assembly removal SUZUKI SWIFT 2007 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 330 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-45 Engine Mechanical:

Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation

S7RS0B1406030

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

3) Mark cylinder number on all pistons, connecting rods

and connecting rod caps using silver pencil or quick

drying paint.

4) Remove rod bearing caps.

5) Decarbonize top of cylinder bore before removing piston from cylinder.

6) Push piston and connecting rod assembly out through the top of cylinder bore.

Installation 1) Apply engine oil to pistons, rings, cylinder walls, connecting rod bearings and crank pins.

NOTE

Do not apply oil between connecting rod and

bearing or between bearing cap and bearing.

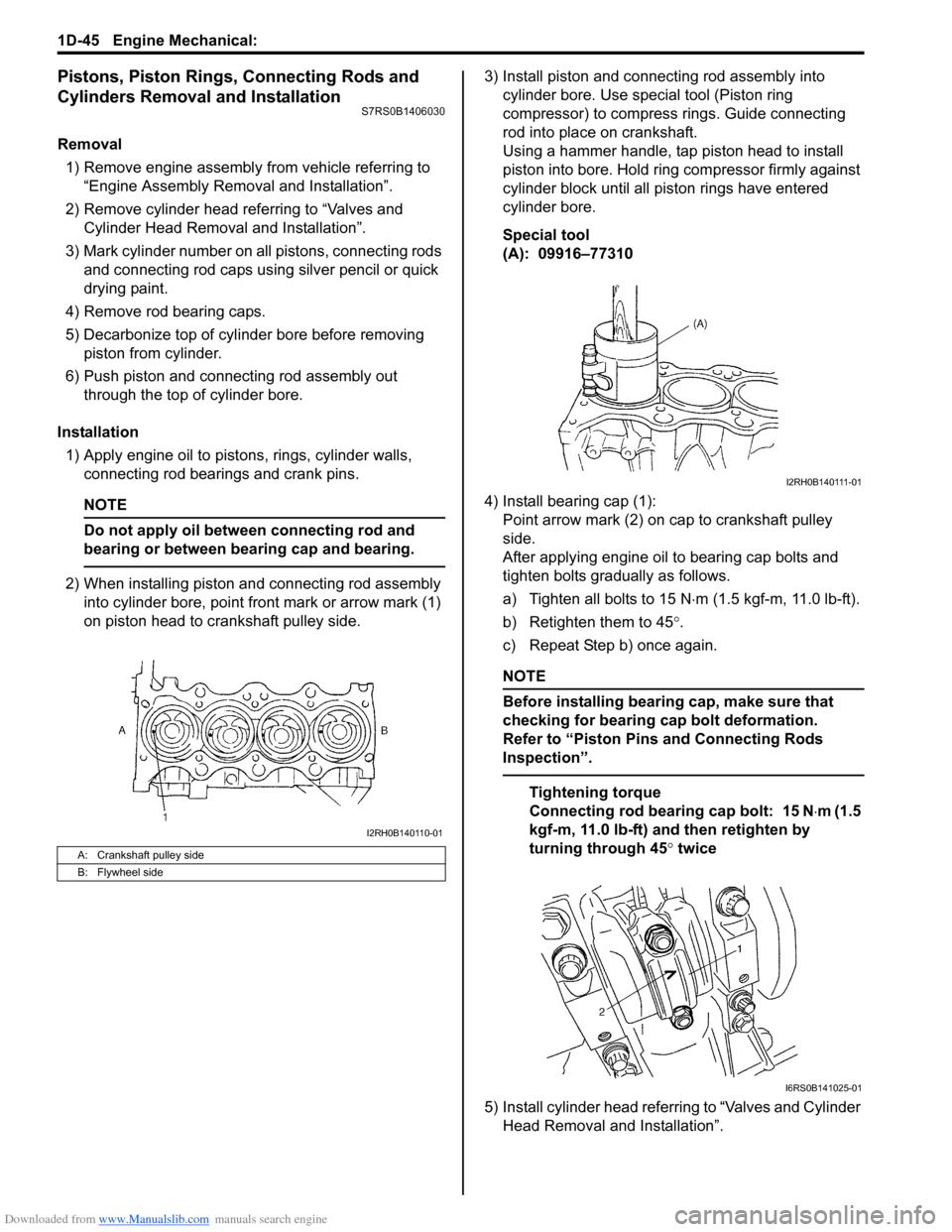

2) When installing piston and connecting rod assembly into cylinder bore, point front mark or arrow mark (1)

on piston head to crankshaft pulley side. 3) Install piston and connecting rod assembly into

cylinder bore. Use special tool (Piston ring

compressor) to compress rings. Guide connecting

rod into place on crankshaft.

Using a hammer handle, tap piston head to install

piston into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

Special tool

(A): 09916–77310

4) Install bearing cap (1): Point arrow mark (2) on cap to crankshaft pulley

side.

After applying engine oil to bearing cap bolts and

tighten bolts gradually as follows.

a) Tighten all bolts to 15 N ⋅m (1.5 kgf-m, 11.0 lb-ft).

b) Retighten them to 45 °.

c) Repeat Step b) once again.

NOTE

Before installing bearing cap, make sure that

checking for bearing cap bolt deformation.

Refer to “Piston Pins and Connecting Rods

Inspection”.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

turning through 45 ° twice

5) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

A: Crankshaft pulley side

B: Flywheel side

I2RH0B140110-01

I2RH0B140111-01

I6RS0B141025-01

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

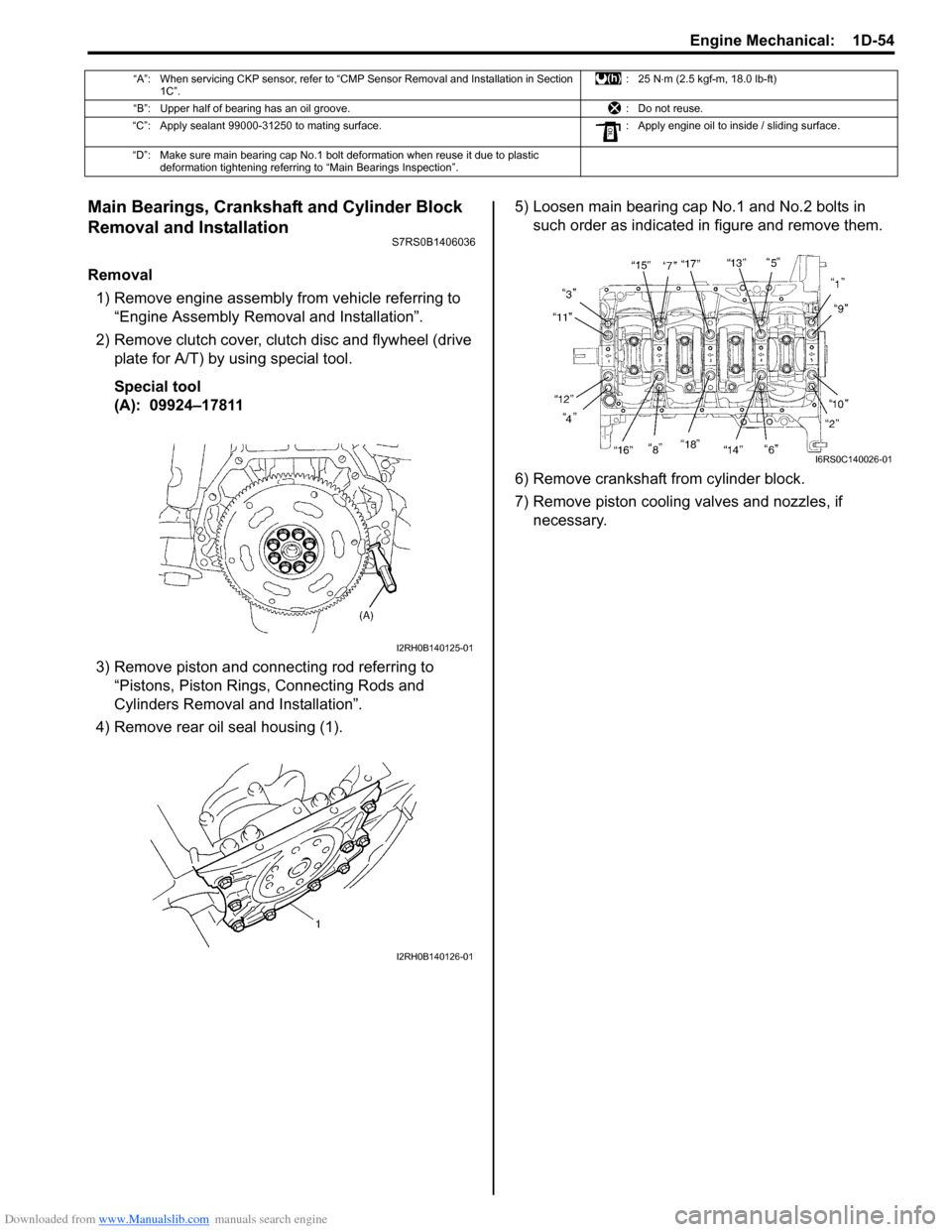

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

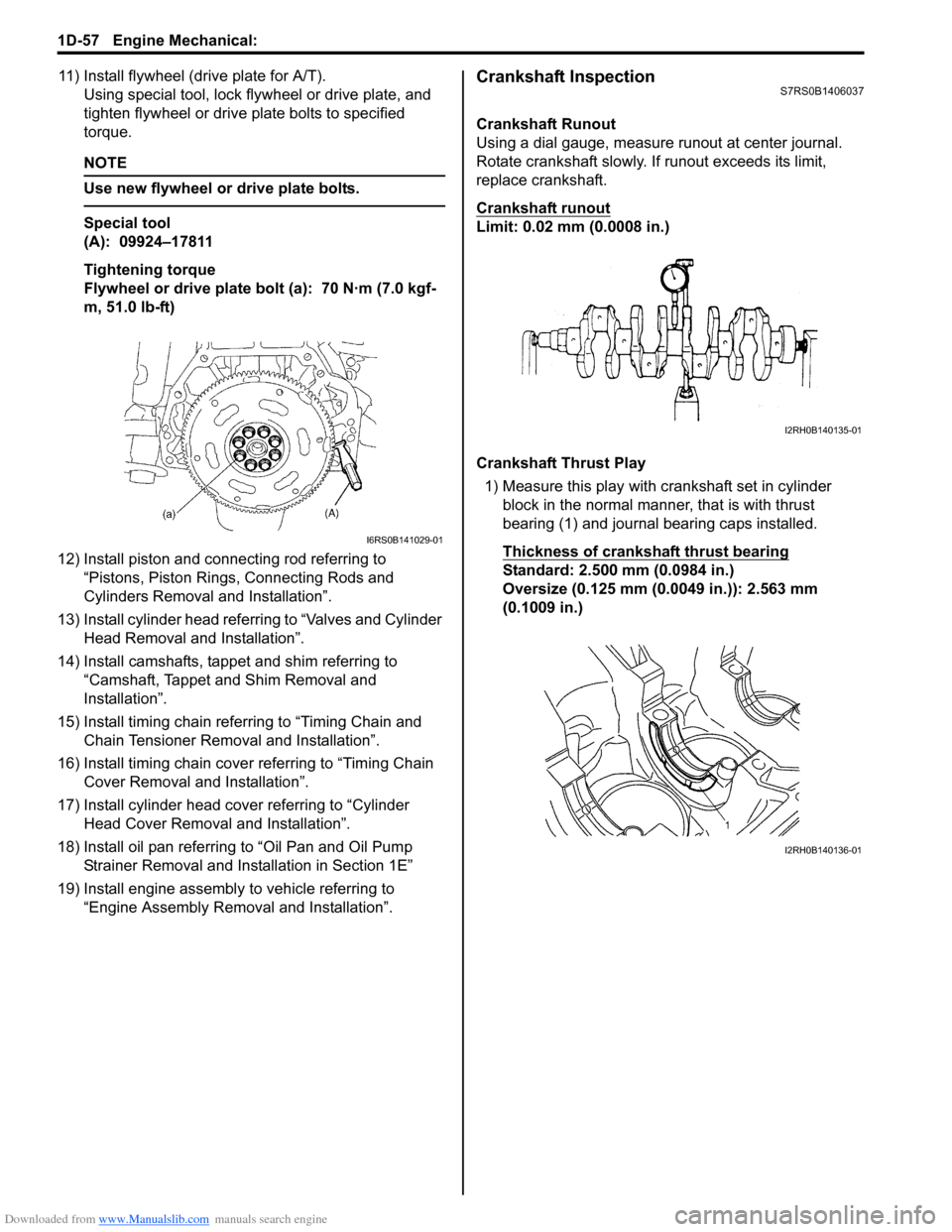

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 360 of 1496

Downloaded from www.Manualslib.com manuals search engine 1E-8 Engine Lubrication System:

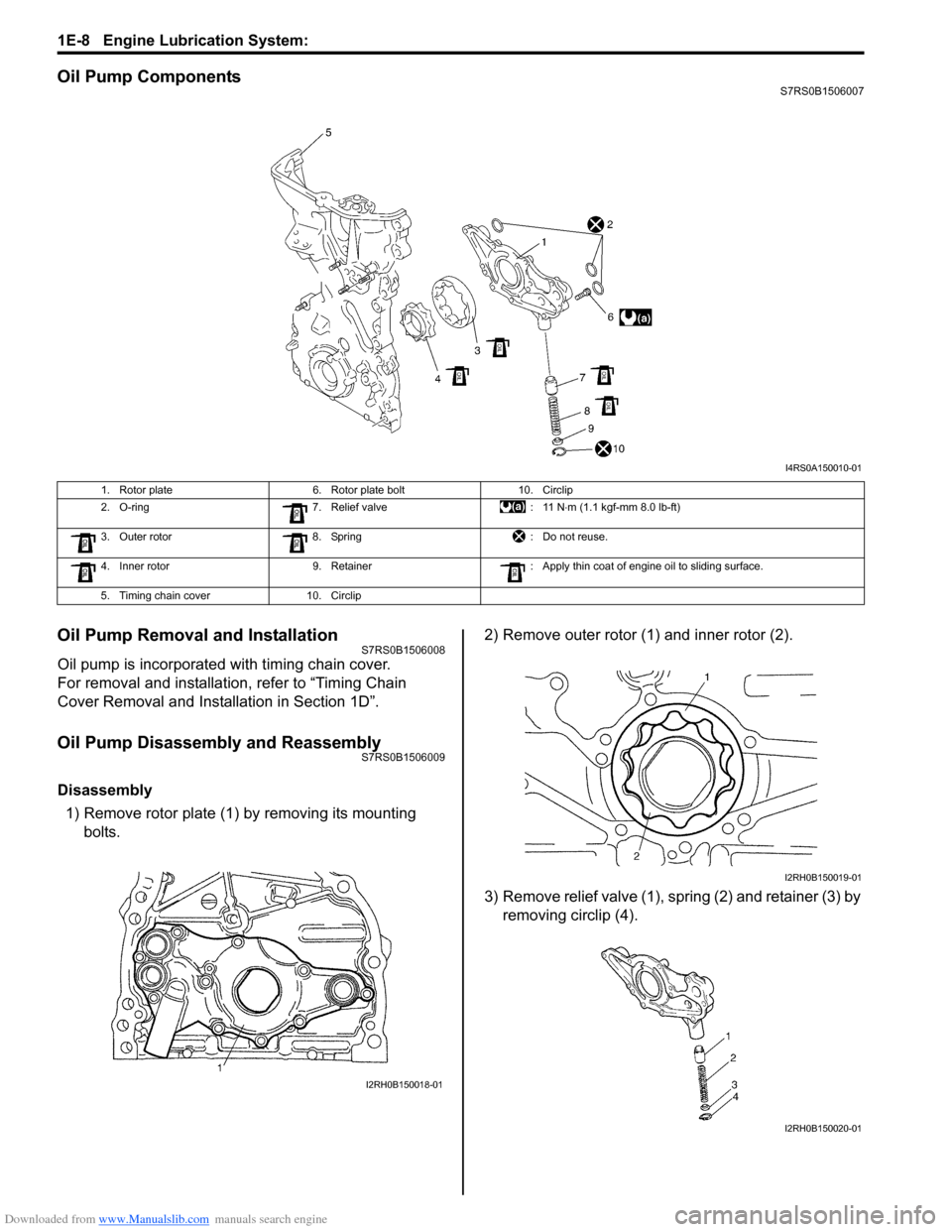

Oil Pump ComponentsS7RS0B1506007

Oil Pump Removal and InstallationS7RS0B1506008

Oil pump is incorporated with timing chain cover.

For removal and installation, refer to “Timing Chain

Cover Removal and Installation in Section 1D”.

Oil Pump Disassembly and ReassemblyS7RS0B1506009

Disassembly1) Remove rotor plate (1) by removing its mounting bolts. 2) Remove outer rotor (1) and inner rotor (2).

3) Remove relief valve (1), spring (2) and retainer (3) by

removing circlip (4).

I4RS0A150010-01

1. Rotor plate 6. Rotor plate bolt10. Circlip

2. O-ring 7. Relief valve : 11 N⋅m (1.1 kgf-mm 8.0 lb-ft)

3. Outer rotor 8. Spring : Do not reuse.

4. Inner rotor 9. Retainer : Apply thin coat of engine oil to sliding surface.

5. Timing chain cover 10. Circlip

I2RH0B150018-01

I2RH0B150019-01

I2RH0B150020-01

Page 374 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Water Pump Removal and InstallationS7RS0B1606014

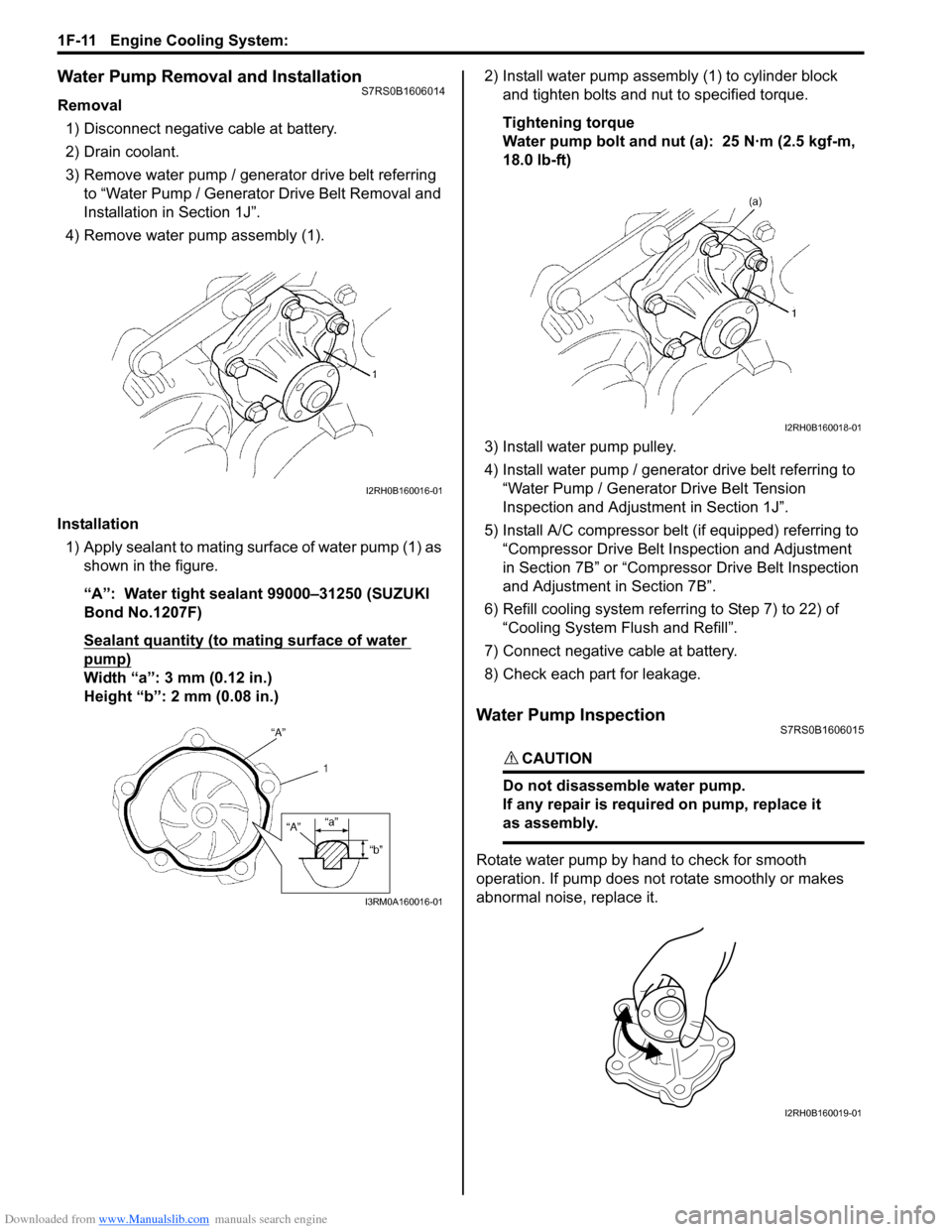

Removal1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Removal and

Installation in Section 1J”.

4) Remove water pump assembly (1).

Installation 1) Apply sealant to mating surface of water pump (1) as shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

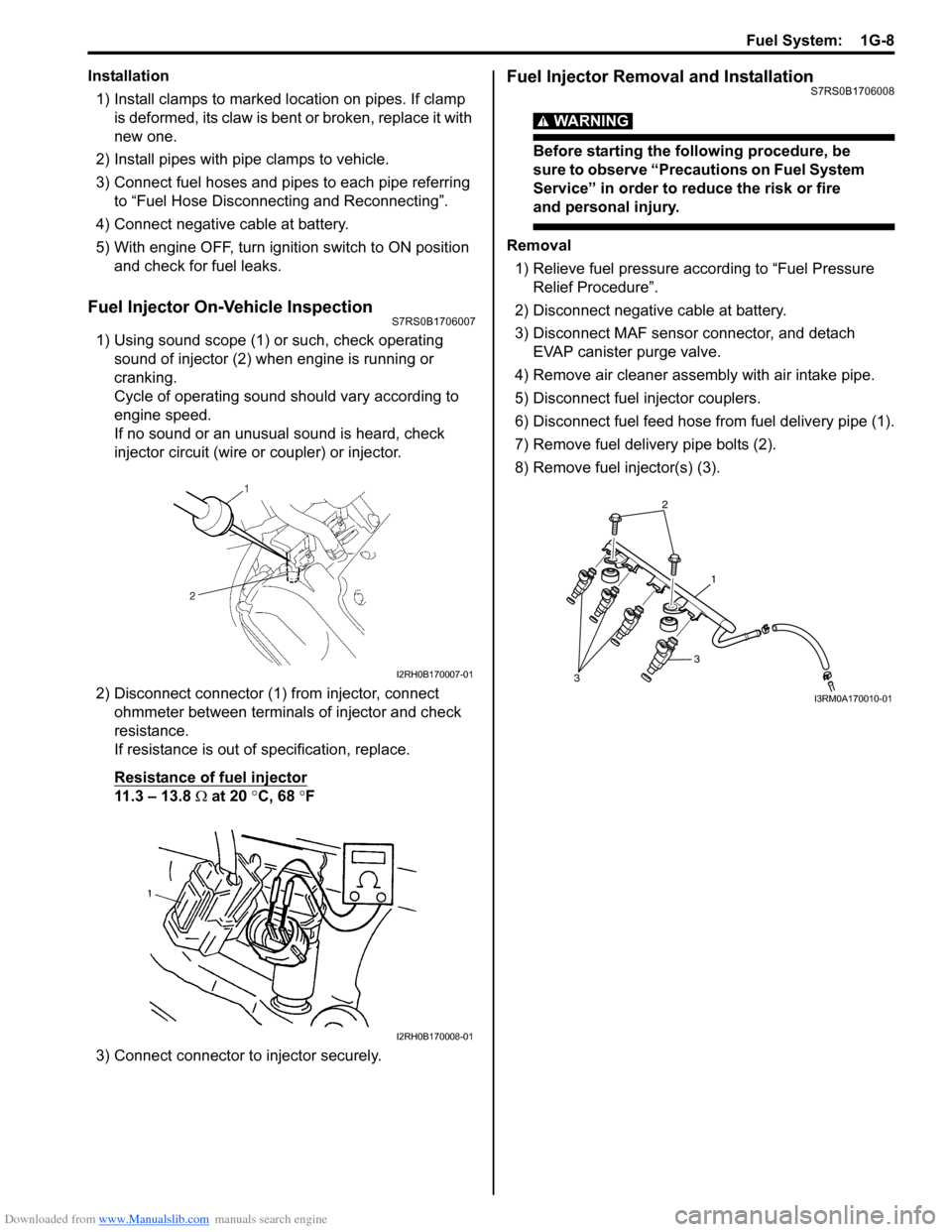

Height “b”: 2 mm (0.08 in.) 2) Install water pump assemb

ly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

5) Install A/C compressor belt (if equipped) referring to “Compressor Drive Belt Inspection and Adjustment

in Section 7B” or “Compressor Drive Belt Inspection

and Adjustment in Section 7B”.

6) Refill cooling system referri ng to Step 7) to 22) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

Water Pump InspectionS7RS0B1606015

CAUTION!

Do not disassemble water pump.

If any repair is requir ed on pump, replace it

as assembly.

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

I2RH0B160019-01

Page 383 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-8

Installation1) Install clamps to marked location on pipes. If clamp is deformed, its claw is bent or broken, replace it with

new one.

2) Install pipes with pipe clamps to vehicle.

3) Connect fuel hoses and pipes to each pipe referring to “Fuel Hose Disconnecting and Reconnecting”.

4) Connect negative cable at battery.

5) With engine OFF, turn igniti on switch to ON position

and check for fuel leaks.

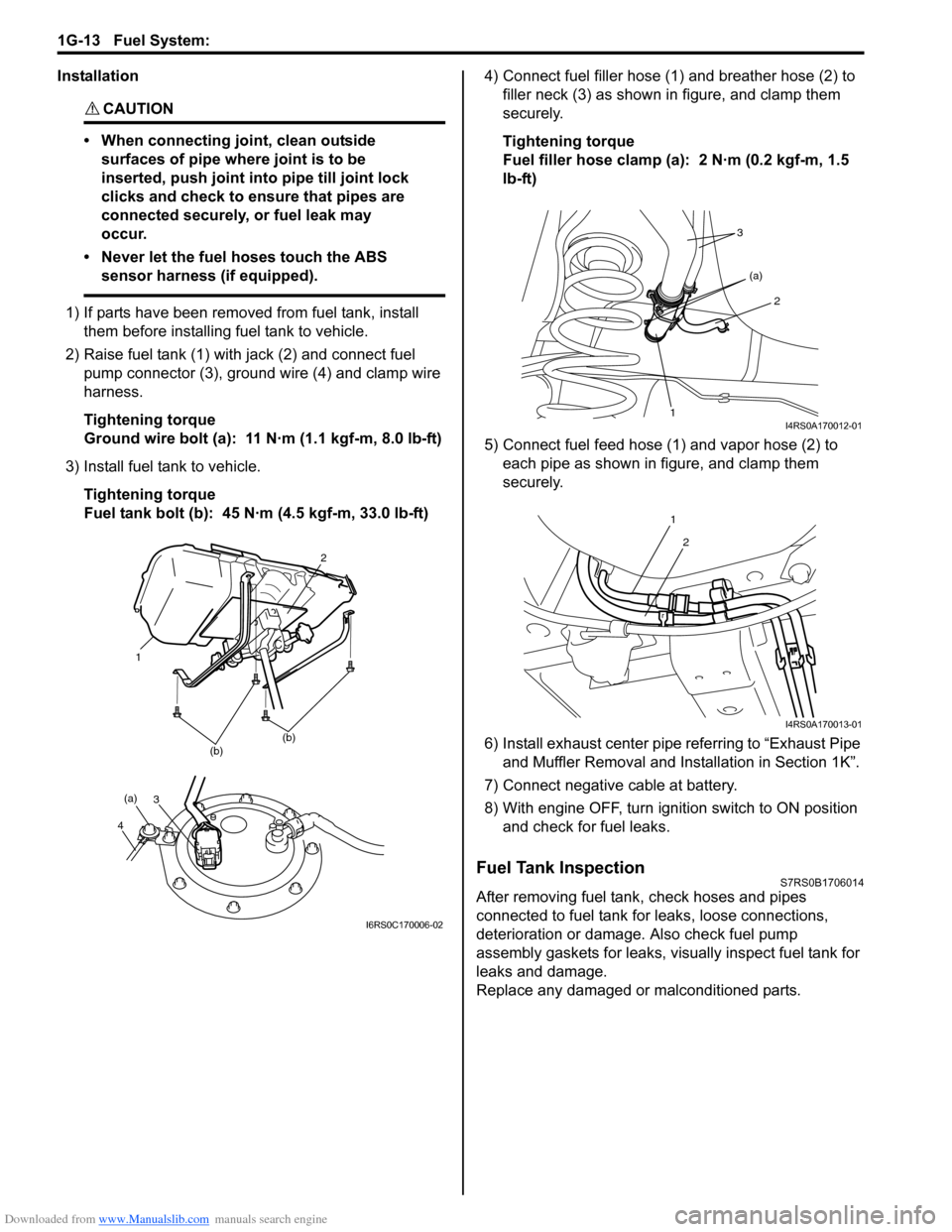

Fuel Injector On-Vehicle InspectionS7RS0B1706007

1) Using sound scope (1) or such, check operating sound of injector (2) when engine is running or

cranking.

Cycle of operating sound should vary according to

engine speed.

If no sound or an unusual sound is heard, check

injector circuit (wire or coupler) or injector.

2) Disconnect connector (1) from injector, connect ohmmeter between terminals of injector and check

resistance.

If resistance is out of specification, replace.

Resistance of fuel injector

11.3 – 13.8 Ω at 20 °C, 68 °F

3) Connect connector to injector securely.

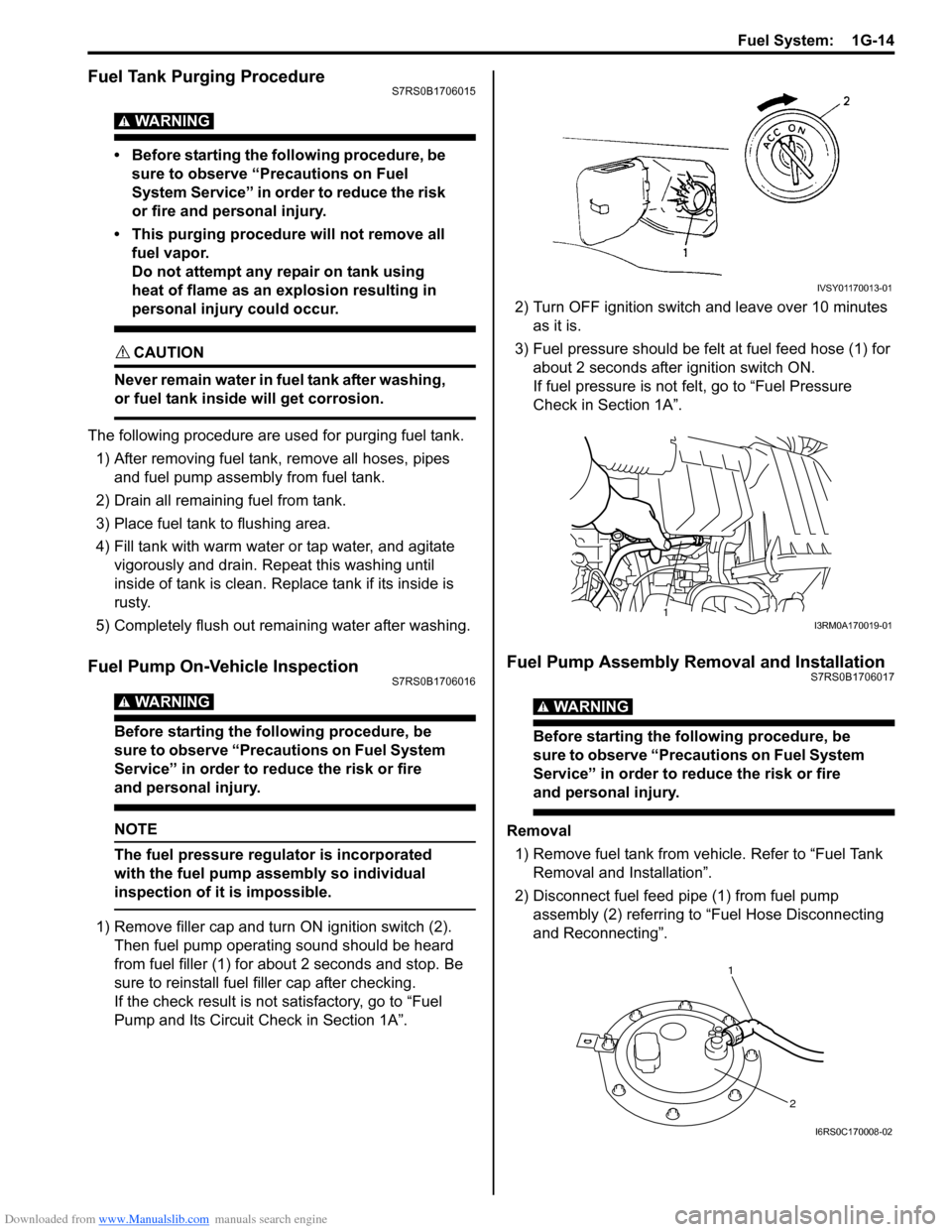

Fuel Injector Removal and InstallationS7RS0B1706008

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal 1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect MAF sensor connector, and detach EVAP canister purge valve.

4) Remove air cleaner assembly with air intake pipe.

5) Disconnect fuel injector couplers.

6) Disconnect fuel feed hose from fuel delivery pipe (1).

7) Remove fuel delivery pipe bolts (2).

8) Remove fuel injector(s) (3).

I2RH0B170007-01

I2RH0B170008-01

2

1

3

3

I3RM0A170010-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 389 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

Fuel Tank Purging ProcedureS7RS0B1706015

WARNING!

• Before starting the following procedure, be sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

or fire and personal injury.

• This purging procedure will not remove all fuel vapor.

Do not attempt any repair on tank using

heat of flame as an explosion resulting in

personal injury could occur.

CAUTION!

Never remain water in fu el tank after washing,

or fuel tank inside will get corrosion.

The following procedure are used for purging fuel tank.

1) After removing fuel tank, remove all hoses, pipes and fuel pump assembly from fuel tank.

2) Drain all remaining fuel from tank.

3) Place fuel tank to flushing area.

4) Fill tank with warm water or tap water, and agitate

vigorously and drain. Repeat this washing until

inside of tank is clean. Replace tank if its inside is

rusty.

5) Completely flush out rema ining water after washing.

Fuel Pump On-Vehicle InspectionS7RS0B1706016

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

NOTE

The fuel pressure regulator is incorporated

with the fuel pump assembly so individual

inspection of it is impossible.

1) Remove filler cap and turn ON ignition switch (2).

Then fuel pump operating sound should be heard

from fuel filler (1) for about 2 seconds and stop. Be

sure to reinstall fuel filler cap after checking.

If the check result is not satisfactory, go to “Fuel

Pump and Its Circuit Check in Section 1A”. 2) Turn OFF ignition switch and leave over 10 minutes

as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for about 2 seconds after ignition switch ON.

If fuel pressure is not felt, go to “Fuel Pressure

Check in Section 1A”.

Fuel Pump Assembly Removal and InstallationS7RS0B1706017

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Remove fuel tank from vehicle. Refer to “Fuel Tank Removal and Installation”.

2) Disconnect fuel feed pipe (1) from fuel pump assembly (2) referring to “Fuel Hose Disconnecting

and Reconnecting”.

IVSY01170013-01

1I3RM0A170019-01

1

2

I6RS0C170008-02

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

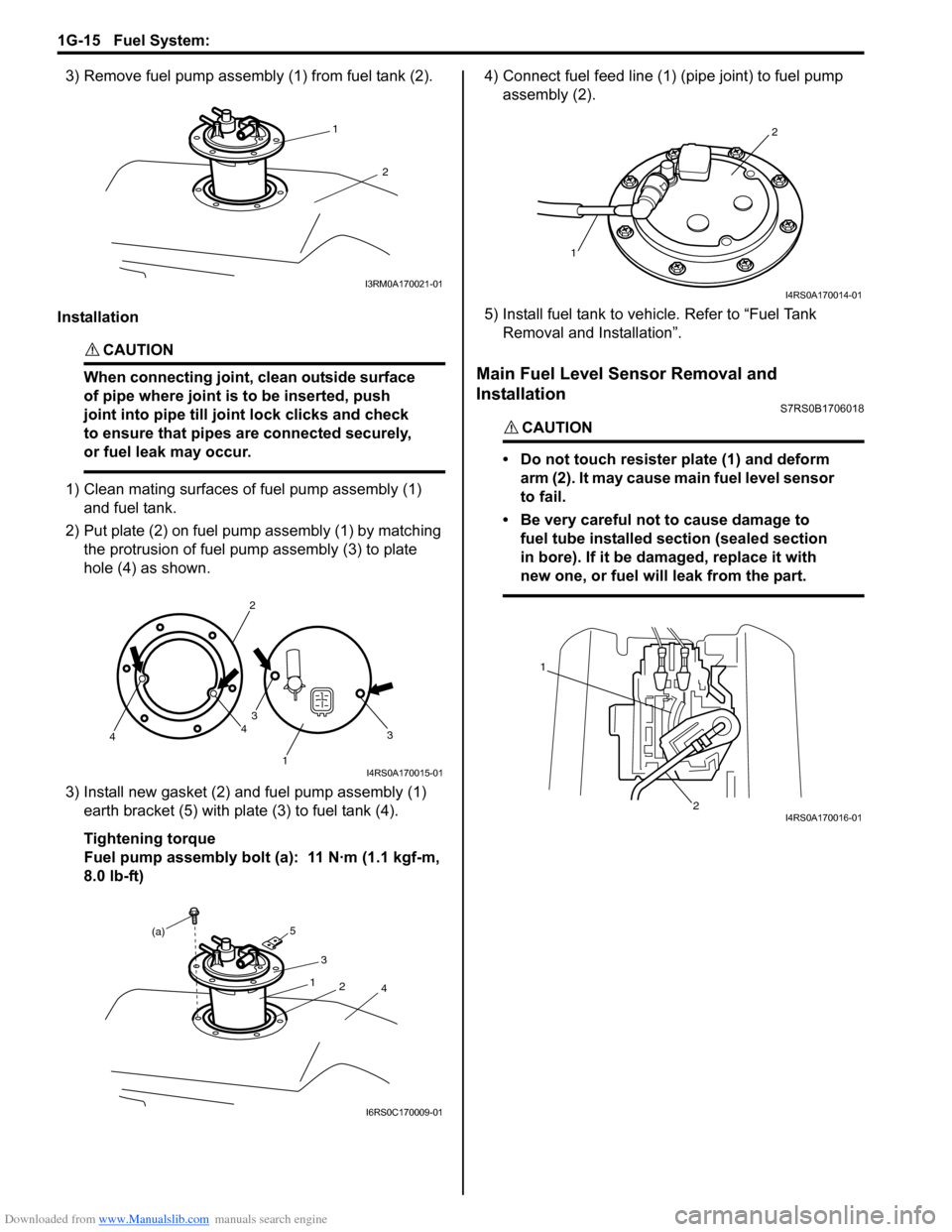

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

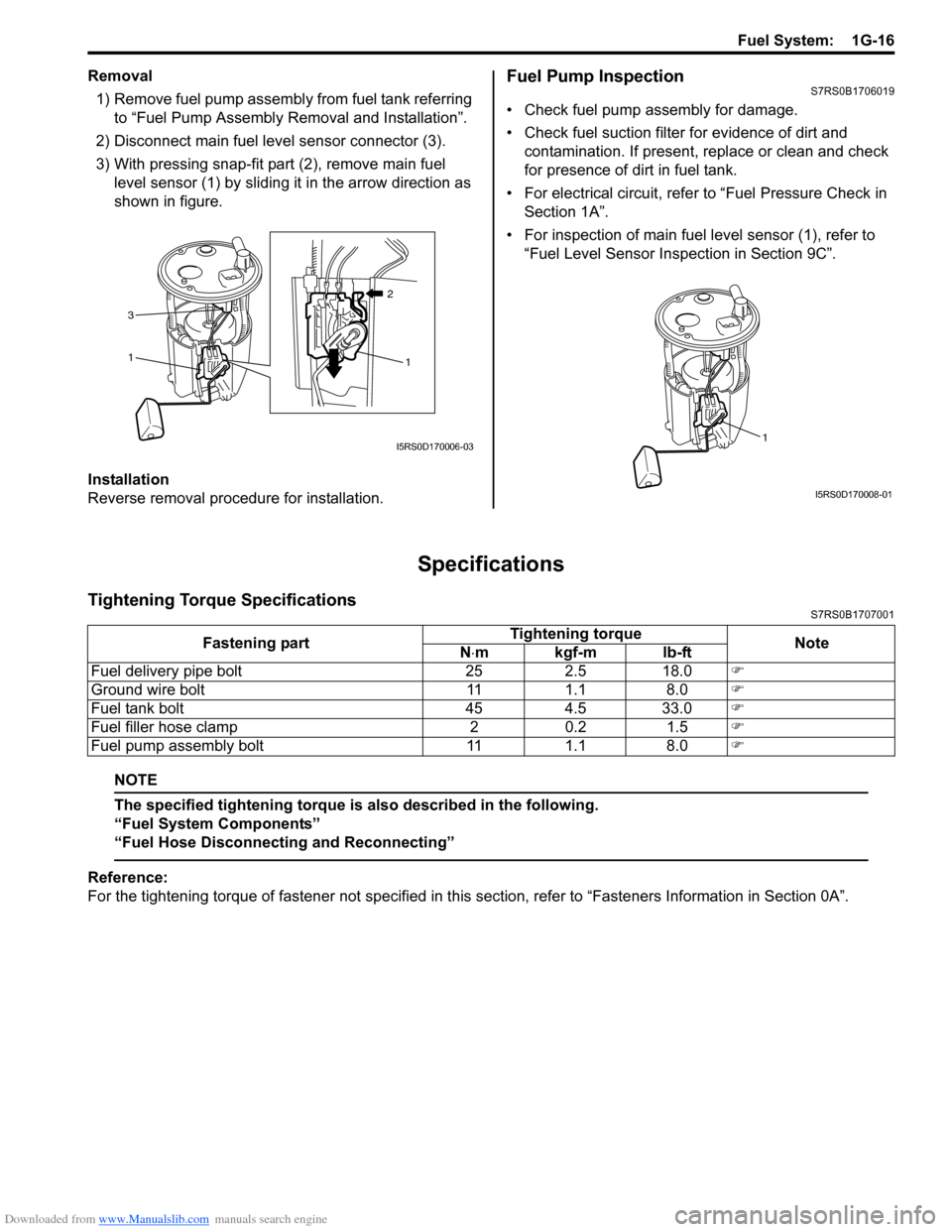

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 391 of 1496

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-16

Removal1) Remove fuel pump assembly from fuel tank referring to “Fuel Pump Assembly Removal and Installation”.

2) Disconnect main fuel level sensor connector (3).

3) With pressing snap-fit part (2), remove main fuel level sensor (1) by sliding it in the arrow direction as

shown in figure.

Installation

Reverse removal procedure for installation.Fuel Pump InspectionS7RS0B1706019

• Check fuel pump assembly for damage.

• Check fuel suction filter for evidence of dirt and contamination. If present, replace or clean and check

for presence of dirt in fuel tank.

• For electrical circuit, refer to “Fuel Pressure Check in Section 1A”.

• For inspection of main fuel level sensor (1), refer to “Fuel Level Sensor Inspection in Section 9C”.

Specifications

Tightening Torque SpecificationsS7RS0B1707001

NOTE

The specified tightening torque is also described in the following.

“Fuel System Components”

“Fuel Hose Disconnecting and Reconnecting”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

1

21

3

I5RS0D170006-031

I5RS0D170008-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Fuel delivery pipe bolt 25 2.5 18.0 �)

Ground wire bolt 11 1.1 8.0 �)

Fuel tank bolt 45 4.5 33.0 �)

Fuel filler hose clamp 2 0.2 1.5 �)

Fuel pump assembly bolt 11 1.1 8.0 �)