Position sensor SUZUKI SWIFT 2007 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 155 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-105

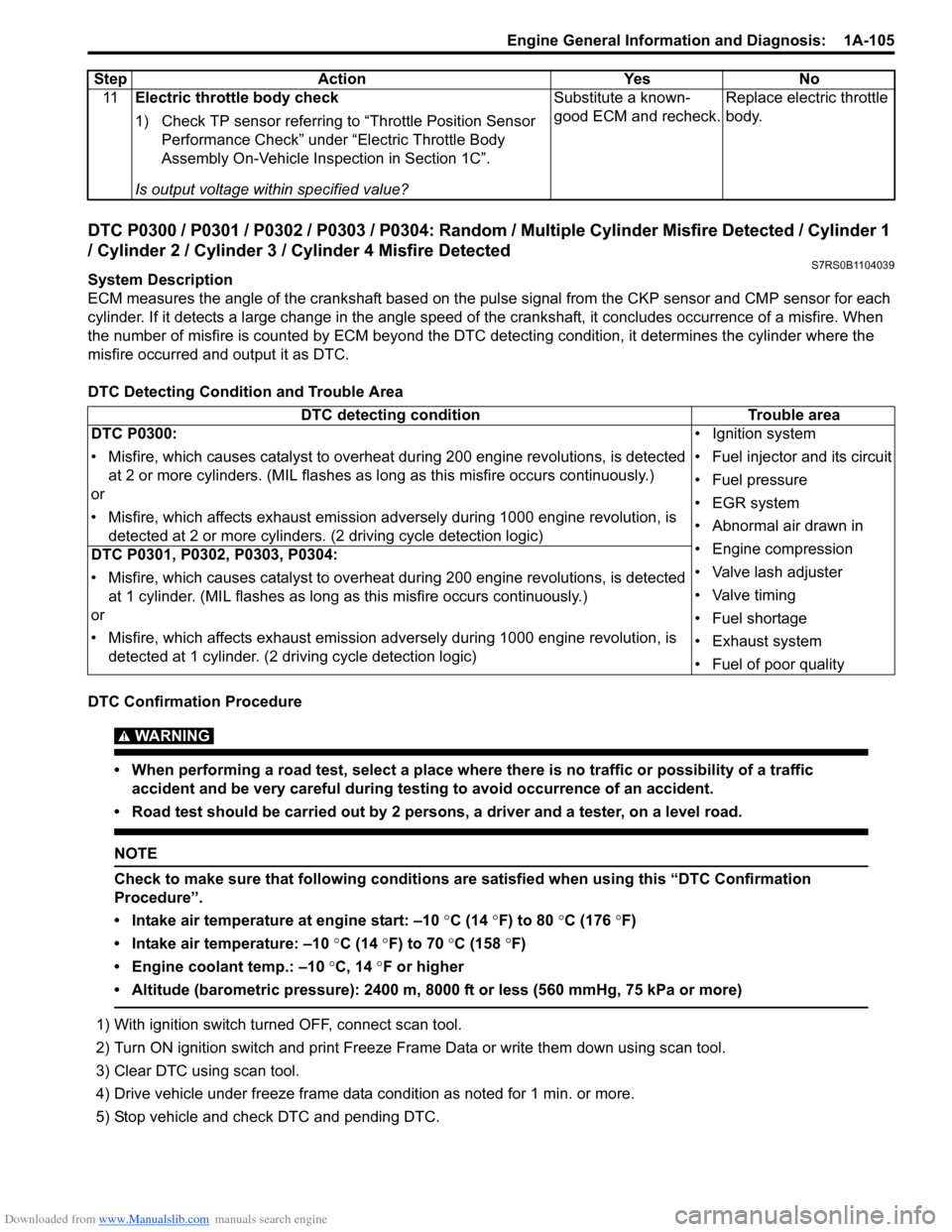

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylinder Misfire Detected / Cylinder 1

/ Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected

S7RS0B1104039

System Description

ECM measures the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC de tecting condition, it determines the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: –10 °C, 14 °F or higher

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

5) Stop vehicle and check DTC and pending DTC. 11

Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0300:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected at 2 or more cylinders. (MIL flashes as lo ng as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 2 or more cylinders. (2 driving cycle detection logic) • Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system

• Abnormal air drawn in

• Engine compression

• Valve lash adjuster

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality

DTC P0301, P0302, P0303, P0304:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 1 cylinder. (2 driving cycle detection logic)

Page 159 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-109

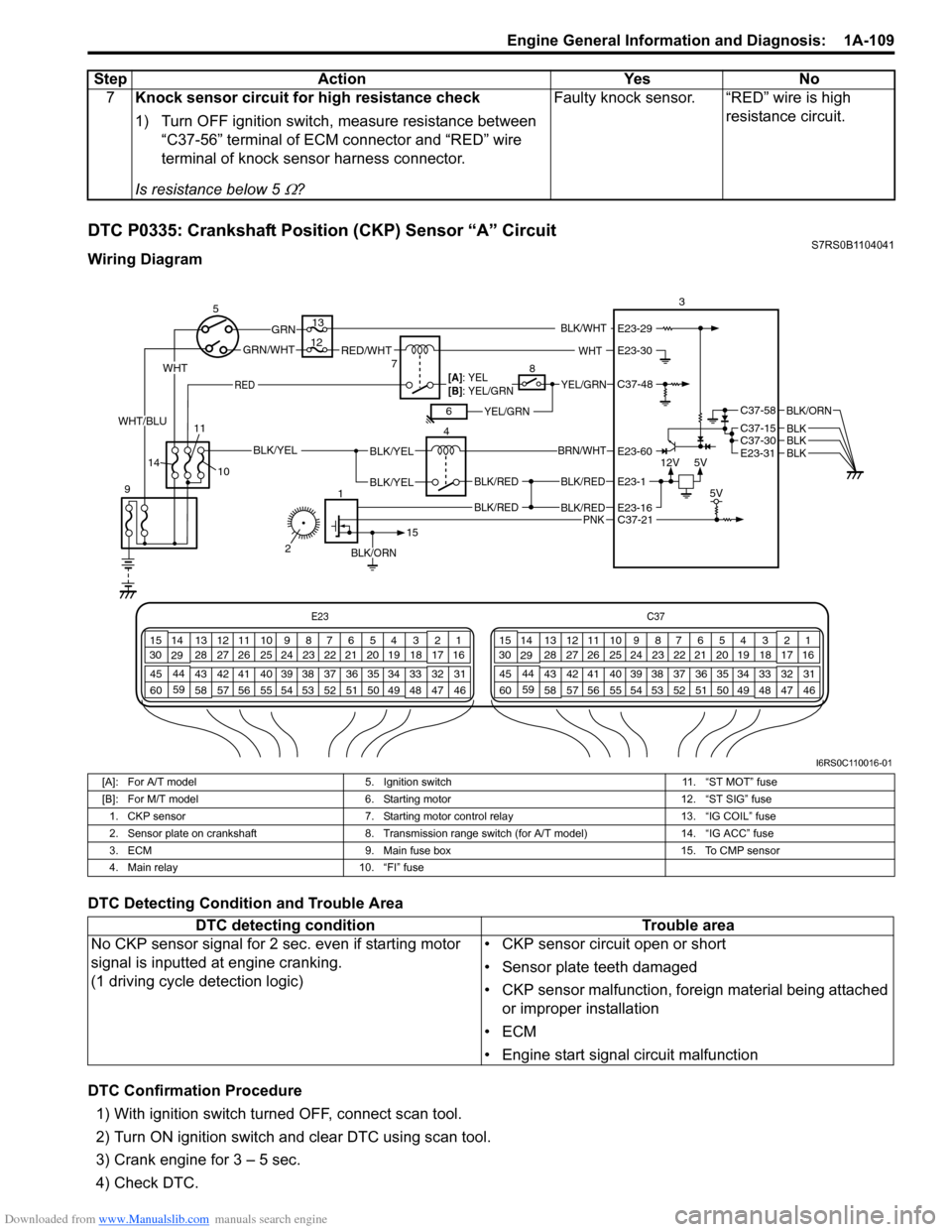

DTC P0335: Crankshaft Position (CKP) Sensor “A” CircuitS7RS0B1104041

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Crank engine for 3 – 5 sec.

4) Check DTC. 7

Knock sensor circuit for high resistance check

1) Turn OFF ignition switch, measure resistance between

“C37-56” terminal of ECM connector and “RED” wire

terminal of knock sensor harness connector.

Is resistance below 5

Ω? Faulty knock sensor. “RED” wire is high

resistance circuit.

Step

Action YesNo

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

12V

5V

BLK/RED

BLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

5

9 4

13

3

C37-30C37-15

C37-58

E23-31

BLK/ORN

BLKBLKBLK

10

BLK/RED

BLK/RED

E23-16

E23-60

E23-1

BLK/ORN

1

15

C37-21 5V

7RED/WHTGRN/WHT

GRN

RED

BLK/WHT

YEL/GRN

YEL/GRN

WHT

[A]: YEL

[B]: YEL/GRN

68

12

11

14

PNK

2

WHT

WHT/BLU

C37-48

E23-30

E23-29

I6RS0C110016-01

[A]: For A/T model 5. Ignition switch 11. “ST MOT” fuse

[B]: For M/T model 6. Starting motor 12. “ST SIG” fuse

1. CKP sensor 7. Starting motor control relay 13. “IG COIL” fuse

2. Sensor plate on crankshaft 8. Transmission range switch (for A/T model) 14. “IG ACC” fuse

3. ECM 9. Main fuse box 15. To CMP sensor

4. Main relay 10. “FI” fuse

DTC detecting condition Trouble area

No CKP sensor signal for 2 se c. even if starting motor

signal is inputted at engine cranking.

(1 driving cycle detection logic) • CKP sensor circuit open or short

• Sensor plate teeth damaged

• CKP sensor malfunction, foreign material being attached

or improper installation

•ECM

• Engine start signal circuit malfunction

Page 160 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-110 Engine General Information and Diagnosis:

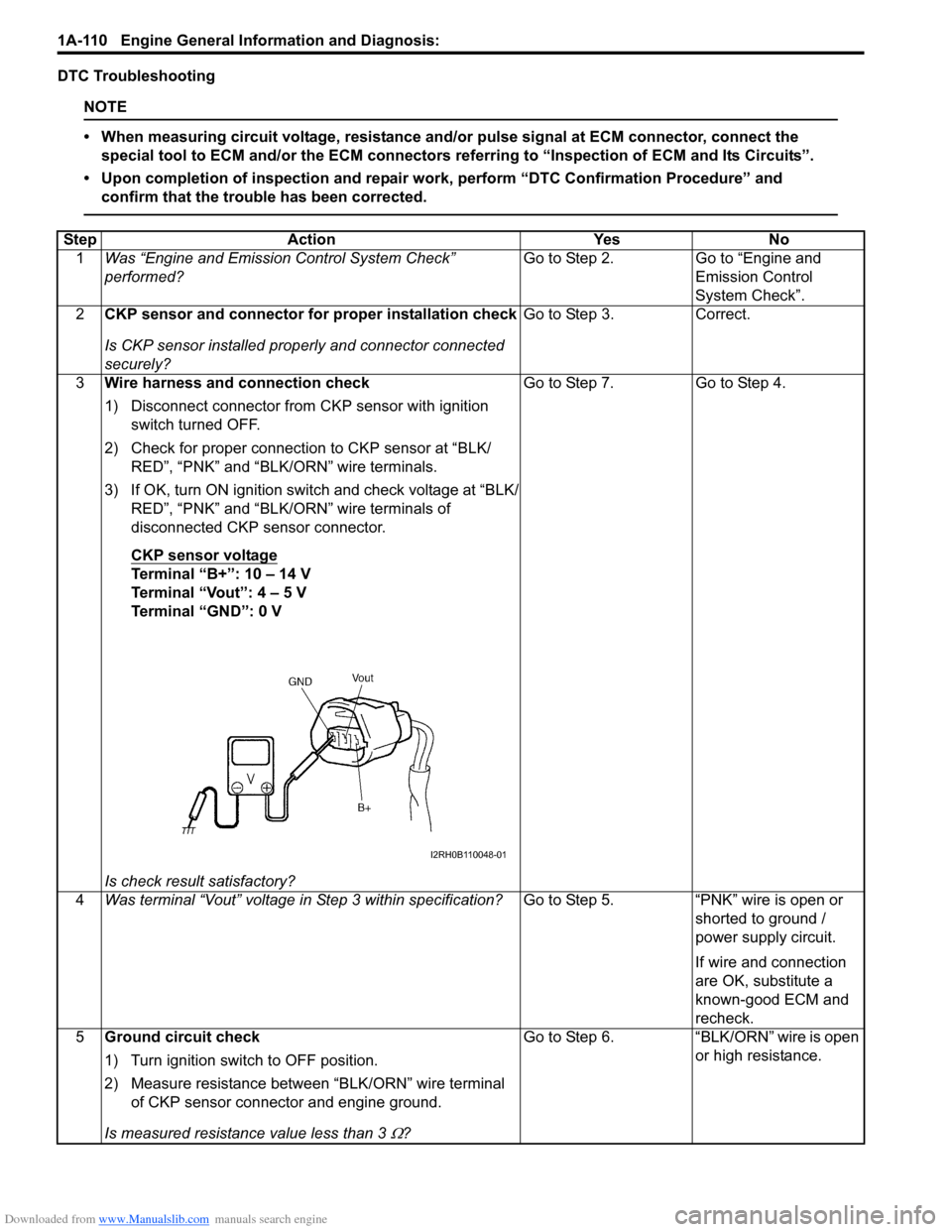

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 CKP sensor and connector for proper installation check

Is CKP sensor installed properly and connector connected

securely? Go to Step 3.

Correct.

3 Wire harness and connection check

1) Disconnect connector from CKP sensor with ignition

switch turned OFF.

2) Check for proper connection to CKP sensor at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “PNK” and “BLK/ORN” wire terminals of

disconnected CKP sensor connector.

CKP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “PNK” wire is open or

shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CKP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance.

I2RH0B110048-01

Page 161 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-111

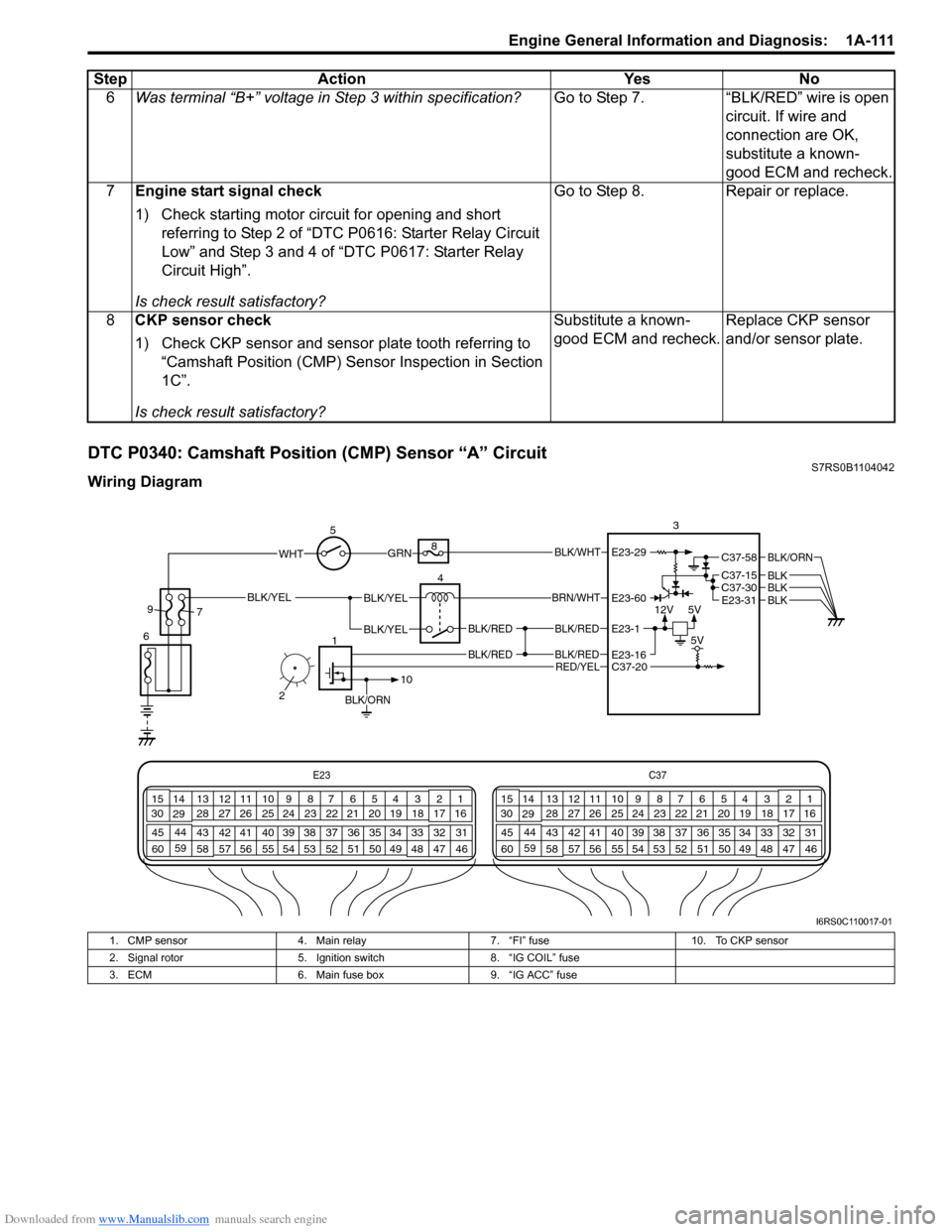

DTC P0340: Camshaft Position (CMP) Sensor “A” CircuitS7RS0B1104042

Wiring Diagram6

Was terminal “B+” voltage in Step 3 within specification? Go to Step 7. “BLK/RED” wire is open

circuit. If wire and

connection are OK,

substitute a known-

good ECM and recheck.

7 Engine start signal check

1) Check starting motor circuit for opening and short

referring to Step 2 of “DTC P0616: Starter Relay Circuit

Low” and Step 3 and 4 of “DTC P0617: Starter Relay

Circuit High”.

Is check result satisfactory? Go to Step 8. Repair or replace.

8 CKP sensor check

1) Check CKP sensor and sensor plate tooth referring to

“Camshaft Position (CMP) Sensor Inspection in Section

1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace CKP sensor

and/or sensor plate.

Step Action Yes No

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

12V

5V

BLK/RED

BLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

5

6 4

8

3

C37-30C37-15

C37-58

E23-31

BLK/ORN

BLKBLKBLK

BLK/RED

BLK/RED

E23-16

E23-60

E23-1

BLK/ORN

1

10

C37-20 5V

GRNBLK/WHT

9

7

RED/YEL

2

WHTE23-29

I6RS0C110017-01

1. CMP sensor 4. Main relay 7. “FI” fuse 10. To CKP sensor

2. Signal rotor 5. Ignition switch 8. “IG COIL” fuse

3. ECM 6. Main fuse box 9. “IG ACC” fuse

Page 163 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-113

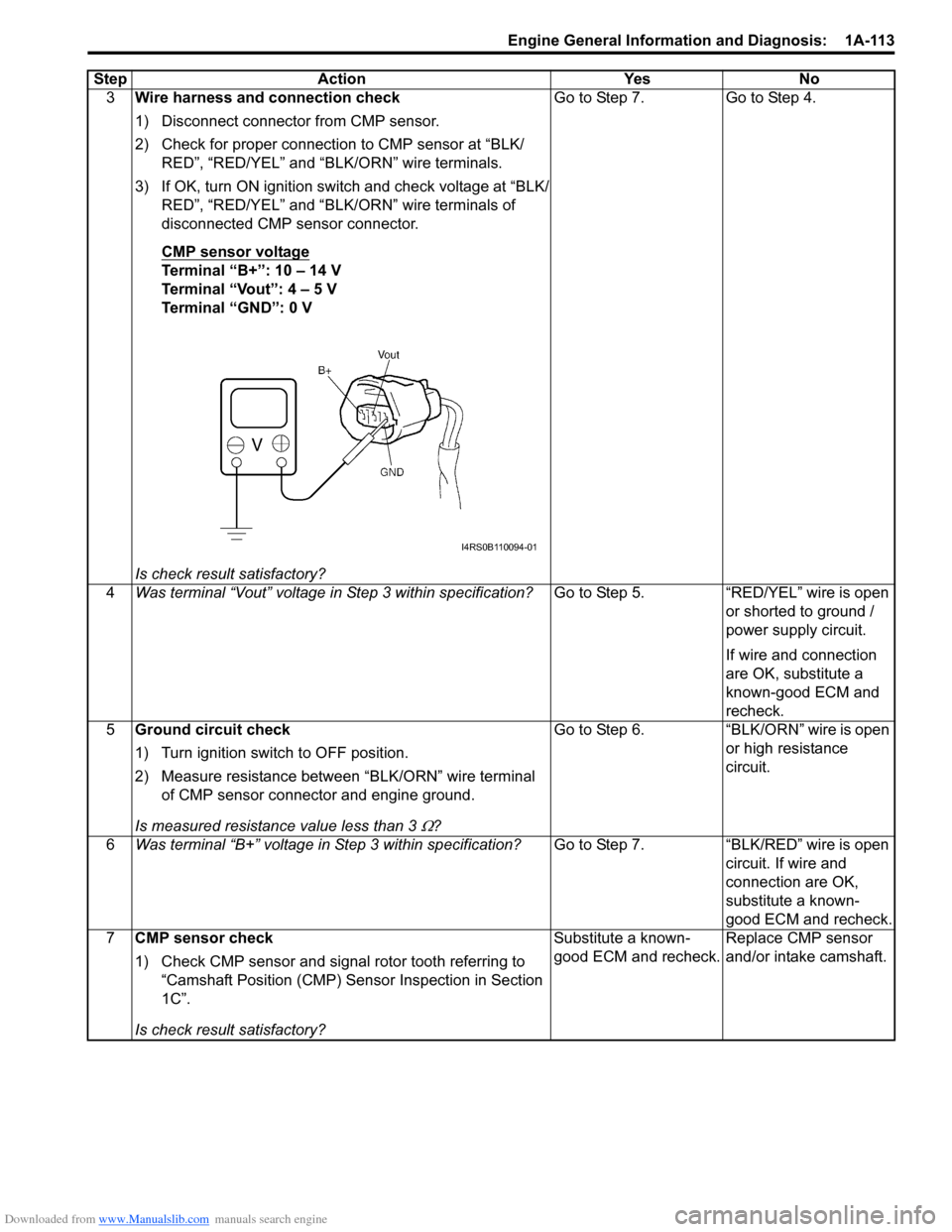

3Wire harness and connection check

1) Disconnect connector from CMP sensor.

2) Check for proper connection to CMP sensor at “BLK/

RED”, “RED/YEL” and “B LK/ORN” wire terminals.

3) If OK, turn ON ignition switch and check voltage at “BLK/ RED”, “RED/YEL” and “BLK/ORN” wire terminals of

disconnected CMP sensor connector.

CMP sensor voltage

Terminal “B+”: 10 – 14 V

Terminal “Vout”: 4 – 5 V

Terminal “GND”: 0 V

Is check result satisfactory? Go to Step 7. Go to Step 4.

4 Was terminal “Vout” voltage in Step 3 within specification? Go to Step 5. “RED/YEL” wire is open

or shorted to ground /

power supply circuit.

If wire and connection

are OK, substitute a

known-good ECM and

recheck.

5 Ground circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “BLK/ORN” wire terminal

of CMP sensor connector and engine ground.

Is measured resistance value less than 3

Ω? Go to Step 6. “BLK/ORN” wire is open

or high resistance

circuit.

6 Was terminal “B+” voltage in Step 3 within specification? Go to Step 7. “BLK/RED” wire is open

circuit. If wire and

connection are OK,

substitute a known-

good ECM and recheck.

7 CMP sensor check

1) Check CMP sensor and signal rotor tooth referring to

“Camshaft Position (CMP) Sensor Inspection in Section

1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace CMP sensor

and/or intake camshaft.

Step Action Yes No

I4RS0B110094-01

Page 188 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-138 Engine General Information and Diagnosis:

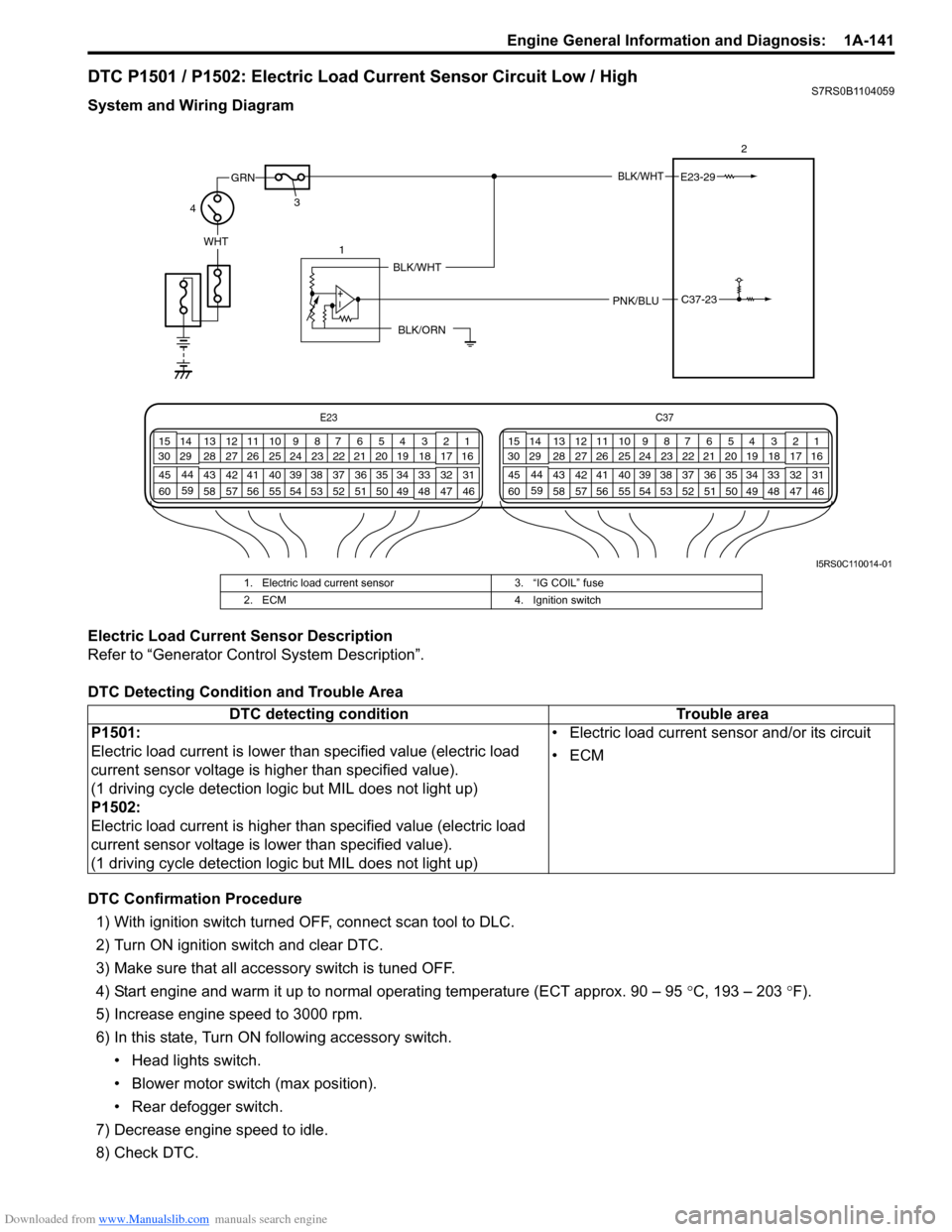

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switches are tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Turn ON the followi ng accessory switches.

• Head light switch.

• Blower motor switch (max position).

• Rear defogger switch.

6) Increase engine speed to 4000 rpm and keep it for 10 sec or more.

7) Decrease engine speed to idle.

8) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

• Battery voltage is higher than specification even through generator control is maximum regulation (duty 100%).

• Battery voltage is lower than specification even through generator control is minimum regulation (duty 0%) and electric

load is less than 15 A.

(1 driving cycle detection logic but MIL does not light up) • Generator and/or its circuit

• Electric load current sensor

•ECM

• Generator drive belt

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Generator drive belt check

1) Check generator drive belt tension referring to “Water

Pump / Generator Drive Belt Tension Inspection and

Adjustment in Section 1J”.

Is check result satisfactory? Go to Step 3.

Adjust or replace

generator drive belt.

Page 191 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-141

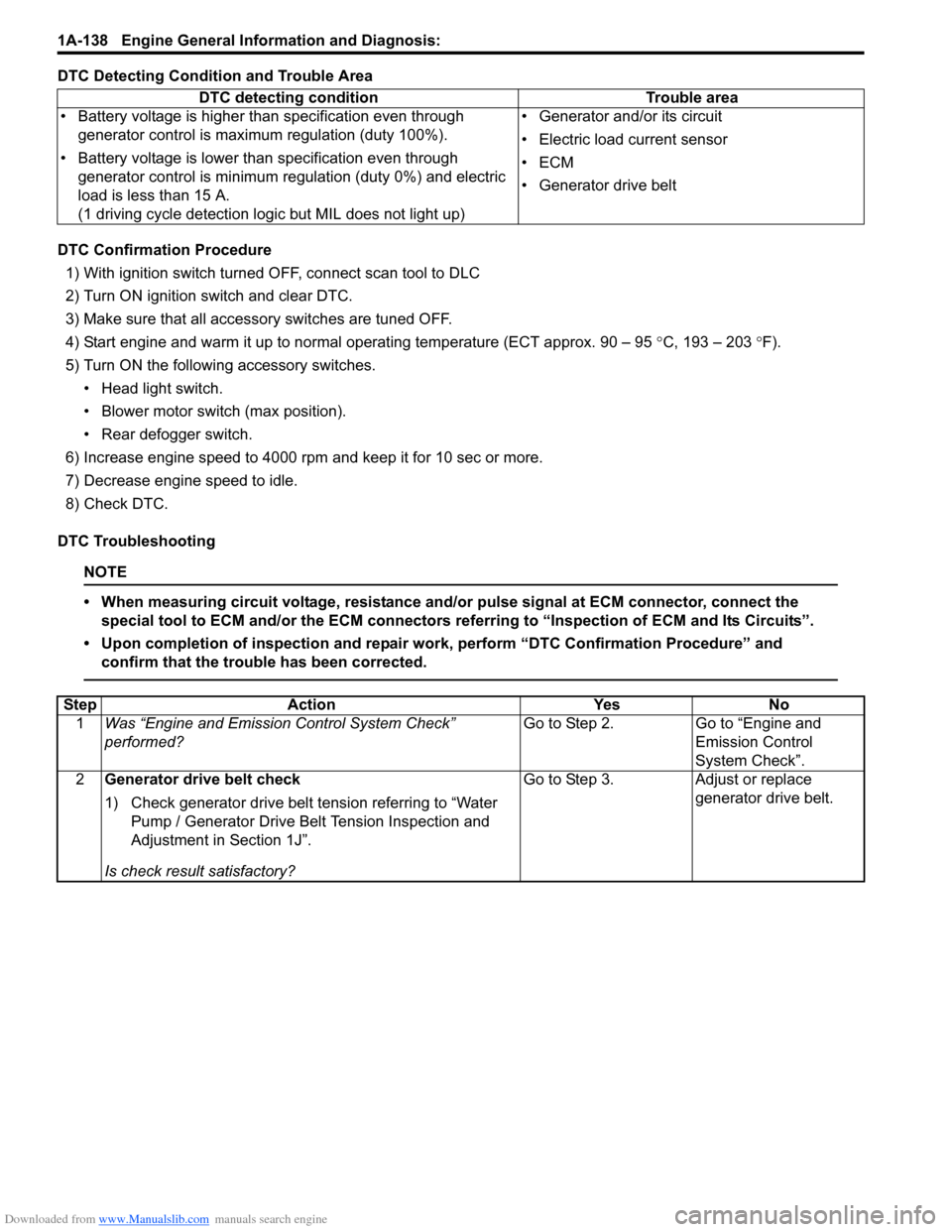

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / HighS7RS0B1104059

System and Wiring Diagram

Electric Load Current Sensor Description

Refer to “Generator Control System Description”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switch is tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Increase engine speed to 3000 rpm.

6) In this state, Turn ON following accessory switch.

• Head lights switch.

• Blower motor switch (max position).

• Rear defogger switch.

7) Decrease engine speed to idle.

8) Check DTC.

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/WHT

WHT

GRN

4

3 2

E23-29

1

C37-23PNK/BLU

BLK/ORN

BLK/WHT

I5RS0C110014-01

1. Electric load current sensor

3. “IG COIL” fuse

2. ECM 4. Ignition switch

DTC detecting condition Trouble area

P1501:

Electric load current is lower th an specified value (electric load

current sensor voltage is higher than specified value).

(1 driving cycle detection logic but MIL does not light up)

P1502:

Electric load current is higher than specified value (electric load

current sensor voltage is lo wer than specified value).

(1 driving cycle detection logic but MIL does not light up) • Electric load current sensor and/or its circuit

•ECM

Page 197 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-147

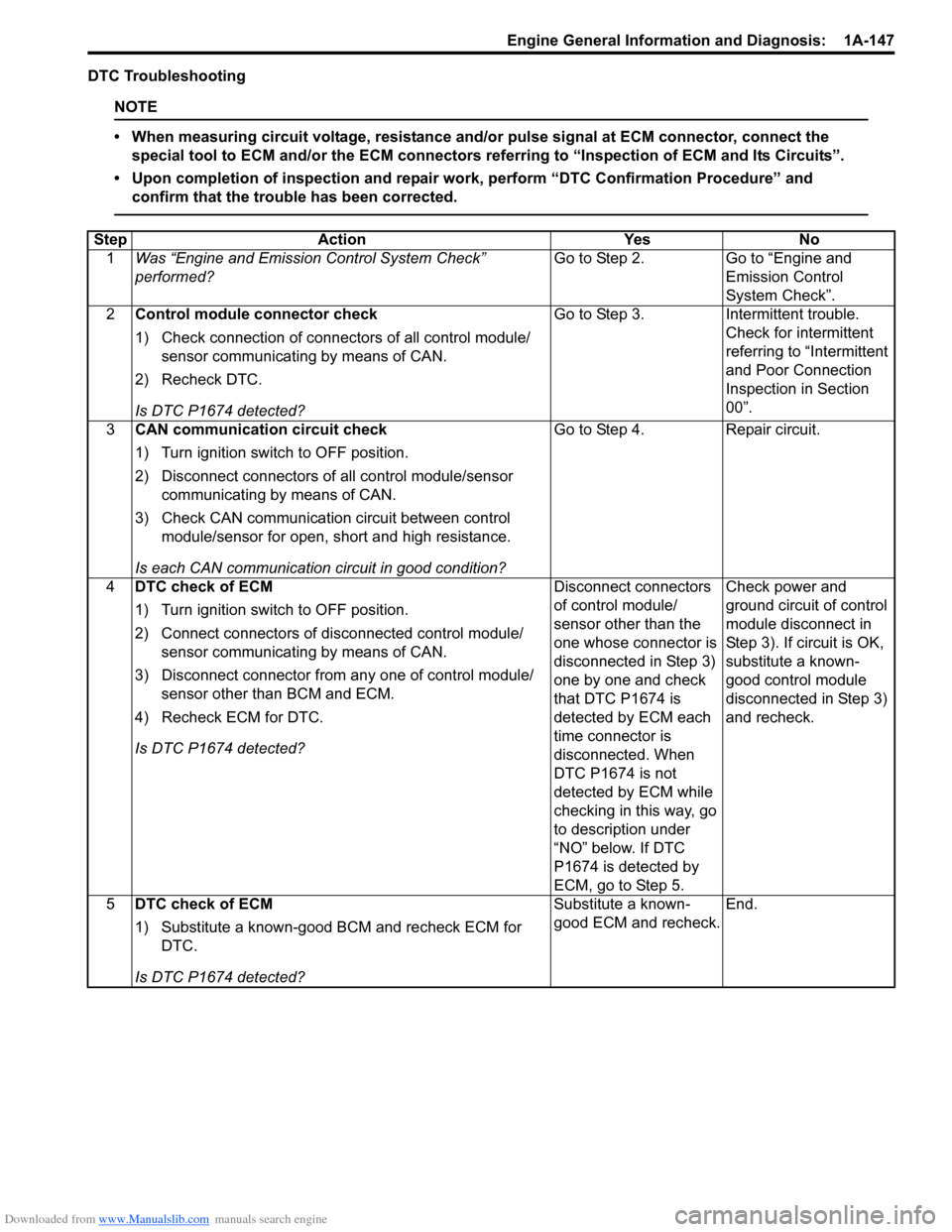

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Control module connector check

1) Check connection of connectors of all control module/

sensor communicating by means of CAN.

2) Recheck DTC.

Is DTC P1674 detected? Go to Step 3.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control module/sensor

communicating by means of CAN.

3) Check CAN communication circuit between control module/sensor for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 4.

Repair circuit.

4 DTC check of ECM

1) Turn ignition switch to OFF position.

2) Connect connectors of di sconnected control module/

sensor communicating by means of CAN.

3) Disconnect connector from any one of control module/ sensor other than BCM and ECM.

4) Recheck ECM for DTC.

Is DTC P1674 detected? Disconnect connectors

of control module/

sensor other than the

one whose connector is

disconnected in Step 3)

one by one and check

that DTC P1674 is

detected by ECM each

time connector is

disconnected. When

DTC P1674 is not

detected by ECM while

checking in this way, go

to description under

“NO” below. If DTC

P1674 is detected by

ECM, go to Step 5.Check power and

ground circuit of control

module disconnect in

Step 3). If circuit is OK,

substitute a known-

good control module

disconnected in Step 3)

and recheck.

5 DTC check of ECM

1) Substitute a known-good BCM and recheck ECM for

DTC.

Is DTC P1674 detected? Substitute a known-

good ECM and recheck.

End.

Page 202 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-152 Engine General Information and Diagnosis:

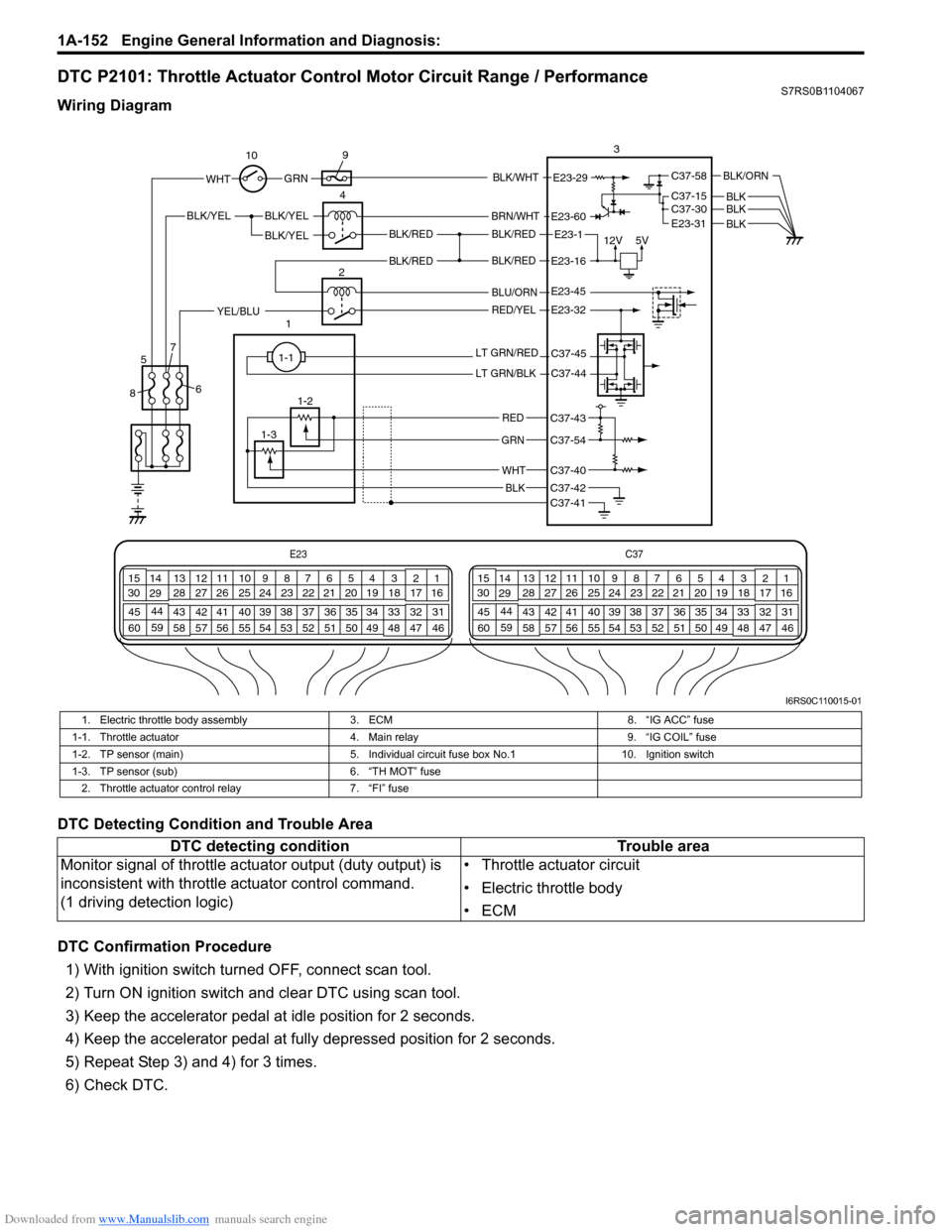

DTC P2101: Throttle Actuator Control Motor Circuit Range / PerformanceS7RS0B1104067

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

12V

5VBLK/REDBLK/RED

BLK/YEL

12BLK/YEL

BLK/YEL

BRN/WHT

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLK/RED

BLU/ORN

RED/YELYEL/BLU

LT GRN/RED

LT GRN/BLK

RED

GRN

WHT

BLK

E23-16

E23-45

E23-32

C37-45

C37-44

C37-41C37-42

C37-40

C37-54

C37-43

1-1

1-2

1-3 3

4

5

8 67

10

9

E23-29 GRNBLK/WHTWHT

BLK/RED

I6RS0C110015-01

1. Electric throttle body assembly

3. ECM 8. “IG ACC” fuse

1-1. Throttle actuator 4. Main relay9. “IG COIL” fuse

1-2. TP sensor (main) 5. Individual circuit fuse box No.1 10. Ignition switch

1-3. TP sensor (sub) 6. “TH MOT” fuse

2. Throttle actuator control relay 7. “FI” fuse

DTC detecting condition Trouble area

Monitor signal of throttle actu ator output (duty output) is

inconsistent with throttle actuator control command.

(1 driving detection logic) • Throttle actuator circuit

• Electric throttle body

•ECM

Page 207 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-157

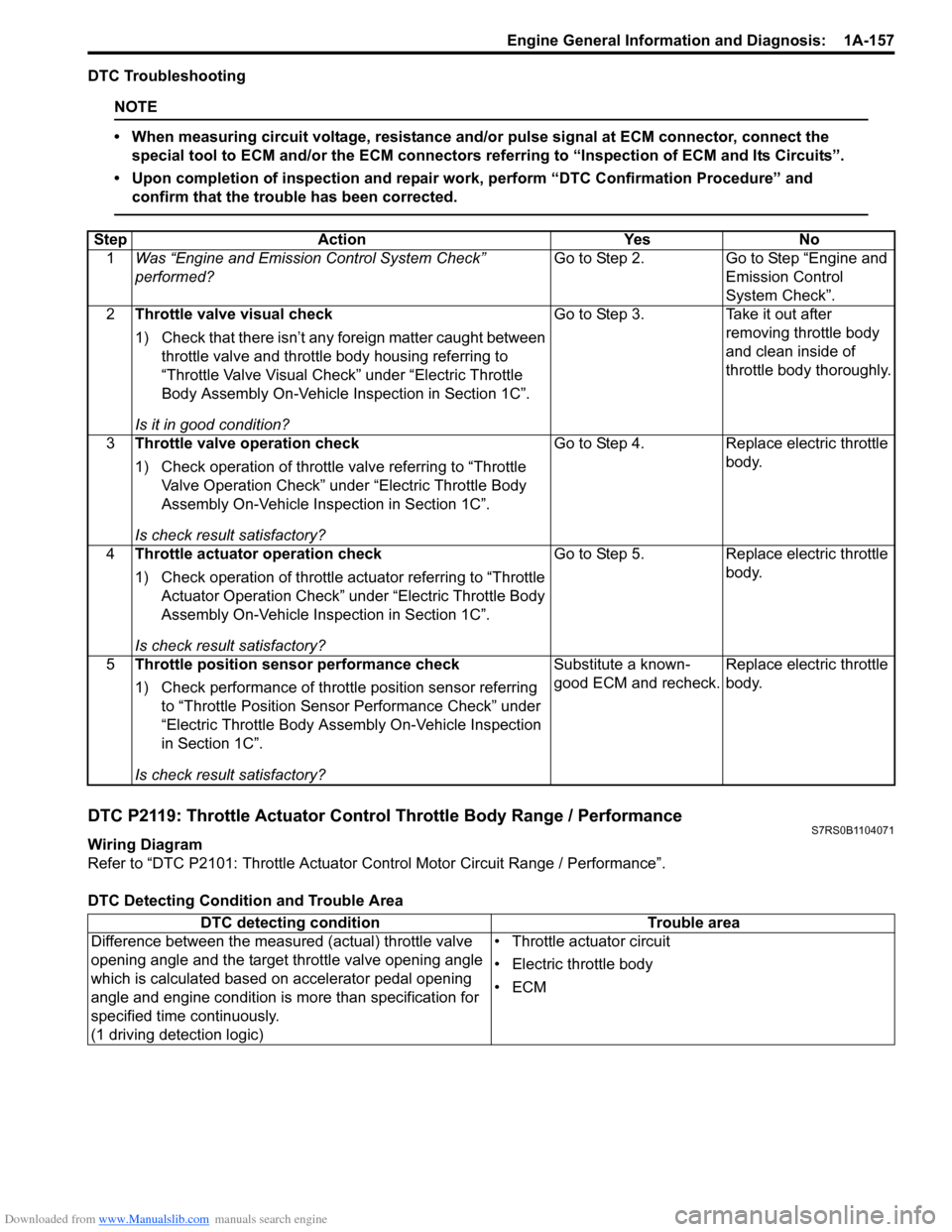

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2119: Throttle Actuator Control Throttle Body Range / PerformanceS7RS0B1104071

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to Step “Engine and

Emission Control

System Check”.

2 Throttle valve visual check

1) Check that there isn’t any foreign matter caught between

throttle valve and throttle body housing referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

Is it in good condition? Go to Step 3. Take it out after

removing throttle body

and clean inside of

throttle body thoroughly.

3 Throttle valve operation check

1) Check operation of throttle valve referring to “Throttle

Valve Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 4. Replace electric throttle

body.

4 Throttle actuator operation check

1) Check operation of throttle ac tuator referring to “Throttle

Actuator Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 5. Replace electric throttle

body.

5 Throttle position sensor performance check

1) Check performance of throttle position sensor referring

to “Throttle Position Sensor Performance Check” under

“Electric Throttle Body Assembly On-Vehicle Inspection

in Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

DTC detecting condition

Trouble area

Difference between the measured (actual) throttle valve

opening angle and the target throttle valve opening angle

which is calculated based on accelerator pedal opening

angle and engine condition is more than specification for

specified time continuously.

(1 driving detection logic) • Throttle actuator circuit

• Electric throttle body

•ECM