set time SUZUKI SWIFT 2007 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1109 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-71

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side-air bag (driver or passenger) init iator circuit is below a specified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in side-air bag (inflator) module.

Step 2: Check side-air bag initiator circuit in floor harness.

Step 3: Check side-air bag init iator circuit in seat harness.

DTC Troubleshooting Step Action YesNo

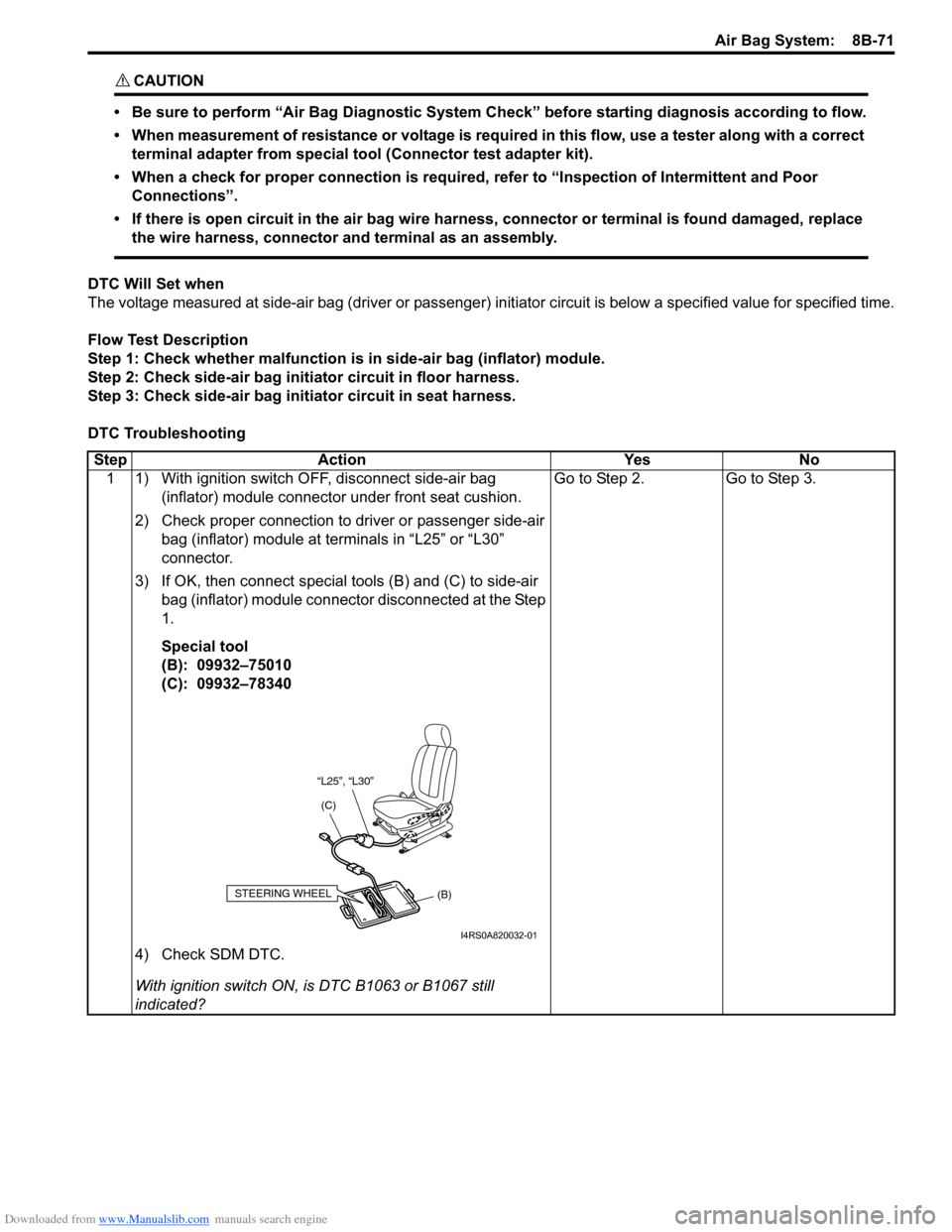

1 1) With ignition switch OFF, disconnect side-air bag (inflator) module connector under front seat cushion.

2) Check proper connection to driver or passenger side-air bag (inflator) module at terminals in “L25” or “L30”

connector.

3) If OK, then connect special tools (B) and (C) to side-air bag (inflator) module connector disconnected at the Step

1.

Special tool

(B): 09932–75010

(C): 09932–78340

4) Check SDM DTC.

With ignition switch ON, is DTC B1063 or B1067 still

indicated? Go to Step 2.

Go to Step 3.

“L25”, “L30”

(C)

(B)

STEERING WHEEL

I4RS0A820032-01

Page 1111 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-73

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components, ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1064 / B1068: Driver / Passenger Side-Air Bag Initiator Circuit Short to Power CircuitS7RS0B8204033

Wiring Diagram

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side-air bag (driver or passenger) init iator circuit is above a specified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in side-air bag (inflator) module.

Step 2: Check side-air bag initiator circuit in floor harness.

Step 3: Check side-air bag init iator circuit in seat harness.

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-12

DS+

L29-11

DS-GRY

GRY/RED

56

“L25”

L29-13

PS+

L29-14

PS-BRN

BRN/WHT7

“L30”[A]

I7RS0A820020-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1118 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-80 Air Bag System:

DTC B1081 / B1091: Driver / Passenger Side-Sensor Performance ProblemS7RS0B8204038

DTC Will Set when

SDM receives internal fault signal from side-sensor.

DTC Troubleshooting1) Turn ignition switch OFF.

2) Replace driver or passenger side-sensor referr ing to “Side-Sensor Removal and Installation”.

3) Repeat “Air Bag Diagnostic System Check”.

DTC B1082 / B1092: Driver / Passenger Side-Sensor Communication ErrorS7RS0B8204039

DTC Will Set when

Side-sensor abnormal signal is detected by SDM.

DTC Troubleshooting

1) Turn ignition switch OFF.

2) Replace driver or passenger side-sensor referr ing to “Side-Sensor Removal and Installation”.

3) Repeat “Air Bag Diagnostic System Check”.

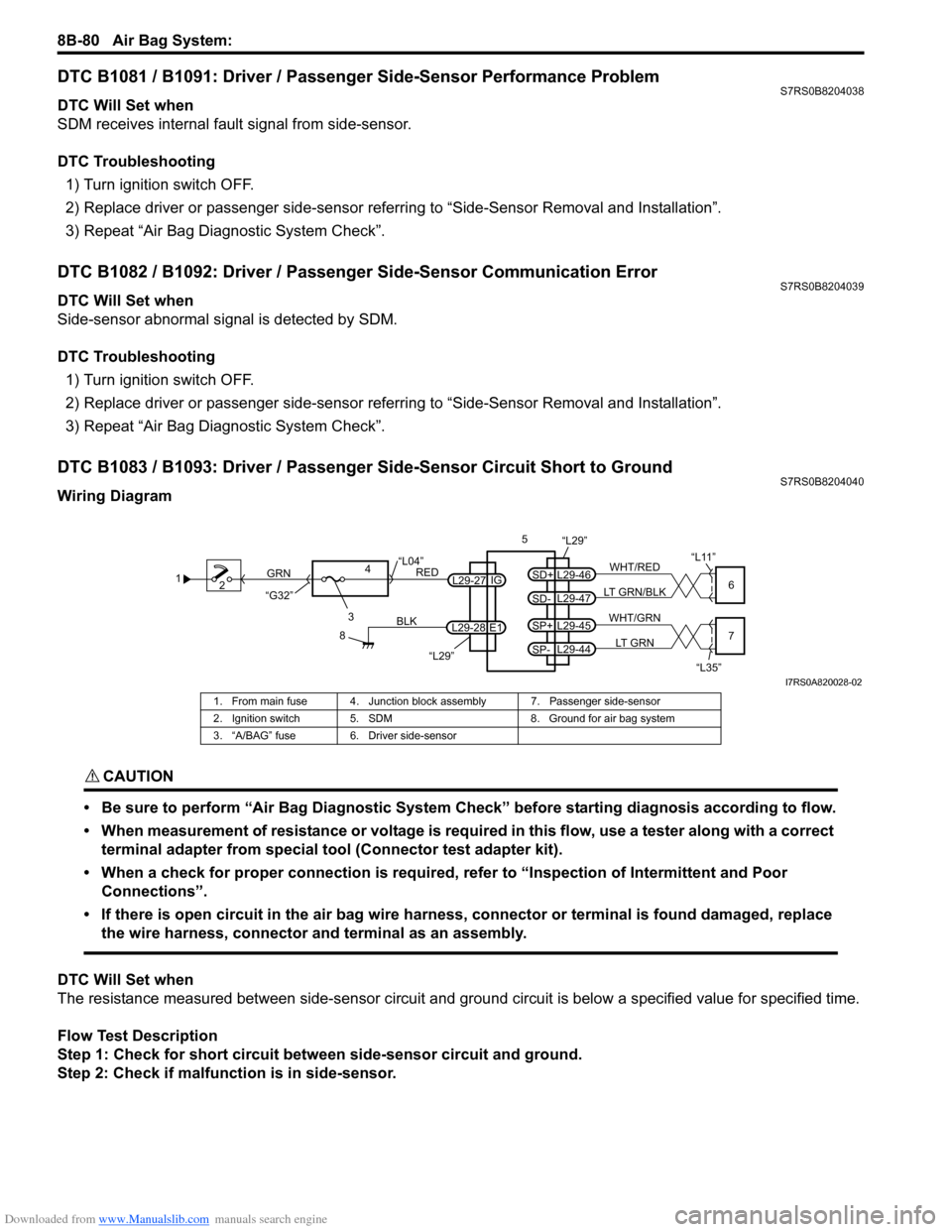

DTC B1083 / B1093: Driver / Passenger Side-Sensor Circuit Short to GroundS7RS0B8204040

Wiring Diagram

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The resistance measured between side-sen sor circuit and ground circuit is below a specified value for specified time.

Flow Test Description

Step 1: Check for short circuit between side-sensor circuit and ground.

Step 2: Check if malfunction is in side-sensor.

1 2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”5

WHT/RED

LT GRN/BLKL29-46

SD+

L29-47

SD-6

“L11”

WHT/GRN

LT GRNL29-45

SP+

L29-44

SP-7

“L35”

I7RS0A820028-02

1. From main fuse 4. Junction blo ck assembly 7. Passenger side-sensor

2. Ignition switch 5. SDM 8. Ground for air bag system

3. “A/BAG” fuse 6. Driver side-sensor

Page 1120 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-82 Air Bag System:

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

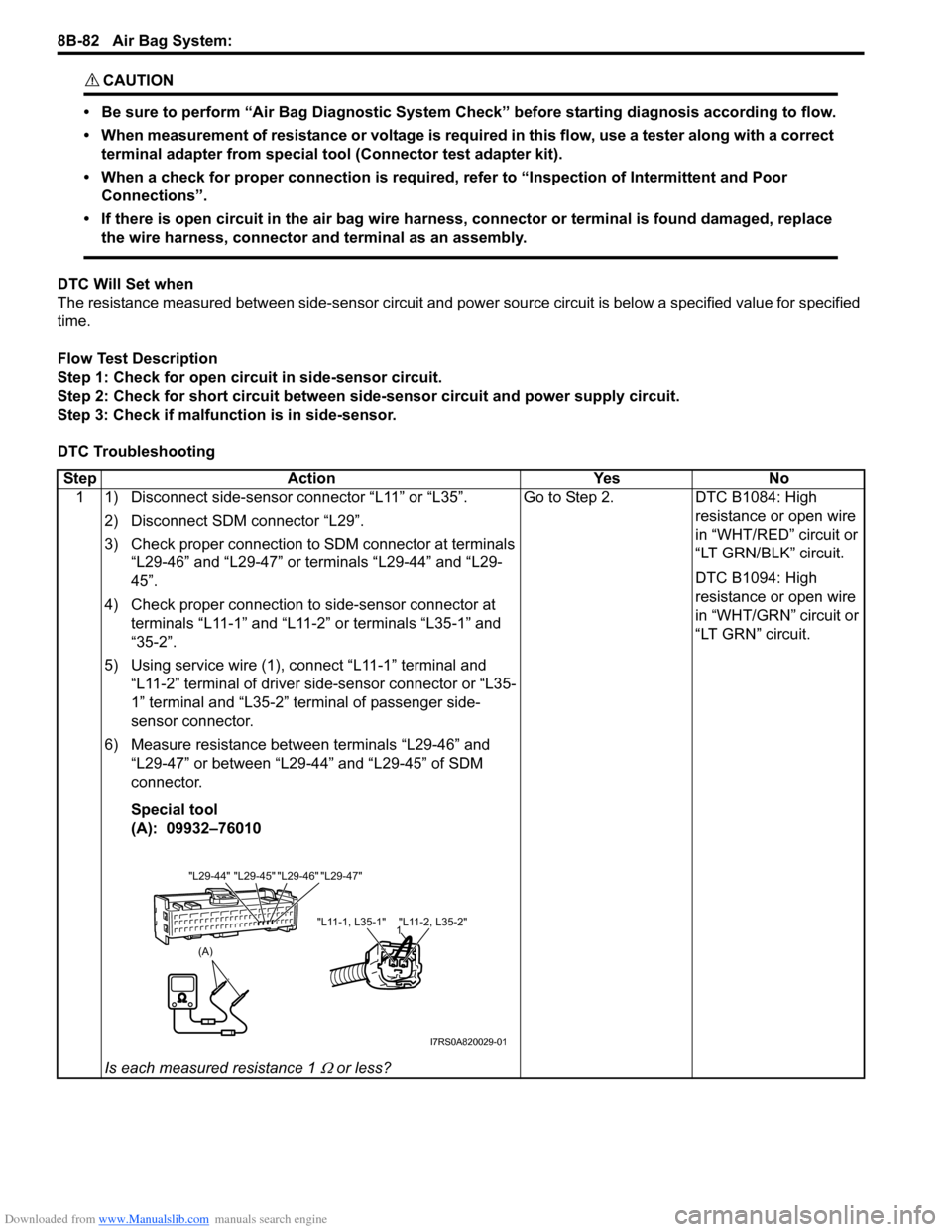

DTC Will Set when

The resistance measured between side-sensor circuit and power source circuit is below a specified value for specified

time.

Flow Test Description

Step 1: Check for open circuit in side-sensor circuit.

Step 2: Check for short circuit between side-sensor circuit and power supply circuit.

Step 3: Check if malfunction is in side-sensor.

DTC Troubleshooting

Step Action YesNo

1 1) Disconnect side-sensor connector “L11” or “L35”.

2) Disconnect SDM connector “L29”.

3) Check proper connection to SDM connector at terminals “L29-46” and “L29-47” or terminals “L29-44” and “L29-

45”.

4) Check proper connection to side-sensor connector at terminals “L11-1” and “L11-2” or terminals “L35-1” and

“35-2”.

5) Using service wire (1), connect “L11-1” terminal and “L11-2” terminal of driver side-sensor connector or “L35-

1” terminal and “L35-2” terminal of passenger side-

sensor connector.

6) Measure resistance between terminals “L29-46” and “L29-47” or between “L29-44” and “L29-45” of SDM

connector.

Special tool

(A): 09932–76010

Is each measured resistance 1

Ω or less? Go to Step 2. DTC B1084: High

resistance or open wire

in “WHT/RED” circuit or

“LT GRN/BLK” circuit.

DTC B1094: High

resistance or open wire

in “WHT/GRN” circuit or

“LT GRN” circuit.

(A)

"L11-1, L35-1" "L11-2, L35-2"1

"L29-45" "L29-46" "L29-47"

"L29-44"

I7RS0A820029-01

Page 1122 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-84 Air Bag System:

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance HighS7RS0B8204043

Wiring Diagram

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The combined resistance of the side curtain-air bag (inflator) module (driver or passenger), harness wiring and

connector terminal contact is above a specified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

1 2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-20

DC+

L29-19

DC-YEL/BLU

YEL/GRN

56

“L18”

L29-21

PC+

L29-22

PC-BRN/YEL BLK/YEL7

“L41”[A]

I7RS0A820031-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side curtain-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side curtain-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1125 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-87

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

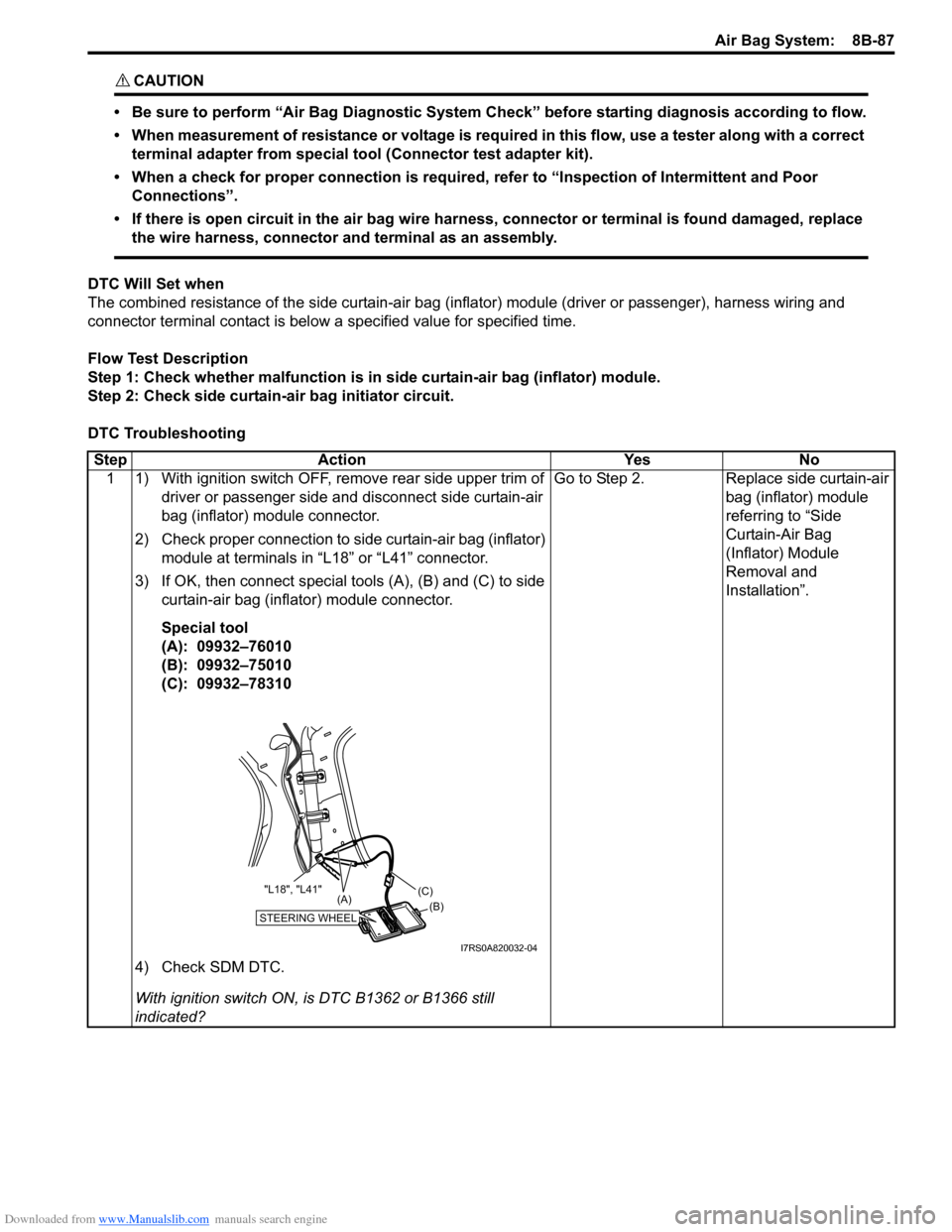

DTC Will Set when

The combined resistance of the side curtain-air bag (inflator) module (driver or passenger), harness wiring and

connector terminal contact is below a specified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1362 or B1366 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1127 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-89

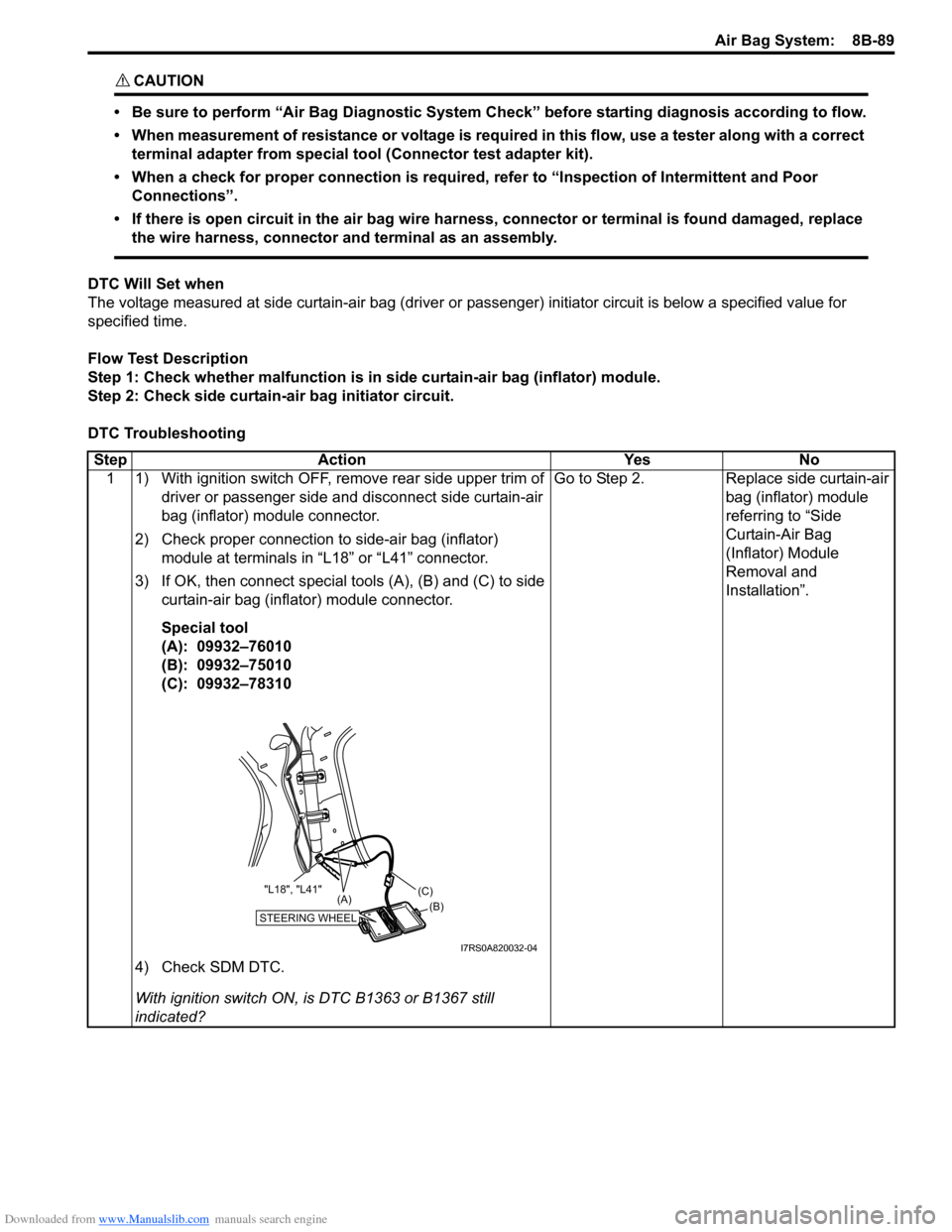

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1363 or B1367 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

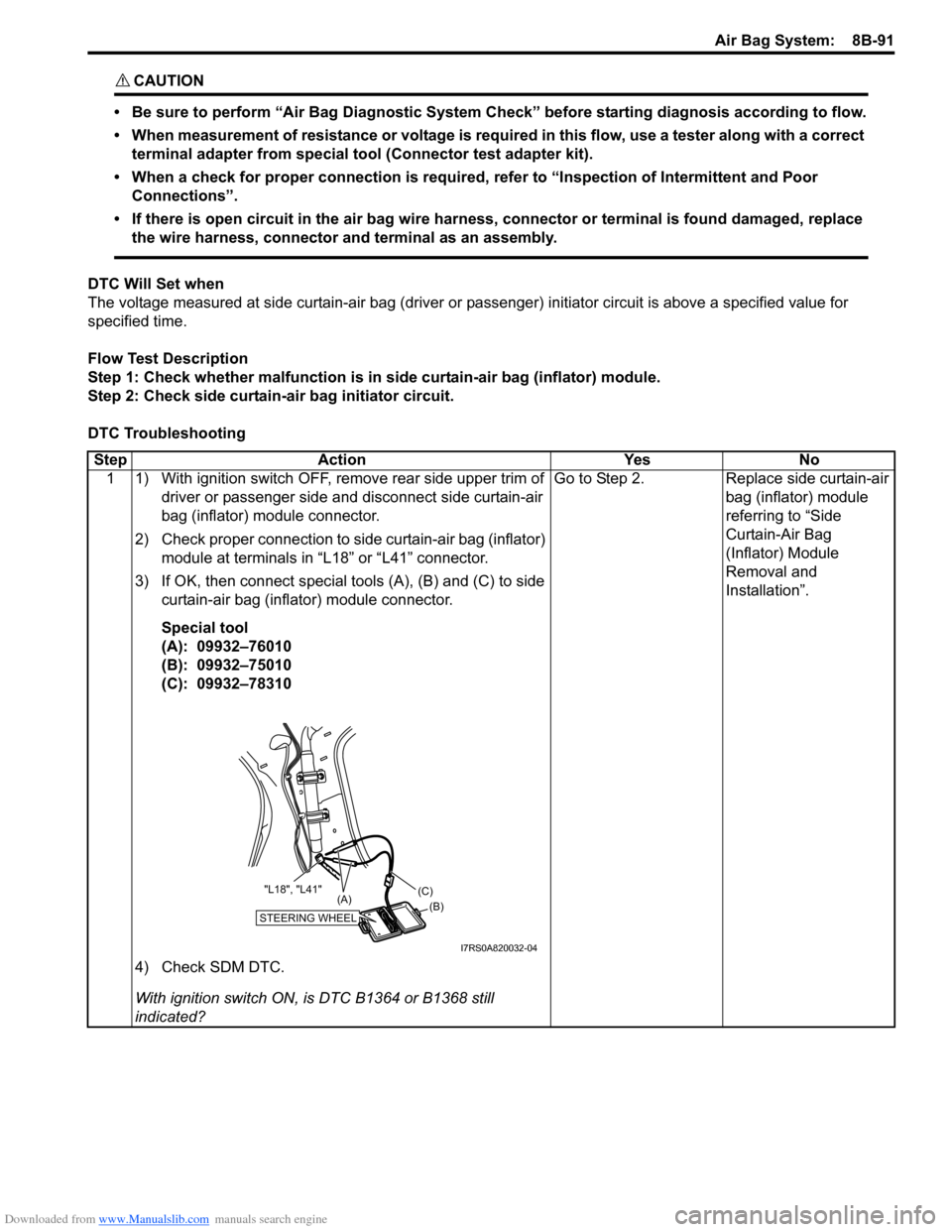

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1155 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-117

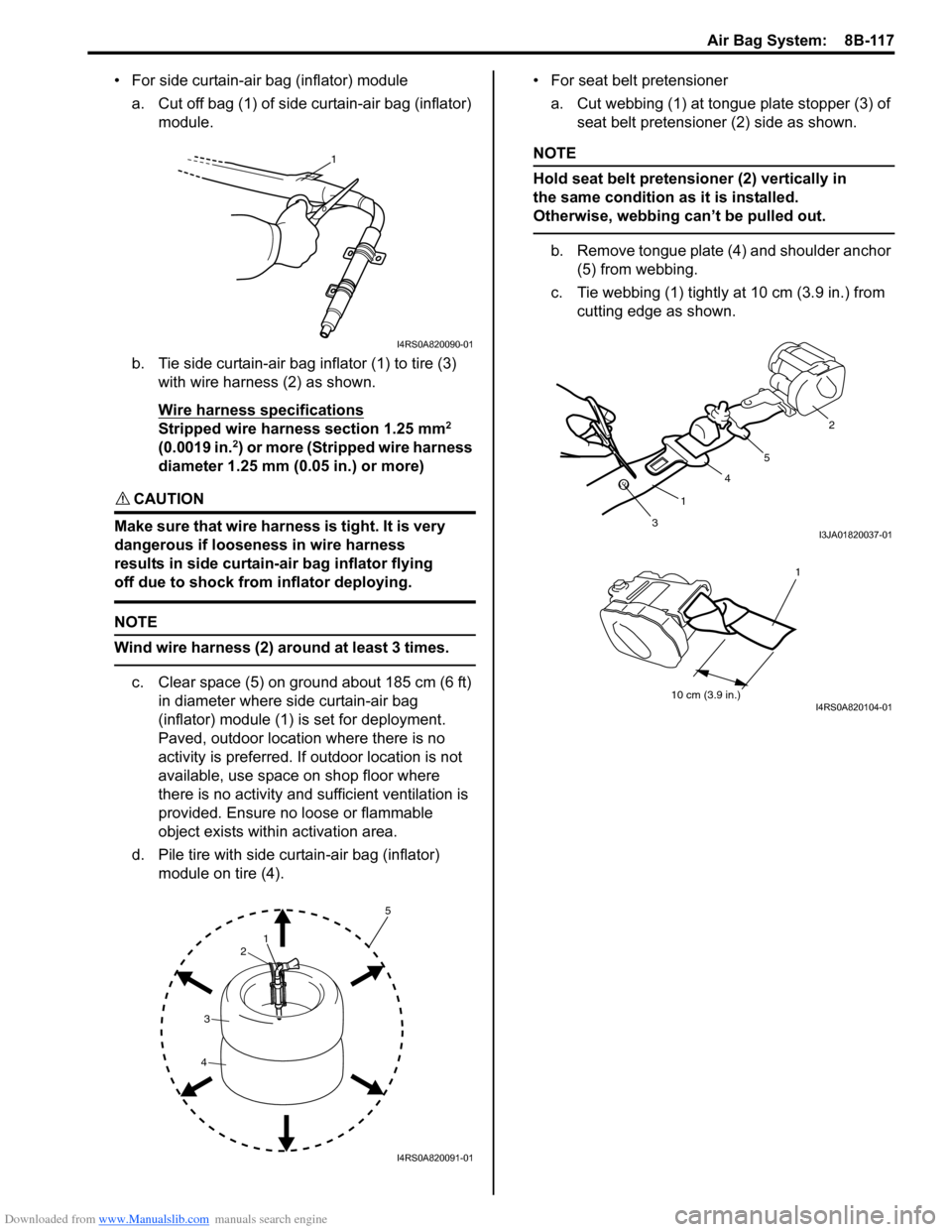

• For side curtain-air bag (inflator) modulea. Cut off bag (1) of side curtain-air bag (inflator) module.

b. Tie side curtain-air bag inflator (1) to tire (3) with wire harness (2) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

CAUTION!

Make sure that wire harness is tight. It is very

dangerous if looseness in wire harness

results in side curtain-air bag inflator flying

off due to shock from inflator deploying.

NOTE

Wind wire harness (2) around at least 3 times.

c. Clear space (5) on ground about 185 cm (6 ft) in diameter where side curtain-air bag

(inflator) module (1) is set for deployment.

Paved, outdoor location where there is no

activity is preferred. If outdoor location is not

available, use space on shop floor where

there is no activity and sufficient ventilation is

provided. Ensure no loose or flammable

object exists within activation area.

d. Pile tire with side curtain-air bag (inflator) module on tire (4). • For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor (5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

1

I4RS0A820090-01

1

2

3

4

5

I4RS0A820091-01

3 1 4

5 2I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01

Page 1307 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-12

Clock Symptom Diagnosis (If Equipped)S7RS0B9304016

Audio System Symptom Diagnosis (If Equipped)S7RS0B9304017

Radio

NOTE

Electronic part / system with undiagnosed pr oblem may cause electromagnetic interference.

Electromagnetic interference condition may have poor radio reception. To test for presence of

electromagnetic interference in part / system, perform the following procedures.

1. Turn ignition switch to OFF.

2. Systematically disconnect the electronic part / system connector(s) one at a time.

3. Turn ignition switch to ON.

4. Check any improvement in radio reception.

Display of fuel

consumption does not

change at “– – – l / 100 km

(km/l, MPG)” Vehicle is not running (instantaneous

fuel consumption mode)

—

Fuel consumption was reset (average

fuel consumption mo de, if equipped)Vehicle runs for a while.

Vehicle speed signal faulty Check ECM for DTC referring to “DTC Check

in Section 1A”.

Wiring and/or grounding faulty Repair as necessary.

ECM faulty Check input and output signal of ECM referring

to “Inspection of ECM and Its Circuits in

Section 1A”.

Information display unit faulty Replace unit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

No displaying of clock Circuit fuse Blown Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Clock unit faulty Replace unit.

ConditionPossible cause Correction / Reference Item

Poor radio reception Out of service area (Poor location) —

Antenna faulty Replace antenna.

Electrical part / system faulty Repair or replace electrical part / system

referring to after-mentioned NOTE.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate

and speaker does not

sound Circuit fuse(s) blown

Replace fuse(s) and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio does not operate,

but speaker sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Radio is operative, but all

speakers does not sound Wiring and/or grounding faulty

Repair as necessary.

Radio assembly faulty Replace radio assembly.

Individual speaker is

noisy or inoperative Wiring and/or grounding faulty

Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.

Sound quality is poor Out of service area (Poor location) —

Speaker installed incorrectly Install correctly.

Wiring and/or grounding faulty Repair as necessary.

Speaker faulty Replace speaker.

Radio assembly faulty Replace radio assembly.