold differential assembly with soft jawed vise and apply measuring tip of dial gauge to top

surface of gear (2).

2. Using 2 screwdrivers (1), move gear up and down and read movement of dial gauge pointer.

Right side

1. Using similar procedure to the left side, set dial gauge tip to gear (2) shoulder.

2. Move gear up and down by hand and read dial gauge.

2) If thrust play is out of sp ecification, select suitable

thrust washer from among the following available

size, install it and check again that specified gear

play is obtained.

Available thrust washer thickness

3) Drive in new differential pinion shaft pin (2) till the depth from differential case (3) surface is about 1

mm (0.04 in.).

4) Press-fit left bearing (2) using special tool and copper hammer.

Special tool

(A): 09913–76010

5) Support differential assembly (1) as illustrated so as to left bearing is floating , and then press-fit right

bearing (3) using special tools.

Special tool

(A): 09913–76010

(B): 09951–16060

0.85 mm (0.033 in.) 1.05 mm (0.041 in.)

0.90 mm (0.035 in.) 1.10 mm (0.043 in.)

0.95 mm (0.037 in.) 1.15 mm (0.045 in.)

1.00 mm (0.039 in.)

[A]: Left side

[B]: Right side

I3RH0A520083-01

1

(A)

3

2 (B)

I6RS0C520008-01

Page 849 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-35

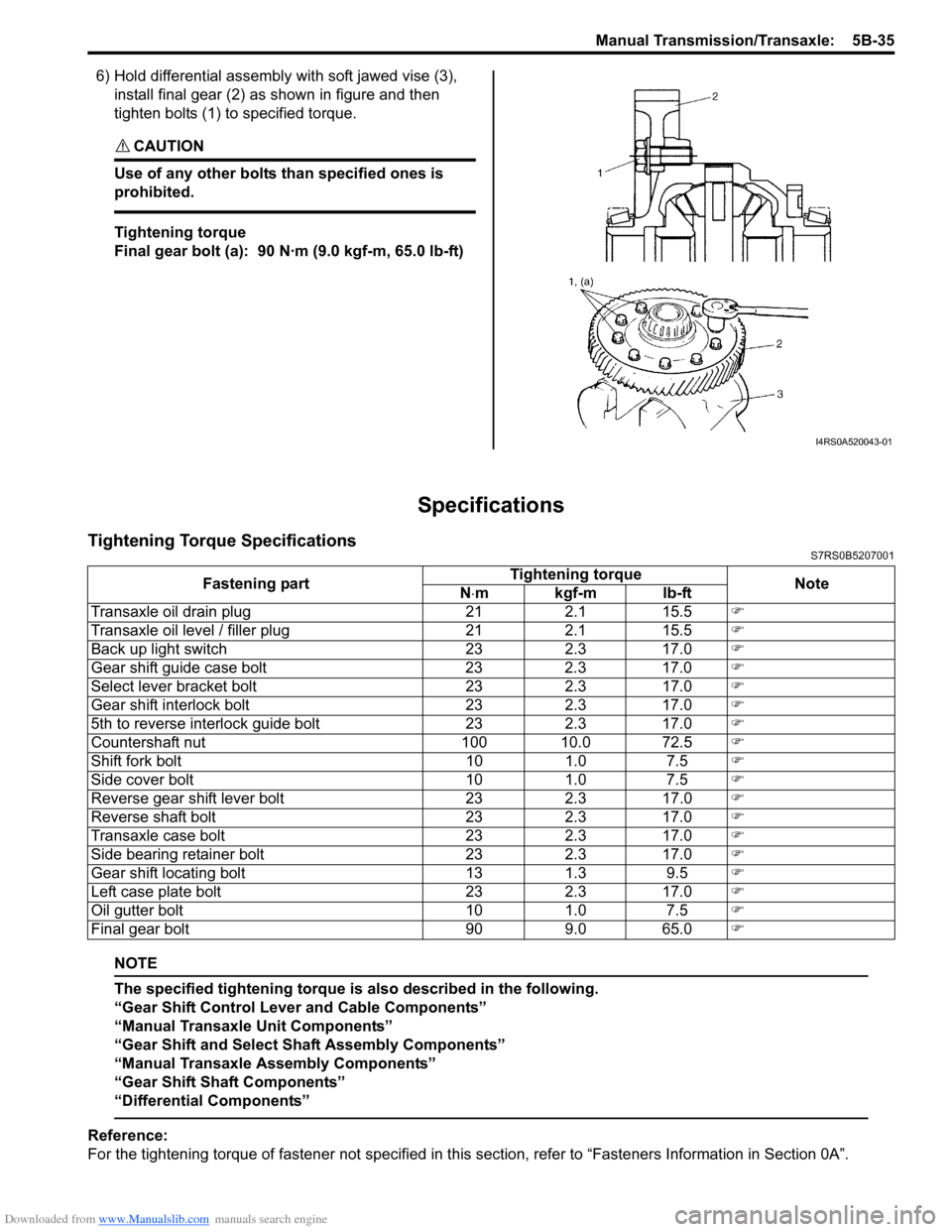

6) Hold differential assembly with soft jawed vise (3),

install final gear (2) as shown in figure and then

tighten bolts (1) to specified torque.

CAUTION!

Use of any other bolts than specified ones is

prohibited.

Tightening torque

Final gear bolt (a): 90 N·m (9.0 kgf-m, 65.0 lb-ft)

Specifications

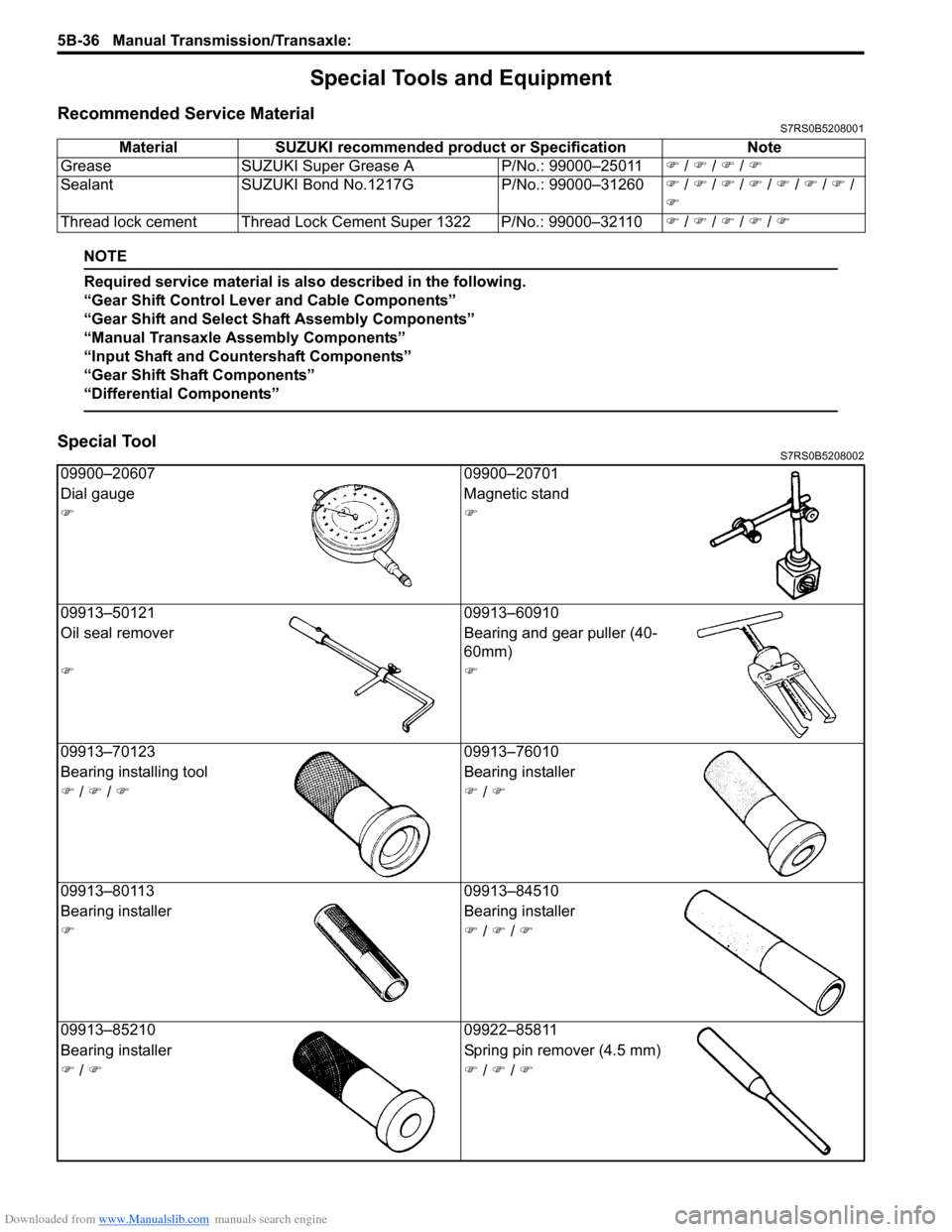

Tightening Torque SpecificationsS7RS0B5207001

NOTE

The specified tightening torque is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Manual Transaxle Unit Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Gear Shift Shaft Components”

“Differential Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

I4RS0A520043-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Transaxle oil drain plug 21 2.1 15.5 �)

Transaxle oil level / filler plug 21 2.1 15.5 �)

Back up light switch 23 2.3 17.0 �)

Gear shift guide case bolt 23 2.3 17.0 �)

Select lever bracket bolt 23 2.3 17.0 �)

Gear shift interlock bolt 23 2.3 17.0 �)

5th to reverse interlock guide bolt 23 2.3 17.0 �)

Countershaft nut 100 10.0 72.5 �)

Shift fork bolt 10 1.0 7.5 �)

Side cover bolt 10 1.0 7.5 �)

Reverse gear shift lever bolt 23 2.3 17.0 �)

Reverse shaft bolt 23 2.3 17.0 �)

Transaxle case bolt 23 2.3 17.0 �)

Side bearing retainer bolt 23 2.3 17.0 �)

Gear shift locating bolt 13 1.3 9.5 �)

Left case plate bolt 23 2.3 17.0 �)

Oil gutter bolt 10 1.0 7.5 �)

Final gear bolt 90 9.0 65.0 �)

Page 850 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-36 Manual Transmission/Transaxle:

Special Tools and Equipment

Recommended Service MaterialS7RS0B5208001

NOTE

Required service material is also described in the following.

“Gear Shift Control Leve r and Cable Components”

“Gear Shift and Select Shaft Assembly Components”

“Manual Transaxle Assembly Components”

“Input Shaft and Countershaft Components”

“Gear Shift Shaft Components”

“Differential Components”

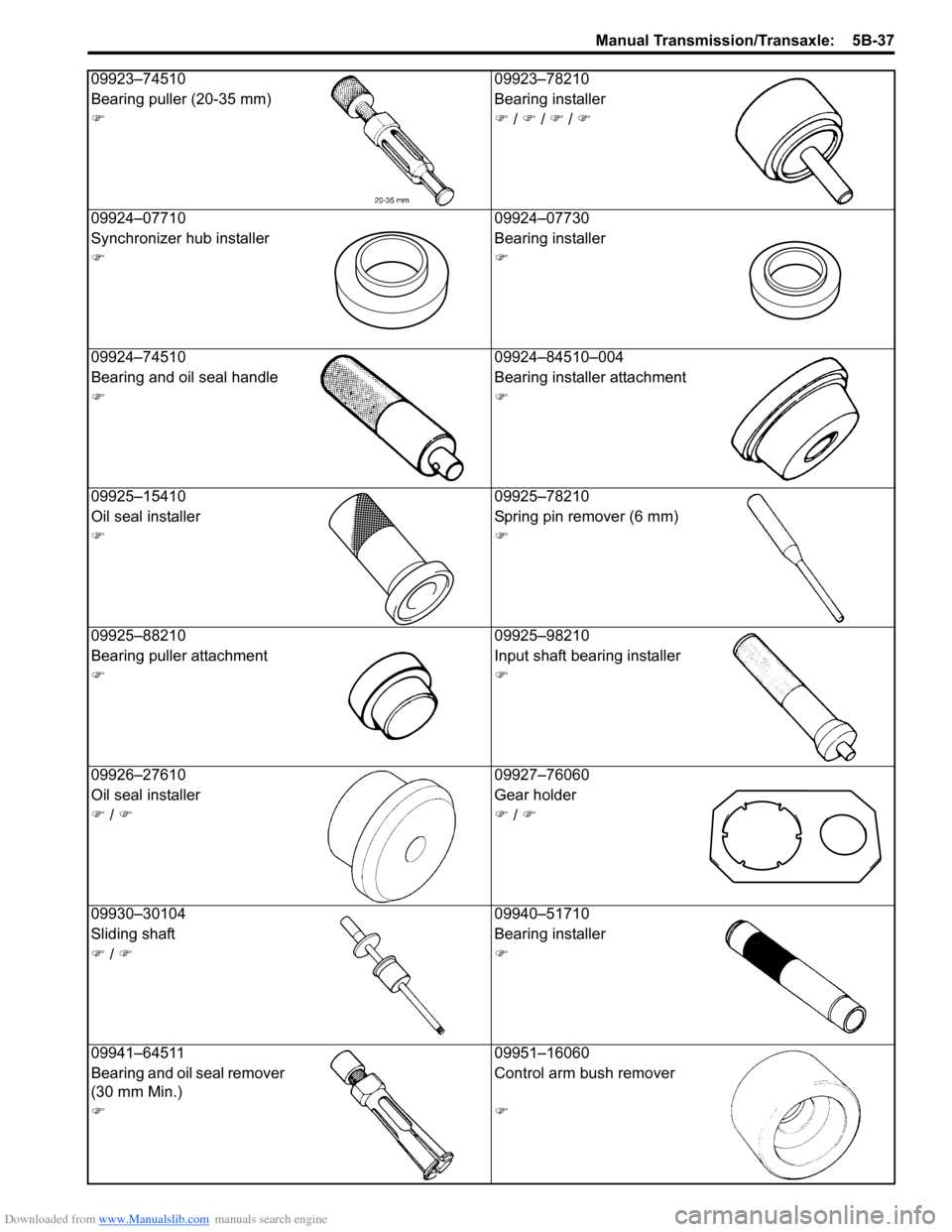

Special ToolS7RS0B5208002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�) / �) / �) / �)

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�) / �) / �) / �) / �) / �) / �) /

�)

Thread lock cement Thread Lock Cement Super 1322 P/No.: 99000–32110 �) / �) / �) / �) / �)

09900–20607 09900–20701

Dial gauge Magnetic stand

�)�)

09913–50121 09913–60910

Oil seal remover Bearing and gear puller (40-

60mm)

�)�)

09913–70123 09913–76010

Bearing installing t ool Bearing installer

�) / �) / �)�) / �)

09913–80113 09913–84510

Bearing installer Bearing installer

�)�) / �) / �)

09913–85210 09922–85811

Bearing installer Spring pin remover (4.5 mm)

�) / �)�) / �) / �)

Page 851 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-37

09923–7451009923–78210

Bearing puller (20-35 mm) Bearing installer

�)�) / �) / �) / �)

09924–07710 09924–07730

Synchronizer hub installer Bearing installer

�)�)

09924–74510 09924–84510–004

Bearing and oil seal handle Bearing installer attachment

�)�)

09925–15410 09925–78210

Oil seal installer Spring pin remover (6 mm)

�)�)

09925–88210 09925–98210

Bearing puller attachment Input shaft bearing installer

�)�)

09926–27610 09927–76060

Oil seal installer Gear holder

�) / �)�) / �)

09930–30104 09940–51710

Sliding shaft Bearing installer

�) / �)�)

09941–64511 09951–16060

Bearing and oil seal remover

(30 mm Min.) Control arm bush remover

�)�)

Page 852 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-38 Manual Transmission/Transaxle:

09951–16080

Bearing installer

�)

Page 853 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-1

Transmission / Transaxle

Clutch

General Description

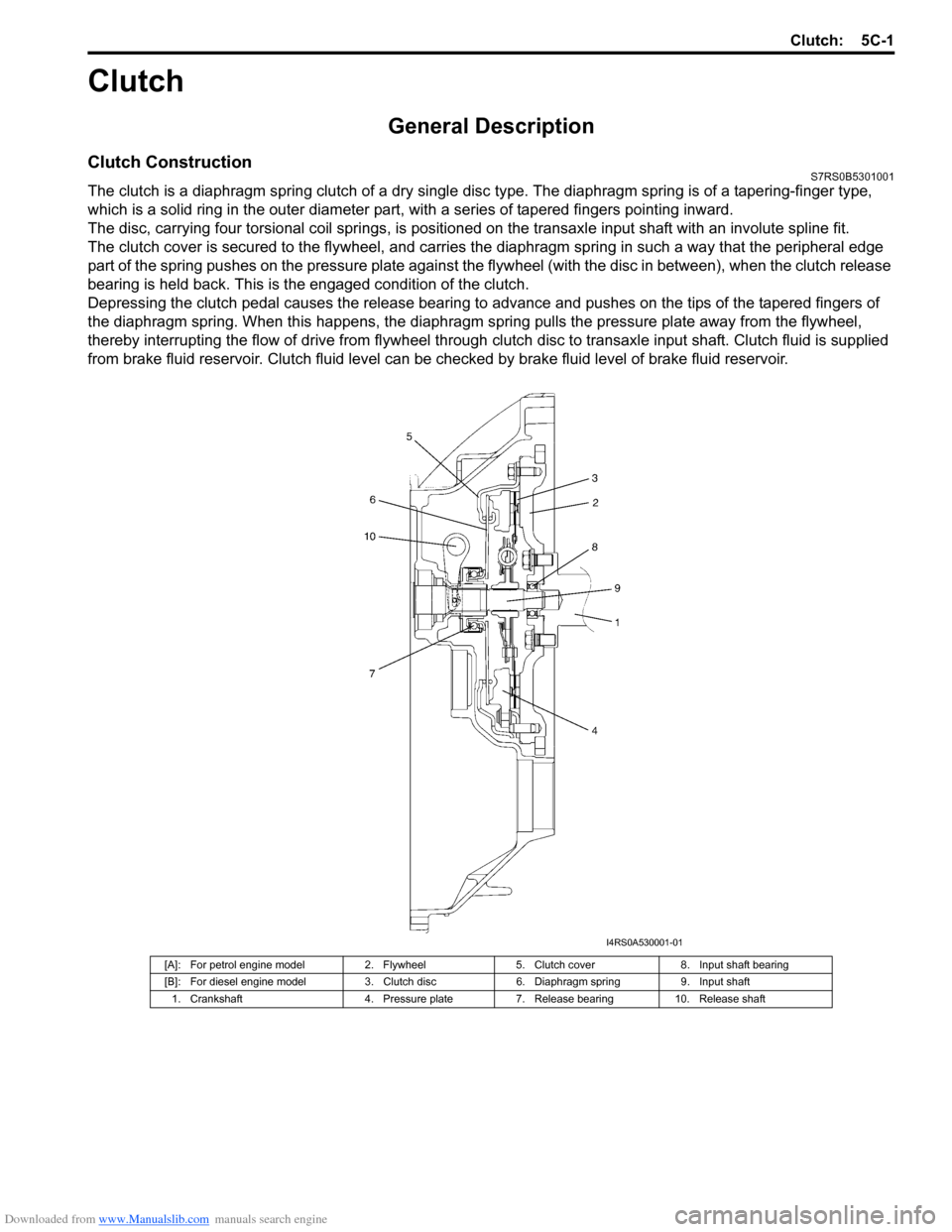

Clutch ConstructionS7RS0B5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positione d on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal c auses the release bearing to advance and pushes on the tips of the tapered fingers of

the diaphragm spring. When this happens, the diaphragm sp ring pulls the pressure plate away from the flywheel,

thereby interrupting the flow of drive from flywheel through clutch disc to transaxle input shaft. Clutch fluid is supplied

from brake fluid reservoir. Clutch fluid level can be checked by brake fluid level of brake fluid reservoir.

[A]: For petrol engine model2. Flywheel5. Clutch cover 8. Input shaft bearing

[B]: For diesel engine model 3. Clutch disc6. Diaphragm spring 9. Input shaft

1. Crankshaft 4. Pressure plate7. Release bearing 10. Release shaft

I4RS0A530001-01

Page 1286 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-4 Lighting Systems:

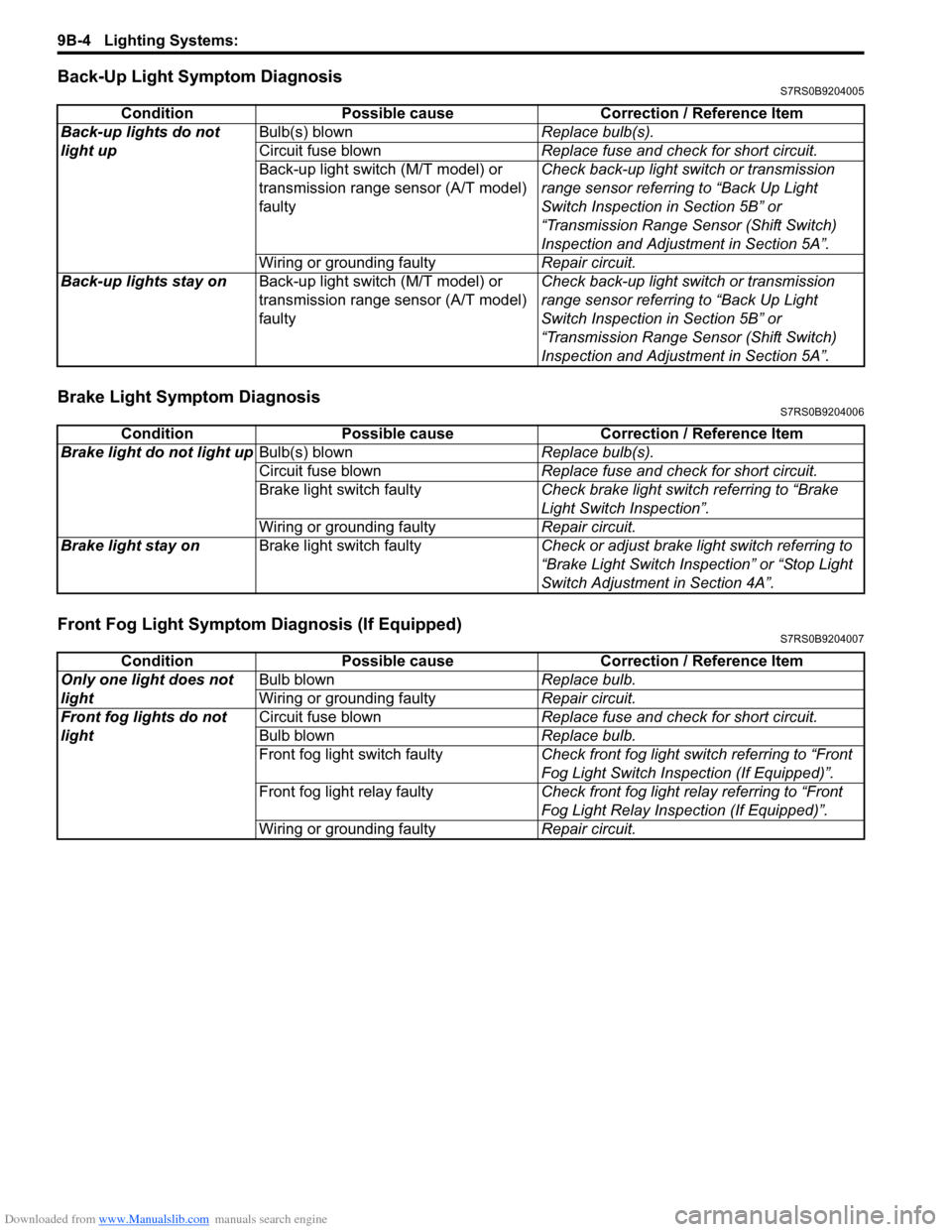

Back-Up Light Symptom DiagnosisS7RS0B9204005

Brake Light Symptom DiagnosisS7RS0B9204006

Front Fog Light Symptom Diagnosis (If Equipped)S7RS0B9204007

ConditionPossible cause Correction / Reference Item

Back-up lights do not

light up Bulb(s) blown

Replace bulb(s).

Circuit fuse blown Replace fuse and check for short circuit.

Back-up light switch (M/T model) or

transmission range sensor (A/T model)

faulty Check back-up light switch or transmission

range sensor referring to “Back Up Light

Switch Inspection in Section 5B” or

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Wiring or grounding faulty Repair circuit.

Back-up lights stay on Back-up light switch (M/T model) or

transmission range sensor (A/T model)

faulty Check back-up light switch or transmission

range sensor referring to “Back Up Light

Switch Inspection in Section 5B” or

“Transmission Range Sensor (Shift Switch)

Inspection and Adjustment in Section 5A”.

Condition

Possible cause Correction / Reference Item

Brake light do not light up Bulb(s) blown Replace bulb(s).

Circuit fuse blown Replace fuse and check for short circuit.

Brake light switch faulty Check brake light switch referring to “Brake

Light Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Brake light stay on Brake light switch faulty Check or adjust brake light switch referring to

“Brake Light Switch Inspection” or “Stop Light

Switch Adjustment in Section 4A”.

ConditionPossible cause Correction / Reference Item

Only one light does not

light Bulb blown

Replace bulb.

Wiring or grounding faulty Repair circuit.

Front fog lights do not

light Circuit fuse blown

Replace fuse and check for short circuit.

Bulb blown Replace bulb.

Front fog light switch faulty Check front fog light switch referring to “Front

Fog Light Switch Inspection (If Equipped)”.

Front fog light relay faulty Check front fog light relay referring to “Front

Fog Light Relay Inspection (If Equipped)”.

Wiring or grounding faulty Repair circuit.