Clé SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 328 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-43 Engine Mechanical:

Valve Spring InspectionS7RS0B1406028

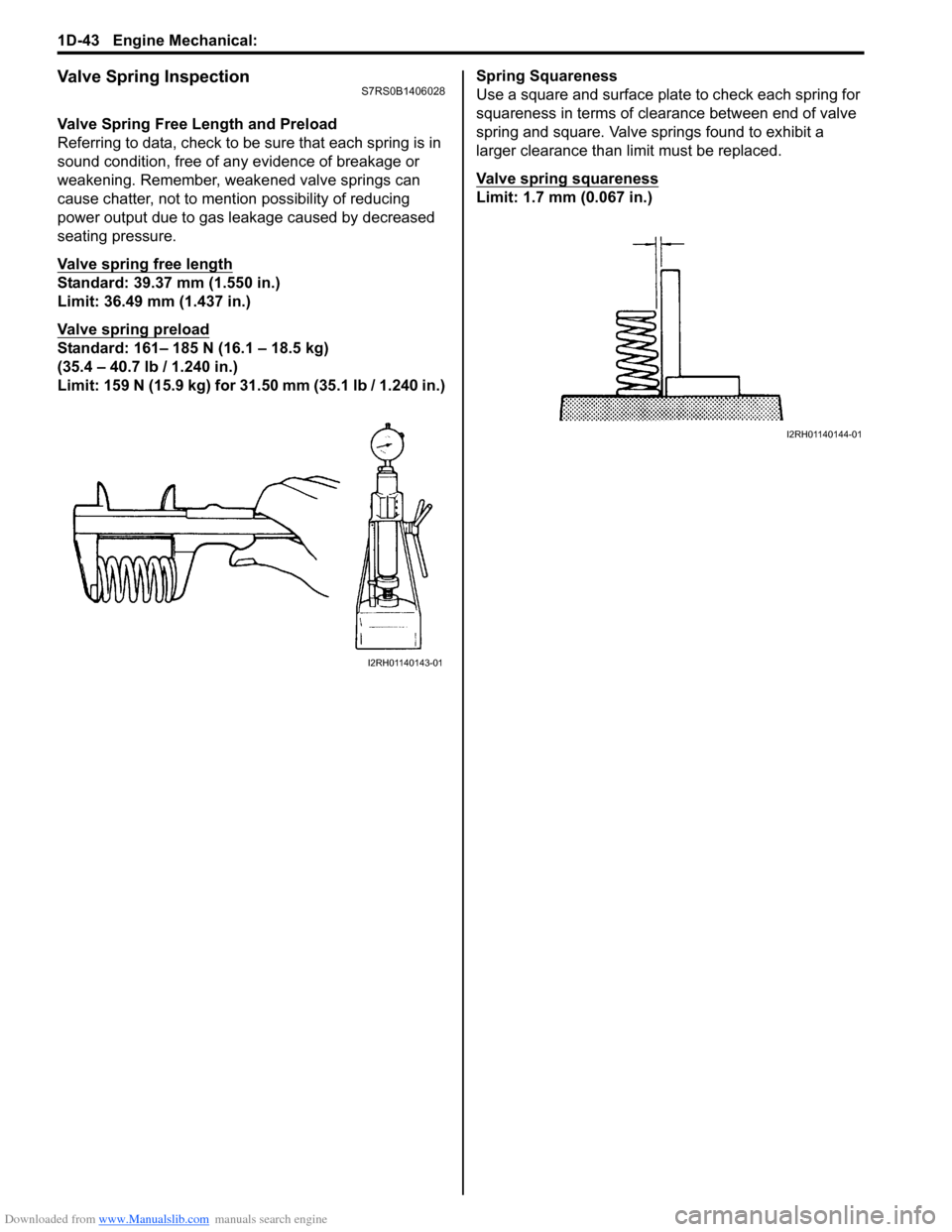

Valve Spring Free Length and Preload

Referring to data, check to be sure that each spring is in

sound condition, free of any evidence of breakage or

weakening. Remember, weakened valve springs can

cause chatter, not to mention possibility of reducing

power output due to gas leakage caused by decreased

seating pressure.

Valve spring free length

Standard: 39.37 mm (1.550 in.)

Limit: 36.49 mm (1.437 in.)

Valve spring preload

Standard: 161– 185 N (16.1 – 18.5 kg)

(35.4 – 40.7 lb / 1.240 in.)

Limit: 159 N (15.9 kg) for 31.50 mm (35.1 lb / 1.240 in.) Spring Squareness

Use a square and surface plate to check each spring for

squareness in terms of clearance between end of valve

spring and square. Valve springs found to exhibit a

larger clearance than limit must be replaced.

Valve spring squareness

Limit: 1.7 mm (0.067 in.)

I2RH01140143-01

I2RH01140144-01

Page 330 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-45 Engine Mechanical:

Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation

S7RS0B1406030

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

3) Mark cylinder number on all pistons, connecting rods

and connecting rod caps using silver pencil or quick

drying paint.

4) Remove rod bearing caps.

5) Decarbonize top of cylinder bore before removing piston from cylinder.

6) Push piston and connecting rod assembly out through the top of cylinder bore.

Installation 1) Apply engine oil to pistons, rings, cylinder walls, connecting rod bearings and crank pins.

NOTE

Do not apply oil between connecting rod and

bearing or between bearing cap and bearing.

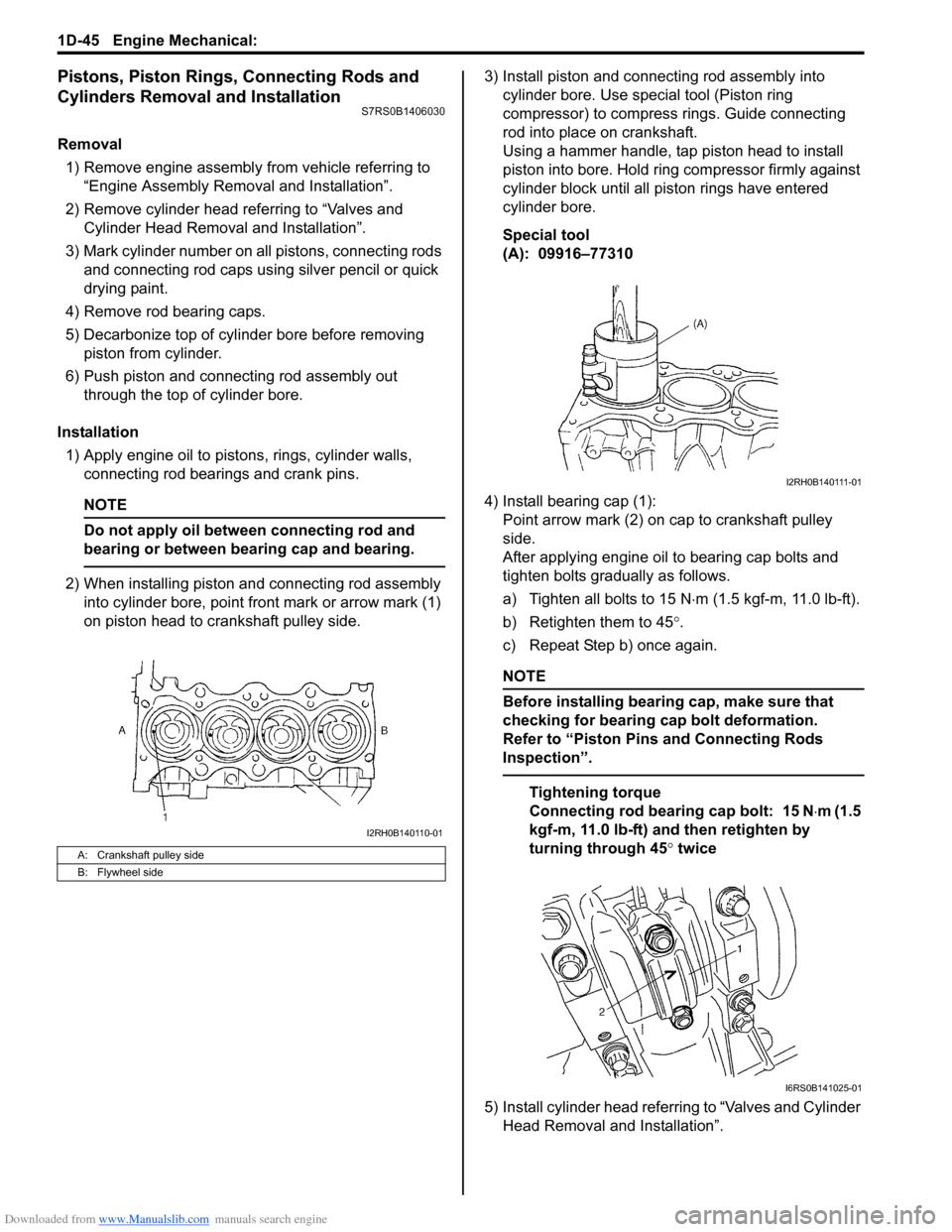

2) When installing piston and connecting rod assembly into cylinder bore, point front mark or arrow mark (1)

on piston head to crankshaft pulley side. 3) Install piston and connecting rod assembly into

cylinder bore. Use special tool (Piston ring

compressor) to compress rings. Guide connecting

rod into place on crankshaft.

Using a hammer handle, tap piston head to install

piston into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

Special tool

(A): 09916–77310

4) Install bearing cap (1): Point arrow mark (2) on cap to crankshaft pulley

side.

After applying engine oil to bearing cap bolts and

tighten bolts gradually as follows.

a) Tighten all bolts to 15 N ⋅m (1.5 kgf-m, 11.0 lb-ft).

b) Retighten them to 45 °.

c) Repeat Step b) once again.

NOTE

Before installing bearing cap, make sure that

checking for bearing cap bolt deformation.

Refer to “Piston Pins and Connecting Rods

Inspection”.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

turning through 45 ° twice

5) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

A: Crankshaft pulley side

B: Flywheel side

I2RH0B140110-01

I2RH0B140111-01

I6RS0B141025-01

Page 333 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-48

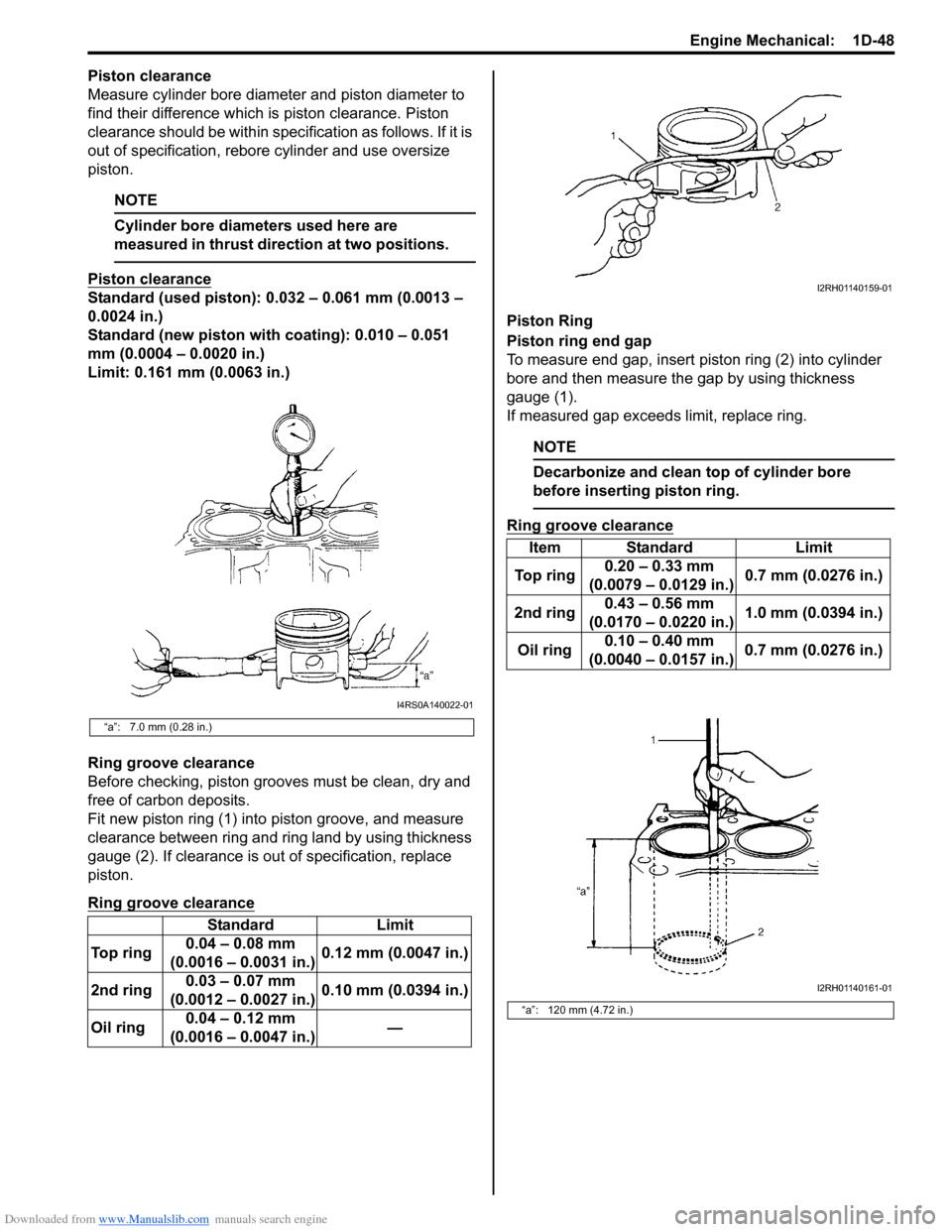

Piston clearance

Measure cylinder bore diameter and piston diameter to

find their difference which is piston clearance. Piston

clearance should be within spec ification as follows. If it is

out of specification, rebore cylinder and use oversize

piston.

NOTE

Cylinder bore diameters used here are

measured in thrust direction at two positions.

Piston clearance

Standard (used piston): 0.032 – 0.061 mm (0.0013 –

0.0024 in.)

Standard (new piston with coating): 0.010 – 0.051

mm (0.0004 – 0.0020 in.)

Limit: 0.161 mm (0.0063 in.)

Ring groove clearance

Before checking, piston grooves must be clean, dry and

free of carbon deposits.

Fit new piston ring (1) into piston groove, and measure

clearance between ring and ring land by using thickness

gauge (2). If clearance is ou t of specification, replace

piston.

Ring groove clearance

Piston Ring

Piston ring end gap

To measure end gap, insert piston ring (2) into cylinder

bore and then measure the gap by using thickness

gauge (1).

If measured gap exceeds limit, replace ring.

NOTE

Decarbonize and clean top of cylinder bore

before inserting piston ring.

Ring groove clearance

“a”: 7.0 mm (0.28 in.)

Standard Limit

Top ring 0.04 – 0.08 mm

(0.0016 – 0.0031 in.) 0.12 mm (0.0047 in.)

2nd ring 0.03 – 0.07 mm

(0.0012 – 0.0027 in.) 0.10 mm (0.0394 in.)

Oil ring 0.04 – 0.12 mm

(0.0016 – 0.0047 in.) —

I4RS0A140022-01

Item Standard

Limit

To p r i n g 0.20 – 0.33 mm

(0.0079 – 0.0129 in.) 0.7 mm (0.0276 in.)

2nd ring 0.43 – 0.56 mm

(0.0170 – 0.0220 in.) 1.0 mm (0.0394 in.)

Oil ring 0.10 – 0.40 mm

(0.0040 – 0.0157 in.) 0.7 mm (0.0276 in.)

“a”: 120 mm (4.72 in.)

I2RH01140159-01

I2RH01140161-01

Page 334 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-49 Engine Mechanical:

Piston Pins and Connecting Rods InspectionS7RS0B1406033

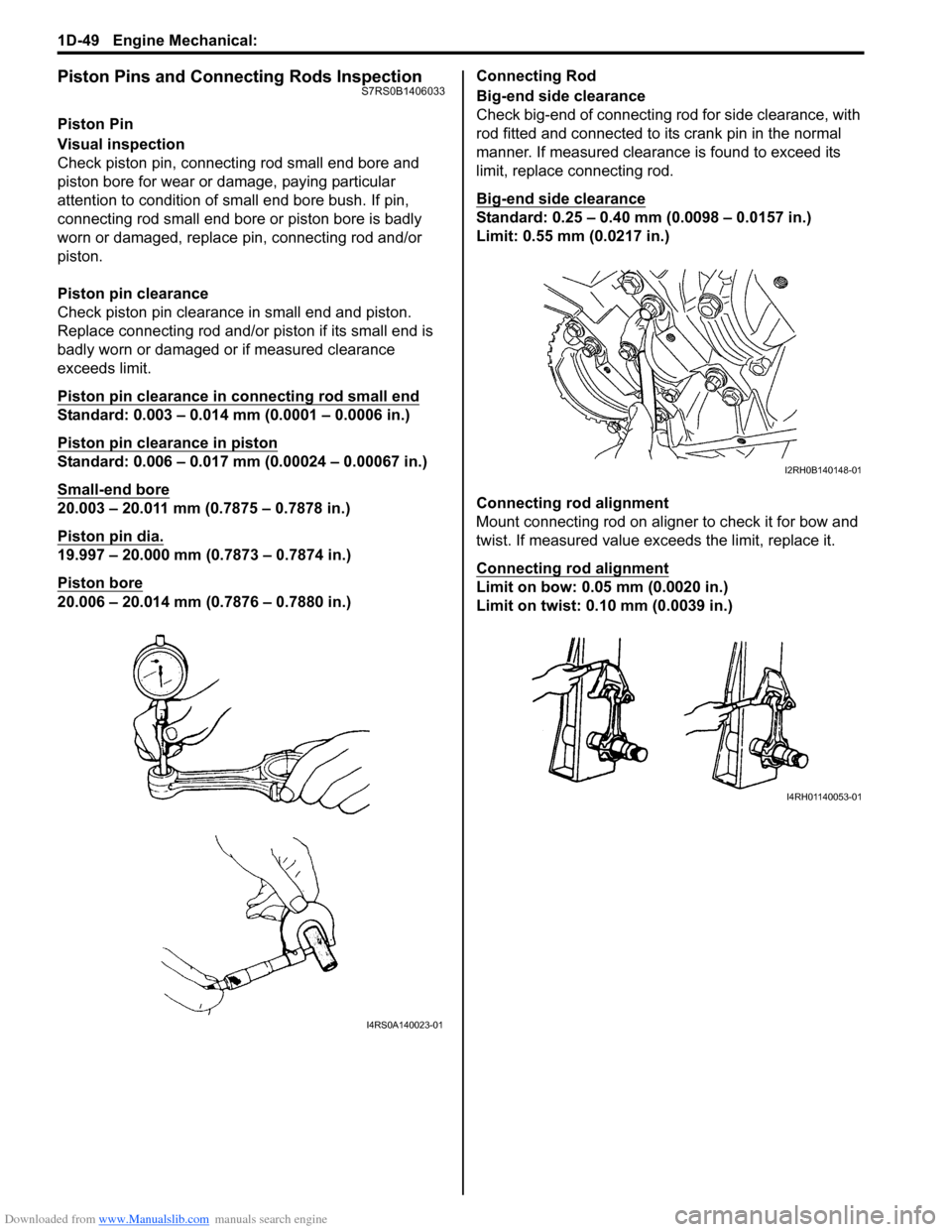

Piston Pin

Visual inspection

Check piston pin, connecting rod small end bore and

piston bore for wear or damage, paying particular

attention to condition of small end bore bush. If pin,

connecting rod small end bore or piston bore is badly

worn or damaged, replace pin, connecting rod and/or

piston.

Piston pin clearance

Check piston pin clearance in small end and piston.

Replace connecting rod and/or piston if its small end is

badly worn or damaged or if measured clearance

exceeds limit.

Piston pin clearance in connecting rod small end

Standard: 0.003 – 0.014 mm (0.0001 – 0.0006 in.)

Piston pin clearance in piston

Standard: 0.006 – 0.017 mm (0.00024 – 0.00067 in.)

Small-end bore

20.003 – 20.011 mm (0.7875 – 0.7878 in.)

Piston pin dia.

19.997 – 20.000 mm (0.7873 – 0.7874 in.)

Piston bore

20.006 – 20.014 mm (0.7876 – 0.7880 in.)Connecting Rod

Big-end side clearance

Check big-end of connecting rod for side clearance, with

rod fitted and connected to its crank pin in the normal

manner. If measured clearance is found to exceed its

limit, replace connecting rod.

Big-end side clearance

Standard: 0.25 – 0.40 mm (0.0098 – 0.0157 in.)

Limit: 0.55 mm (0.0217 in.)

Connecting rod alignment

Mount connecting rod on aligner to check it for bow and

twist. If measured value exceeds the limit, replace it.

Connecting rod alignment

Limit on bow: 0.05 mm (0.0020 in.)

Limit on twist: 0.10 mm (0.0039 in.)

I4RS0A140023-01

I2RH0B140148-01

I4RH01140053-01

Page 336 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-51 Engine Mechanical:

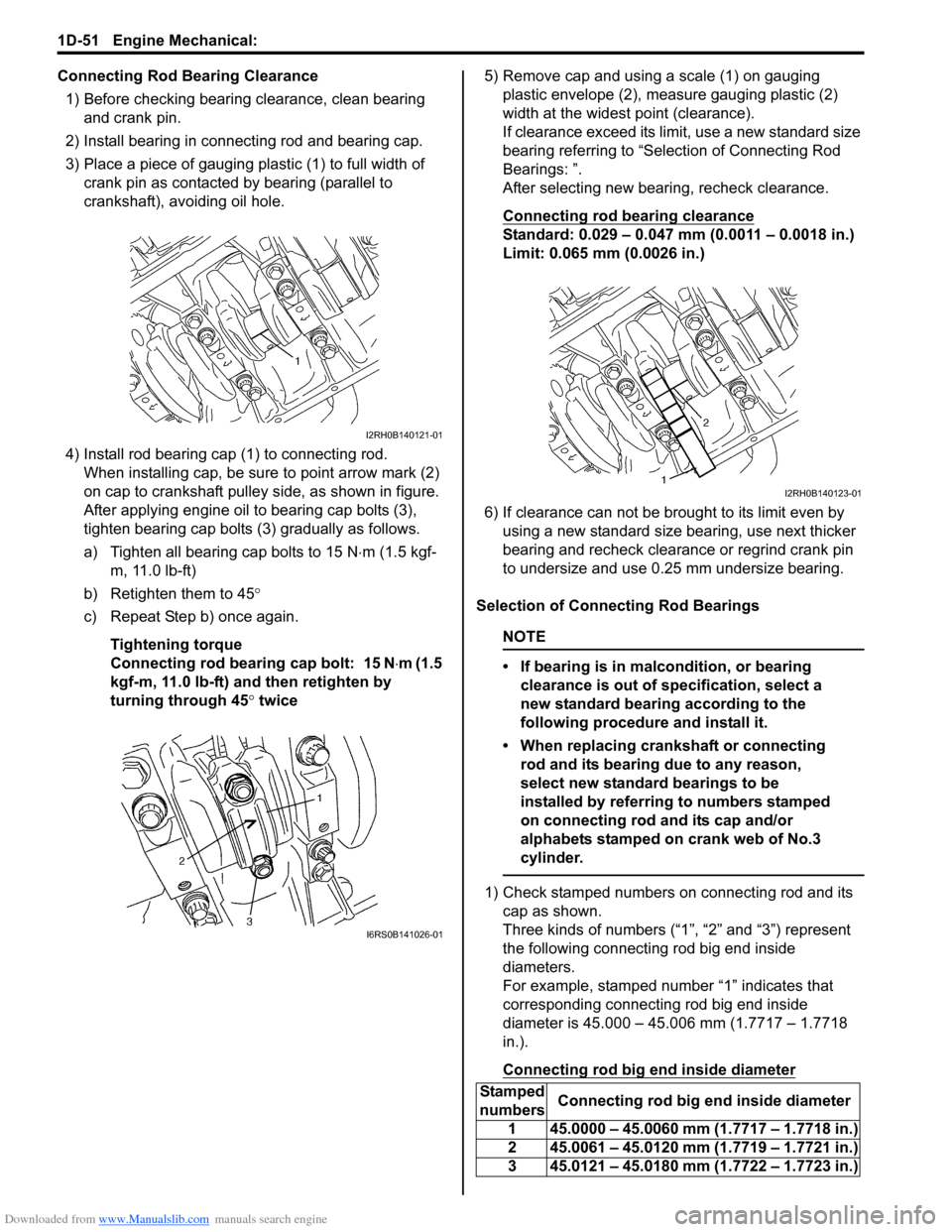

Connecting Rod Bearing Clearance1) Before checking bearing clearance, clean bearing and crank pin.

2) Install bearing in connecting rod and bearing cap.

3) Place a piece of gauging plastic (1) to full width of crank pin as contacted by bearing (parallel to

crankshaft), avoiding oil hole.

4) Install rod bearing cap (1) to connecting rod. When installing cap, be sure to point arrow mark (2)

on cap to crankshaft pulley side, as shown in figure.

After applying engine oil to bearing cap bolts (3),

tighten bearing cap bolts (3) gradually as follows.

a) Tighten all bearing cap bolts to 15 N ⋅m (1.5 kgf-

m, 11.0 lb-ft)

b) Retighten them to 45°

c) Repeat Step b) once again.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

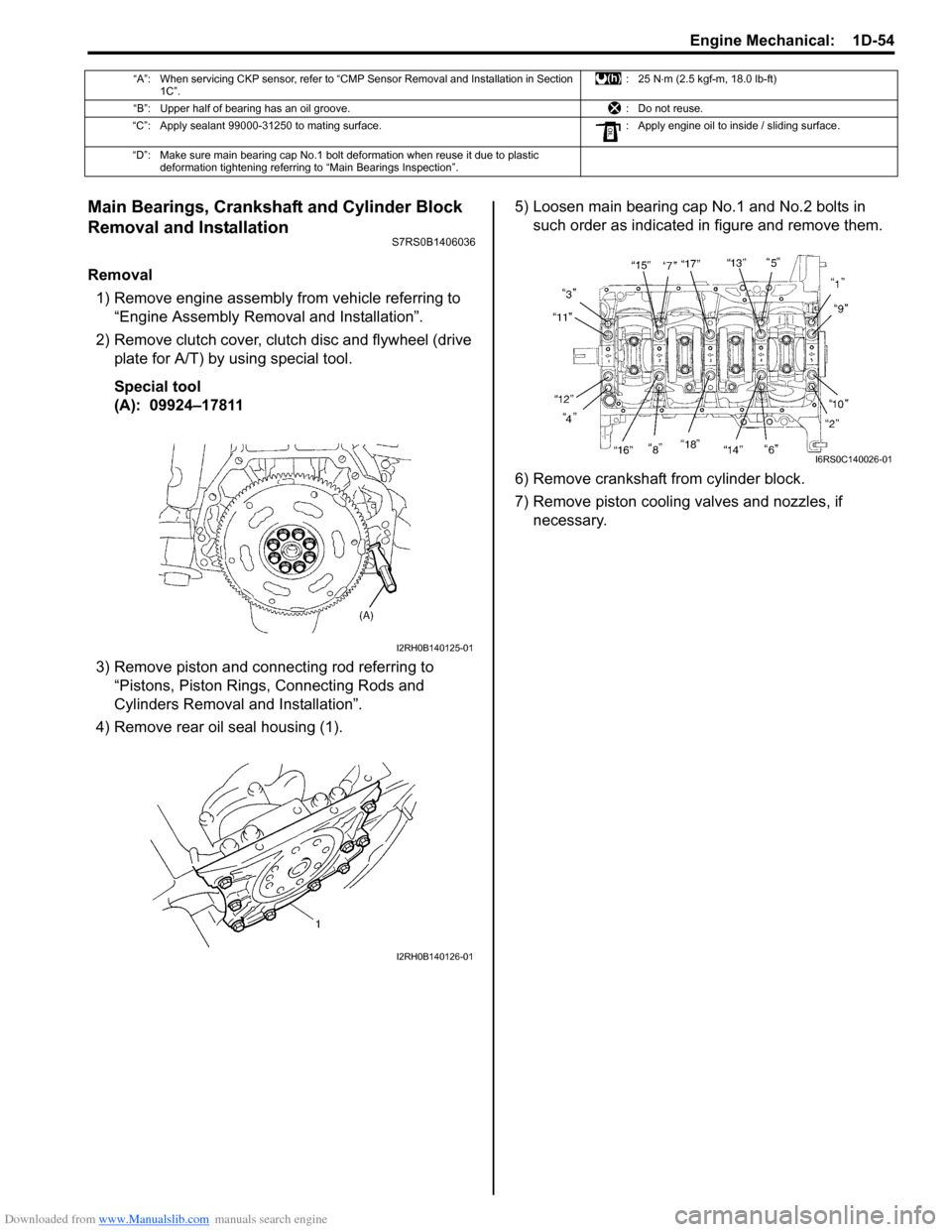

turning through 45 ° twice 5) Remove cap and using a scale (1) on gauging

plastic envelope (2), measure gauging plastic (2)

width at the widest point (clearance).

If clearance exceed its limit, use a new standard size

bearing referring to “Selection of Connecting Rod

Bearings: ”.

After selecting new bearing, recheck clearance.

Connecting rod bearing clearance

Standard: 0.029 – 0.047 mm (0.0011 – 0.0018 in.)

Limit: 0.065 mm (0.0026 in.)

6) If clearance can not be brought to its limit even by using a new standard size bearing, use next thicker

bearing and recheck clearance or regrind crank pin

to undersize and use 0.25 mm undersize bearing.

Selection of Connecting Rod Bearings

NOTE

• If bearing is in malcondition, or bearing clearance is out of specification, select a

new standard bearing according to the

following procedure and install it.

• When replacing crankshaft or connecting rod and its bearing due to any reason,

select new standard bearings to be

installed by referring to numbers stamped

on connecting rod and its cap and/or

alphabets stamped on crank web of No.3

cylinder.

1) Check stamped numbers on connecting rod and its cap as shown.

Three kinds of numbers (“1”, “2” and “3”) represent

the following connecting rod big end inside

diameters.

For example, stamped number “1” indicates that

corresponding connecting rod big end inside

diameter is 45.000 – 45.006 mm (1.7717 – 1.7718

in.).

Connecting rod big end inside diameter

I2RH0B140121-01

I6RS0B141026-01

Stamped

numbers Connecting rod big end inside diameter

1 45.0000 – 45.0060 mm (1.7717 – 1.7718 in.)

2 45.0061 – 45.0120 mm (1.7719 – 1.7721 in.)

3 45.0121 – 45.0180 mm (1.7722 – 1.7723 in.)

I2RH0B140123-01

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

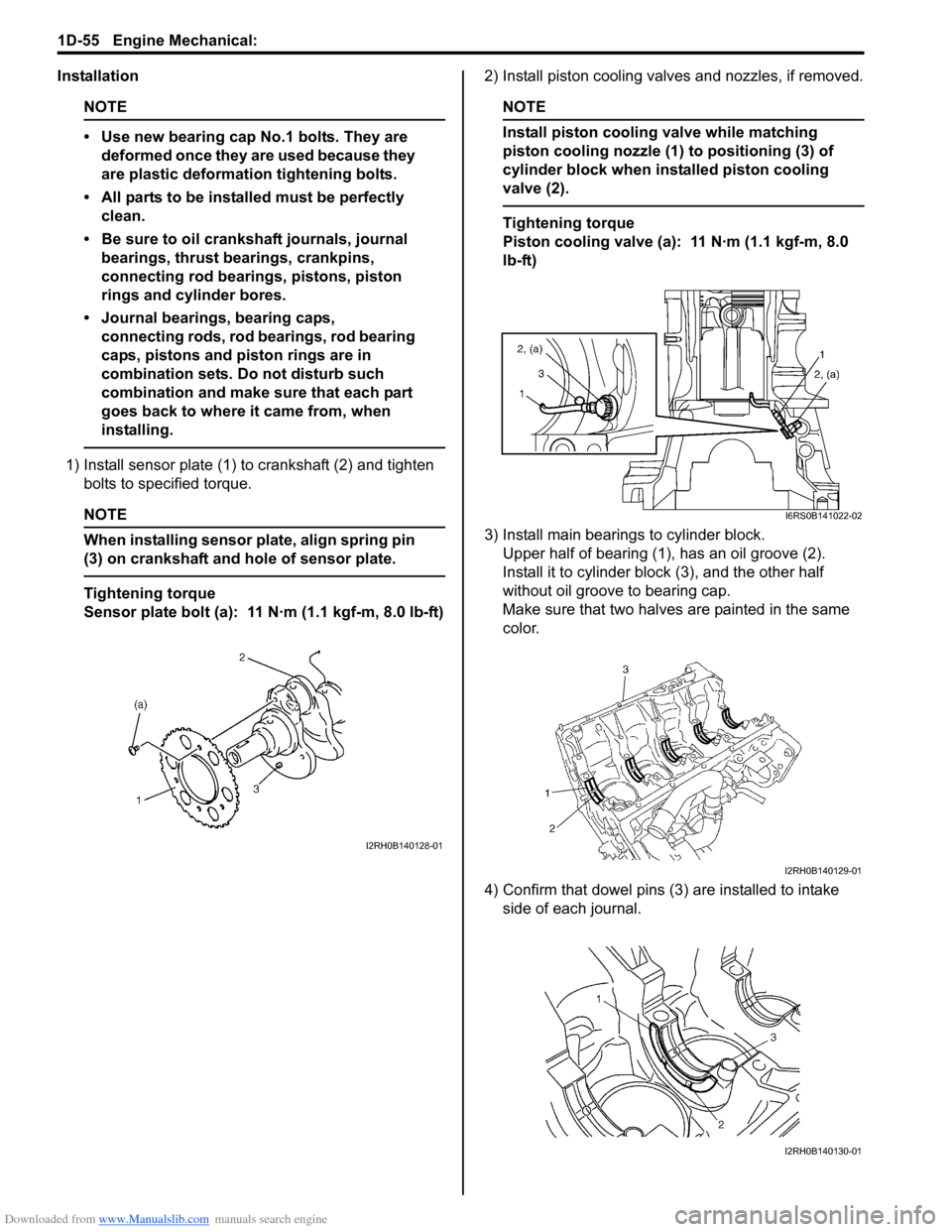

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 340 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-55 Engine Mechanical:

Installation

NOTE

• Use new bearing cap No.1 bolts. They are deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be insta lled must be perfectly

clean.

• Be sure to oil crankshaft journals, journal bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps, connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to spec ified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft) 2) Install piston cooling valves and nozzles, if removed.

NOTE

Install piston cooling valve while matching

piston cooling nozzle (1) to positioning (3) of

cylinder block when installed piston cooling

valve (2).

Tightening torque

Piston cooling valve (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

3) Install main bearings to cylinder block. Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

4) Confirm that dowel pins (3 ) are installed to intake

side of each journal.

I2RH0B140128-01

I6RS0B141022-02

I2RH0B140129-01

I2RH0B140130-01

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

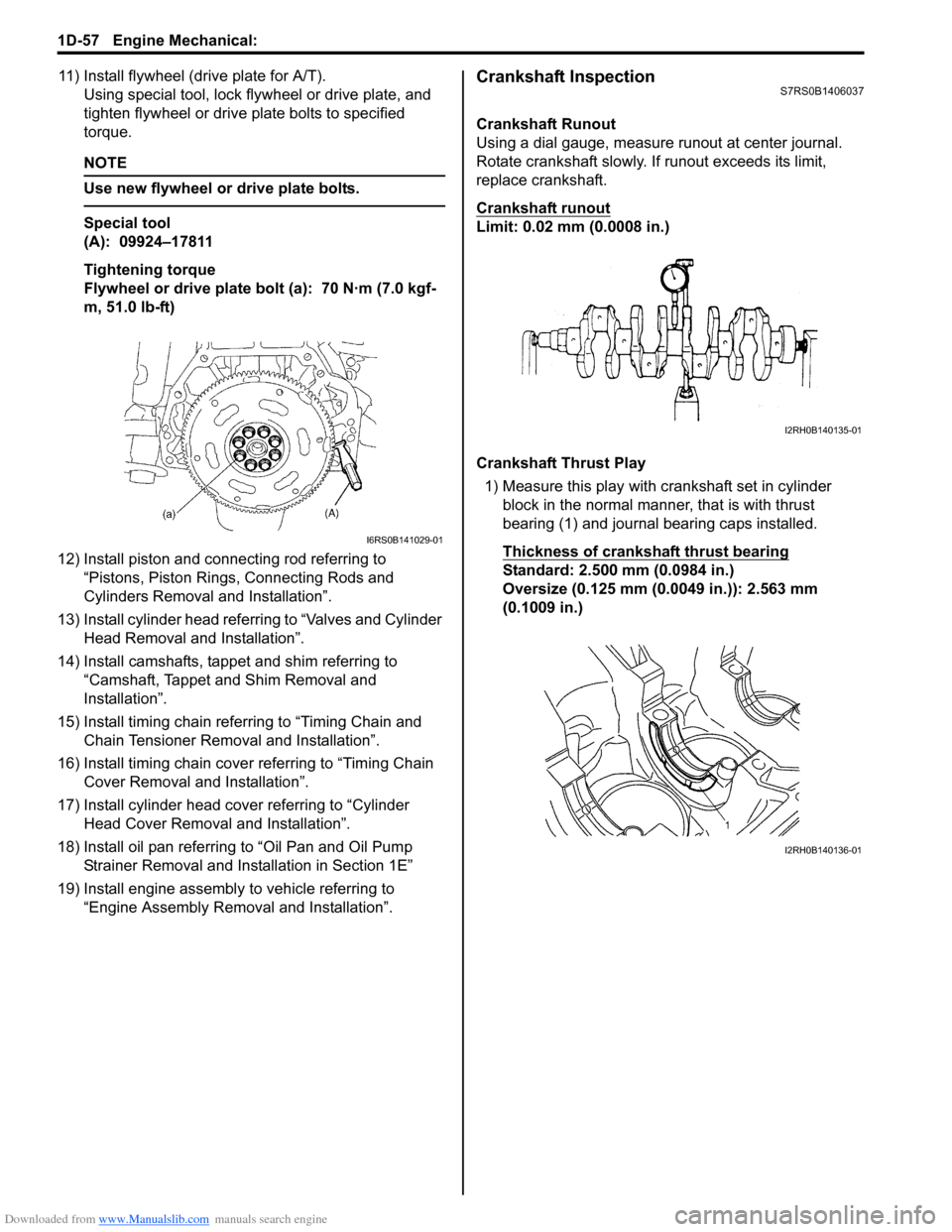

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 344 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-59 Engine Mechanical:

Main Bearings InspectionS7RS0B1406038

General Information

• Service main bearings are available in standard size and 0.25 mm (0.0098 in.) undersize, and each of them

has 5 kinds of bearings differing in tolerance.

• Upper half of bearing (1) has oil groove (2) as shown in figure.

Install this half with o il groove to cylinder block.

• Lower half of bearing does not have an oil groove.

Visual Inspection

Check bearings for pitting, scratches, wear or damage.

If any malcondition is foun d, replace both upper and

lower halves. Never replace either half without replacing

the other half.

Main Bearing Clearance

NOTE

Do not rotate crankshaft while gauging

plastic is installed.

Check clearance by using ga uging plastic according to

the following procedure.

1) Remove bearing caps.

2) Clean bearings and main journals.

3) Place a piece of gauging plastic (1) the full width of bearing (parallel to crankshaft) on journal, avoiding

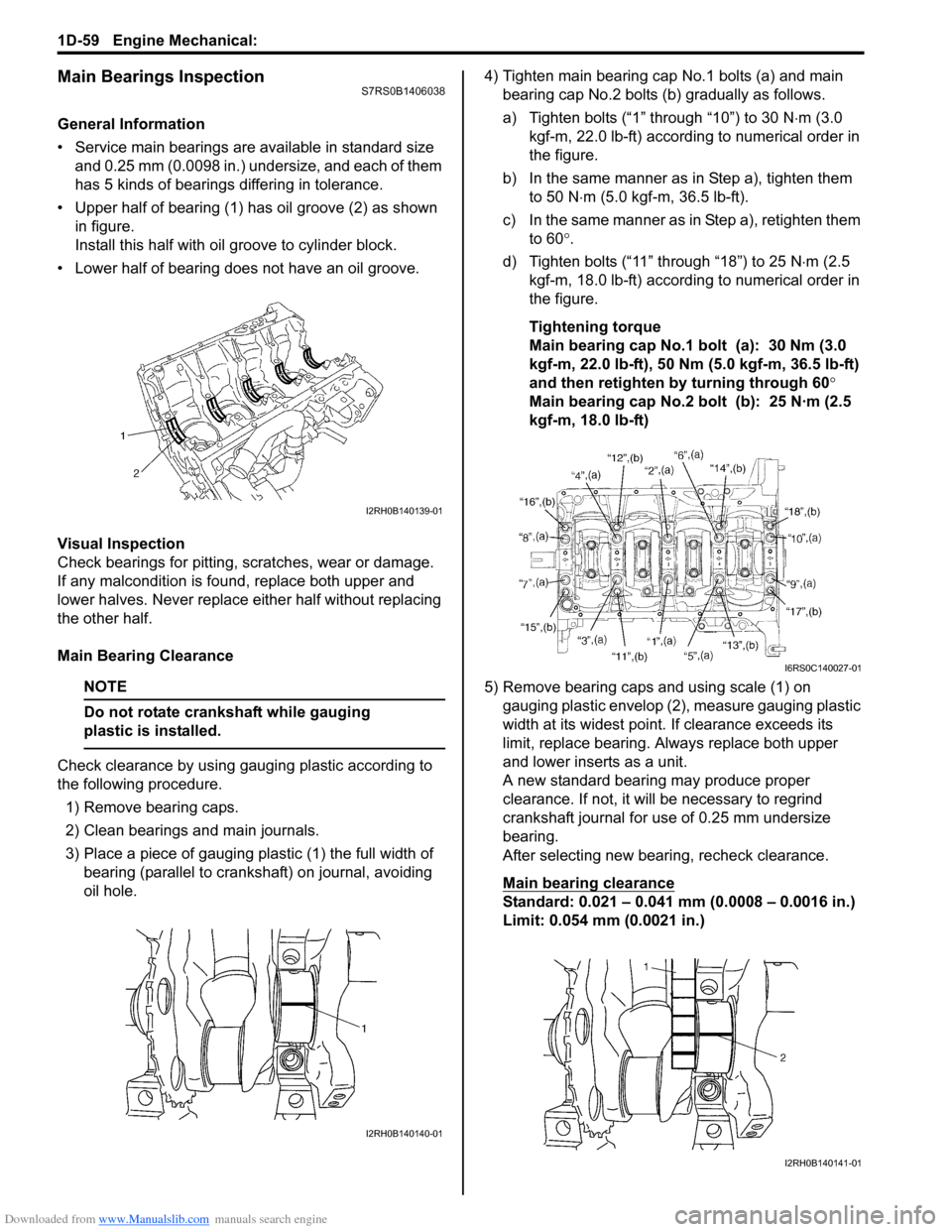

oil hole. 4) Tighten main bearing cap No.1 bolts (a) and main

bearing cap No.2 bolts (b) gradually as follows.

a) Tighten bolts (“1” through “10”) to 30 N ⋅m (3.0

kgf-m, 22.0 lb-ft) according to numerical order in

the figure.

b) In the same manner as in Step a), tighten them to 50 N ⋅m (5.0 kgf-m, 36.5 lb-ft).

c) In the same manner as in Step a), retighten them to 60 °.

d) Tighten bolts (“11” through “18”) to 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) according to numerical order in

the figure.

Tightening torque

Main bearing cap No.1 bolt (a): 30 Nm (3.0

kgf-m, 22.0 lb-ft), 50 Nm (5.0 kgf-m, 36.5 lb-ft)

and then retighten by turning through 60°

Main bearing cap No.2 bolt (b): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

5) Remove bearing caps and using scale (1) on gauging plastic envelop (2), measure gauging plastic

width at its widest point. If clearance exceeds its

limit, replace bearing. Always replace both upper

and lower inserts as a unit.

A new standard bearing may produce proper

clearance. If not, it will be necessary to regrind

crankshaft journal for use of 0.25 mm undersize

bearing.

After selecting new bearing, recheck clearance.

Main bearing clearance

Standard: 0.021 – 0.041 mm (0.0008 – 0.0016 in.)

Limit: 0.054 mm (0.0021 in.)

I2RH0B140139-01

I2RH0B140140-01

I6RS0C140027-01

I2RH0B140141-01

Page 345 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-60

Selection of Main Bearings

Standard bearing

If bearing is in malcondition, or bearing clearance is out

of specification, select a new standard bearing according

to the following procedure and install it.

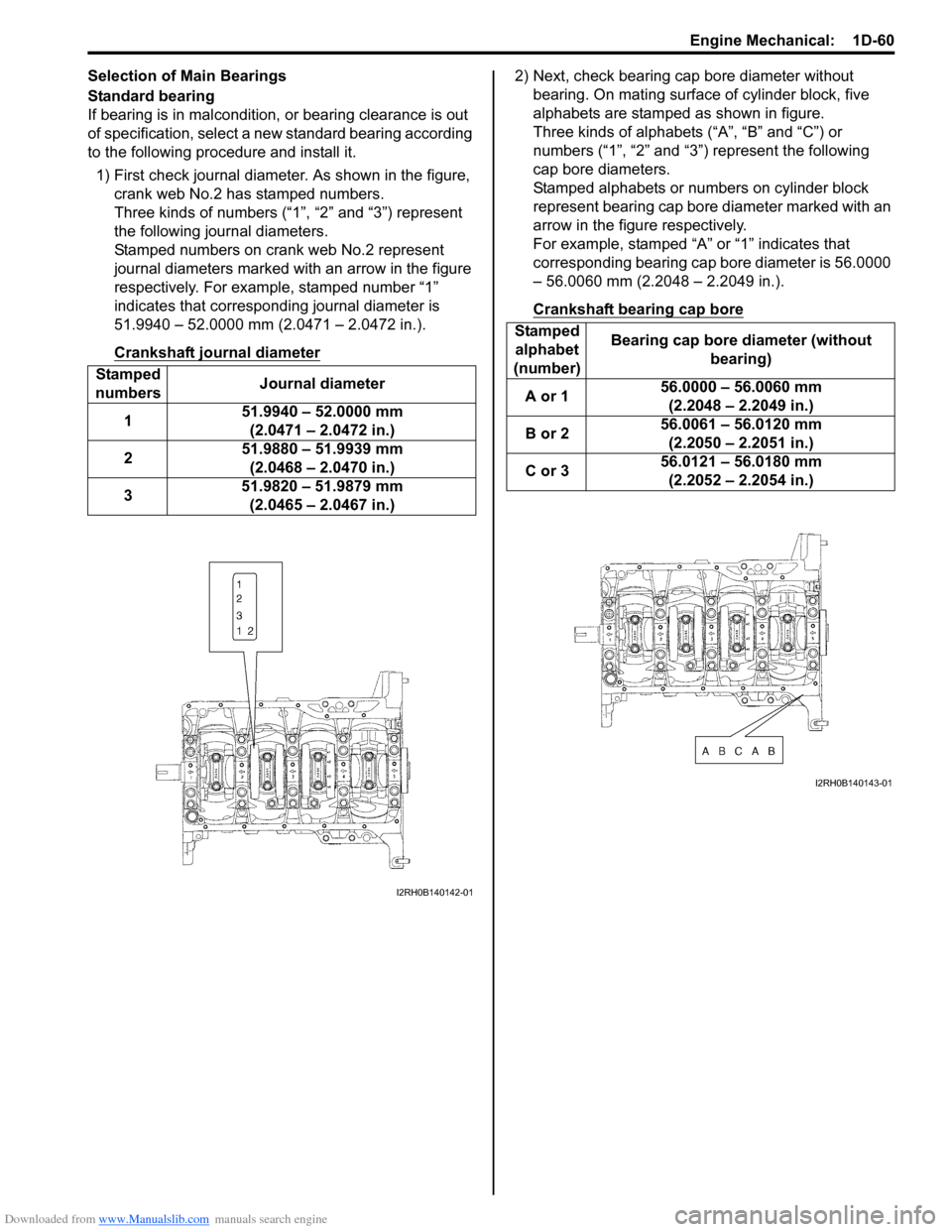

1) First check journal diameter. As shown in the figure, crank web No.2 has stamped numbers.

Three kinds of numbers (“1”, “2” and “3”) represent

the following journal diameters.

Stamped numbers on crank web No.2 represent

journal diameters marked with an arrow in the figure

respectively. For example, stamped number “1”

indicates that corresponding journal diameter is

51.9940 – 52.0000 mm (2.0471 – 2.0472 in.).

Crankshaft journal diameter2) Next, check bearing cap bore diameter without bearing. On mating surface of cylinder block, five

alphabets are stamped as shown in figure.

Three kinds of alphabets (“A”, “B” and “C”) or

numbers (“1”, “2” and “3”) represent the following

cap bore diameters.

Stamped alphabets or numbers on cylinder block

represent bearing cap bore diameter marked with an

arrow in the figure respectively.

For example, stamped “A” or “1” indicates that

corresponding bearing cap bo re diameter is 56.0000

– 56.0060 mm (2.2048 – 2.2049 in.).

Crankshaft bearing cap bore

Stamped

numbers Journal diameter

1 51.9940 – 52.0000 mm

(2.0471 – 2.0472 in.)

2 51.9880 – 51.9939 mm

(2.0468 – 2.0470 in.)

3 51.9820 – 51.9879 mm

(2.0465 – 2.0467 in.)

I2RH0B140142-01

Stamped alphabet

(number) Bearing cap bore diameter (without

bearing)

A or 1 56.0000 – 56.0060 mm

(2.2048 – 2.2049 in.)

B or 2 56.0061 – 56.0120 mm

(2.2050 – 2.2051 in.)

C or 3 56.0121 – 56.0180 mm

(2.2052 – 2.2054 in.)

I2RH0B140143-01