Keyless battery SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 88 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-38 Engine General Information and Diagnosis:

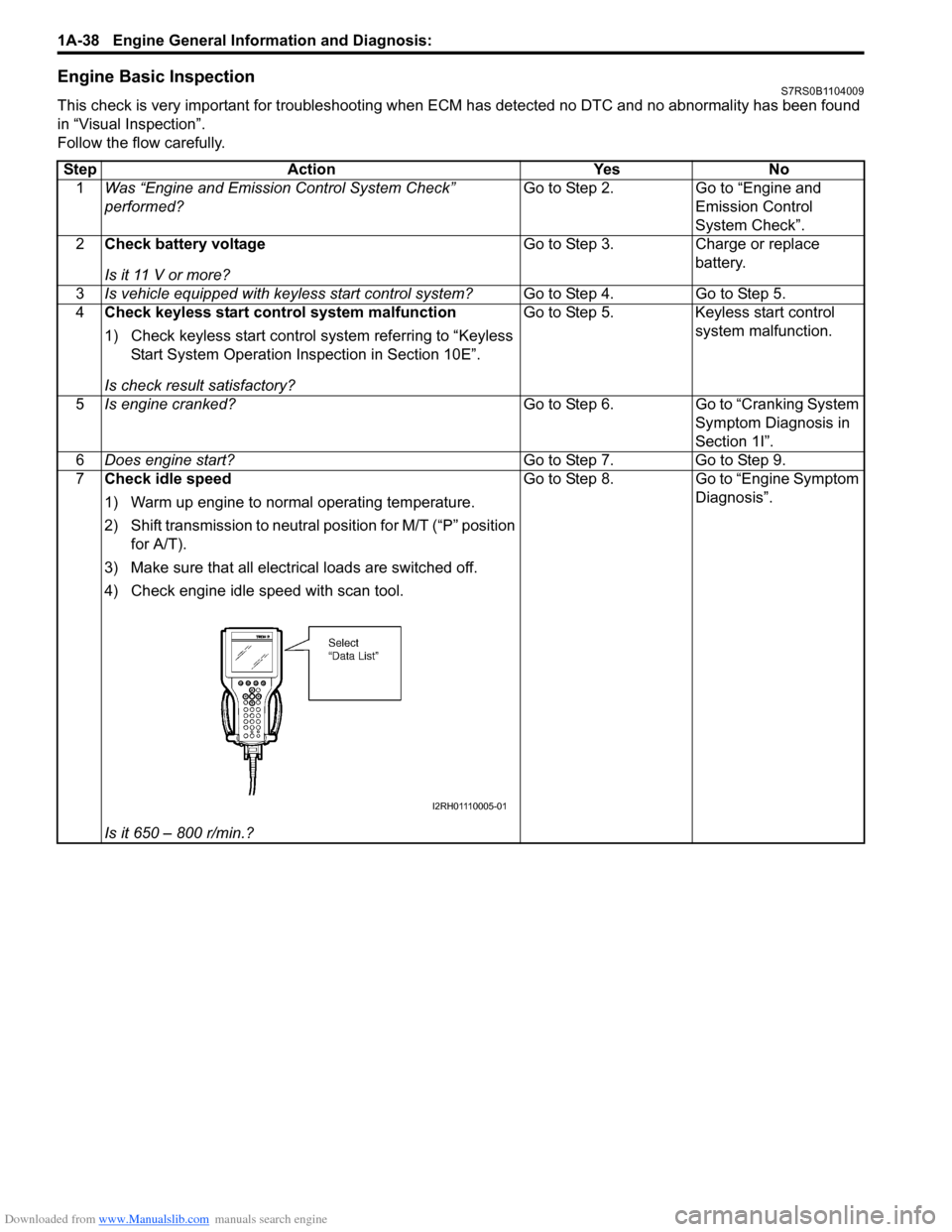

Engine Basic InspectionS7RS0B1104009

This check is very important for troubleshooting when ECM has detected no DTC and no abnormality has been found

in “Visual Inspection”.

Follow the flow carefully.Step Action Yes No 1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Check battery voltage

Is it 11 V or more? Go to Step 3. Charge or replace

battery.

3 Is vehicle equipped with keyless start control system? Go to Step 4. Go to Step 5.

4 Check keyless start control system malfunction

1) Check keyless start control system referring to “Keyless

Start System Operation In spection in Section 10E”.

Is check result satisfactory? Go to Step 5. Keyless start control

system malfunction.

5 Is engine cranked? Go to Step 6. Go to “Cranking System

Symptom Diagnosis in

Section 1I”.

6 Does engine start? Go to Step 7. Go to Step 9.

7 Check idle speed

1) Warm up engine to normal operating temperature.

2) Shift transmission to neutral position for M/T (“P” position

for A/T).

3) Make sure that all electrical loads are switched off.

4) Check engine idle speed with scan tool.

Is it 650 – 800 r/min.? Go to Step 8. Go to “Engine Symptom

Diagnosis”.

I2RH01110005-01

Page 583 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-9

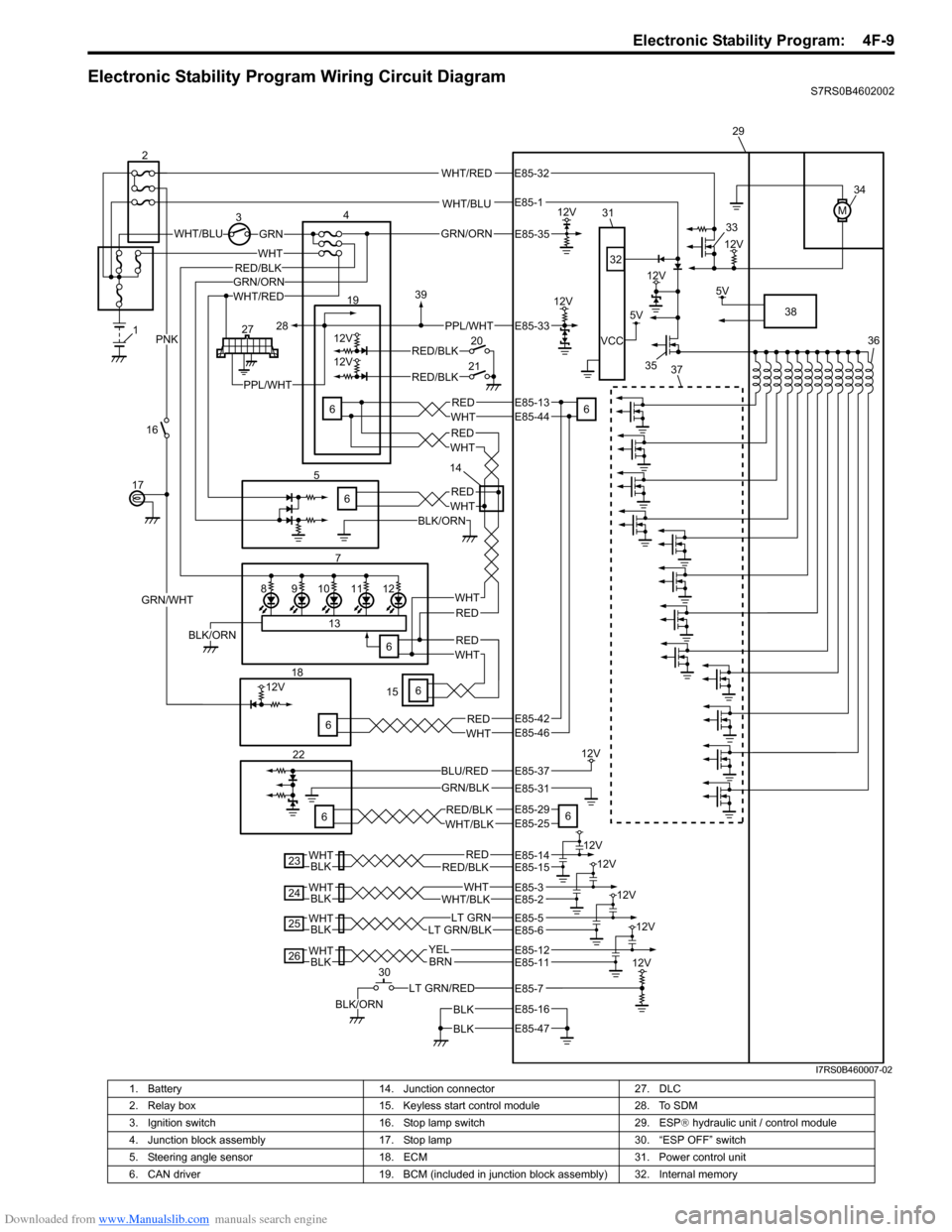

Electronic Stability Program Wiring Circuit DiagramS7RS0B4602002

WHT/BLU

WHT/BLUGRN

M

12V3

12V

5V

12V

VCC

WHT/RED

WHT

7

REDWHT

12V

12V

6 19

20

21RED/BLK

RED/BLK

GRN/WHT

PNK

12V

GRN/BLK

5V

LT GRN/RED

BLK/ORN

4

16

17

186

22

6 29

30 34

36

38

33

35

32

31

6

6 37

BLK

BLK

RED/BLKRED12V

BLKWHT

23

WHT/BLKWHT

12V

BLKWHT

24

BLKWHTLT GRN/BLKLT GRN

12V

25

BLKWHTBRN

12V

26YEL

12V

98101211

13

6BLK/ORN

1

227

5

WHT/REDGRN/ORN

BLK/ORN

REDWHT

REDWHT

PPL/WHT

6

REDWHT

REDWHT

6

REDWHT

RED/BLK

PPL/WHT

28

39

15 14

BLU/RED

GRN/ORN

12V

12V

E85-35

E85-33

E85-13E85-44

E85-46

E85-29E85-25

E85-37

E85-31

E85-14E85-15

E85-12E85-11

E85-16

E85-47

E85-3

E85-32

E85-1

E85-2

E85-5E85-6

E85-7

E85-42

RED/BLKWHT/BLK

I7RS0B460007-02

1. Battery 14. Junction connector 27. DLC

2. Relay box 15. Keyless start control module 28. To SDM

3. Ignition switch 16. Stop lamp switch 29. ESP® hydraulic unit / control module

4. Junction block assembly 17. Stop lamp 30. “ESP OFF” switch

5. Steering angle sensor 18. ECM 31. Power control unit

6. CAN driver 19. BCM (included in junction block assembly) 32. Internal memory

Page 611 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-37

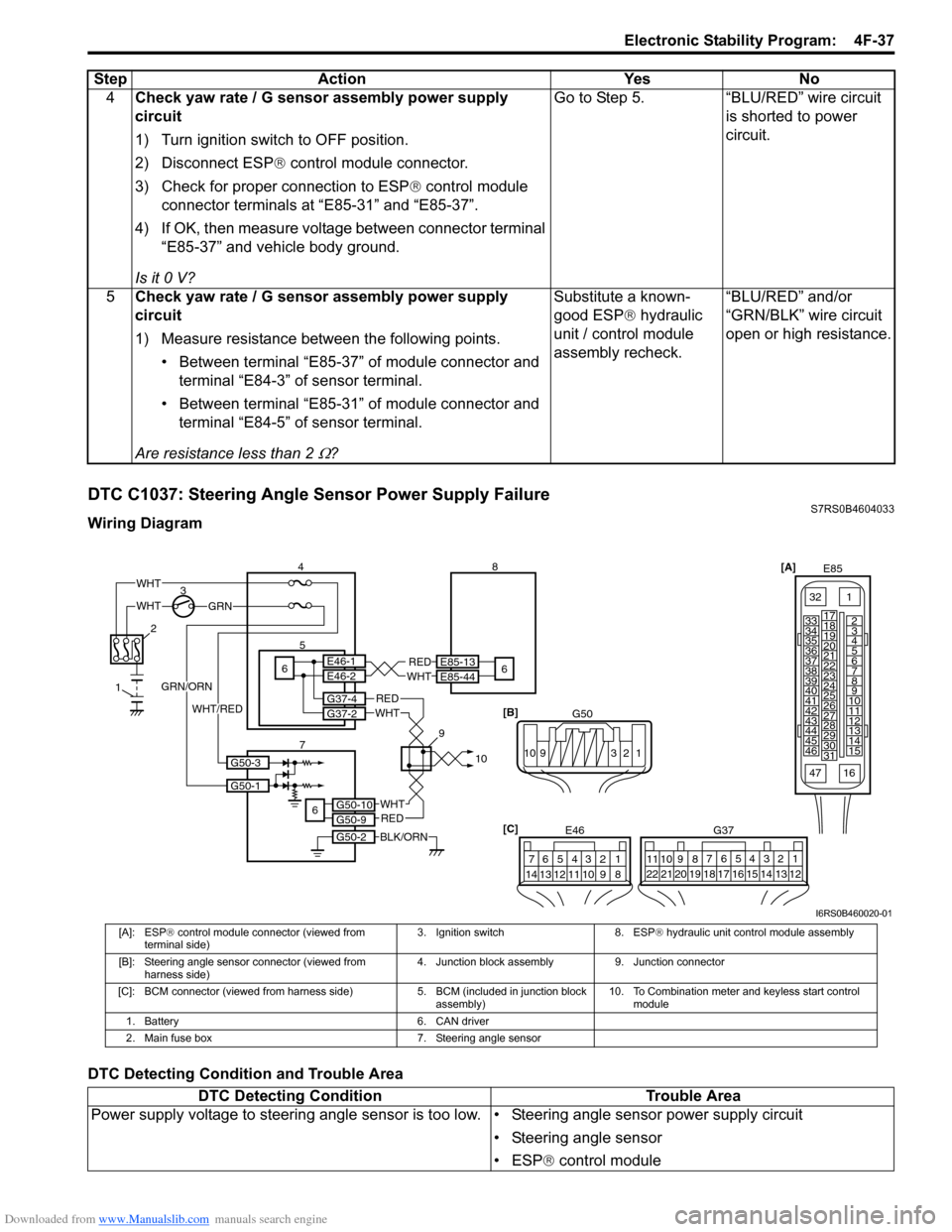

DTC C1037: Steering Angle Sensor Power Supply FailureS7RS0B4604033

Wiring Diagram

DTC Detecting Condition and Trouble Area4

Check yaw rate / G sensor assembly power supply

circuit

1) Turn ignition switch to OFF position.

2) Disconnect ESP ® control module connector.

3) Check for proper connection to ESP ® control module

connector terminals at “E85-31” and “E85-37”.

4) If OK, then measure voltage between connector terminal “E85-37” and vehicle body ground.

Is it 0 V? Go to Step 5. “BLU/RED” wire circuit

is shorted to power

circuit.

5 Check yaw rate / G sensor assembly power supply

circuit

1) Measure resistance between the following points.

• Between terminal “E85-37” of module connector and terminal “E84-3” of sensor terminal.

• Between terminal “E85-31” of module connector and terminal “E84-5” of sensor terminal.

Are resistance less than 2

Ω? Substitute a known-

good ESP

® hydraulic

unit / control module

assembly recheck. “BLU/RED” and/or

“GRN/BLK” wire circuit

open or high resistance.

Step

Action YesNo

[A]

E85

161

15

2

3

4

5

6

7

8

9

10

11

12

13

14

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

3233

34

35

36

37

38

39

40

41

42

43

44

45

46

47

[C] G37

E46

124

53

67

891011121314124

53

67

891011

1213141516171819202122

WHTGRN

3

E85-13

E85-44REDWHT65E46-1E46-2

4 8

6

BLK/ORN

REDWHT

REDWHT

G37-4G37-2

G50-10G50-9

G50-2

6

2

1

7 910

G50-1

G50-3

GRN/ORN

WHT/RED

WHT

[B]

G50

109 321

I6RS0B460020-01

[A]: ESP® control module connector (viewed from

terminal side) 3. Ignition switch 8. ESP

® hydraulic unit control module assembly

[B]: Steering angle sensor connector (viewed from harness side) 4. Junction block assembly 9. Junction connector

[C]: BCM connector (viewed from harnes s side) 5. BCM (included in junction block

assembly) 10. To Combination meter and keyless start control

module

1. Battery 6. CAN driver

2. Main fuse box 7. Steering angle sensor

DTC Detecting Condition Trouble Area

Power supply voltage to steering angle sensor is to o low. • Steering angle sensor power supply circuit

• Steering angle sensor

• ESP® control module

Page 645 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-1

Transmission / Transaxle

Automatic Transmission/Transaxle

Precautions

Precautions in Diagnosing TroubleS7RS0B5100001

• Do not disconnect couplers from TCM, battery cable from battery, TCM ground wire harness from engine or

main fuse before checking the diagnostic information

(DTC, freeze frame data, etc.) stored in TCM memory.

Such disconnection will clea r memorized information

in TCM memory.

• Diagnostic information stored in TCM memory can be cleared as well as checked by using SUZUKI scan

tool or generic scan tool. Before using scan tool, read

its Operator’s (Instruction) Manual carefully to have

good understanding as to what functions are available

and how to use it.

It is indistinguishable wh ich module turns on MIL

because not only ECM but also TCM turns on MIL.

Therefore, check both ECM and TCM for DTC when

MIL lights on.

When checking TCM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by TCM.

– Generic scan tool displays DTC detected by each of ECM and TCM simultaneously.

• Using SUZUKI scan tool the diagnostic information stored in TCM memory can be checked and cleared

as well. Before its use, be sure to read Operator’s

Manual supplied with it carefully to have good

understanding of its functions and usage.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• TCM replacement

– When substituting a known-good TCM, check that all relays and actuators have resistance of

specified value.

Neglecting this check may result in damage to good

TCM.

• Communication of ECUs , ECM, TCM, ABS control

module, keyless start control module and BCM is

established by CAN (Controller Area Network).

Therefore, handle CAN communication line with care

referring to “Precaution for CAN Communication

System in Section 00”.

Precautions for Disassembly and ReassemblyS7RS0B5100002

When repairing automatic transaxle, it is necessary to

conduct the on-vehicle test to investigate where the

cause of the trouble lies first.

Then whether overhaul should be done or not is

determined. If the transaxle is disassembled without

such preliminary procedure, not only the cause of the

trouble would be unknown, but also a secondary trouble

may occur and often time would be wasted.

As the automatic transaxle consists of high precision

component, the following cautions should be strictly

observed when handling its parts in disassembly and

reassembly.

• Disassembling valve body assembly is prohibited

essentially. However, a few parts can be

disassembled. When disassembling valve body

component parts, confirm whether their parts are

allowed to disassemble or not referring to “Valve Body

Assembly Disassembly and Reassembly”.

• When component part of forward clutch, direct clutch, 2nd brake and/or O/D and 2nd coast brake, namely

clutch disc, brake disc, retaining plate and/or

separator plate, have been replaced, all learned

contents, which have been stored in TCM memory by

executing learning control, should be initialized

referring to “Learning Control Initialization”.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

dismounting and remounting.

• Select a clean place free from dust and dirt for overhauling.

• Place a rubber mat on the work bench to protect parts from damage.

• Work gloves or shop cloth should not be used. (Use a nylon cloth or a paper towel.)

• When separating the case joint, do not pry with a screwdriver or such but tap with a plastic hammer

lightly.

• Make sure to wash dirt off from the transaxle so that no such dirt will enter the transaxle during

disassembly and reassembly.

• Wash the disassembled parts in ATF (Automatic Transaxle Fluid) or kerosene (using care not to allow

ATF or kerosene to get on your face, etc.) and confirm

that each fluid passage is not clogged by blowing air

into it. But use kerosene to wash the discs, resin

washers and rubber parts.

• Replace each gasket, oil seal and O-ring with a new one.

• Apply ATF to sliding or rotating parts before

reassembly.

Page 880 of 1496

Downloaded from www.Manualslib.com manuals search engine 6B-9 Steering Wheel and Column:

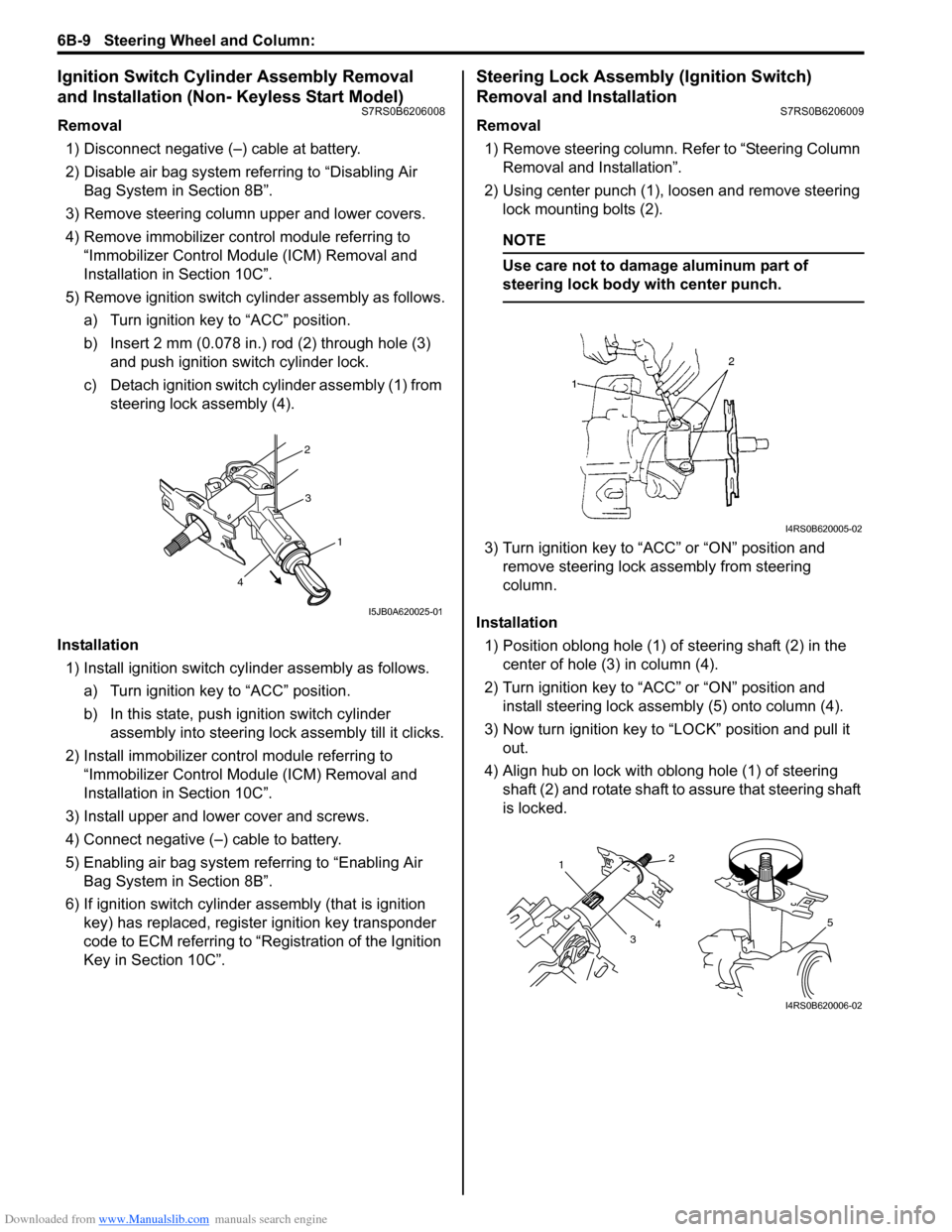

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)

S7RS0B6206008

Removal1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column upper and lower covers.

4) Remove immobilizer co ntrol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

5) Remove ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) Insert 2 mm (0.078 in.) rod (2) through hole (3) and push ignition switch cylinder lock.

c) Detach ignition switch cylinder assembly (1) from steering lock assembly (4).

Installation 1) Install ignition switch cy linder assembly as follows.

a) Turn ignition key to “ACC” position.

b) In this state, push ignition switch cylinder assembly into steering lock assembly till it clicks.

2) Install immobilizer cont rol module referring to

“Immobilizer Control Modu le (ICM) Removal and

Installation in Section 10C”.

3) Install upper and lower cover and screws.

4) Connect negative (–) cable to battery.

5) Enabling air bag system referring to “Enabling Air Bag System in Section 8B”.

6) If ignition switch cylinder assembly (that is ignition

key) has replaced, register ignition key transponder

code to ECM referring to “R egistration of the Ignition

Key in Section 10C”.

Steering Lock Assembly (Ignition Switch)

Removal and Installation

S7RS0B6206009

Removal

1) Remove steering column. Refer to “Steering Column

Removal and Installation”.

2) Using center punch (1), loosen and remove steering lock mounting bolts (2).

NOTE

Use care not to damage aluminum part of

steering lock body with center punch.

3) Turn ignition key to “ACC” or “ON” position and remove steering lock a ssembly from steering

column.

Installation 1) Position oblong hole (1) of steering shaft (2) in the center of hole (3) in column (4).

2) Turn ignition key to “ACC” or “ON” position and install steering lock assemb ly (5) onto column (4).

3) Now turn ignition key to “LOCK” position and pull it out.

4) Align hub on lock with oblong hole (1) of steering shaft (2) and rotate shaft to assure that steering shaft

is locked.

2

3

1

4

I5JB0A620025-01

I4RS0B620005-02

1

32

4

5

I4RS0B620006-02

Page 1170 of 1496

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Rear End Door Opener System Symptom Diagnosis .......................................................... 9F-5

Rear End Door Opener System Operation Inspection .......................................................... 9F-5

Repair Instructions ........... ................................... 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch In spection.................... 9F-8

Door Key Cylinder Switch Inspection .................. 9F-8

Power Door Lock Actuator Inspection ................. 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and Installation ....................................................... 9F-11

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection ........ 9F-12

Replacement of Transmitte r Battery ................. 9F-13

Programming Transmitter Code for Keyless Entry System (Vehicle without Keyless Start

System) ........................................................... 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation ....................................................... 9F-14

Keyless Entry Receiver and Its Circuit Inspection ........................................................ 9F-15

Specifications .... ................................................. 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipmen t ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ............. ............................................ 9G-1

Repair Instructions ............................................. 9G-1

Front Seat Components ..................................... 9G-1

Front Seat Removal and In stallation .................. 9G-2

Rear Seat Components...................................... 9G-3

Rear Seat Removal and Installation................... 9G-4

Specifications .... .................................................. 9G-4

Tightening Torque Specifications ....................... 9G-4

Special Tools and Equipmen t ............................ 9G-4

Recommended Service Material ........................ 9G-4

Interior Trim ................. ............................ 9H-1

Repair Instructions ............ ..................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-1

Console Box Components ..................................9H-2

Specifications ..................... ..................................9H-3

Tightening Torque Specifications ........................9H-3

Hood / Fenders / Doors ...... ...................... 9J-1

Repair Instructions ............ .................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Comp onents ..................... 9J-3

Front Door Assembly Removal and Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and Installation ......................................................... 9J-6

Specifications ..................... .................................. 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipmen t ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure............... .......................... 9K-1

Repair Instructions ............ ..................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top Components........................................ 9K-2

Specifications ..................... ..................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Paint / Coatings ............. ...........................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ............ ............................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ........................ 9L-8

Anti-Corrosion Compound Application Area ..... 9L-10

Exterior Trim ...... ...................................... 9M-1

Repair Instructions ......... .................................... 9M-1

Roof Molding Components................................. 9M-1

Splash Guard (If Equipped) Components .......... 9M-2

Page 1309 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-14

Navigation Symptom Diagnosis (If Equipped)S7RS0B9304019

Repair Instructions

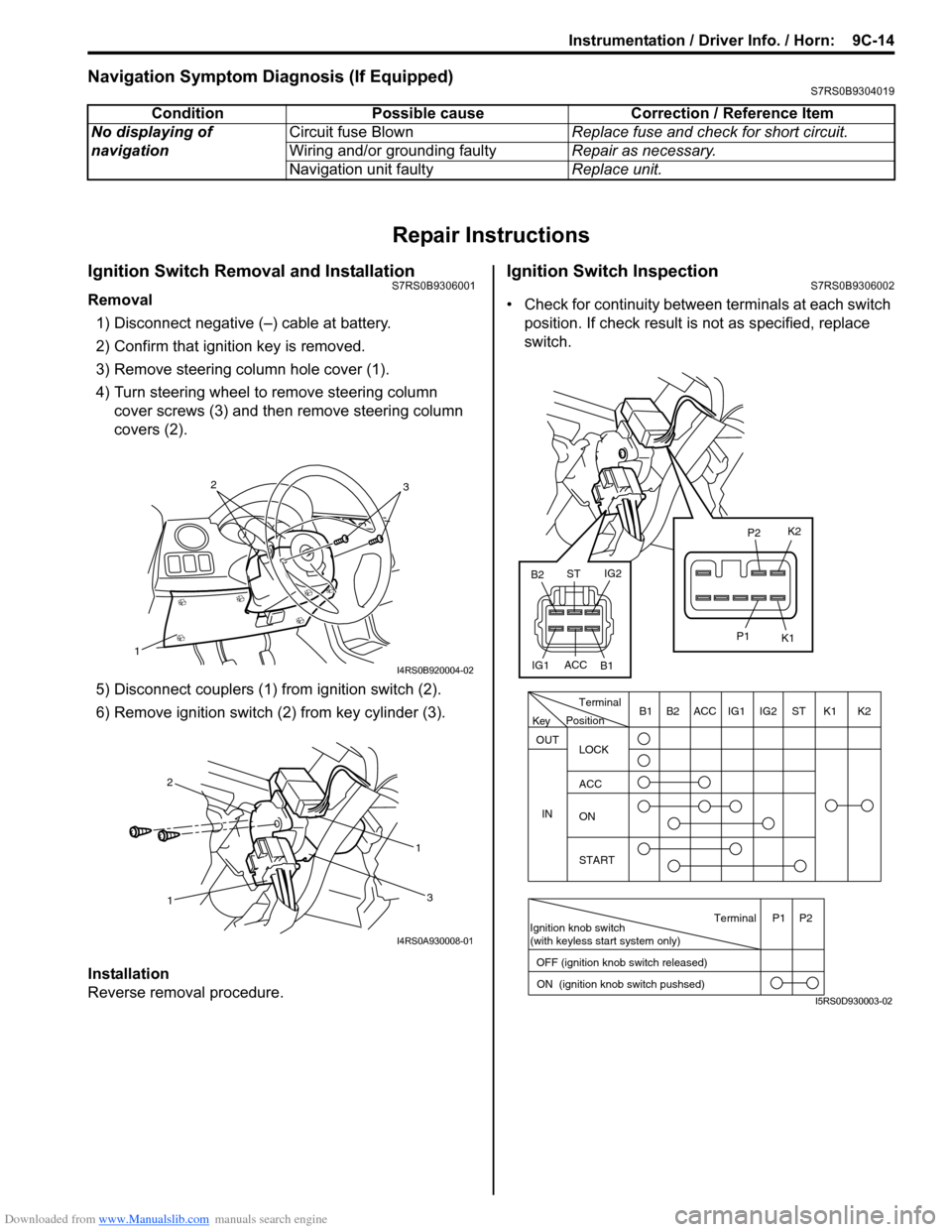

Ignition Switch Removal and InstallationS7RS0B9306001

Removal

1) Disconnect negative (–) cable at battery.

2) Confirm that ignition key is removed.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3) and then remove steering column

covers (2).

5) Disconnect couplers (1) from ignition switch (2).

6) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure.

Ignition Switch InspectionS7RS0B9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Condition Possible cause Correction / Reference Item

No displaying of

navigation Circuit fuse Blown

Replace fuse and check for short circuit.

Wiring and/or grounding faulty Repair as necessary.

Navigation unit faulty Replace unit.

1

32

I4RS0B920004-02

1 1

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START

OUT

INK2K1ST

IG2

IG1

ACC

B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1 IG2

ST

B2

B1 K2

K1

P2

P1

Terminal

OFF (ignition knob switch released) ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02

Page 1350 of 1496

Downloaded from www.Manualslib.com manuals search engine 9F-4 Security and Locks:

Keyless Entry System Symptom Diagnosis (If Equipped)S7RS0B9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitter Transmitter battery dead

Replace battery referring to “Replacement of

Transmitter Battery”.

Door switch faulty Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faulty Replace transmitter.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

BCM faulty Replace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitter Wiring or grounding faulty

Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitter Turn signal and hazard warning relay

faulty

Check turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCM Door switch faulty

Check door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faulty Check keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection”.

Key reminder switch in ignition switch

faulty Check ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Page 1359 of 1496

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-13

Replacement of Transmitter Battery S7RS0B9606014

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter co ver (2) and screw (1).

7) Make sure that door locks can be operated with transmitter.

NOTE

• To prevent theft, be sure to break the transmitter before discarding it.

• Dispose of the used battery properly according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Vehicle without Keyless Start

System)

S7RS0B9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered, the oldest one will be cleared.

• As for vehicle equipped with keyless start system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Vehicle

without Keyless Start System):”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

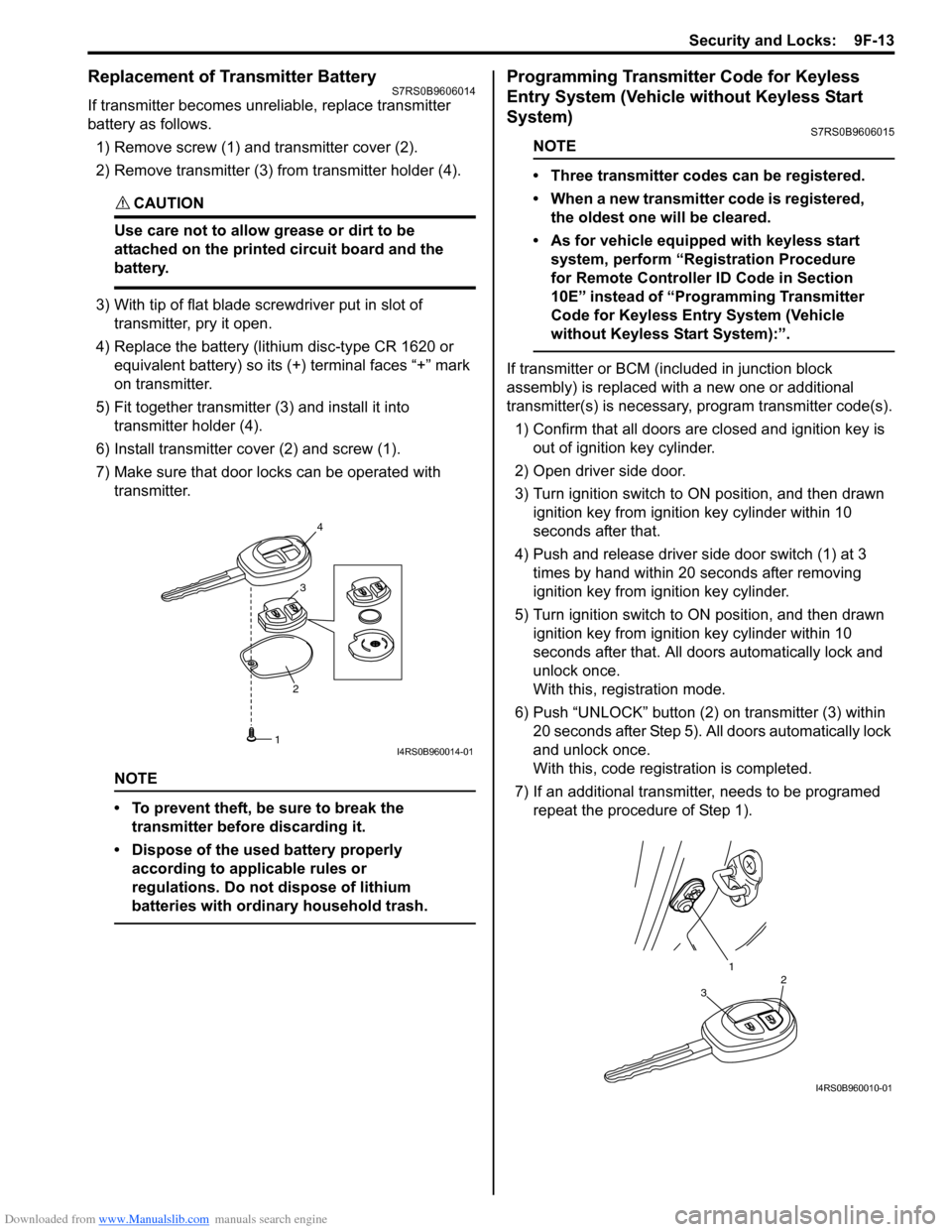

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3 times by hand within 20 seconds after removing

ignition key from ig nition key cylinder.

5) Turn ignition switch to ON position, and then drawn ignition key from igniti on key cylinder within 10

seconds after that. All d oors automatically lock and

unlock once.

With this, registration mode.

6) Push “UNLOCK” button (2) on transmitter (3) within

20 seconds after Step 5). All doors automatically lock

and unlock once.

With this, code registration is completed.

7) If an additional transmitter, needs to be programed repeat the procedure of Step 1).

23

4

1I4RS0B960014-01

1

32

I4RS0B960010-01