C16 SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 365 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-2

Coolant capacity

For M/T model:• Engine, radiator and heater: 5.5 liters (11.62/9.68 US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 US/lmp pt.)

• Total: 6.2 liters (13.10/10.91 US/lmp pt.)

For A/T model: • Engine, radiator and heater: 5.4 liters (11.41/9.50 US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 US/lmp pt.)

• Total: 6.1 liters (12.89/10.74 US/lmp pt.)

Schematic and Routing Diagram

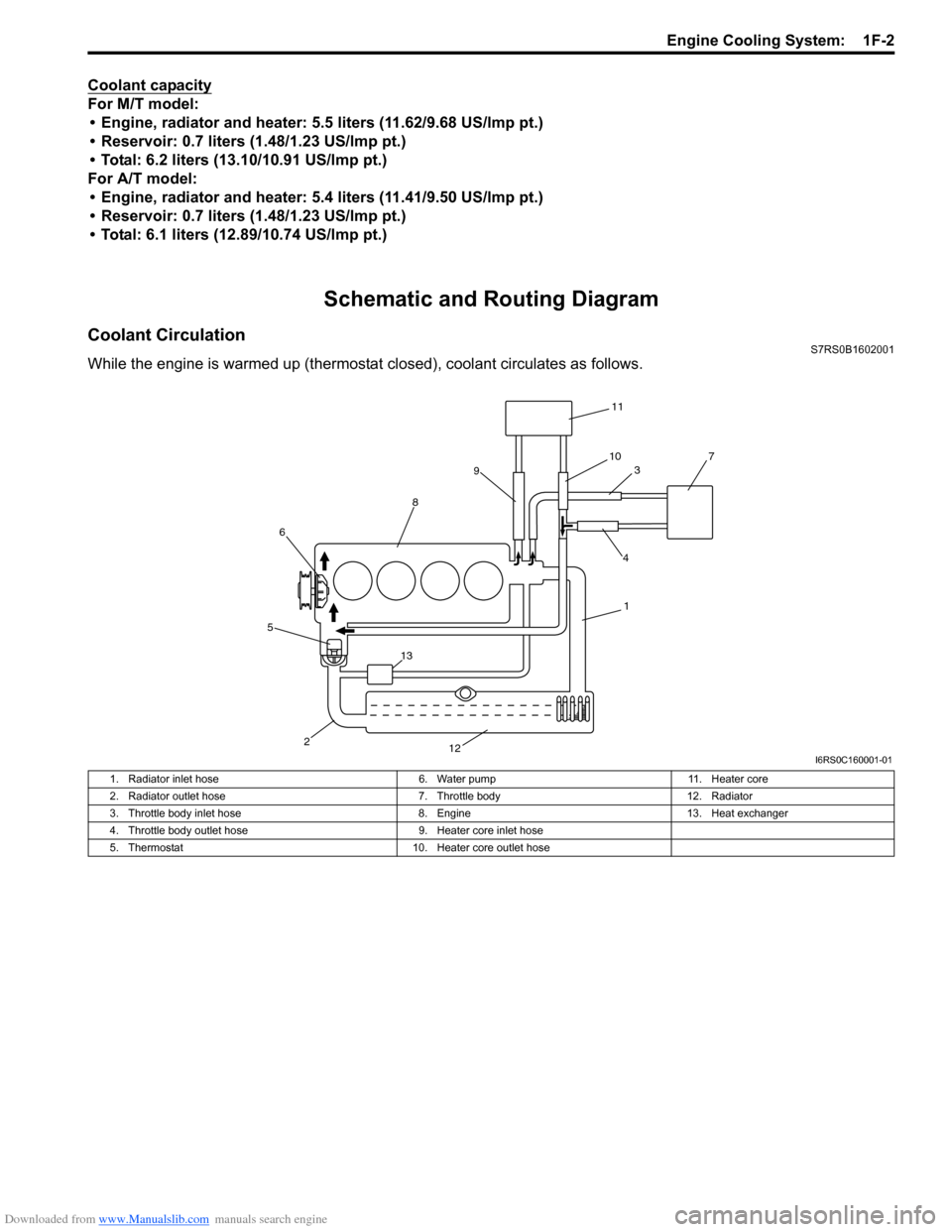

Coolant CirculationS7RS0B1602001

While the engine is warmed up (thermosta t closed), coolant circulates as follows.

11

10 3 7

4

9

8

6

5

2 12 1

13

I6RS0C160001-01

1. Radiator inlet hose

6. Water pump11. Heater core

2. Radiator outlet hose 7. Throttle body12. Radiator

3. Throttle body inlet hose 8. Engine13. Heat exchanger

4. Throttle body outlet hose 9. Heater core inlet hose

5. Thermostat 10. Heater core outlet hose

Page 366 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-3 Engine Cooling System:

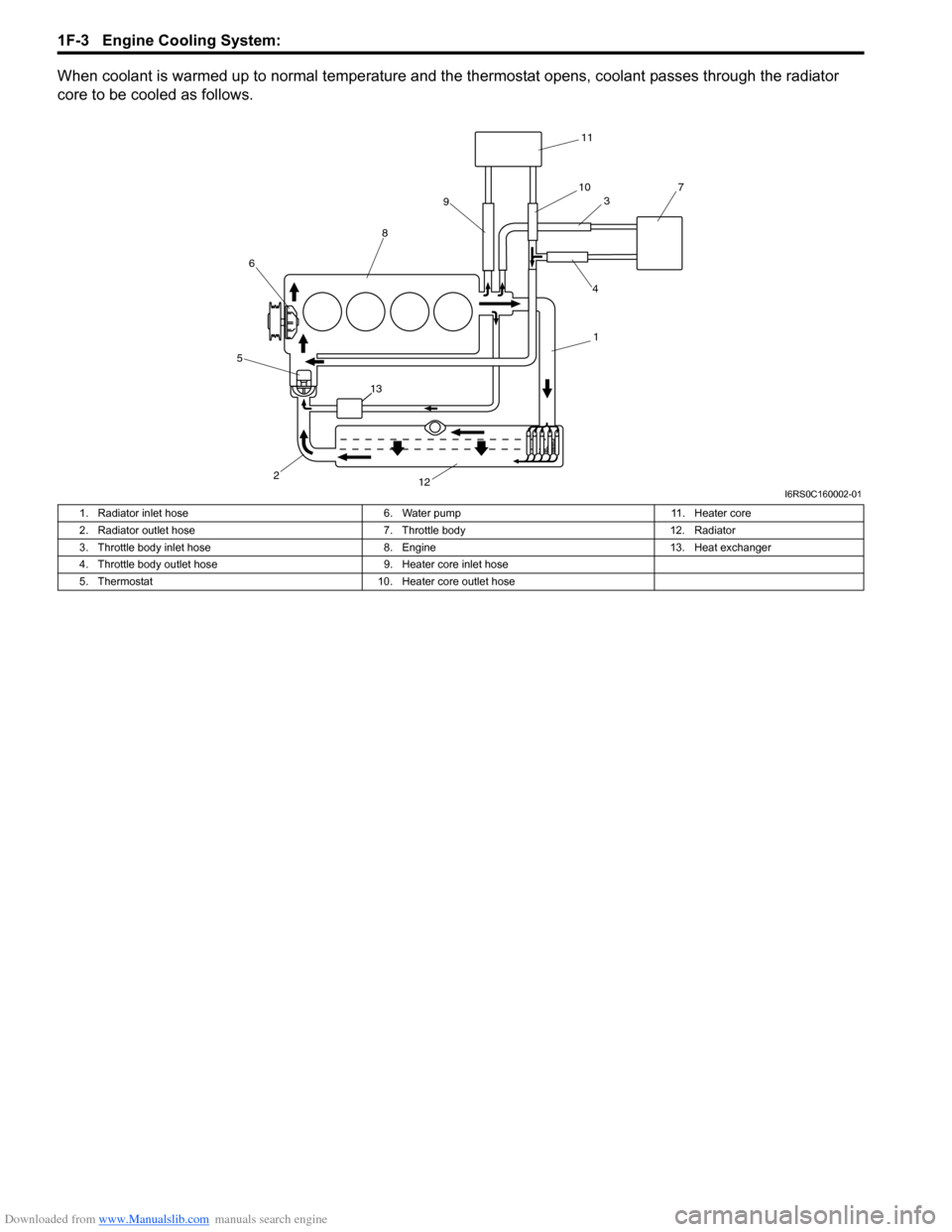

When coolant is warmed up to normal temperature and the thermostat opens, coolant passes through the radiator

core to be cooled as follows.

11

10 3 7

4

9

8

6

5

2 12 1

13

I6RS0C160002-01

1. Radiator inlet hose

6. Water pump11. Heater core

2. Radiator outlet hose 7. Throttle body12. Radiator

3. Throttle body inlet hose 8. Engine13. Heat exchanger

4. Throttle body outlet hose 9. Heater core inlet hose

5. Thermostat 10. Heater core outlet hose

Page 418 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

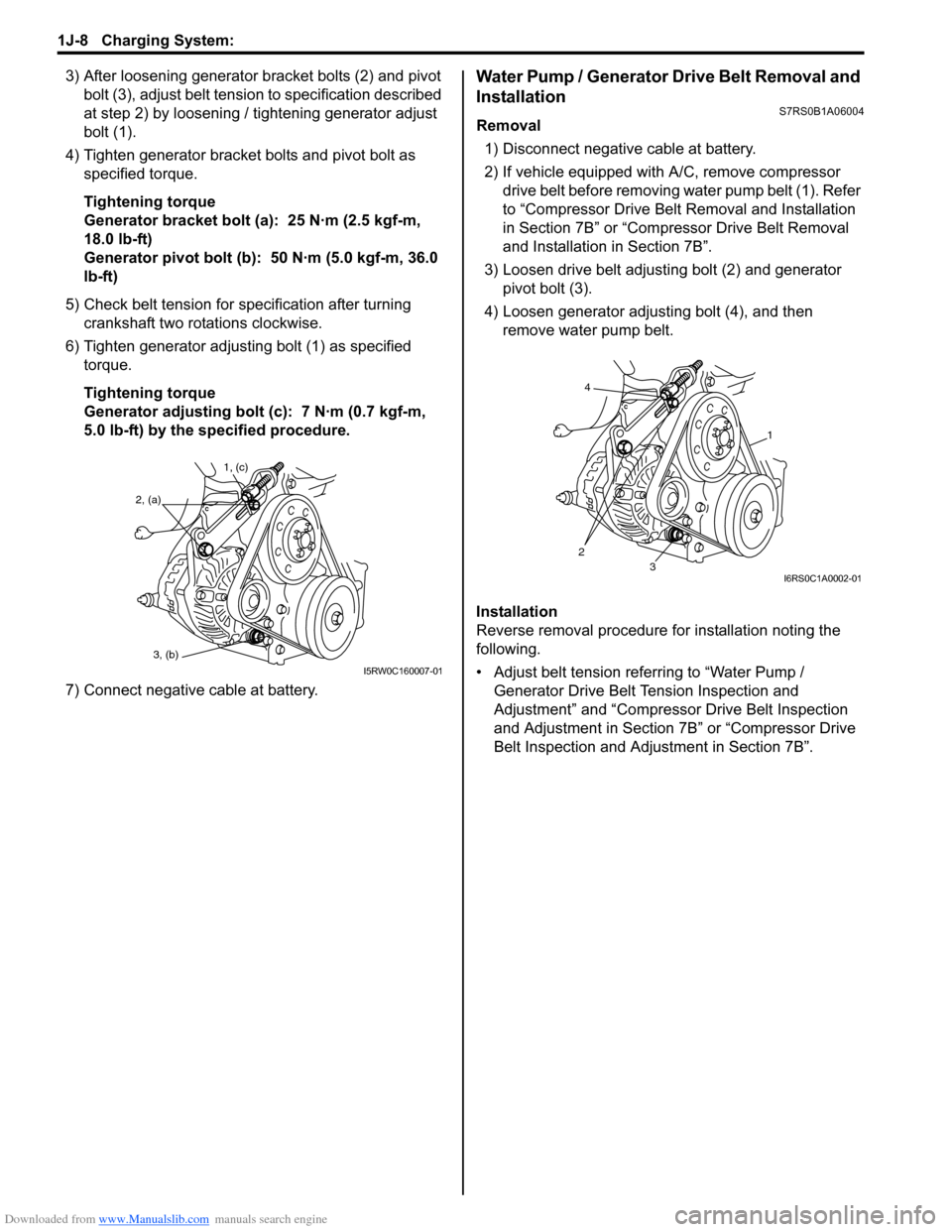

3) After loosening generator bracket bolts (2) and pivot bolt (3), adjust belt tensio n to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified torque.

Tightening torque

Generator adjusting bolt (c): 7 N·m (0.7 kgf-m,

5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.Water Pump / Generator Drive Belt Removal and

Installation

S7RS0B1A06004

Removal 1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor drive belt before removing water pump belt (1). Refer

to “Compressor Drive Belt Removal and Installation

in Section 7B” or “Compr essor Drive Belt Removal

and Installation in Section 7B”.

3) Loosen drive belt adjusting bolt (2) and generator pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then remove water pump belt.

Installation

Reverse removal procedure for installation noting the

following.

• Adjust belt tension referring to “Water Pump / Generator Drive Belt Tension Inspection and

Adjustment” and “Compressor Drive Belt Inspection

and Adjustment in Section 7B” or “Compressor Drive

Belt Inspection and Adjustment in Section 7B”.

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I6RS0C1A0002-01

Page 1181 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

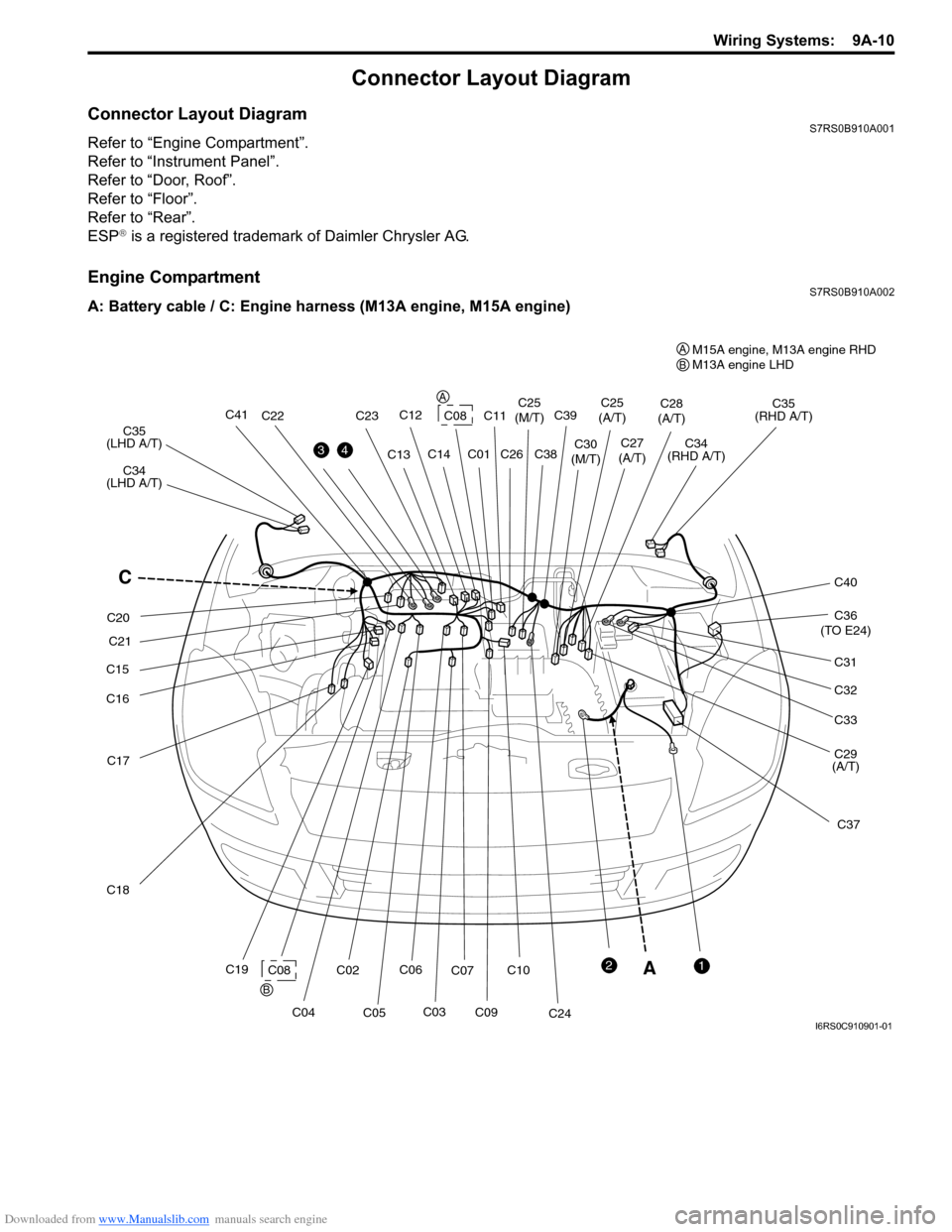

Connector Layout Diagram

Connector Layout DiagramS7RS0B910A001

Refer to “Engine Compartment”.

Refer to “Instrument Panel”.

Refer to “Door, Roof”.

Refer to “Floor”.

Refer to “Rear”.

ESP

® is a registered trademark of Daimler Chrysler AG.

Engine CompartmentS7RS0B910A002

A: Battery cable / C: Engine harness (M13A engine, M15A engine)

A

C36

(TO E24)

C17

C18

C19 C35

(RHD A/T)

C34

(LHD A/T) C35

(LHD A/T) C34

(RHD A/T)

C37

C15

C16

C02C08

C03

C10

C0912

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)

C24

C25

(M/T)

C26

C07

C06

C05

C04

C22

C21

C20 C23

C13

C12C14

C08

C01

CC40

C41C39

C38C11

A

A

B

BM15A engine, M13A engine RHD

M13A engine LHD

I6RS0C910901-01

Page 1182 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-11 Wiring Systems:

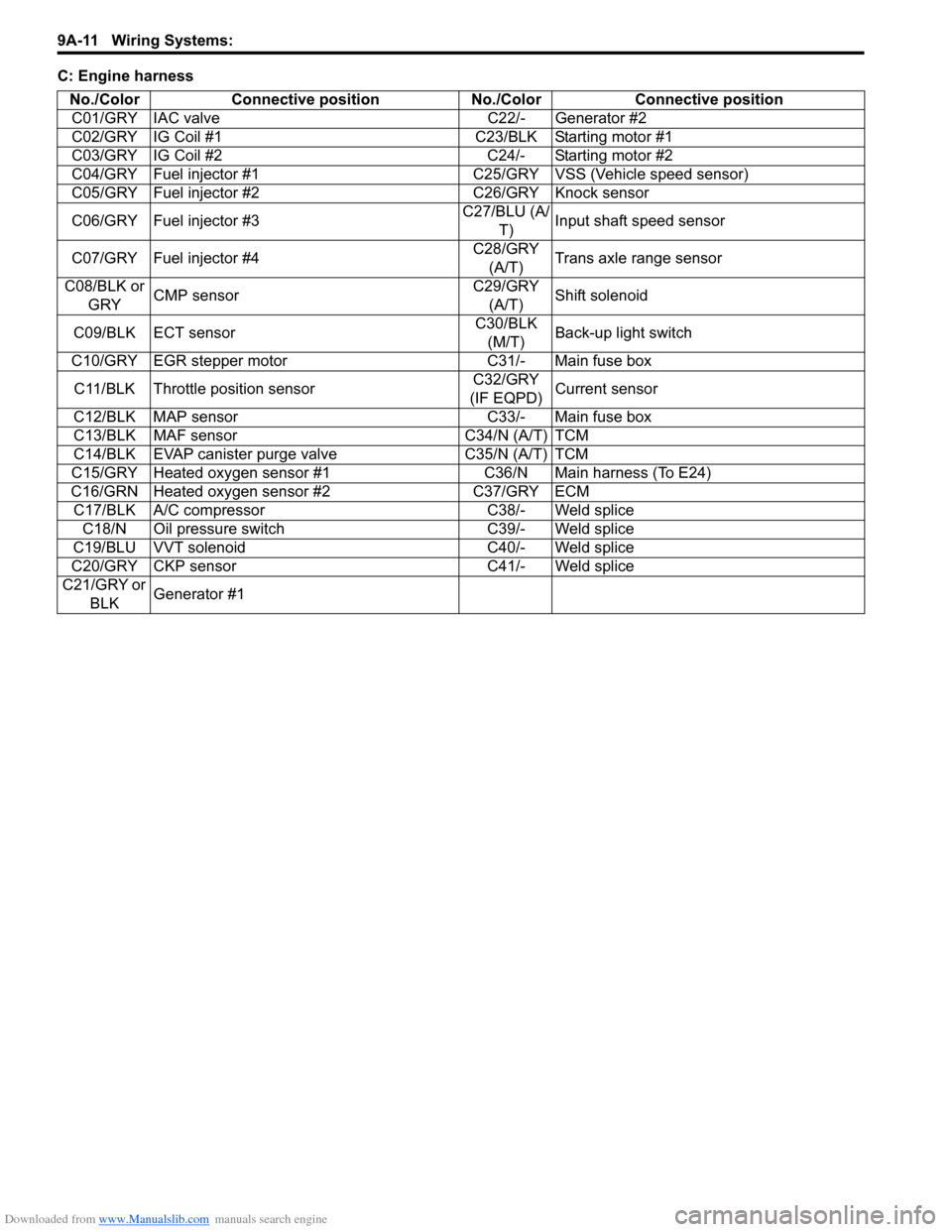

C: Engine harnessNo./Color Connective position No./Color Connective positionC01/GRY IAC valve C22/- Generator #2

C02/GRY IG Coil #1 C23/BLK Starting motor #1

C03/GRY IG Coil #2 C24/- Starting motor #2

C04/GRY Fuel injector #1 C25/GR Y VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK or GRY CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C11/BLK Throttle position sensor C32/GRY

(IF EQPD) Current sensor

C12/BLK MAP sensor C33/- Main fuse box

C13/BLK MAF sensor C34/N (A/T) TCM

C14/BLK EVAP canister purge valve C35/N (A/T) TCM

C15/GRY Heated oxygen sensor #1 C36/N Main harness (To E24)

C16/GRN Heated oxygen sensor #2 C37/GRY ECM C17/BLK A/C compressor C38/- Weld splice C18/N Oil pressure switch C39/- Weld splice

C19/BLU VVT solenoid C40/- Weld splice

C20/GRY CKP sensor C41/- Weld splice

C21/GRY or BLK Generator #1

Page 1183 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-12

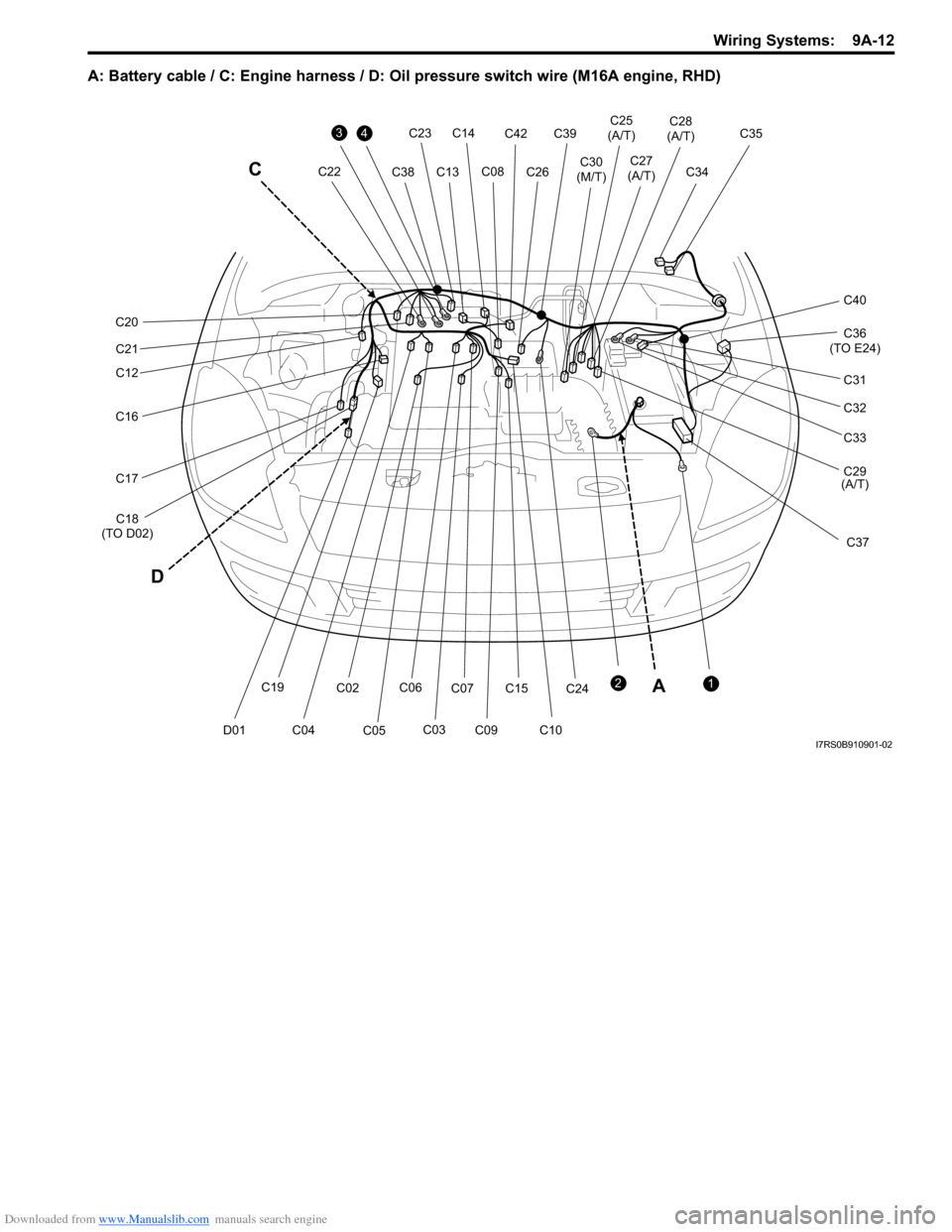

A: Battery cable / C: Engine harness / D: Oil pressure switch wire (M16A engine, RHD)

C36

(TO E24)

C35

C34

C37

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)C26C22 C23C13C38

C14

C08

C40

C39

C42

A

C17

C18

(TO D02)

C19

C16

C02

C03C10

C09

12C24C07C15

C06

C05

C04D01

C21

C12

C20

C

D

I7RS0B910901-02

Page 1184 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

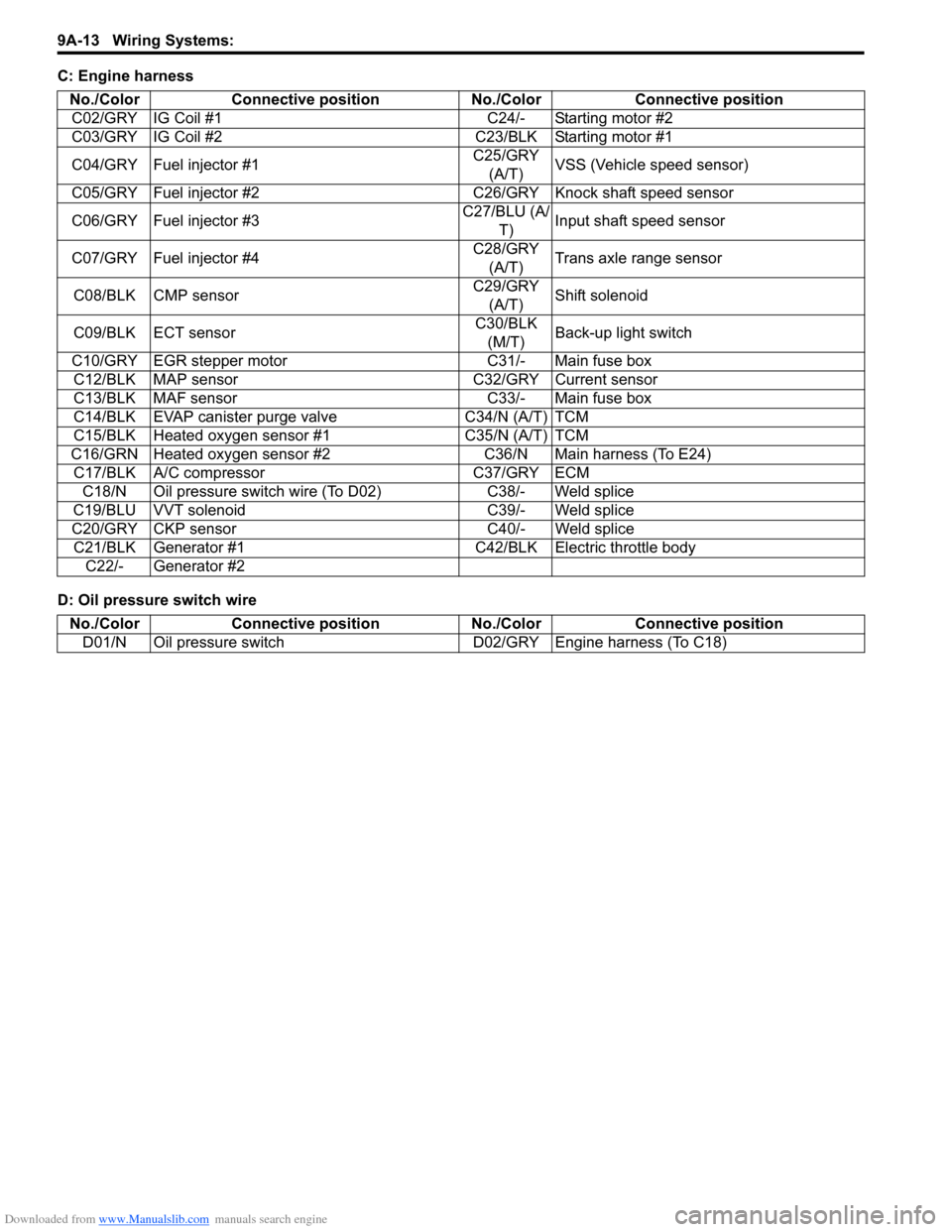

C: Engine harness

D: Oil pressure switch wireNo./Color Connective position No./Color Connective position

C02/GRY IG Coil #1 C24/- Starting motor #2

C03/GRY IG Coil #2 C23/BLK Starting motor #1

C04/GRY Fuel injector #1 C25/GRY

(A/T) VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock shaft speed sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C12/BLK MAP sensor C32/GRY Current sensor

C13/BLK MAF sensor C33/- Main fuse box

C14/BLK EVAP canister purge valve C34/N (A/T) TCM

C15/BLK Heated oxygen sensor #1 C35/N (A/T) TCM

C16/GRN Heated oxygen sensor #2 C36/N Main harness (To E24) C17/BLK A/C compressor C37/GRY ECM C18/N Oil pressure switch wire (To D02) C38/- Weld splice

C19/BLU VVT solenoid C39/- Weld splice

C20/GRY CKP sensor C40/- Weld splice C21/BLK Generator #1 C42/BLK Electric throttle body C22/- Generator #2

No./Color Connective position No./ColorConnective position

D01/N Oil pressure switch D02/GRY Engine harness (To C18)

Page 1221 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-50

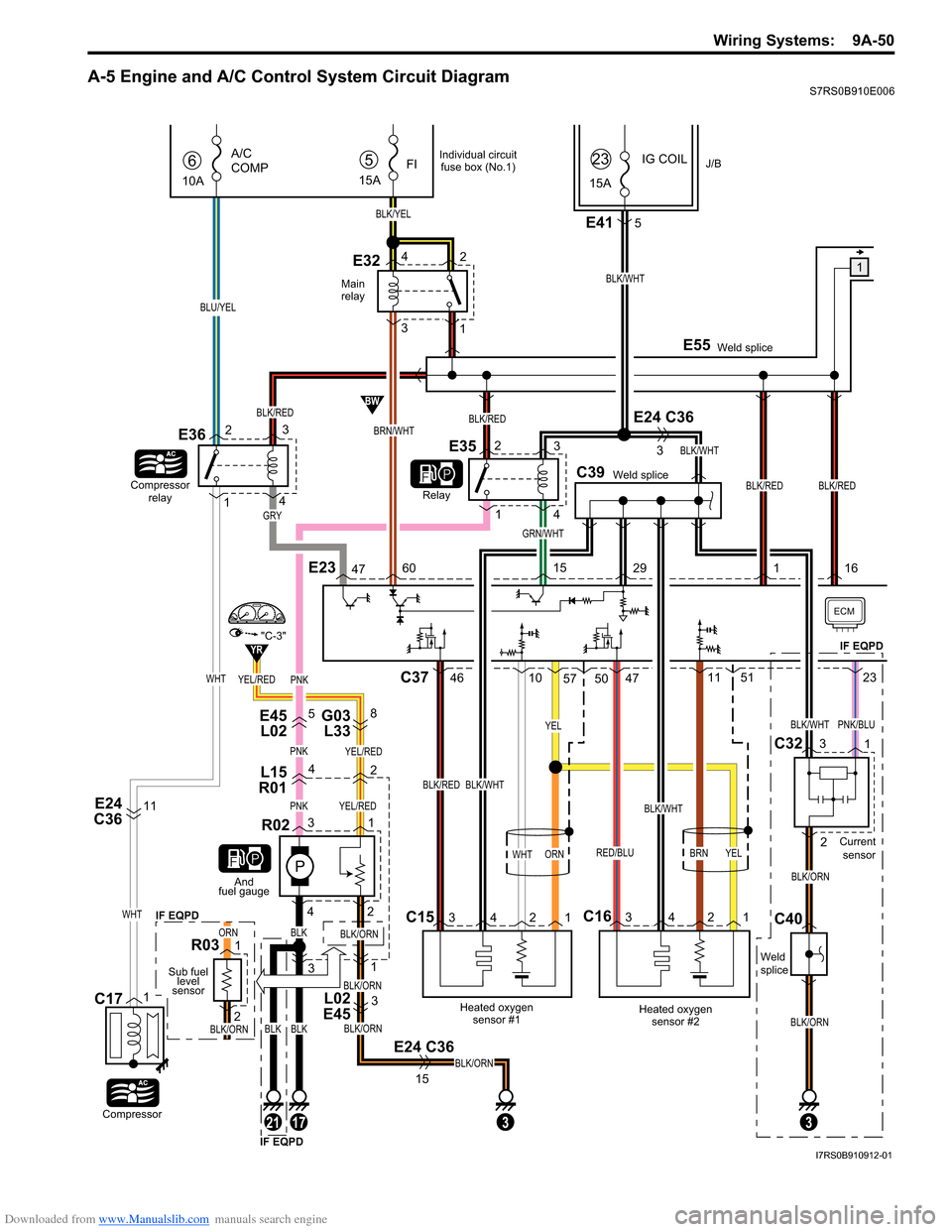

A-5 Engine and A/C Control System Circuit DiagramS7RS0B910E006

YEL/RED

E45L02 G03

L33

L02

E4558

L15

R0142

PNKYEL/RED

P

PNKYEL/RED

31

3

3 1

E24 C36

BLK/ORN

BLK/ORN

BLK/ORN

BLK/ORN

3

15

BLK

42

R02

1

2

R03

And

fuel gauge

Sub fuel level

sensor

Main

relay

1BLK/WHT

BLK/WHT

C39Weld splice Weld splice

E55

GRN/WHT

IG COILJ/B5

15A

FI

BLK/YEL

E324

32

1 15A

23

BRN/WHT

BW

YR

6

10A

A/C

COMP

Compressor

relay

E36

Relay

BLU/YEL

Compressor

C171

E415

E24 C36

3

E24

C3611

BLK/WHT

C15 C16

Heated oxygen

sensor #1

BLK/RED

WHT

Heated oxygensensor #2

BRN

BLK/WHT

RED/BLU

C37

34213421

4610574711

YEL

5123PNK

ECM

41 3

2

WHT

WHT

BLK/REDBLK/RED

BLK/RED

E23476015291

GRY

E3523

1

4

ORN

BLKBLKBLK/ORN

ORN

YEL

50

BLK/RED

16

17213

Individual circuit

fuse box (No.1)

BLK/ORN

BLK/ORN

BLK/WHTPNK/BLU

IF EQPD

IF EQPD IF EQPD

Weld

splice

C40 C32

Current

sensor

3

2 1

"C-3"

I7RS0B910912-01

Page 1274 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-103 Wiring Systems:

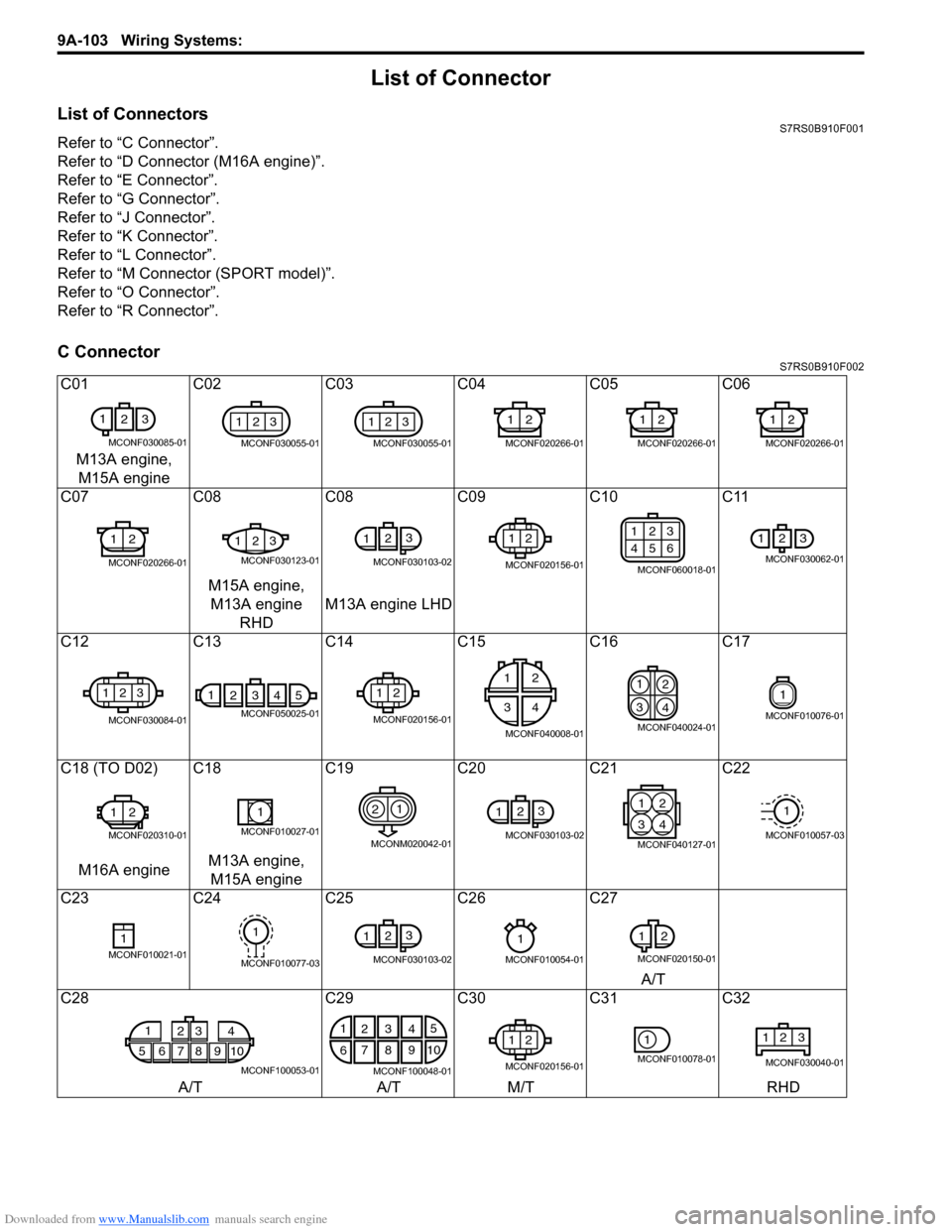

List of Connector

List of ConnectorsS7RS0B910F001

Refer to “C Connector”.

Refer to “D Connector (M16A engine)”.

Refer to “E Connector”.

Refer to “G Connector”.

Refer to “J Connector”.

Refer to “K Connector”.

Refer to “L Connector”.

Refer to “M Connector (SPORT model)”.

Refer to “O Connector”.

Refer to “R Connector”.

C ConnectorS7RS0B910F002

C01C02C03 C04 C05 C06

M13A engine, M15A engine

C07 C08C08 C09 C10 C11

M15A engine, M13A engine RHD M13A engine LHD

C12 C13C14 C15 C16 C17

C18 (TO D02) C18 C19C20C21C22

M16A engine M13A engine,

M15A engine

C23 C24C25 C26 C27

A/T

C28 C29C30C31C32

A/T A/TM/T RHD

1

23

MCONF030085-01

123

MCONF030055-01

123

MCONF030055-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

12

MCONF020266-01

123

MCONF030123-01

123

MCONF030103-02

12

MCONF020156-01

123

456

MCONF060018-01

123

MCONF030062-01

123

MCONF030084-01

14325

MCONF050025-01

12

MCONF020156-01

12

34

MCONF040008-01

1

2

3 4

MCONF040024-01

1

MCONF010076-01

12

MCONF020310-01

1

MCONF010027-01

21

MCONM020042-01

12

3

MCONF030103-02

21

43

MCONF040127-01

1

MCONF010057-03

1MCONF010021-01

1

MCONF010077-03

123

MCONF030103-02

1

MCONF010054-01

1

2

MCONF020150-01

1

5678910 23 4

MCONF100053-01

1

2 5

6 7

103

84

9

MCONF100048-01

12

MCONF020156-01

1

MCONF010078-01

123

MCONF030040-01