SUZUKI SWIFT 2007 2.G Service Manual PDF

Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 71 of 1496

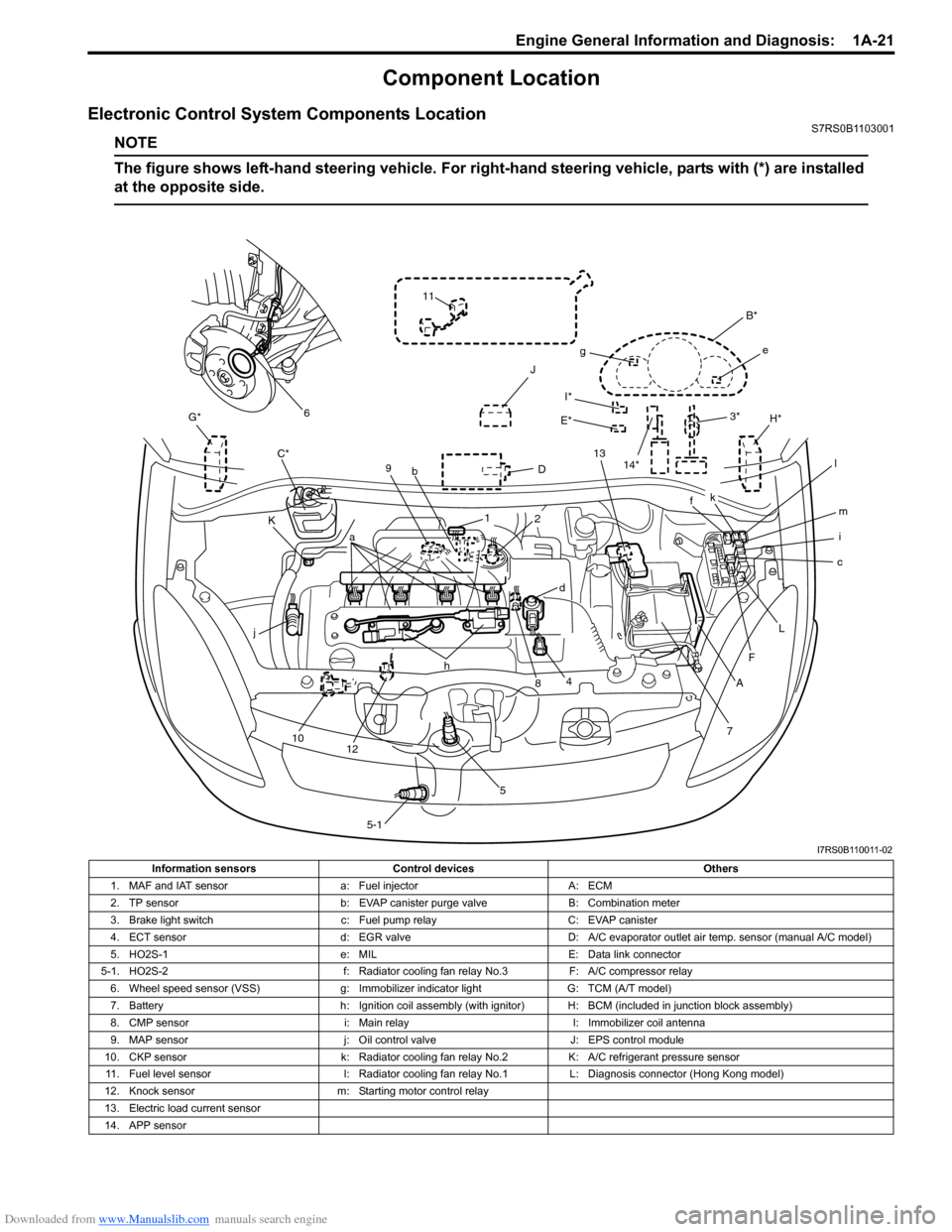

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-21

Component Location

Electronic Control System Components LocationS7RS0B1103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

I*

E*

G*

D

K H*

J

C*

7

A

F

c

L

i m

f

B*

e

g

k

l

13

3*

4

j

10 12 h

58

a

9

b

1

5-1

d

2

11

6

14*

I7RS0B110011-02

Information sensors Control devices Others

1. MAF and IAT sensor a: Fuel injectorA: ECM

2. TP sensor b: EVAP canister purge valve B: Combination meter

3. Brake light switch c: Fuel pump relayC: EVAP canister

4. ECT sensor d: EGR valveD: A/C evaporator outlet air temp. sensor (manual A/C model)

5. HO2S-1 e: MILE: Data link connector

5-1. HO2S-2 f: Radiator cooling fan relay No.3F: A/C compressor relay

6. Wheel speed sensor (VSS) g: Immobilizer indicator lightG: TCM (A/T model)

7. Battery h: Ignition coil assembly (with ignitor) H: BCM (included in junction block assembly)

8. CMP sensor i: Main relayI: Immobilizer coil antenna

9. MAP sensor j: Oil control valveJ: EPS control module

10. CKP sensor k: Radiator cooling fan relay No.2K: A/C refrigerant pressure sensor

11. Fuel level sensor l: Radiator cooling fan relay No.1L: Diagnosis connector (Hong Kong model)

12. Knock sensor m: Starting motor control relay

13. Electric load current sensor

14. APP sensor

Page 72 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-22 Engine General Information and Diagnosis:

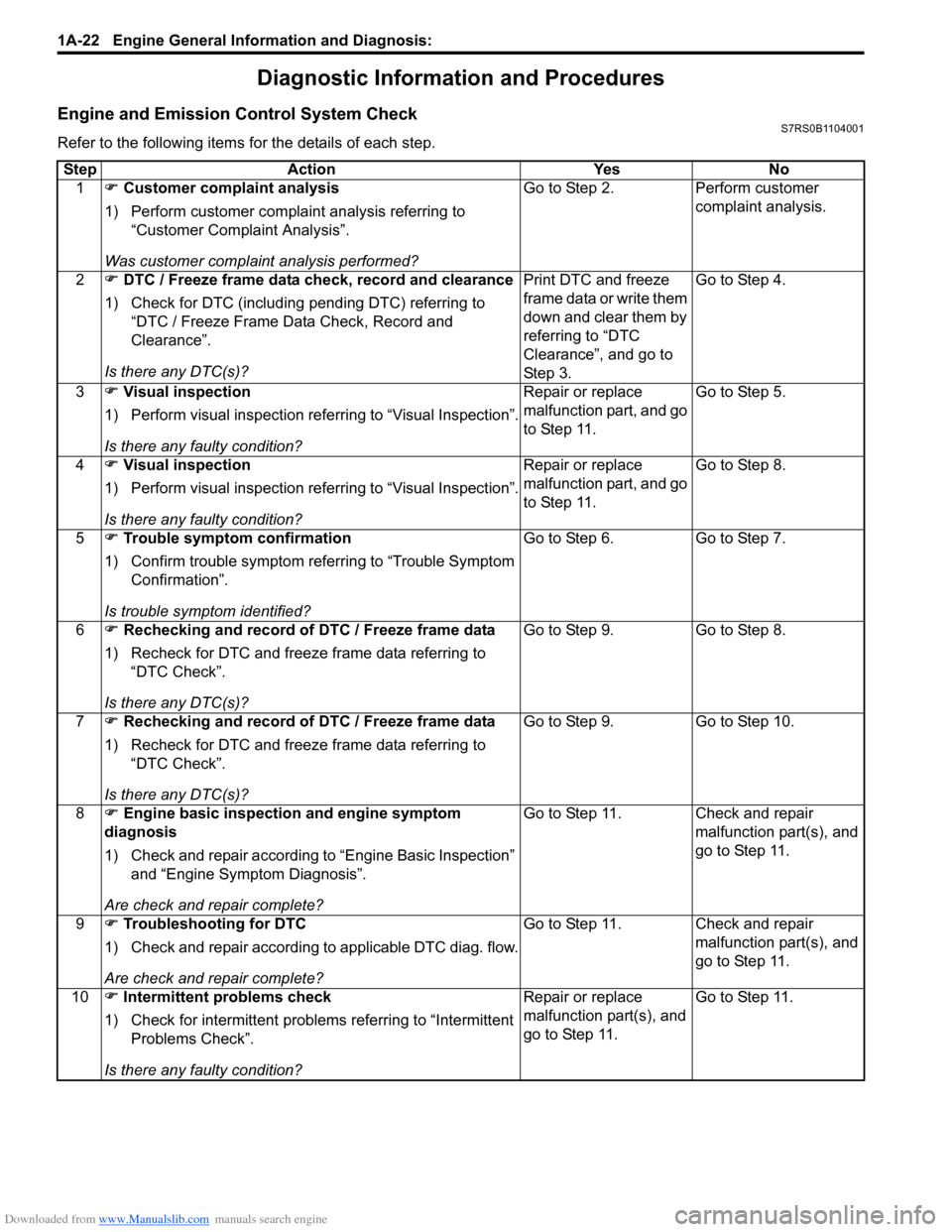

Diagnostic Information and Procedures

Engine and Emission Control System CheckS7RS0B1104001

Refer to the following items for the details of each step.Step Action Yes No 1 �) Customer complaint analysis

1) Perform customer complaint analysis referring to “Customer Complaint Analysis”.

Was customer complaint analysis performed? Go to Step 2. Perform customer

complaint analysis.

2 �) DTC / Freeze frame data check, record and clearance

1) Check for DTC (including pending DTC) referring to “DTC / Freeze Frame Data Check, Record and

Clearance”.

Is there any DTC(s)? Print DTC and freeze

frame data or write them

down and clear them by

referring to “DTC

Clearance”, and go to

St ep 3 .Go to Step 4.

3 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 5.

4 �) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition? Repair or replace

malfunction part, and go

to Step 11.

Go to Step 8.

5 �) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom Confirmation”.

Is trouble symptom identified? Go to Step 6.

Go to Step 7.

6 �) Rechecking and record of DTC / Freeze frame data

1) Recheck for DTC and freeze frame data referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 8.

7 �) Rechecking and record of DTC / Freeze frame data

1) Recheck for DTC and freeze frame data referring to “DTC Check”.

Is there any DTC(s)? Go to Step 9.

Go to Step 10.

8 �) Engine basic inspection and engine symptom

diagnosis

1) Check and repair according to “Engine Basic Inspection”

and “Engine Symptom Diagnosis”.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

9 �) Troubleshooting for DTC

1) Check and repair according to applicable DTC diag. flow.

Are check and repair complete? Go to Step 11. Check and repair

malfunction part(s), and

go to Step 11.

10 �) Intermittent problems check

1) Check for intermittent problems referring to “Intermittent Problems Check”.

Is there any faulty condition? Repair or replace

malfunction part(s), and

go to Step 11.

Go to Step 11.

Page 73 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-23

11�) Final confirmation test

1) Clear DTC if any.

2) Perform final confirmation test referring to “Final Confirmation Test”.

Is there any problem symptom, DTC or abnormal condition? Go to Step 6. End.

Step Action Yes No

Page 74 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-24 Engine General Information and Diagnosis:

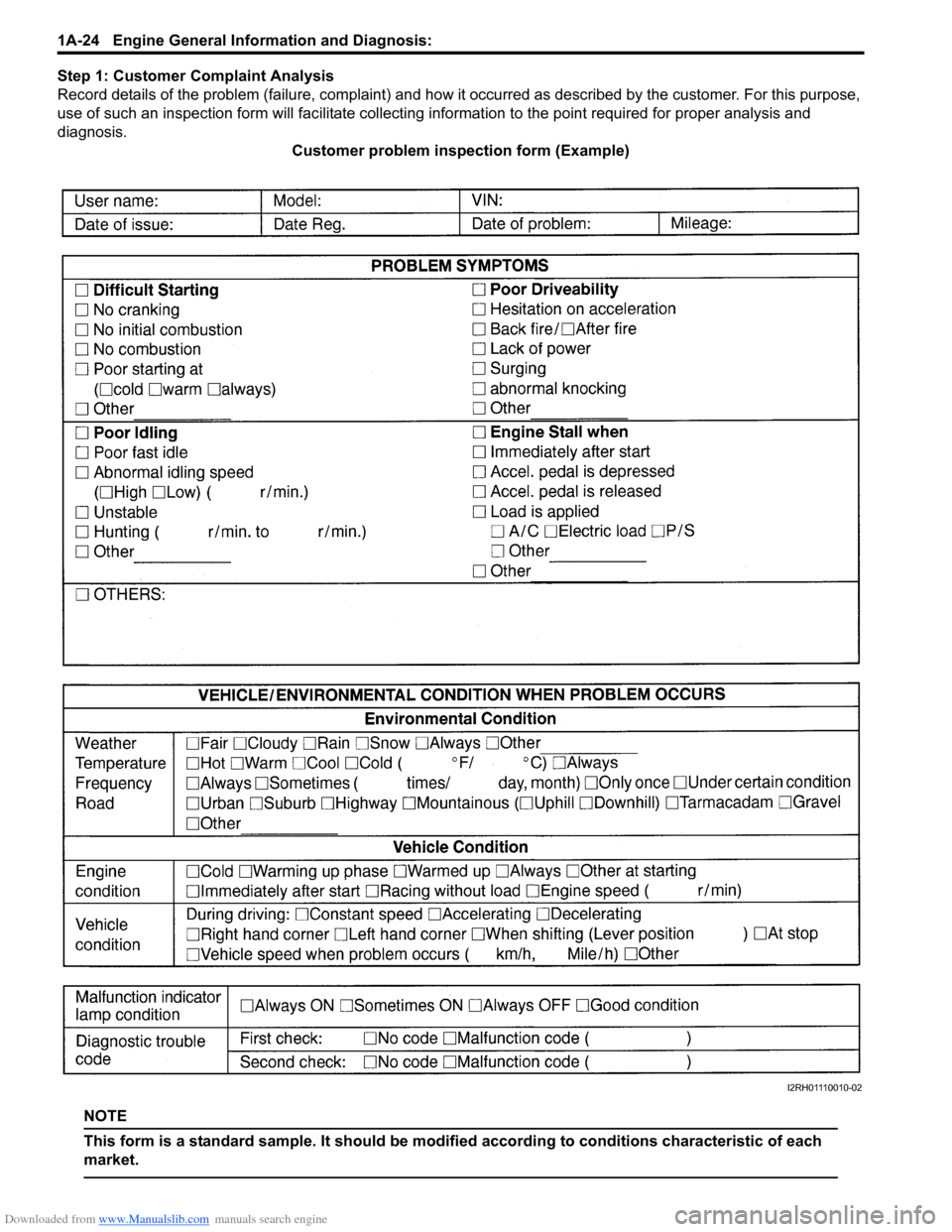

Step 1: Customer Complaint Analysis

Record details of the problem (failure, co mplaint) and how it occurred as described by the customer. For this purpose,

use of such an inspection form will fac ilitate collecting information to the point required for proper analysis and

diagnosis. Customer problem inspection form (Example)

NOTE

This form is a standard sample. It should be modified according to conditions characteristic of each

market.

I2RH01110010-02

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

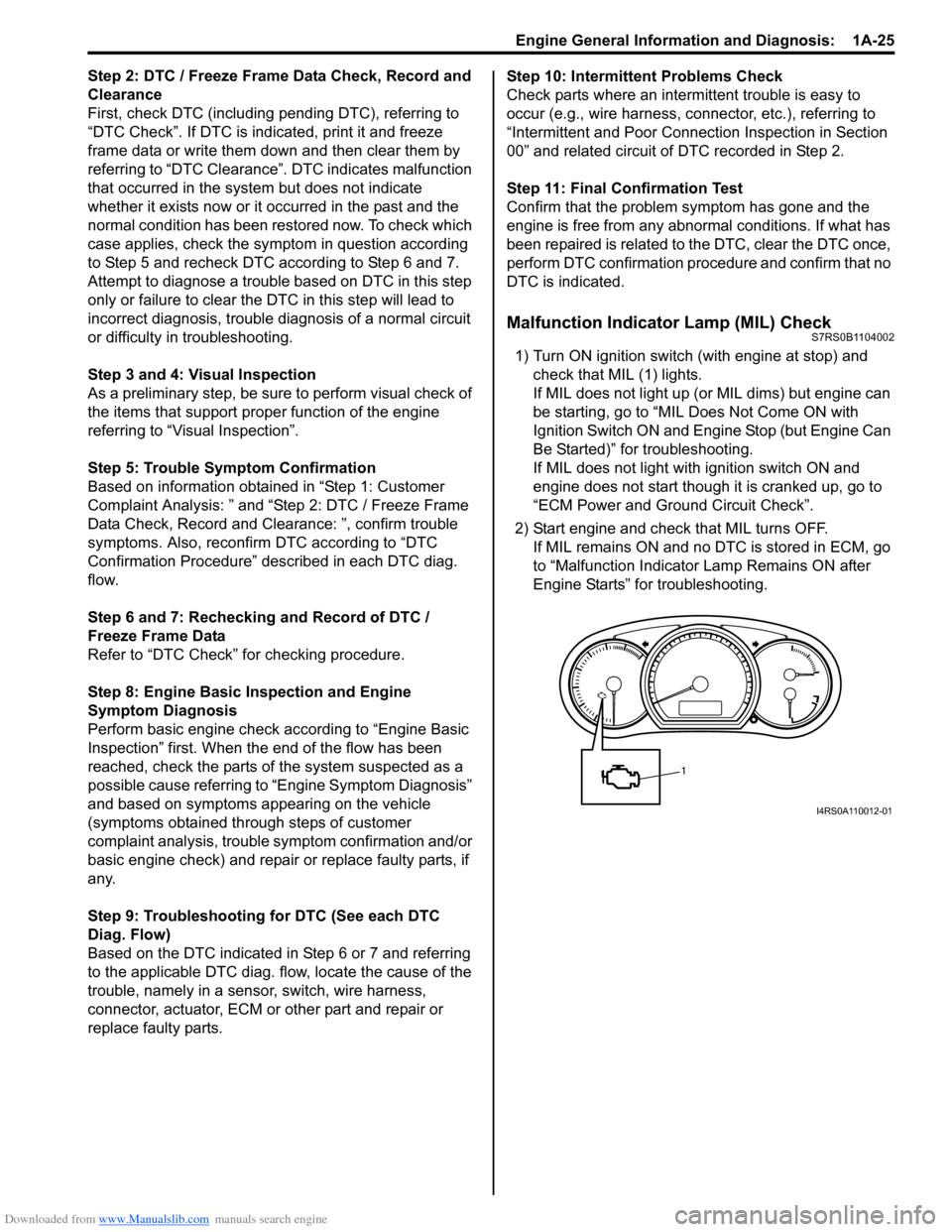

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01

Page 76 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

DTC CheckS7RS0B1104003

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

• The MIL is turned on when the ECM and/or TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs th e DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the SUZUKI scan tool

because the DTC stored in ECM and TCM

is not read and displayed at a time.

However, each of the ECM and TCM needs

not to be checked with the generic scan

tool because the DTC stored in ECM and

TCM is read and displayed at a time.

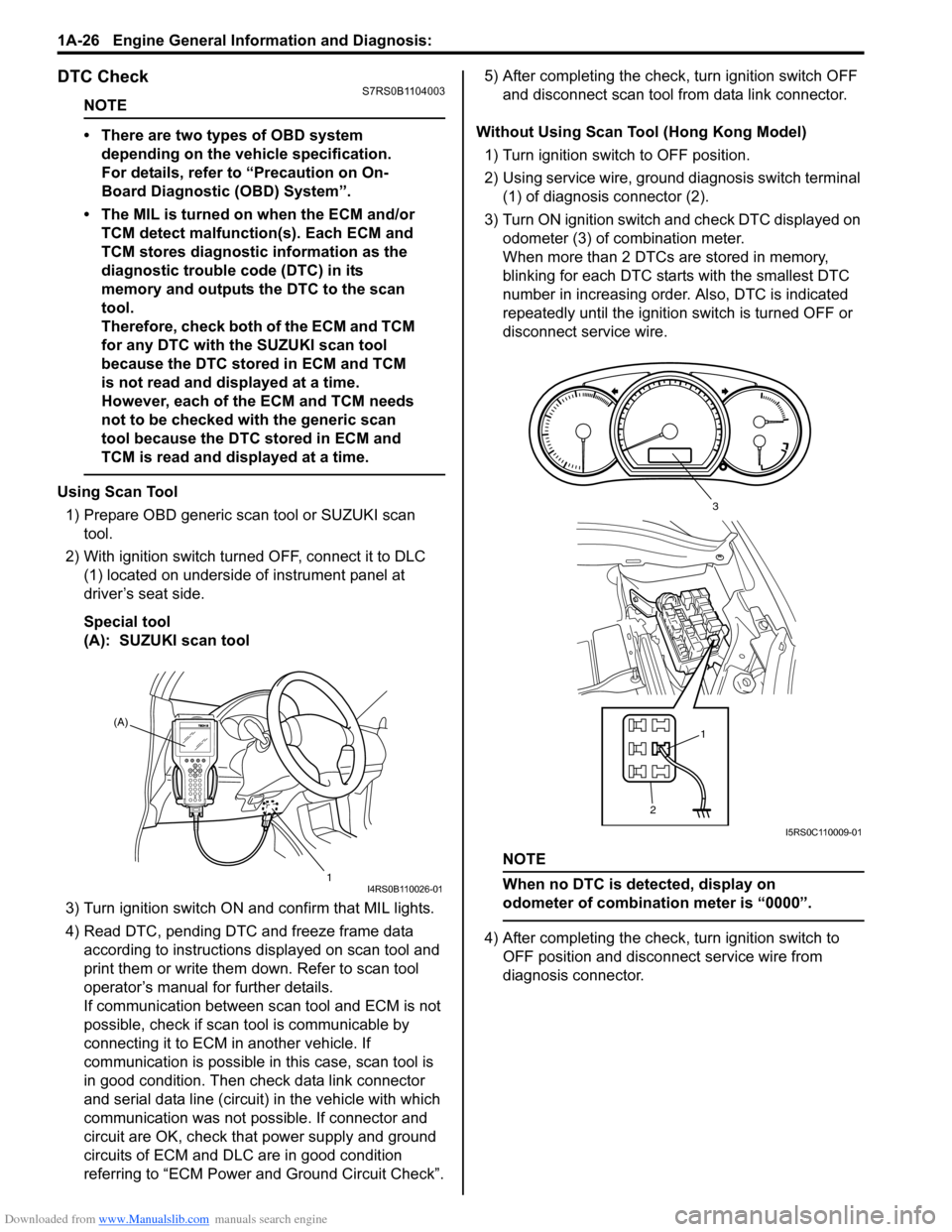

Using Scan Tool

1) Prepare OBD generic scan tool or SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to DLC (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to instructions displayed on scan tool and

print them or write them down. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. If connector and

circuit are OK, check that power supply and ground

circuits of ECM and DLC are in good condition

referring to “ECM Power and Ground Circuit Check”. 5) After completing the check,

turn ignition switch OFF

and disconnect scan tool from data link connector.

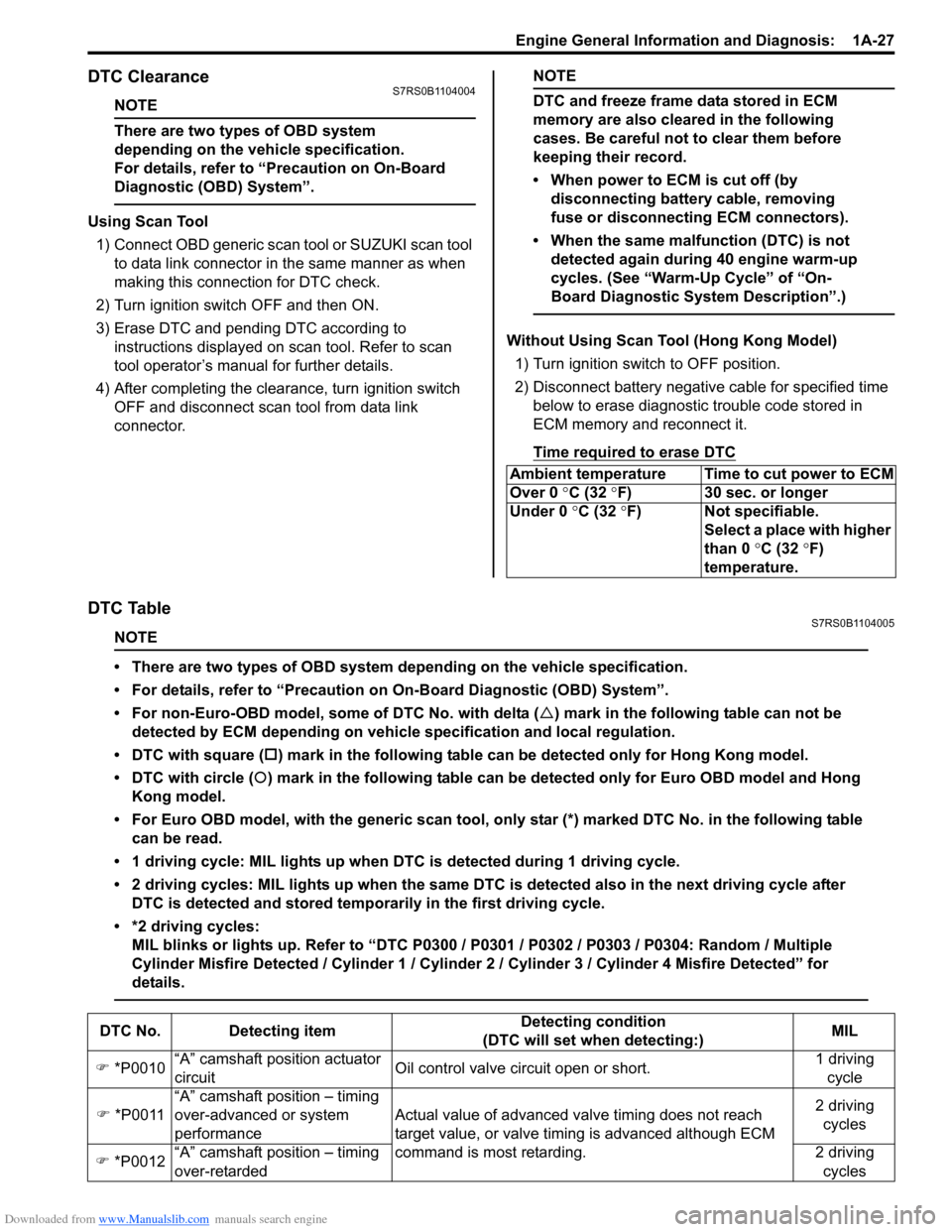

Without Using Scan Tool (Hong Kong Model) 1) Turn ignition switch to OFF position.

2) Using service wire, ground diagnosis switch terminal (1) of diagnosis connector (2).

3) Turn ON ignition switch and check DTC displayed on

odometer (3) of combination meter.

When more than 2 DTCs are stored in memory,

blinking for each DTC star ts with the smallest DTC

number in increasing order. Also, DTC is indicated

repeatedly until the ignition switch is turned OFF or

disconnect service wire.

NOTE

When no DTC is detected, display on

odometer of combinatio n meter is “0000”.

4) After completing the check, turn ignition switch to

OFF position and disconnect service wire from

diagnosis connector.

(A)

1

I4RS0B110026-01

21

3

I5RS0C110009-01

Page 77 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-27

DTC ClearanceS7RS0B1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Using Scan Tool1) Connect OBD generic scan to ol or SUZUKI scan tool

to data link connector in the same manner as when

making this connection for DTC check.

2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to instructions displayed on scan tool. Refer to scan

tool operator’s manual for further details.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Without Using Scan Tool (Hong Kong Model)

1) Turn ignition switch to OFF position.

2) Disconnect battery negative cable for specified time below to erase diagnostic trouble code stored in

ECM memory and reconnect it.

Time required to erase DTC

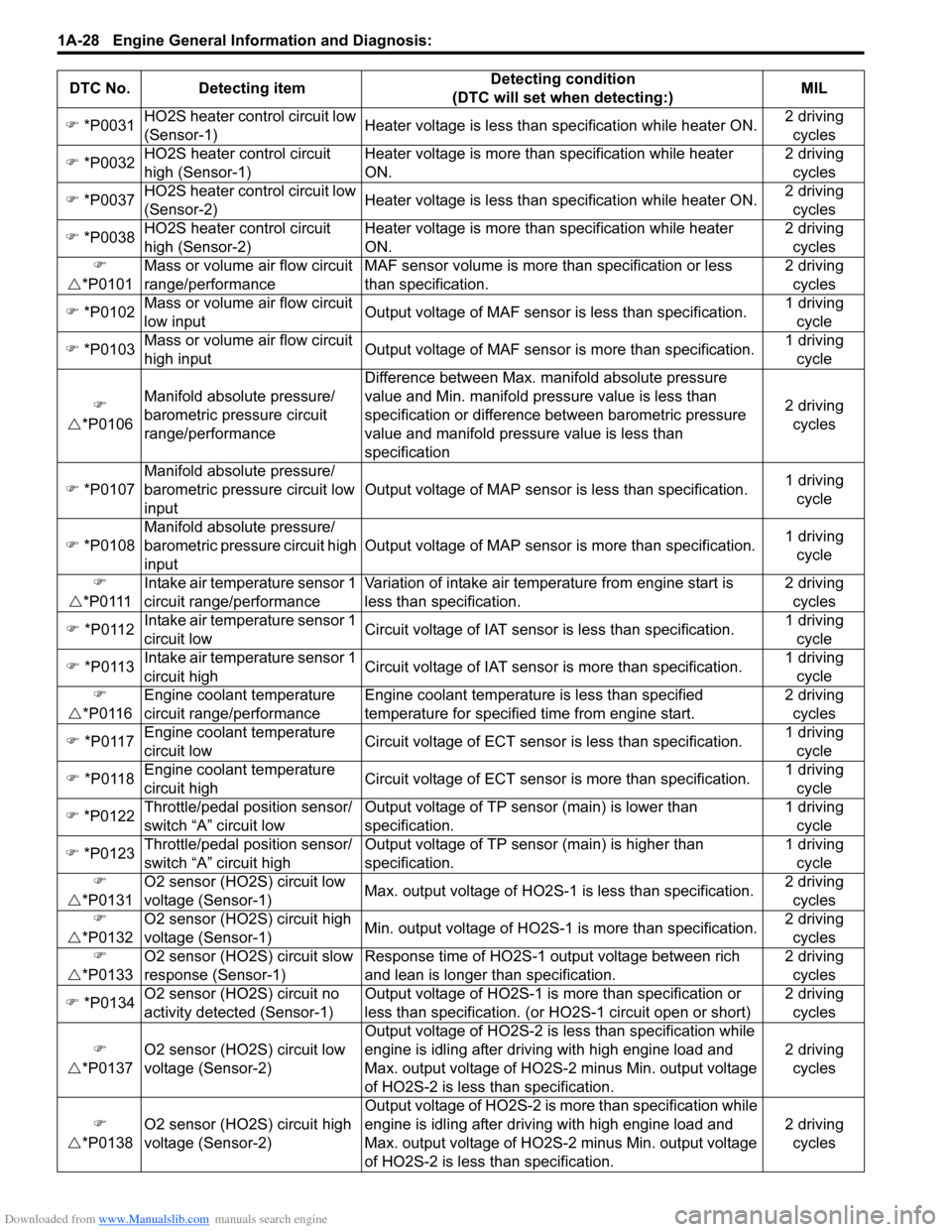

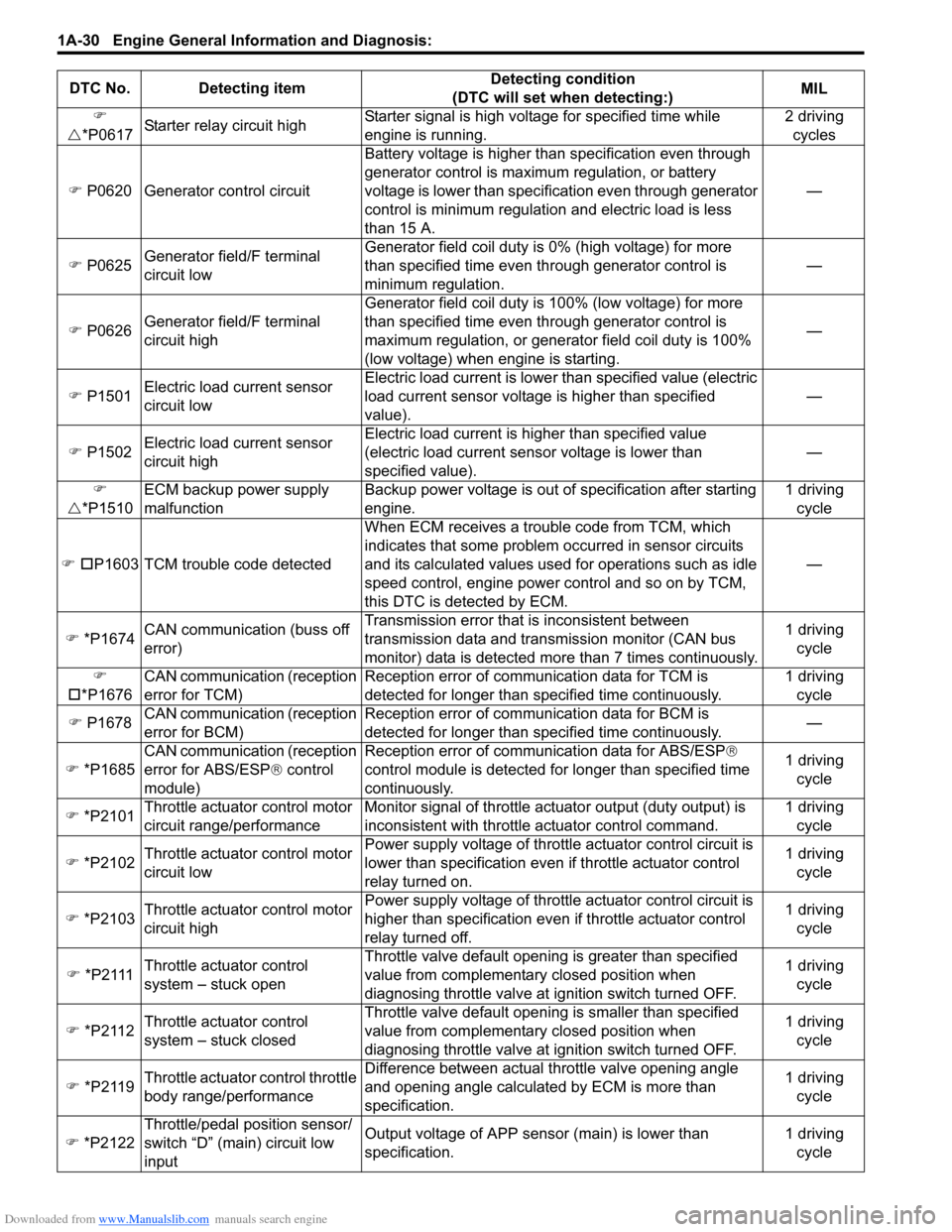

DTC TableS7RS0B1104005

NOTE

• There are two types of OBD system depending on the vehicle specification.

• For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• For non-Euro-OBD model, some of DTC No. with delta ( �U) mark in the following table can not be

detected by ECM depending on vehicl e specification and local regulation.

• DTC with square ( �†) mark in the following table can be detected only for Hong Kong model.

• DTC with circle ( �{) mark in the following table can be detected only for Euro OBD model and Hong

Kong model.

• For Euro OBD model, with the generic scan tool, onl y star (*) marked DTC No. in the following table

can be read.

• 1 driving cycle: MIL lights up when DTC is detected during 1 driving cycle.

• 2 driving cycles: MIL lights up when the same DTC is detected also in the next driving cycle after DTC is detected and stored temporarily in the first driving cycle.

• *2 driving cycles: MIL blinks or lights up. Refer to “DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple

Cylinder Misfire Detected / Cylinder 1 / Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected” for

details.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 ° F) 30 sec. or longer

Under 0 °C (32 °F) Not specifiable.

Select a place with higher

than 0 °C (32 °F)

temperature.

DTC No. Detecting item Detecting condition

(DTC will set when detecting:) MIL

�) *P0010 “A” camshaft position actuator

circuit Oil control valve circuit open or short. 1 driving

cycle

�) *P0011 “A” camshaft position – timing

over-advanced or system

performance Actual value of advanced va

lve timing does not reach

target value, or valve timi ng is advanced although ECM

command is most retarding. 2 driving

cycles

�) *P0012 “A” camshaft position – timing

over-retarded 2 driving

cycles

Page 78 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-28 Engine General Information and Diagnosis:

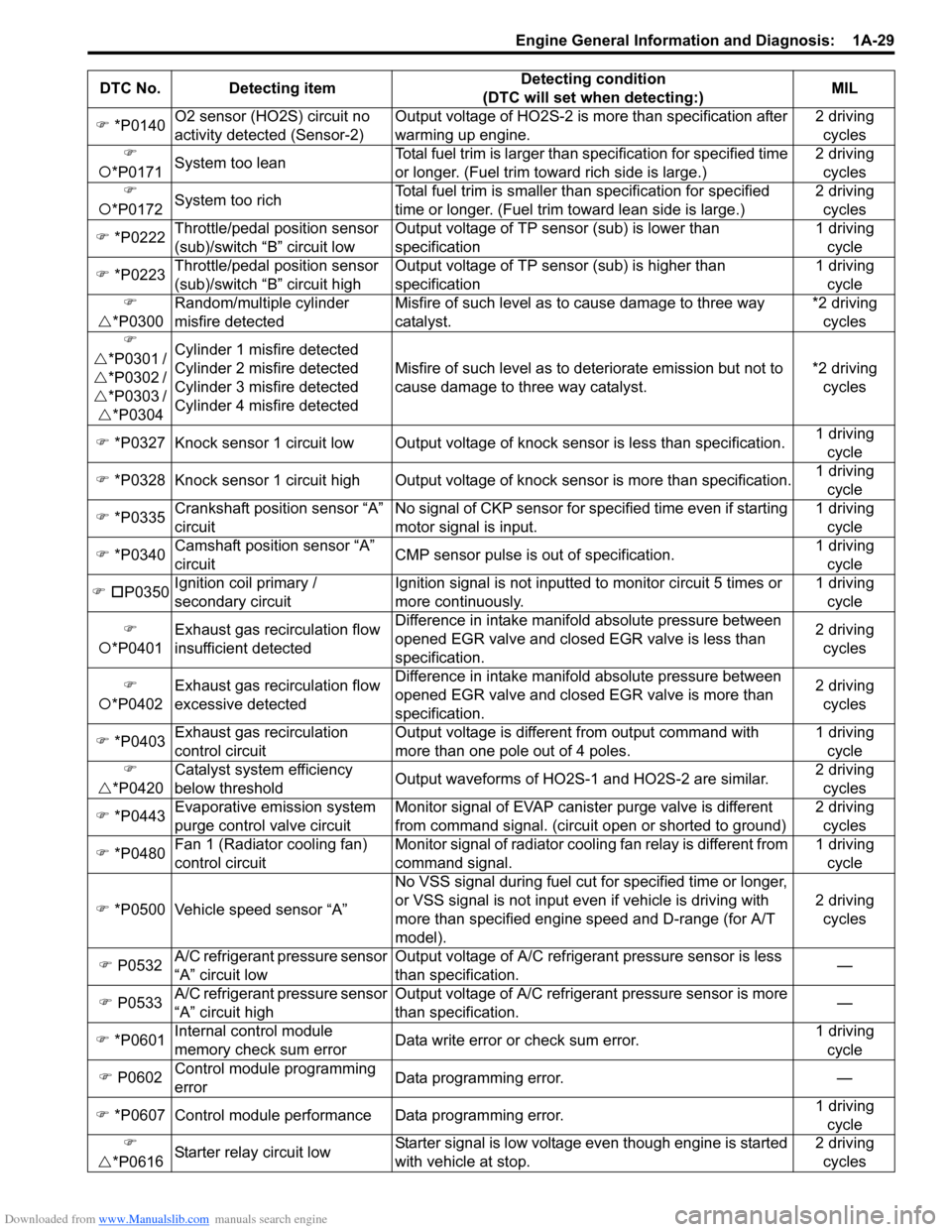

�) *P0031 HO2S heater control circuit low

(Sensor-1) Heater voltage is less than specification while heater ON. 2 driving

cycles

�) *P0032 HO2S heater control circuit

high (Sensor-1) Heater voltage is more than

specification while heater

ON. 2 driving

cycles

�) *P0037 HO2S heater control circuit low

(Sensor-2) Heater voltage is less than specification while heater ON. 2 driving

cycles

�) *P0038 HO2S heater control circuit

high (Sensor-2) Heater voltage is more than

specification while heater

ON. 2 driving

cycles

�)

�U *P0101 Mass or volume air flow circuit

range/performance MAF sensor volume is more

than specification or less

than specification. 2 driving

cycles

�) *P0102 Mass or volume air flow circuit

low input Output voltage of MAF sensor is less than specification. 1 driving

cycle

�) *P0103 Mass or volume air flow circuit

high input Output voltage of MAF sensor is more than specification. 1 driving

cycle

�)

�U *P0106 Manifold absolute pressure/

barometric pressure circuit

range/performance Difference between Max. manifold absolute pressure

value and Min. manifold pressure value is less than

specification or difference between barometric pressure

value and manifold pressure value is less than

specification

2 driving

cycles

�) *P0107 Manifold absolute pressure/

barometric pressure circuit low

input Output voltage of MAP sensor

is less than specification.1 driving

cycle

�) *P0108 Manifold absolute pressure/

barometric pressure circuit high

input Output voltage of MAP sensor is more than specification.

1 driving

cycle

�)

�U *P0111 Intake air temperature sensor 1

circuit range/performance Variation of intake air temperature from engine start is

less than specification. 2 driving

cycles

�) *P0112 Intake air temperature sensor 1

circuit low Circuit voltage of IAT sensor is less than specification. 1 driving

cycle

�) *P0113 Intake air temperature sensor 1

circuit hig

h Circuit voltage of IAT sensor

is more than specification. 1 driving

cycle

�)

�U *P0116 Engine coolant temperature

circuit range/performance Engine coolant temperature is less than specified

temperature for specified time from engine start. 2 driving

cycles

�) *P0117 Engine coolant temperature

circuit low Circuit voltage of ECT sensor

is less than specification. 1 driving

cycle

�) *P0118 Engine coolant temperature

circuit high Circuit voltage of ECT sensor

is more than specification. 1 driving

cycle

�) *P0122 Throttle/pedal position sensor/

switch “A” circuit low Output voltage of TP sensor (main) is lower than

specification. 1 driving

cycle

�) *P0123 Throttle/pedal position sensor/

switch “A” circuit high Output voltage of TP sensor (main) is higher than

specification. 1 driving

cycle

�)

�U *P0131 O2 sensor (HO2S) circuit low

voltage (Sensor-1)

Max. output voltage of HO2S-1

is less than specification.2 driving

cycles

�)

�U *P0132 O2 sensor (HO2S) circuit high

voltage (Sensor-1)

Min. output voltage of HO2S-1

is more than specification. 2 driving

cycles

�)

�U *P0133 O2 sensor (HO2S) circuit slow

response (Sensor-1) Response time of HO2S-1 output voltage between rich

and lean is longer than specification. 2 driving

cycles

�) *P0134 O2 sensor (HO2S) circuit no

activity detected (Sensor-1) Output voltage of HO2S-1 is

more than specification or

less than specification. (or HO2S-1 circuit open or short) 2 driving

cycles

�)

�U *P0137 O2 sensor (HO2S) circuit low

voltage (Sensor-2) Output voltage of HO2S-2 is

less than specification while

engine is idling after driving with high engine load and

Max. output voltage of HO2S-2 minus Min. output voltage

of HO2S-2 is less than specification. 2 driving

cycles

�)

�U *P013

8 O2 sensor (HO2S) circuit high

voltage (Sensor-2) Output voltage of HO2S-2 is

more than specification while

engine is idling after driving with high engine load and

Max. output voltage of HO2S-2 minus Min. output voltage

of HO2S-2 is less than specification. 2 driving

cycles

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

Page 79 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-29

�) *P0140 O2 sensor (HO2S) circuit no

activity detected (Sensor-2) Output voltage of HO2S-2 is more than specification after

warming up engine. 2 driving

cycles

�)

�{ *P0171 System too lean Total fuel trim is larger than

specification for specified time

or longer. (Fuel trim towa rd rich side is large.) 2 driving

cycles

�)

�{ *P0172 System too rich Total fuel trim is smaller th

an specification for specified

time or longer. (Fue l trim toward lean side is large.) 2 driving

cycles

�) *P0222 Throttle/pedal position sensor

(sub)/switch “B” circuit low Output voltage of TP sensor (sub) is lower than

specification 1 driving

cycle

�) *P0223 Throttle/pedal position sensor

(sub)/switch “B” circuit high Output voltage of TP sensor (sub) is higher than

specification 1 driving

cycle

�)

�U *P0300 Random/multiple cylinder

misfire detected Misfire of such level as to cause damage to three way

catalyst. *2 driving

cycles

�)

�U *P0301 /

�U *P0302 /

�U *P0303 /

�U *P0304 Cylinder 1 misfire detected

Cylinder 2 misfire detected

Cylinder 3 misfire detected

Cylinder 4 misfire detected

Misfire of such level as to deteriorate emission but not to

cause damage to three way catalyst.

*2 driving

cycles

�) *P0327 Knock sensor 1 circuit low Output voltage of knock sensor is less than specification.1 driving

cycle

�) *P0328 Knock sensor 1 circuit high Output volta ge of knock sensor is more than specification.1 driving

cycle

�) *P0335 Crankshaft position sensor “A”

circuit No signal of CKP sensor for sp

ecified time even if starting

motor signal is input. 1 driving

cycle

�) *P0340 Camshaft position sensor “A”

circuit CMP sensor pulse is out of specification. 1 driving

cycle

�) �† P0350 Ignition c

oil primary /

secondary circuit Ignition signal is not inputted to monitor circuit 5 times or

more continuously. 1 driving

cycle

�)

�{ *P0401 Exhaust gas recirculation flow

insufficient detected Difference in intake manifold absolute pressure between

opened EGR valve and closed EGR valve is less than

specification. 2 driving

cycles

�)

�{ *P0402 Exhaust gas recirculation flow

excessive detected Difference in intake manifold absolute pressure between

opened EGR valve and closed EGR valve is more than

specification. 2 driving

cycles

�) *P0403 Exhaust gas recirculation

control circuit Output voltage is different from output command with

more than one pole out of 4 poles. 1 driving

cycle

�)

�U *P0420 Catalyst system efficiency

below threshold

Output waveforms of HO2S-1 and HO2S-2 are similar. 2 driving

cycles

�) *P0443 Evaporative emission system

purge control valve circuit Monitor signal of EVAP canister purge valve is different

from command signal. (circuit open or shorted to ground) 2 driving

cycles

�) *P0480 Fan 1 (Radiator cooling fan)

control circuit Monitor signal of radiator cooling fan relay is different from

command signal. 1 driving

cycle

�) *P0500 Vehicle speed sensor “A” No VSS signal during fuel cut fo

r specified time or longer,

or VSS signal is not input even if vehicle is driving with

more than specified engine speed and D-range (for A/T

model). 2 driving

cycles

�) P0532 A/C refrigerant pressure sensor

“A” circuit low Output voltage of A/C refrigerant pressure sensor is less

than specification.

—

�) P0533 A/C refrigerant pressure sensor

“A” circuit high Output voltage of A/C refrigerant pressure sensor is more

than specification.

—

�) *P0601 Internal control module

memory check sum error Data write error or check sum error. 1 driving

cycle

�) P0602 Control module programming

error Data programming error.

—

�) *P0607 Control module performance Data programming error. 1 driving

cycle

�)

�U *P061

6Starter relay circuit low Starter signal is low voltage even though engine is started

with vehicle at stop. 2 driving

cycles

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

Page 80 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-30 Engine General Information and Diagnosis:

�)

�U *P0617 Starter relay circuit high Starter signal is high voltage for specified time while

engine is running. 2 driving

cycles

�) P0620 Generator control circuit Battery voltage is higher than specification even through

generator control is maximum regulation, or battery

voltage is lower than specification even through generator

control is minimum regulation

and electric load is less

than 15 A. —

�) P0625 Generator field/F terminal

circuit low Generator field coil duty is

0% (high voltage) for more

than specified time even through generator control is

minimum regulation. —

�) P0626 Generator field/F terminal

circuit high Generator field coil duty is

100% (low voltage) for more

than specified time even through generator control is

maximum regulation, or generator field coil duty is 100%

(low voltage) when engine is starting. —

�) P1501 Electric load current sensor

circuit low Electric load current is lowe

r than specified value (electric

load current sensor voltage is higher than specified

value). —

�) P1502 Electric load current sensor

circuit high Electric load current is higher than specified value

(electric load current sens

or voltage is lower than

specified value). —

�)

�U *P1510 ECM backup power supply

malfunction Backup power voltage is out of

specification after starting

engine. 1 driving

cycle

�) �† P1603 TCM trouble code detected When ECM receives a trouble code from TCM, which

indicates that some problem occurred in sensor circuits

and its calculated values used for operations such as idle

speed control, engine power control and so on by TCM,

this DTC is detected by ECM. —

�) *P1674 CAN communication (buss off

error) Transmission error that

is inconsistent between

transmission data and transmission monitor (CAN bus

monitor) data is detected more than 7 times continuously. 1 driving

cycle

�)

�† *P1676 CAN communication (reception

error for TCM) Reception error of communication data for TCM is

detected for longer than specified time continuously. 1 driving

cycle

�) P1678 CAN communication (reception

error for BCM) Reception error of communication data for BCM is

detected for longer than specified time continuously.

—

�) *P1685 CAN communication (reception

error for ABS/ESP

® control

module) Reception error of communication data for ABS/ESP

®

co

ntrol module is detected for longer than specified time

continuously. 1 driving

cycle

�) *P2101 Throttle actuator control motor

circuit range/performance Monitor signal of throttle actuator output (duty output) is

inconsistent with throttle actuator control command. 1 driving

cycle

�) *P2102 Throttle actuator control motor

circuit low Power supply voltage of throttle actuator control circuit is

lower than specification even

if throttle actuator control

relay turned on. 1 driving

cycle

�) *P2103 Throttle actuator control motor

circuit high Power supply voltage of throttle actuator control circuit is

higher than specification even if throttle actuator control

relay turned off. 1 driving

cycle

�) *P2111 Throttle actuator control

system – stuck open Throttle valve default opening is greater than specified

value from complementary closed position when

diagnosing throttle valve at ignition switch turned OFF. 1 driving

cycle

�) *P2112 Throttle actuator control

system – stuck closed Throttle valve default opening is smaller than specified

value from complementary closed position when

diagnosing throttle valve at ignition switch turned OFF. 1 driving

cycle

�) *P2119 Throttle actuator control throttle

body range/performance Difference between actual throttle valve opening angle

and opening angle calculated by ECM is more than

specification. 1 driving

cycle

�) *P2122 Throttle/pedal position sensor/

switch “D” (main) circuit low

input Output voltage of APP sensor (main) is lower than

specification.

1 driving

cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL