Wiring ecm SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 250 of 1496

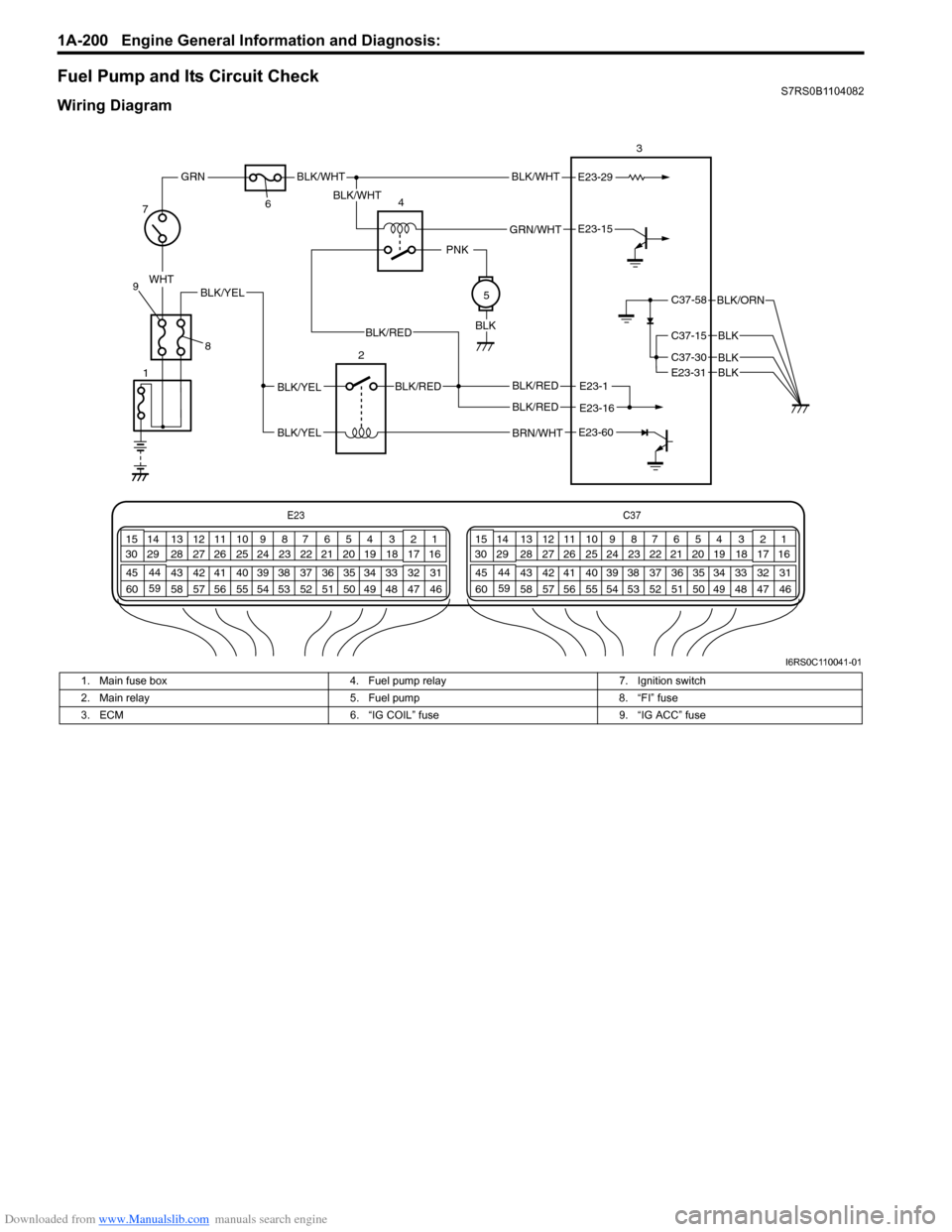

Downloaded from www.Manualslib.com manuals search engine 1A-200 Engine General Information and Diagnosis:

Fuel Pump and Its Circuit CheckS7RS0B1104082

Wiring Diagram

E23-1

E23-60

E23-15

BRN/WHT

BLK/REDBLK/YEL

BLK/YEL

BLK/RED

E23-29BLK/WHT

GRN/WHT

BLK/WHT

BLK/WHT

PNK

BLK

WHT

GRN

C37-58

C37-15

C37-30

BLK/ORN

BLK

BLKE23-31BLK

78

9 6

4 3

2 5

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/YEL

1

E23-16BLK/RED

BLK/RED

I6RS0C110041-01

1. Main fuse box 4. Fuel pump relay 7. Ignition switch

2. Main relay 5. Fuel pump 8. “FI” fuse

3. ECM 6. “IG COIL” fuse 9. “IG ACC” fuse

Page 255 of 1496

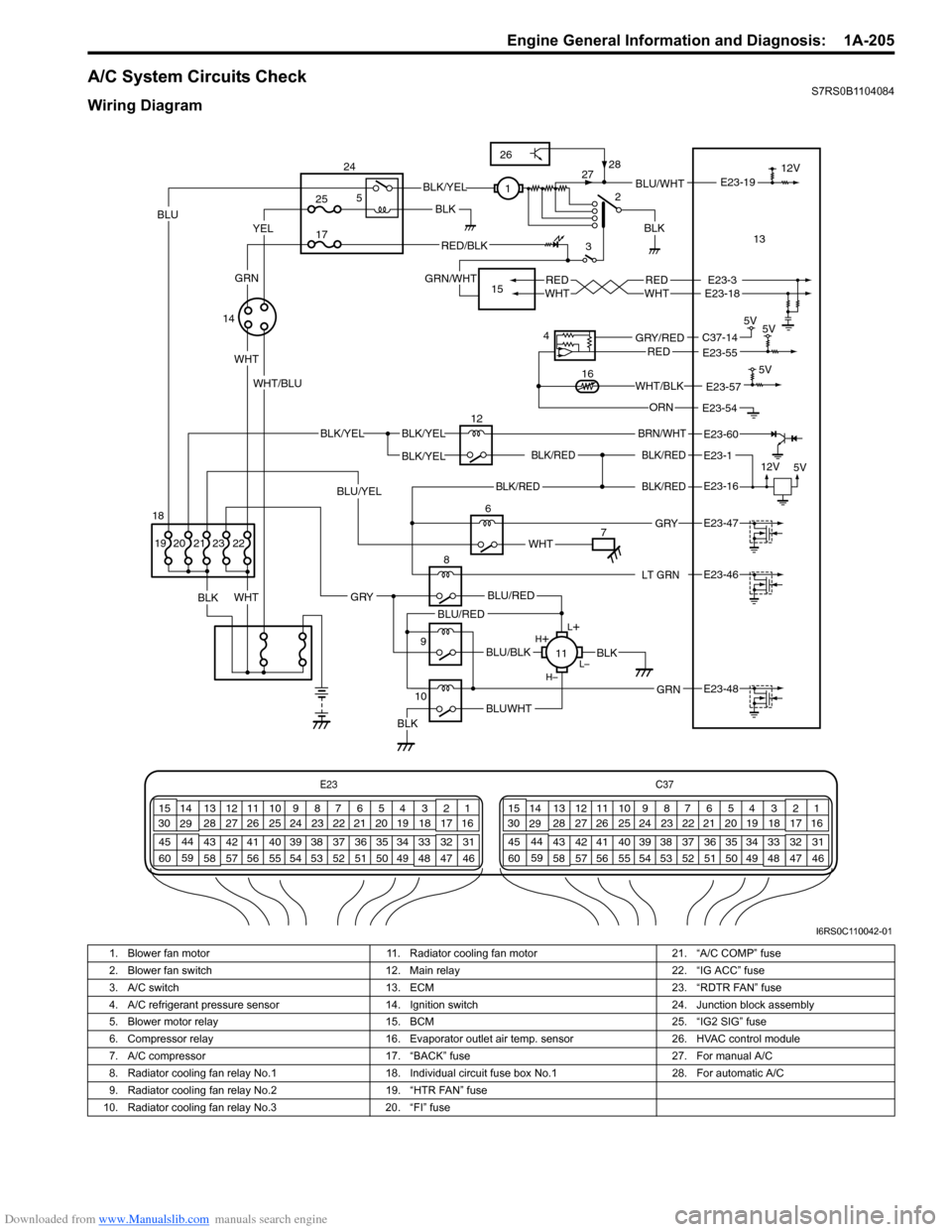

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-205

A/C System Circuits CheckS7RS0B1104084

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V

12

E23-1

E23-60

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

GRN

GRY

E23-48

8

11

2

3BLU/WHT

REDWHTREDWHTE23-3E23-18

E23-19

6

BLK

WHT

BLK 12V

E23-47 GRY

WHT

YELBLU

WHT

BLK/YEL

RED/BLK

GRN/WHT

WHT/BLU1

713

14

5V

5V

4

E23-55C37-14GRY/REDRED

E23-54ORN 5V

E23-57WHT/BLK16

9

10

25

17

5

24

15

22

BLU/YEL

23212019

GRN

BLK

18

26

28

27

I6RS0C110042-01

1. Blower fan motor 11. Radiator cooling fan motor 21. “A/C COMP” fuse

2. Blower fan switch 12. Main relay 22. “IG ACC” fuse

3. A/C switch 13. ECM 23. “RDTR FAN” fuse

4. A/C refrigerant pressure sensor 14. Ignition switch 24. Junction block assembly

5. Blower motor relay 15. BCM 25. “IG2 SIG” fuse

6. Compressor relay 16. Evaporator outlet air temp. sensor 26. HVAC control module

7. A/C compressor 17. “BACK” fuse 27. For manual A/C

8. Radiator cooling fan relay No.1 18. Individual circuit fuse box No.1 28. For automatic A/C

9. Radiator cooling fan relay No.2 19. “HTR FAN” fuse

10. Radiator cooling fan relay No.3 20. “FI” fuse

Page 259 of 1496

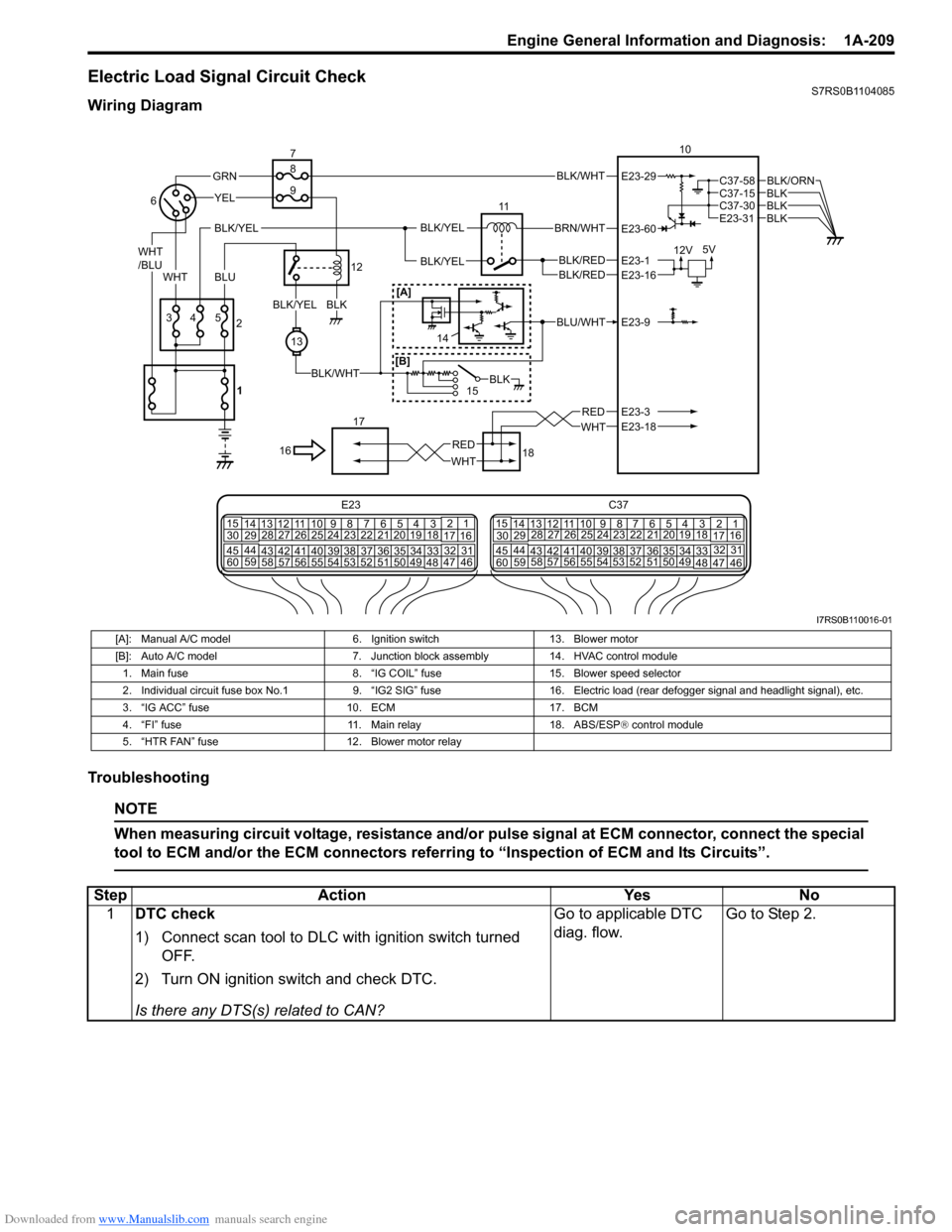

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-209

Electric Load Signal Circuit CheckS7RS0B1104085

Wiring Diagram

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

BLK/WHT

BLK/RED

WHT

BRN/WHT

12V5V

11

BLK/YELBLK/YEL

BLK/YEL

BLKBLKBLK

BLK/ORN

10

18

17

BLU/WHT

15

WHTRED

43

YEL

5

13

BLK/WHT

BLKBLK/YEL

GRN

WHT

/BLU

BLU

16

2

6

7

12

8

9

BLK

WHT

RED

E23-29

E23-60

E23-1E23-16

E23-9

E23-3E23-18

C37-58C37-15

E23-31C37-30

BLK/RED

[A]

[B]

E23 C37

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

1213

238

34

1819

567

10

11

17

20

47 46

495051

2122

52 16

25 9

24

14

29

5557 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

4042 39 38

44

45 43 41 331

12

13

238

1

14

I7RS0B110016-01

[A]: Manual A/C model

6. Ignition switch13. Blower motor

[B]: Auto A/C model 7. Junction block assembly14. HVAC control module

1. Main fuse 8. “IG COIL” fuse15. Blower speed selector

2. Individual circuit fuse box No.1 9. “IG2 SIG” fuse16. Electric load (rear defogger signal and headlight signal), etc.

3. “IG ACC” fuse 10. ECM17. BCM

4. “FI” fuse 11. Main relay18. ABS/ESP® control module

5. “HTR FAN” fuse 12. Blower motor relay

StepAction YesNo

1 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there any DTS(s) related to CAN? Go to applicable DTC

diag. flow.

Go to Step 2.

Page 261 of 1496

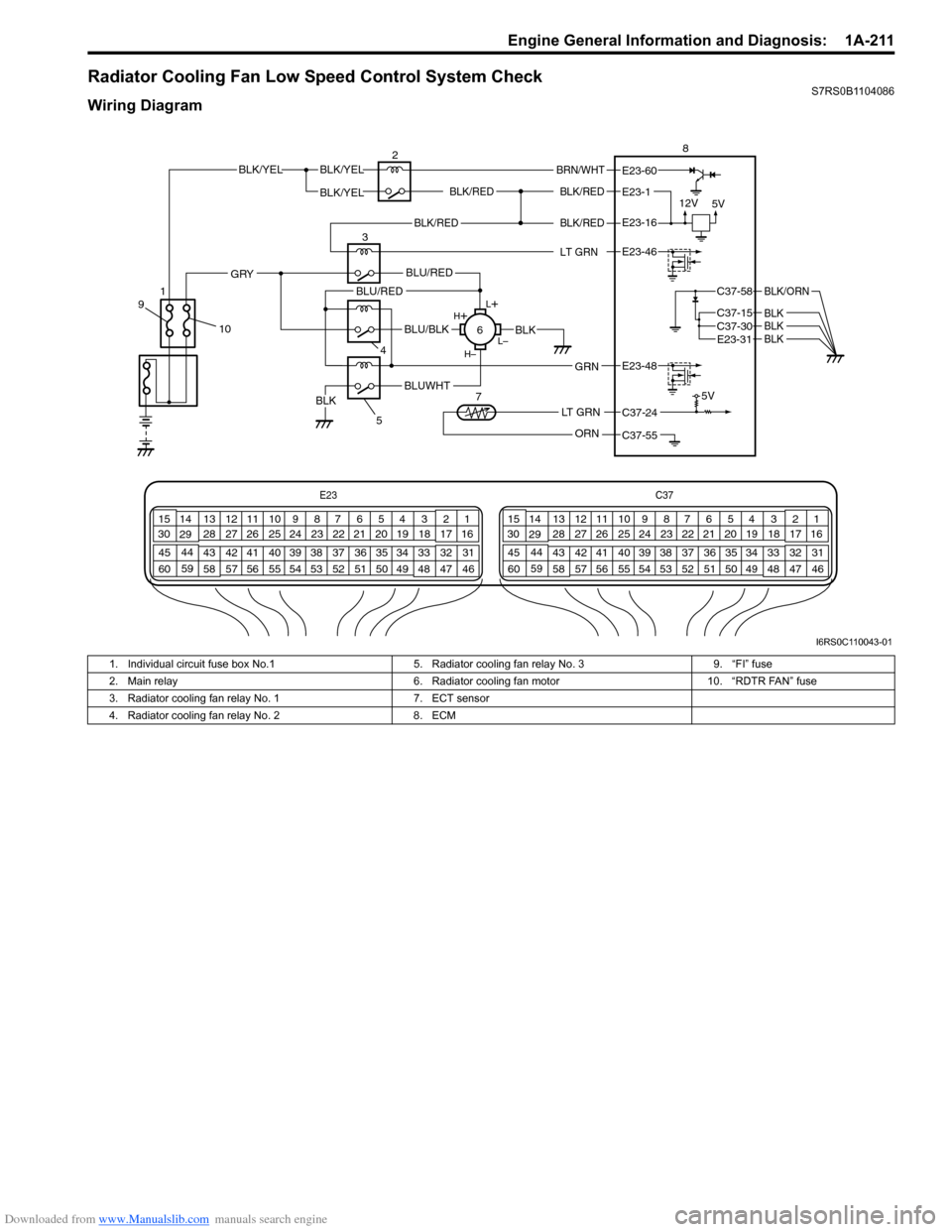

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-211

Radiator Cooling Fan Low Speed Control System CheckS7RS0B1104086

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

2

8

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

4

GRN

GRY

E23-48

LT GRN

ORN

C37-24

C37-55

35

6

7

10

9

1

I6RS0C110043-01

1. Individual circuit fuse box No.1

5. Radiator cooling fan relay No. 3 9. “FI” fuse

2. Main relay 6. Radiator cooling fan motor10. “RDTR FAN” fuse

3. Radiator cooling fan relay No. 1 7. ECT sensor

4. Radiator cooling fan relay No. 2 8. ECM

Page 263 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-213

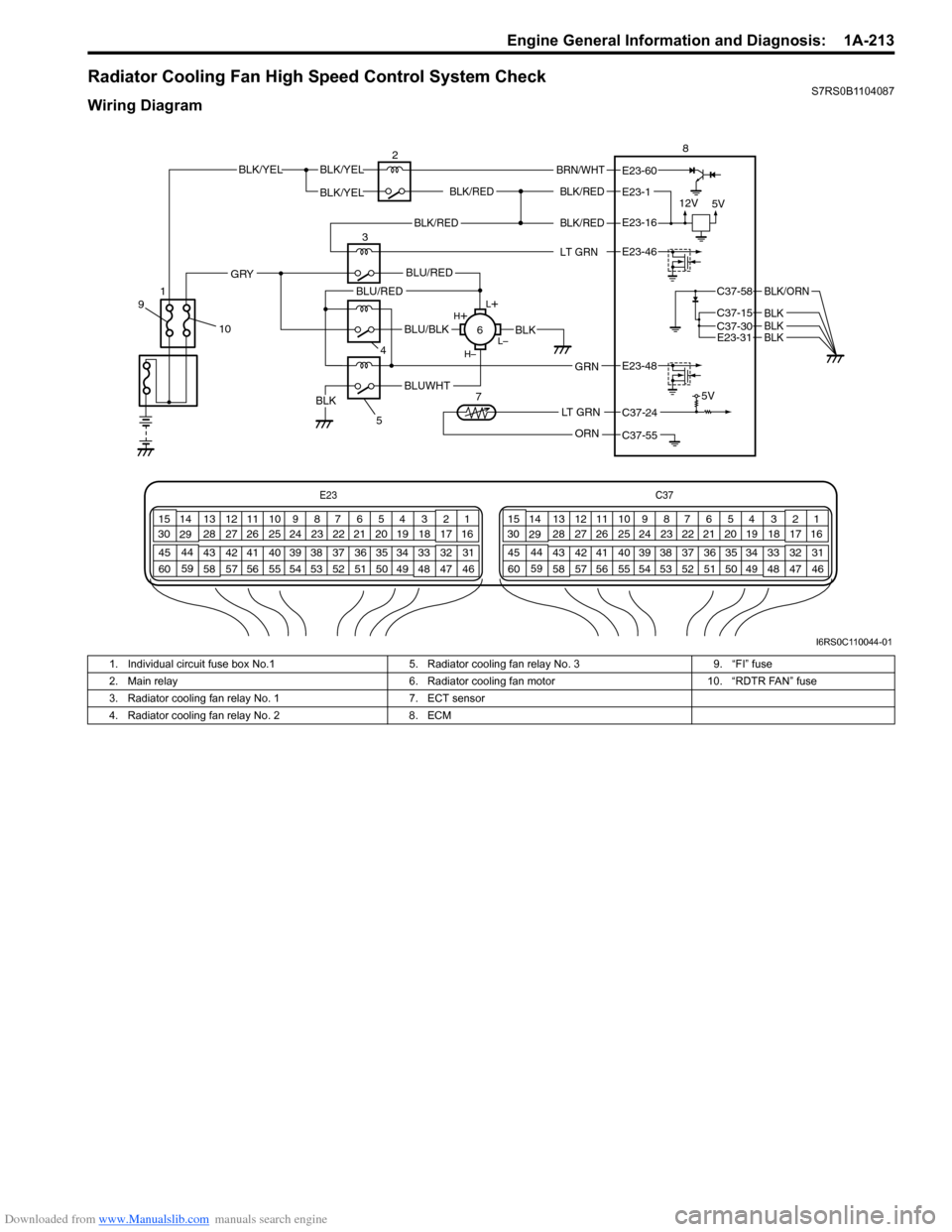

Radiator Cooling Fan High Speed Control System CheckS7RS0B1104087

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V5V

2

8

E23-1

E23-60

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

4

GRN

GRY

E23-48

LT GRN

ORN

C37-24

C37-55

35

6

7

10

9

1

I6RS0C110044-01

1. Individual circuit fuse box No.1

5. Radiator cooling fan relay No. 3 9. “FI” fuse

2. Main relay 6. Radiator cooling fan motor10. “RDTR FAN” fuse

3. Radiator cooling fan relay No. 1 7. ECT sensor

4. Radiator cooling fan relay No. 2 8. ECM

Page 367 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

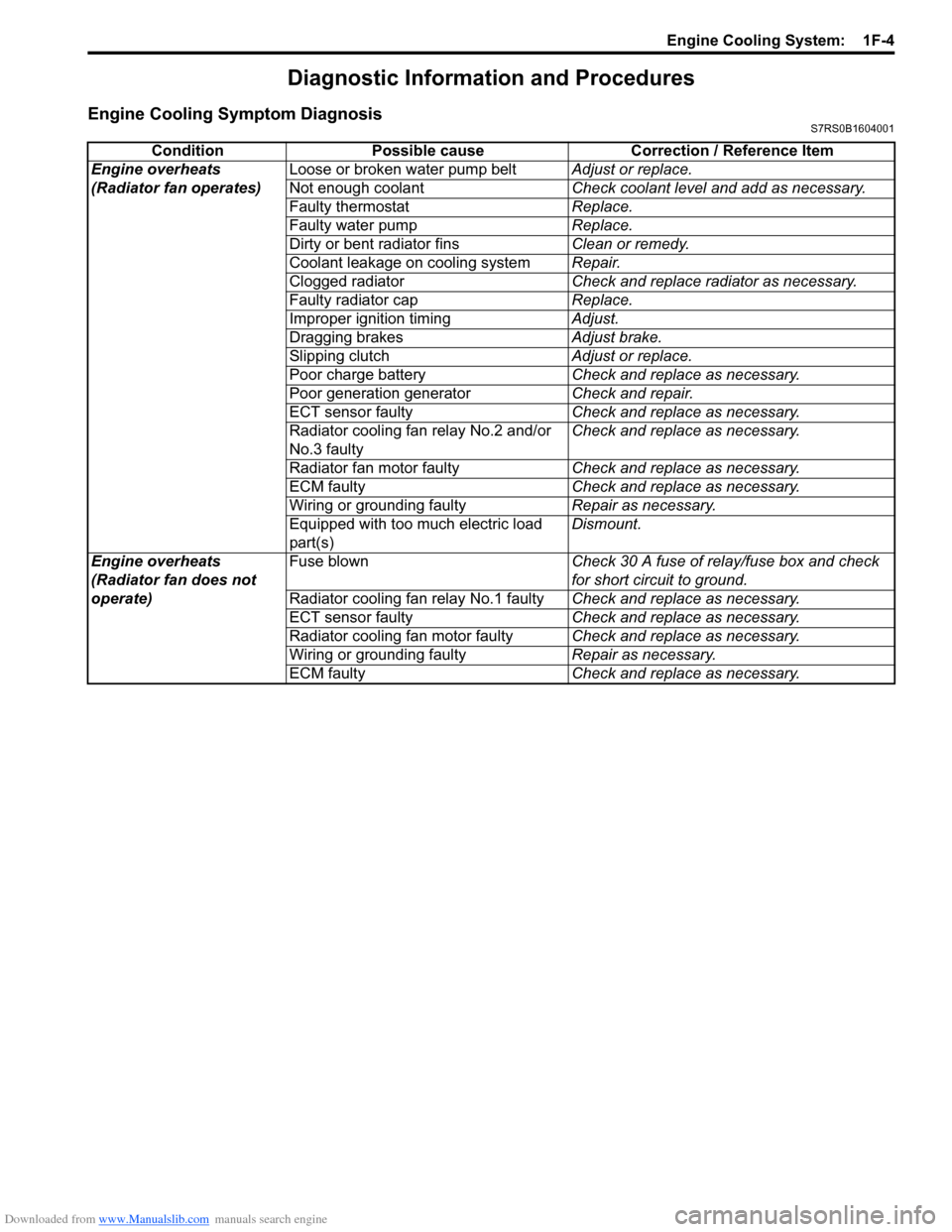

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS7RS0B1604001

ConditionPossible cause Correction / Reference Item

Engine overheats

(Radiator fan operates) Loose or broken water pump belt

Adjust or replace.

Not enough coolant Check coolant level and add as necessary.

Faulty thermostat Replace.

Faulty water pump Replace.

Dirty or bent radiator fins Clean or remedy.

Coolant leakage on cooling system Repair.

Clogged radiator Check and replace radiator as necessary.

Faulty radiator cap Replace.

Improper ignition timing Adjust.

Dragging brakes Adjust brake.

Slipping clutch Adjust or replace.

Poor charge battery Check and replace as necessary.

Poor generation generator Check and repair.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan relay No.2 and/or

No.3 faulty Check and replace as necessary.

Radiator fan motor faulty Check and replace as necessary.

ECM faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

Equipped with too much electric load

part(s) Dismount.

Engine overheats

(Radiator fan does not

operate) Fuse blown

Check 30 A fuse of relay/fuse box and check

for short circuit to ground.

Radiator cooling fan relay No.1 faulty Check and replace as necessary.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan motor faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check and replace as necessary.

Page 402 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-1 Starting System:

Engine

Starting System

Schematic and Routing Diagram

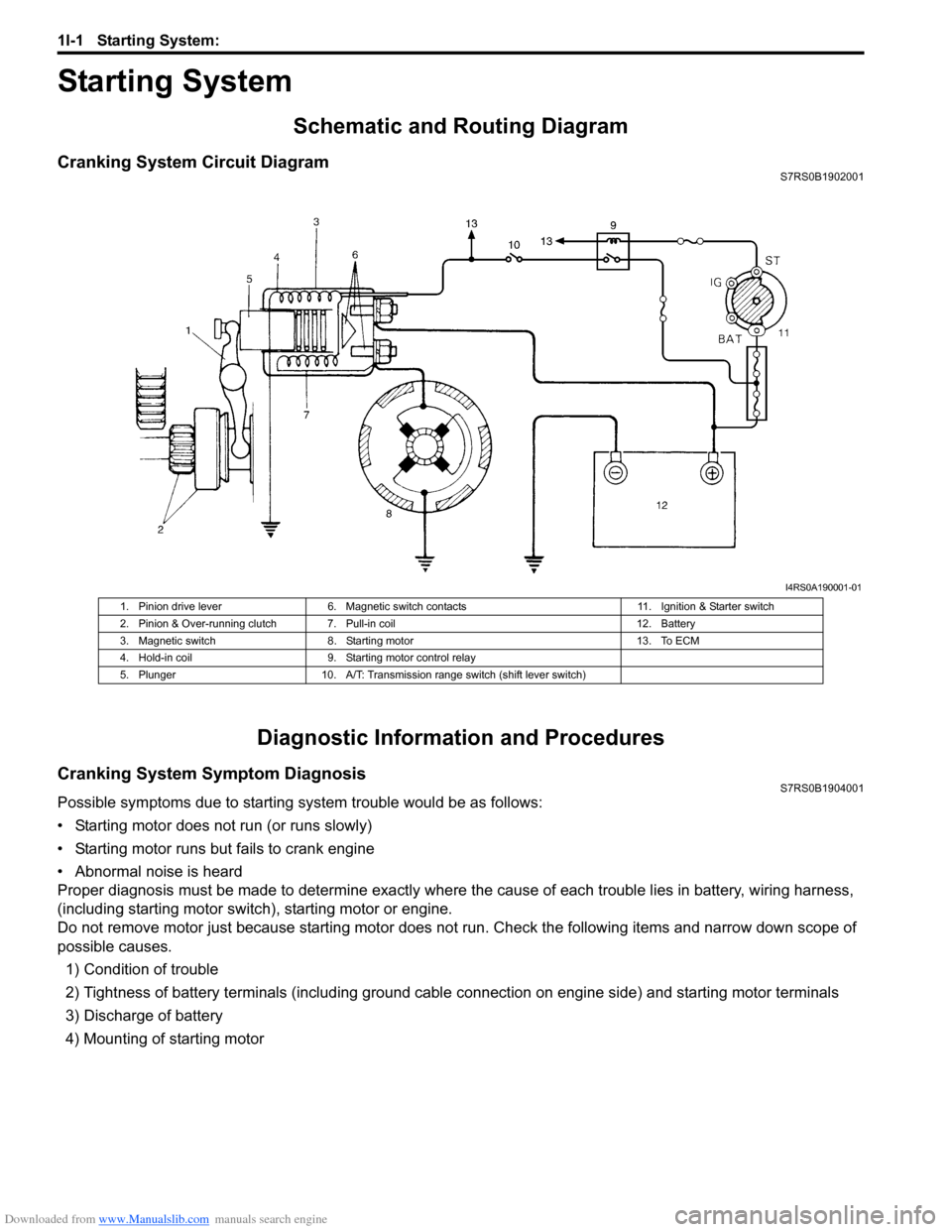

Cranking System Circuit DiagramS7RS0B1902001

Diagnostic Information and Procedures

Cranking System Symptom DiagnosisS7RS0B1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

I4RS0A190001-01

1. Pinion drive lever 6. Magnetic switch contacts 11. Ignition & Starter switch

2. Pinion & Over-running clutch 7. Pull-in coil 12. Battery

3. Magnetic switch 8. Starting motor 13. To ECM

4. Hold-in coil 9. Starting motor control relay

5. Plunger 10. A/T: Transmission range switch (shift lever switch)

Page 403 of 1496

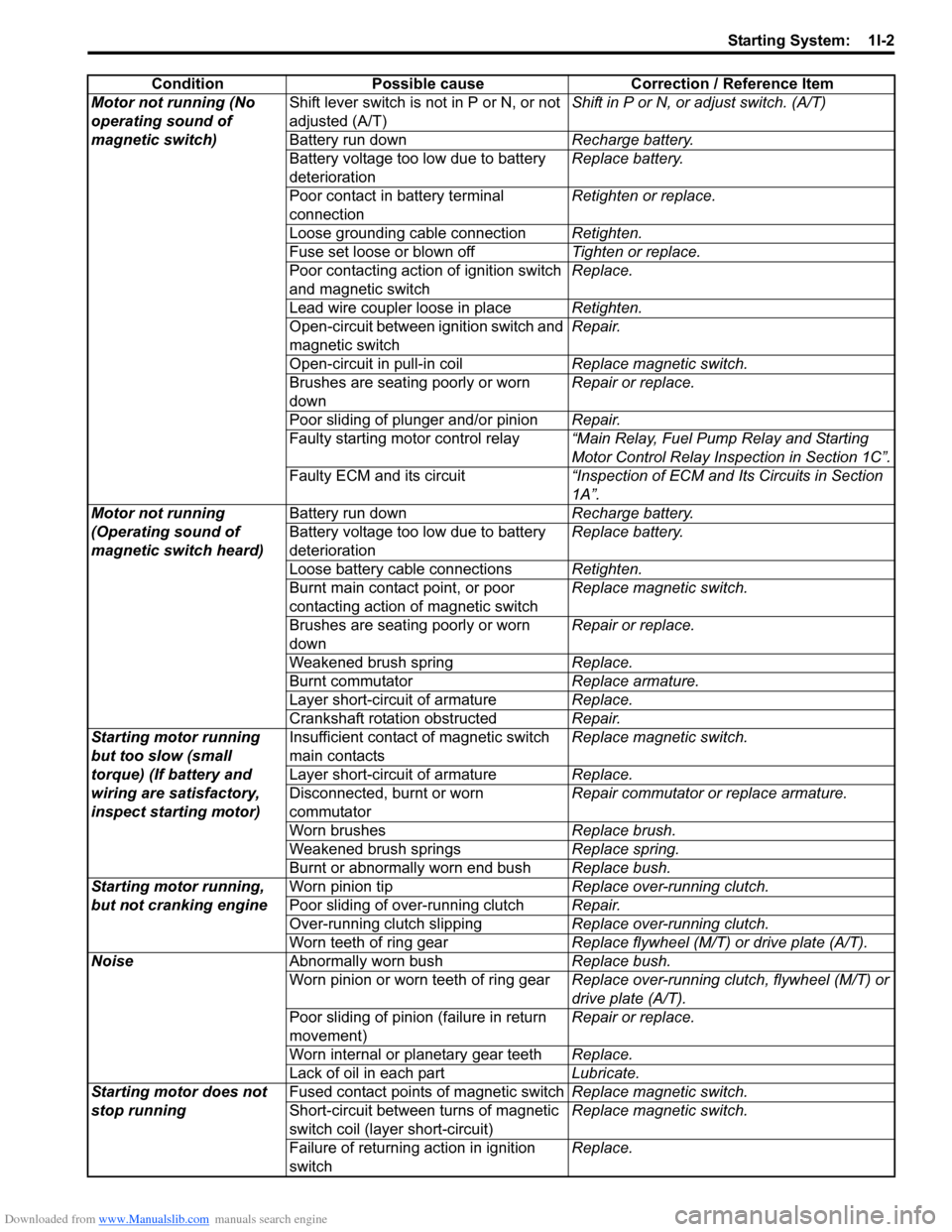

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

ConditionPossible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch) Shift lever switch is not in P or N, or not

adjusted (A/T)

Shift in P or N, or

adjust switch. (A/T)

Battery run down Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Poor contact in battery terminal

connection Retighten or replace.

Loose grounding cable connection Retighten.

Fuse set loose or blown off Tighten or replace.

Poor contacting action of ignition switch

and magnetic switch Replace.

Lead wire coupler loose in place Retighten.

Open-circuit between ignition switch and

magnetic switch Repair.

Open-circuit in pull-in coil Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Poor sliding of plunger and/or pinion Repair.

Faulty starting motor control relay “Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection in Section 1C”.

Faulty ECM and its circuit “Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard) Battery run down

Recharge battery.

Battery voltage too low due to battery

deterioration Replace battery.

Loose battery cable connections Retighten.

Burnt main contact point, or poor

contacting action of magnetic switch Replace magnetic switch.

Brushes are seating poorly or worn

down Repair or replace.

Weakened brush spring Replace.

Burnt commutator Replace armature.

Layer short-circuit of armature Replace.

Crankshaft rotation obstructed Repair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor) Insufficient contact

of magnetic switch

main contacts Replace magnetic switch.

Layer short-circuit of armature Replace.

Disconnected, burnt or worn

commutator Repair commutator or replace armature.

Worn brushes Replace brush.

Weakened brush springs Replace spring.

Burnt or abnormally worn end bush Replace bush.

Starting motor running,

but not cranking engine Worn pinion tip

Replace over-running clutch.

Poor sliding of over-running clutch Repair.

Over-running clutch slipping Replace over-running clutch.

Worn teeth of ring gear Replace flywheel (M/T) or drive plate (A/T).

Noise Abnormally worn bush Replace bush.

Worn pinion or worn teeth of ring gear Replace over-running clutch, flywheel (M/T) or

drive plate (A/T).

Poor sliding of pinion (failure in return

movement) Repair or replace.

Worn internal or planetary gear teeth Replace.

Lack of oil in each part Lubricate.

Starting motor does not

stop running Fused contact points of magnetic switch

Replace magnetic switch.

Short-circuit between turns of magnetic

switch coil (layer short-circuit) Replace magnetic switch.

Failure of returning action in ignition

switch Replace.

Page 496 of 1496

Downloaded from www.Manualslib.com manuals search engine 4-ii Table of Contents

Repair Instructions ..............................................4D-2Parking Brake Inspection and Adjustment ..........4D-2

Parking Brake Cable Removal and Installation ......................................................... 4D-3

Parking Brake Lever Removal and Installation ....4D-3

Specifications .... ...................................................4D-4

Tightening Torque Specifications ........................4D-4

ABS ........................................... .................4E-1

Precautions........................................................... 4E-1

Precautions in Diagnosing Troubles ................... 4E-1

Precautions in On-Vehicle Service...................... 4E-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4E-1

General Description ............................................. 4E-2 ABS Description .................................................. 4E-2

ABS Hydraulic Unit / Control Module Assembly Description ....................................... 4E-2

CAN Communication System Description........... 4E-3

Schematic and Routing Diagram ........................ 4E-4 ABS Schematic ................................................... 4E-4

ABS Wiring Circuit Diagram ................................ 4E-5

Component Location ........... ................................ 4E-7

ABS Components Location ................................. 4E-7

Front Wheel Speed Sensor Components Location ............................................................ 4E-7

Rear Wheel Speed Sensor Components Location ............................................................ 4E-8

Diagnostic Information and Procedures ............ 4E-8 ABS Check .......................................................... 4E-8

ABS Warning Light Check................................. 4E-10

EBD Warning Light (Brake Warning Light) Check .............................................................. 4E-10

DTC Check........................................................ 4E-11

DTC Table ......................................................... 4E-11

DTC Clearance ................................................. 4E-12

Scan Tool Data ................................................. 4E-12

ABS Warning Light Does Not Come ON at Ignition Switch ON .......................................... 4E-13

ABS Warning Light Comes ON Steady ............. 4E-14

EBD Warning Light (Brake Warning Light) Comes ON Steady .......................................... 4E-15

Serial Data Link Circuit Check .......................... 4E-16

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Right-Front / Left-

Front / Right-Rear / Left-Rear Wheel Speed

Sensor Circuit or Sensor Ring ........................ 4E-18

DTC C1041 / C1045 / C1051 / C1055, DTC C1042 / C1046 / C1052 / C1056: Right-Front

/ Left-Front / Right-Rear / Left-Rear Inlet

Solenoid Circuit, Right-Front / Left-Front /

Right-Rear / Left-Rear Outlet Solenoid

Circuit .............................................................. 4E-20

DTC C1057: Power Source Circuit ................... 4E-21

DTC C1061: ABS Pump Motor and/or Motor Driver Circuit ................................................... 4E-22

DTC C1063: Solenoid Valve Power Supply Driver Circuit ................................................... 4E-23

DTC C1071: ABS Control Module..................... 4E-24 DTC U1073: Control Module Communication

Bus Off ............................................................ 4E-25

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4E-27

Repair Instructions ............ ................................ 4E-28

ABS Hydraulic Unit Operati on Check................ 4E-28

ABS Hydraulic Unit / Control Module

Assembly Components ...... ............................. 4E-29

ABS Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4E-29

ABS Hydraulic Unit / Control Module

Assembly Removal and Inst allation ................ 4E-29

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4E-31

Front Wheel Speed Sensor Removal and Installation ....................................................... 4E-32

Front Wheel Speed Sensor Inspection ............. 4E-32

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4E-33

Rear Wheel Speed Sensor Inspection .............. 4E-34

Front Wheel Encoder On-Veh icle Inspection .... 4E-34

Front wheel Enco der Removal and

Installation ....................................................... 4E-34

Rear Wheel Encoder On-Veh icle Inspection..... 4E-34

Rear Wheel Encoder Removal and Installation ....................................................... 4E-34

Specifications ..................... ................................ 4E-35

Tightening Torque Specifications ...................... 4E-35

Special Tools and Equipmen t ........................... 4E-35

Special Tool ...................................................... 4E-35

Electronic Stability Prog ram ...................4F-1

Precautions ........................................................... 4F-1

Precautions in Diagnosing Troubles ................... 4F-1

Precautions in On-Vehicle Service...................... 4F-1

Precautions in Hydraulic Unit Operation Check ................................................................ 4F-1

Precautions in Sensor Calibration ....................... 4F-1

Precautions in Speedometer Test or Other Tests ................................................................. 4F-2

General Description ............................................. 4F-2 Electronic Stability Program Description ............. 4F-2

Electronic Stability Program Construction ........... 4F-3

ESP® Hydraulic Unit / Control Module

Assembly Description........................................ 4F-5

Warning Lamp, Indicator Lamp Description ........ 4F-6

CAN Communication System Description........... 4F-6

CAN Communication System For Electronic Stability Program Description ............................ 4F-7

Schematic and Routing Diagram ........................ 4F-8 Electronic Stability Program Schematic .............. 4F-8

Electronic Stability Program Wiring Circuit Diagram............................................................. 4F-9

Component Location ............ ............................. 4F-11

Electronic Stability Program Component

Location........................................................... 4F-11

Diagnostic Information and Procedures .......... 4F-12 Electronic Stability Program System Check ...... 4F-12

ESP® Warning lamp Check .............................. 4F-14

Page 544 of 1496

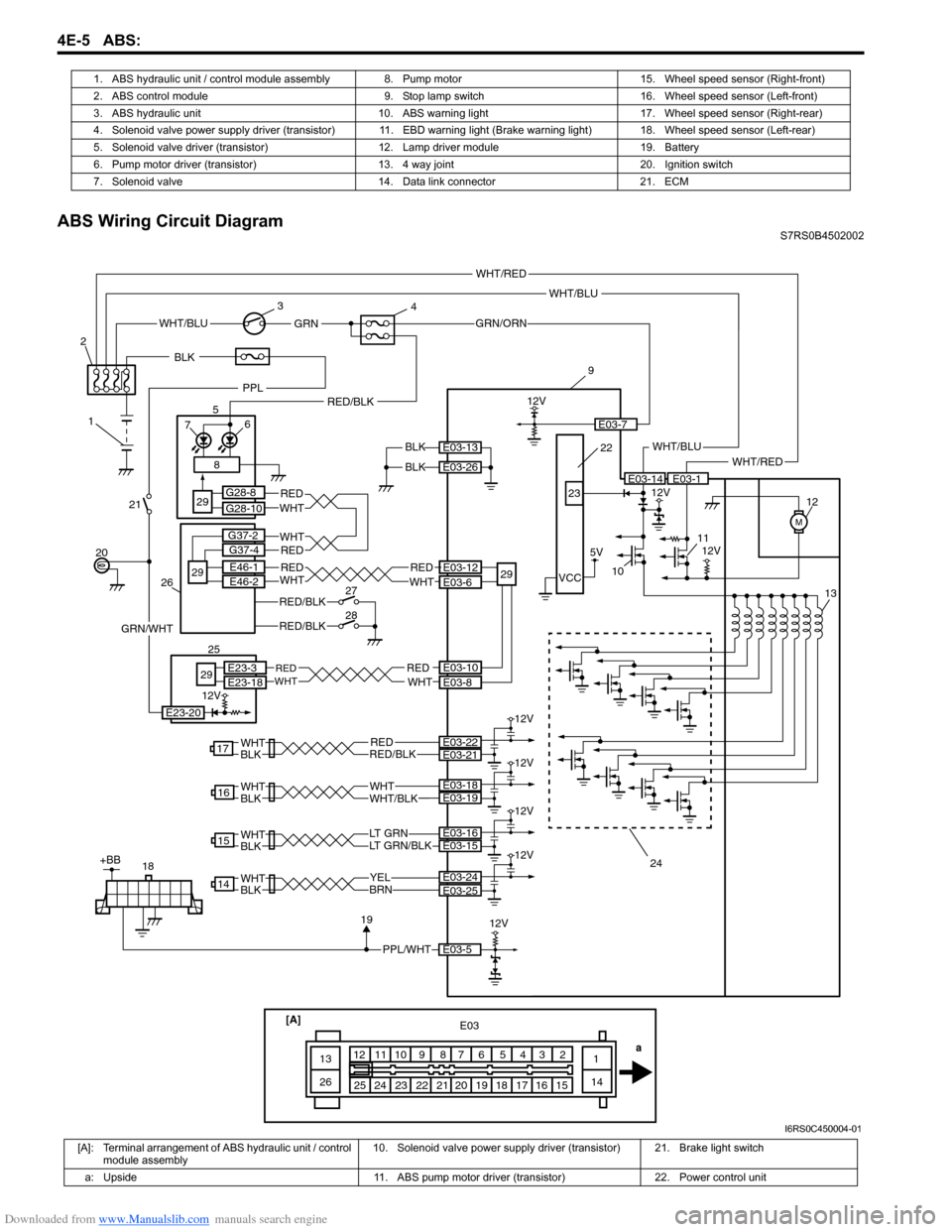

Downloaded from www.Manualslib.com manuals search engine 4E-5 ABS:

ABS Wiring Circuit DiagramS7RS0B4502002

1. ABS hydraulic unit / control module assembly 8.

Pump motor 15. Wheel speed sensor (Right-front)

2. ABS control module 9. Stop lamp switch 16. Wheel speed sensor (Left-front)

3. ABS hydraulic unit 10. ABS warning light 17. Wheel speed sensor (Right-rear)

4. Solenoid valve power supply driver (transistor) 11. EBD warnin g light (Brake warning light) 18. Wheel speed sensor (Left-rear)

5. Solenoid valve driver (transistor) 12. Lamp driver module 19. Battery

6. Pump motor driver (transistor) 13. 4 way joint 20. Ignition switch

7. Solenoid valve 14. Data link connector 21. ECM

[A]

14

1516171819202122232425 1

23456789101112

13

26 E03

a

WHT/BLU

BLKWHT/BLU

M

12V

9

10 11 12

13

BLKE03-14E03-1

E03-13

E03-26

YELBRN

14E03-24

LT GRN/BLKLT GRN

15

WHTWHT/BLK

16

RED

WHTBLK

WHTBLK

WHTBLK

WHTBLKRED/BLK

17

12V

PPL/WHT

18E03-5

1912V

5V

12V

23

24

VCC22

E03-25

E03-15E03-16

E03-19E03-18

E03-22E03-21

WHT/RED

WHT/RED

+BB

GRN/ORN

E03-7

WHT/BLUGRN

1

2

3

4

8

RED/BLK

E03-12

E03-6

RED

WHTE03-10E03-8

REDWHT

20 7

6

529

29

G28-8

G28-10

25

29

E23-3E23-18

GRN/WHT

21

PPL

12V

E23-20

12V

12V

12V

12V

REDWHTE46-1

E46-2

BLK

RED/BLK

RED/BLK

RED

RED

WHT

WHT

27

28

26

29

G37-2

G37-4

REDWHT

I6RS0C450004-01

[A]: Terminal arrangement of ABS hydraulic unit / control module assembly 10. Solenoid valve power supply driver

(transistor) 21. Brake light switch

a: Upside 11. ABS pump motor driver (transistor) 22. Power control unit