Water pump SUZUKI SWIFT 2007 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 417 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

Battery Dismounting and RemountingS7RS0B1A06002

WARNING!

When handling battery, following safety

precautions should be followed:

• Hydrogen gas is produced by battery. A flame or spark near battery may cause the

gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing or other fabric. Any spilled

electrolyte should be flushed with large

quantity of water and cleaned immediately.

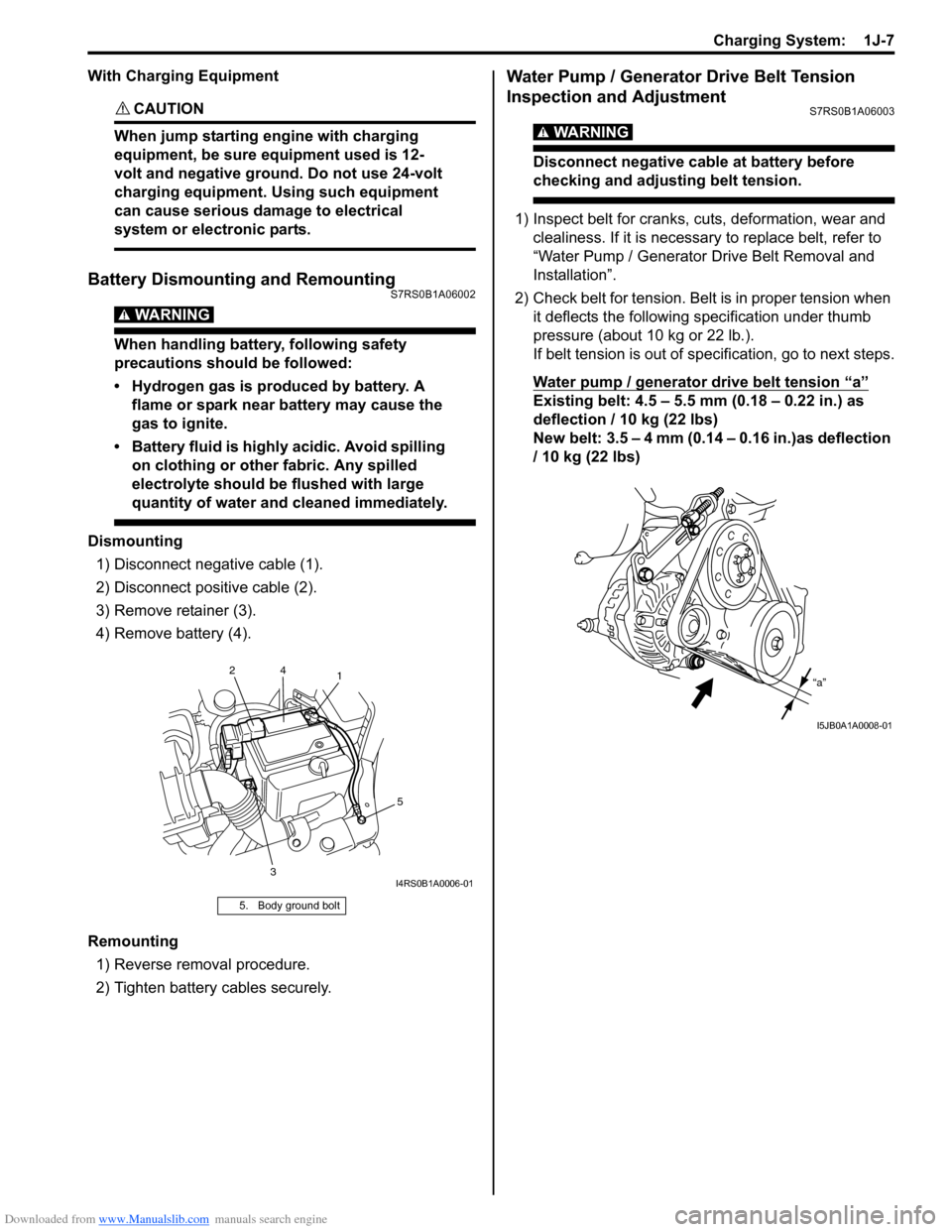

Dismounting

1) Disconnect negative cable (1).

2) Disconnect positive cable (2).

3) Remove retainer (3).

4) Remove battery (4).

Remounting 1) Reverse removal procedure.

2) Tighten battery cables securely.

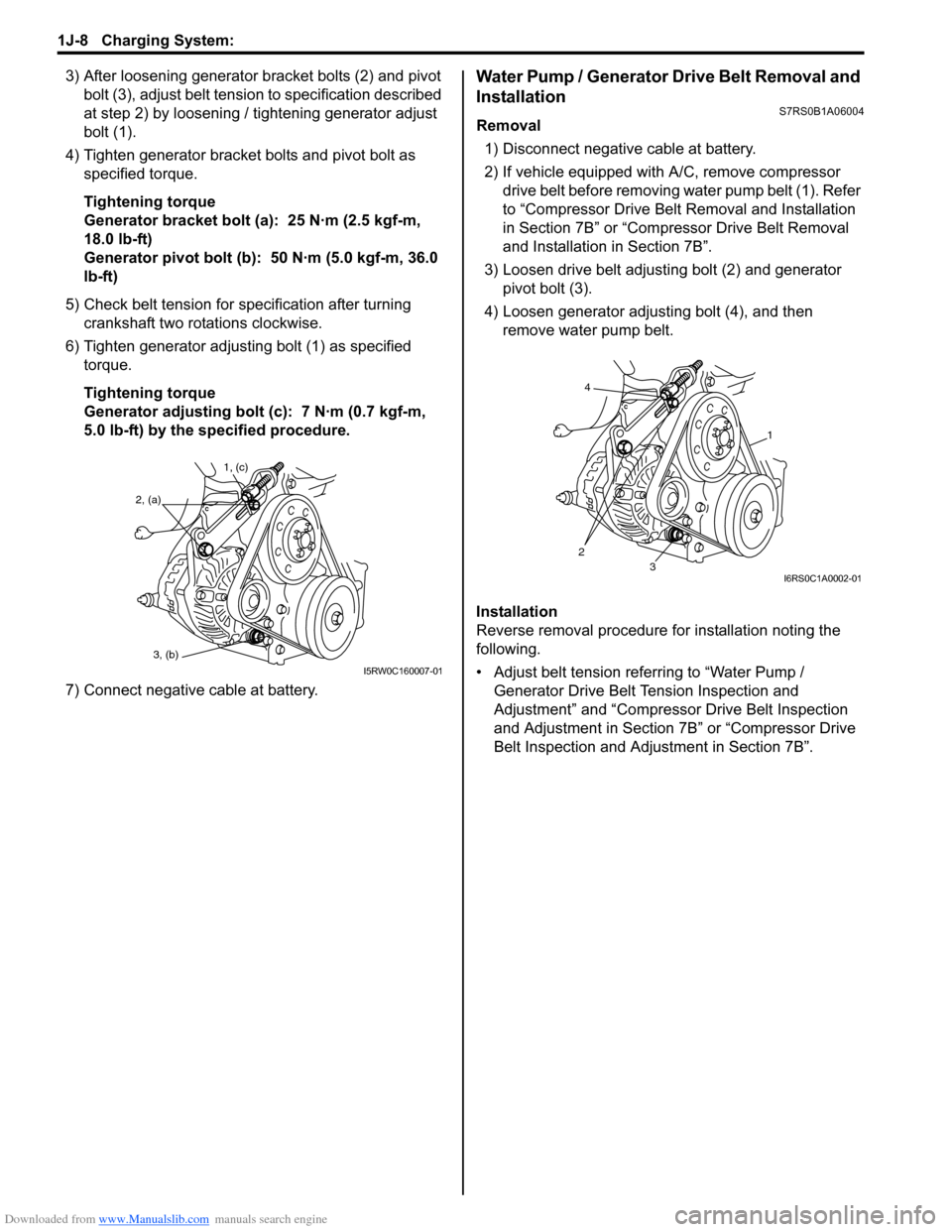

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S7RS0B1A06003

WARNING!

Disconnect negative cable at battery before

checking and adjusting belt tension.

1) Inspect belt for cranks, cuts, deformation, wear and clealiness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when it deflects the following specification under thumb

pressure (about 10 kg or 22 lb.).

If belt tension is out of spec ification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 3.5 – 4 mm (0.14 – 0.16 in.)as deflection

/ 10 kg (22 lbs)

5. Body ground bolt

1

3 5

2

4

I4RS0B1A0006-01

“a”

I5JB0A1A0008-01

Page 418 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

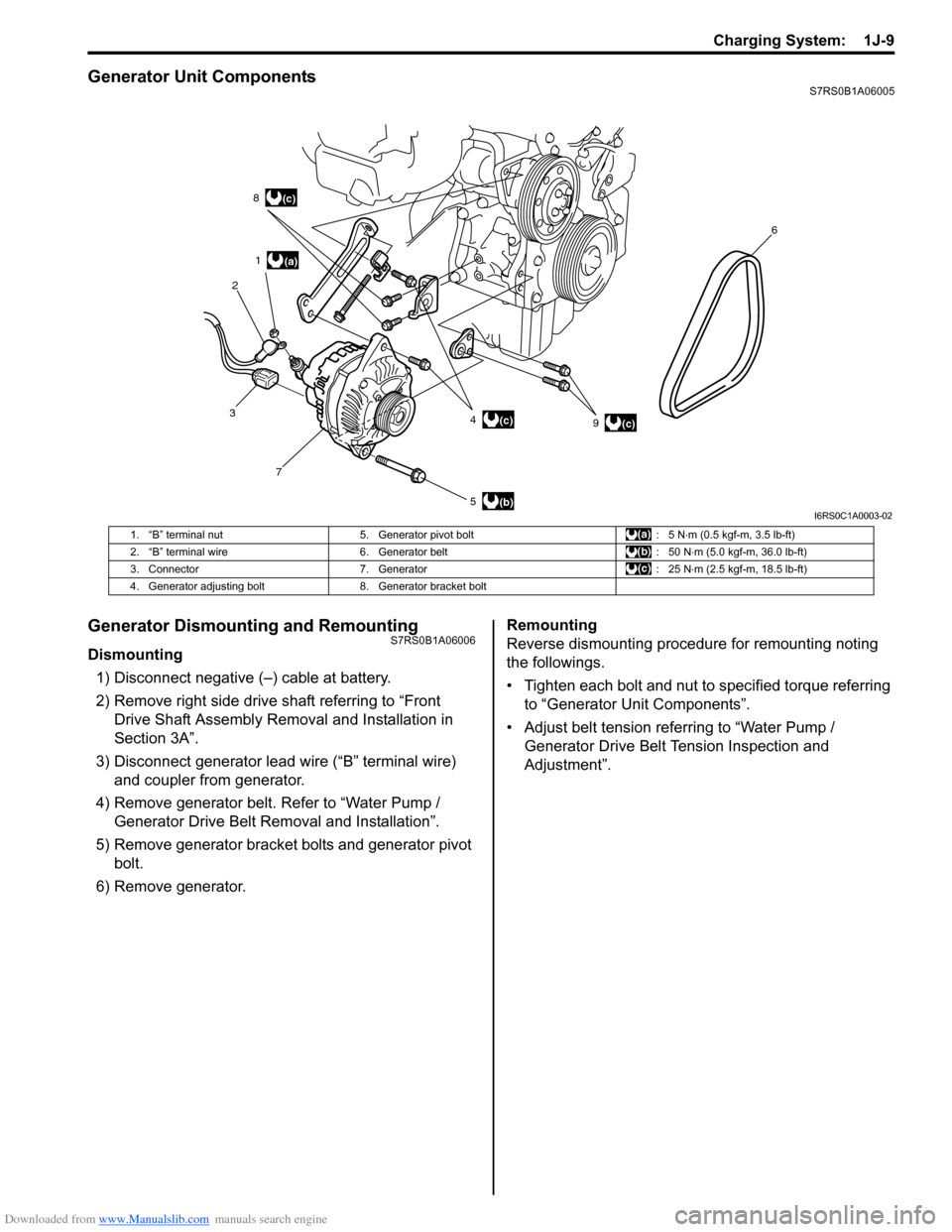

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 419 of 1496

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

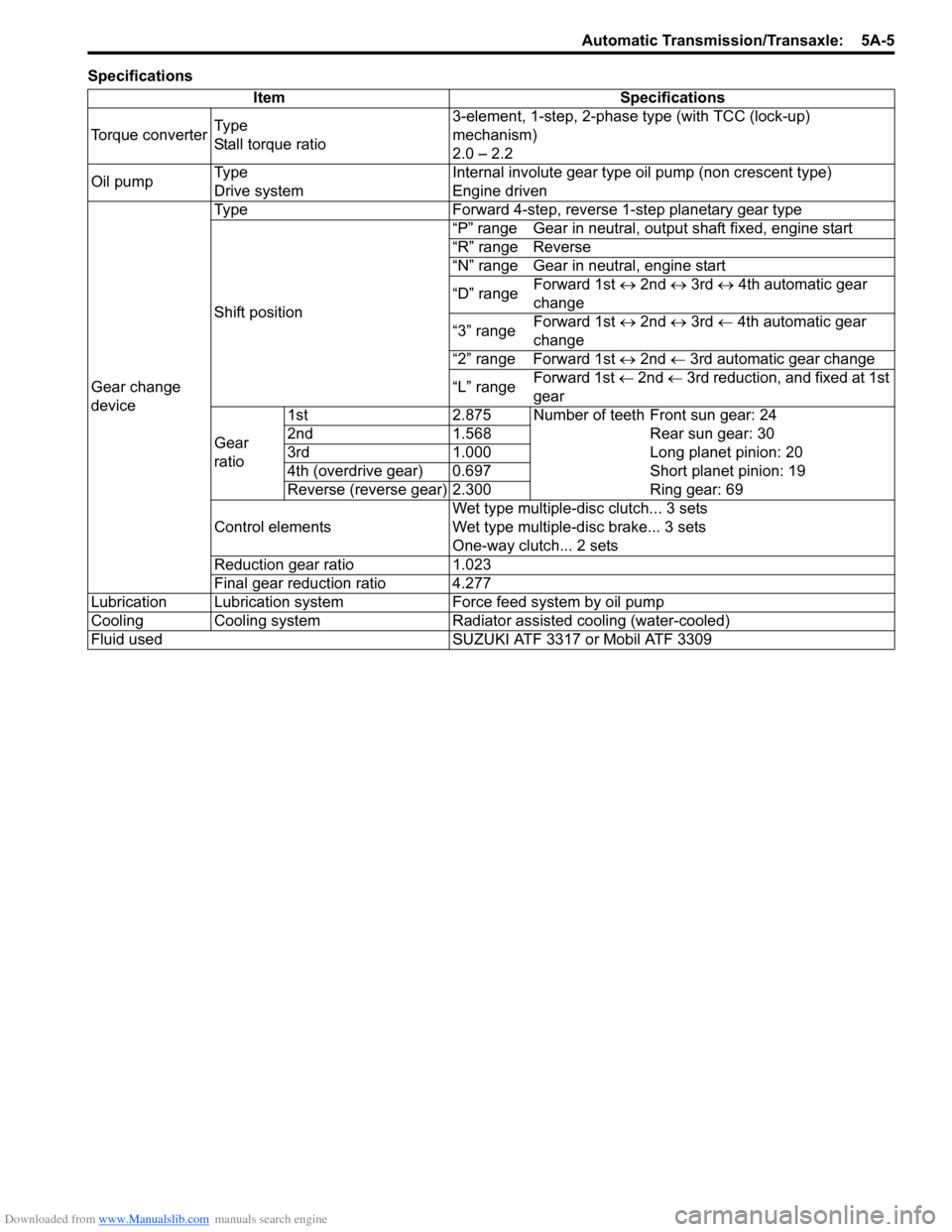

Generator Unit ComponentsS7RS0B1A06005

Generator Dismounting and RemountingS7RS0B1A06006

Dismounting1) Disconnect negative (–) cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in

Section 3A”.

3) Disconnect generator lead wire (“B” terminal wire) and coupler from generator.

4) Remove generator belt. Refer to “Water Pump / Generator Drive Belt Re moval and Installation”.

5) Remove generator bracket bolts and generator pivot bolt.

6) Remove generator. Remounting

Reverse dismounting procedure for remounting noting

the followings.

• Tighten each bolt and nut to specified torque referring

to “Generator Unit Components”.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment”.

(a)

(b)

(c)

1

2 8

3 7 5 49 6(c)

(c)

I6RS0C1A0003-02

1. “B” terminal nut

5. Generator pivot bolt : 5 N⋅m (0.5 kgf-m, 3.5 lb-ft)

2. “B” terminal wire 6. Generator belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator : 25 N⋅m (2.5 kgf-m, 18.5 lb-ft)

4. Generator adjusting bolt 8. Generator bracket bolt

Page 649 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-5

SpecificationsItem Specifications

Torque converter Ty p e

Stall torque ratio 3-element, 1-step, 2-phase type (with TCC (lock-up)

mechanism)

2.0 – 2.2

Oil pump Ty p e

Drive system Internal involute gear type oil pump (non crescent type)

Engine driven

Gear change

device Type Forward 4-step, reverse 1-step planetary gear type

Shift position

“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

Forward 1st

↔ 2nd ↔ 3rd ↔ 4th automatic gear

change

“3” range Forward 1st

↔ 2nd ↔ 3rd ← 4th automatic gear

change

“2” range Forward 1st ↔ 2nd ← 3rd automatic gear change

“L” range Forward 1st

← 2nd ← 3rd reduction, and fixed at 1st

gear

Gear

ratio 1st 2.875 Number of teeth Front sun gear: 24

2nd 1.568 Rear sun gear: 30

3rd 1.000 Long planet pinion: 20

4th (overdrive gear) 0.697 Short planet pinion: 19

Reverse (reverse gear) 2.300 Ring gear: 69

Control elements Wet type multiple-disc clutch... 3 sets

Wet type multiple-d

isc brake... 3 sets

One-way clutch... 2 sets

Reduction gear ratio 1.023

Final gear reduction ratio 4.277

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used SUZUKI ATF 3317 or Mobil ATF 3309