Front bumper and rear bumper components SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 354 of 1496

Downloaded from www.Manualslib.com manuals search engine 1E-2 Engine Lubrication System:

Diagnostic Information and Procedures

Oil Pressure CheckS7RS0B1504001

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

NOTE

Prior to checking oil pressure, check the

following.

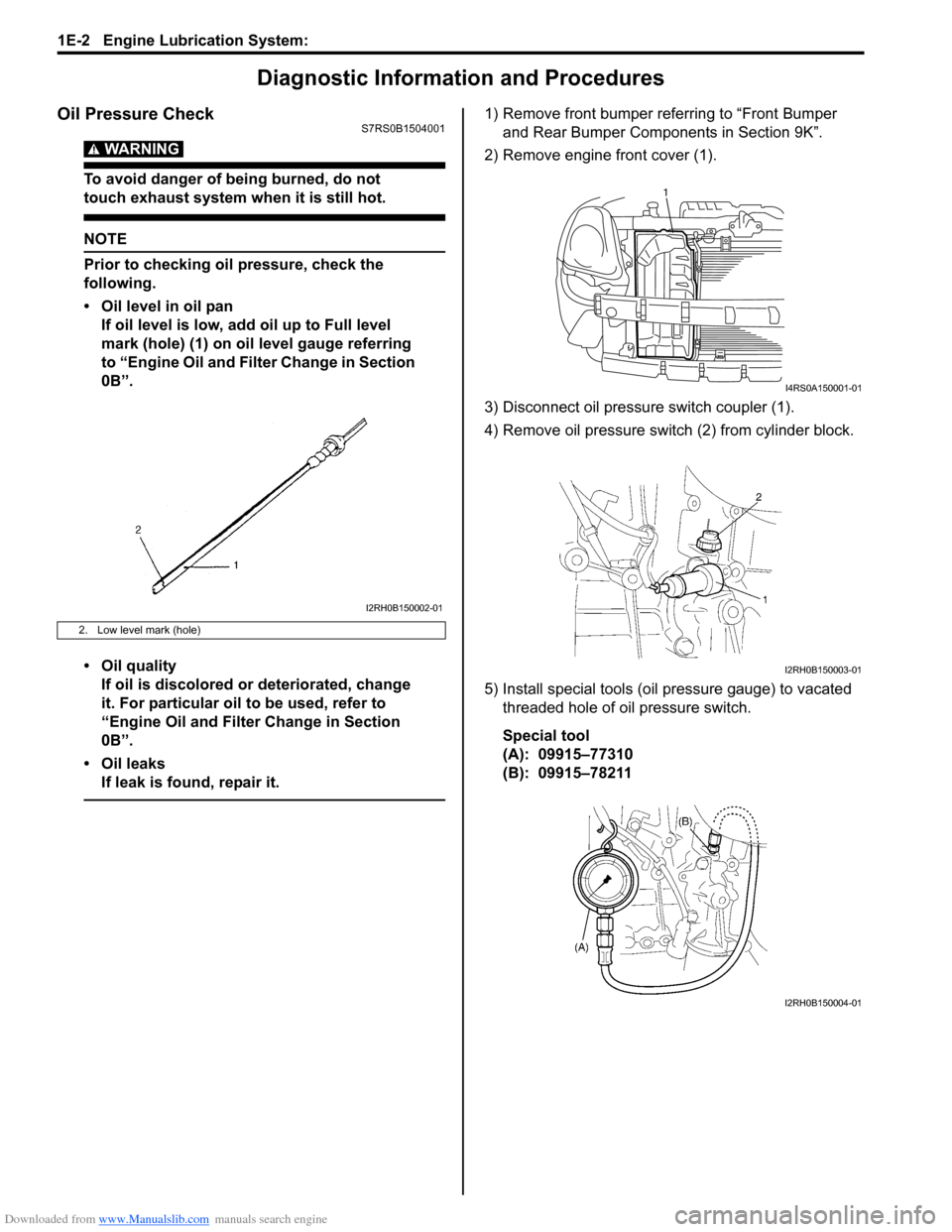

• Oil level in oil pan

If oil level is low, add oil up to Full level

mark (hole) (1) on oil level gauge referring

to “Engine Oil and Filter Change in Section

0B”.

• Oil quality If oil is discolored or deteriorated, change

it. For particular oil to be used, refer to

“Engine Oil and Filter Change in Section

0B”.

• Oil leaks If leak is found, repair it.

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove engine front cover (1).

3) Disconnect oil pressure switch coupler (1).

4) Remove oil pressure swit ch (2) from cylinder block.

5) Install special tools (oil pressure gauge) to vacated threaded hole of oil pressure switch.

Special tool

(A): 09915–77310

(B): 09915–78211

2. Low level mark (hole)

I2RH0B150002-01

1

I4RS0A150001-01

I2RH0B150003-01

I2RH0B150004-01

Page 426 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS7RS0B1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Remove front bumper with front grille referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

4) Remove radiator referring to “Radiator Removal and Installation in Section 1F ” for equipped with A/C.

5) With hose connected, detach A/C condenser from vehicle body for equipped with A/C.

6) Remove exhaust manifold cover from exhaust manifold.

7) Disconnect heated oxygen sensor No.2 connector (1) (connector color: green) and heated oxygen

sensor No.1 connector (2) (connector color: black),

and then detach it from its stay.

8) Remove exhaust manifold stiffener (1).

9) Remove heated oxygen sensors (3) from exhaust manifold and exhaust No.1 pipe, if necessary.

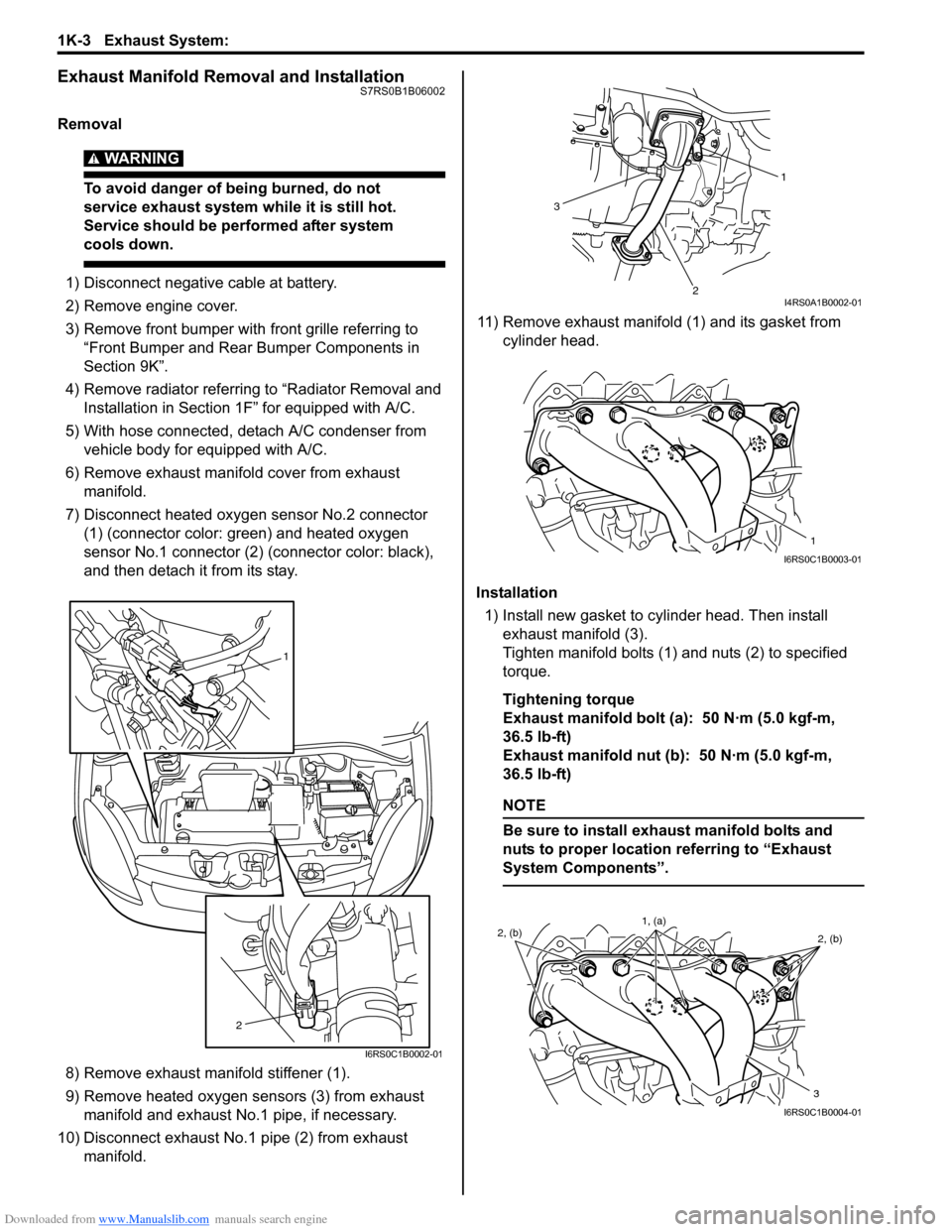

10) Disconnect exhaust No.1 pipe (2) from exhaust manifold. 11) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation 1) Install new gasket to cylinder head. Then install exhaust manifold (3).

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location referring to “Exhaust

System Components”.

1

2

I6RS0C1B0002-01

1

2

3

I4RS0A1B0002-01

1

I6RS0C1B0003-01

2, (b) 2, (b)

3

1, (a)

I6RS0C1B0004-01

Page 427 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

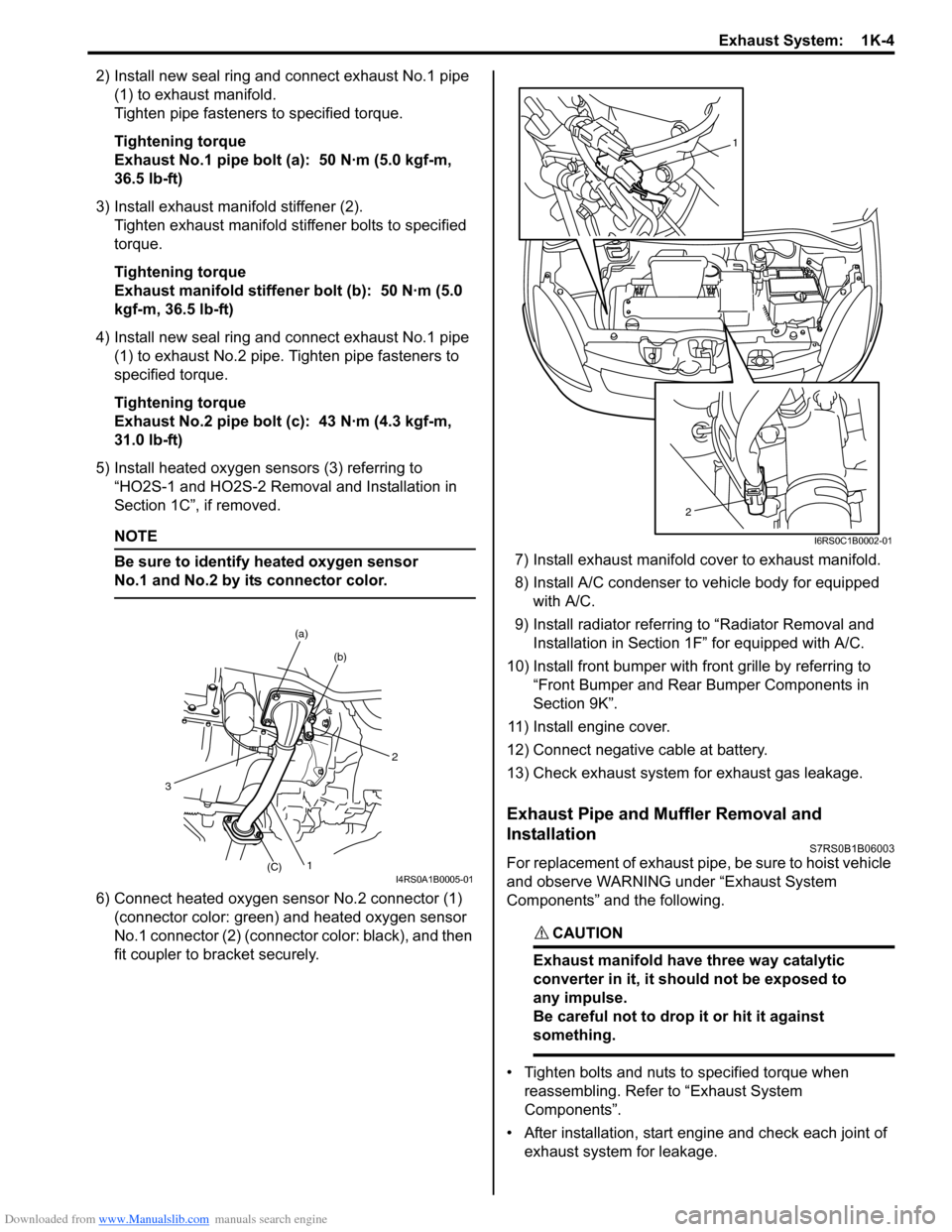

2) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2). Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install heated oxygen sensors (3) referring to “HO2S-1 and HO2S-2 Removal and Installation in

Section 1C”, if removed.

NOTE

Be sure to identify heated oxygen sensor

No.1 and No.2 by its connector color.

6) Connect heated oxygen sensor No.2 connector (1)

(connector color: green) and heated oxygen sensor

No.1 connector (2) (connector color: black), and then

fit coupler to br acket securely. 7) Install exhaust manifold cover to exhaust manifold.

8) Install A/C condenser to vehicle body for equipped

with A/C.

9) Install radiator referrin g to “Radiator Removal and

Installation in Section 1F” for equipped with A/C.

10) Install front bumper with fr ont grille by referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

11) Install engine cover.

12) Connect negative cable at battery.

13) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S7RS0B1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of exhaust system for leakage.

2

(b)

(a)

1(C)

3

I4RS0A1B0005-01

1

2

I6RS0C1B0002-01

Page 969 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set. (The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service valves. This operation must be performed quickly.

5) Put caps on service valves.

Check A/C System for Refrigerant Leaks

Whenever a refrigerant leak is suspected in the system

or any service operation has been performed which may

result in malfunction of lines and connections, it is

advisable to check for leaks.

Common sense should be used during refrigerant leak

test, since the need and extent of any such test will, in

general, depend upon the nature of a complaint and the

type of a service performed on the system.

Liquid leak detector

WARNING!

• To prevent explosions and fires, make sure that there are no flammables in the vicinity.

• When the refrigerant exposed to fire, it turns into a poisonous gas (phosgene). Do

not inhale this gas.

There is a number of fittings and places throughout the

A/C system where a liquid leak detector solution may be

used to pinpoint refrigerant leaks.

By merely applying the solution to the area in question

with a swab, such as attached to the cap of a vial,

bubbles will form within seconds if there is a leak.

For confined areas, such as sections of the evaporator

and condenser, an electronic (refrigerant) leak detector

is more practical fo r determining leaks.

Special tool

(A): 09990–86012

Condenser Assembly On-Vehicle InspectionS7RS0B7216002

Check the followings.

• Clog of condenser fins If any clog is found, cond enser fins should be washed

with water and should be dried with compressed air.

• Condenser fins for leakage and breakage If any defects are found, repair or replace condenser.

• Condenser fittings for leakage. If any defects are found, repair or replace condenser.

Condenser Assembly Removal and InstallationS7RS0B7216003

CAUTION!

Do not damage condenser fins. If condenser

fin is bent, straighten it by using flat head

screwdriver or pair of pliers.

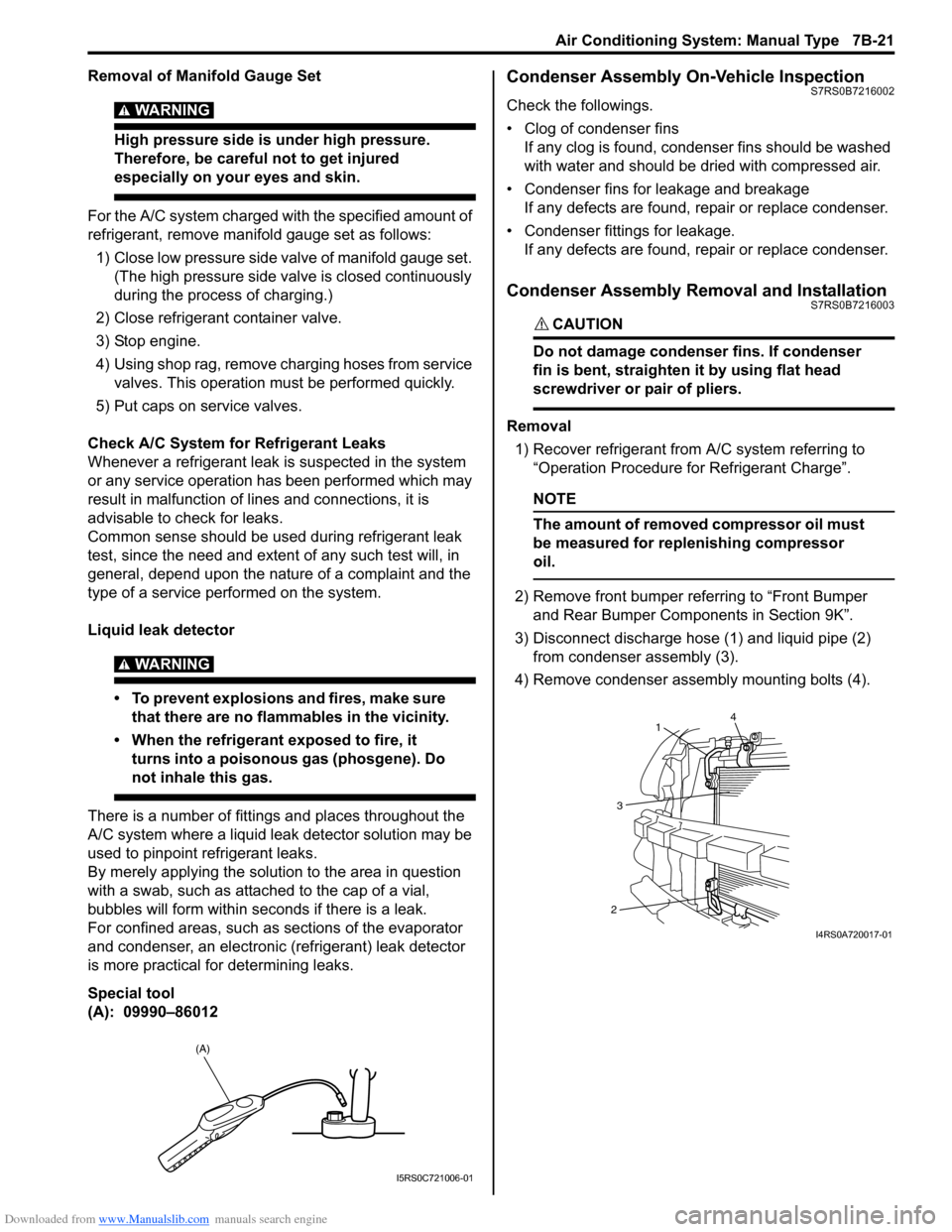

Removal

1) Recover refrigerant from A/C system referring to “Operation Procedure for Refrigerant Charge”.

NOTE

The amount of removed compressor oil must

be measured for replenishing compressor

oil.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect discharge hose (1) and liquid pipe (2) from condenser assembly (3).

4) Remove condenser assembly mounting bolts (4).

(A)

I5RS0C721006-01

4

1

3

2

I4RS0A720017-01

Page 970 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-22 Air Conditioning System: Manual Type

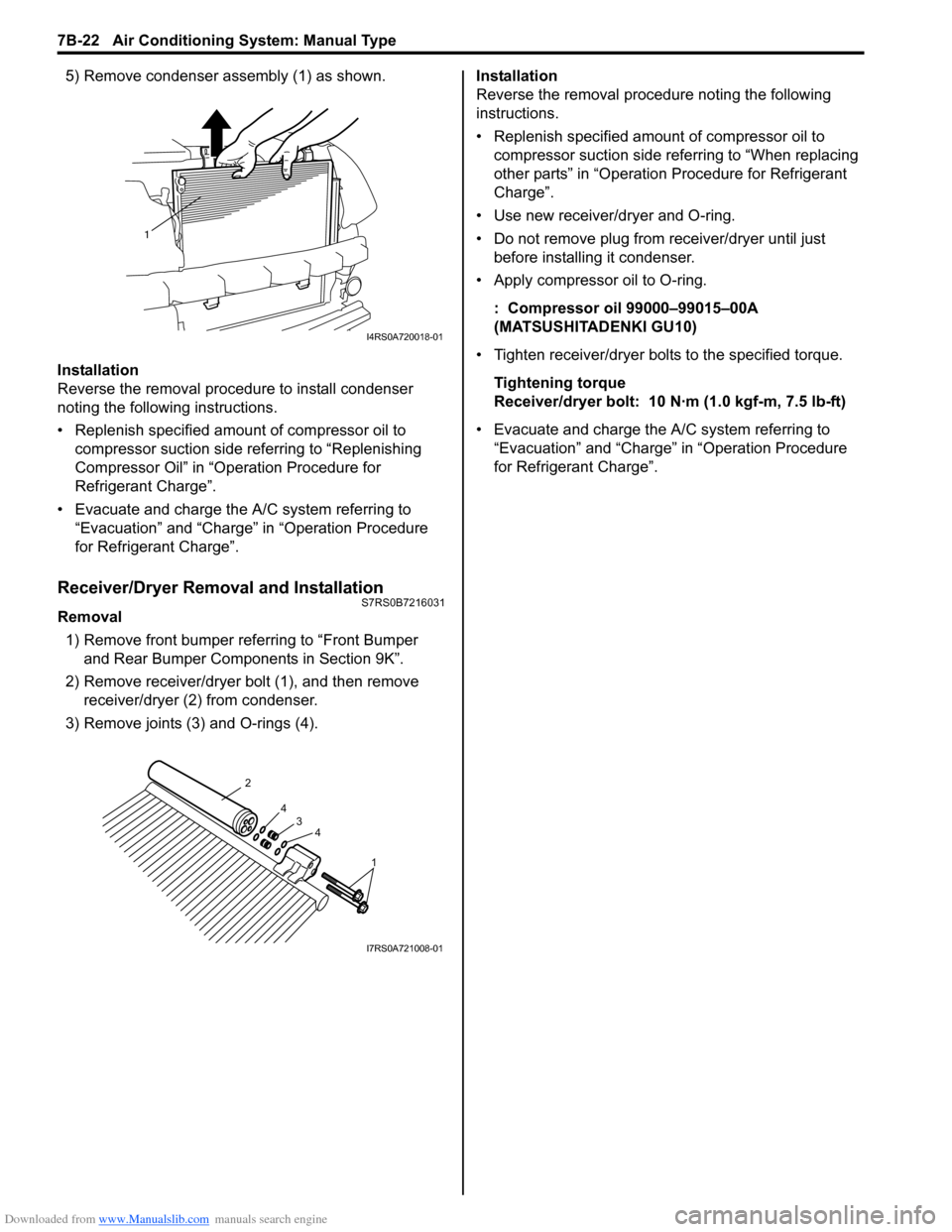

5) Remove condenser assembly (1) as shown.

Installation

Reverse the removal procedure to install condenser

noting the following instructions.

• Replenish specified amount of compressor oil to compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

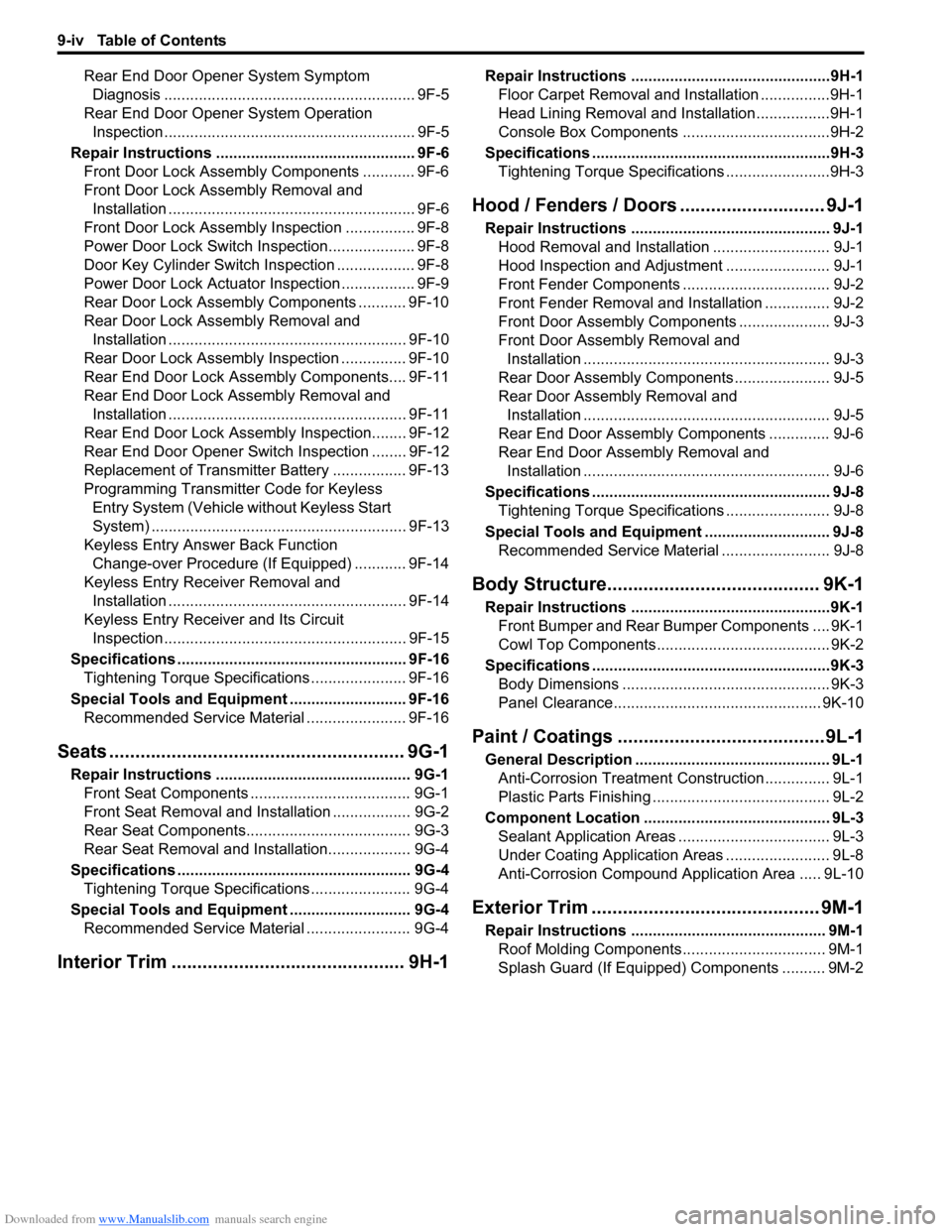

Receiver/Dryer Removal and InstallationS7RS0B7216031

Removal

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove receiver/dryer bolt (1), and then remove receiver/dryer (2) from condenser.

3) Remove joints (3) and O-rings (4). Installation

Reverse the removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “When replacing

other parts” in “Operation Procedure for Refrigerant

Charge”.

• Use new receiver/dryer and O-ring.

• Do not remove plug from receiver/dryer until just before installin g it condenser.

• Apply compressor oil to O-ring.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

• Tighten receiver/dryer bolts to the specified torque. Tightening torque

Receiver/dryer bolt: 10 N· m (1.0 kgf-m, 7.5 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

I4RS0A720018-01

1

4

4

3

2

I7RS0A721008-01

Page 1170 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Rear End Door Opener System Symptom Diagnosis .......................................................... 9F-5

Rear End Door Opener System Operation Inspection .......................................................... 9F-5

Repair Instructions ........... ................................... 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch In spection.................... 9F-8

Door Key Cylinder Switch Inspection .................. 9F-8

Power Door Lock Actuator Inspection ................. 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and Installation ....................................................... 9F-11

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection ........ 9F-12

Replacement of Transmitte r Battery ................. 9F-13

Programming Transmitter Code for Keyless Entry System (Vehicle without Keyless Start

System) ........................................................... 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation ....................................................... 9F-14

Keyless Entry Receiver and Its Circuit Inspection ........................................................ 9F-15

Specifications .... ................................................. 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipmen t ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ............. ............................................ 9G-1

Repair Instructions ............................................. 9G-1

Front Seat Components ..................................... 9G-1

Front Seat Removal and In stallation .................. 9G-2

Rear Seat Components...................................... 9G-3

Rear Seat Removal and Installation................... 9G-4

Specifications .... .................................................. 9G-4

Tightening Torque Specifications ....................... 9G-4

Special Tools and Equipmen t ............................ 9G-4

Recommended Service Material ........................ 9G-4

Interior Trim ................. ............................ 9H-1

Repair Instructions ............ ..................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-1

Console Box Components ..................................9H-2

Specifications ..................... ..................................9H-3

Tightening Torque Specifications ........................9H-3

Hood / Fenders / Doors ...... ...................... 9J-1

Repair Instructions ............ .................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Comp onents ..................... 9J-3

Front Door Assembly Removal and Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and Installation ......................................................... 9J-6

Specifications ..................... .................................. 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipmen t ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure............... .......................... 9K-1

Repair Instructions ............ ..................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top Components........................................ 9K-2

Specifications ..................... ..................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Paint / Coatings ............. ...........................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ............ ............................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ........................ 9L-8

Anti-Corrosion Compound Application Area ..... 9L-10

Exterior Trim ...... ...................................... 9M-1

Repair Instructions ......... .................................... 9M-1

Roof Molding Components................................. 9M-1

Splash Guard (If Equipped) Components .......... 9M-2

Page 1292 of 1496

Downloaded from www.Manualslib.com manuals search engine 9B-10 Lighting Systems:

Turn Signal and Hazard Warning Relay

Inspection

S7RS0B9206012

1) Connect turn signal and hazard warning relay (1), battery (2) and six test bulbs ((12V, 21W) (3) and 12

V, 5W (4)) as shown.

2) Check turn L circuit Connect terminal “5” and battery negative (–)

terminal by a jumper wire.

Check left side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

3) Check turn R circuit Connect terminal “6” and battery negative (–)

terminal by a jumper wire.

Check right side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute 4) Check Hazard ON circuit

Connect terminal “8” and battery negative (–)

terminal by a jumper wire.

Check all bulbs (1) for flashing cycle.

If check result is not as sp ecified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

License Light Removal and InstallationS7RS0B9206013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear bumper. Refe r to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Disconnect coupler (1) from license light (2).

4) Push locking part to arrow direction, and then remove license light (2).

Installation

Reverse removal procedure for installation.

2

4

33

3

87

12

654

1

I4RS0A920014-01

13

87

12

654

I4RS0A920015-01

3

87

12

6541

I4RS0A920016-01

3

87

12

6

5411

I4RS0A920017-01

2

2

1

2

I4RS0B920010-01

Page 1293 of 1496

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-11

Front Fog Light Removal and Installation (If

Equipped)

S7RS0B9206014

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper, and then remove front bumper guard from front bumper referring to “Front

Bumper and Rear Bumper Components in Section

9K”.

3) Disconnect coupler from fog light.

4) Remove fog light screws (1), and remove front fog light (2).

Installation

Reverse removal procedure for installation nothing the

following:

• After installing, adjust aimi ng referring to “Front Fog

Light Aiming Adjustment with Screen (If Equipped)”.

Front Fog Light Bulb Replacement (If Equipped)S7RS0B9206015

WARNING!

• To avoid danger of being burned, don’t touch when the bulb is hot.

• Don’t touch glass surface of bulb to avoid deteriorate as the case may be unclear

when bulb light on at dirty condition.

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove fog light bulb (1) as shown.

3) Replace fog light bulb and assemble all removed parts.

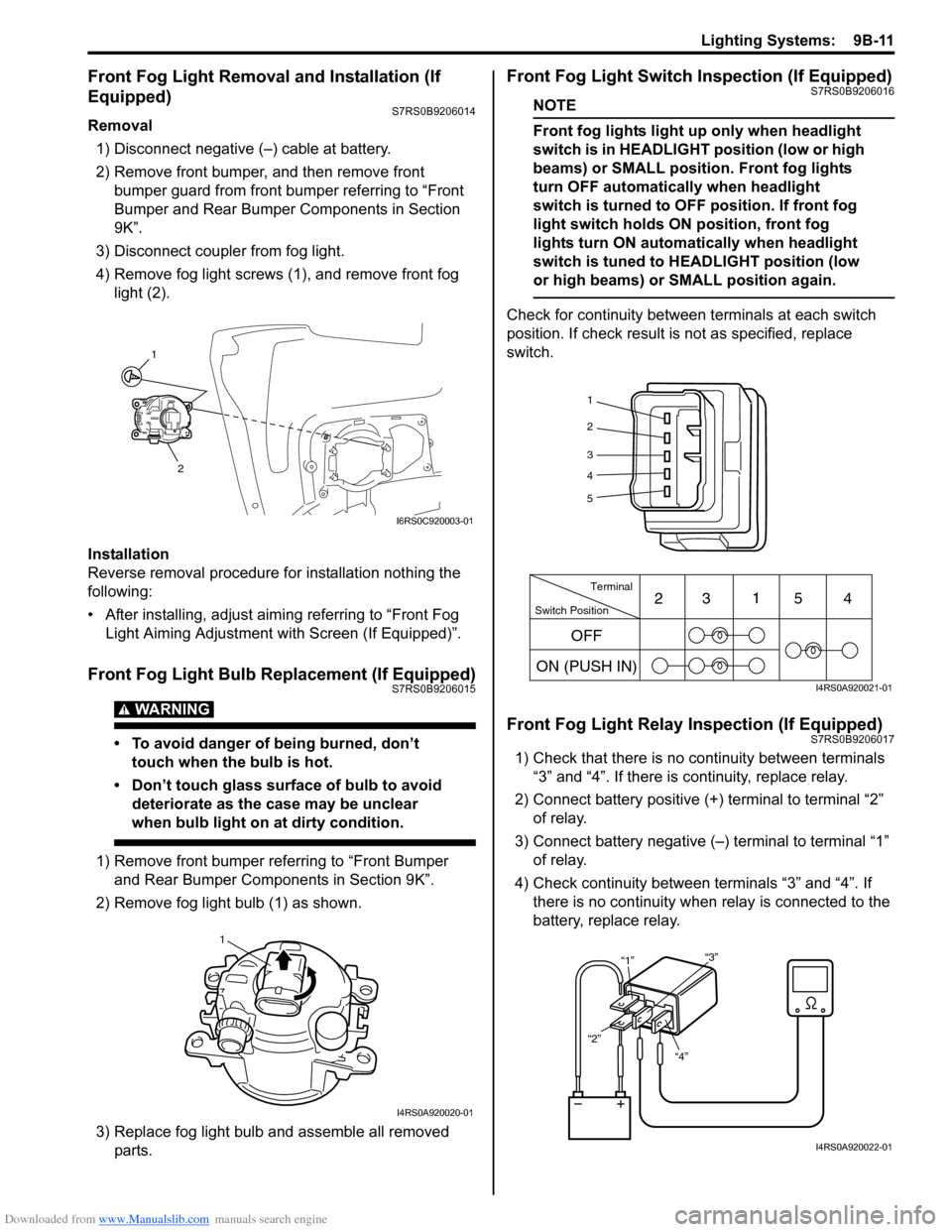

Front Fog Light Switch Inspection (If Equipped)S7RS0B9206016

NOTE

Front fog lights light up only when headlight

switch is in HEADLIGHT position (low or high

beams) or SMALL position. Front fog lights

turn OFF automatically when headlight

switch is turned to OFF position. If front fog

light switch holds ON position, front fog

lights turn ON automa tically when headlight

switch is tuned to HEADLIGHT position (low

or high beams) or SMALL position again.

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Front Fog Light Relay Inspection (If Equipped)S7RS0B9206017

1) Check that there is no continuity between terminals “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminals “3” and “4”. If there is no continuity when relay is connected to the

battery, replace relay.

1

2

I6RS0C920003-01

1

I4RS0A920020-01

1

2

3

4

5

Switch Position Terminal

ON (PUSH IN) 23

1

54

OFF

I4RS0A920021-01

“4”

“2” “1”

“3”

I4RS0A920022-01

Page 1312 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-17 Instrumentation / Driver Info. / Horn:

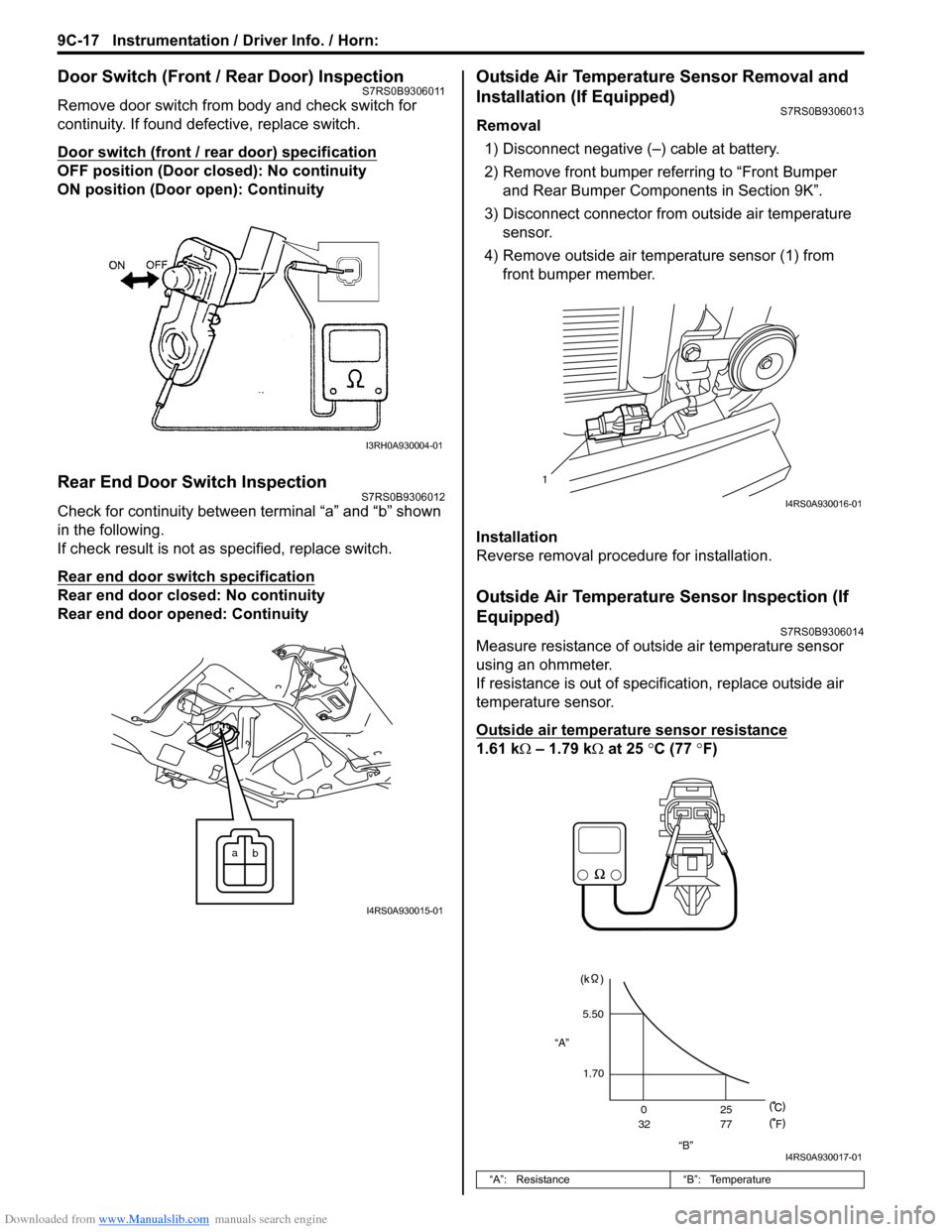

Door Switch (Front / Rear Door) InspectionS7RS0B9306011

Remove door switch from body and check switch for

continuity. If found defective, replace switch.

Door switch (front / rear door) specification

OFF position (Door closed): No continuity

ON position (Door open): Continuity

Rear End Door Switch InspectionS7RS0B9306012

Check for continuity between terminal “a” and “b” shown

in the following.

If check result is not as specified, replace switch.

Rear end door switch specification

Rear end door closed: No continuity

Rear end door opened: Continuity

Outside Air Temperature Sensor Removal and

Installation (If Equipped)

S7RS0B9306013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect connector from outside air temperature sensor.

4) Remove outside air temperature sensor (1) from front bumper member.

Installation

Reverse removal procedure for installation.

Outside Air Temperature Sensor Inspection (If

Equipped)

S7RS0B9306014

Measure resistance of outside air temperature sensor

using an ohmmeter.

If resistance is out of specif ication, replace outside air

temperature sensor.

Outside air temperature sensor resistance

1.61 kΩ – 1.79 k Ω at 25 °C (77 °F)

I3RH0A930004-01

a

b

I4RS0A930015-01

“A”: Resistance “B”: Temperature

1

I4RS0A930016-01

“B”

“A”

5.50

1.70 0

32 25

77

F

I4RS0A930017-01

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

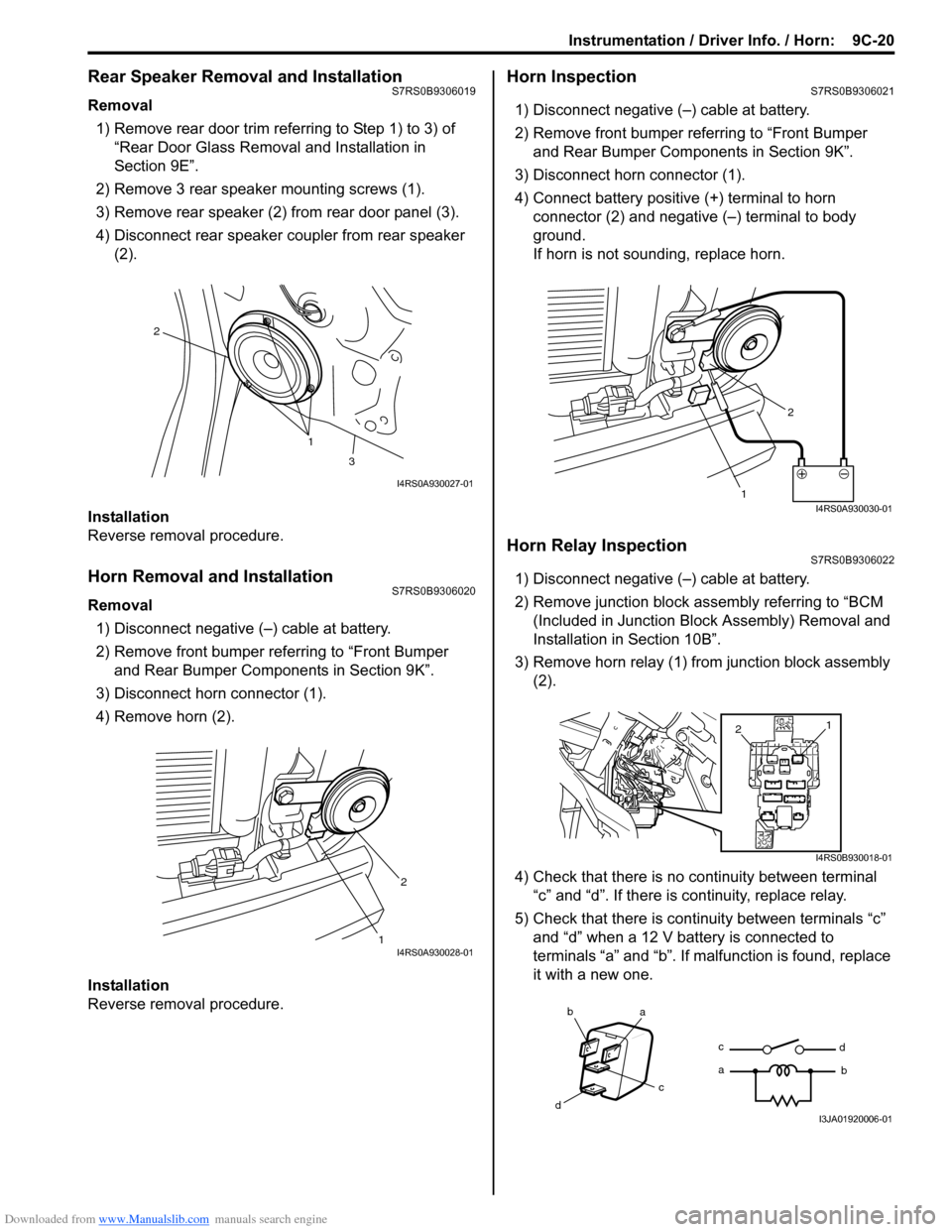

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01