Panel SUZUKI SWIFT 2007 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 940 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-4 Heater and Ventilation:

Repair Instructions

HVAC Unit ComponentsS7RS0B7106001

For manual type A/C, refer to “HVAC Unit Components

in Section 7B”.

For automatic type A/C, refer to “HVAC Unit

Components in Section 7B”.

HVAC Unit Removal and InstallationS7RS0B7106002

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove cowl top panel from vehicle body referring to “Cowl Top Components in Section 9K”.

4) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

5) Remove instrument panel from vehicle body referring to “Instrument Panel Removal and

Installation in Section 9C”.

6) Remove nuts (3).

7) Remove HVAC unit from vehicle body.

Installation

Reverse removal procedure noting the following

instructions.

• Be careful not to catch any cable and wiring harness in inappropriate position.

• Adjust control cables of HVAC control unit referring to “HVAC Control Unit Remo val and Installation”.

• Fill engine coolant to radiator.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

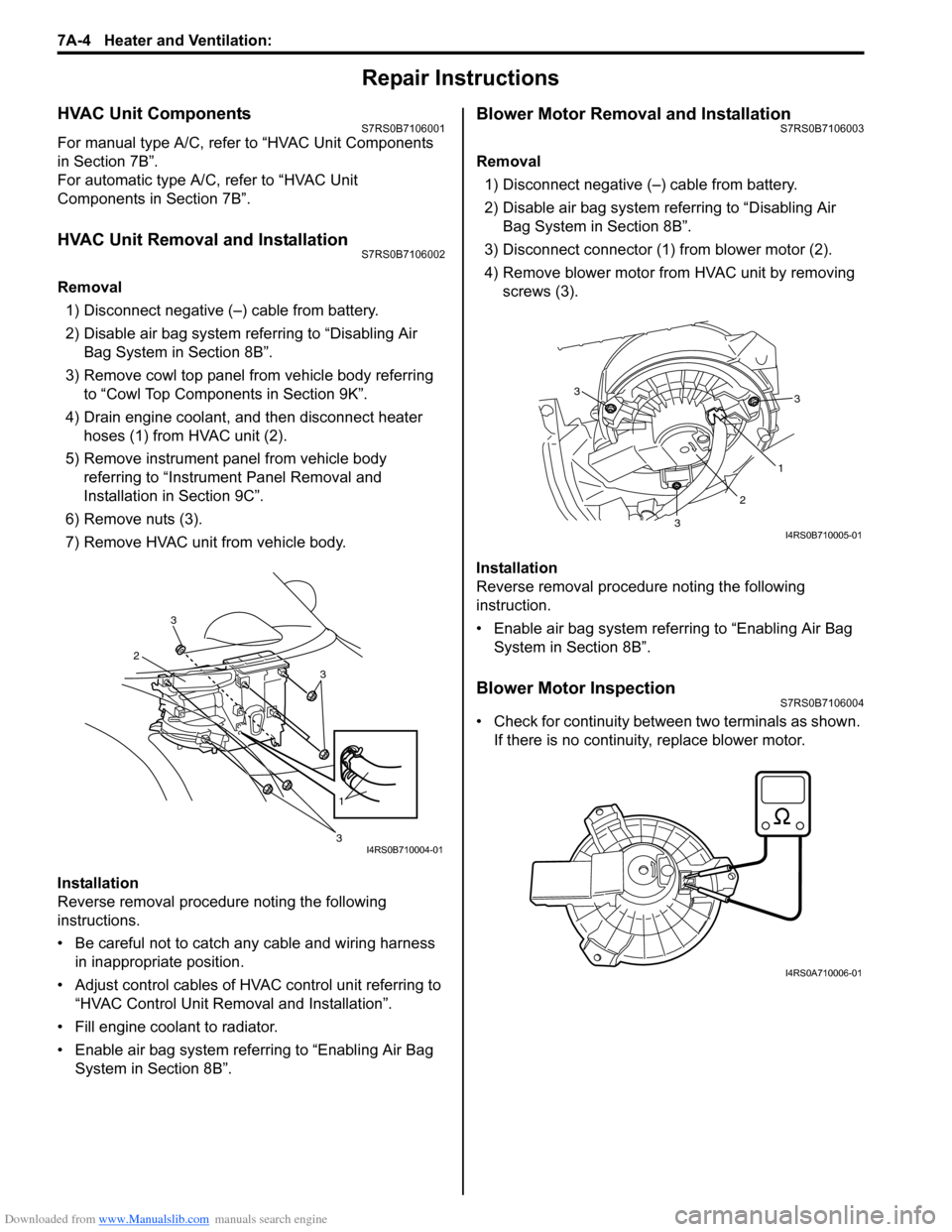

Blower Motor Removal and InstallationS7RS0B7106003

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Disconnect connector (1) from blower motor (2).

4) Remove blower motor from HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor InspectionS7RS0B7106004

• Check for continuity between two terminals as shown. If there is no continuity, replace blower motor.

3

2

3

1

3I4RS0B710004-01

3

1

2

3

3

I4RS0B710005-01

I4RS0A710006-01

Page 941 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-5

• Check for operation and current.a. Put blower motor (1) in a soft-jawed vise.

b. Connect battery to blower motor as shown.

c. Check if blower motor operates smoothly without noise.

d. Check if ammeter indicates the specified current. If measured current is out of specification, replace

blower motor.

Blower motor specified current at 12 V

16 A maximum

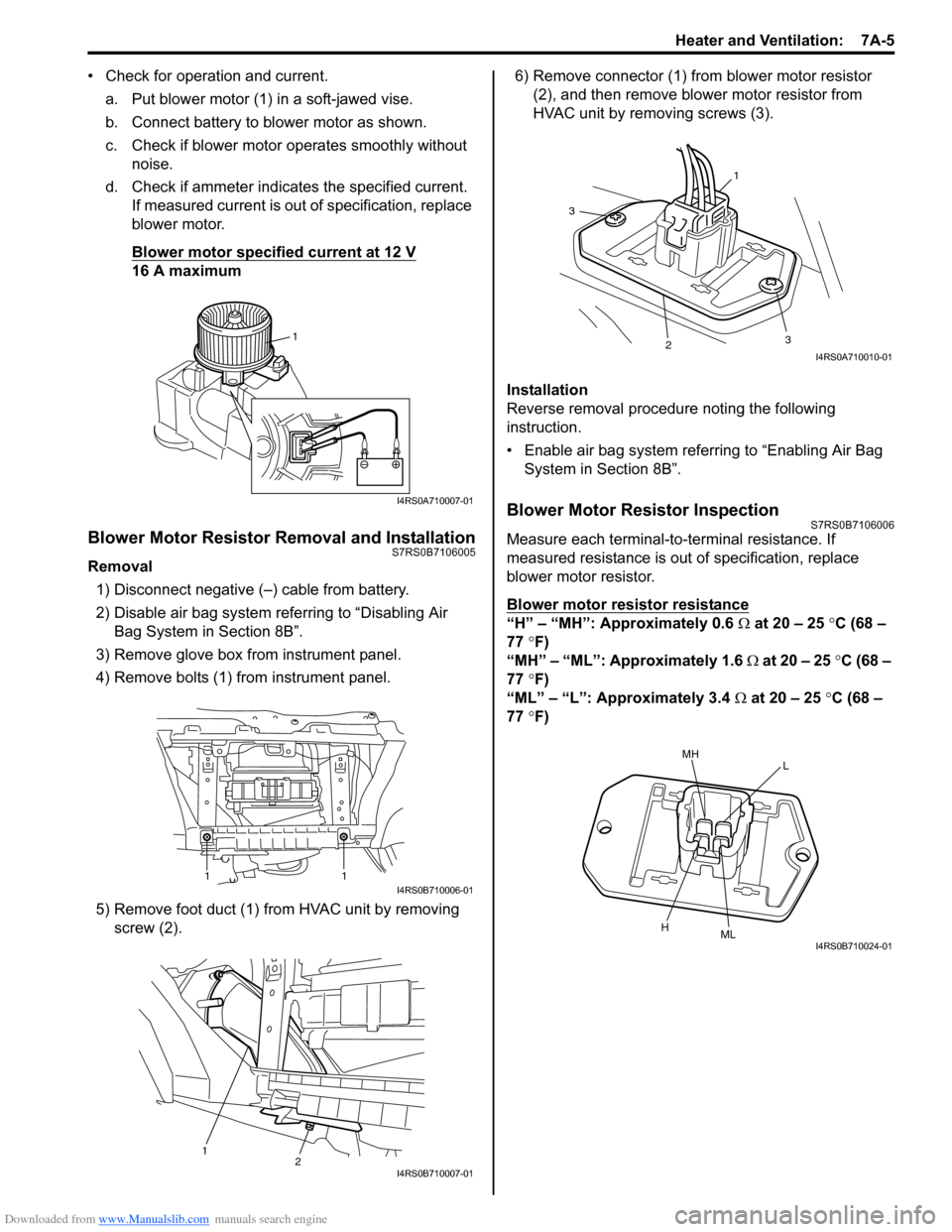

Blower Motor Resistor Removal and InstallationS7RS0B7106005

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove bolts (1) from instrument panel.

5) Remove foot duct (1) from HVAC unit by removing screw (2). 6) Remove connector (1) from blower motor resistor

(2), and then remove blower motor resistor from

HVAC unit by removing screws (3).

Installation

Reverse removal procedure noting the following

instruction.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Blower Motor Resistor InspectionS7RS0B7106006

Measure each terminal-to-terminal resistance. If

measured resistance is out of specification, replace

blower motor resistor.

Blower motor resistor resistance

“H” – “MH”: Approximately 0.6 Ω at 20 – 25 °C (68 –

77 °F)

“MH” – “ML”: Approximately 1.6 Ω at 20 – 25 °C (68 –

77 °F)

“ML” – “L”: Approximately 3.4 Ω at 20 – 25 °C (68 –

77 °F)

1

I4RS0A710007-01

11I4RS0B710006-01

12I4RS0B710007-01

1

3

23

I4RS0A710010-01

MHL

HMLI4RS0B710024-01

Page 943 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-7

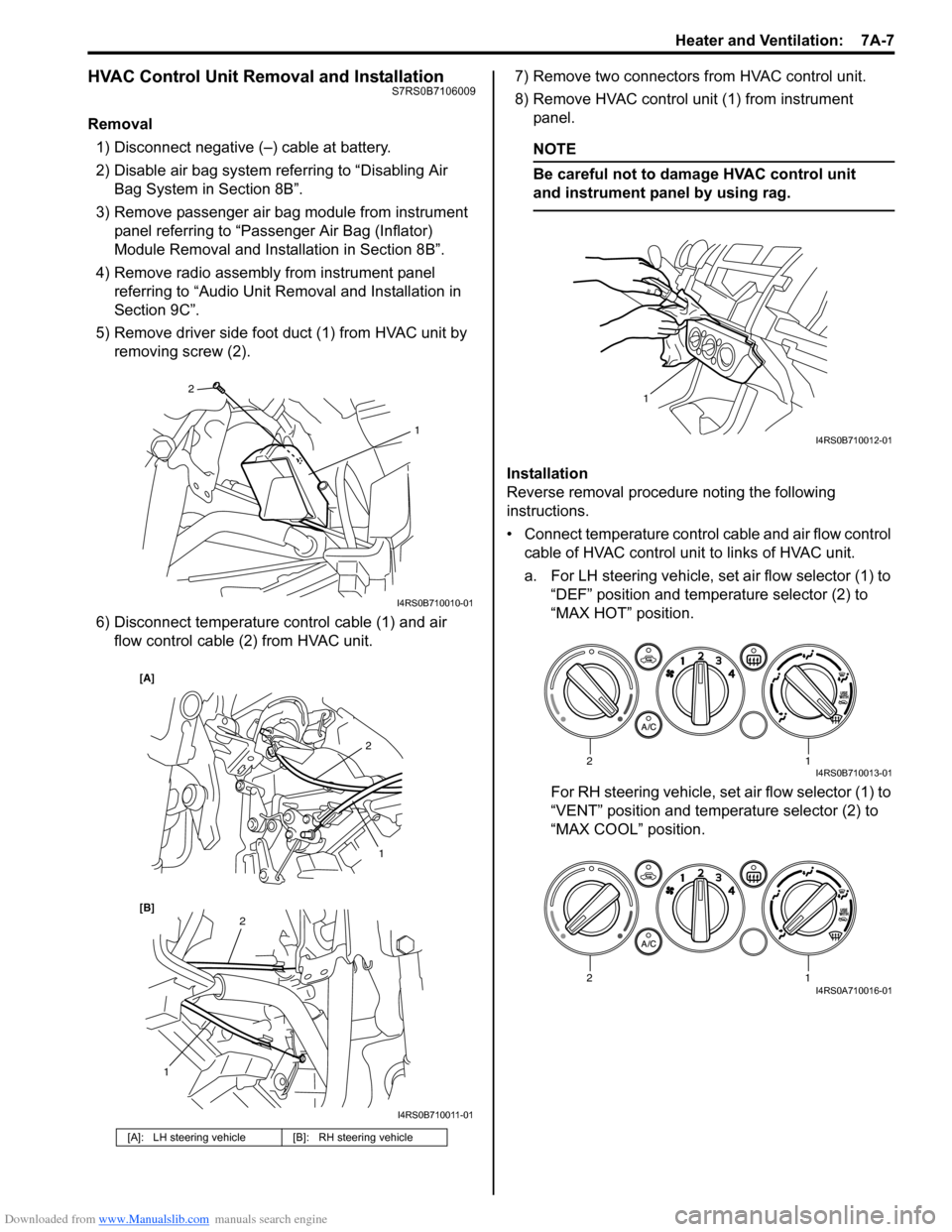

HVAC Control Unit Removal and InstallationS7RS0B7106009

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

5) Remove driver side foot duct (1) from HVAC unit by removing screw (2).

6) Disconnect temperature control cable (1) and air flow control cable (2) from HVAC unit. 7) Remove two connectors from HVAC control unit.

8) Remove HVAC control unit (1) from instrument

panel.

NOTE

Be careful not to damage HVAC control unit

and instrument panel by using rag.

Installation

Reverse removal procedure noting the following

instructions.

• Connect temperature control cable and air flow control

cable of HVAC control unit to links of HVAC unit.

a. For LH steering vehicle, set air flow selector (1) to “DEF” position and temperature selector (2) to

“MAX HOT” position.

For RH steering vehicle, set air flow selector (1) to

“VENT” position and temperature selector (2) to

“MAX COOL” position.

[A]: LH steering vehicle [B]: RH steering vehicle

2

1

I4RS0B710010-01

2

1

1

2

[B] [A]

I4RS0B710011-01

1

I4RS0B710012-01

12I4RS0B710013-01

12I4RS0A710016-01

Page 945 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-9

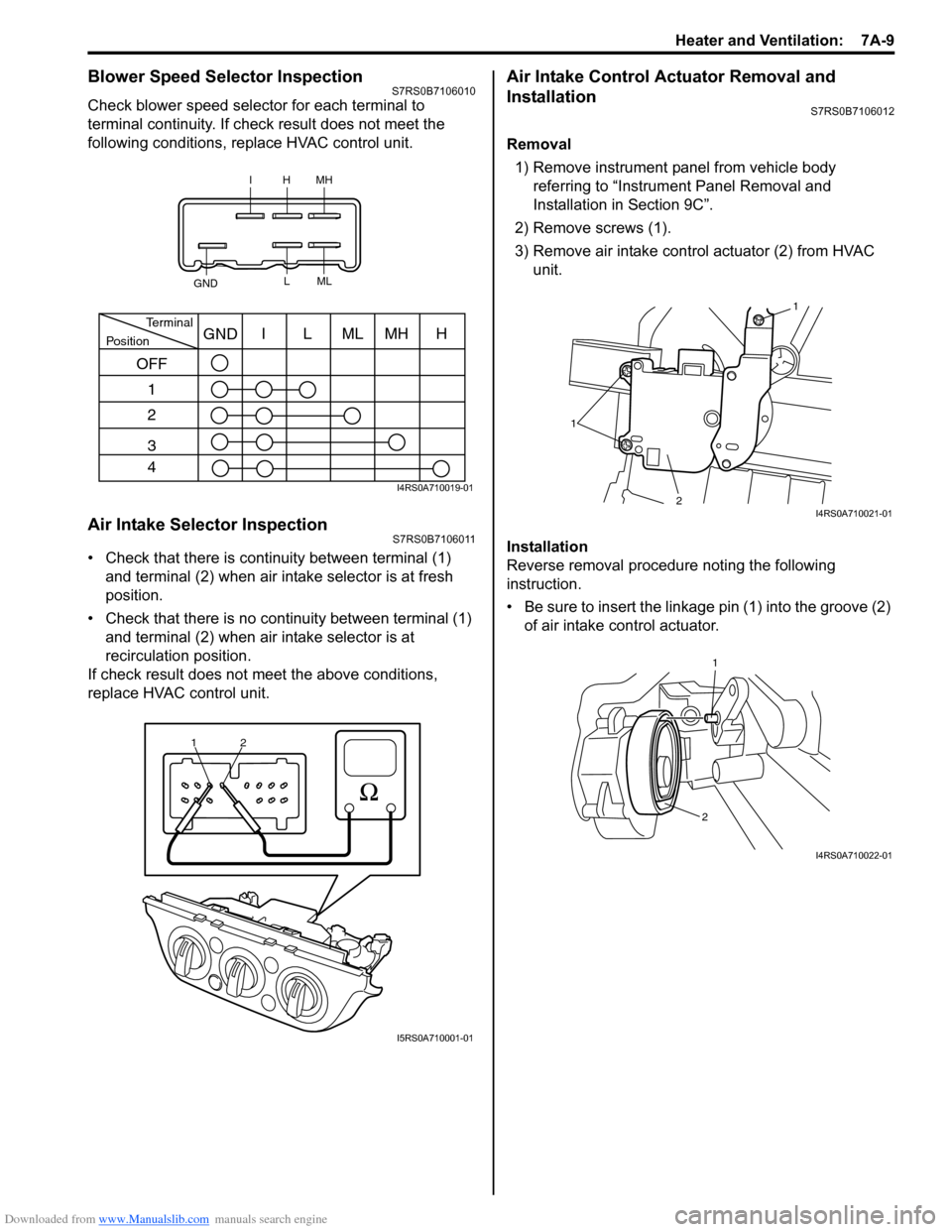

Blower Speed Selector InspectionS7RS0B7106010

Check blower speed selector for each terminal to

terminal continuity. If check result does not meet the

following conditions, replace HVAC control unit.

Air Intake Selector InspectionS7RS0B7106011

• Check that there is continuity between terminal (1) and terminal (2) when air intake selector is at fresh

position.

• Check that there is no continuity between terminal (1) and terminal (2) when air intake selector is at

recirculation position.

If check result does not meet the above conditions,

replace HVAC control unit.

Air Intake Control Actuator Removal and

Installation

S7RS0B7106012

Removal

1) Remove instrument panel from vehicle body referring to “Instrum ent Panel Removal and

Installation in Section 9C”.

2) Remove screws (1).

3) Remove air intake control actuator (2) from HVAC unit.

Installation

Reverse removal procedure noting the following

instruction.

• Be sure to insert the linkage pin (1) into the groove (2) of air intake control actuator.

IHMH

GND LML

PositionTerminalI

OFF 1

2

3

4 LMLMHHGND

I4RS0A710019-01

1

2

I5RS0A710001-01

1 1

2

I4RS0A710021-01

1

2

I4RS0A710022-01

Page 946 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-10 Heater and Ventilation:

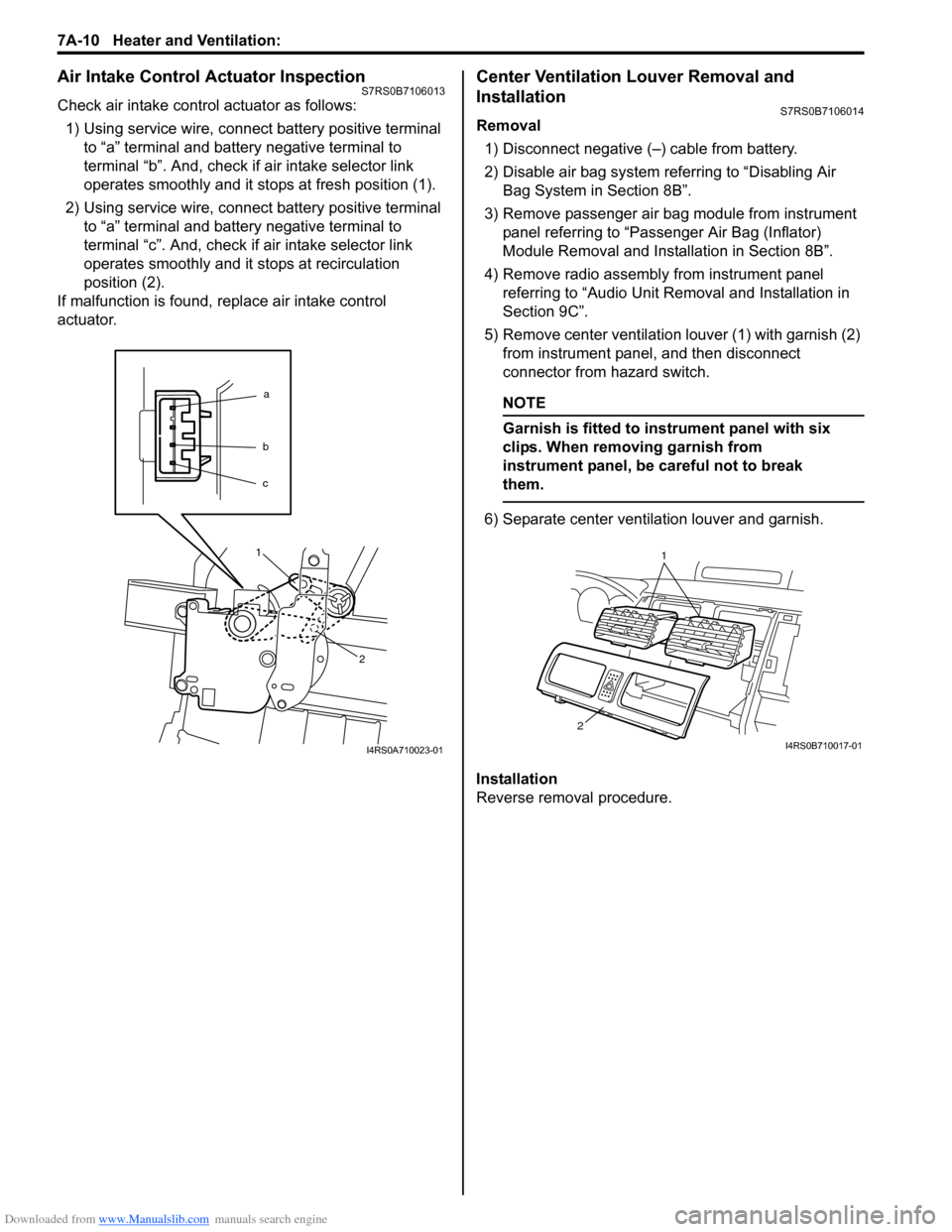

Air Intake Control Actuator InspectionS7RS0B7106013

Check air intake control actuator as follows:1) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “b”. And, check if air intake selector link

operates smoothly and it st ops at fresh position (1).

2) Using service wire, connect battery positive terminal to “a” terminal and battery negative terminal to

terminal “c”. And, check if air intake selector link

operates smoothly and it stops at recirculation

position (2).

If malfunction is found, replace air intake control

actuator.

Center Ventilation Louver Removal and

Installation

S7RS0B7106014

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

4) Remove radio assembly from instrument panel referring to “Audio Unit Re moval and Installation in

Section 9C”.

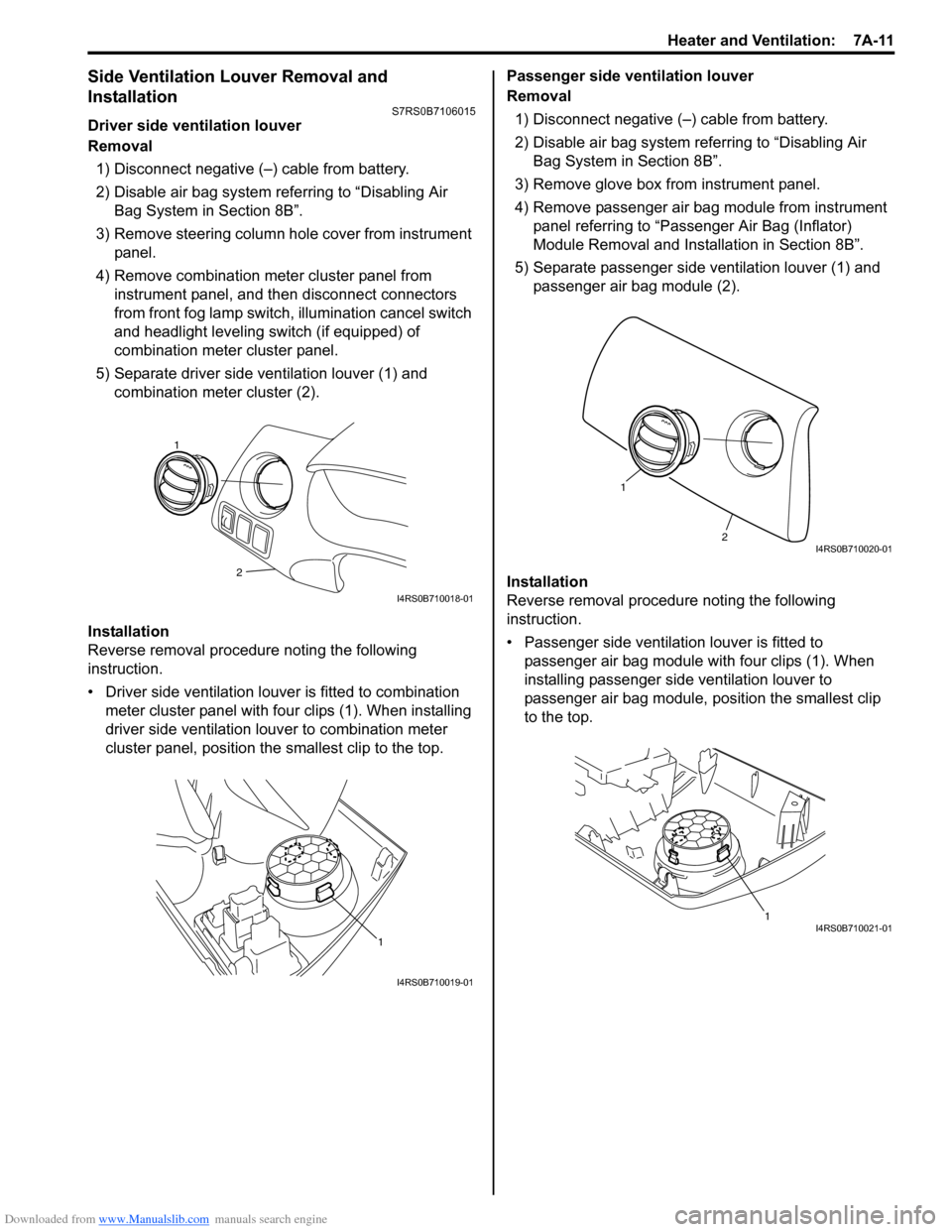

5) Remove center ventilation louver (1) with garnish (2) from instrument panel, and then disconnect

connector from hazard switch.

NOTE

Garnish is fitted to in strument panel with six

clips. When removing garnish from

instrument panel, be careful not to break

them.

6) Separate center ventilation louver and garnish.

Installation

Reverse removal procedure.

a

b

c

1

2

I4RS0A710023-01

1

2

I4RS0B710017-01

Page 947 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-11

Side Ventilation Louver Removal and

Installation

S7RS0B7106015

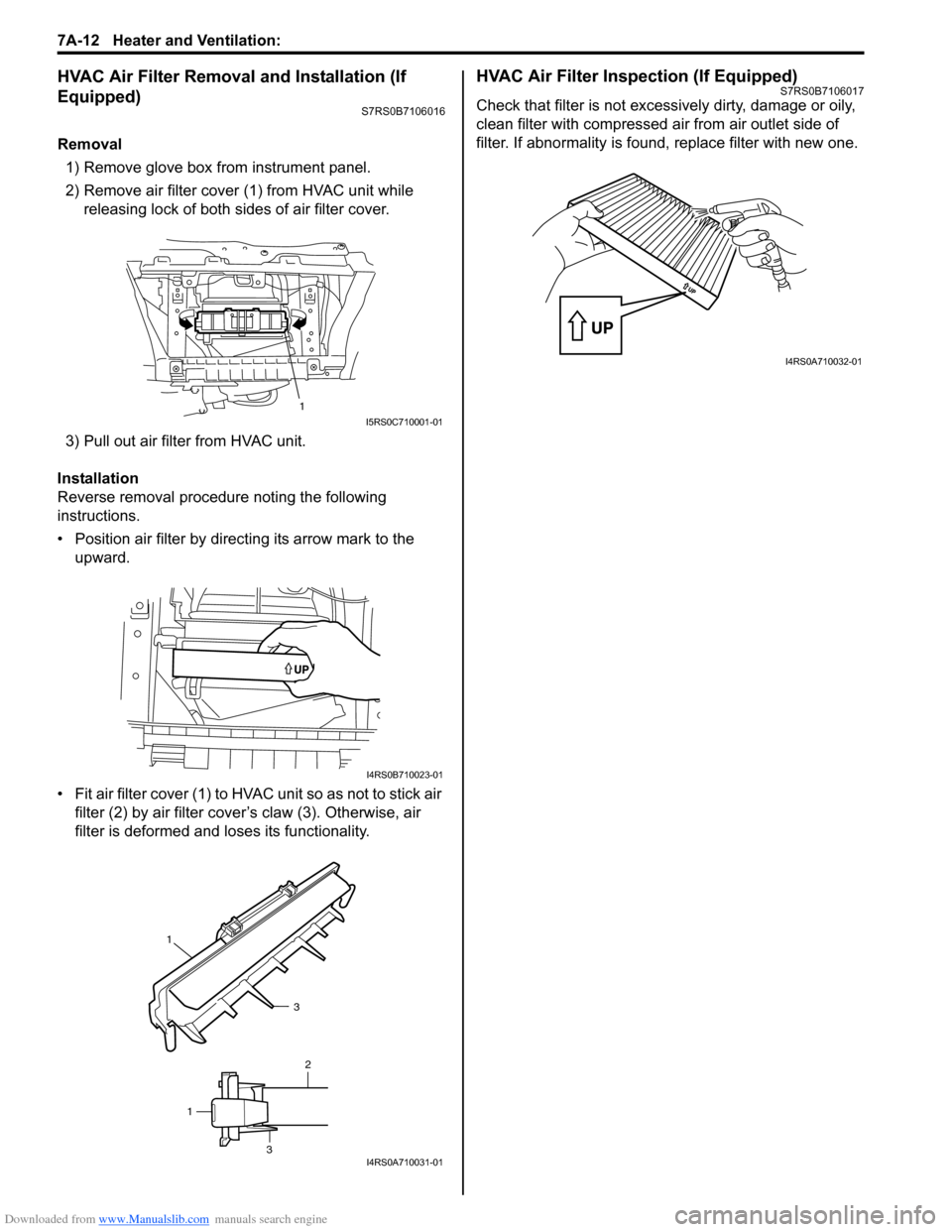

Driver side ventilation louver

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hol e cover from instrument

panel.

4) Remove combination meter cluster panel from instrument panel, and then disconnect connectors

from front fog lamp switch, illumination cancel switch

and headlight leveling switch (if equipped) of

combination meter cluster panel.

5) Separate driver side ventilation louver (1) and combination meter cluster (2).

Installation

Reverse removal procedure noting the following

instruction.

• Driver side ventilation louver is fitted to combination meter cluster panel with four clips (1). When installing

driver side ventilation louv er to combination meter

cluster panel, position the smallest clip to the top. Passenger side ventilation louver

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove glove box from instrument panel.

4) Remove passenger air bag module from instrument panel referring to “Passenger Air Bag (Inflator)

Module Removal and Installation in Section 8B”.

5) Separate passenger side ventilation louver (1) and passenger air bag module (2).

Installation

Reverse removal procedure noting the following

instruction.

• Passenger side ventilation louver is fitted to passenger air bag module with four clips (1). When

installing passenger side ventilation louver to

passenger air bag module, position the smallest clip

to the top.

2

1

I4RS0B710018-01

1

I4RS0B710019-01

2

1

I4RS0B710020-01

1I4RS0B710021-01

Page 948 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

HVAC Air Filter Removal and Installation (If

Equipped)

S7RS0B7106016

Removal1) Remove glove box from instrument panel.

2) Remove air filter cover (1) from HVAC unit while

releasing lock of both sides of air filter cover.

3) Pull out air filter from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the upward.

• Fit air filter cover (1) to HVAC unit so as not to stick air

filter (2) by air filter cove r’s claw (3). Otherwise, air

filter is deformed and loses its functionality.

HVAC Air Filter Inspection (If Equipped)S7RS0B7106017

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1I5RS0C710001-01

I4RS0B710023-01

1

3

2

1

3I4RS0A710031-01

I4RS0A710032-01

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

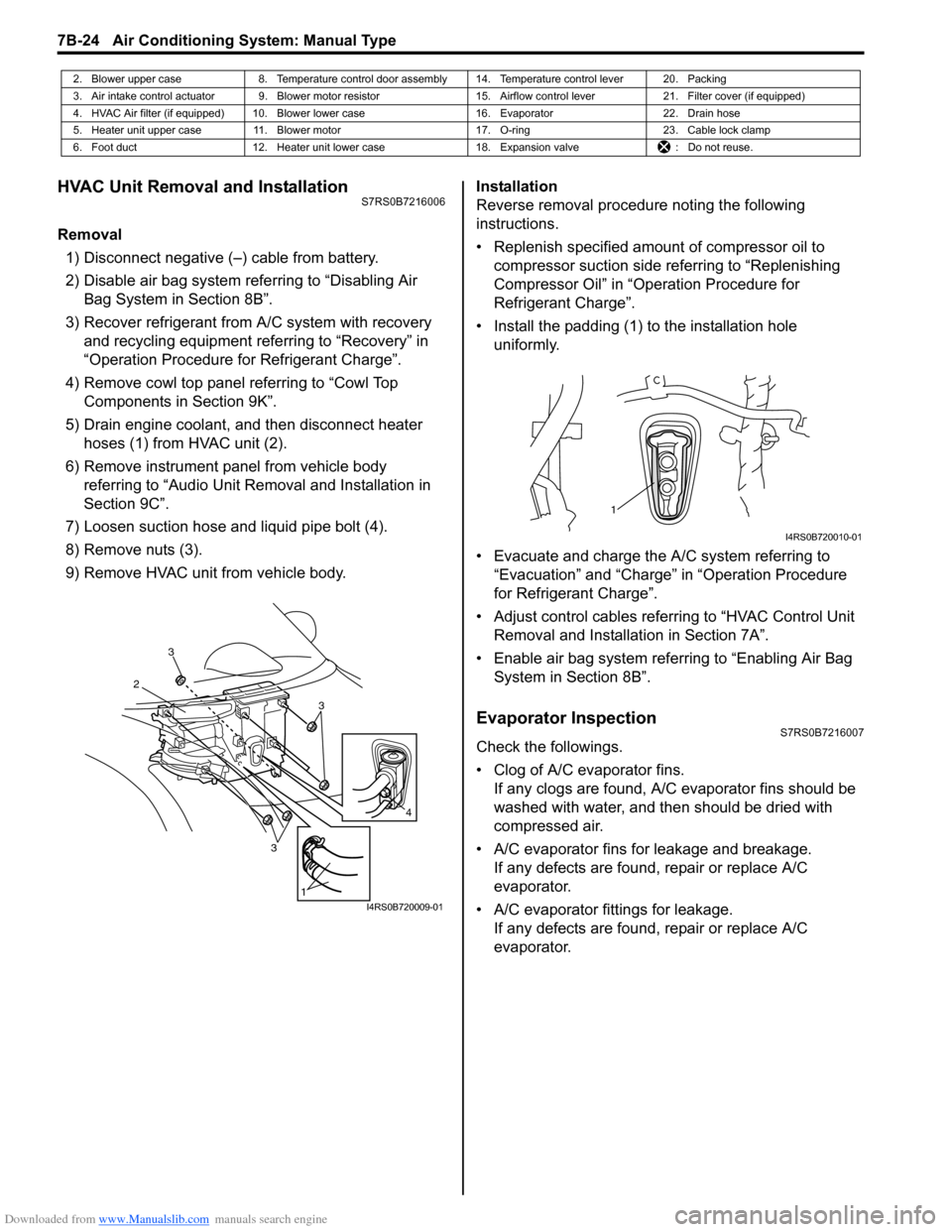

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 990 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-42 Air Conditioning System: Automatic Type

Abnormal Noise Symptom Diagnosis of A/C

System

S7RS0B7224002

Refer to “Abnormal Noise Symptom Diagnosis of A/C

System”.

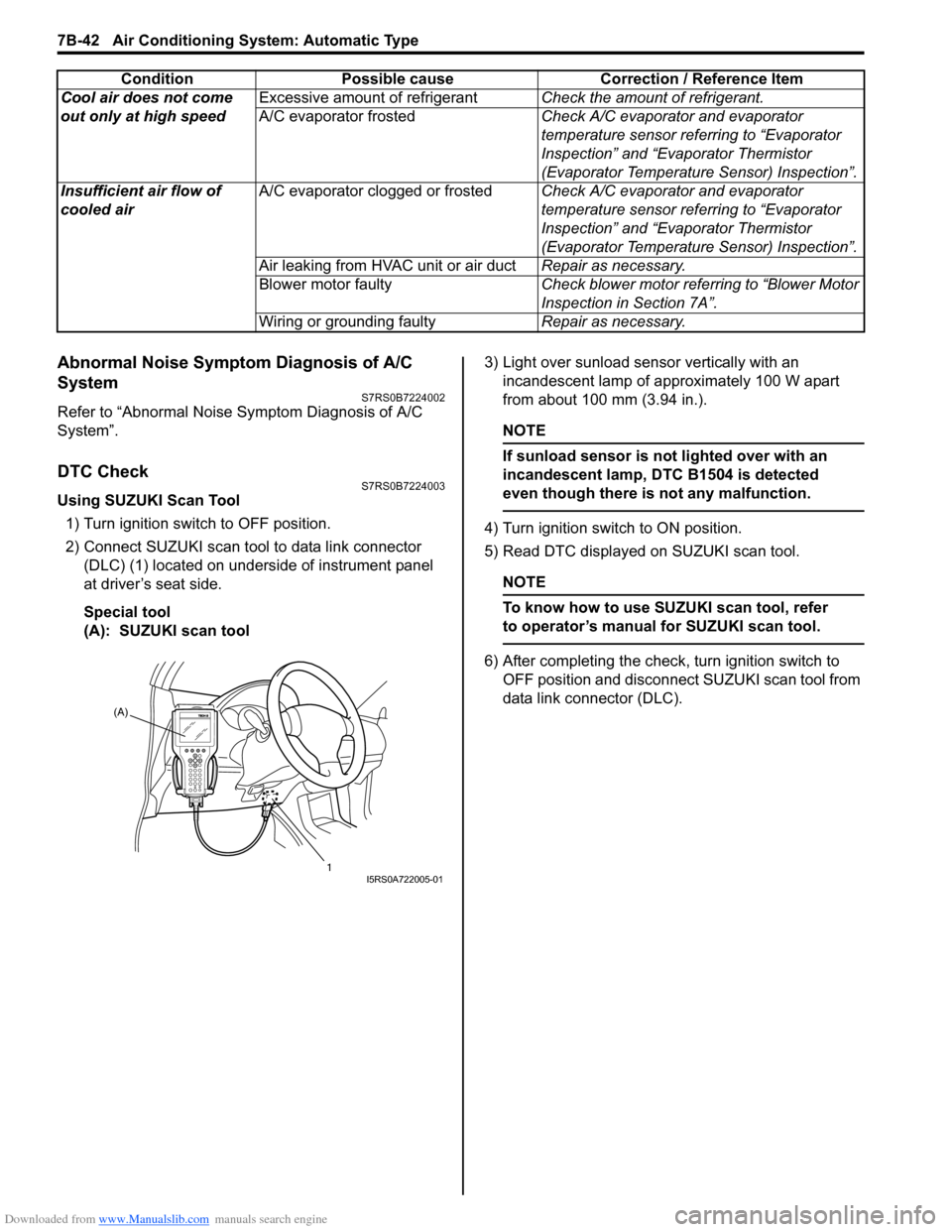

DTC CheckS7RS0B7224003

Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool 3) Light over sunload sensor vertically with an

incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

even though there is not any malfunction.

4) Turn ignition switch to ON position.

5) Read DTC displayed on SUZUKI scan tool.

NOTE

To know how to use SUZUKI scan tool, refer

to operator’s manual for SUZUKI scan tool.

6) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

data link connector (DLC).

Cool air does not come

out only at high speed

Excessive amount of refrigerant

Check the amount of refrigerant.

A/C evaporator frosted Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Insufficient air flow of

cooled air A/C evaporator clogged or frosted

Check A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Thermistor

(Evaporator Temperature Sensor) Inspection”.

Air leaking from HVAC unit or air duct Repair as necessary.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faulty Repair as necessary.

Condition Possible cause Correction / Reference Item

(A)

1

I5RS0A722005-01

Page 991 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-43

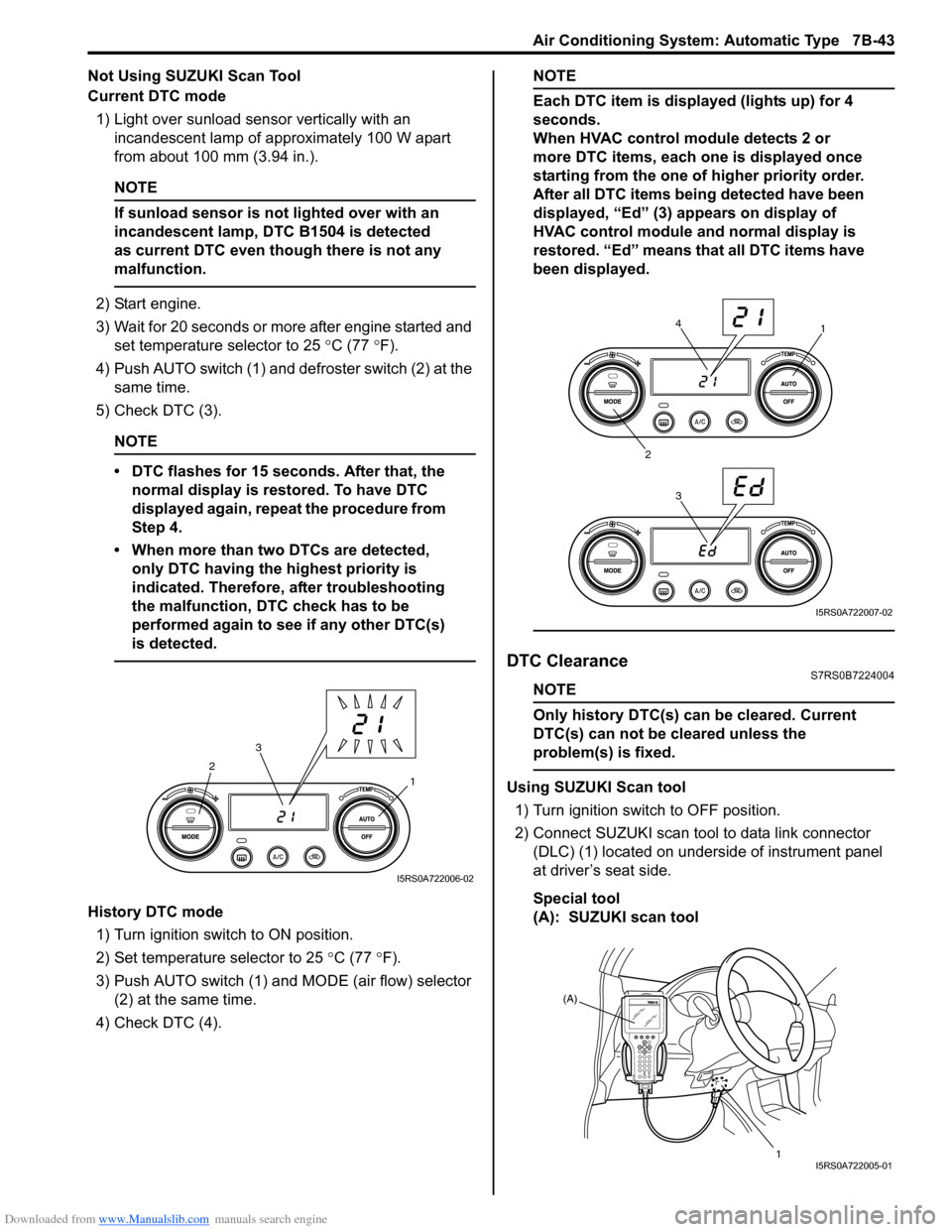

Not Using SUZUKI Scan Tool

Current DTC mode1) Light over sunload sensor vertically with an incandescent lamp of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent lamp, DTC B1504 is detected

as current DTC even though there is not any

malfunction.

2) Start engine.

3) Wait for 20 seconds or more after engine started and set temperature selector to 25 °C (77 °F).

4) Push AUTO switch (1) and defroster switch (2) at the same time.

5) Check DTC (3).

NOTE

• DTC flashes for 15 seconds. After that, the normal display is rest ored. To have DTC

displayed again, repeat the procedure from

Step 4.

• When more than two DTCs are detected, only DTC having the highest priority is

indicated. Therefore, after troubleshooting

the malfunction, DTC check has to be

performed again to see if any other DTC(s)

is detected.

History DTC mode

1) Turn ignition switch to ON position.

2) Set temperature selector to 25 °C (77 °F).

3) Push AUTO switch (1) and MODE (air flow) selector

(2) at the same time.

4) Check DTC (4).

NOTE

Each DTC item is displayed (lights up) for 4

seconds.

When HVAC control module detects 2 or

more DTC items, each one is displayed once

starting from the one of higher priority order.

After all DTC items being detected have been

displayed, “Ed” (3) appears on display of

HVAC control module and normal display is

restored. “Ed” means that all DTC items have

been displayed.

DTC ClearanceS7RS0B7224004

NOTE

Only history DTC(s) can be cleared. Current

DTC(s) can not be cleared unless the

problem(s) is fixed.

Using SUZUKI Scan tool

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool1

2

3

I5RS0A722006-02

1

2 34

I5RS0A722007-02

(A)

1

I5RS0A722005-01