Vent SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 674 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-30 Automatic Transmission/Transaxle:

Troubleshooting

Engine Brake TestS7RS0B5104013

WARNING!

Before test, make sure that there is no vehicle behind so as to prevent rear-end collision.

1) While driving vehicle in 3rd gear of “D” range, shift select lever down to “2” range and check if engine brake

operates.

2) In the same way as in Step 1), check engine brake for operation when select lever is shifted down to “L” range.

3) Engine brake should operate in the test.

Troubleshooting

Stall TestS7RS0B5104014

This test is to check overall performance of automatic tr ansaxle and engine by measuring stall speed at “D” and “R”

ranges. Be sure to perform this test only when transaxle fluid is at normal operating temperature and its level is

between FULL and LOW marks.

CAUTION!

• Do not run engine at stall more than 5 seconds continuously, or fluid temperature may rise excessively high.

• After performing stall test, be su re to leave engine running at idle for longer than 1 minute before

another stall test.

1) Apply parking brake and block wheels.

2) Install tachometer.

3) Start engine with select lever shifted to “P” range.

4) Depress brake pedal fully.

5) Shift select lever to “D” range and depress accelerator pedal fully while watching tachometer. Read engine rpm quickly when it has become constant (stall speed).

6) Release accelerator pedal immediately after stall speed is checked.

7) In the same way, check stall speed in “R” range.

8) Stall speed should be withi n the following specification.

Engine stall speed

Standard: 2100 – 2400 rpm Condition Possible cause Correction / Reference Item

Operated gear is not

correct Faulty valve body component

Replace valve body assembly.

Faulty clutch or brake Inspect clutch and brake. If any parts are faulty,

replace them.

Condition Possible cause Correction / Reference Item

Failure to operate when

shifted down to “2” range Faulty valve body component

Replace valve body assembly.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Failure to operate when

shifted down to “L” range Faulty valve body component

Replace valve body assembly.

Faulty 1st and reverse brake Inspect. If NG, replace.

Page 744 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

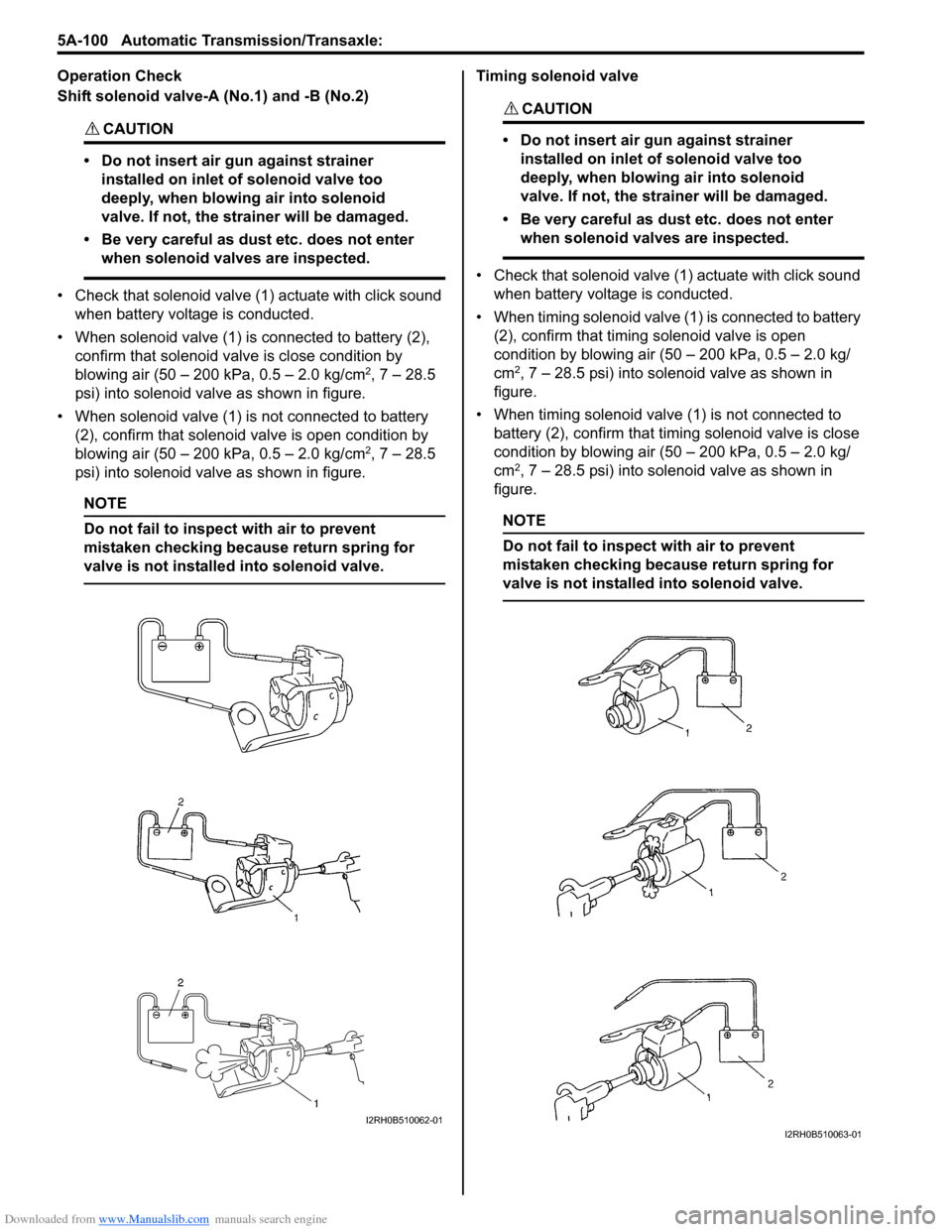

Operation Check

Shift solenoid valve-A (No.1) and -B (No.2)

CAUTION!

• Do not insert air gun against strainer installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound when battery voltage is conducted.

• When solenoid valve (1) is connected to battery (2), confirm that solenoid valve is close condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

• When solenoid valve (1) is not connected to battery (2), confirm that solenoid valve is open condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installe d into solenoid valve.

Timing solenoid valve

CAUTION!

• Do not insert air gun against strainer

installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound

when battery voltage is conducted.

• When timing solenoid valve (1 ) is connected to battery

(2), confirm that timing solenoid valve is open

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

• When timing solenoid valve (1) is not connected to battery (2), confirm that timi ng solenoid valve is close

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installed into solenoid valve.

I2RH0B510062-01I2RH0B510063-01

Page 763 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-119

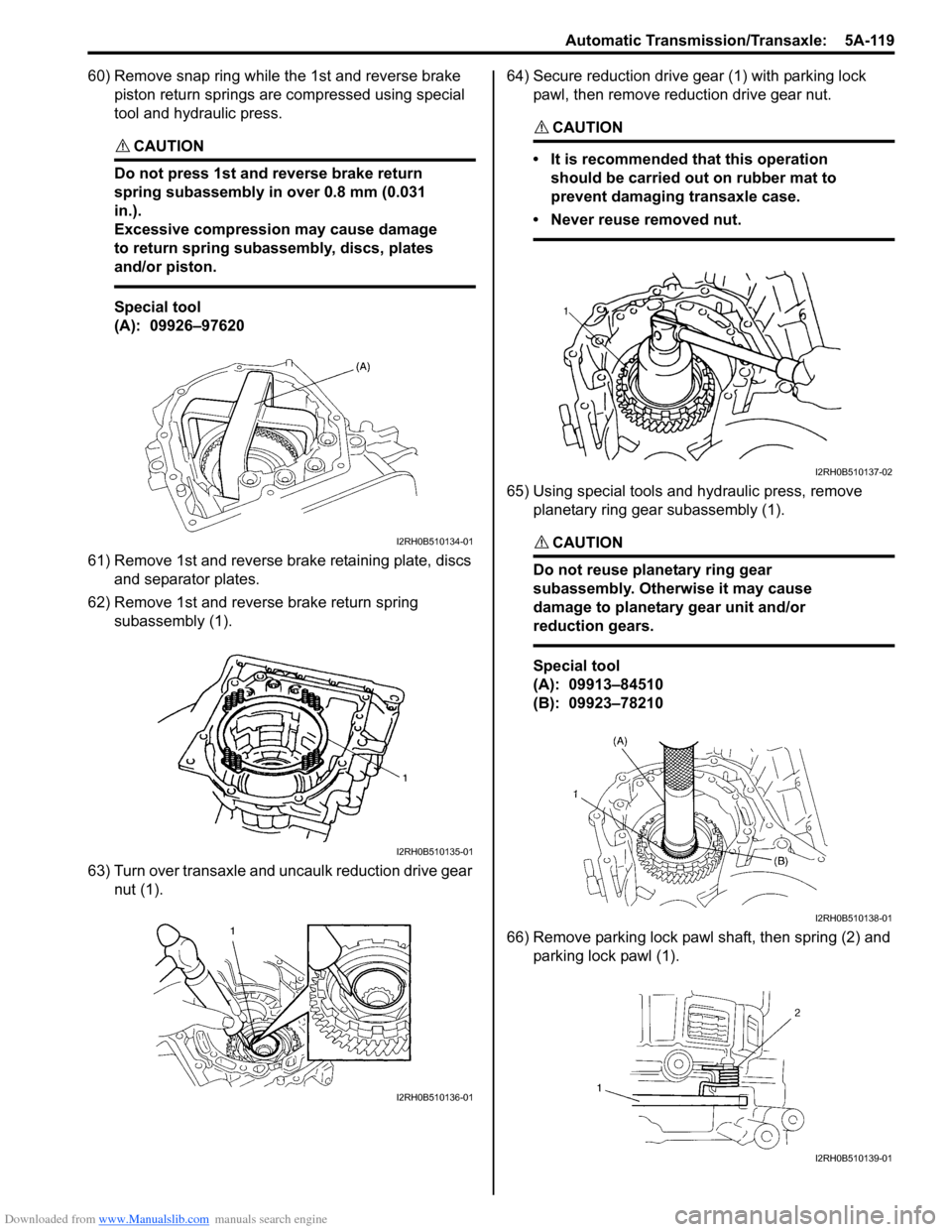

60) Remove snap ring while the 1st and reverse brake piston return springs are compressed using special

tool and hydraulic press.

CAUTION!

Do not press 1st and reverse brake return

spring subassembly in over 0.8 mm (0.031

in.).

Excessive compression may cause damage

to return spring subassembly, discs, plates

and/or piston.

Special tool

(A): 09926–97620

61) Remove 1st and reverse brake retaining plate, discs and separator plates.

62) Remove 1st and reverse brake return spring subassembly (1).

63) Turn over transaxle and uncaulk reduction drive gear nut (1). 64) Secure reduction drive gear (1) with parking lock

pawl, then remove reduction drive gear nut.

CAUTION!

• It is recommended that this operation should be carried out on rubber mat to

prevent damaging transaxle case.

• Never reuse removed nut.

65) Using special tools and hydraulic press, remove planetary ring gear subassembly (1).

CAUTION!

Do not reuse planetary ring gear

subassembly. Otherwise it may cause

damage to planetary gear unit and/or

reduction gears.

Special tool

(A): 09913–84510

(B): 09923–78210

66) Remove parking lock pawl shaft, then spring (2) and parking lock pawl (1).

I2RH0B510134-01

I2RH0B510135-01

I2RH0B510136-01

I2RH0B510137-02

I2RH0B510138-01

I2RH0B510139-01

Page 810 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-166 Automatic Transmission/Transaxle:

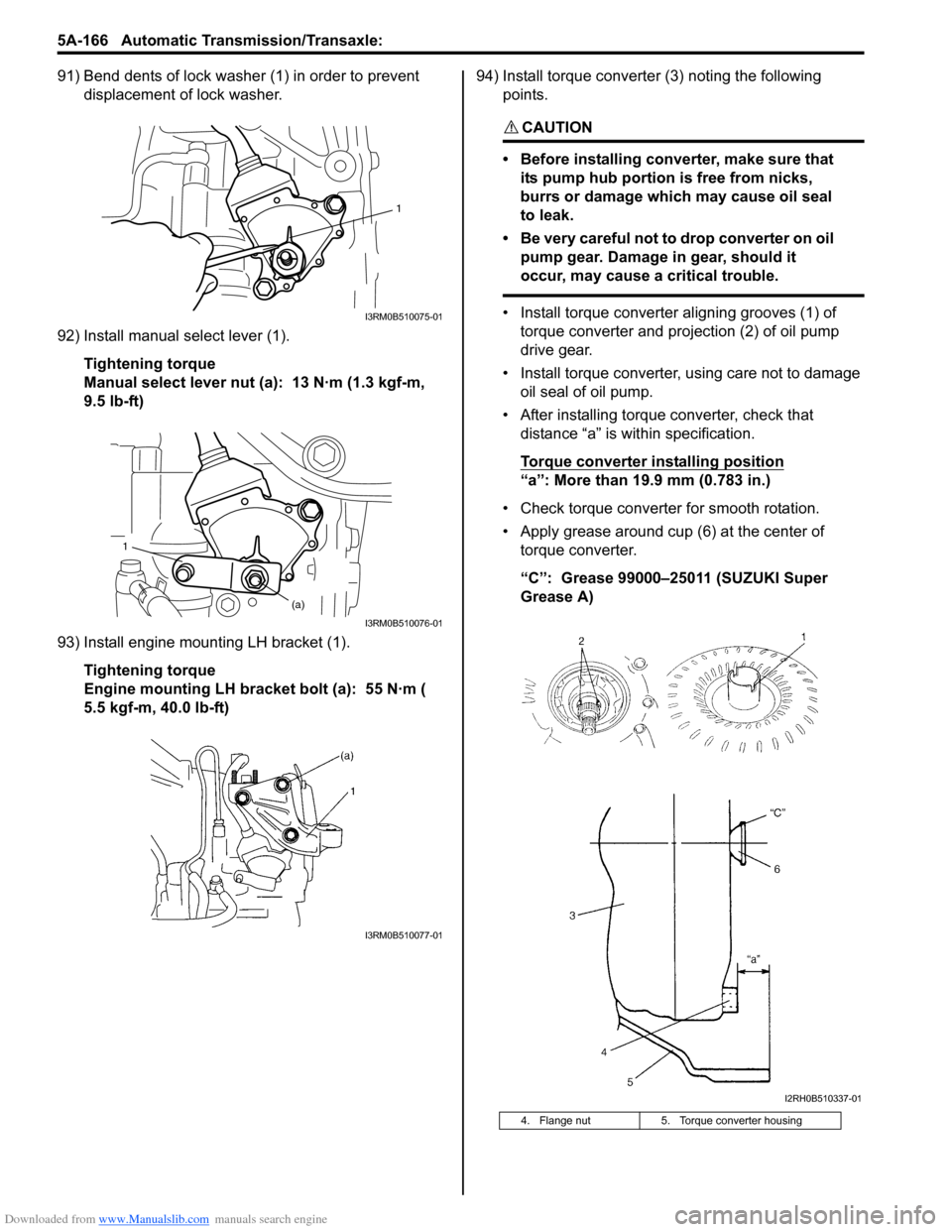

91) Bend dents of lock washer (1) in order to prevent displacement of lock washer.

92) Install manual select lever (1). Tightening torque

Manual select lever nut (a): 13 N·m (1.3 kgf-m,

9.5 lb-ft)

93) Install engine mounting LH bracket (1). Tightening torque

Engine mounting LH bracket bolt (a): 55 N·m (

5.5 kgf-m, 40.0 lb-ft) 94) Install torque converter (3) noting the following

points.

CAUTION!

• Before installing converter, make sure that its pump hub portion is free from nicks,

burrs or damage which may cause oil seal

to leak.

• Be very careful not to drop converter on oil pump gear. Damage in gear, should it

occur, may cause a critical trouble.

• Install torque converter aligning grooves (1) of torque converter and projection (2) of oil pump

drive gear.

• Install torque converter, using care not to damage oil seal of oil pump.

• After installing torque converter, check that distance “a” is within specification.

Torque converter installing position

“a”: More than 19.9 mm (0.783 in.)

• Check torque converter for smooth rotation.

• Apply grease around cup (6) at the center of torque converter.

“C”: Grease 99000–25011 (SUZUKI Super

Grease A)

1

I3RM0B510075-01

1

(a)

I3RM0B510076-01

I3RM0B510077-01

4. Flange nut 5. Torque converter housing

I2RH0B510337-01

Page 815 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-1

Transmission / Transaxle

Manual Transmission/Transaxle

General Description

Manual Transaxle Construction and ServicingS7RS0B5201001

The transaxle provides five forward speeds and one reverse speed by means of three synchromeshs and three shafts

(input shaft, countershaft and reverse gear shaft). All forward gears are in constant mesh, and reverse uses a sliding

idler gear arrangement.

The low speed synchronizer sleeve & hub is mounted on countershaft and engaged with countershaft 1st gear or 2nd

gear, while the high speed synchronizer sleeve & hub is don e on input shaft and engaged with input shaft 3rd gear or

4th gear. The 5th speed synchronizer sleev e & hub on input shaft is engaged with input shaft fifth gear mounted on the

input shaft.

To prevent the cracking noise from the reverse gear when shifting transaxle gear into the reverse gear, the reverse

shift braking device is used.

The device utilizes the 5th synchromesh, which is the lever synchro type, to appl y the brake on the input shaft rotation.

The double cone synchronizing mechanism is provided to 2nd gear synchromesh device for high performance of

shifting to 2nd gear.

The countershaft turns the final gear and differential assembly, thereby turning the front drive shafts which are

attached to the front wheels.

For servicing, it is ne cessary to use genuine sealant or its equivalent on mating surfaces of transaxle case which is

made of aluminum. The case fastening bolts must be tight ened to specified torque by means of torque wrench. It is

also important that all parts are thoroughly cleaned with cleaning fluid and air dried before reassembling.

Further, care must be taken to adjust preload of count ershaft taper roller bearings. New synchronizer rings are

prohibited from being lapped with respective gear cones by using lapping compound before they are assembled.

Page 826 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-12 Manual Transmission/Transaxle:

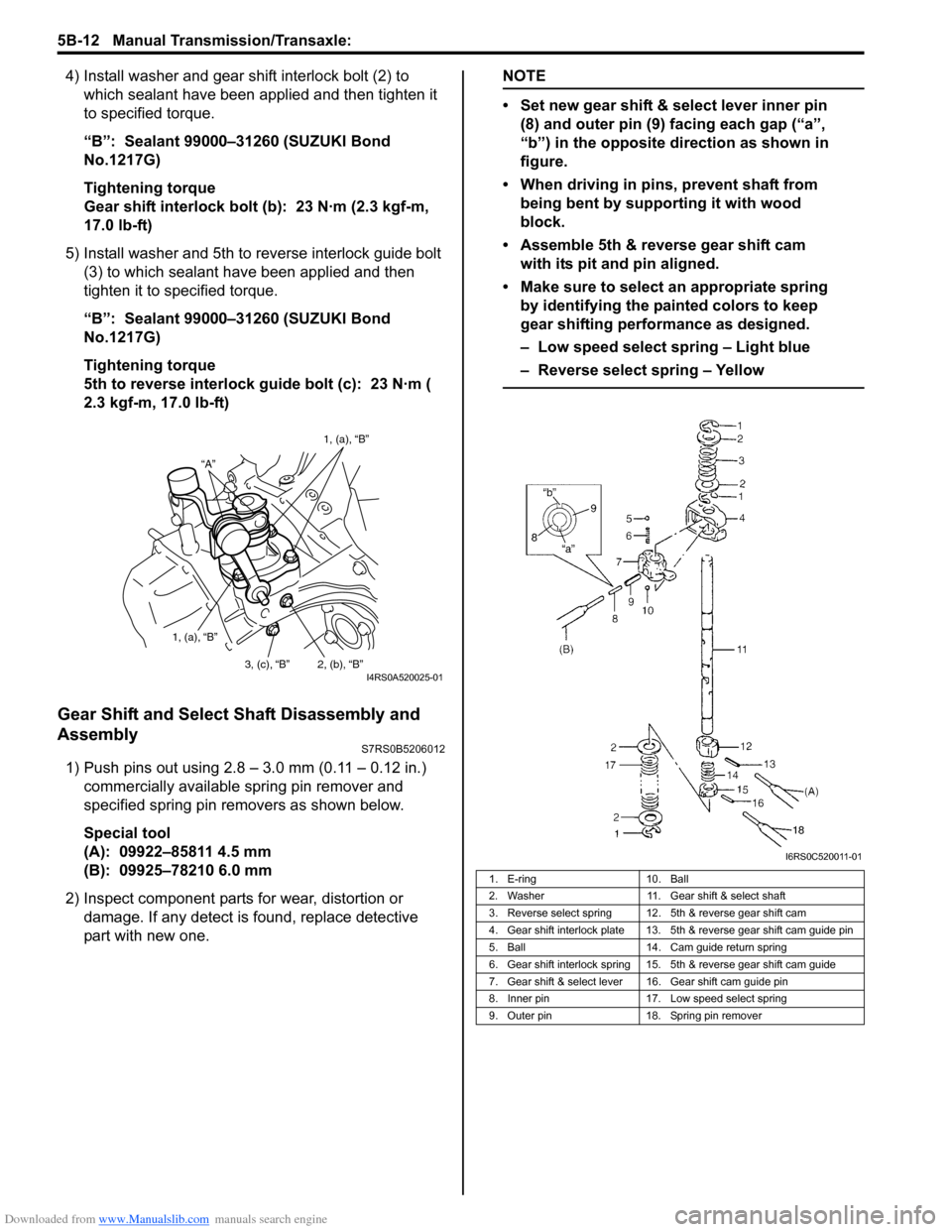

4) Install washer and gear shift interlock bolt (2) to which sealant have been app lied and then tighten it

to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Gear shift interlock bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

5) Install washer and 5th to reverse interlock guide bolt (3) to which sealant have been applied and then

tighten it to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

5th to reverse interlock guide bolt (c): 23 N·m (

2.3 kgf-m, 17.0 lb-ft)

Gear Shift and Select Shaft Disassembly and

Assembly

S7RS0B5206012

1) Push pins out using 2.8 – 3.0 mm (0.11 – 0.12 in.) commercially available spring pin remover and

specified spring pin removers as shown below.

Special tool

(A): 09922–85811 4.5 mm

(B): 09925–78210 6.0 mm

2) Inspect component parts for wear, distortion or

damage. If any detect is found, replace detective

part with new one.

NOTE

• Set new gear shift & select lever inner pin (8) and outer pin (9) facing each gap (“a”,

“b”) in the opposite direction as shown in

figure.

• When driving in pins, prevent shaft from being bent by supporting it with wood

block.

• Assemble 5th & reverse gear shift cam with its pit and pin aligned.

• Make sure to select an appropriate spring by identifying the painted colors to keep

gear shifting performance as designed.

– Low speed select spring – Light blue

– Reverse select spring – Yellow

“A” 1, (a), “B”

1, (a), “B” 2, (b), “B”

3, (c), “B”

I4RS0A520025-01

1. E-ring 10. Ball

2. Washer 11. Gear shift & select shaft

3. Reverse select spring 12. 5th & reverse gear shift cam

4. Gear shift interlock plate 13. 5th & reverse gear shift cam guide pin

5. Ball 14. Cam guide return spring

6. Gear shift interlock spring 15. 5th & reverse gear shift cam guide

7. Gear shift & select lever 16. Gear shift cam guide pin

8. Inner pin 17. Low speed select spring

9. Outer pin 18. Spring pin remover

I6RS0C520011-01

Page 842 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-28 Manual Transmission/Transaxle:

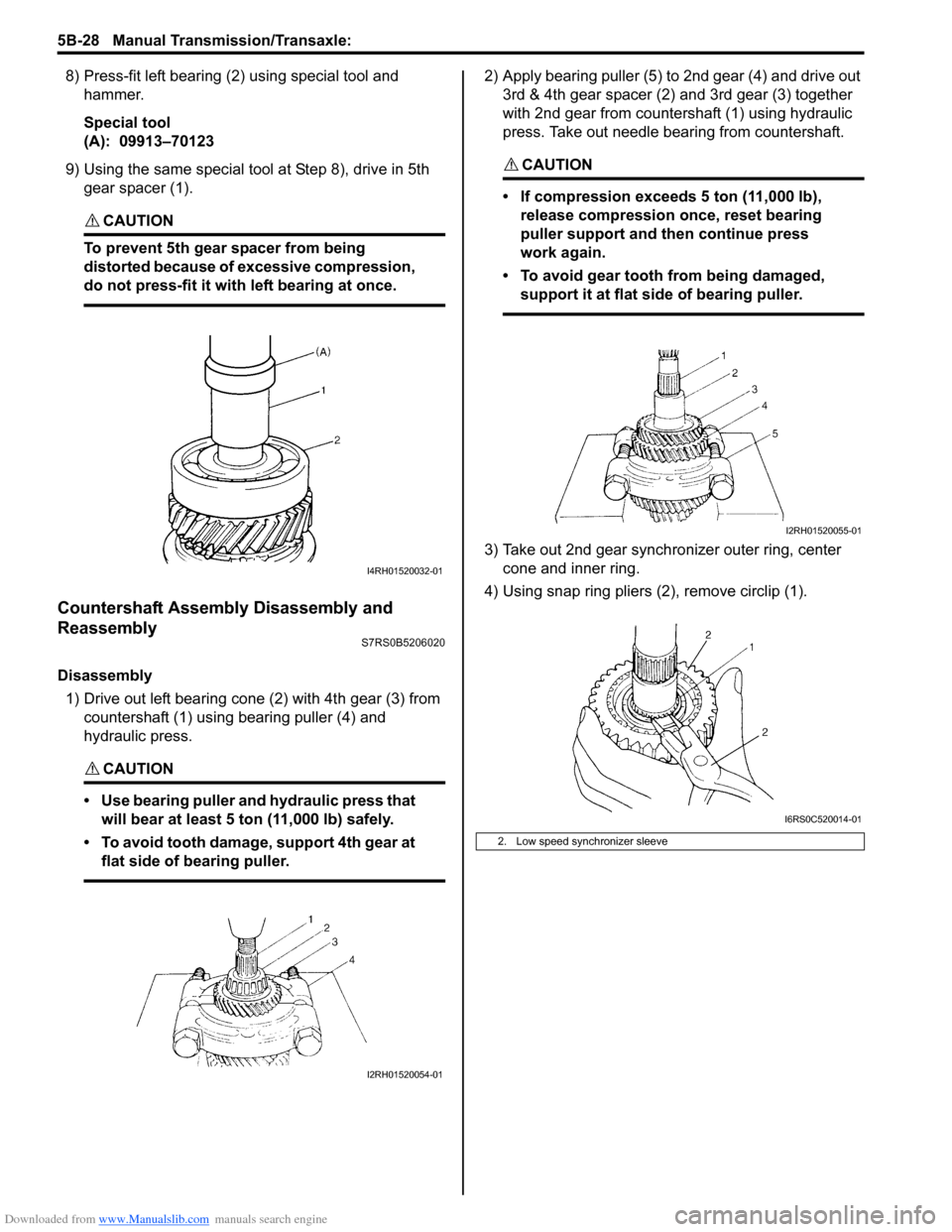

8) Press-fit left bearing (2) using special tool and hammer.

Special tool

(A): 09913–70123

9) Using the same special tool at Step 8), drive in 5th

gear spacer (1).

CAUTION!

To prevent 5th gear spacer from being

distorted because of excessive compression,

do not press-fit it with left bearing at once.

Countershaft Assembly Disassembly and

Reassembly

S7RS0B5206020

Disassembly

1) Drive out left bearing cone (2) with 4th gear (3) from countershaft (1) using bearing puller (4) and

hydraulic press.

CAUTION!

• Use bearing puller and hydraulic press that will bear at least 5 ton (11,000 lb) safely.

• To avoid tooth damage, support 4th gear at flat side of bearing puller.

2) Apply bearing puller (5) to 2nd gear (4) and drive out 3rd & 4th gear spacer (2) and 3rd gear (3) together

with 2nd gear from countershaft (1) using hydraulic

press. Take out needle bearing from countershaft.

CAUTION!

• If compression exceeds 5 ton (11,000 lb), release compression once, reset bearing

puller support and then continue press

work again.

• To avoid gear tooth from being damaged, support it at flat side of bearing puller.

3) Take out 2nd gear synchronizer outer ring, center cone and inner ring.

4) Using snap ring pliers (2), remove circlip (1).

I4RH01520032-01

I2RH01520054-01

2. Low speed synchronizer sleeve

I2RH01520055-01

I6RS0C520014-01

Page 872 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-1 Steering Wheel and Column:

Steeri ng

Steering Wheel and Column

Precautions

Service Precautions of Steering Wheel and

Column

S7RS0B6200001

For service precautions, refer to “Precautions on Service

and Diagnosis of Air Bag System in Section 8B”.

Service and Diagnosis

For diagnosis and servicing, refer to “Precautions on

Service and Diagnosis of Air Bag System in Section 8B”.

Disabling Air Bag System

For disabling air bag system, refer to “Disabling Air Bag

System in Section 8B”. Enabling Air Bag System

For enabling air bag system, refer to “Enabling Air Bag

System in Section 8B”.

Handling and Storage

For handling and storage, refer to “Precautions on

Handling and Storage of Air Bag System Components in

Section 8B”.

Disposal

For disposal, refer to “Prec

autions on Disposal of Air

Bag and Seat Belt Pretensioner in Section 8B”.

General Description

Steering Wheel and Column ConstructionS7RS0B6201001

This double tube type steering column has the following three important features in addition to the steering function:

• The column is energy absorbing, desig ned to compress in a front-end collision.

• The ignition switch and lock are mounted conveniently on this column.

• With the column mounted lock, the ignition and steering op erations can be locked to inhibit theft of the vehicle.

To insure the energy absorbing action, it is important th at only the specified screws, bolts and nuts be used as

designated, and that they are tightened to the specified torque. When the column assembly is removed from the

vehicle, special care must be taken in handling it. Use of a steering wheel puller or a sharp blow on the end of the

steering shaft, leaning on the assembly, or dropping the a ssembly could shear the plastic shear pins which maintain

column length and position.

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is mounted

to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the restraint of the

driver’s and passenger’s seat belts by deploying the air b ags. The air bag (inflator) module should be handled with

care to prevent accidental deployment. When servicing, be sure to observe “Precautions on Service and Diagnosis of

Air Bag System in Section 8B”.

Page 887 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-5

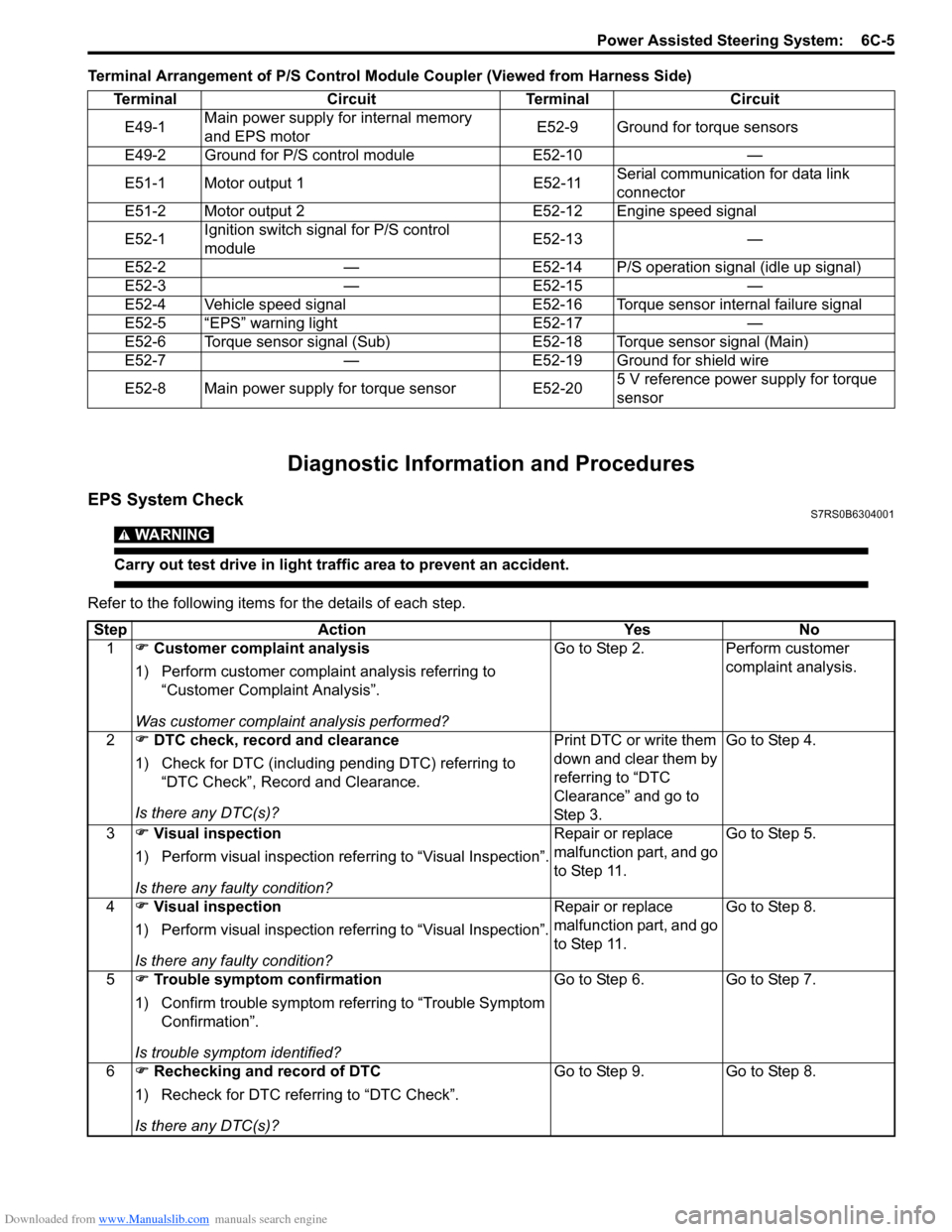

Terminal Arrangement of P/S Control Module Coupler (Viewed from Harness Side)

Diagnostic Information and Procedures

EPS System CheckS7RS0B6304001

WARNING!

Carry out test drive in light traffic area to prevent an accident.

Refer to the following items for the details of each step.Terminal Circuit Terminal Circuit

E49-1 Main power supply for internal memory

and EPS motor E52-9 Ground for torque sensors

E49-2 Ground for P/S control module E52-10 —

E51-1 Motor output 1 E52-11 Serial communication for data link

connector

E51-2 Motor output 2 E52-12 Engine speed signal

E52-1 Ignition switch signal for P/S control

module E52-13 —

E52-2 — E52-14 P/S operation signal (idle up signal)

E52-3 — E52-15 —

E52-4 Vehicle speed signal E52-16 Torque sensor internal failure signal

E52-5 “EPS” warning light E52-17 —

E52-6 Torque sensor signal (Sub) E52-18 Torque sensor signal (Main)

E52-7 — E52-19 Ground for shield wire

E52-8 Main power supply for torque sensor E52-20 5 V reference power supply for torque

sensor

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) DTC check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC Check”, Record and Clearance.

Is there any DTC(s)? Print DTC or write them

down and clear them by

referring to “DTC

Clearance” and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

Page 933 of 1496

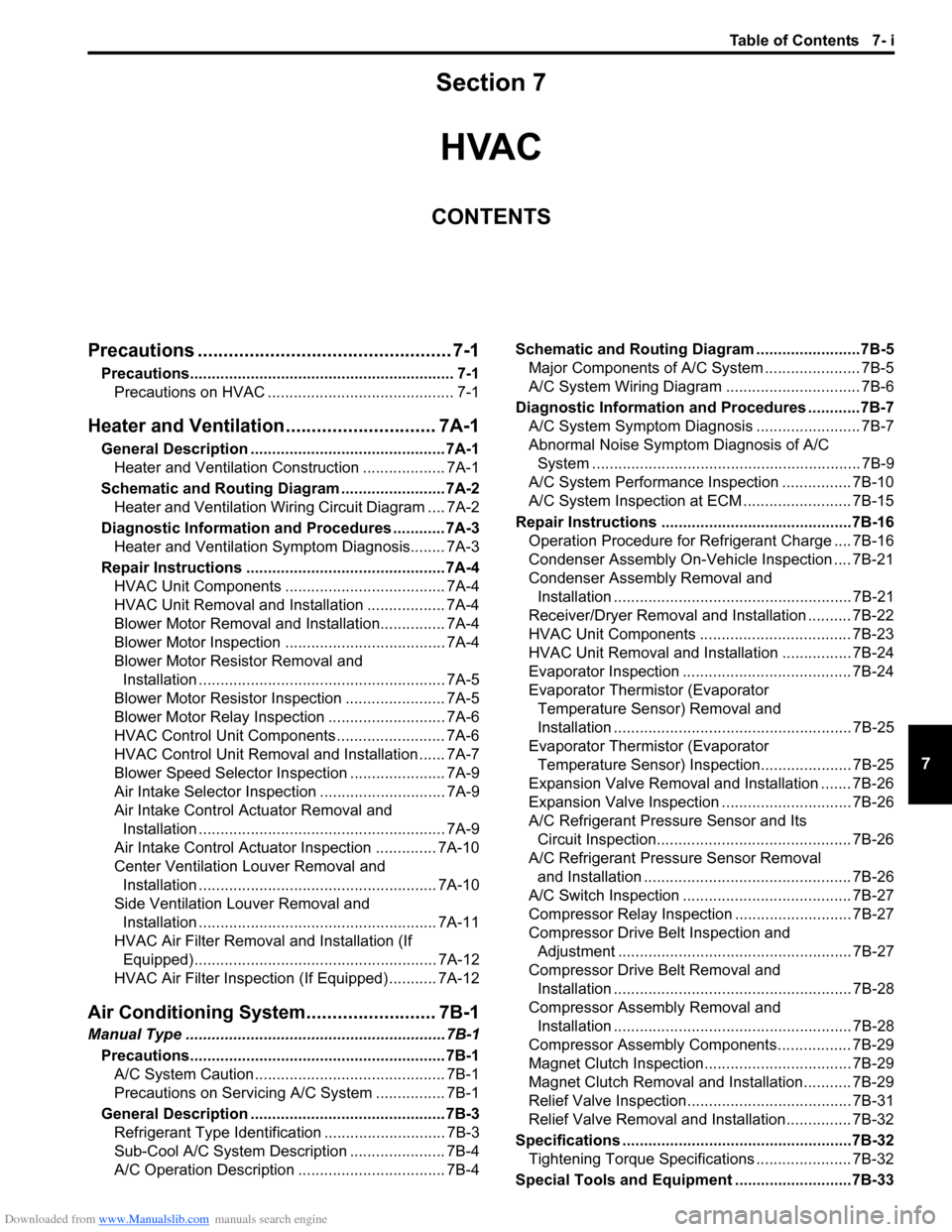

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33