C23 SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 455 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-1

Suspension

Rear Suspension

General Description

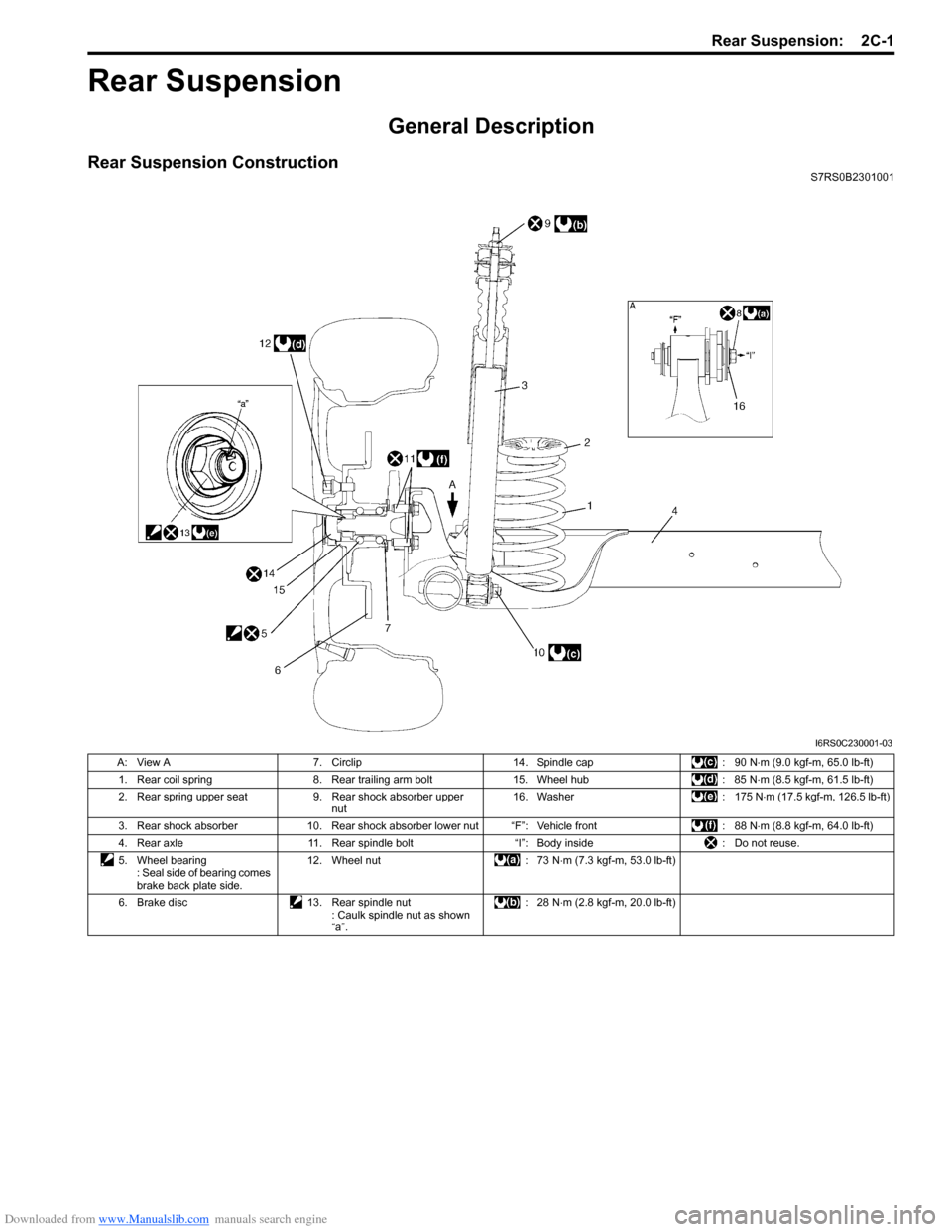

Rear Suspension ConstructionS7RS0B2301001

I6RS0C230001-03

A: View A7. Circlip 14. Spindle cap : 90 N⋅m (9.0 kgf-m, 65.0 lb-ft)

1. Rear coil spring 8. Rear trailing arm bolt 15. Wheel hub : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

2. Rear spring upper seat 9. Rear shock absorber upper

nut 16. Washer

: 175 N⋅m (17.5 kgf-m, 126.5 lb-ft)

3. Rear shock absorber 10. Rear shock absorber lower nut “F”: Vehicle front : 88 N⋅m (8.8 kgf-m, 64.0 lb-ft)

4. Rear axle 11. Rear spindle bolt “I”: Body inside : Do not reuse.

5. Wheel bearing : Seal side of bearing comes

brake back plate side. 12. Wheel nut

: 73 N⋅m (7.3 kgf-m, 53.0 lb-ft)

6. Brake disc 13. Rear spindle nut

: Caulk spindle nut as shown

“a”. :28 N

⋅m (2.8 kgf-m, 20.0 lb-ft)

Page 456 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-2 Rear Suspension:

Repair Instructions

Rear Wheel Alignment InspectionS7RS0B2306017

Measure toe and camber referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

NOTE

Rear suspension is not adjustable structure.

Rear toe (total)

: IN 3.8 ± 3.8 mm (IN 0.1969 ± 0.1969 in)

Rear camber

: –1 ° ± 1

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Rear axle (torsion beam)

• Spindle, wheel hub or wheel bearing

• Vehicle body

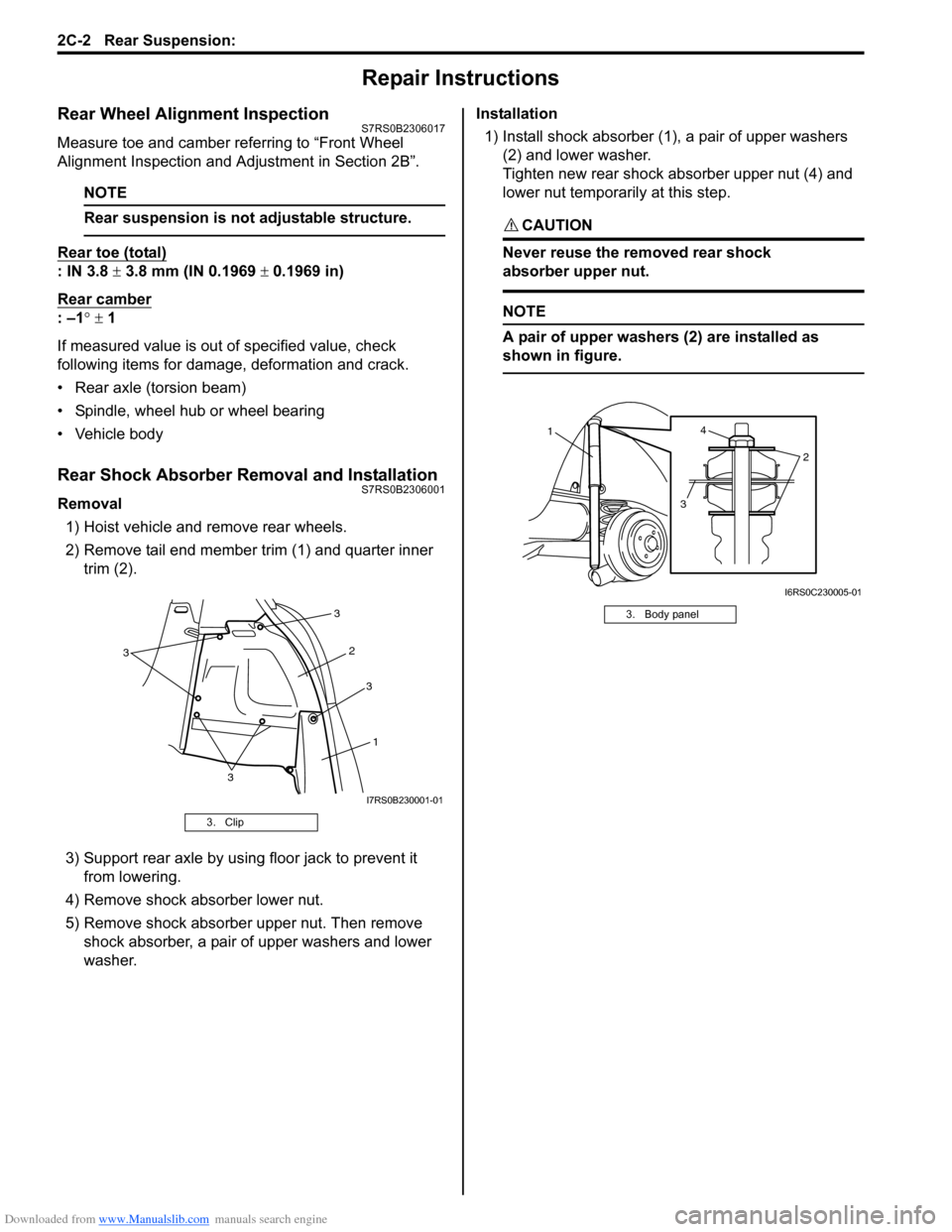

Rear Shock Absorber Removal and InstallationS7RS0B2306001

Removal 1) Hoist vehicle and remove rear wheels.

2) Remove tail end member trim (1) and quarter inner trim (2).

3) Support rear axle by using floor jack to prevent it from lowering.

4) Remove shock absorber lower nut.

5) Remove shock absorber upper nut. Then remove shock absorber, a pair of upper washers and lower

washer. Installation

1) Install shock absorber (1), a pair of upper washers (2) and lower washer.

Tighten new rear shock absorber upper nut (4) and

lower nut temporarily at this step.

CAUTION!

Never reuse the removed rear shock

absorber upper nut.

NOTE

A pair of upper washers (2) are installed as

shown in figure.

3. Clip

3

3 2

3

1

3

I7RS0B230001-01

3. Body panel

14

3 2

I6RS0C230005-01

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

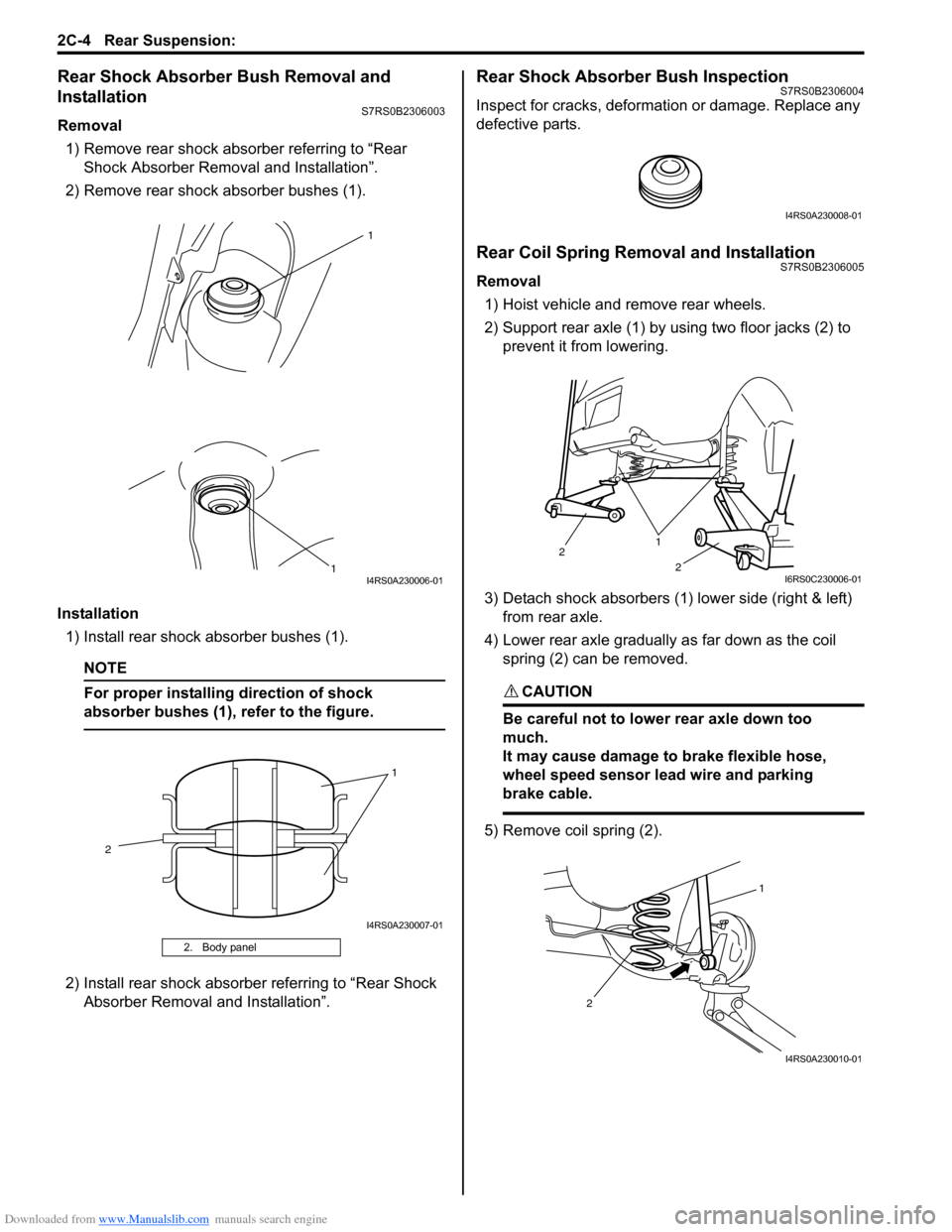

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 464 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-10 Rear Suspension:

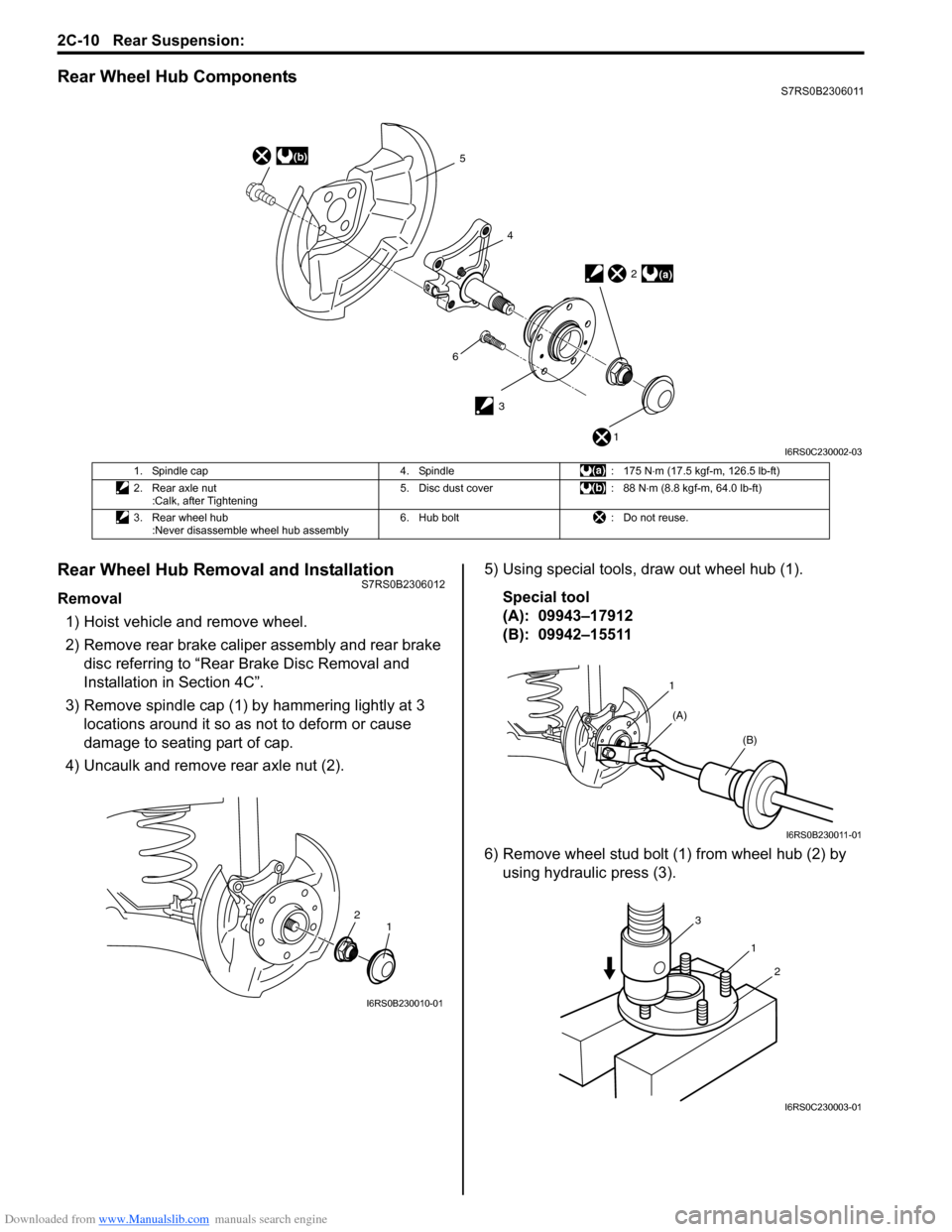

Rear Wheel Hub ComponentsS7RS0B2306011

Rear Wheel Hub Removal and InstallationS7RS0B2306012

Removal1) Hoist vehicle and remove wheel.

2) Remove rear brake caliper assembly and rear brake disc referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

3) Remove spindle cap (1) by hammering lightly at 3 locations around it so as not to deform or cause

damage to seating part of cap.

4) Uncaulk and remove rear axle nut (2). 5) Using special tools, draw out wheel hub (1).

Special tool

(A): 09943–17912

(B): 09942–15511

6) Remove wheel stud bolt (1) from wheel hub (2) by using hydraulic press (3).

(b)5

4

3

(a)2

1

6

I6RS0C230002-03

1. Spindle cap 4. Spindle: 175 N⋅m (17.5 kgf-m, 126.5 lb-ft)

2. Rear axle nut :Calk, after Tightening 5. Disc dust cover

: 88 N⋅m (8.8 kgf-m, 64.0 lb-ft)

3. Rear wheel hub :Never disassemble wheel hub assembly 6. Hub bolt

: Do not reuse.

2

1

I6RS0B230010-01

1

(A) (B)

I6RS0B230011-01

1

3

2

I6RS0C230003-01

Page 465 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-11

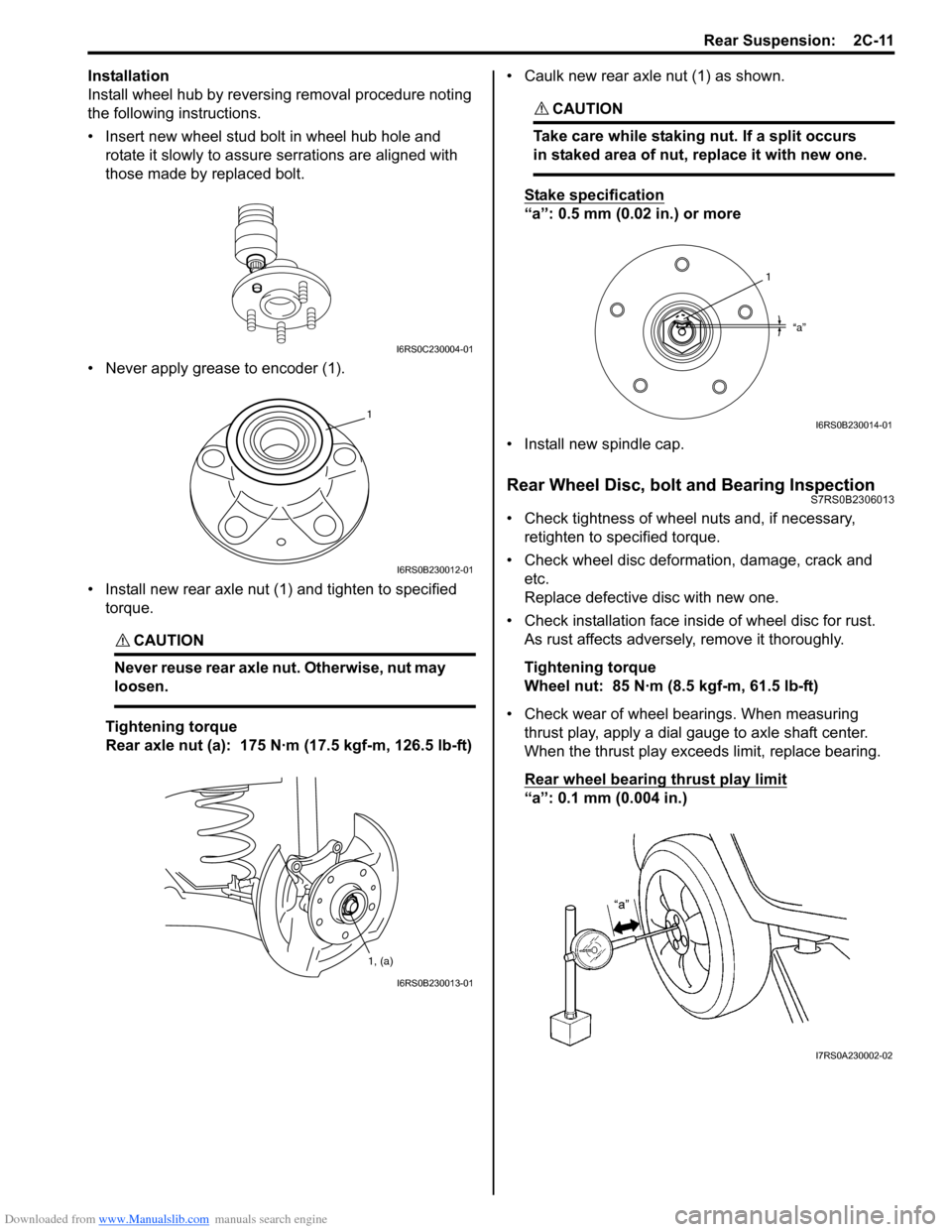

Installation

Install wheel hub by reversing removal procedure noting

the following instructions.

• Insert new wheel stud bolt in wheel hub hole and rotate it slowly to assure serrations are aligned with

those made by replaced bolt.

• Never apply grease to encoder (1).

• Install new rear axle nut (1) and tighten to specified torque.

CAUTION!

Never reuse rear axle nut. Otherwise, nut may

loosen.

Tightening torque

Rear axle nut (a): 175 N·m (17.5 kgf-m, 126.5 lb-ft) • Caulk new rear axle nut (1) as shown.

CAUTION!

Take care while staking nut. If a split occurs

in staked area of nut,

replace it with new one.

Stake specification

“a”: 0.5 mm (0.02 in.) or more

• Install new spindle cap.

Rear Wheel Disc, bolt and Bearing InspectionS7RS0B2306013

• Check tightness of wheel nuts and, if necessary, retighten to specified torque.

• Check wheel disc deformation, damage, crack and etc.

Replace defective disc with new one.

• Check installation face insi de of wheel disc for rust.

As rust affects adversely, remove it thoroughly.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearings. When measuring thrust play, apply a dial gauge to axle shaft center.

When the thrust play exce eds limit, replace bearing.

Rear wheel bearing thrust play

limit

“a”: 0.1 mm (0.004 in.)

I6RS0C230004-01

1

I6RS0B230012-01

1, (a)

I6RS0B230013-01

1

“a”

I6RS0B230014-01

I7RS0A230002-02

Page 1181 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

Connector Layout Diagram

Connector Layout DiagramS7RS0B910A001

Refer to “Engine Compartment”.

Refer to “Instrument Panel”.

Refer to “Door, Roof”.

Refer to “Floor”.

Refer to “Rear”.

ESP

® is a registered trademark of Daimler Chrysler AG.

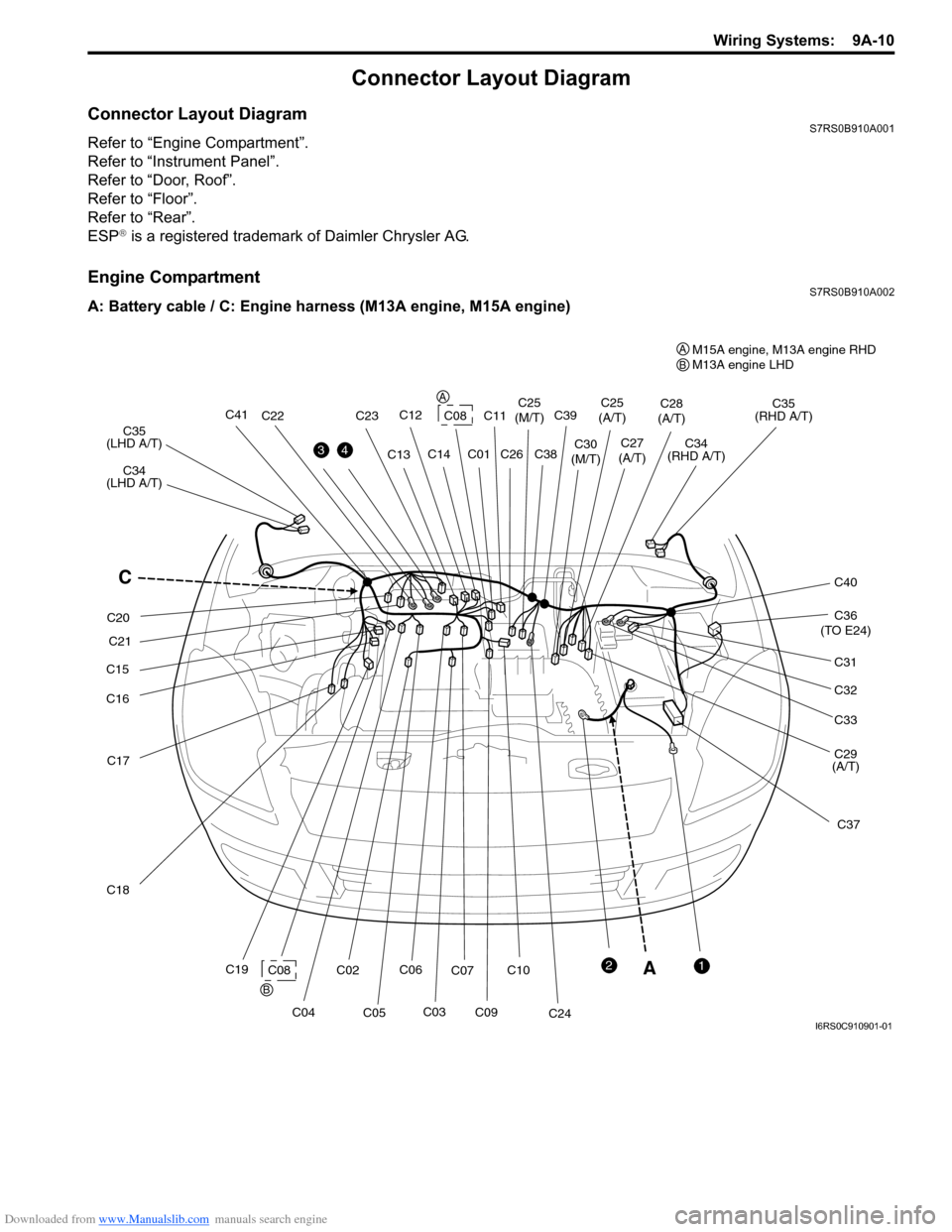

Engine CompartmentS7RS0B910A002

A: Battery cable / C: Engine harness (M13A engine, M15A engine)

A

C36

(TO E24)

C17

C18

C19 C35

(RHD A/T)

C34

(LHD A/T) C35

(LHD A/T) C34

(RHD A/T)

C37

C15

C16

C02C08

C03

C10

C0912

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)

C24

C25

(M/T)

C26

C07

C06

C05

C04

C22

C21

C20 C23

C13

C12C14

C08

C01

CC40

C41C39

C38C11

A

A

B

BM15A engine, M13A engine RHD

M13A engine LHD

I6RS0C910901-01

Page 1182 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-11 Wiring Systems:

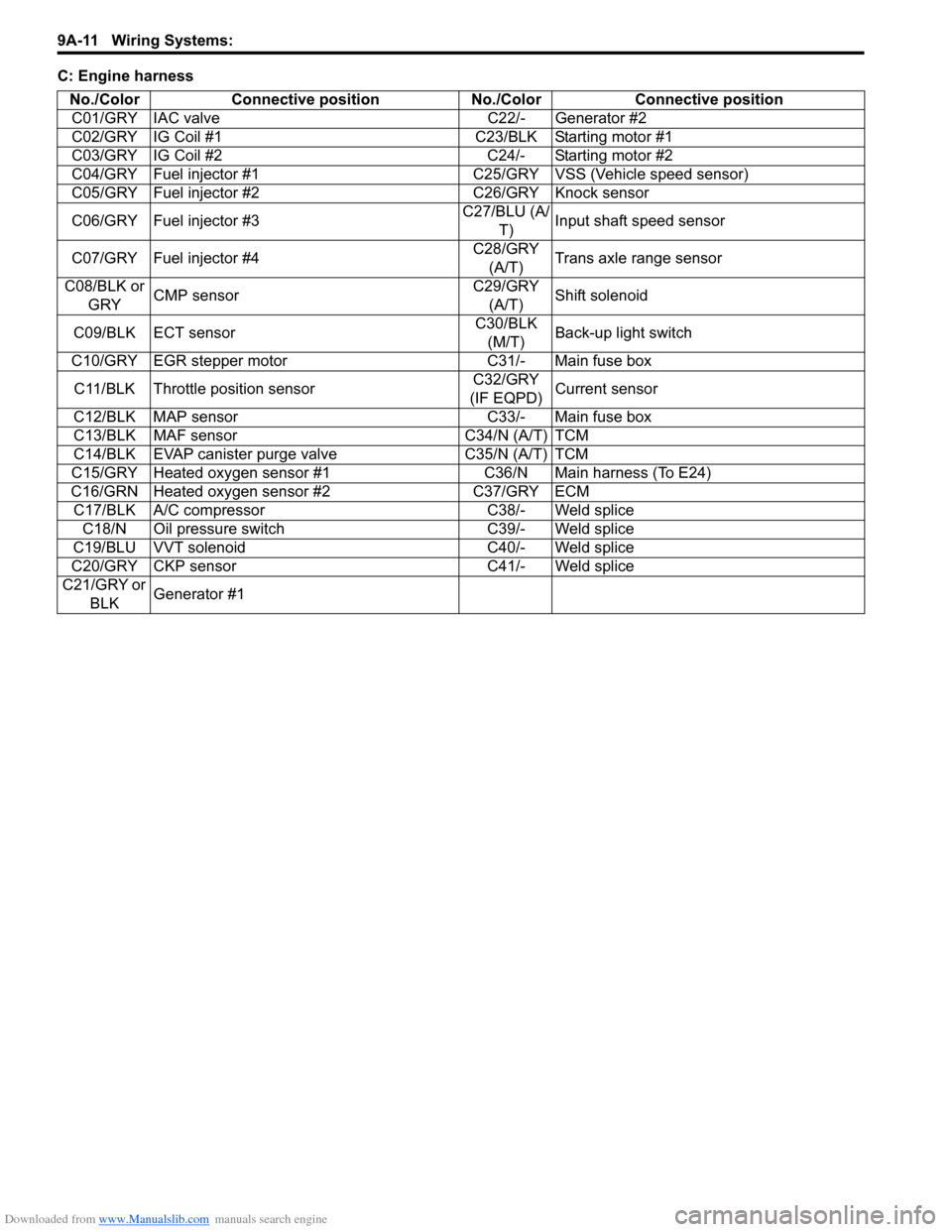

C: Engine harnessNo./Color Connective position No./Color Connective positionC01/GRY IAC valve C22/- Generator #2

C02/GRY IG Coil #1 C23/BLK Starting motor #1

C03/GRY IG Coil #2 C24/- Starting motor #2

C04/GRY Fuel injector #1 C25/GR Y VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK or GRY CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C11/BLK Throttle position sensor C32/GRY

(IF EQPD) Current sensor

C12/BLK MAP sensor C33/- Main fuse box

C13/BLK MAF sensor C34/N (A/T) TCM

C14/BLK EVAP canister purge valve C35/N (A/T) TCM

C15/GRY Heated oxygen sensor #1 C36/N Main harness (To E24)

C16/GRN Heated oxygen sensor #2 C37/GRY ECM C17/BLK A/C compressor C38/- Weld splice C18/N Oil pressure switch C39/- Weld splice

C19/BLU VVT solenoid C40/- Weld splice

C20/GRY CKP sensor C41/- Weld splice

C21/GRY or BLK Generator #1

Page 1183 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-12

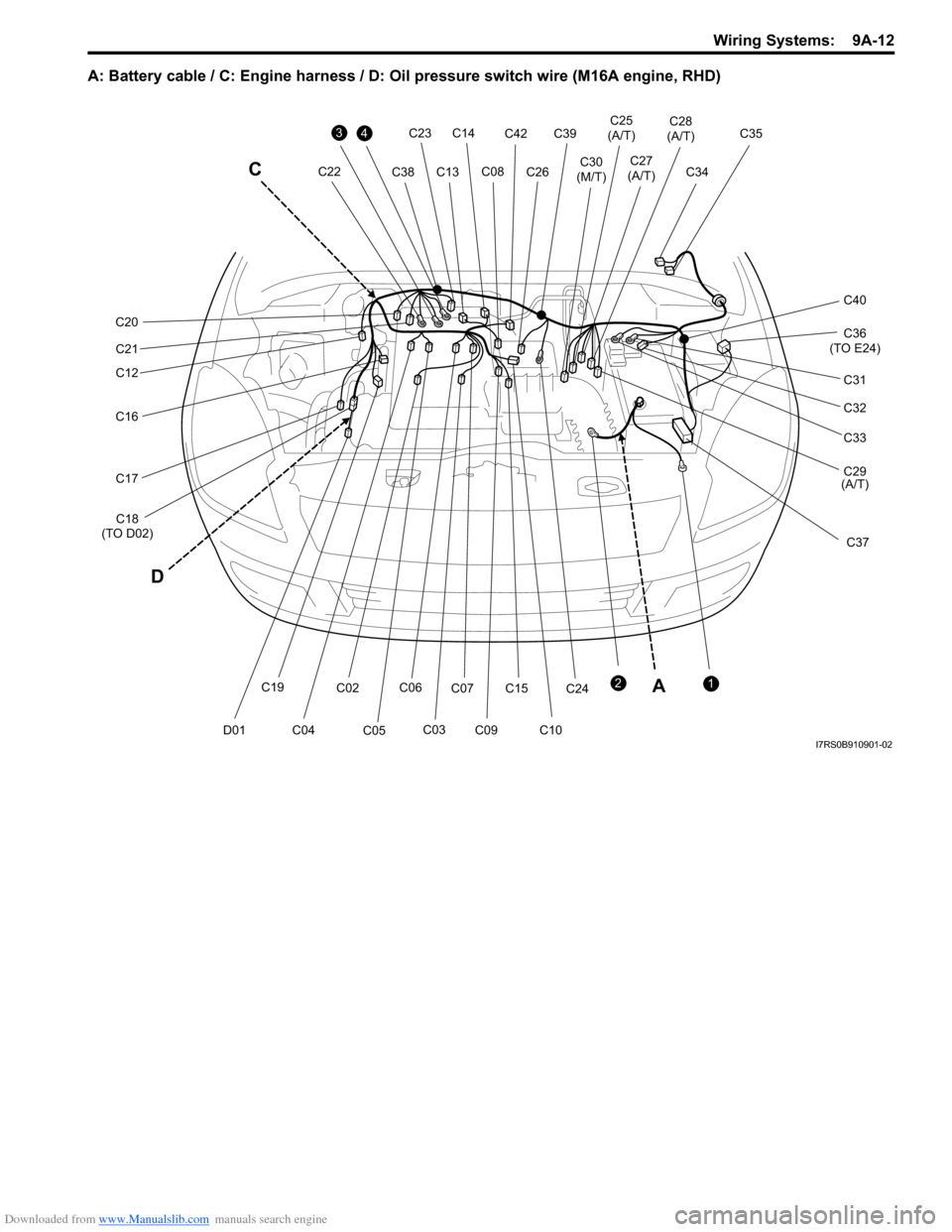

A: Battery cable / C: Engine harness / D: Oil pressure switch wire (M16A engine, RHD)

C36

(TO E24)

C35

C34

C37

34

C31

C32

C33

C29

(A/T)

C28

(A/T)

C27

(A/T)C30

(M/T) C25

(A/T)C26C22 C23C13C38

C14

C08

C40

C39

C42

A

C17

C18

(TO D02)

C19

C16

C02

C03C10

C09

12C24C07C15

C06

C05

C04D01

C21

C12

C20

C

D

I7RS0B910901-02

Page 1184 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

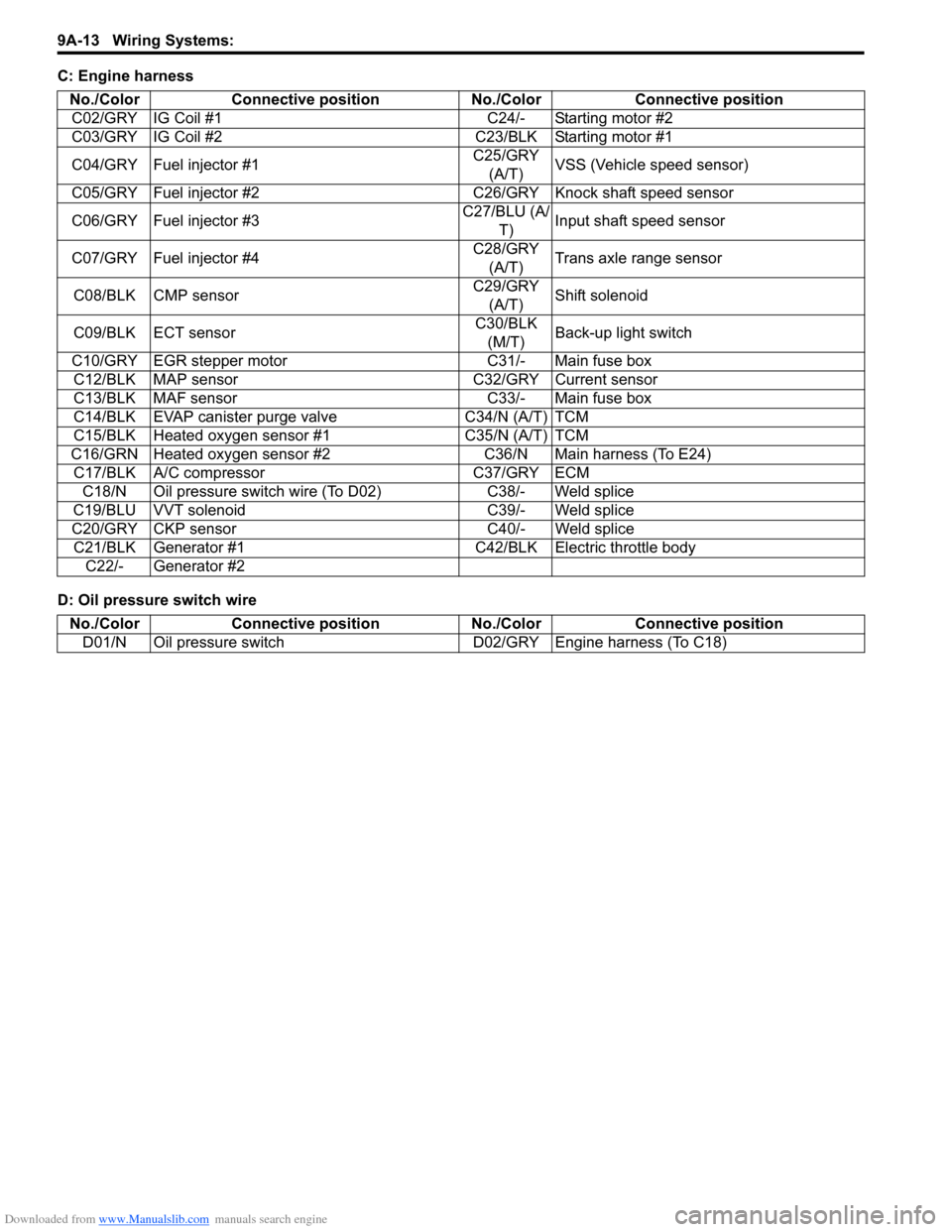

C: Engine harness

D: Oil pressure switch wireNo./Color Connective position No./Color Connective position

C02/GRY IG Coil #1 C24/- Starting motor #2

C03/GRY IG Coil #2 C23/BLK Starting motor #1

C04/GRY Fuel injector #1 C25/GRY

(A/T) VSS (Vehicle speed sensor)

C05/GRY Fuel injector #2 C26/GRY Knock shaft speed sensor

C06/GRY Fuel injector #3 C27/BLU (A/

T) Input shaft speed sensor

C07/GRY Fuel injector #4 C28/GRY

(A/T) Trans axle range sensor

C08/BLK CMP sensor C29/GRY

(A/T) Shift solenoid

C09/BLK ECT sensor C30/BLK

(M/T) Back-up light switch

C10/GRY EGR stepper motor C31/- Main fuse box C12/BLK MAP sensor C32/GRY Current sensor

C13/BLK MAF sensor C33/- Main fuse box

C14/BLK EVAP canister purge valve C34/N (A/T) TCM

C15/BLK Heated oxygen sensor #1 C35/N (A/T) TCM

C16/GRN Heated oxygen sensor #2 C36/N Main harness (To E24) C17/BLK A/C compressor C37/GRY ECM C18/N Oil pressure switch wire (To D02) C38/- Weld splice

C19/BLU VVT solenoid C39/- Weld splice

C20/GRY CKP sensor C40/- Weld splice C21/BLK Generator #1 C42/BLK Electric throttle body C22/- Generator #2

No./Color Connective position No./ColorConnective position

D01/N Oil pressure switch D02/GRY Engine harness (To C18)

Page 1217 of 1496

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-46

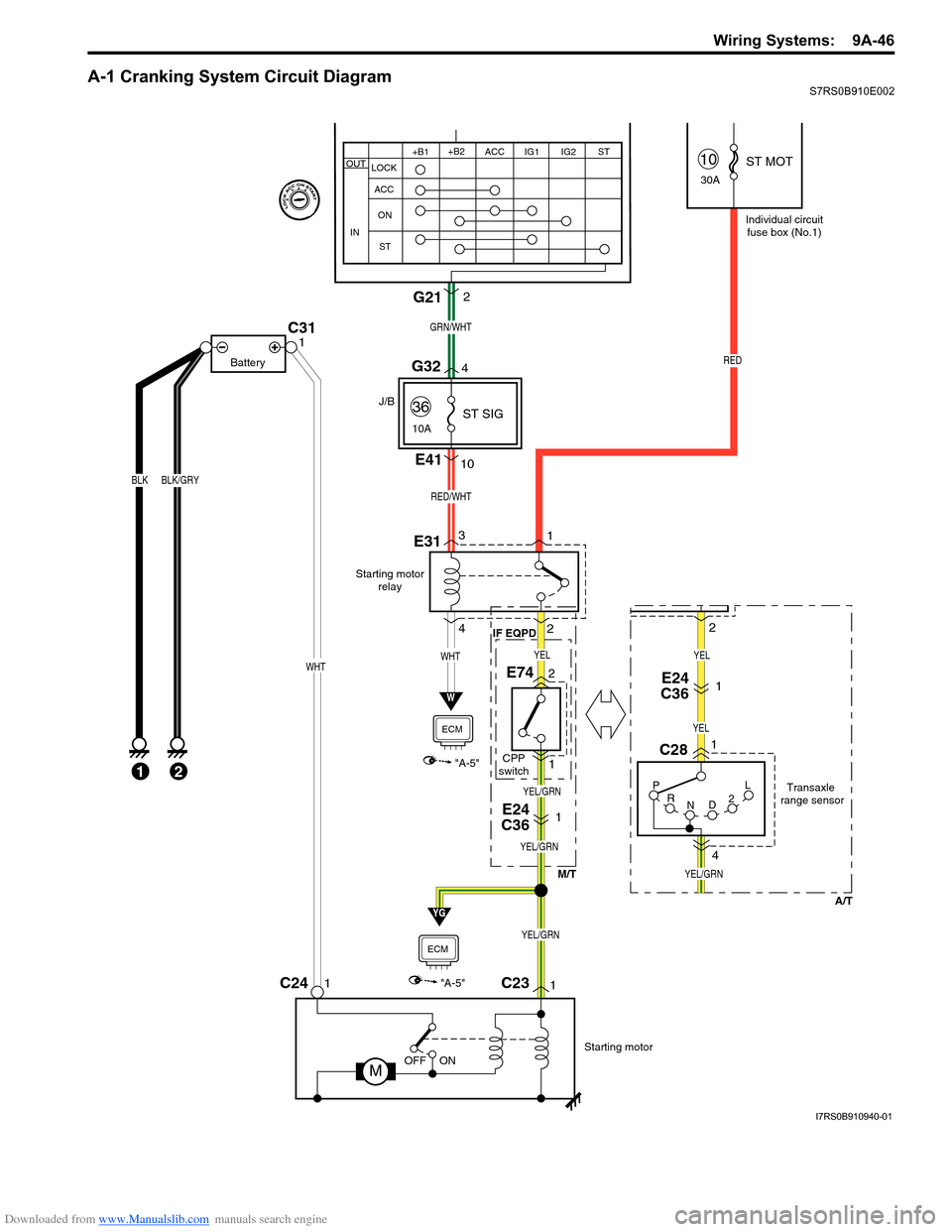

A-1 Cranking System Circuit DiagramS7RS0B910E002

Starting motorrelay

W

"A-5"

ECM

P

R N D2LTransaxle

range sensor

C28

E741

4

E31

C231C241

Starting motor

MOFF ON

BLK

1

BLK/GRY

C311

Battery

E24

C361

RED

Individual circuit

fuse box (No.1)

10

30A

36

10A

WHTWHT

M/T

IF EQPD

E24

C361

J/B

A/T

E4110

13

2

4

RED/WHT

2 ST MOT

ST SIG

YEL/GRN

YG

"A-5"

ECM

GRN/WHT

G212

YEL/GRN

YEL/GRN

YEL

YEL/GRN

YEL

YEL

G324

+B1

LOCK

ACC

ON

ST ACC IG1 IG2

STOUT

IN

+B2

21CPP

switch

2

I7RS0B910940-01