range SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 281 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-9

CKP Sensor Removal and InstallationS7RS0B1306014

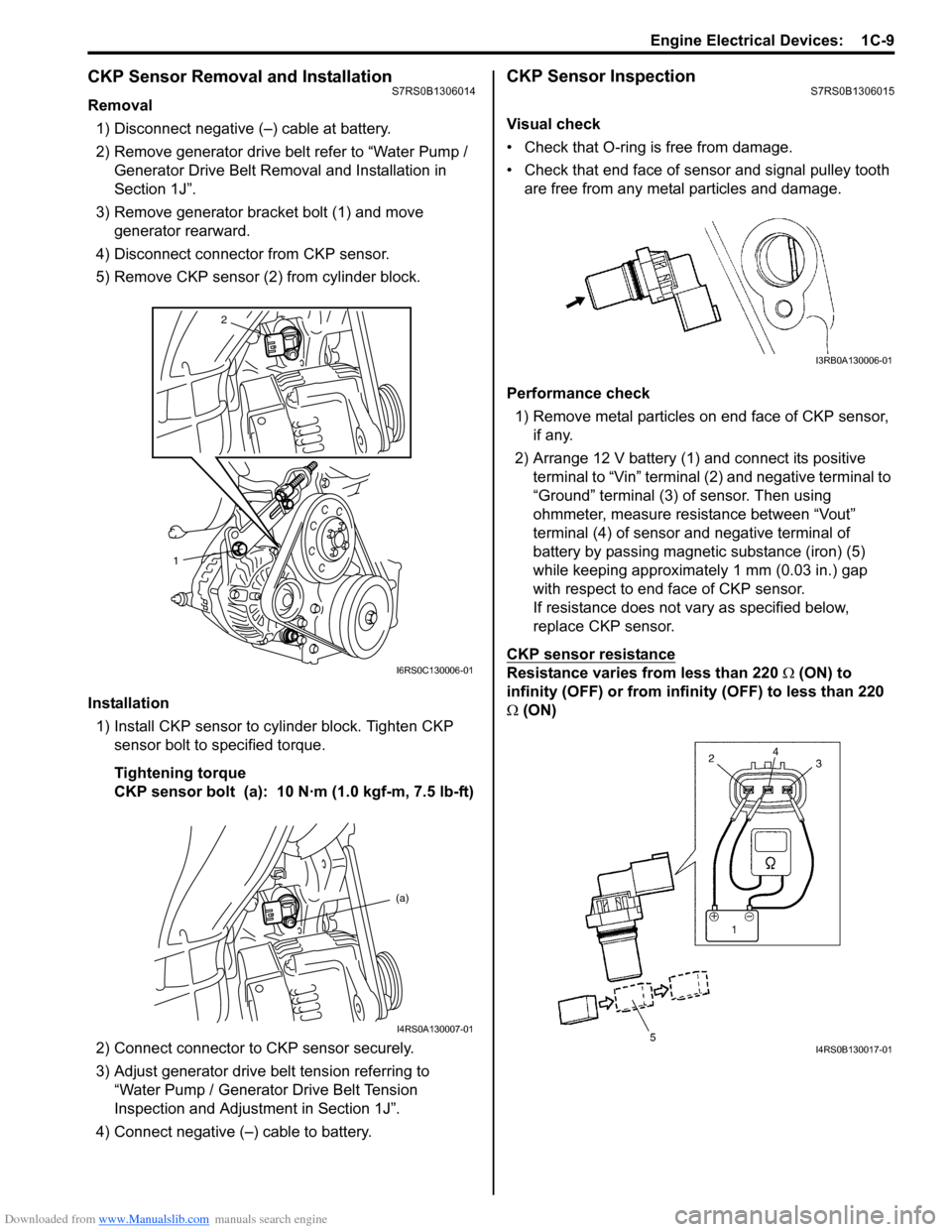

Removal1) Disconnect negative (–) cable at battery.

2) Remove generator drive belt refer to “Water Pump / Generator Drive Belt Remo val and Installation in

Section 1J”.

3) Remove generator bracket bolt (1) and move generator rearward.

4) Disconnect connector from CKP sensor.

5) Remove CKP sensor (2) from cylinder block.

Installation 1) Install CKP sensor to cylinder block. Tighten CKP sensor bolt to specified torque.

Tightening torque

CKP sensor bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

2) Connect connector to CKP sensor securely.

3) Adjust generator drive belt tension referring to “Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1J”.

4) Connect negative (–) cable to battery.

CKP Sensor InspectionS7RS0B1306015

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal pulley tooth are free from any metal particles and damage.

Performance check 1) Remove metal particles on end face of CKP sensor, if any.

2) Arrange 12 V battery (1) and connect its positive terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CKP sensor.

If resistance does not vary as specified below,

replace CKP sensor.

CKP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

2

1

I6RS0C130006-01

(a)

I4RS0A130007-01

I3RB0A130006-01

I4RS0B130017-01

Page 286 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-1 Engine Mechanical:

Engine

Engine Mechanical

General Description

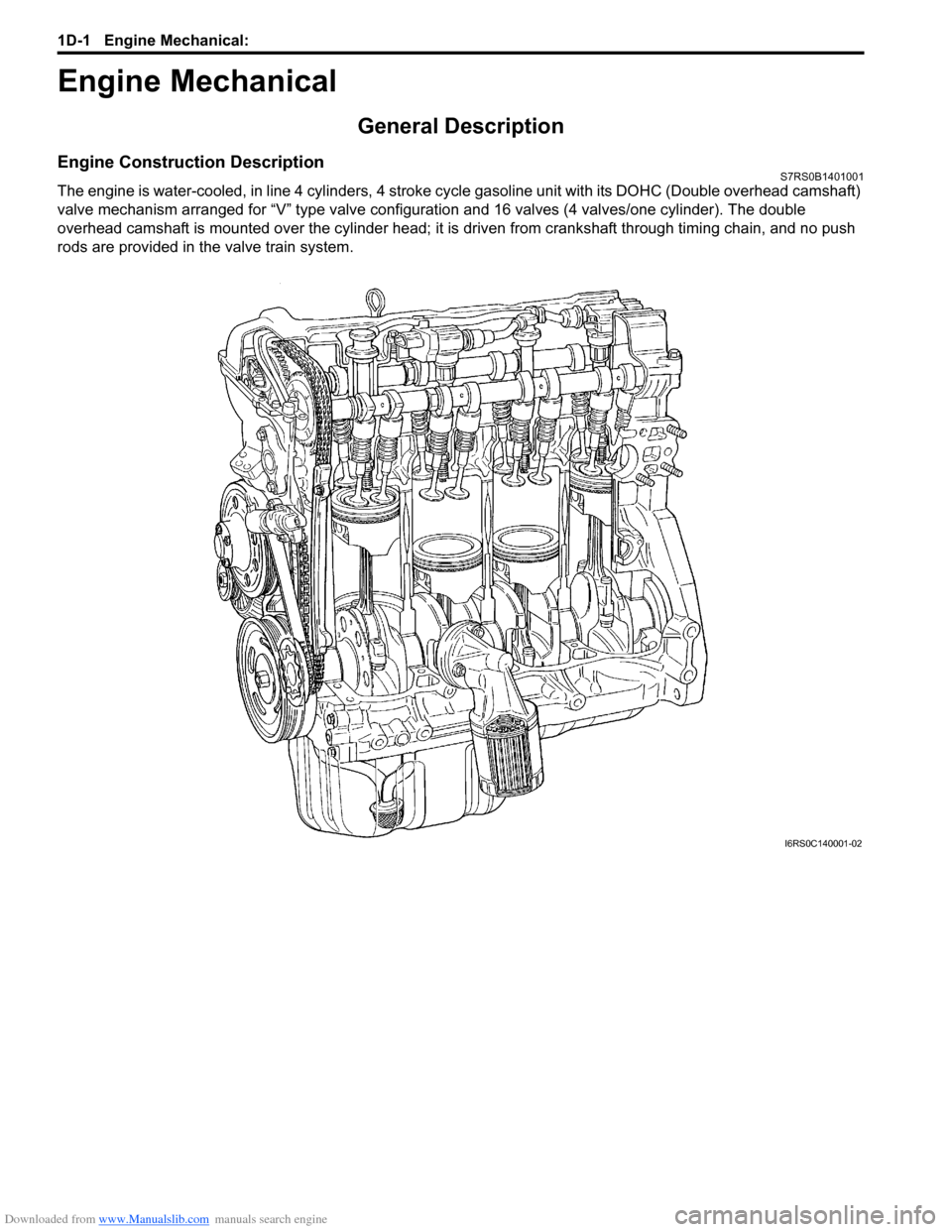

Engine Construction DescriptionS7RS0B1401001

The engine is water-cooled, in line 4 cylinders, 4 stroke cycle gasoline unit with its DOHC (Double overhead camshaft)

valve mechanism arranged for “V” type valve configurat ion and 16 valves (4 valves/one cylinder). The double

overhead camshaft is mounted over the cy linder head; it is driven from crankshaft through timing chain, and no push

rods are provided in the valve train system.

I6RS0C140001-02

Page 287 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-2

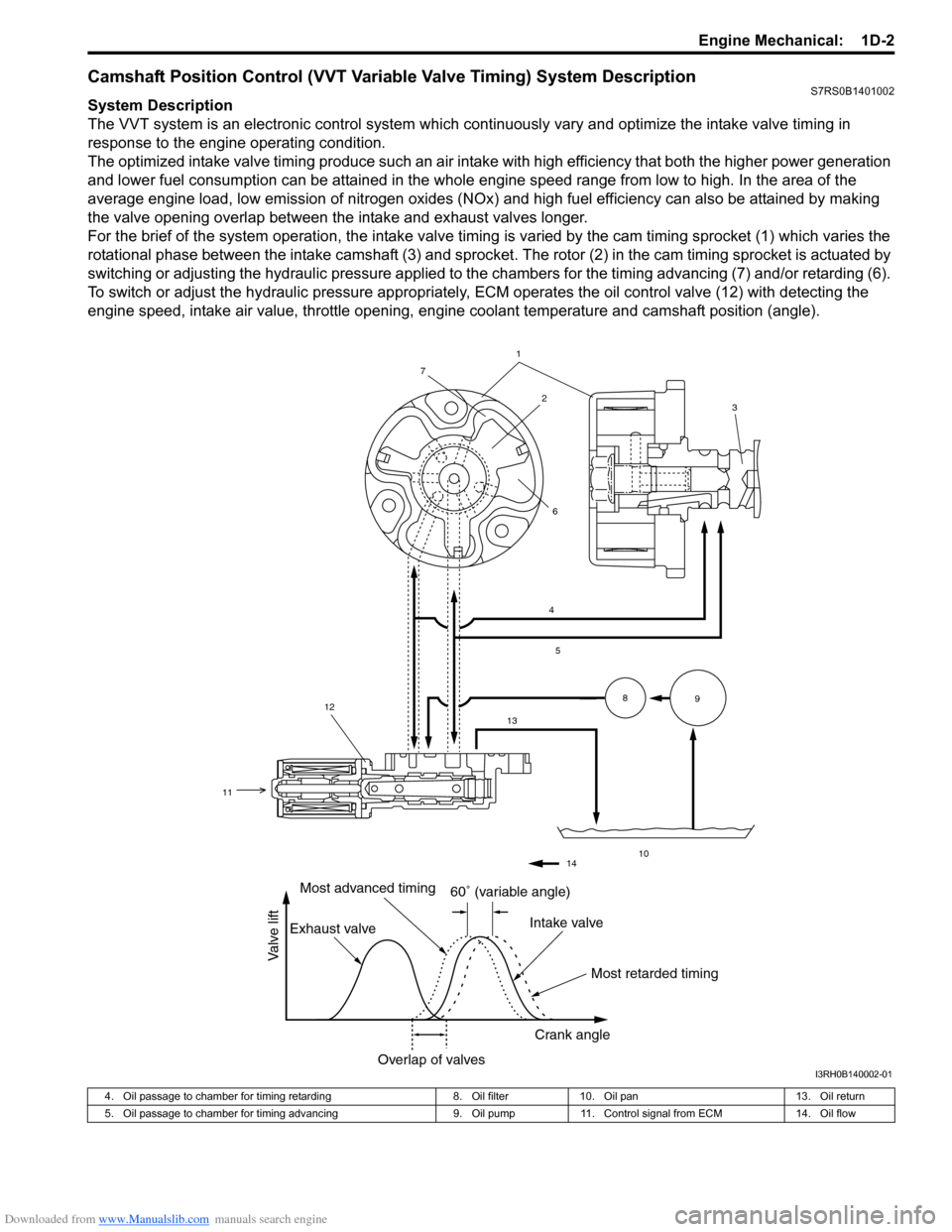

Camshaft Position Control (VVT Variable Valve Timing) System DescriptionS7RS0B1401002

System Description

The VVT system is an electronic control system which continuously vary and optimize the intake valve timing in

response to the engine operating condition.

The optimized intake valve timing produce such an air intake with high efficiency that both the higher power generation

and lower fuel consumption can be attained in the whole engine speed range from low to high. In the area of the

average engine load, low emission of nitrogen oxides (NOx) and high fuel efficiency can also be attained by making

the valve opening overlap between the intake and exhaust valves longer.

For the brief of the system operation, the intake valve timing is varied by the cam timing sprocket (1) which varies the

rotational phase between the intake camshaft (3) and sprocket . The rotor (2) in the cam timing sprocket is actuated by

switching or adjusting the hydraulic pressure applied to the chambers for the timing advancing (7) and/or retarding (6).

To switch or adjust the hydraulic pressure appropriately, ECM operates the oil control valve (12) with detecting the

engine speed, intake air value, throttle opening, engine coolant temperature and camshaft position (angle).

1

4

5

13

10

89

2

7

6

12

11

3

14

60� (variable angle)

Most retarded timing

Most advanced timing

Exhaust valve Intake valve

Crank angle

Overlap of valves

Valve lift

I3RH0B140002-01

4. Oil passage to chamber for timing retarding 8. Oil filter10. Oil pan 13. Oil return

5. Oil passage to chamber for timing advancing 9. Oil pump11. Control signal from ECM 14. Oil flow

Page 289 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-4

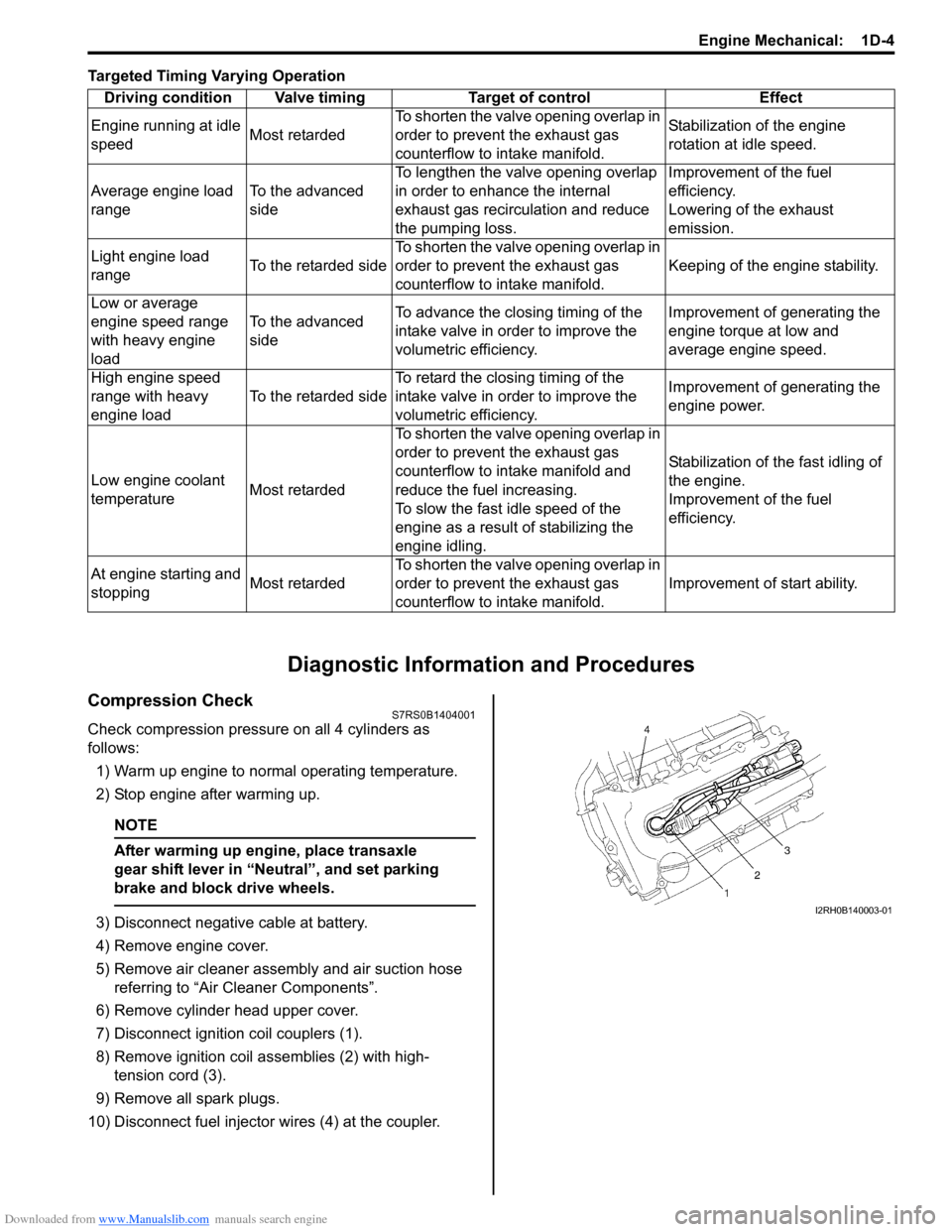

Targeted Timing Varying Operation

Diagnostic Information and Procedures

Compression CheckS7RS0B1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

3) Disconnect negative cable at battery.

4) Remove engine cover.

5) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

6) Remove cylinder head upper cover.

7) Disconnect ignition coil couplers (1).

8) Remove ignition coil assemblies (2) with high- tension cord (3).

9) Remove all spark plugs.

10) Disconnect fuel injector wires (4) at the coupler. Driving condition Valve timing Target of control Effect

Engine running at idle

speed Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Stabilization of the engine

rotation at idle speed.

Average engine load

range To the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss. Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range To the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load To the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine power.

Low engine coolant

temperature Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling. Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Improvement of start ability.I2RH0B140003-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

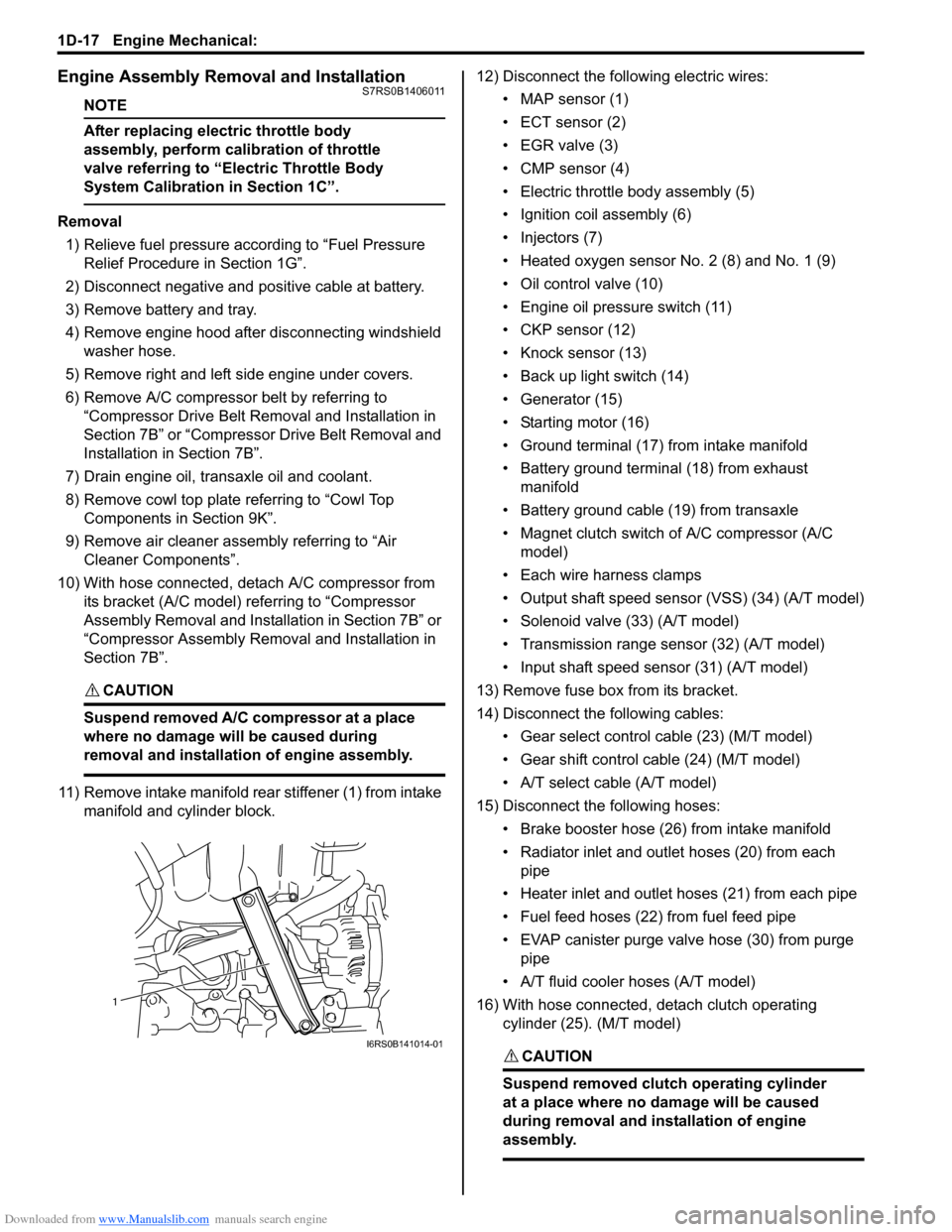

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 310 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-25 Engine Mechanical:

Timing Chain and Chain Tensioner Removal

and Installation

S7RS0B1406018

Removal

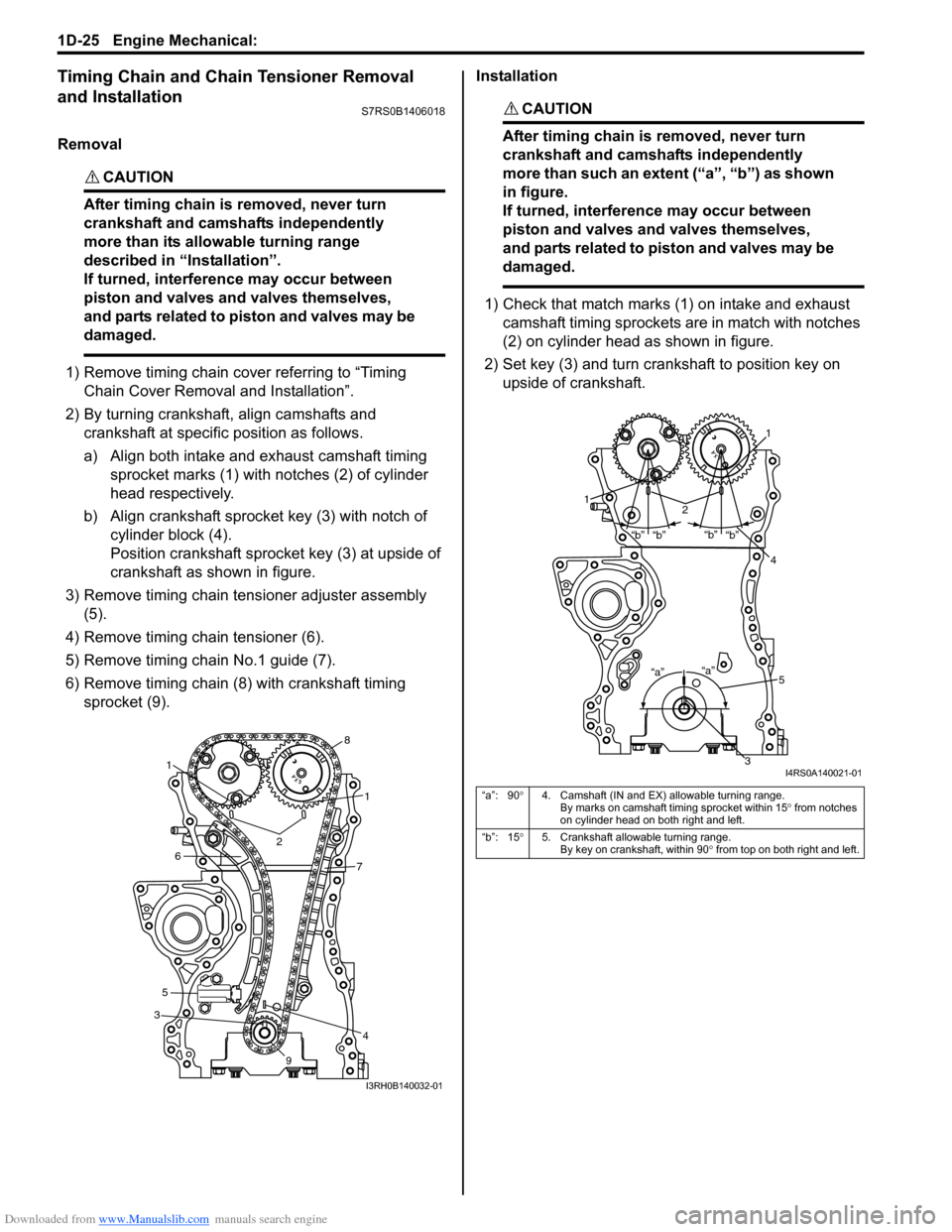

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than its allowable turning range

described in “Installation”.

If turned, interferen ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

2) By turning crankshaft, align camshafts and crankshaft at specific position as follows.

a) Align both intake and exhaust camshaft timing sprocket marks (1) with notches (2) of cylinder

head respectively.

b) Align crankshaft sprocket key (3) with notch of cylinder block (4).

Position crankshaft sprocke t key (3) at upside of

crankshaft as shown in figure.

3) Remove timing chain tensioner adjuster assembly (5).

4) Remove timing chain tensioner (6).

5) Remove timing chain No.1 guide (7).

6) Remove timing chain (8) with crankshaft timing sprocket (9). Installation

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than such an extent (“a”, “b”) as shown

in figure.

If turned, interferen

ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Check that match marks (1) on intake and exhaust camshaft timing sprockets are in match with notches

(2) on cylinder head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of crankshaft.

3

4

1

1

2

5

67

8

9

I3RH0B140032-01

“a”: 90 °4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15 ° from notches

on cylinder head on both right and left.

“b”: 15 °5. Crankshaft allowable turning range.

By key on crankshaft, within 90 ° from top on both right and left.

“a”

“b”

“b”“b”

“b”

“a”

1

12

4

3

5

I4RS0A140021-01

Page 326 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-41 Engine Mechanical:

Valve head radial runout

Check each valve for radial runout with a dial gauge and

“V” block. To check runout, rotate valve slowly. If runout

exceeds its limit, replace valve.

Valve head radial runout

Limit: 0.08 mm (0.003 in.)

Seating contact width

Create contact pattern on each valve in the usual

manner, i.e., by giving uniform coat of marking

compound to valve seat and by rotatingly tapping seat

with valve head. Valve lapper (tool used in valve lapping)

must be used.

Pattern produced on seating face of valve must be a

continuous ring without any break, and the width of

pattern must be within specified range.

Standard seating width “a” revealed by contact

pattern on valve face

Intake and Exhaust: 1.0 – 1.4 mm (0.0389 – 0.0551

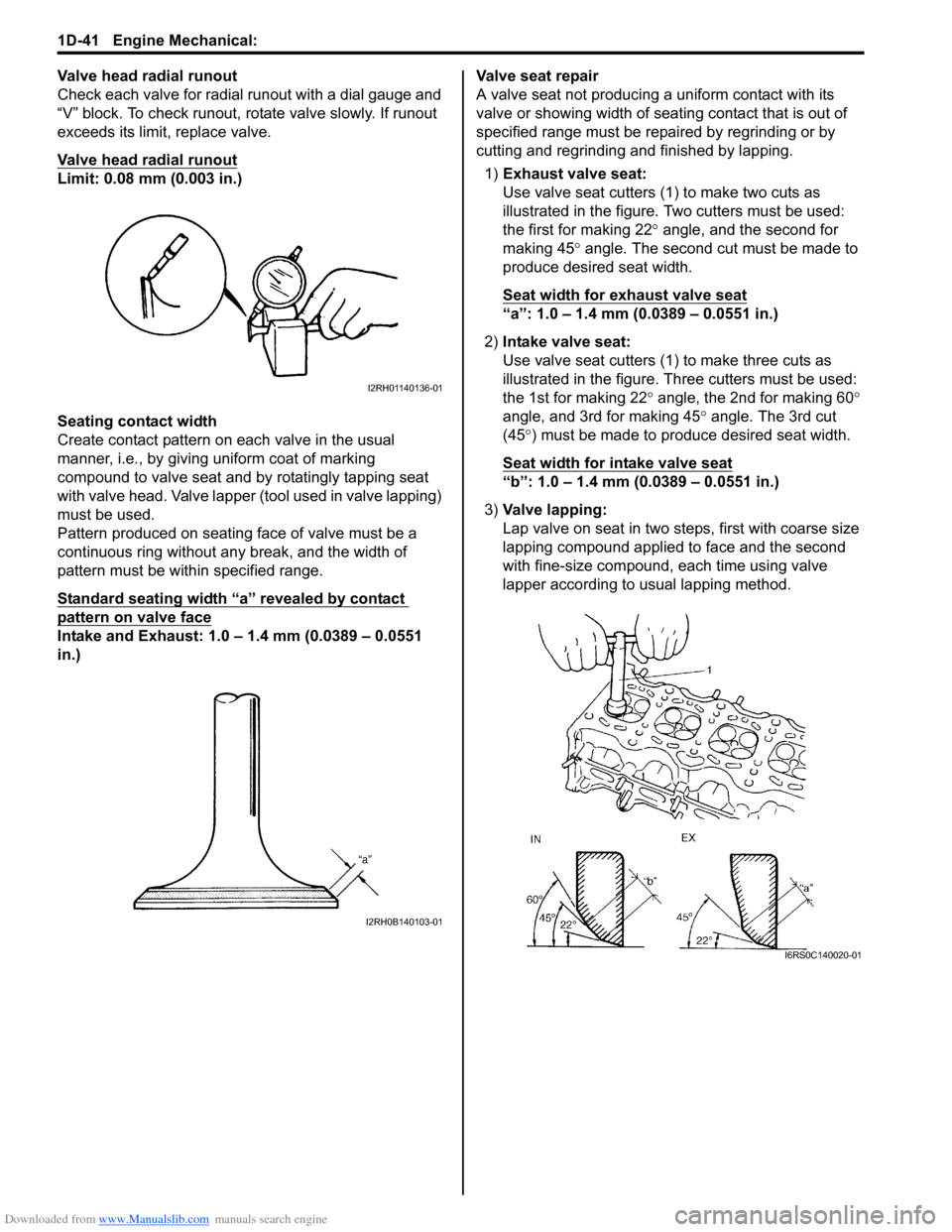

in.)Valve seat repair

A valve seat not producing

a uniform contact with its

valve or showing width of seating contact that is out of

specified range must be repaired by regrinding or by

cutting and regrinding and finished by lapping.

1) Exhaust valve seat:

Use valve seat cutters (1 ) to make two cuts as

illustrated in the figure. Two cutters must be used:

the first for making 22 ° angle, and the second for

making 45 ° angle. The second cut must be made to

produce desired seat width.

Seat width for exhaust valve seat

“a”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

2) Intake valve seat:

Use valve seat cutters (1) to make three cuts as

illustrated in the figure. Th ree cutters must be used:

the 1st for making 22 ° angle, the 2nd for making 60 °

angle, and 3rd for making 45 ° angle. The 3rd cut

(45 °) must be made to produce desired seat width.

Seat width for intake valve seat

“b”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

3) Valve lapping:

Lap valve on seat in two steps, first with coarse size

lapping compound applied to face and the second

with fine-size compound, each time using valve

lapper according to usual lapping method.

I2RH01140136-01

I2RH0B140103-01

I6RS0C140020-01

Page 331 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-46

Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly

S7RS0B1406031

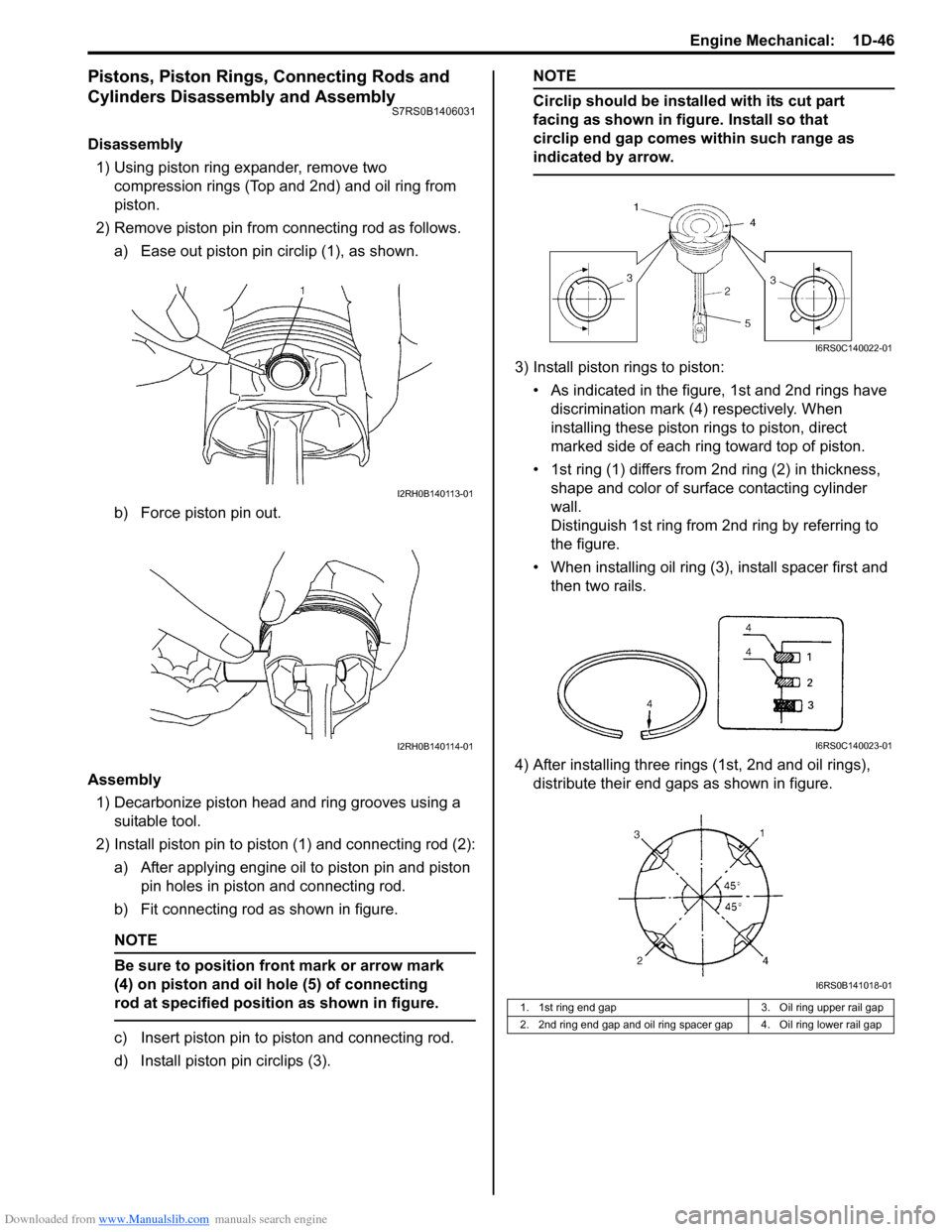

Disassembly1) Using piston ring expander, remove two compression rings (Top and 2nd) and oil ring from

piston.

2) Remove piston pin from connecting rod as follows. a) Ease out piston pin circlip (1), as shown.

b) Force piston pin out.

Assembly 1) Decarbonize piston head and ring grooves using a suitable tool.

2) Install piston pin to piston (1) and connecting rod (2): a) After applying engine oil to piston pin and piston pin holes in piston and connecting rod.

b) Fit connecting rod as shown in figure.

NOTE

Be sure to position front mark or arrow mark

(4) on piston and oil hole (5) of connecting

rod at specified position as shown in figure.

c) Insert piston pin to piston and connecting rod.

d) Install piston pin circlips (3).

NOTE

Circlip should be installed with its cut part

facing as shown in figure. Install so that

circlip end gap comes within such range as

indicated by arrow.

3) Install piston rings to piston:

• As indicated in the figure, 1st and 2nd rings have discrimination mark (4) respectively. When

installing these piston rings to piston, direct

marked side of each ring toward top of piston.

• 1st ring (1) differs from 2nd ring (2) in thickness, shape and color of surface contacting cylinder

wall.

Distinguish 1st ring from 2nd ring by referring to

the figure.

• When installing oil ring (3), install spacer first and then two rails.

4) After installing three rings (1st, 2nd and oil rings), distribute their end gaps as shown in figure.

I2RH0B140113-01

I2RH0B140114-01

1. 1st ring end gap 3. Oil ring upper rail gap

2. 2nd ring end gap and oil ring spacer gap 4. Oil ring lower rail gap

I6RS0C140022-01

I6RS0C140023-01

I6RS0B141018-01

Page 355 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

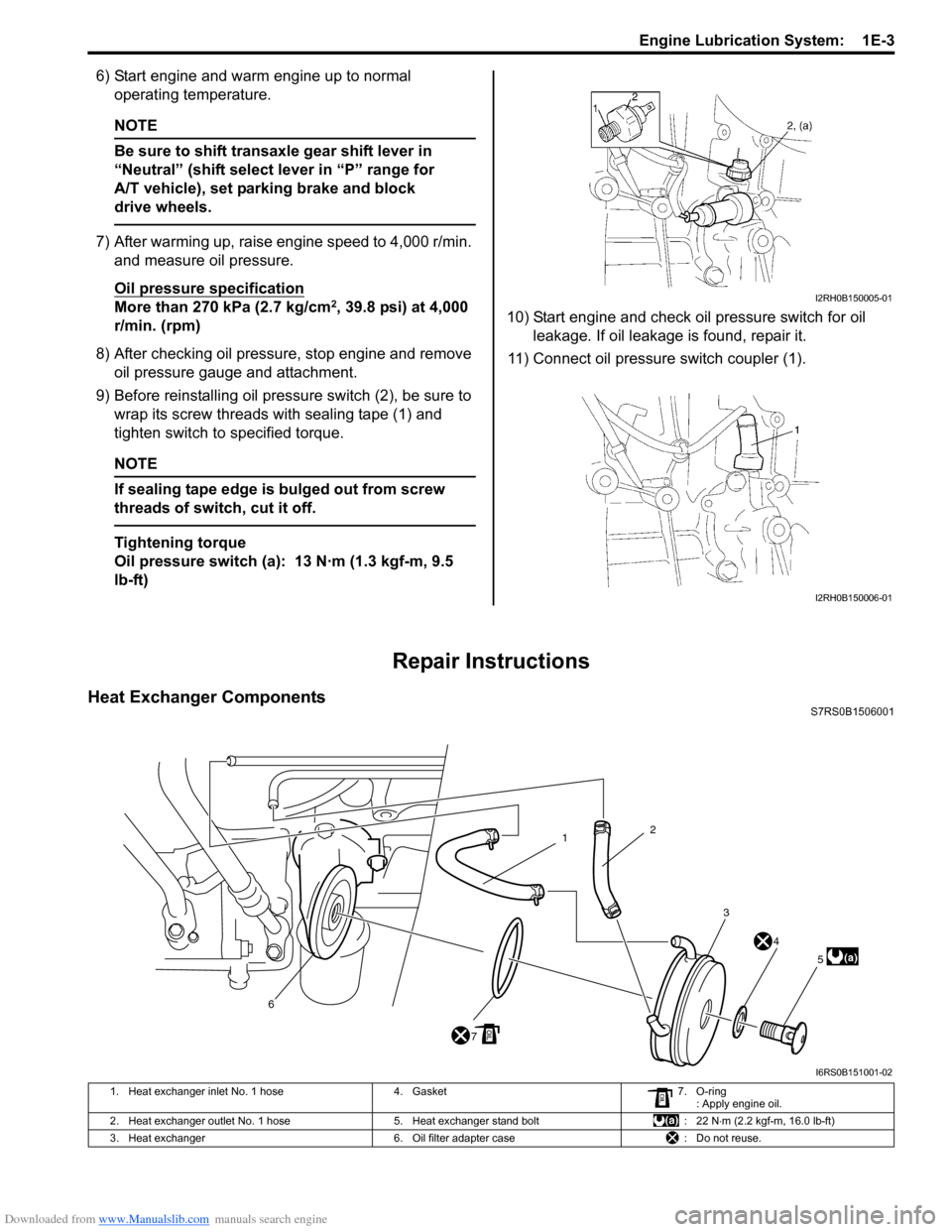

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 378 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine

stopped: 270 – 310 kPa (2.7 – 3.1 kg/cm2, 38.4

– 44.0 psi)

b) Start engine and warm it up to normal operating temperature, and measure fuel pressure at

idling.

Fuel pressure specification

At specified idle speed: 270 – 310 kPa (2.7 –

3.1 kg/cm2, 38.4 – 44.0 psi)

c) Stop engine, and measure fuel pressure at one minute after stopping.

Fuel pressure specification

With 1 min. after engine (fuel pump) stop

(Pressure reduces as time passes): Over 300

kPa (3.0 kg/cm

2, 42.7 psi)

6) After checking fuel pressure, remove fuel pressure gauge.

WARNING!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag and loosen joint nut slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel delivery pipe and fuel feed hose.

8) Connect fuel feed hose to fuel delivery pipe and clamp it securely.

9) With engine OFF and ignition switch ON, check for fuel leaks.

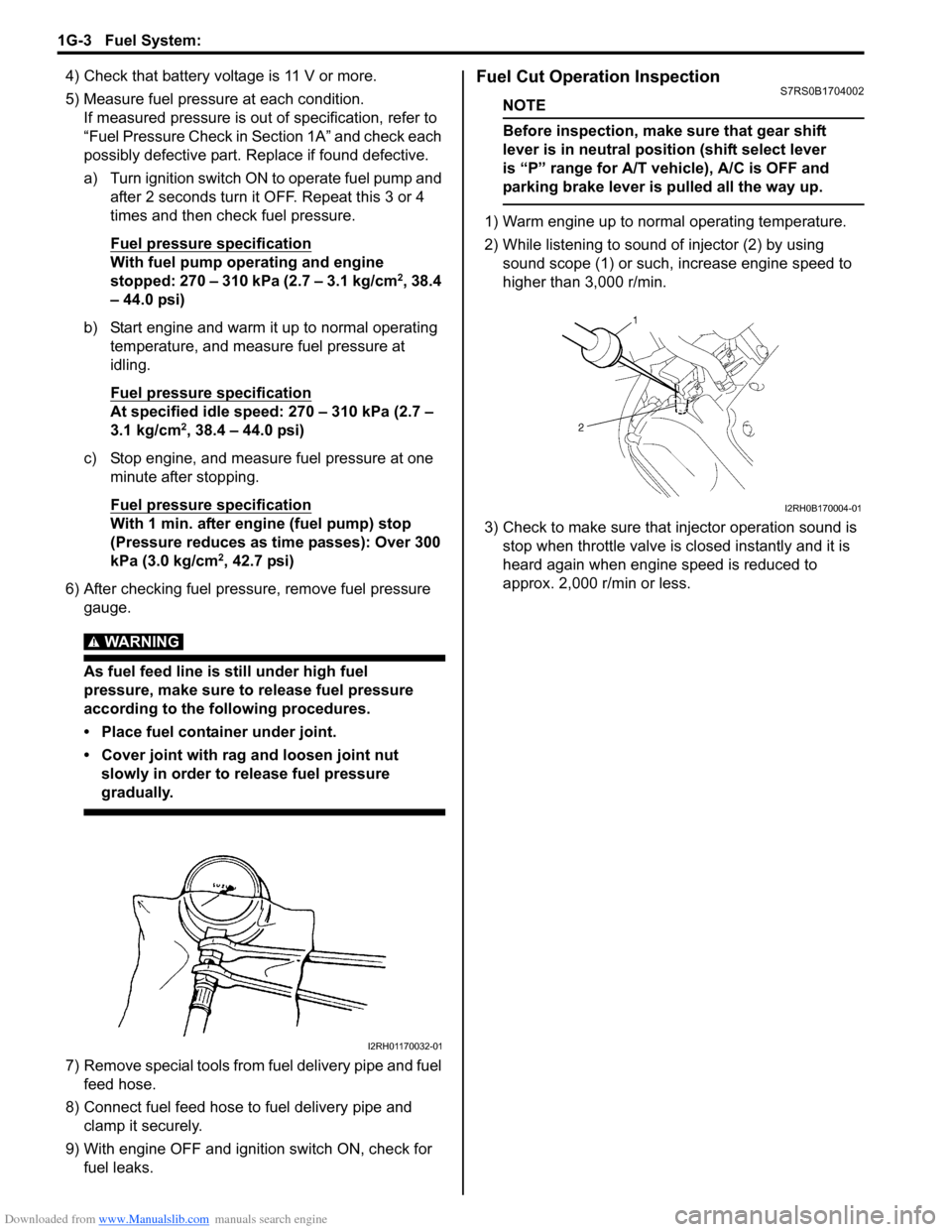

Fuel Cut Operation InspectionS7RS0B1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral positi on (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I2RH01170032-01

I2RH0B170004-01