ignition coil check SUZUKI SWIFT 2007 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 250 of 1496

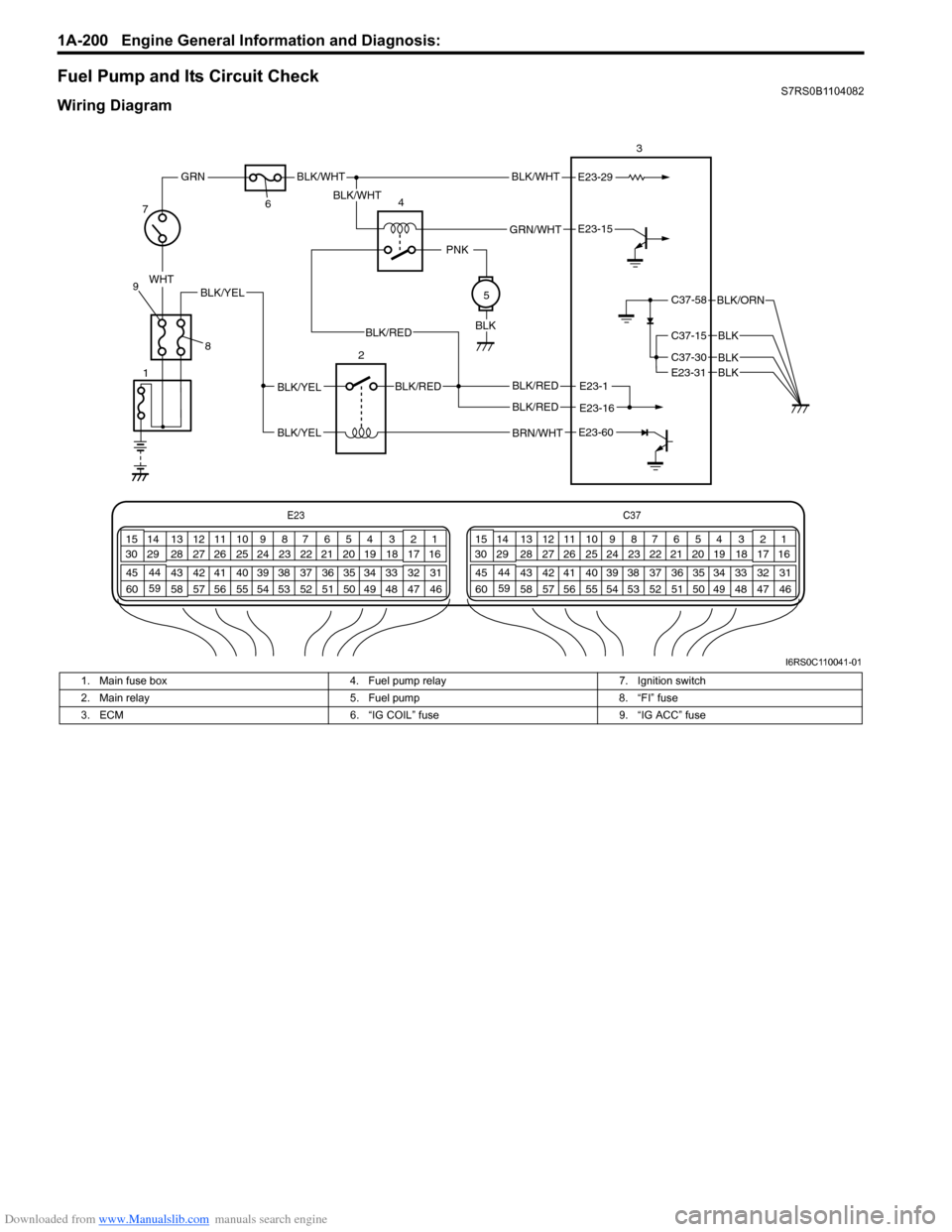

Downloaded from www.Manualslib.com manuals search engine 1A-200 Engine General Information and Diagnosis:

Fuel Pump and Its Circuit CheckS7RS0B1104082

Wiring Diagram

E23-1

E23-60

E23-15

BRN/WHT

BLK/REDBLK/YEL

BLK/YEL

BLK/RED

E23-29BLK/WHT

GRN/WHT

BLK/WHT

BLK/WHT

PNK

BLK

WHT

GRN

C37-58

C37-15

C37-30

BLK/ORN

BLK

BLKE23-31BLK

78

9 6

4 3

2 5

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/YEL

1

E23-16BLK/RED

BLK/RED

I6RS0C110041-01

1. Main fuse box 4. Fuel pump relay 7. Ignition switch

2. Main relay 5. Fuel pump 8. “FI” fuse

3. ECM 6. “IG COIL” fuse 9. “IG ACC” fuse

Page 259 of 1496

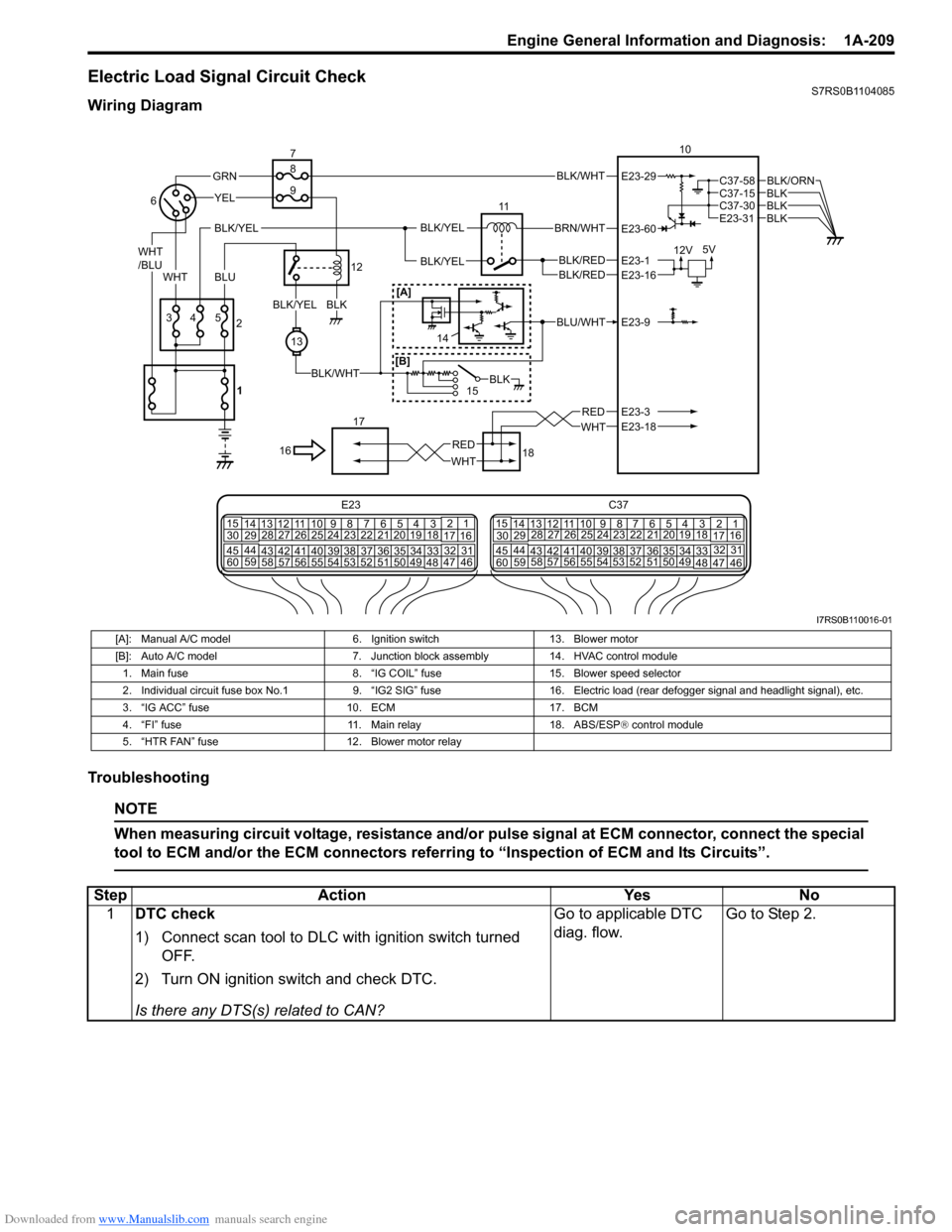

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-209

Electric Load Signal Circuit CheckS7RS0B1104085

Wiring Diagram

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

BLK/WHT

BLK/RED

WHT

BRN/WHT

12V5V

11

BLK/YELBLK/YEL

BLK/YEL

BLKBLKBLK

BLK/ORN

10

18

17

BLU/WHT

15

WHTRED

43

YEL

5

13

BLK/WHT

BLKBLK/YEL

GRN

WHT

/BLU

BLU

16

2

6

7

12

8

9

BLK

WHT

RED

E23-29

E23-60

E23-1E23-16

E23-9

E23-3E23-18

C37-58C37-15

E23-31C37-30

BLK/RED

[A]

[B]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

1

14

I7RS0B110016-01

[A]: Manual A/C model

6. Ignition switch13. Blower motor

[B]: Auto A/C model 7. Junction block assembly14. HVAC control module

1. Main fuse 8. “IG COIL” fuse15. Blower speed selector

2. Individual circuit fuse box No.1 9. “IG2 SIG” fuse16. Electric load (rear defogger signal and headlight signal), etc.

3. “IG ACC” fuse 10. ECM17. BCM

4. “FI” fuse 11. Main relay18. ABS/ESP® control module

5. “HTR FAN” fuse 12. Blower motor relay

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there any DTS(s) related to CAN? Go to applicable DTC

diag. flow.

Go to Step 2.

Page 284 of 1496

Downloaded from www.Manualslib.com manuals search engine 1C-12 Engine Electrical Devices:

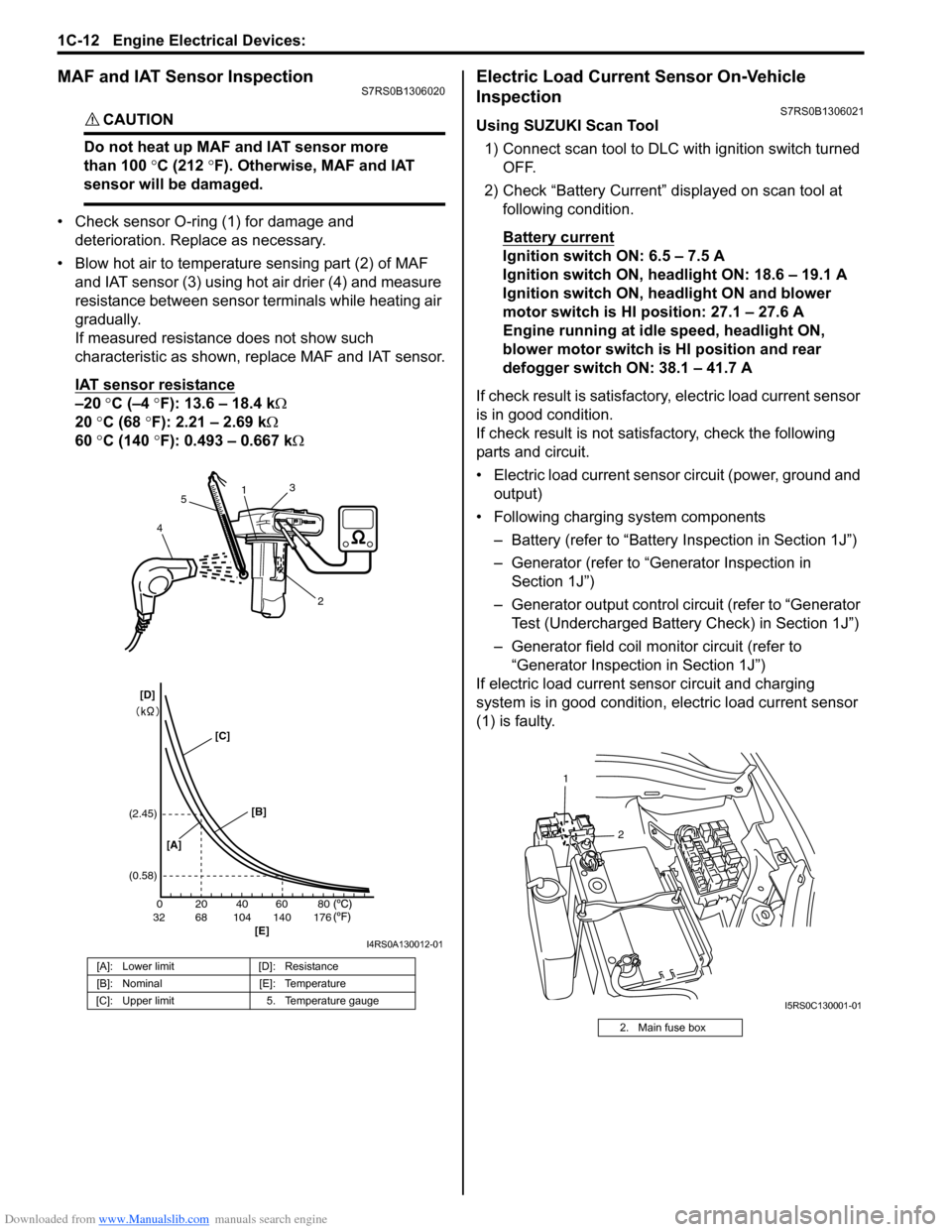

MAF and IAT Sensor InspectionS7RS0B1306020

CAUTION!

Do not heat up MAF and IAT sensor more

than 100 °C (212 °F). Otherwise, MAF and IAT

sensor will be damaged.

• Check sensor O-ring (1) for damage and deterioration. Replace as necessary.

• Blow hot air to temperature sensing part (2) of MAF and IAT sensor (3) using hot air drier (4) and measure

resistance between sensor terminals while heating air

gradually.

If measured resistance does not show such

characteristic as shown, replace MAF and IAT sensor.

IAT sensor resistance

–20 °C (–4 °F): 13.6 – 18.4 k Ω

20 °C (68 °F): 2.21 – 2.69 k Ω

60 °C (140 °F): 0.493 – 0.667 k Ω

Electric Load Current Sensor On-Vehicle

Inspection

S7RS0B1306021

Using SUZUKI Scan Tool

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Check “Battery Current” displayed on scan tool at following condition.

Battery current

Ignition switch ON: 6.5 – 7.5 A

Ignition switch ON, headlight ON: 18.6 – 19.1 A

Ignition switch ON, headlight ON and blower

motor switch is HI position: 27.1 – 27.6 A

Engine running at idle speed, headlight ON,

blower motor switch is HI position and rear

defogger switch ON: 38.1 – 41.7 A

If check result is satisfactory, electric load current sensor

is in good condition.

If check result is not satisf actory, check the following

parts and circuit.

• Electric load current sensor circuit (power, ground and output)

• Following charging system components

– Battery (refer to “Battery Inspection in Section 1J”)

– Generator (refer to “Generator Inspection in Section 1J”)

– Generator output control ci rcuit (refer to “Generator

Test (Undercharged Battery Check) in Section 1J”)

– Generator field coil monitor circuit (refer to “Generator Inspection in Section 1J”)

If electric load current sensor circuit and charging

system is in good condition, electric load current sensor

(1) is faulty.

[A]: Lower limit [D]: Resistance

[B]: Nominal [E]: Temperature

[C]: Upper limit 5. Temperature gauge

200

6832104 140 17640 60 80

(2.45)

(0.58)

1

2

3

4 5

[A] [B]

[E]

[C]

[D]

I4RS0A130012-01

2. Main fuse box

2

1

I5RS0C130001-01

Page 289 of 1496

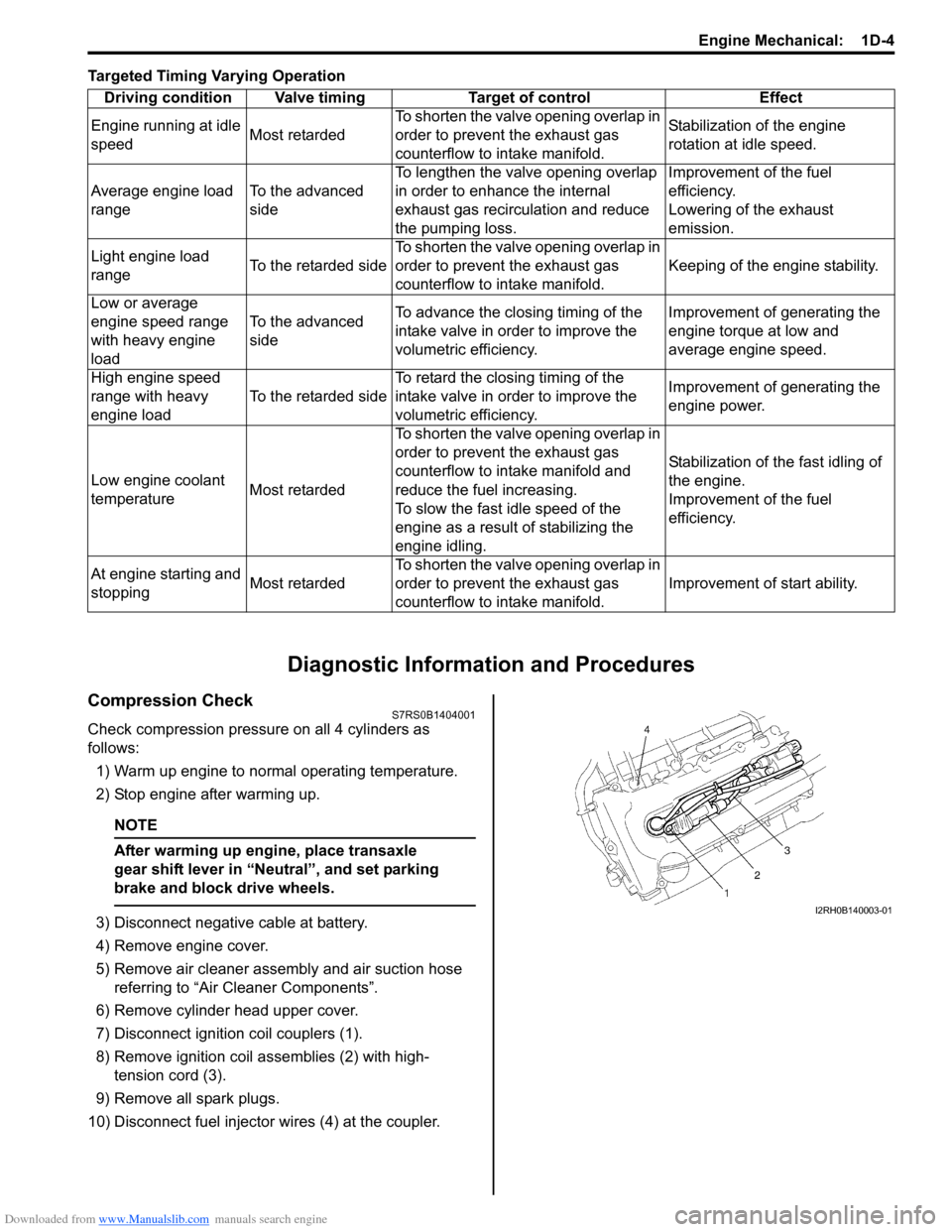

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-4

Targeted Timing Varying Operation

Diagnostic Information and Procedures

Compression CheckS7RS0B1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

3) Disconnect negative cable at battery.

4) Remove engine cover.

5) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

6) Remove cylinder head upper cover.

7) Disconnect ignition coil couplers (1).

8) Remove ignition coil assemblies (2) with high- tension cord (3).

9) Remove all spark plugs.

10) Disconnect fuel injector wires (4) at the coupler. Driving condition Valve timing Target of control Effect

Engine running at idle

speed Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Stabilization of the engine

rotation at idle speed.

Average engine load

range To the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss. Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range To the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load To the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine power.

Low engine coolant

temperature Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling. Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Improvement of start ability.I2RH0B140003-01

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

11) Connect negative cable at battery.

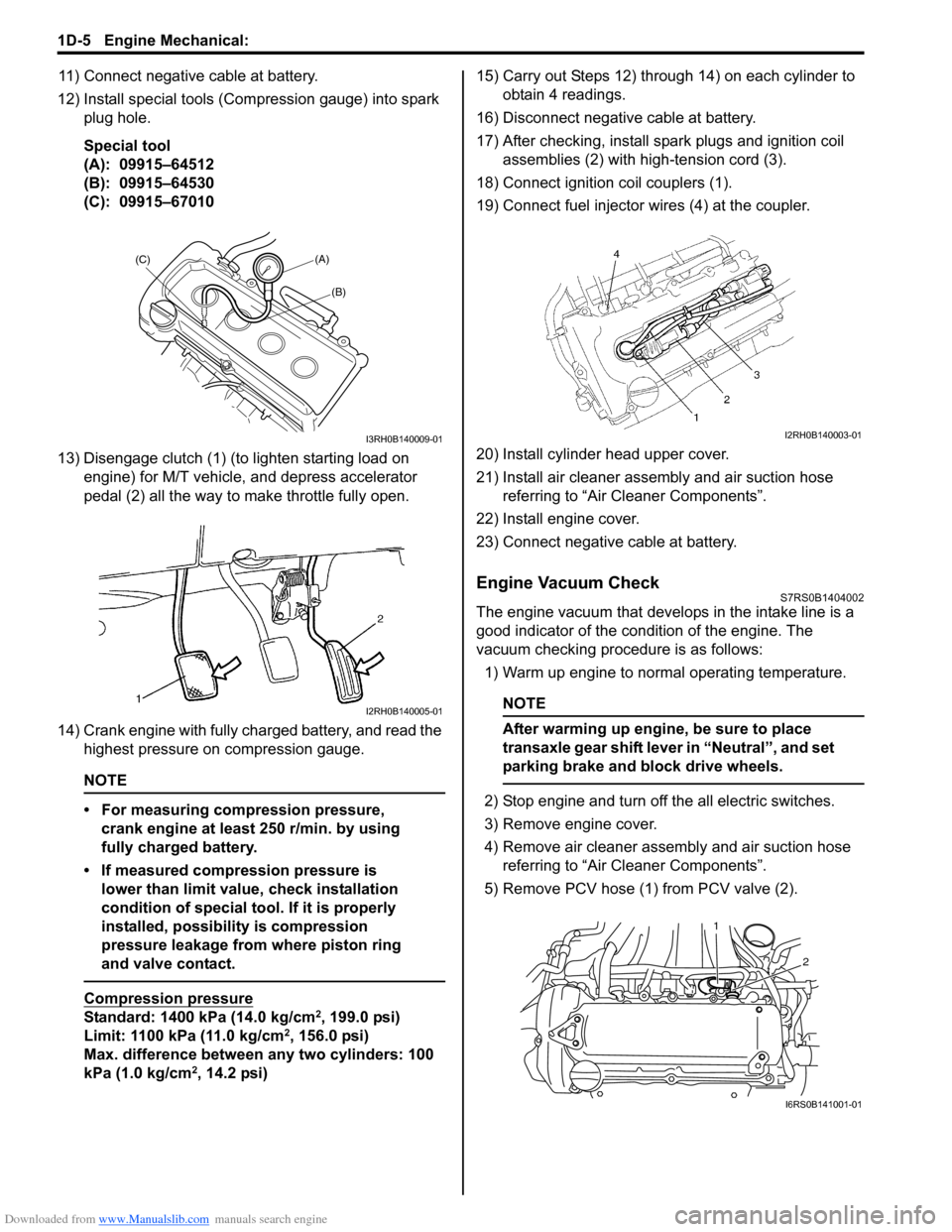

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

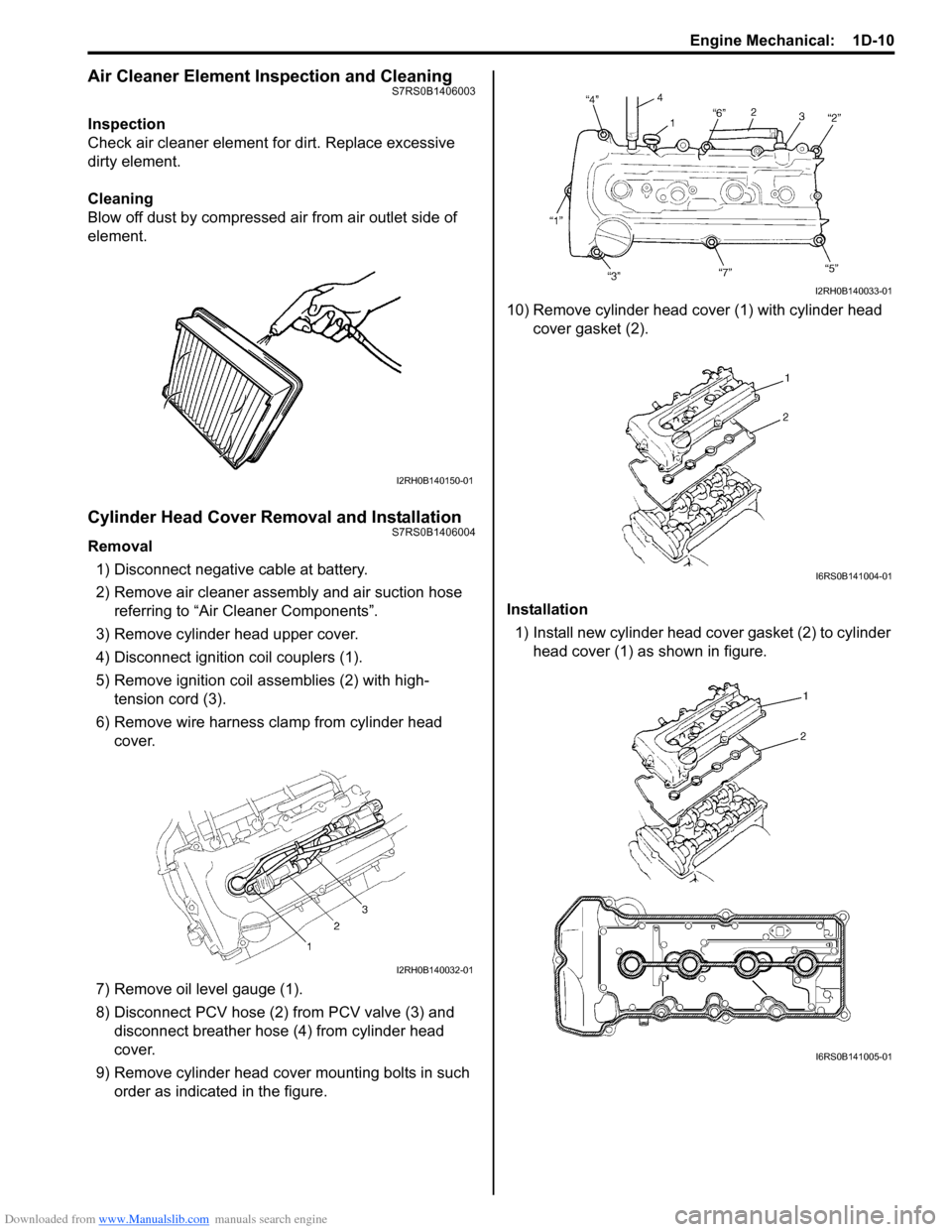

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 295 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-10

Air Cleaner Element Inspection and CleaningS7RS0B1406003

Inspection

Check air cleaner element for dirt. Replace excessive

dirty element.

Cleaning

Blow off dust by compressed air from air outlet side of

element.

Cylinder Head Cover Removal and InstallationS7RS0B1406004

Removal1) Disconnect negative cable at battery.

2) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

3) Remove cylinder head upper cover.

4) Disconnect ignition coil couplers (1).

5) Remove ignition coil assemblies (2) with high- tension cord (3).

6) Remove wire harness clamp from cylinder head cover.

7) Remove oil level gauge (1).

8) Disconnect PCV hose (2) from PCV valve (3) and disconnect breather hose (4) from cylinder head

cover.

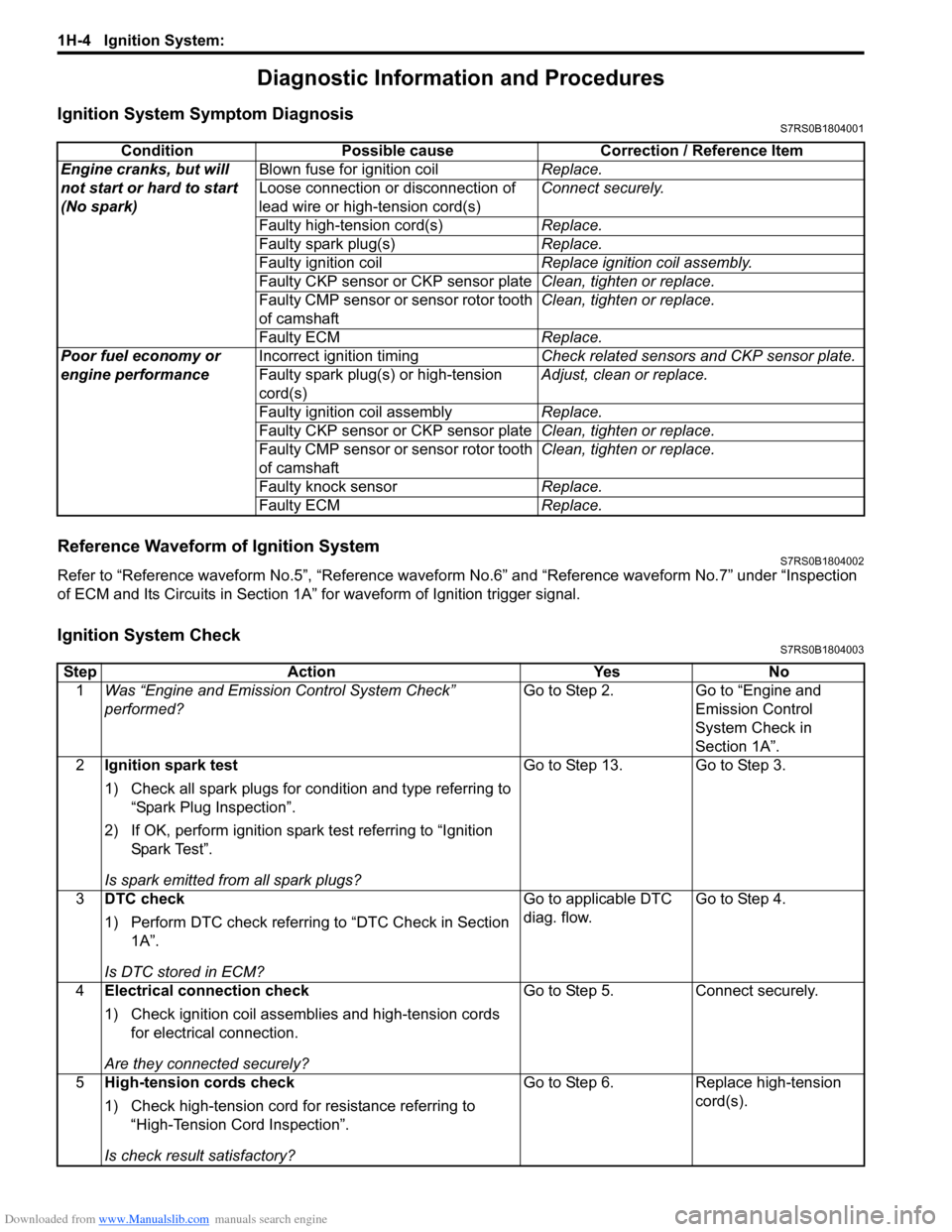

9) Remove cylinder head cove r mounting bolts in such

order as indicated in the figure. 10) Remove cylinder head cover (1) with cylinder head

cover gasket (2).

Installation 1) Install new cylinder head cover gasket (2) to cylinder

head cover (1) as shown in figure.

I2RH0B140150-01

I2RH0B140032-01

I2RH0B140033-01

I6RS0B141004-01

I6RS0B141005-01

Page 396 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-4 Ignition System:

Diagnostic Information and Procedures

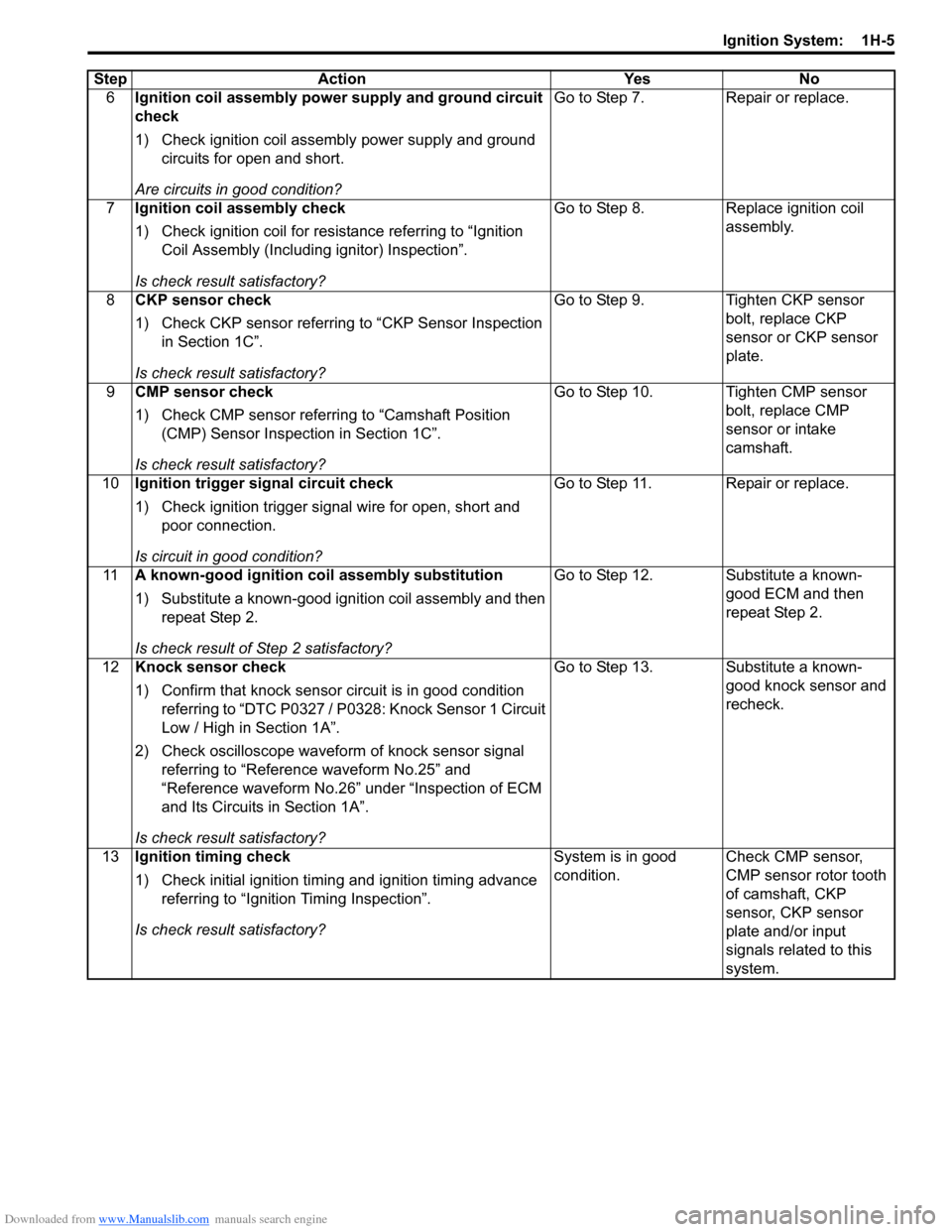

Ignition System Symptom DiagnosisS7RS0B1804001

Reference Waveform of Ignition SystemS7RS0B1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS7RS0B1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark) Blown fuse for ignition coil

Replace.

Loose connection or disconnection of

lead wire or high-tension cord(s) Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performance Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaft Clean, tighten or replace.

Faulty knock sensor Replace.

Faulty ECM Replace.

StepAction YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2 Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition Spar k Tes t”.

Is spark emitted from all spark plugs? Go to Step 13. Go to Step 3.

3 DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely? Go to Step 5.

Connect securely.

5 High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory? Go to Step 6.

Replace high-tension

cord(s).

Page 397 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-5

6Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition? Go to Step 7.

Repair or replace.

7 Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Including ignitor) Inspection”.

Is check result satisfactory? Go to Step 8.

Replace ignition coil

assembly.

8 CKP sensor check

1) Check CKP sensor referring to “CKP Sensor Inspection

in Section 1C”.

Is check result satisfactory? Go to Step 9.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

9 CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor Inspection in Section 1C”.

Is check result satisfactory? Go to Step 10. Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

10 Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition? Go to Step 11. Repair or replace.

11 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory? Go to Step 12. Substitute a known-

good ECM and then

repeat Step 2.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.25” and

“Reference waveform No.26” under “Inspection of ECM

and Its Circuits in Section 1A”.

Is check result satisfactory? Go to Step 13. Substitute a known-

good knock sensor and

recheck.

13 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory? System is in good

condition.

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Step

Action YesNo

Page 398 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-6 Ignition System:

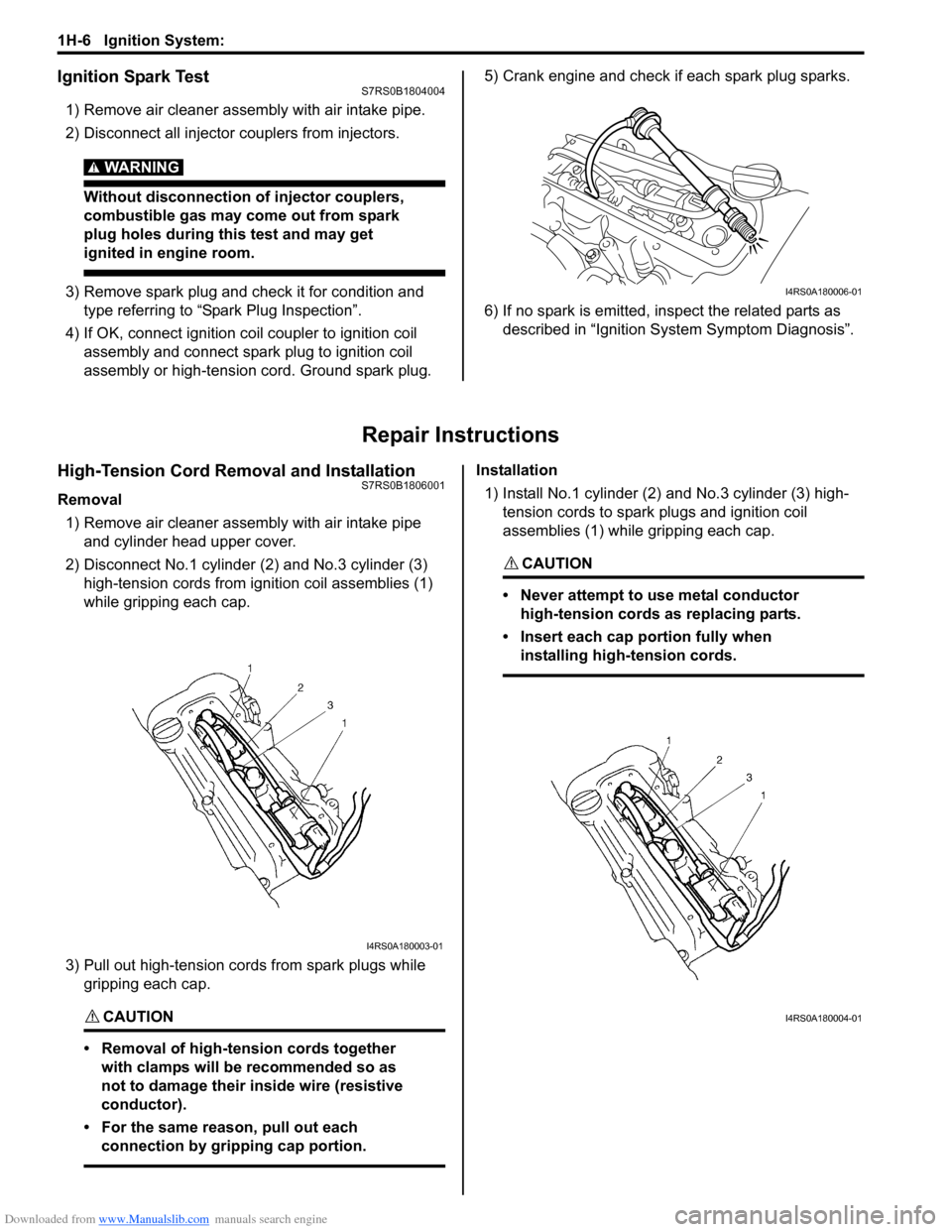

Ignition Spark TestS7RS0B1804004

1) Remove air cleaner assembly with air intake pipe.

2) Disconnect all injector couplers from injectors.

WARNING!

Without disconnection of injector couplers,

combustible gas may come out from spark

plug holes during this test and may get

ignited in engine room.

3) Remove spark plug and check it for condition and

type referring to “Spark Plug Inspection”.

4) If OK, connect ignition coil coupler to ignition coil assembly and connect spark plug to ignition coil

assembly or high-tension cord. Ground spark plug. 5) Crank engine and check if each spark plug sparks.

6) If no spark is emitted, inspect the related parts as

described in “Ignition System Symptom Diagnosis”.

Repair Instructions

High-Tension Cord Removal and InstallationS7RS0B1806001

Removal

1) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

2) Disconnect No.1 cylinder (2) and No.3 cylinder (3)

high-tension cords from ignition coil assemblies (1)

while gripping each cap.

3) Pull out high-tension cords from spark plugs while gripping each cap.

CAUTION!

• Removal of high-tension cords together with clamps will be recommended so as

not to damage their inside wire (resistive

conductor).

• For the same reason, pull out each connection by gripping cap portion.

Installation

1) Install No.1 cylinder (2) and No.3 cylinder (3) high-

tension cords to spark plugs and ignition coil

assemblies (1) while gripping each cap.

CAUTION!

• Never attempt to use metal conductor high-tension cords as replacing parts.

• Insert each cap portion fully when installing high-tension cords.

I4RS0A180006-01

I4RS0A180003-01

I4RS0A180004-01

Page 400 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-8 Ignition System:

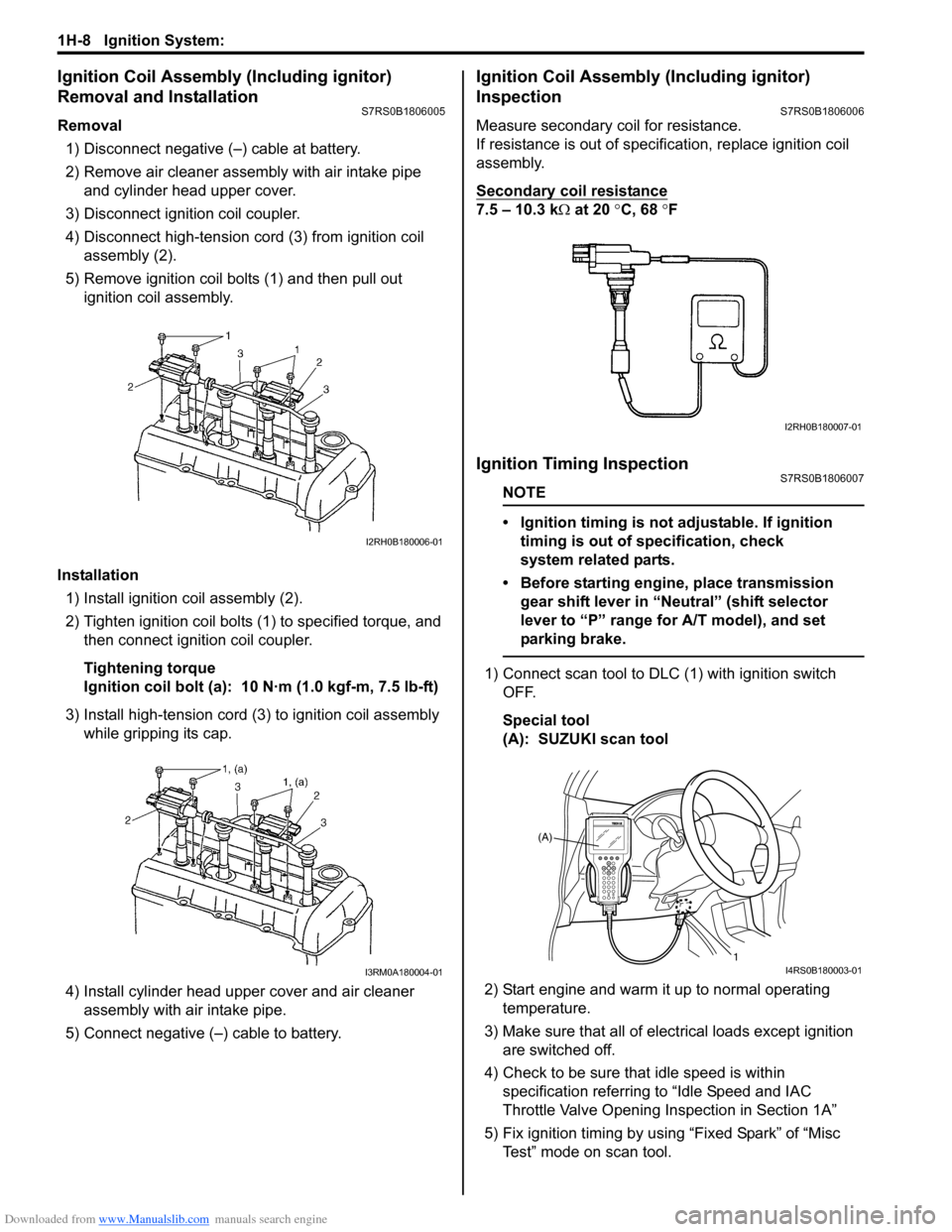

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S7RS0B1806005

Removal1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly (2).

5) Remove ignition coil bolts (1) and then pull out ignition coil assembly.

Installation 1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and then connect igni tion coil coupler.

Tightening torque

Ignition coil bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly while gripping its cap.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

5) Connect negative (–) cable to battery.

Ignition Coil Assembly (Including ignitor)

Inspection

S7RS0B1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.5 – 10.3 k Ω at 20 °C, 68 ° F

Ignition Timing InspectionS7RS0B1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating temperature.

3) Make sure that all of electrical loads except ignition are switched off.

4) Check to be sure that idle speed is within specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”

5) Fix ignition timing by using “Fixed Spark” of “Misc Test” mode on scan tool.

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A)

1

I4RS0B180003-01