manifold SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

Generator Test (Overcharged Battery Check)S7RS0B1A04004

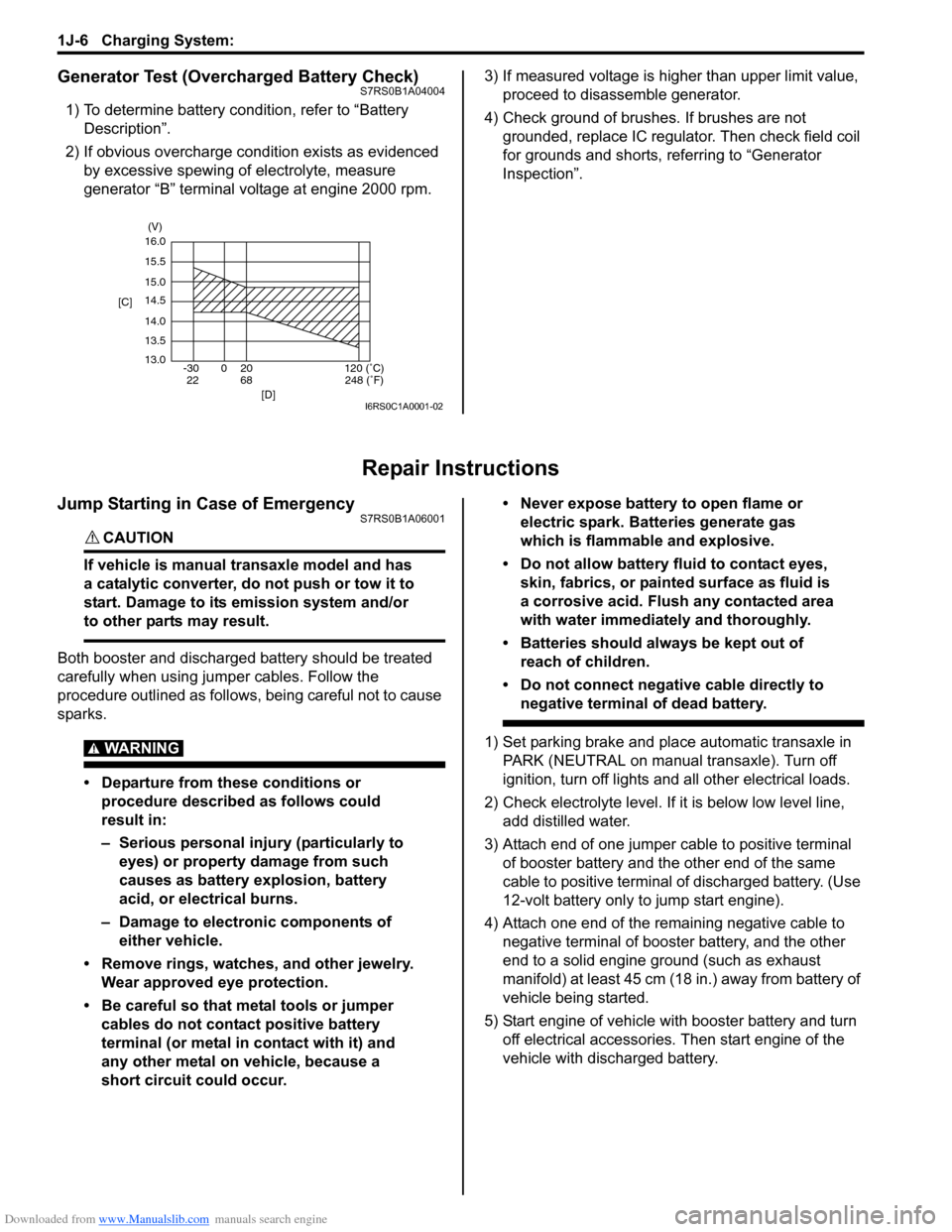

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 424 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-1 Exhaust System:

Engine

Exhaust System

General Description

Exhaust System DescriptionS7RS0B1B01001

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case, exhaust

pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels of

Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

Diagnostic Information and Procedures

Exhaust System CheckS7RS0B1B04001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

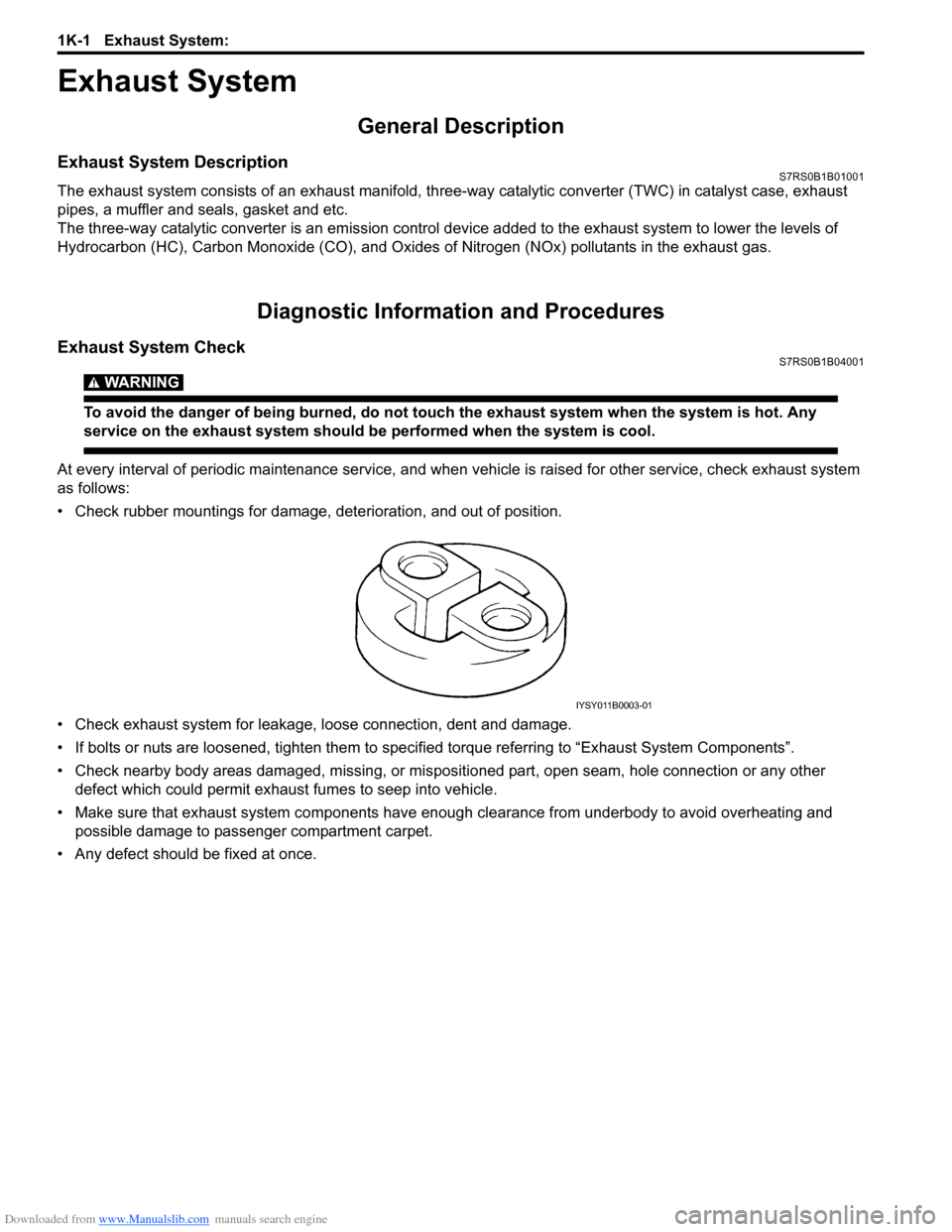

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust system

as follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connection, dent and damage.

• If bolts or nuts are loosened, tighten them to specified torque referring to “Exhaust System Components”.

• Check nearby body areas damaged, missing, or mispositio ned part, open seam, hole connection or any other

defect which could permit exhaust fumes to seep into vehicle.

• Make sure that exhaust system components have enough clearance from underbody to avoid overheating and

possible damage to passenger compartment carpet.

• Any defect should be fixed at once.

IYSY011B0003-01

Page 425 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

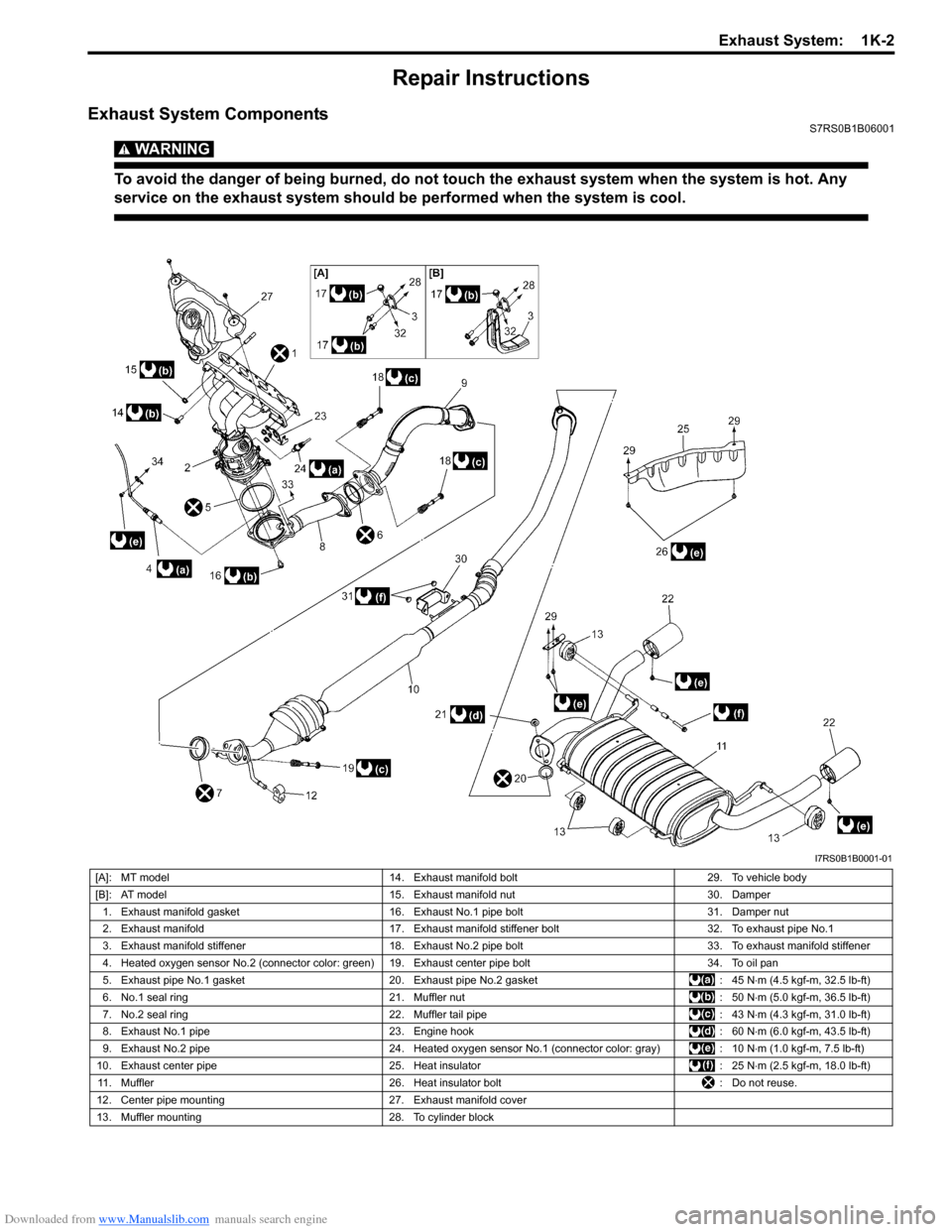

Exhaust System ComponentsS7RS0B1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

I7RS0B1B0001-01

[A]: MT model14. Exhaust manifold bolt 29. To vehicle body

[B]: AT model 15. Exhaust manifold nut 30. Damper

1. Exhaust manifold gasket 16. Exhaust No.1 pipe bolt 31. Damper nut

2. Exhaust manifold 17. Exhaust manifold stiffener bolt 32. To exhaust pipe No.1

3. Exhaust manifold stiffener 18. Exhaust No.2 pipe bolt 33. To exhaust manifold stiffener

4. Heated oxygen sensor No.2 (connector color: green) 19. Exhaust center pipe bolt 34. To oil pan

5. Exhaust pipe No.1 gasket 20. Exhaust pipe No.2 gasket : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 21. Muffler nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 22. Muffler tail pipe : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 23. Engine hook : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

9. Exhaust No.2 pipe 24. Heated oxygen sensor No.1 (connector color: gray) : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

10. Exhaust center pipe 25. Heat insulator : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Muffler 26. Heat insulator bolt : Do not reuse.

12. Center pipe mounting 27. Exhaust manifold cover

13. Muffler mounting 28. To cylinder block

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

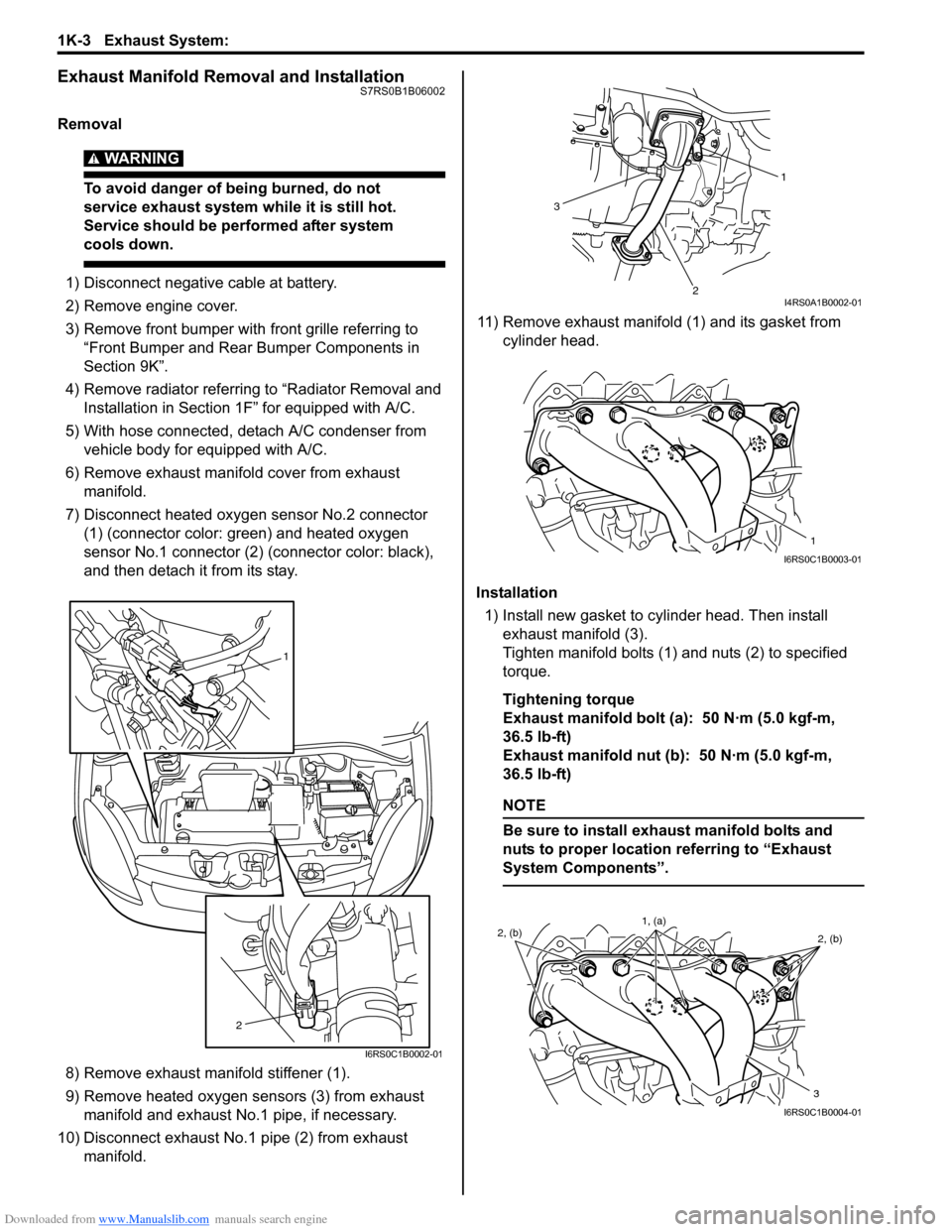

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01

Page 427 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

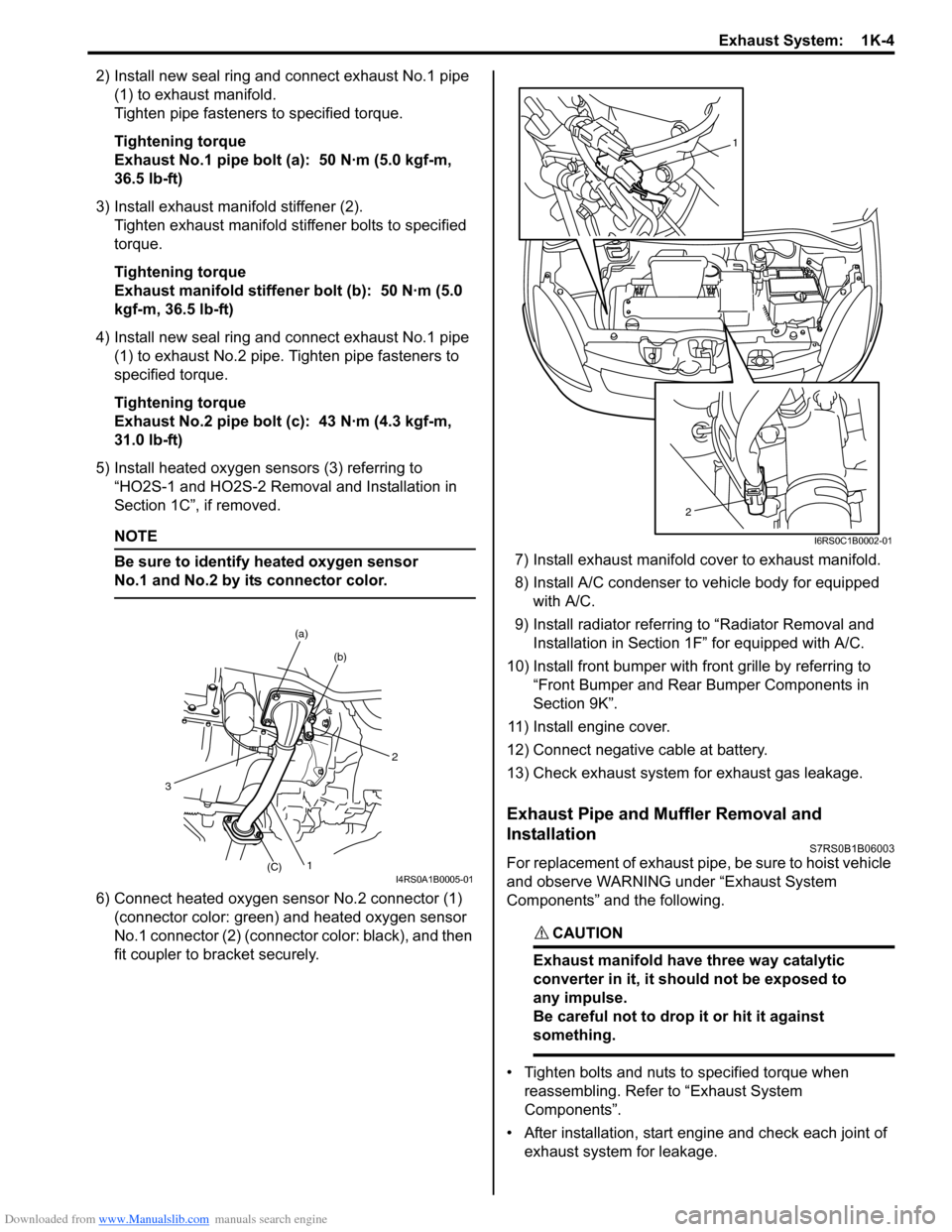

2) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2). Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install heated oxygen sensors (3) referring to “HO2S-1 and HO2S-2 Removal and Installation in

Section 1C”, if removed.

NOTE

Be sure to identify heated oxygen sensor

No.1 and No.2 by its connector color.

6) Connect heated oxygen sensor No.2 connector (1)

(connector color: green) and heated oxygen sensor

No.1 connector (2) (connector color: black), and then

fit coupler to br acket securely. 7) Install exhaust manifold cover to exhaust manifold.

8) Install A/C condenser to vehicle body for equipped

with A/C.

9) Install radiator referrin g to “Radiator Removal and

Installation in Section 1F” for equipped with A/C.

10) Install front bumper with fr ont grille by referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

11) Install engine cover.

12) Connect negative cable at battery.

13) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S7RS0B1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of exhaust system for leakage.

2

(b)

(a)

1(C)

3

I4RS0A1B0005-01

1

2

I6RS0C1B0002-01

Page 428 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-5 Exhaust System:

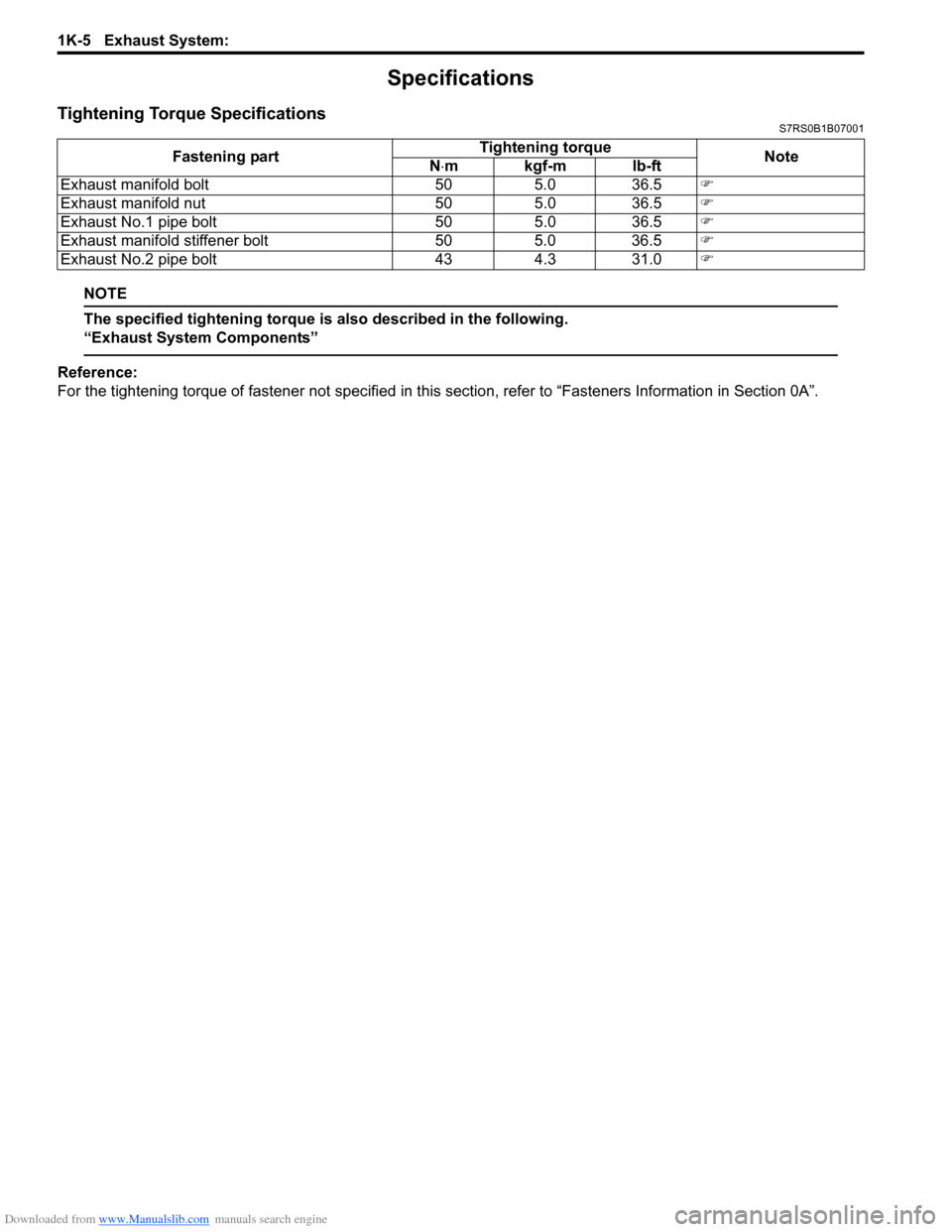

Specifications

Tightening Torque SpecificationsS7RS0B1B07001

NOTE

The specified tightening torque is also described in the following.

“Exhaust System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Exhaust manifold bolt 505.0 36.5 �)

Exhaust manifold nut 505.0 36.5 �)

Exhaust No.1 pipe bolt 505.0 36.5 �)

Exhaust manifold stiffener bolt 505.0 36.5 �)

Exhaust No.2 pipe bolt 434.3 31.0 �)

Page 958 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-10 Air Conditioning System: Manual Type

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower Motor

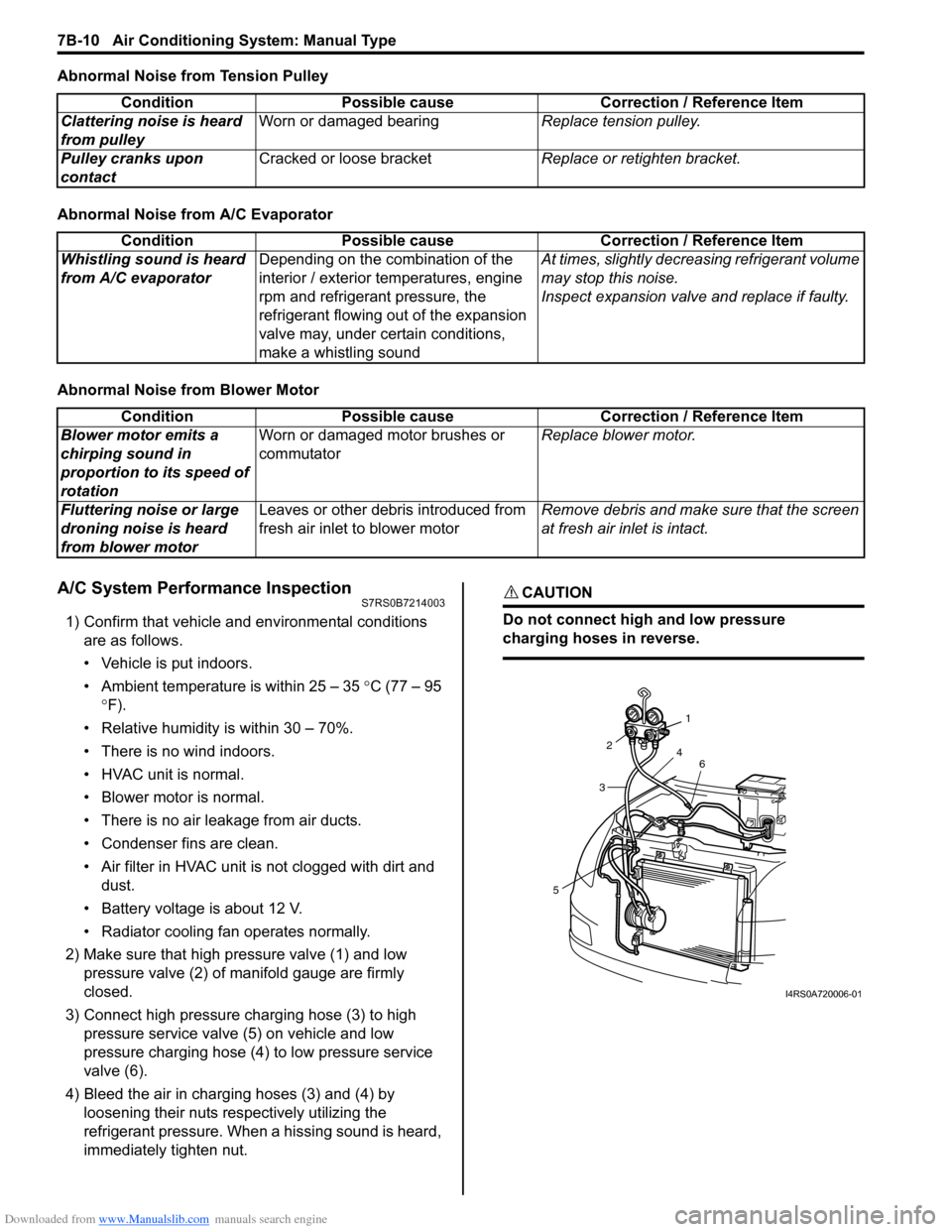

A/C System Performance InspectionS7RS0B7214003

1) Confirm that vehicle and environmental conditions are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

° F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Air filter in HVAC unit is not clogged with dirt and

dust.

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulley Worn or damaged bearing

Replace tension pulley.

Pulley cranks upon

contact Cracked or loose bracket

Replace or retighten bracket.

ConditionPossible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporator Depending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling sound At times, slightly decrea

sing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotation Worn or damaged motor brushes or

commutator

Replace blower motor.

Fluttering noise or large

droning noise is heard

from blower motor Leaves or other debris introduced from

fresh air inlet to blower motor

Remove debris and make sure that the screen

at fresh air inlet is intact.

53

2

1

4 6

I4RS0A720006-01

Page 962 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-14 Air Conditioning System: Manual Type

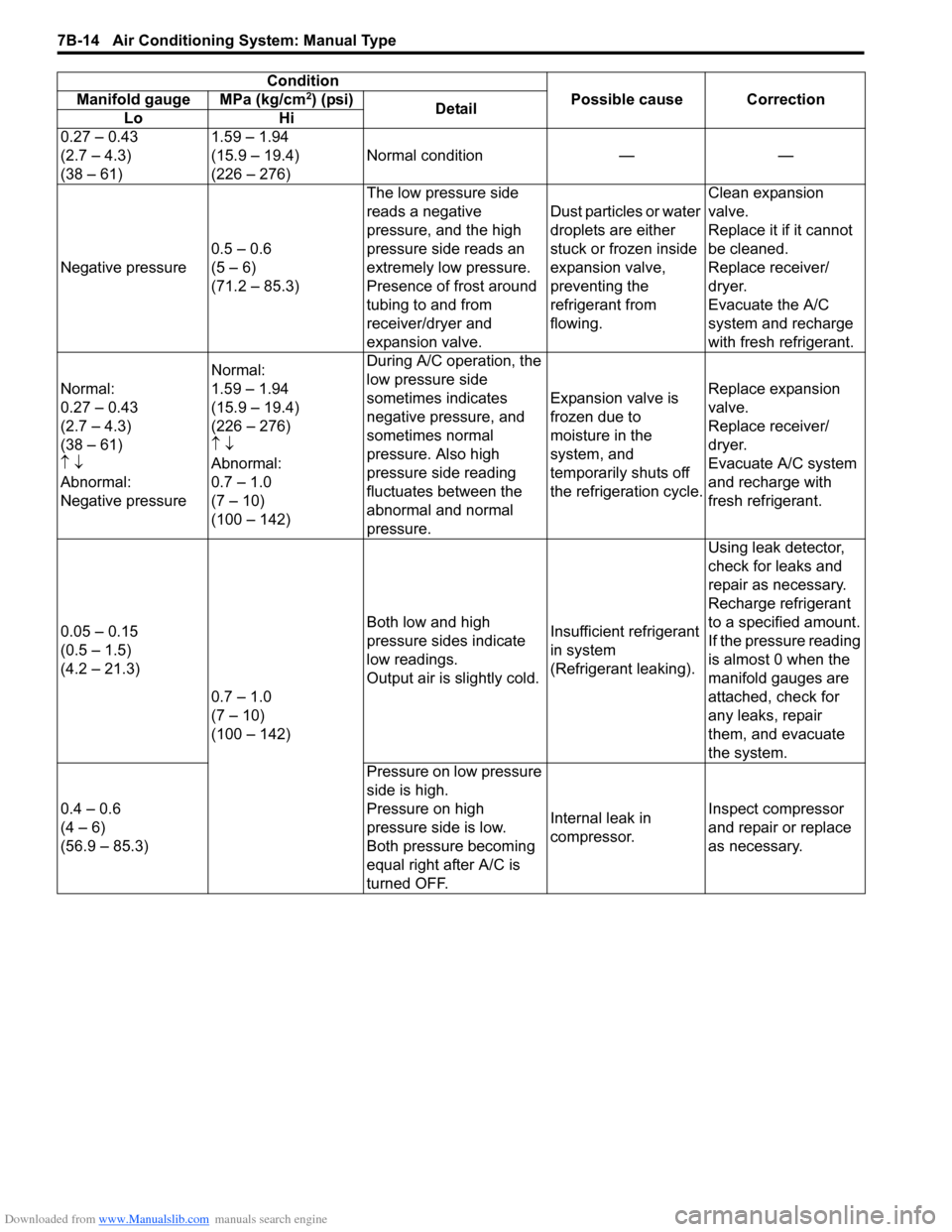

ConditionPossible cause Correction

Manifold gauge MPa (kg/cm2) (psi)

Detail

Lo Hi

0.27 – 0.43

(2.7 – 4.3)

(38 – 61) 1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

Normal condition — —

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3) The low pressure side

reads a negative

pressure, and the high

pressure side reads an

extremely low pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve. Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Clean expansion

valve.

Replace it if it cannot

be cleaned.

Replace receiver/

dryer.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.43

(2.7 – 4.3)

(38 – 61)

↑ ↓

Abnormal:

Negative pressure Normal:

1.59 – 1.94

(15.9 – 19.4)

(226 – 276)

↑

↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142) During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.

Expansion valve is

frozen due to

moisture in the

system, and

temporarily shuts off

the refrigeration cycle.

Replace expansion

valve.

Replace receiver/

dryer.

Evacuate A/C system

and recharge with

fresh refrigerant.

0.05 – 0.15

(0.5 – 1.5)

(4.2 – 21.3) 0.7 – 1.0

(7 – 10)

(100 – 142) Both low and high

pressure sides indicate

low readings.

Output air is slightly cold.

Insufficient refrigerant

in system

(Refrigerant leaking).Using leak detector,

check for leaks and

repair as necessary.

Recharge refrigerant

to a specified amount.

If the pressure reading

is almost 0 when the

manifold gauges are

attached, check for

any leaks, repair

them, and evacuate

the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85.3) Pressure on low pressure

side is high.

Pressure on high

pressure side is low.

Both pressure becoming

equal right after A/C is

turned OFF.

Internal leak in

compressor.

Inspect compressor

and repair or replace

as necessary.

Page 963 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

A/C System Inspection at ECMS7RS0B7214004

Voltage Check

When checking voltage at ECM connector terminals related to A/C system, refer to “DTC P2101: Throttle Actuator

Control Motor Circuit Range / Performance in Section 1A”.

0.40 – 0.45

(4.0 – 4.5)

(57 – 64)

2.0 – 2.5

(20 – 25)

(285 – 355) High pressure reading on

both low and high

pressure sides.

Overcharged A/C

system.

Adjust refrigerant to

specified amount.

Faulty condenser

cooling operation. Clean condenser.

Faulty radiator cooling

fan operation. Inspect and repair

radiator cooling fan.

High pressure reading on

both low and high

pressure sides.

Low pressure side tubing

is not cold when touched. Presence of air in A/C

system

(Improperly

evacuated).Replace receiver/

dryer.

Inspect quantity of

compressor oil and

presence of

contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78) High pressure reading on

both low and high

pressure sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion

valve.

Refrigerant flow is not

regulated properly.

Replace expansion

valve.

Condition

Possible cause Correction

Manifold gauge MPa (kg/cm

2) (psi)

Detail

Lo Hi

Page 966 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-18 Air Conditioning System: Manual Type

When replacing other parts

Replenish the following amount of oil to compressor.

Amount of compressor oil to be replenished

Evaporator: 25 cm3 (25 ml, 0.85 US. oz, 0.88 Imp. oz)

Condenser: 15 cm3 (15 ml, 0.51 US. oz, 0.53 Imp. oz)

Receiver/dryer: 10 cm3 (10 ml, 0.34 US. oz, 0.35 lmp.

oz)

Hoses: 10 cm

3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

Pipes: 10 cm3 (10 ml, 0.34 US. oz, 0.35 Imp. oz) each

Evacuation

CAUTION!

Do not evacuate before recovering

refrigerant in A/C system.

NOTE

Once air conditioning system circuit is

opened (exposed) to atmospheric air, system

must be evacuated by using a vacuum pump.

The A/C system should be attached with a

manifold gauge set, and should be evacuated

for approximately 15 minutes.

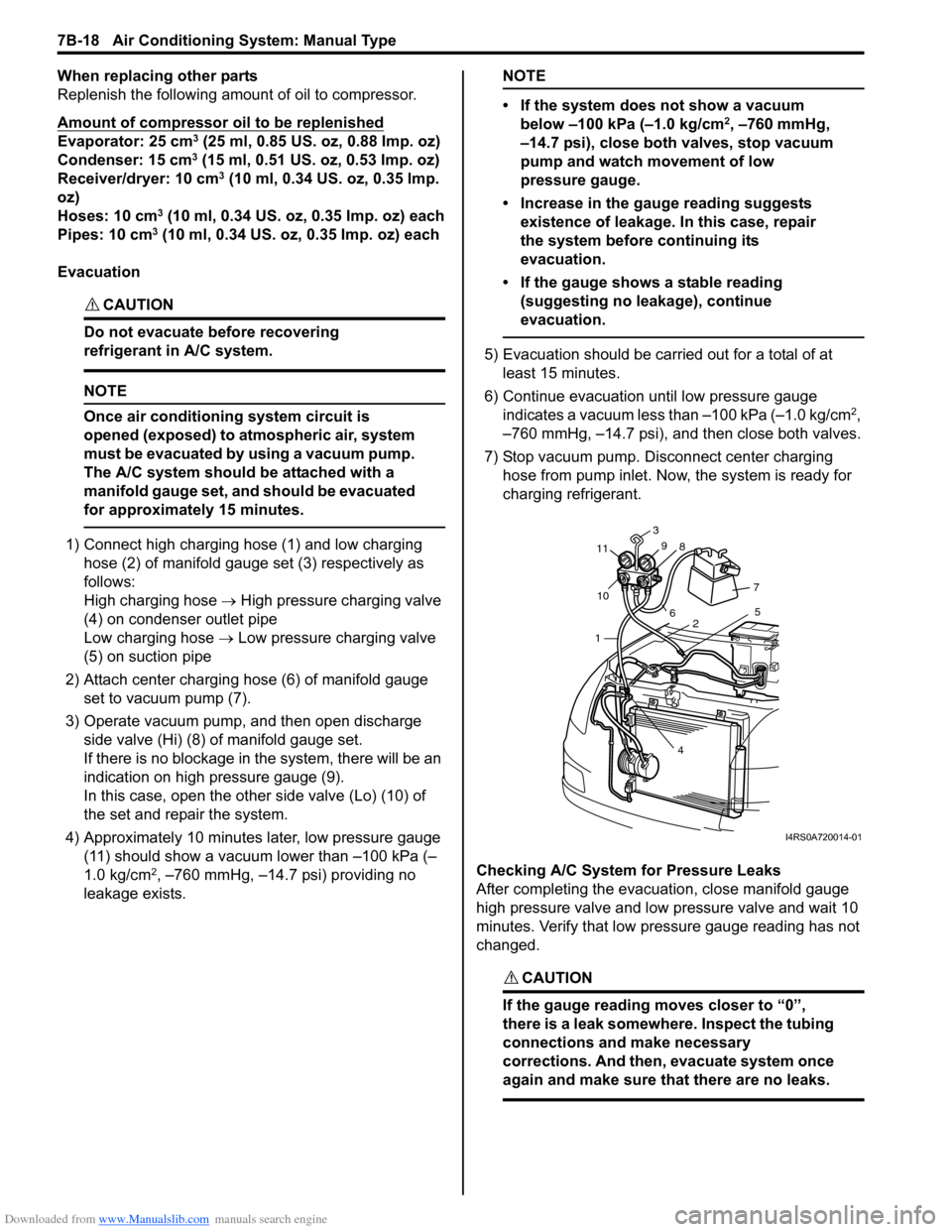

1) Connect high charging hose (1) and low charging hose (2) of manifold gauge set (3) respectively as

follows:

High charging hose → High pressure charging valve

(4) on condenser outlet pipe

Low charging hose → Low pressure charging valve

(5) on suction pipe

2) Attach center charging hose (6) of manifold gauge set to vacuum pump (7).

3) Operate vacuum pump, and then open discharge

side valve (Hi) (8) of manifold gauge set.

If there is no blockage in the system, there will be an

indication on high pressure gauge (9).

In this case, open the other side valve (Lo) (10) of

the set and repair the system.

4) Approximately 10 minutes later, low pressure gauge (11) should show a vacuum lower than –100 kPa (–

1.0 kg/cm

2, –760 mmHg, –14.7 psi) providing no

leakage exists.

NOTE

• If the system does not show a vacuum below –100 kPa (–1.0 kg/cm

2, –760 mmHg,

–14.7 psi), close both valves, stop vacuum

pump and watch movement of low

pressure gauge.

• Increase in the gauge reading suggests existence of leakage. In this case, repair

the system before continuing its

evacuation.

• If the gauge shows a stable reading (suggesting no leakage), continue

evacuation.

5) Evacuation should be carried out for a total of at least 15 minutes.

6) Continue evacuation until low pressure gauge indicates a vacuum less than –100 kPa (–1.0 kg/cm

2,

–760 mmHg, –14.7 psi), and then close both valves.

7) Stop vacuum pump. Disconnect center charging hose from pump inlet. No w, the system is ready for

charging refrigerant.

Checking A/C System for Pressure Leaks

After completing the evacuation, close manifold gauge

high pressure valve and low pressure valve and wait 10

minutes. Verify that low pressure gauge reading has not

changed.

CAUTION!

If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing

connections and make necessary

corrections. And then, evacuate system once

again and make sure that there are no leaks.

7 5

2

4

1

10

11

3

9 8

6

I4RS0A720014-01