App SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1395 of 1496

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-8

Under Coating Application AreasS7RS0B9C03002

I7RS0B9C0001-01

“A”: Apply undercoating (PVC, 400 µm or more). “C”: Apply undercoating (PVC, 400 µm or more) covering flange end.

“B”: Do not apply undercoating. “D”: Apply undercoating (PVC, 400 µm or more) after painted black paint.

Page 1396 of 1496

Downloaded from www.Manualslib.com manuals search engine 9L-9 Paint / Coatings:

I7RS0B9C0002-01

“A”: Apply undercoating (PVC, 400 µm or more). “C”: Do not apply undercoating.

“B”: Apply undercoating (PVC, 600 µm or more).

Page 1397 of 1496

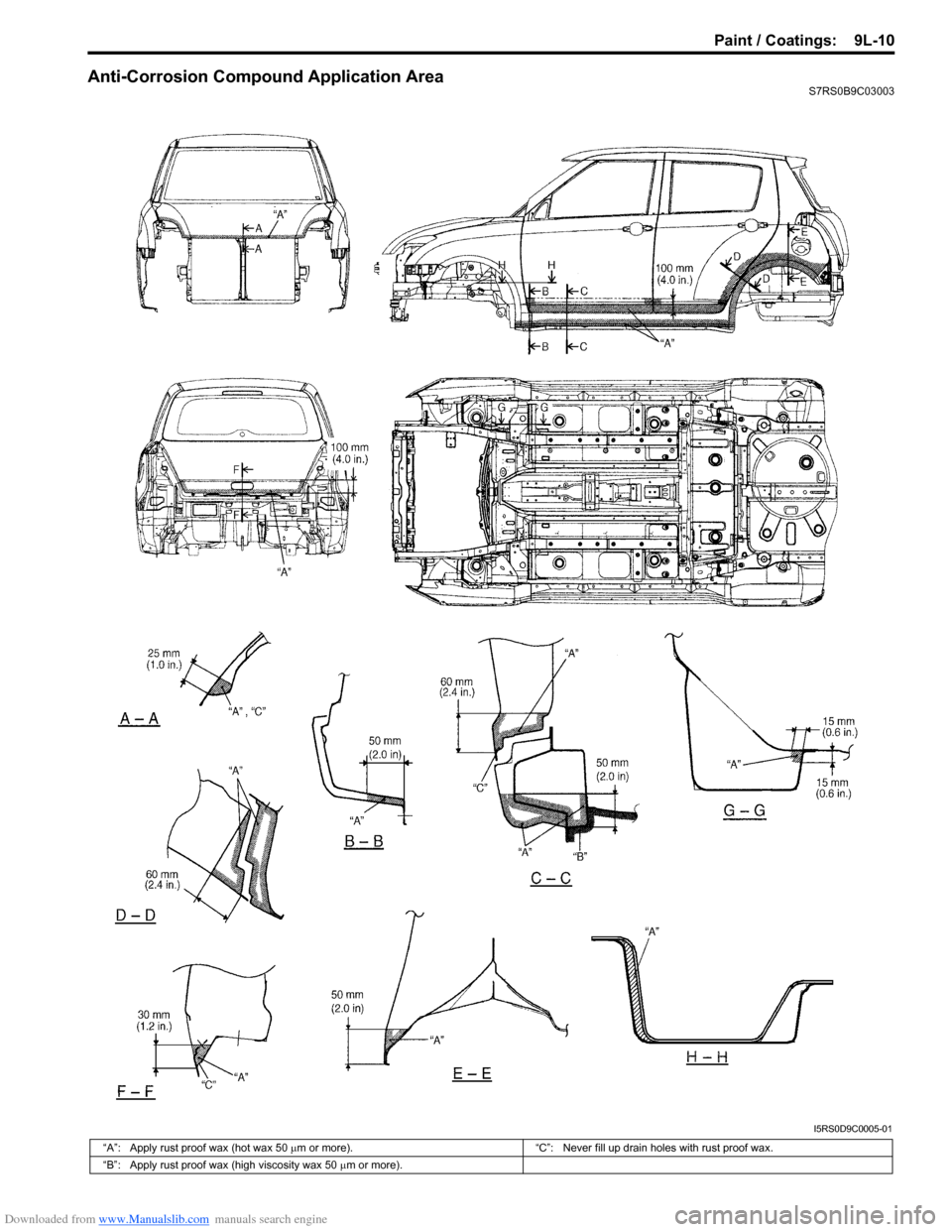

Downloaded from www.Manualslib.com manuals search engine Paint / Coatings: 9L-10

Anti-Corrosion Compound Application AreaS7RS0B9C03003

I5RS0D9C0005-01

“A”: Apply rust proof wax (hot wax 50 µm or more). “C”: Never fill up drain holes with rust proof wax.

“B”: Apply rust proof wax (high viscosity wax 50 µm or more).

Page 1398 of 1496

![SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0 SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.0](/img/20/7607/w960_7607-1397.png)

Downloaded from www.Manualslib.com manuals search engine 9M-1 Exterior Trim:

Body, Cab and Accessories

Exterior Trim

Repair Instructions

Roof Molding ComponentsS7RS0B9D06001

42

2

1

3

[A]

2

53 mm (2.09 in.)

I6RS0C9D0001-01

[A]: Roof side weather-strip installation position

3. Roof molding clip (Push-in type)

: Install roof molding clip to specified position on body with epoxy adhesive applied.

1. Roof molding 4. Windshield side garnish

2. Roof side weather-strip

Page 1414 of 1496

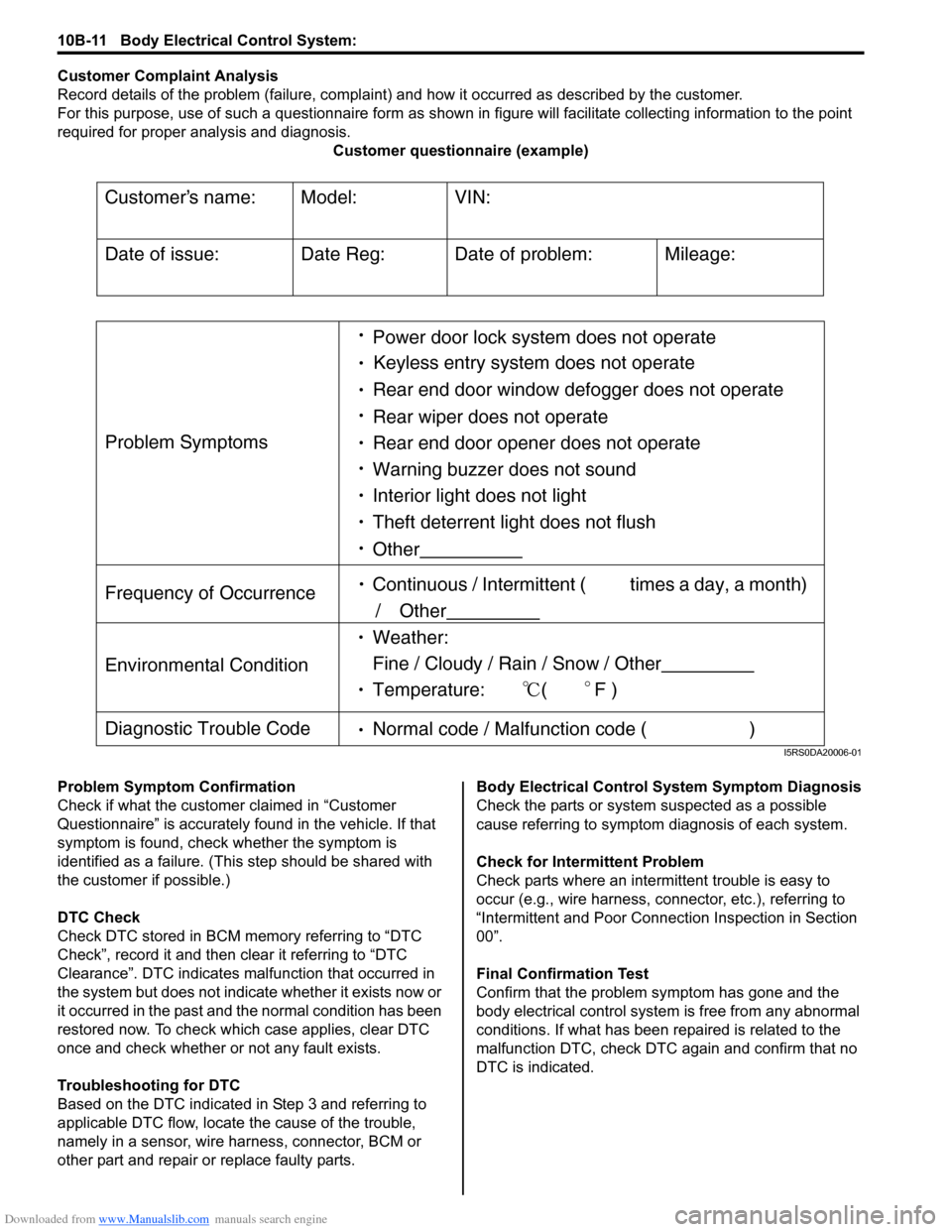

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01

Page 1415 of 1496

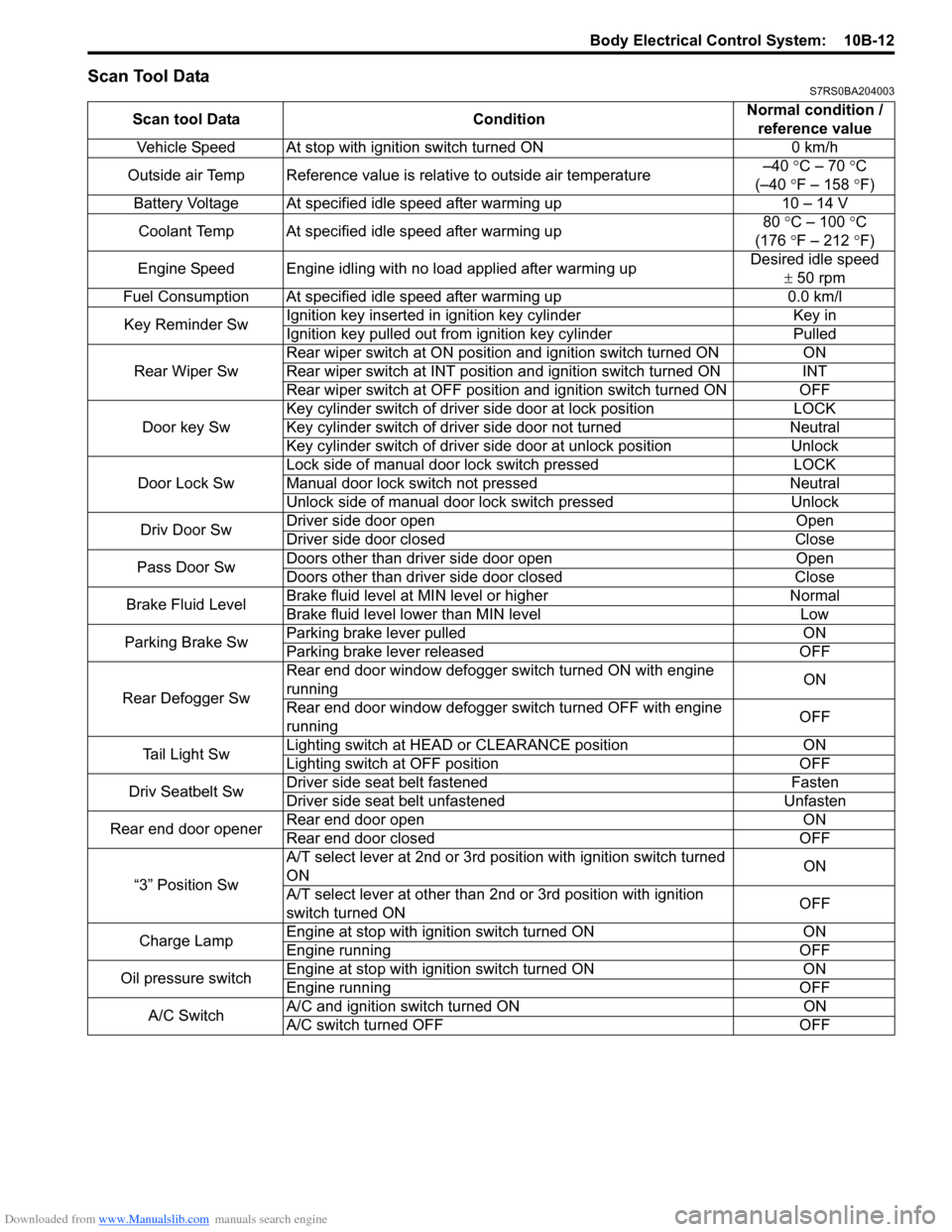

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-12

Scan Tool DataS7RS0BA204003

Scan tool DataConditionNormal condition /

reference value

Vehicle Speed At stop with ignition switch turned ON 0 km/h

Outside air Temp Reference value is relative to outside air temperature –40

°C – 70 °C

(–40 °F – 158 ° F)

Battery Voltage At specified idle speed after warming up 10 – 14 V

Coolant Temp At specified idle speed after warming up 80

°C – 100 ° C

(176 °F – 212 ° F)

Engine Speed Engine idling with no load applied after warming up Desired idle speed

± 50 rpm

Fuel Consumption At specified idle speed after warming up 0.0 km/l

Key Reminder Sw Ignition key inserted in

ignition key cylinder Key in

Ignition key pulled out from ignition key cylinder Pulled

Rear Wiper Sw Rear wiper switch at ON position and ignition switch turned ON

ON

Rear wiper switch at INT position and ignition switch turned ON INT

Rear wiper switch at OFF position and ignition switch turned ON OFF

Door key Sw Key cylinder switch of driver side door at lock position

LOCK

Key cylinder switch of driver side door not turned Neutral

Key cylinder switch of driver side door at unlock position Unlock

Door Lock Sw Lock side of manual door lock switch pressed

LOCK

Manual door lock switch not pressed Neutral

Unlock side of manual door lock switch pressed Unlock

Driv Door Sw Driver side door open

Open

Driver side door closed Close

Pass Door Sw Doors other than driver side door open

Open

Doors other than driver side door closed Close

Brake Fluid Level Brake fluid level at MIN level or higher

Normal

Brake fluid level lower than MIN level Low

Parking Brake Sw Parking brake lever pulled

ON

Parking brake lever released OFF

Rear Defogger Sw Rear end door window defogger switch turned ON with engine

running

ON

Rear end door window defogger switch turned OFF with engine

running OFF

Tail Light Sw Lighting switch at HEAD

or CLEARANCE position ON

Lighting switch at OFF position OFF

Driv Seatbelt Sw Driver side seat belt fastened

Fasten

Driver side seat belt unfastened Unfasten

Rear end door opener Rear end door open

ON

Rear end door closed OFF

“3” Position Sw A/T select lever at 2nd or 3rd position with ignition switch turned

ON

ON

A/T select lever at other than 2nd or 3rd position with ignition

switch turned ON OFF

Charge Lamp Engine at stop with ignition switch turned ON

ON

Engine running OFF

Oil pressure switch Engine at stop with ignition switch turned ON

ON

Engine running OFF

A/C Switch A/C and ignition switch turned ON

ON

A/C switch turned OFF OFF

Page 1435 of 1496

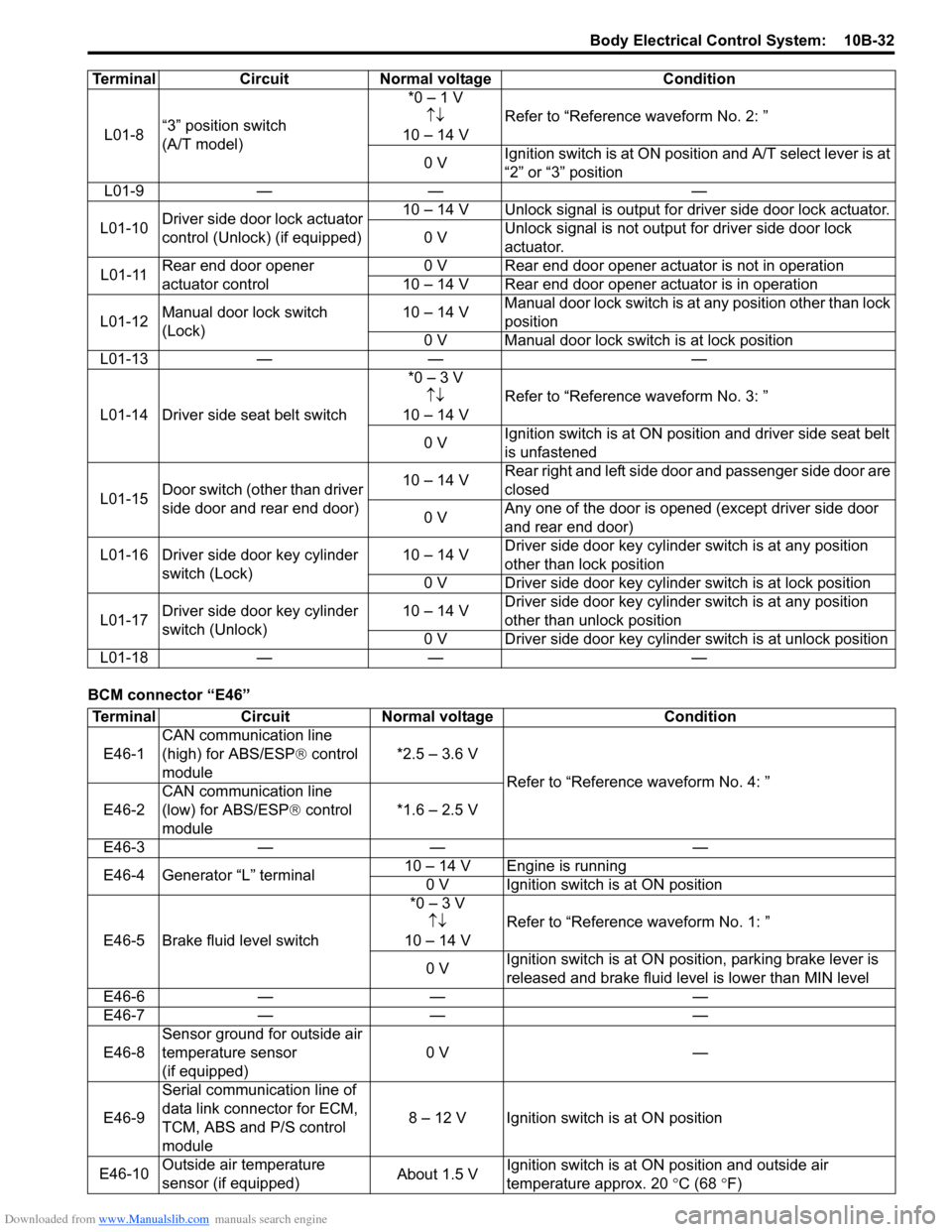

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-32

BCM connector “E46”L01-8

“3” position switch

(A/T model) *0 – 1 V

↑↓

10 – 14 V Refer to “Reference waveform No. 2: ”

0 V Ignition switch is at ON positi

on and A/T select lever is at

“2” or “3” position

L01-9 — — —

L01-10 Driver side door lock actuator

control (Unlock) (if equipped) 10 – 14 V Unlock signal is output for driver side door lock actuator.

0 V Unlock signal is not output for driver side door lock

actuator.

L01-11 Rear end door opener

actuator control 0 V Rear end door opener actuator is not in operation

10 – 14 V Rear end door opener actuator is in operation

L01-12 Manual door lock switch

(Lock) 10 – 14 V

Manual door lock switch is at any position other than lock

position

0 V Manual door lock swit ch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 3: ”

0 V Ignition switch is at ON position and driver side seat belt

is unfastened

L01-15 Door switch (other than driver

side door and rear end door) 10 – 14 V

Rear right and left side door and passenger side door are

closed

0 V Any one of the door is opened (except driver side door

and rear end door)

L01-16 Driver side door key cylinder switch (Lock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than lock position

0 V Driver side door key cylinder switch is at lock position

L01-17 Driver side door key cylinder

switch (Unlock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than unlock position

0 V Driver side door key cylinder switch is at unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

E46-1 CAN communication line

(high) for ABS/ESP

® control

module *2.5 – 3.6 V

Refer to “Reference waveform No. 4: ”

E46-2 CAN communication line

(low) for ABS/ESP

® control

module *1.6 – 2.5 V

E46-3 — — —

E46-4 Generator “L” terminal 10 – 14 V Engine is running

0 V Ignition switch is at ON position

E46-5 Brake fluid level switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON position, parking brake lever is

released and brake fluid level is lower than MIN level

E46-6 — — —

E46-7 — — —

E46-8 Sensor ground for outside air

temperature sensor

(if equipped) 0 V

—

E46-9 Serial communication line of

data link connector for ECM,

TCM, ABS and

P/S control

module 8 – 12 V Ignition switch is at ON position

E46-10 Outside air temperature

sensor (if equipped) About 1.5 VIgnition switch is at ON position and outside air

temperature approx. 20

°C (68 °F)

Page 1444 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-1 Immobilizer Control System:

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS7RS0BA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection.

• Communication of ECM, BCM, keyless start control module (if equipped), ABS / ESP ® control module,

steering angle sensor (ESP ® model), combination

meter and TCM (A/T model) is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”. For

CAN communication system, refer to description on

“CAN Communication System Description in Section

1A”.

Precaution in Replacing ECMS7RS0BA300002

• If ECM is replaced with new or used one without immobilizer control function , the engine will not be

started. In case of the above, check if the newly

installed ECM has immobilizer control function.

• After ECM is replaced with new one or used one, the transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precautions in Handling Immobilizer Control

System

S7RS0BA300003

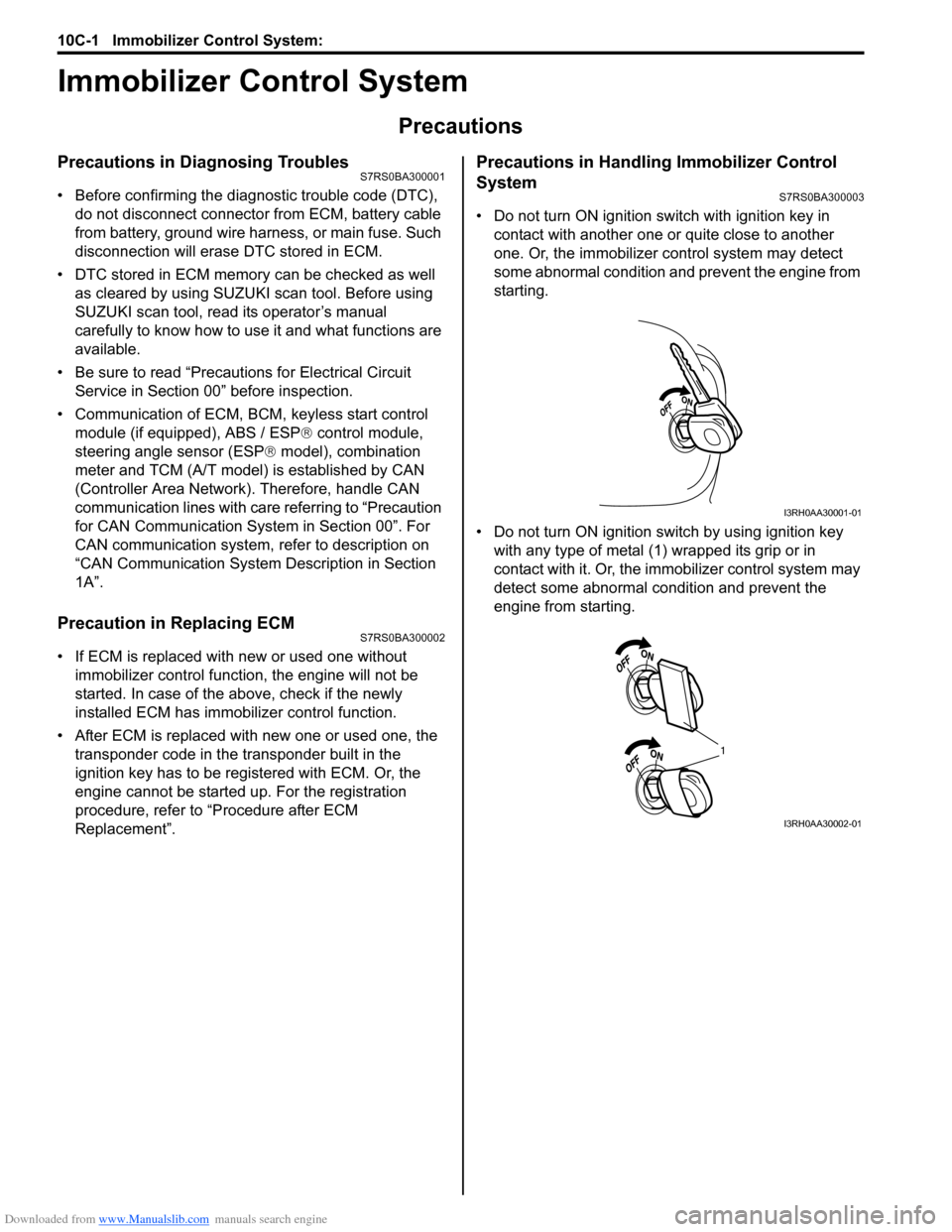

• Do not turn ON ignition sw itch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer co ntrol system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key with any type of metal (1) wrapped its grip or in

contact with it. Or, the i mmobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1448 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-5 Immobilizer Control System:

Diagnostic Information and Procedures

Immobilizer Control System CheckS7RS0BA304001

Diagnostic Trouble Code (DTC) CheckS7RS0BA304002

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

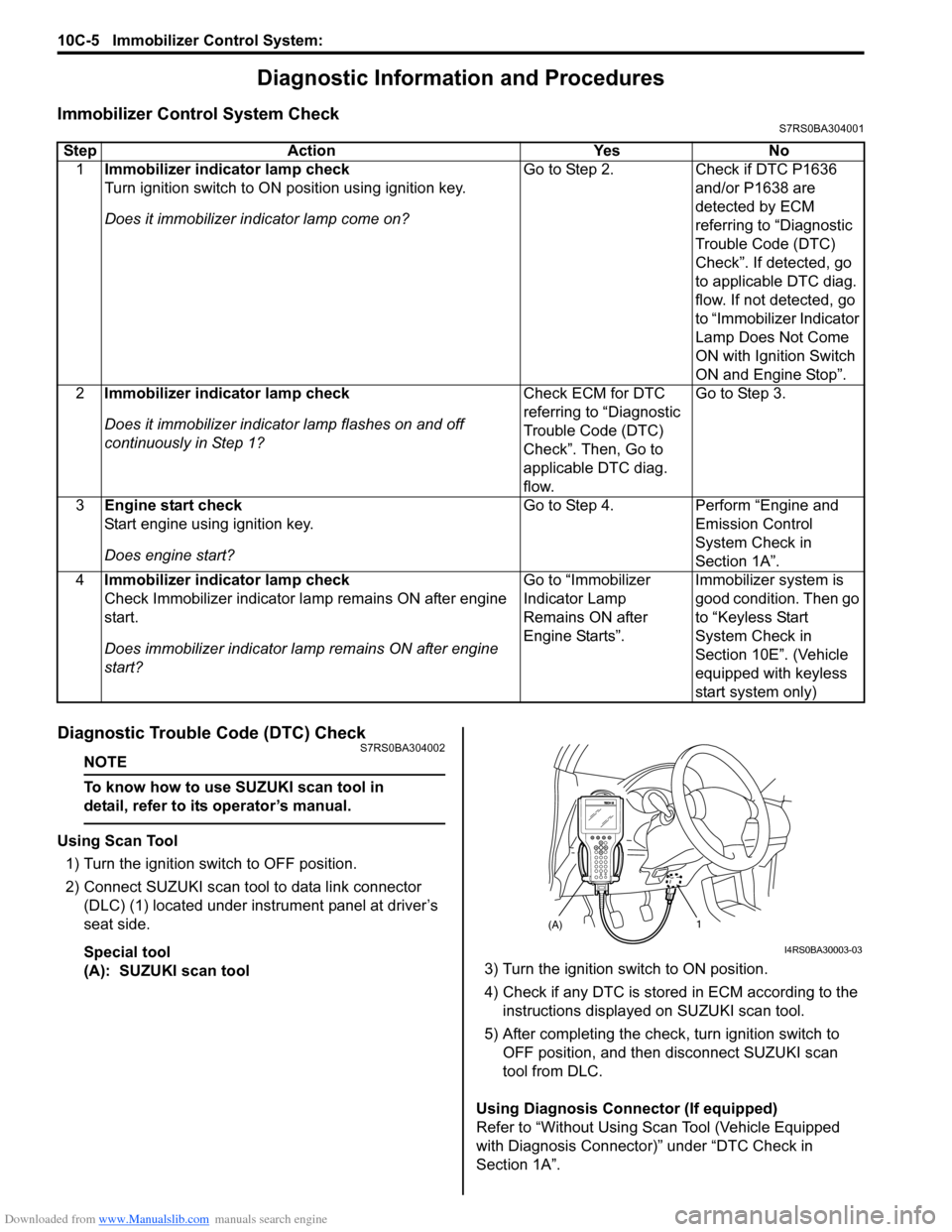

Using Scan Tool

1) Turn the ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool 3) Turn the ignition switch to ON position.

4) Check if any DTC is stored

in ECM according to the

instructions displayed on SUZUKI scan tool.

5) After completing the check, turn ignition switch to

OFF position, and then di sconnect SUZUKI scan

tool from DLC.

Using Diagnosis Connector (If equipped)

Refer to “Without Using Scan Tool (Vehicle Equipped

with Diagnosis Connector)” under “DTC Check in

Section 1A”.

Step Action Yes No

1 Immobilizer indicator lamp check

Turn ignition switch to ON position using ignition key.

Does it immobilizer in dicator lamp come on? Go to Step 2.

Check if DTC P1636

and/or P1638 are

detected by ECM

referring to “Diagnostic

Trouble Code (DTC)

Check”. If detected, go

to applicable DTC diag.

flow. If not detected, go

to “Immobilizer Indicator

Lamp Does Not Come

ON with Ignition Switch

ON and Engine Stop”.

2 Immobilizer indicator lamp check

Does it immobilizer indicato r lamp flashes on and off

continuously in Step 1? Check ECM for DTC

referring to “Diagnostic

Trouble Code (DTC)

Check”. Then, Go to

applicable DTC diag.

flow.Go to Step 3.

3 Engine start check

Start engine using ignition key.

Does engine start? Go to Step 4.

Perform “Engine and

Emission Control

System Check in

Section 1A”.

4 Immobilizer indicator lamp check

Check Immobilizer indicator la mp remains ON after engine

start.

Does immobilizer indicator la mp remains ON after engine

start? Go to “Immobilizer

Indicator Lamp

Remains ON after

Engine Starts”.

Immobilizer system is

good condition. Then go

to “Keyless Start

System Check in

Section 10E”. (Vehicle

equipped with keyless

start system only)

(A)1

I4RS0BA30003-03

Page 1450 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-7 Immobilizer Control System:

Scan Tool DataS7RS0BA304005

Scan Tool Data Definitions

NUMBER OF LEARNT KEY

0 – 4 PCS: The number of the transponder code in the transponder built in the ignition key that is registered with ECM

NOTE

A maximum of four transponder codes can be registered with ECM. Therefore, the maximal value

should be 4.

INPUT YEAR

20**: The year in which the transponder code in the transpon der built in the ignition key is registered with ECM

INPUT MONTH

1 – 12: The month in which the transponder code in the transpond er built in the ignition key is registered with ECM

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine StopS7RS0BA304006

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the ignition switch is turned ON, ECM read the code by the coil antenna from ignition key. Then if the code in

transponder in the key match with the one registered with ECM, transmits indication ON signal of immobilizer indicator

lamp to combination meter in order to turn immobilizer indicator lamp on. And then, combination meter turns

immobilizer indicator lamp on. When th e engine starts to run and no malfunction is detected in the system, ECM

transmits immobilizer indi cator lamp indication OFF signal to combination meter in order to turn immobilizer indicator

lamp off. And then, comb ination meter turns immobilizer indicator lamp off, but if a malfunction was or is detected,

immobilizer indicator lamp is flashes ON and OF F, when ignition switch turn to ON position.

Troubleshooting Scan Tool Data Vehicl

e Condition Normal Data

NUMBER OF LEARNT KEY Ignition switch at ON position 0 – 4 INPUT YEAR Ignition switch at ON position 2005 or later

INPUT MONTH Ignition switch at ON position 1 – 12

Step Action YesNo

1 Immobilizer indicator lamp power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 4.

2 DTC check of ECM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is DTC P1674, P1675, P1678 and/or P1685 detected? Go to applicable DTC

diag. flow.

Go to Step 3.

3 DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U1073, U1100 and/or U1144 detected? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

lamp still remains OFF,

substitute a known good

ECM and recheck.