ESP SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 502 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-4 Brake Control System and Diagnosis:

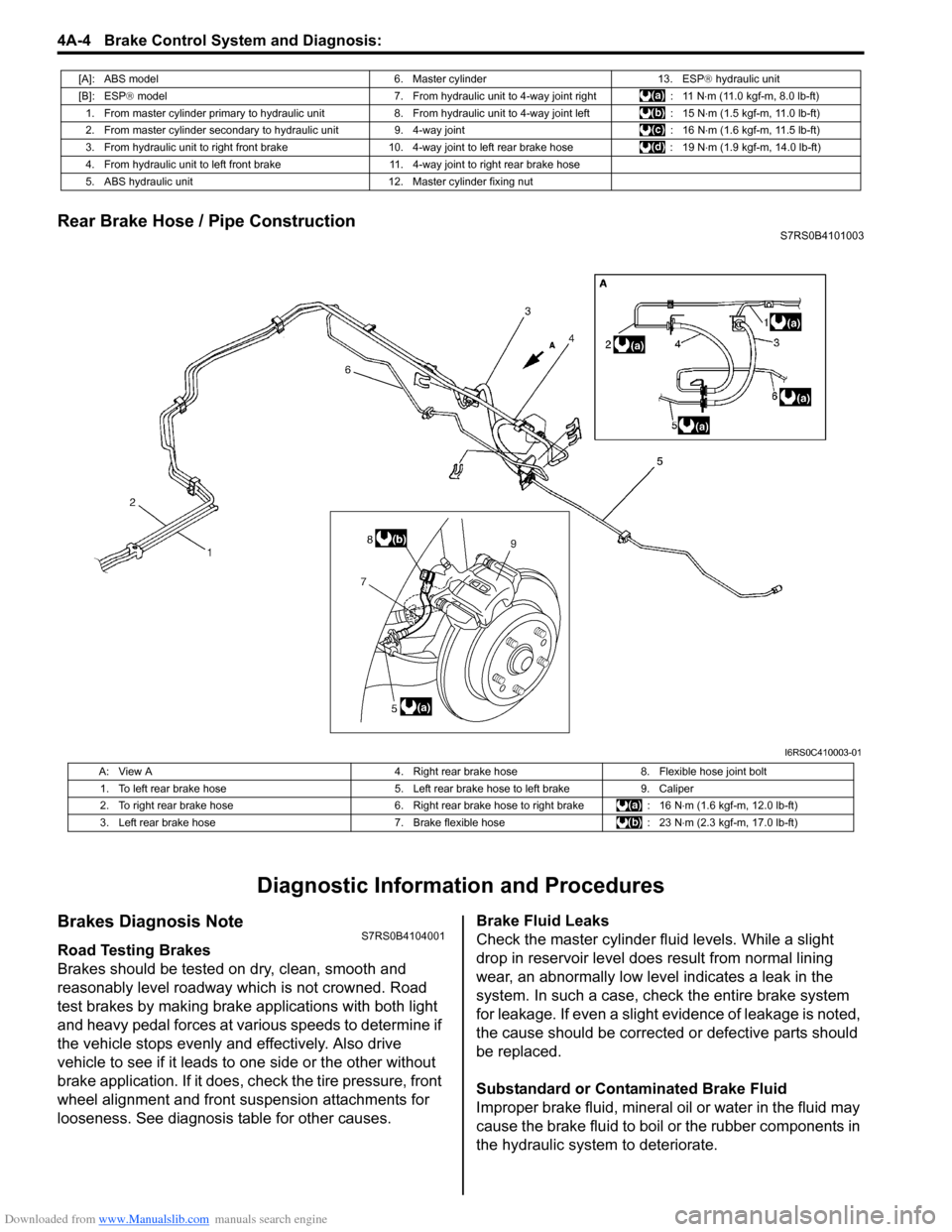

Rear Brake Hose / Pipe ConstructionS7RS0B4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS7RS0B4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at vari ous speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes. Brake Fluid Leaks

Check the master cylinder fl

uid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low leve l indicates a leak in the

system. In such a case, chec k the entire brake system

for leakage. If even a slight ev idence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components in

the hydraulic system to deteriorate.

[A]: ABS model 6. Master cylinder13. ESP® hydraulic unit

[B]: ESP ® model 7. From hydraulic unit to 4-way joint right : 11 N⋅m (11.0 kgf-m, 8.0 lb-ft)

1. From master cylinder primary to hydraulic unit 8. From hydraulic unit to 4-way joint left: 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

2. From master cylinder secondary to hydraulic unit 9. 4-way joint: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. From hydraulic unit to right front brake 10.4-way joint to left rear brake hose : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

4. From hydraulic unit to left front brake 11. 4-way joint to right rear brake hose

5. ABS hydraulic unit 12. Master cylinder fixing nut

I6RS0C410003-01

A: View A4. Right rear brake hose8. Flexible hose joint bolt

1. To left rear brake hose 5. Left rear brake hose to left brake9. Caliper

2. To right rear brake hose 6. Right rear brake hose to right brake: 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

3. Left rear brake hose 7. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 504 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-6 Brake Control System and Diagnosis:

Pedal pulsation (Pedal

pulsates when depressed

for braking)Damaged or loose wheel bearings

Replace wheel bearings.

Distorted steering knuckle or rear wheel

spindle Replace knuckle or rear wheel spindle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine disc.

Parallelism between brake pad and disc

not within specifications Check per instructions. If not within

specifications, replace or machine disc.

Brake caliper piston sticking Repair as necessary.

Braking noise Worn or distorted brake pad Replace pads.

Loose front wheel bearings Replace wheel bearings.

Distorted backing plates or loose

mounting bolts Replace or retighten securing bolts.

Contact wear indicator to brake disc Replace brake pad.

Brake warning light lights

after engine start Parking brake applied

Release parking brake and check that brake

warning light turns off.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake fluid leaking Investigate leaky point, correct it and add

brake fluid.

Brake warning light circuit faulty Repair circuit.

Malfunctioning EBD system Check system referring to “EBD Warning Light

(Brake Warning Light) Comes ON Steady in

Section 4E”.

Brake warning light turns

on when brake is applied Brake fluid leaking

Investigate leaky point, correct it and add

brake fluid.

Insufficient amount of brake fluid Investigate leaky point, correct it and add

brake fluid.

Brake warning light fails

to turn on even when

parking brake is applied Brake warning light circuit faulty

Replace bulb or repair circuit.

ABS warning light or

ESP

® warning light turns

on after engine start Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light turns

on when brake is applied Malfunctioning ABS (ESP

®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light or

ESP

® warning light does

not turn on for 2 sec. after

ignition switch has turned

ON Bulb burnt out

Replace bulb.

Malfunctioning ABS (ESP ®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

ABS warning light flashes New ABS hydraulic unit / control module

assembly installed. Perform “ABS Hydraulic

Unit Operation Check

in Section 4E”.

Condition Possible cause Correction / Reference Item

Page 537 of 1496

Downloaded from www.Manualslib.com manuals search engine Parking Brake: 4D-2

Repair Instructions

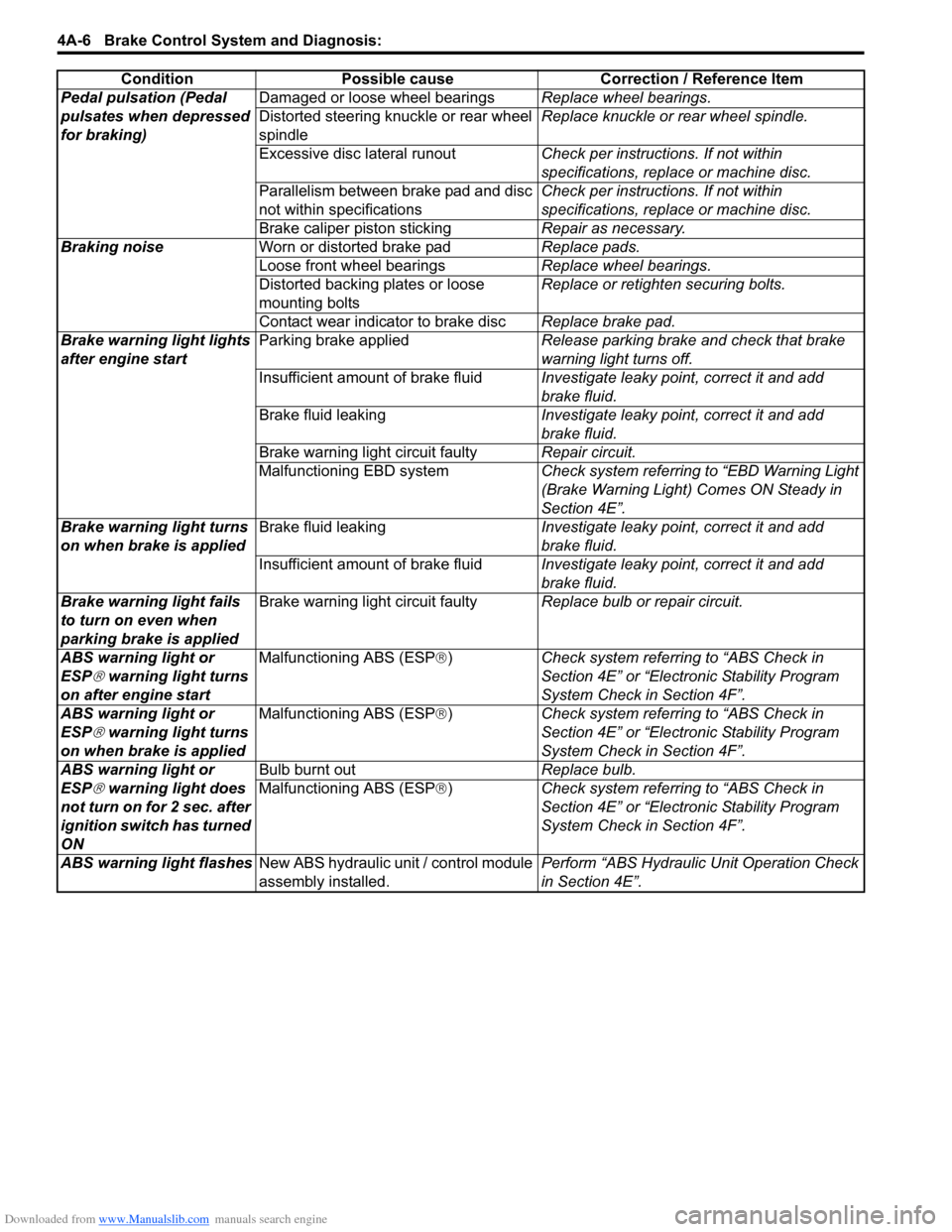

Parking Brake Inspection and AdjustmentS7RS0B4406001

Inspection

Hold center of parking brake lever grip and pull it up with

200 N (20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count

ratchet notches. There should be 4 to 9 notches.

Also, check if both right and left rear wheels are locked

firmly.

To count number of notches easily, listen to click sounds

that ratchet makes while pulling parking brake lever

without pressing its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable

referring to adjustment procedure so as to obtain

specified parking brake stroke.

NOTE

Check tooth tip of each notch for damage or

wear.

If any damage or wear is found, replace

parking brake lever.

Adjustment

NOTE

Make sure for the following conditions before

cable adjustment.

• No air is trapped in brake system.

• Brake pedal travel is proper.

• Start engine and then brake pedal has been depressed at least 3 times with about

160 N (16.0 kg, 35.3 lbs) load.

• Parking brake lever (1) has been pulled up a few times with about 200 N (20 kg, 44 lbs)

load.

If parking brake cable is replaced with new

one, pull up parking brake lever a few

times with about 500 N ⋅m (50 kg, 110 lbs)

force.

1) Release parking brake lever (1).

2) Loosen parking brake lever adjust nut (2) fully.

3) Make sure that lever (3) contacts pin (4).

4) Pull up parking brake lever 1 notch.

5) Rotate rear wheel by hand and fasten parking lever adjust nut until dragging rear wheel lightly.

I4RS0B440002-01

1. Parking brake cable 2. Brake caliper

I4RS0A440003-01

I6RS0C440001-01

I6RS0C440002-01

Page 558 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-19 ABS:

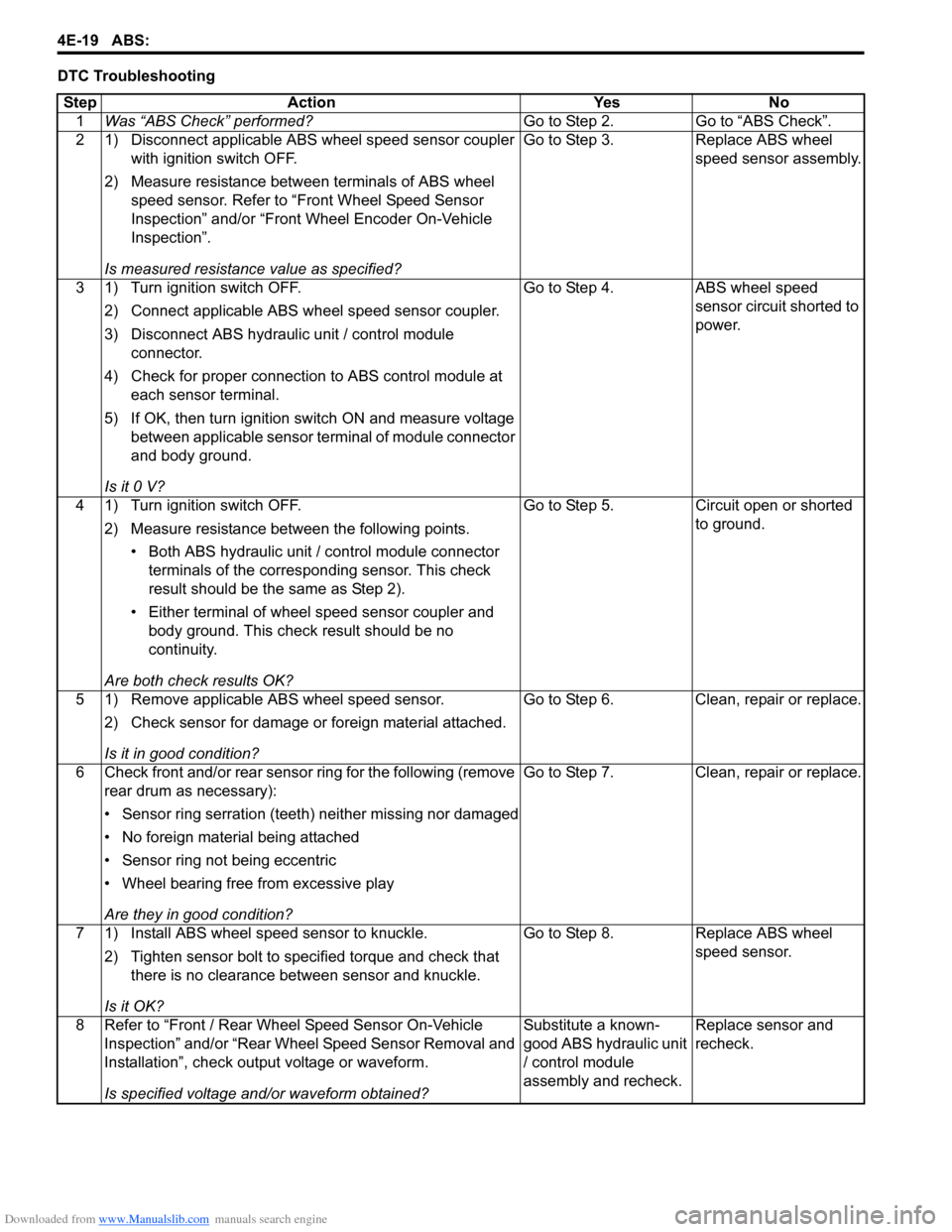

DTC TroubleshootingStep Action Yes No 1 Was “ABS Check” performed? Go to Step 2. Go to “ABS Check”.

2 1) Disconnect applicable ABS wheel speed sensor coupler with ignition switch OFF.

2) Measure resistance betw een terminals of ABS wheel

speed sensor. Refer to “Front Wheel Speed Sensor

Inspection” and/or “Front Wheel Encoder On-Vehicle

Inspection”.

Is measured resistance value as specified? Go to Step 3. Replace ABS wheel

speed sensor assembly.

3 1) Turn ignition switch OFF. 2) Connect applicable ABS wh eel speed sensor coupler.

3) Disconnect ABS hydraulic unit / control module connector.

4) Check for proper connection to ABS control module at each sensor terminal.

5) If OK, then turn ignition switch ON and measure voltage between applicable sensor terminal of module connector

and body ground.

Is it 0 V? Go to Step 4. ABS wheel speed

sensor circuit shorted to

power.

4 1) Turn ignition switch OFF. 2) Measure resistance between the following points.• Both ABS hydraulic unit / control module connector terminals of the correspo nding sensor. This check

result should be the same as Step 2).

• Either terminal of wheel speed sensor coupler and body ground. This check result should be no

continuity.

Are both check results OK? Go to Step 5. Circuit open or shorted

to ground.

5 1) Remove applicable ABS wheel speed sensor. 2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 6. Clean, repair or replace.

6 Check front and/or rear sensor ring for the following (remove rear drum as necessary):

• Sensor ring serration (teeth) neither missing nor damaged

• No foreign material being attached

• Sensor ring not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 7. Clean, repair or replace.

7 1) Install ABS wheel speed sensor to knuckle. 2) Tighten sensor bolt to specified torque and check that there is no clearance between sensor and knuckle.

Is it OK? Go to Step 8. Replace ABS wheel

speed sensor.

8 Refer to “Front / Rear Wheel Speed Sensor On-Vehicle Inspection” and/or “Rear Wheel Speed Sensor Removal and

Installation”, check output voltage or waveform.

Is specified voltage and/or waveform obtained? Substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.

Replace sensor and

recheck.

Page 567 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-28

Repair Instructions

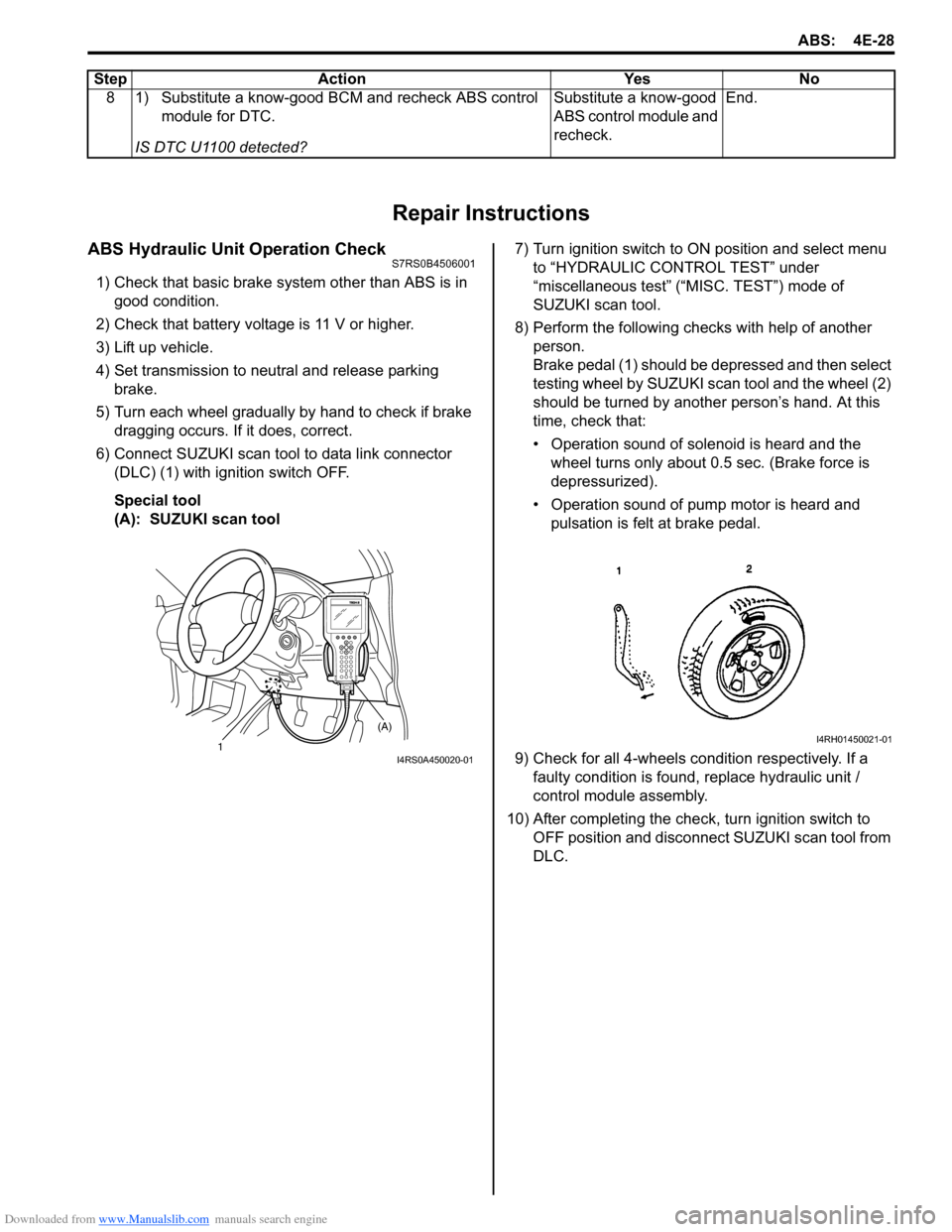

ABS Hydraulic Unit Operation CheckS7RS0B4506001

1) Check that basic brake system other than ABS is in good condition.

2) Check that battery voltage is 11 V or higher.

3) Lift up vehicle.

4) Set transmission to neutral and release parking brake.

5) Turn each wheel gradually by hand to check if brake dragging occurs. If it does, correct.

6) Connect SUZUKI scan tool to data link connector (DLC) (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool 7) Turn ignition switch to ON position and select menu

to “HYDRAULIC CONTROL TEST” under

“miscellaneous test” (“MISC. TEST”) mode of

SUZUKI scan tool.

8) Perform the following checks with help of another person.

Brake pedal (1) should be depressed and then select

testing wheel by SUZUKI scan tool and the wheel (2)

should be turned by another person’s hand. At this

time, check that:

• Operation sound of solenoid is heard and the wheel turns only about 0.5 sec. (Brake force is

depressurized).

• Operation sound of pump motor is heard and pulsation is felt at brake pedal.

9) Check for all 4-wheels co ndition respectively. If a

faulty condition is found, replace hydraulic unit /

control module assembly.

10) After completing the check, turn ignition switch to OFF position and disconnect SUZUKI scan tool from

DLC.

8 1) Substitute a know-good BCM and recheck ABS control

module for DTC.

IS DTC U1100 detected? Substitute a know-good

ABS control module and

recheck.

End.

Step Action Yes No

1 (A)I4RS0A450020-01

I4RH01450021-01

Page 575 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-1

Brakes

Electronic Stability Program

Precautions

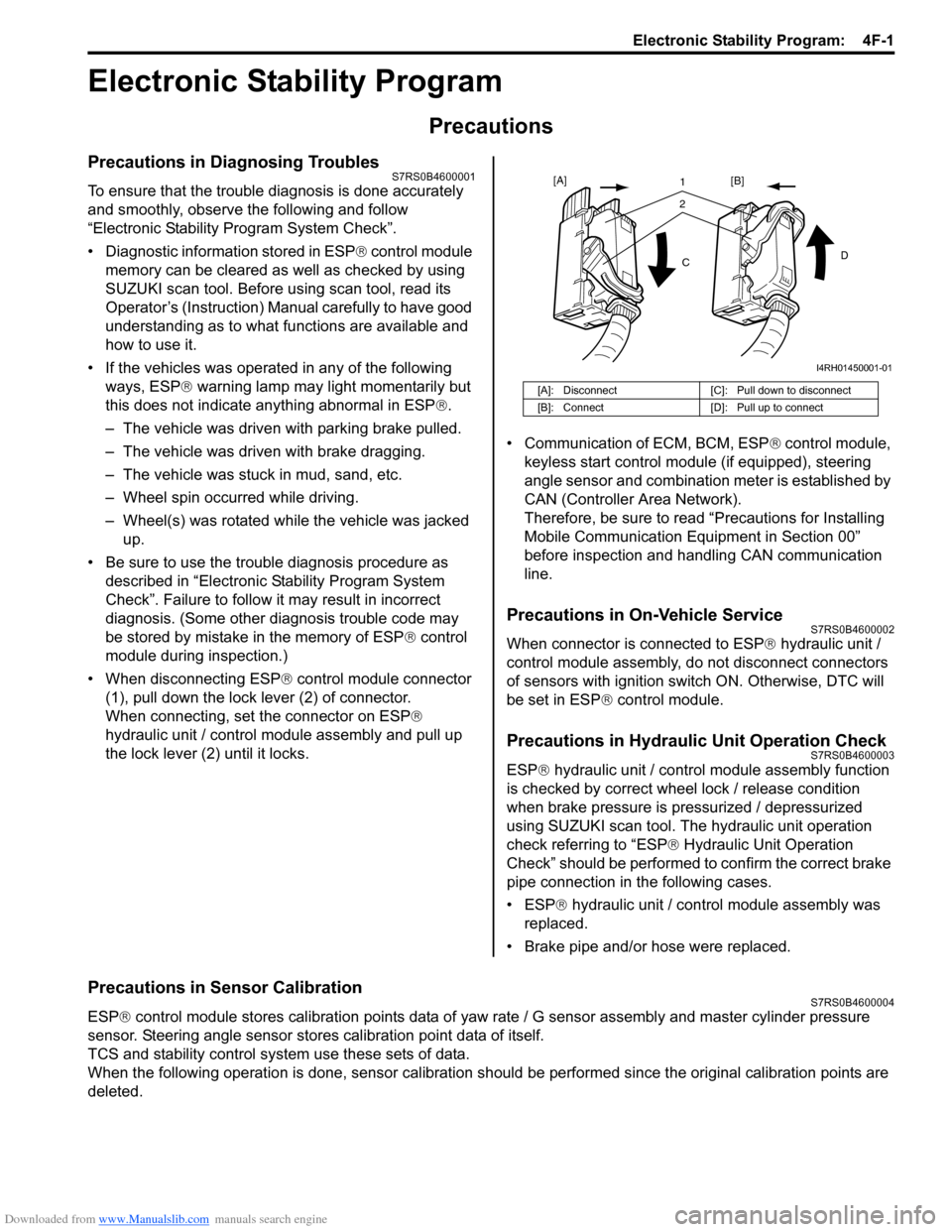

Precautions in Diagnosing TroublesS7RS0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program System Check”.

• Diagnostic information stored in ESP® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ESP ® warning lamp may light momentarily but

this does not indicate anything abnormal in ESP ®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to use the trouble diagnosis procedure as described in “Electronic Stability Program System

Check”. Failure to follow it may resu lt in incorrect

diagnosis. (Some other diagnosis trouble code may

be stored by mistake in the memory of ESP ® control

module during inspection.)

• When disconnecting ESP ® control module connector

(1), pull down the lock lever (2) of connector.

When connecting, set the connector on ESP ®

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks. • Communication of ECM, BCM, ESP

® control module,

keyless start control module (if equipped), steering

angle sensor and combination meter is established by

CAN (Controller Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4600002

When connector is connected to ESP ® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP ® control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4600003

ESP® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “ESP ® Hydraulic Unit Operation

Check” should be performed to confirm the correct brake

pipe connection in the following cases.

• ESP® hydraulic unit / contro l module assembly was

replaced.

• Brake pipe and/or hose were replaced.

Precautions in Sensor CalibrationS7RS0B4600004

ESP ® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, sensor calibration should be performed since the original calibration points are

deleted.

[A]: Disconnect [C]: Pull down to disconnect

[B]: Connect [D]: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 576 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-2 Electronic Stability Program:

Perform sensor calibration according to “Sensor Calibration”.

Precautions in Speedometer Test or Other TestsS7RS0B4600005

When performing speedometer or other tests using speedometer tester or chassis dynamometer, ESP® function must

be deactivated by ESP ® OFF switch or using SUZUKI scan to ol to complete the tests correctly.

When using SUZUKI scan tool, set to the “MISC. TEST” mode to stop the ESP ® function. Refer to SUZUKI scan tool

operator's manual for further details.

General Description

Electronic Stability Program DescriptionS7RS0B4601006

Electronic Stability Program (ESP ®) is an auxiliary function to enable the vehicle to av oid a danger safely while the

vehicle is running, stopping or turning.

Electronic Stability Program (ESP ®) consists of following functions.

ESP ® is a registered trademark of Daimler Chrysler AG.

Antilock Brake System (ABS)

This system prevents tire locking which may occur when br ake is applied suddenly or on slippery roads. With this

function, as the vehicle body is kept in the stable state an d tires unlocked, the driver can avoid any obstacle by turning

the steering wheel.

Electronic Brake force Distribution (EBD)

This function distributes braking force of front and rear wheels properly according to the vehicle load condition.

With this function, the braking force of the front and rear wheels is controlled for the optimum effect to secure the

maximum braking force regardless of the loadage.

Traction Control System (TCS)

This system controls the engine and brake to prevent the dr iving wheels from spinning at the time of starting and

accelerating. Particularly, this fu nction is helpful for safe driving on muddy or icy roads. When ESP ® control module

detects wheel spinning using information from the yaw rate sensor and wheel speed sensor, it lower the engine torque

by closing the electronic controlled thro ttle and controlling ignition. At the same time, brake is applied to the spinning

tire.

Stability Control

This function controls the vehicle body in the stable state by controlling the engine and braking so as to prevent the

vehicle from over-steering or under-steering while turning.

When under-steering occurs, this function lowers the engine torque and applies brake to the inner rear wheel in the

vehicle forward direction so as to pr event the vehicle from moving outward.

When over-steering occurs, this function applies brake to the outer front wheel in the vehicle forward direction so as to

prevent the vehicle from moving inward. Sensor Procedures required calibration

Steering angle sensor • Power is not su pplied to steering angle sensor. (battery, fuse and/or connector is

removed.)

• Steering angle sensor is replaced.

• Power is not supplied to ESP ® control module. (battery, fuse and/or connector is

removed.)

• ESP® hydraulic unit / control module assembly is replaced.

Master cylinder pressure sensor • ESP® hydraulic unit / control module assembly is removed or replaced.

Yaw rate / G sensor assembly • Yaw rate / G sensor assembly is removed or replaced.

• ESP® hydraulic unit / control module assembly is replaced.

Page 577 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-3

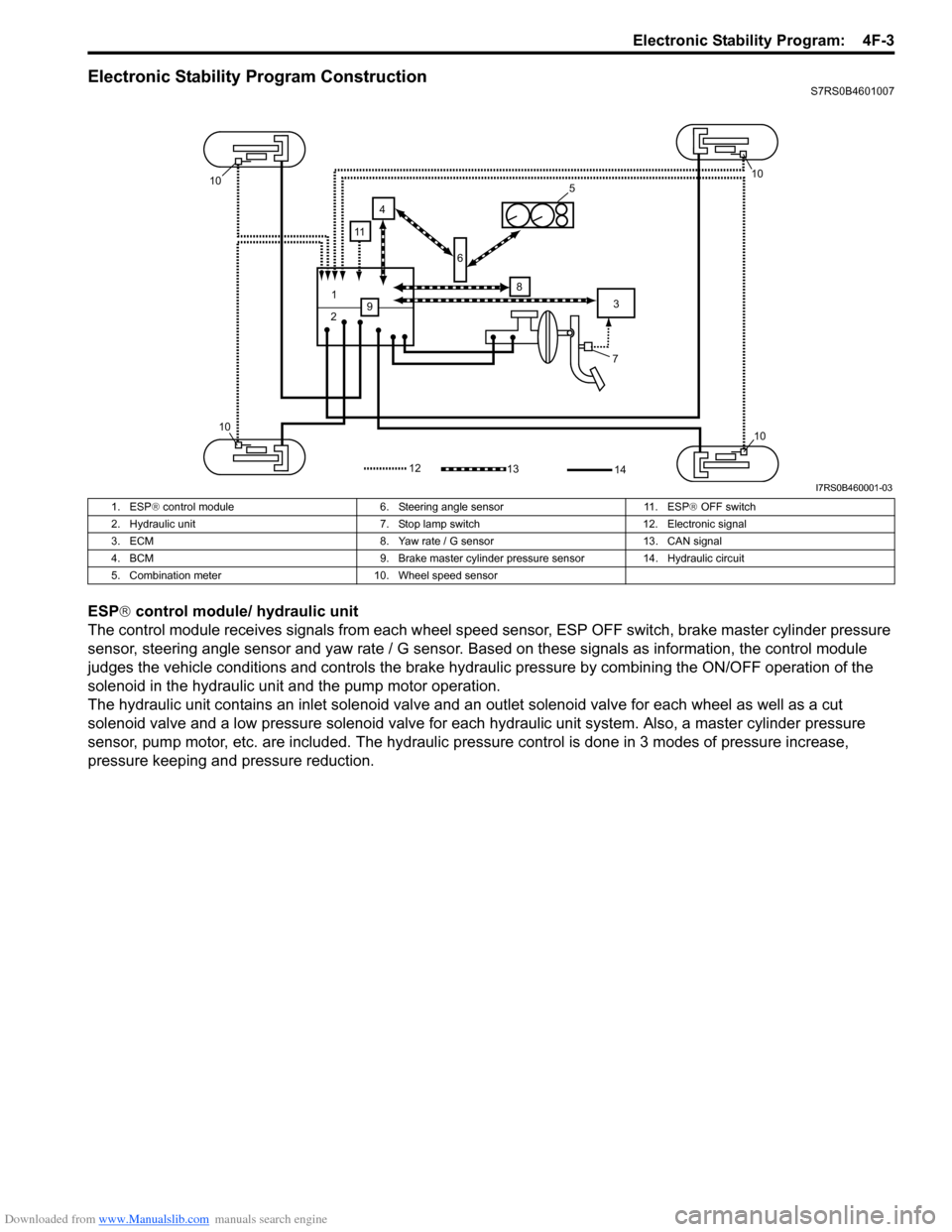

Electronic Stability Program ConstructionS7RS0B4601007

ESP® control module/ hydraulic unit

The control module receives signals from each wheel speed sensor, ESP O FF switch, brake master cylinder pressure

sensor, steering angle sensor and yaw rate / G sensor. Ba sed on these signals as information, the control module

judges the vehicle conditions and controls the brake hydraulic pressure by combining the ON/OFF operation of the

solenoid in the hydraulic unit and the pump motor operation.

The hydraulic unit contains an inlet so lenoid valve and an outlet solenoid valve for each wheel as well as a cut

solenoid valve and a low pressure solenoid valve for each hydraulic unit system. Also, a master cylinder pressure

sensor, pump motor, etc. are included. The hydraulic pre ssure control is done in 3 modes of pressure increase,

pressure keeping and pressure reduction.

7

1

2 3

4

5

6

8

9

10

1010

10

1312

11

14

I7RS0B460001-03

1. ESP ® control module 6. Steering angle sensor 11. ESP ® OFF switch

2. Hydraulic unit 7. Stop lamp switch 12. Electronic signal

3. ECM 8. Yaw rate / G sensor 13. CAN signal

4. BCM 9. Brake master cylinder pre ssure sensor 14. Hydraulic circuit

5. Combination meter 10. Wheel speed sensor

Page 578 of 1496

Downloaded from www.Manualslib.com manuals search engine 4F-4 Electronic Stability Program:

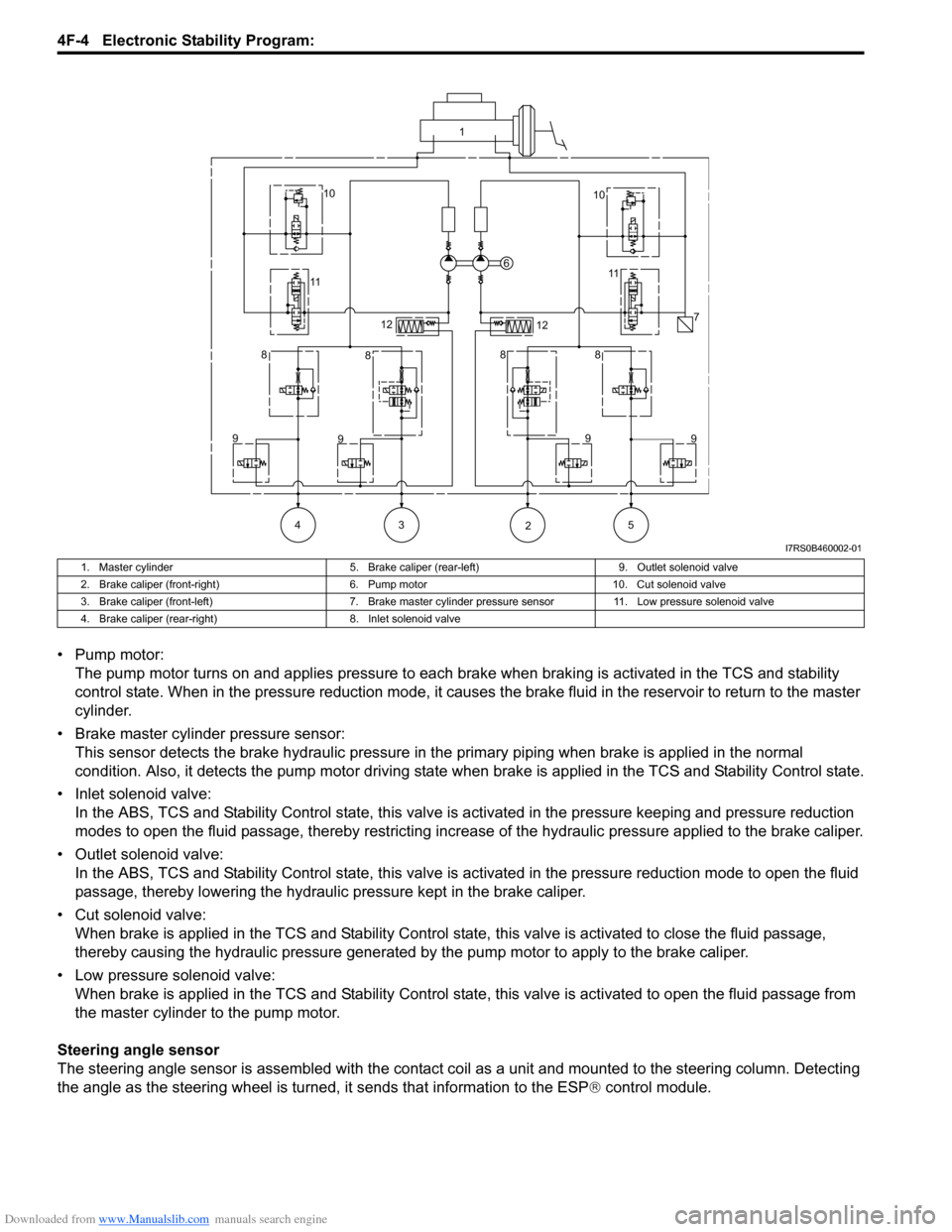

• Pump motor:The pump motor turns on and applies pressure to each brake when braking is activated in the TCS and stability

control state. When in the pressure reduction mode, it causes the brake fluid in the reservoir to return to the master

cylinder.

• Brake master cylinder pressure sensor: This sensor detects the brake hydraulic pressure in th e primary piping when brake is applied in the normal

condition. Also, it detects the pump motor driving state wh en brake is applied in the TCS and Stability Control state.

• Inlet solenoid valve: In the ABS, TCS and Stability Control stat e, this valve is activated in the pressure keeping and pressure reduction

modes to open the fluid passage, thereby restricting increase of the hydraulic pressure applied to the brake caliper.

• Outlet solenoid valve: In the ABS, TCS and Stability Control state, this valve is activated in the pressure reduction mode to open the fluid

passage, thereby lowering the hydraulic pressure kept in the brake caliper.

• Cut solenoid valve: When brake is applied in the TCS and Stability Control state, this valve is activated to close the fluid passage,

thereby causing the hydraulic pressure generated by the pump motor to apply to the brake caliper.

• Low pressure solenoid valve: When brake is applied in the TCS and Stab ility Control state, this valve is activated to open the fluid passage from

the master cylinder to the pump motor.

Steering angle sensor

The steering angle sensor is assembled with the contact co il as a unit and mounted to the steering column. Detecting

the angle as the steering wheel is turned, it sends that information to the ESP ® control module.

1

10 10

11 11

6

7

12 12

8 8 88

9 9 9

9

43 5 2

I7RS0B460002-01

1. Master cylinder 5. Brake caliper (rear-left)9. Outlet solenoid valve

2. Brake caliper (front-right) 6. Pump motor10. Cut solenoid valve

3. Brake caliper (front-left) 7. Brake master cylinder pressure sensor 11. Low pressure solenoid valve

4. Brake caliper (rear-right) 8. Inlet solenoid valve