Dtc SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 8 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-3 Precautions:

WARNING!

SDM

• For handling and storage of a SDM, select a place where the ambient temperature

below 65 °C (150 °F), without high humidity

and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic

Module (SDM). Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the

vehicle. All SDM and mounting bracket

fasteners must be carefully torqued and

the arrow must be pointing toward the

front of the vehicle to ensure proper

operation of the air bag system.

The SDM could be activated when powered

while not rigidly att ached to the vehicle

which could cause deployment and result

in personal injury.

WARNING!

Driver and Passenger Seat Belt

Pretensioners

• For handling and storage of a live seat belt pretensioner, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by wire or connector of pretensioner. When

placing a live seat belt pretensioner on the

workbench or some place like that, never

put something on seat belt pretensioner.

Otherwise, personal injury may result.

• Never dispose of live (inactivated) seat belt pretensioners (drive and passenger). If

disposal is necessary, be sure to activate

them according to activation procedures

described in “Air Bag (Inflator) Module and

Seat Belt Pretensioner Disposal in Section

8B” before disposal.

• The seat belt pretensioner immediately after activation is very hot. Wait for at least

half an hour to cool it off before

proceeding the work.

• With many service procedures, gloves and safety glasses should be worn to prevent

any possible irritation of the skin or eyes.

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect system

parts and other related parts according to instructions

under “Repair and Inspection Required after Accident

in Section 8B”.

• When servicing parts other than air bag system, if shocks may be applied to air bag system component

parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger, side and curtain), seat belt pretensioners

(driver and passenger), forward sensor, side sensors

or SDM, be careful not to drop it or apply an impact to

it. If an excessive impact was applied, never attempt

disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passenger, side

and curtain) or seat belt pretensioners (drive and

passenger), wipe off immediately with a dry cloth.

• Air bag wire harness is included in floor and instrument panel wire harnesses. Air bag wire

harness branched off from floor and instrument panel

wire harnesses can be identifie d easily as it is covered

with a yellow protection tube and it has yellow

connectors. Be very ca reful when handling it.

• When an open in air bag wire harness, damaged wire harness, connector or terminal is found, replace wire

harness, connectors and terminals as an assembly.

• Do not apply power to the air bag system unless all components are connected or a diagnostic flow

requests it, as this will set a DTC.

• Never use air bag system component parts from another vehicle.

• When using electric welding, be sure to disconnect all air bag (inflator) module connectors and pretensioner

connectors from air bag wire harness respectively.

• Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

• WARNING / CAUTION labels are attached on each

part of air bag system components. Be sure to follow

the instructions.

• After vehicle is completely repaired, perform “Air Bag Diagnostic System Check in Section 8B”.

Page 10 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-5 Precautions:

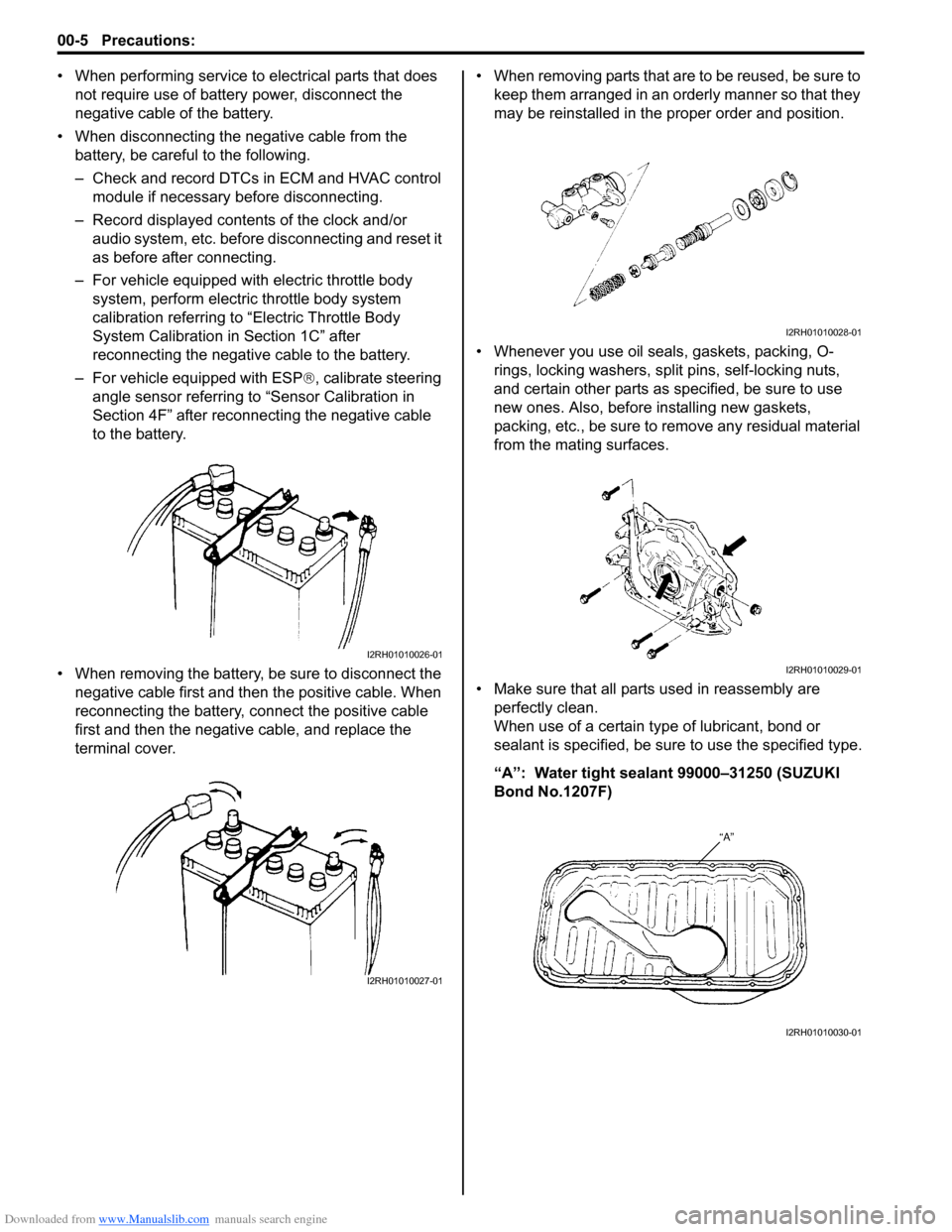

• When performing service to electrical parts that does not require use of battery power, disconnect the

negative cable of the battery.

• When disconnecting the negative cable from the battery, be careful to the following.

– Check and record DTCs in ECM and HVAC control module if necessary before disconnecting.

– Record displayed contents of the clock and/or audio system, etc. before disconnecting and reset it

as before after connecting.

– For vehicle equipped with electric throttle body system, perform electric throttle body system

calibration referring to “Electric Throttle Body

System Calibration in Section 1C” after

reconnecting the negative cable to the battery.

– For vehicle equipped with ESP ®, calibrate steering

angle sensor referring to “Sensor Calibration in

Section 4F” after reconnecting the negative cable

to the battery.

• When removing the battery, be sure to disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable

first and then the negative cable, and replace the

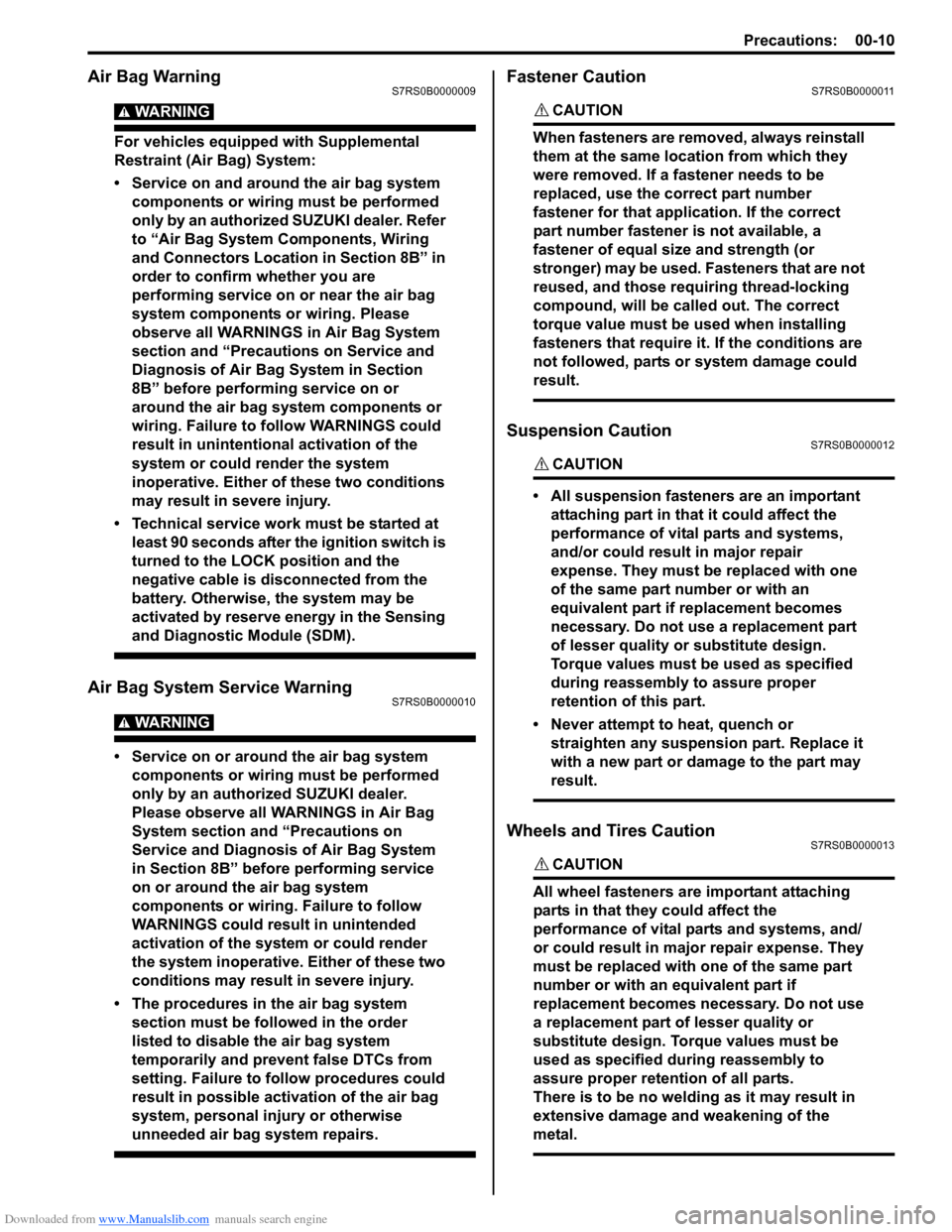

terminal cover. • When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

• Whenever you use oil seals, gaskets, packing, O- rings, locking washers, split pins, self-locking nuts,

and certain other parts as specified, be sure to use

new ones. Also, before installing new gaskets,

packing, etc., be sure to remove any residual material

from the mating surfaces.

• Make sure that all parts used in reassembly are perfectly clean.

When use of a certain type of lubricant, bond or

sealant is specified, be sure to use the specified type.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

I2RH01010026-01

I2RH01010027-01

I2RH01010028-01

I2RH01010029-01

I2RH01010030-01

Page 15 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-10

Air Bag WarningS7RS0B0000009

WARNING!

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer. Refer

to “Air Bag System Components, Wiring

and Connectors Location in Section 8B” in

order to confirm whether you are

performing service on or near the air bag

system components or wiring. Please

observe all WARNINGS in Air Bag System

section and “Precautions on Service and

Diagnosis of Air Bag System in Section

8B” before performing service on or

around the air bag system components or

wiring. Failure to follow WARNINGS could

result in unintentional activation of the

system or could render the system

inoperative. Either of these two conditions

may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is

turned to the LOCK position and the

negative cable is disconnected from the

battery. Otherwise, the system may be

activated by reserve energy in the Sensing

and Diagnostic Module (SDM).

Air Bag System Service WarningS7RS0B0000010

WARNING!

• Service on or around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer.

Please observe all WARNINGS in Air Bag

System section and “Precautions on

Service and Diagnosis of Air Bag System

in Section 8B” before performing service

on or around the air bag system

components or wiring. Failure to follow

WARNINGS could result in unintended

activation of the system or could render

the system inoperative. Either of these two

conditions may result in severe injury.

• The procedures in the air bag system section must be followed in the order

listed to disable the air bag system

temporarily and prevent false DTCs from

setting. Failure to follow procedures could

result in possible activation of the air bag

system, personal injury or otherwise

unneeded air bag system repairs.

Fastener CautionS7RS0B0000011

CAUTION!

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number

fastener for that application. If the correct

part number fastener is not available, a

fastener of equal size and strength (or

stronger) may be used. Fasteners that are not

reused, and those requiring thread-locking

compound, will be called out. The correct

torque value must be used when installing

fasteners that require it. If the conditions are

not followed, parts or system damage could

result.

Suspension CautionS7RS0B0000012

CAUTION!

• All suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems,

and/or could result in major repair

expense. They must be replaced with one

of the same part number or with an

equivalent part if replacement becomes

necessary. Do not use a replacement part

of lesser quality or substitute design.

Torque values must be used as specified

during reassembly to assure proper

retention of this part.

• Never attempt to heat, quench or straighten any suspension part. Replace it

with a new part or damage to the part may

result.

Wheels and Tires CautionS7RS0B0000013

CAUTION!

All wheel fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of the same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts.

There is to be no welding as it may result in

extensive damage and weakening of the

metal.

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 45 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1- i

1

Section 1

CONTENTS

Engine

Precautions ................................................. 1-1

Precautions............................................................. 1-1

Precautions for Engine .......................................... 1-1

Engine General Information and

Diagnosis ............. .................................... 1A-1

Precautions........................................................... 1A-1

Precautions on Engine Service ........................... 1A-1

Precaution on On-Board Diagnostic (OBD) System .............................................................. 1A-1

Precautions in Diagnosing Trouble ..................... 1A-1

Precautions of ECM Circuit Inspection................ 1A-2

Precautions of Electric Throttle Body System

Calibration ......................................................... 1A-2

General Description ............................................. 1A-2 Statement on Cleanliness and Care ................... 1A-2

Engine Diagnosis General Description ............... 1A-3

On-Board Diagnostic System Description ........... 1A-3

Data Link Connector (DLC) ................................. 1A-6

Engine and Emission Control System Description ........................................................ 1A-6

CAN Communication System Description........... 1A-7

Air Intake System Description ............................. 1A-9

Description of Electric Throttle Body System ...... 1A-9

Description of Electric Throttle Body System Calibration ....................................................... 1A-10

Fuel Cut Control Description ............................. 1A-10

Generator Control System Description ............. 1A-11

Electronic Control System Description .............. 1A-12

Engine and Emission Control Input / Output Table ............................................................... 1A-18

Schematic and Routing Diagram ...................... 1A-19 Engine and Emission Control System Diagram .......................................................... 1A-19

Component Locatio n ......................................... 1A-21

Electronic Control System Components Location .......................................................... 1A-21

Diagnostic Information and Procedures .......... 1A-22 Engine and Emission Control System Check.... 1A-22

Malfunction Indicator Lamp (MIL) Check .......... 1A-25

DTC Check ....................................................... 1A-26

DTC Clearance ................................................. 1A-27

DTC Table ......................................................... 1A-27

Fail-Safe Table ................ .................................. 1A-31 Scan Tool Data ................................................. 1A-33

Visual Inspection ............................................... 1A-37

Engine Basic Inspection .................................... 1A-38

Engine Symptom Diagnosis .............................. 1A-41

MIL Does Not Come ON with Ignition Switch

ON and Engine Stop (but Engine Can Be

Started) ........................................................... 1A-47

Malfunction Indicator Lamp Remains ON after Engine Starts................................................... 1A-48

DTC P0010: “A” Camshaft Position Actuator Circuit .............................................................. 1A-49

DTC P0011 / P0012: “A” Camshaft Position - Timing Over-Advanced or System

Performance / -Retarded................................. 1A-52

DTC P0031 / P0032: HO2S Heater Control Circuit Low / High (Sensor-1) .......................... 1A-54

DTC P0037 / P0038: HO2S Heater Control Circuit Low / High (Sensor-2) .......................... 1A-56

DTC P0101: Mass or Volume Air Flow Circuit Range / Performance ...................................... 1A-58

DTC P0102: Mass or Volume Air Flow Circuit Low Input......................................................... 1A-61

DTC P0103: Mass or Volume Air Flow Circuit High Input ........................................................ 1A-63

DTC P0106: Manifold Absolute Pressure /

Barometric Pressure Circuit Range /

Performance.................................................... 1A-64

DTC P0107: Manifold Absolute Pressure /

Barometric Pressure Circ uit Low Input............ 1A-66

DTC P0108: Manifold Absolute Pressure /

Barometric Pressure Circ uit High Input ........... 1A-67

DTC P0111: Intake Air Temperature Sensor 1 Circuit Range / Performance ........................... 1A-69

DTC P0112: Intake Air Temperature Sensor 1 Circuit Low ...................................................... 1A-72

DTC P0113: Intake Air Temperature 1 Sensor Circuit High...................................................... 1A-74

DTC P0116: Engine Coolant Temperature Circuit Range / Performance ........................... 1A-76

DTC P0117: Engine Coolant Temperature Circuit Low ...................................................... 1A-79

DTC P0118: Engine Coolant Temperature Circuit High...................................................... 1A-81

DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low ........................ 1A-83

Page 46 of 1496

Downloaded from www.Manualslib.com manuals search engine 1-ii Table of Contents

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit High ....................... 1A-85

DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

1) ..................................................................... 1A-88

DTC P0133: O2 Sensor (HO2S) Circuit Slow

Response (Sensor- 1) ...................................... 1A-91

DTC P0134: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -1) ........................... 1A-92

DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

2) ..................................................................... 1A-94

DTC P0140: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -2) ........................... 1A-97

DTC P0171 / P0172: Fuel System Too Lean / Rich ................................................................. 1A-98

DTC P0222: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit Low ....................... 1A-100

DTC P0223: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit High ...................... 1A-102

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylin der Misfire Detected

/ Cylinder 1 / Cylinder 2 / Cylinder 3 /

Cylinder 4 Misfire Detected ........................... 1A-105

DTC P0327 / P0328: Knoc k Sensor 1 Circuit

Low / High ..................................................... 1A-107

DTC P0335: Crankshaft Position (CKP) Sensor “A” Circuit .......................................... 1A-109

DTC P0340: Camshaft Position (CMP) Sensor “A” Circuit .......................................... 1A-111

DTC P0350: Ignition Coil Primary / Secondary Circuit ............................................................ 1A-114

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected /

Excessive Detected ...................................... 1A-116

DTC P0403: Exhaust Gas Recirculation Control Circuit ................... ............................ 1A-118

DTC P0420: Catalyst System Efficiency

below Threshold ................ ............................ 1A-120

DTC P0443: Evaporativ e Emission System

Purge Control Valve Circuit ........................... 1A-122

DTC P0480: Fan 1 (Radiator Cooling Fan) Control Circuit ................... ............................ 1A-124

DTC P0500: Vehicle Speed Sensor “A” Malfunction .................................................... 1A-128

DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low ... ............................... 1A-130

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit High ................................. 1A-132

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control

Module Programming Error / Control Module

Performance ................................................. 1A-134

DTC P0616: Starter Relay Circuit Low............ 1A-135

DTC P0617: Starter Relay Circuit High ........... 1A-136

DTC P0620: Generator Control Circuit ........... 1A-137

DTC P0625 / P0626: Generator Field Terminal Circuit Low / High . .......................... 1A-139

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / High . ............................ 1A-141 DTC P1510: ECM Back-Up Power Supply

Malfunction .................................................... 1A-143

DTC P1603: TCM Trouble Code Detected ..... 1A-144

DTC P1674: CAN Communication (Bus Off Error) ............................................................. 1A-145

DTC P1676: CAN Communication (Reception Error for TCM) ............................................... 1A-148

DTC P1678: CAN Communication (Reception Error for BCM) ............................................... 1A-149

DTC P1685: CAN Communication (Reception Error for ABS/ESP ® Control Module) ........... 1A-150

DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance ......................... 1A-152

DTC P2102: Throttle Actuator Control Motor Circuit Low .................................................... 1A-154

DTC P2103: Throttle Actuator Control Motor Circuit High.................................................... 1A-155

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / Closed ...................... 1A-156

DTC P2119: Throttle Actu ator Control Throttle

Body Range / Performance ........................... 1A-157

DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input............. 1A-159

DTC P2123: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit High Input ............ 1A-161

DTC P2127: Throttle Pedal Position Sensor / Switch “E” (Sub) Circuit Low Input ................ 1A-164

DTC P2128: Throttle / Pedal Position Sensor

/ Switc

h “E” (Sub) Circuit High Input ............. 1A-166

DTC P2135: Throttle / Pedal Position Sensor / Switch “A”/“B” (Main / Sub) Voltage

Correlation..................................................... 1A-168

DTC P2138: Throttle / Pedal Position Sensor / Switch “D”/“E” (Main / Sub) Voltage

Correlation..................................................... 1A-171

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit Malfunction ......................... 1A-173

Inspection of ECM and Its Circuits .................. 1A-175

ECM Power and Ground Circuit Check........... 1A-194

Fuel Injector Circuit Check .............................. 1A-198

Fuel Pump and Its Circuit Check..................... 1A-200

Fuel Pressure Check....................................... 1A-203

A/C System Circuits Check ............................. 1A-205

Electric Load Signal Circuit Check .................. 1A-209

Radiator Cooling Fan Low Speed Control System Check ............................................... 1A-211

Radiator Cooling Fan High Speed Control System Check ............................................... 1A-213

Repair Instructions ......... .................................1A-216

Idle Speed and IAC Throttle Valve Opening Inspection ...................................................... 1A-216

Special Tools and Equipmen t .........................1A-217

Special Tool .................................................... 1A-217

Aux. Emission Control Devices ............. 1B-1

Diagnostic Information and Procedures ............1B-1

EGR System Inspection ...................................... 1B-1

Repair Instructions ............ ..................................1B-1

EVAP Canister Purge Inspec tion ........................ 1B-1

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 53 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-3

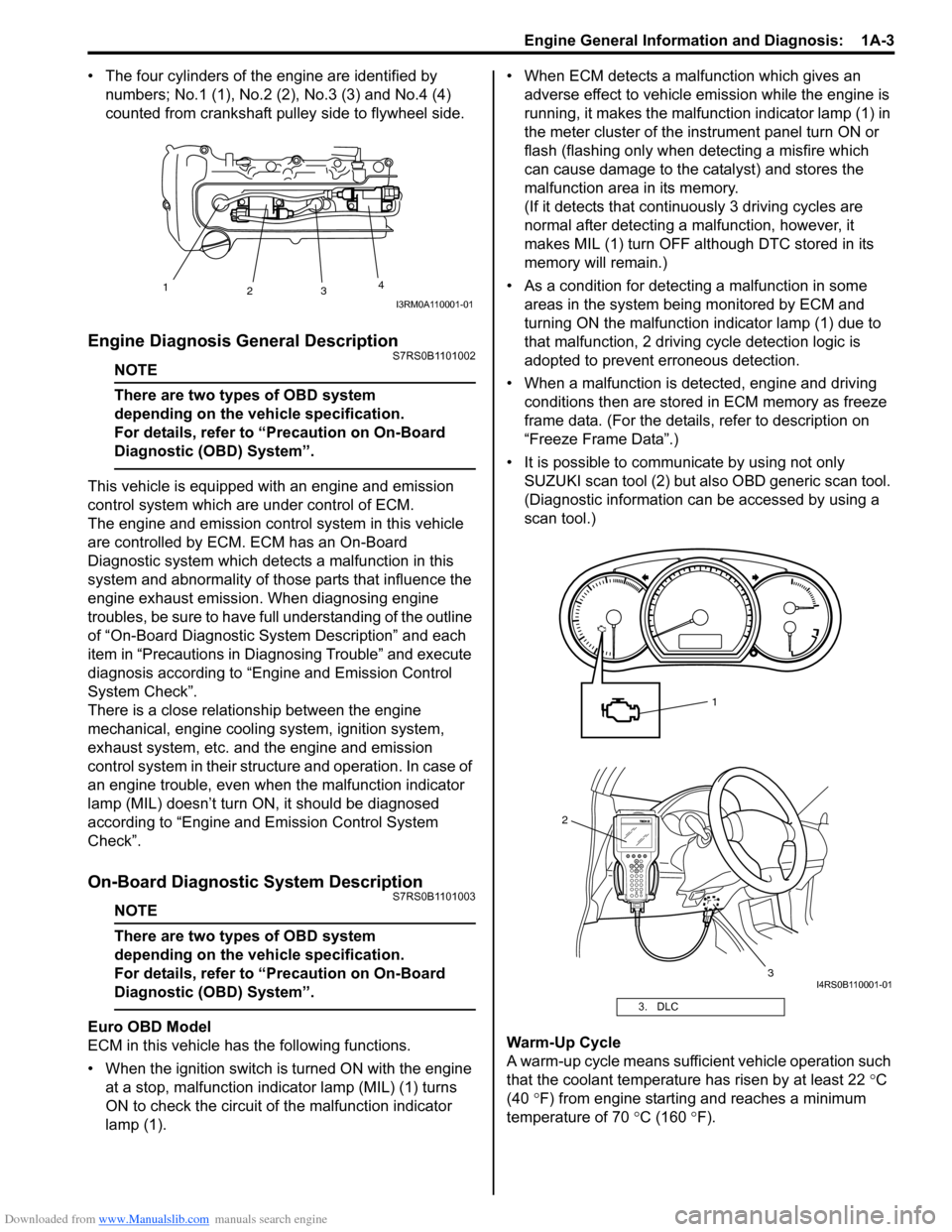

• The four cylinders of the engine are identified by numbers; No.1 (1), No.2 (2 ), No.3 (3) and No.4 (4)

counted from crankshaft pulley side to flywheel side.

Engine Diagnosis General DescriptionS7RS0B1101002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

This vehicle is equipped with an engine and emission

control system which are under control of ECM.

The engine and emission control system in this vehicle

are controlled by ECM. ECM has an On-Board

Diagnostic system which detects a malfunction in this

system and abnormality of those parts that influence the

engine exhaust emission. When diagnosing engine

troubles, be sure to have full understanding of the outline

of “On-Board Diagnostic System Description” and each

item in “Precautions in Diagnosing Trouble” and execute

diagnosis according to “Engine and Emission Control

System Check”.

There is a close relationship between the engine

mechanical, engine cooling system, ignition system,

exhaust system, etc. and the engine and emission

control system in their structure and operation. In case of

an engine trouble, even when the malfunction indicator

lamp (MIL) doesn’t turn ON, it should be diagnosed

according to “Engine and Emission Control System

Check”.

On-Board Diagnostic System DescriptionS7RS0B1101003

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Euro OBD Model

ECM in this vehicle has the following functions.

• When the ignition switch is turned ON with the engine at a stop, malfunction indicator lamp (MIL) (1) turns

ON to check the circuit of the malfunction indicator

lamp (1). • When ECM detects a malfunction which gives an

adverse effect to vehicle emission while the engine is

running, it makes the malfunction indicator lamp (1) in

the meter cluster of the inst rument panel turn ON or

flash (flashing only when detecting a misfire which

can cause damage to the catalyst) and stores the

malfunction area in its memory.

(If it detects that contin uously 3 driving cycles are

normal after detecting a malfunction, however, it

makes MIL (1) turn OFF although DTC stored in its

memory will remain.)

• As a condition for detecting a malfunction in some areas in the system being monitored by ECM and

turning ON the malfunction indicator lamp (1) due to

that malfunction, 2 driving cycle detection logic is

adopted to prevent erroneous detection.

• When a malfunction is detected, engine and driving conditions then are stored in ECM memory as freeze

frame data. (For the details, refer to description on

“Freeze Frame Data”.)

• It is possible to communicate by using not only SUZUKI scan tool (2) but also OBD generic scan tool.

(Diagnostic information can be accessed by using a

scan tool.)

Warm-Up Cycle

A warm-up cycle means sufficie nt vehicle operation such

that the coolant temperature has risen by at least 22 °C

(40 °F) from engine starting and reaches a minimum

temperature of 70 °C (160 ° F).

1

23 4

I3RM0A110001-01

3. DLC

2

3

1

I4RS0B110001-01

Page 54 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-4 Engine General Information and Diagnosis:

Driving Cycle

A “Driving Cycle” consists of engine startup and engine

shutoff.

2 Driving Cycle Detection Logic

The malfunction detected in the first driving cycle is

stored in ECM memory (in t he form of pending DTC) but

the malfunction indicator lamp does not light at this time.

It lights up at the second detection of same malfunction

also in the next driving cycle.

Pending DTC

Pending DTC means a DTC detected and stored

temporarily at 1 driving cycle of the DTC which is

detected in the 2 driving cycle detection logic.

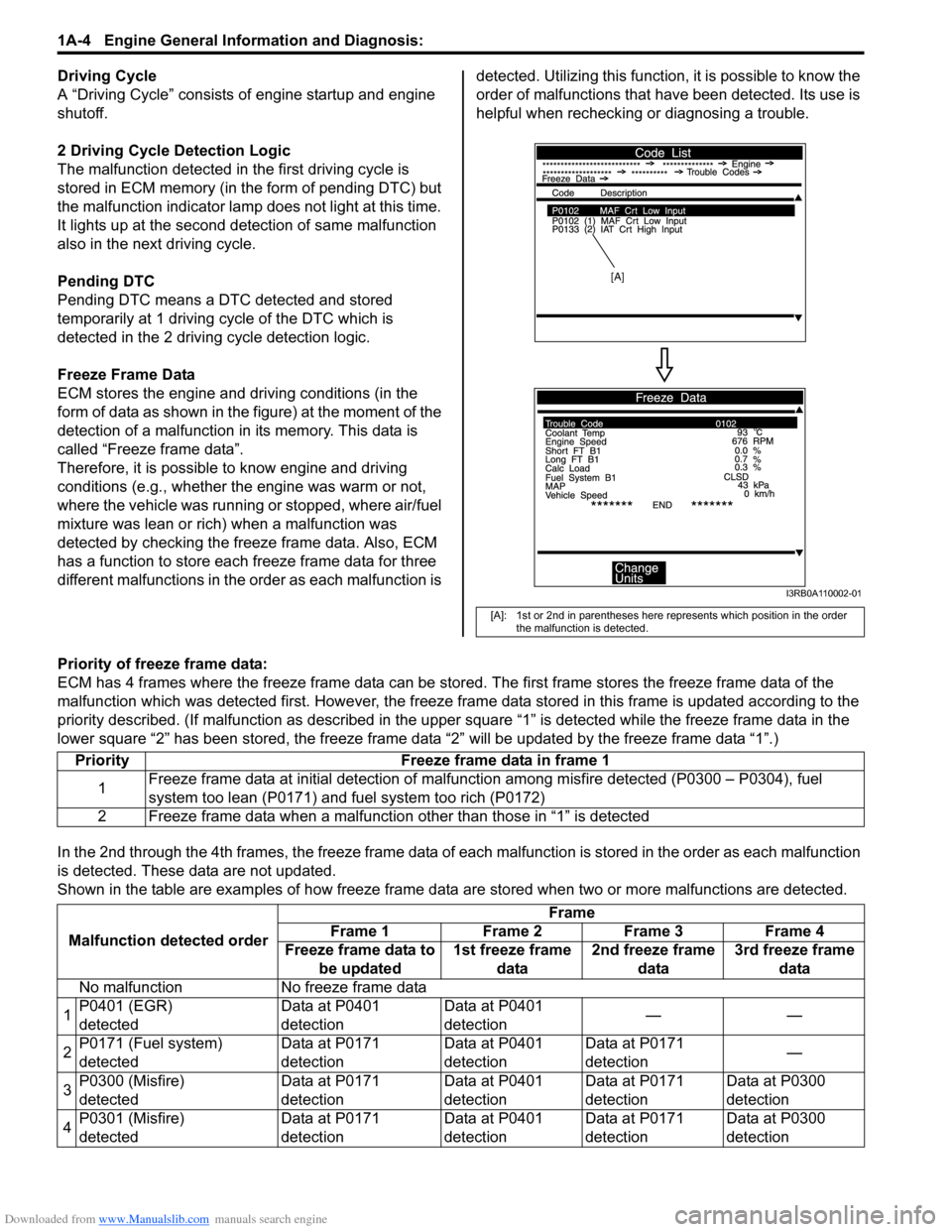

Freeze Frame Data

ECM stores the engine and driving conditions (in the

form of data as shown in the figure) at the moment of the

detection of a malfunction in its memory. This data is

called “Freeze frame data”.

Therefore, it is possible to know engine and driving

conditions (e.g., whether the engine was warm or not,

where the vehicle was running or stopped, where air/fuel

mixture was lean or rich) when a malfunction was

detected by checking the freeze frame data. Also, ECM

has a function to store each freeze frame data for three

different malfunctions in the order as each malfunction is detected. Utilizing this function,

it is possible to know the

order of malfunctions that ha ve been detected. Its use is

helpful when rechecking or diagnosing a trouble.

Priority of freeze frame data:

ECM has 4 frames where the freeze frame data can be stor ed. The first frame stores the freeze frame data of the

malfunction which was detected first. Howe ver, the freeze frame data stored in this frame is updated according to the

priority described. (If malfunction as described in the upper square “1” is detected while the freeze frame data in the

lower square “2” has been stored, the freeze frame data “2” will be updated by the freeze frame data “1”.)

In the 2nd through the 4th frames, the freeze frame data of each malfunction is stored in the order as each malfunction

is detected. These data are not updated.

Shown in the table are examples of how freeze frame data are stored when two or more malfunctions are detected.

[A]: 1st or 2nd in parentheses here represents which position in the order

the malfunction is detected.

[A]

I3RB0A110002-01

Priority Freeze frame data in frame 1

1 Freeze frame data at initial detection of malfuncti

on among misfire detected (P0300 – P0304), fuel

system too lean (P0171) and fuel system too rich (P0172)

2 Freeze frame data when a malfunctio n other than those in “1” is detected

Malfunction detected order Frame

Frame 1 Frame 2 Frame 3 Frame 4

Freeze frame data to be updated 1st freeze frame

data 2nd freeze frame

data 3rd freeze frame

data

No malfunction No freeze frame data

1 P0401 (EGR)

detected Data at P0401

detectionData at P0401

detection

——

2 P0171 (Fuel system)

detected Data at P0171

detectionData at P0401

detectionData at P0171

detection

—

3 P0300 (Misfire)

detected Data at P0171

detectionData at P0401

detectionData at P0171

detectionData at P0300

detection

4 P0301 (Misfire)

detected Data at P0171

detectionData at P0401

detectionData at P0171

detectionData at P0300

detection