Rear wheel hub torque SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 429 of 1496

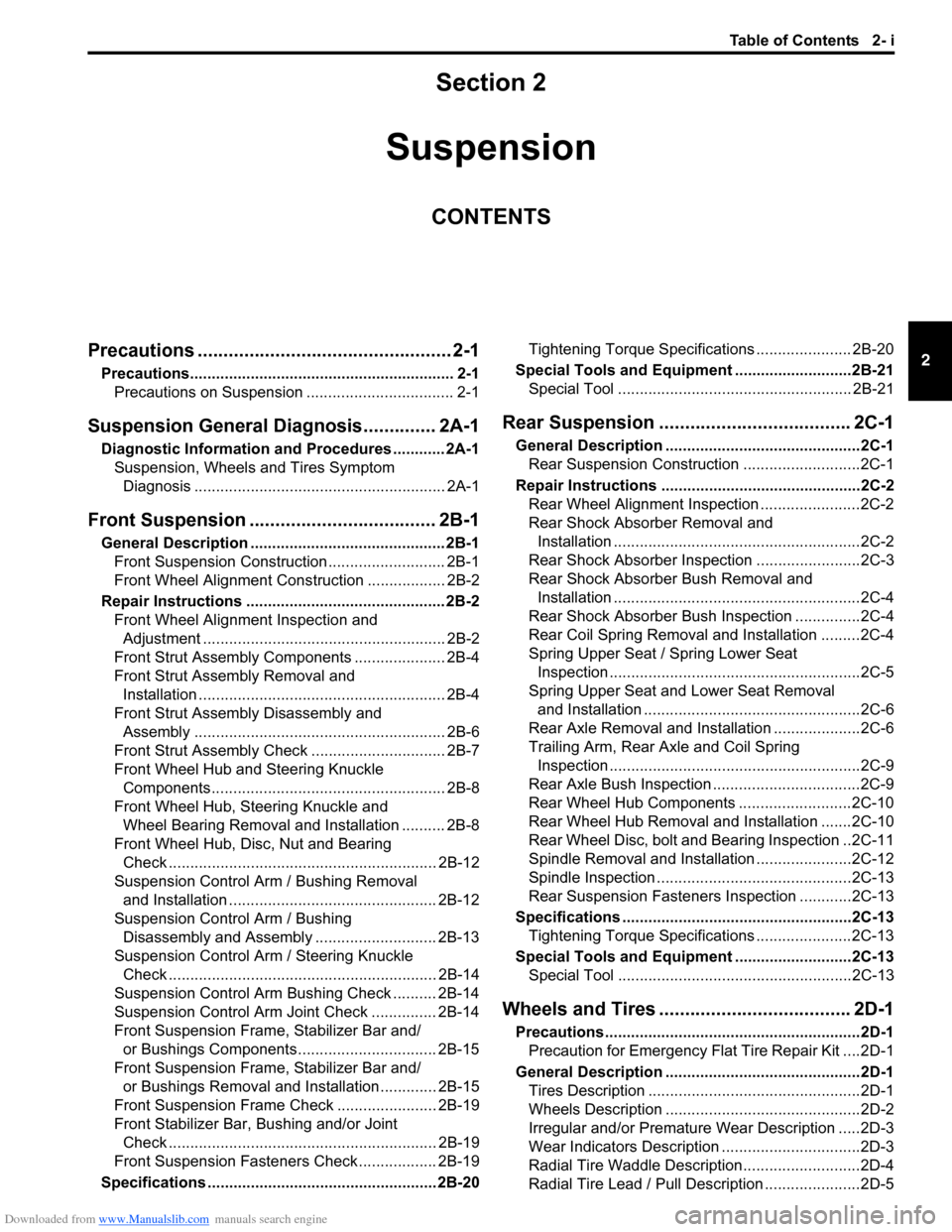

Downloaded from www.Manualslib.com manuals search engine Table of Contents 2- i

2

Section 2

CONTENTS

Suspension

Precautions ................................................. 2-1

Precautions............................................................. 2-1

Precautions on Suspension .................................. 2-1

Suspension General Dia gnosis.............. 2A-1

Diagnostic Information and Procedures ............ 2A-1

Suspension, Wheels and Tires Symptom Diagnosis .......................................................... 2A-1

Front Suspension ........... ......................... 2B-1

General Description ............................................. 2B-1

Front Suspension Construction ........................... 2B-1

Front Wheel Alignment Cons truction .................. 2B-2

Repair Instructions .............................................. 2B-2 Front Wheel Alignment Inspection and Adjustment ........................................................ 2B-2

Front Strut Assembly Comp onents ..................... 2B-4

Front Strut Assembly Removal and Installation ......................................................... 2B-4

Front Strut Assembly Disassembly and Assembly .......................................................... 2B-6

Front Strut Assembly Chec k ............................... 2B-7

Front Wheel Hub and Steering Knuckle Components...................................................... 2B-8

Front Wheel Hub, Steering Knuckle and Wheel Bearing Removal and Installation .......... 2B-8

Front Wheel Hub, Disc, Nut and Bearing Check .............................................................. 2B-12

Suspension Control Arm / Bushing Removal and Installation ................................................ 2B-12

Suspension Control Arm / Bushing Disassembly and Assembly ............................ 2B-13

Suspension Control Arm / Steering Knuckle Check .............................................................. 2B-14

Suspension Control Arm Bushing Check .......... 2B-14

Suspension Control Arm Joint Check ............... 2B-14

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Components................................ 2B-15

Front Suspension Fram e, Stabilizer Bar and/

or Bushings Removal and Installation ............. 2B-15

Front Suspension Frame Ch eck ....................... 2B-19

Front Stabilizer Bar, Bushing and/or Joint Check .............................................................. 2B-19

Front Suspension Fastener s Check .................. 2B-19

Specifications ..................................................... 2B-20 Tightening Torque Specifications ...................... 2B-20

Special Tools and Equipmen t ...........................2B-21

Special Tool ...................................................... 2B-21

Rear Suspension ............ ......................... 2C-1

General Description .............................................2C-1

Rear Suspension Construction ...........................2C-1

Repair Instructions ........... ...................................2C-2

Rear Wheel Alignment Inspection .......................2C-2

Rear Shock Absorber Removal and Installation .........................................................2C-2

Rear Shock Absorber Ins pection ........................2C-3

Rear Shock Absorber Bush Removal and Installation .........................................................2C-4

Rear Shock Absorber Bush Inspection ...............2C-4

Rear Coil Spring Removal and Installation .........2C-4

Spring Upper Seat / Spring Lower Seat Inspection ..........................................................2C-5

Spring Upper Seat and Lower Seat Removal and Installation ..................................................2C-6

Rear Axle Removal and Inst allation ....................2C-6

Trailing Arm, Rear Axle and Coil Spring Inspection ..........................................................2C-9

Rear Axle Bush Inspection ..................................2C-9

Rear Wheel Hub Components ..........................2C-10

Rear Wheel Hub Removal an d Installation .......2C-10

Rear Wheel Disc, bolt and Bearing Inspection ..2C-11

Spindle Removal and Installation ......................2C-12

Spindle Inspection .............................................2C-13

Rear Suspension Fasteners Inspection ............2C-13

Specifications .................... .................................2C-13

Tightening Torque Specifications ......................2C-13

Special Tools and Equipmen t ...........................2C-13

Special Tool ......................................................2C-13

Wheels and Tires ............ ......................... 2D-1

Precautions...........................................................2D-1

Precaution for Emergency Flat Tire Repair Kit ....2D-1

General Description .............................................2D-1 Tires Description .................................................2D-1

Wheels Description .............................................2D-2

Irregular and/or Premature Wear Description .....2D-3

Wear Indicators Description ................................2D-3

Radial Tire Waddle Description...........................2D-4

Radial Tire Lead / Pull Description ......................2D-5

Page 453 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

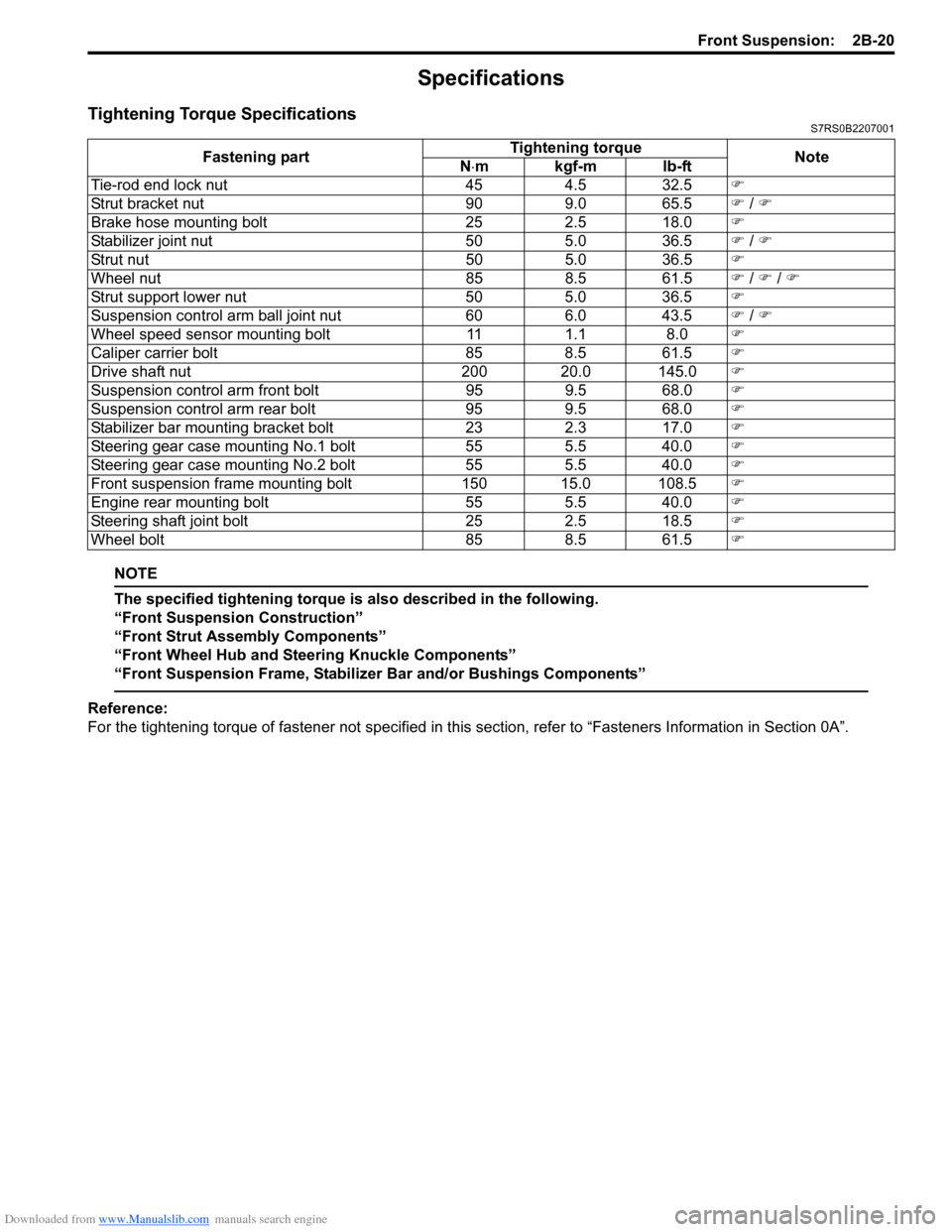

Specifications

Tightening Torque SpecificationsS7RS0B2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushings Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end lock nut 454.5 32.5 �)

Strut bracket nut 909.0 65.5 �) / �)

Brake hose mounting bolt 252.5 18.0 �)

Stabilizer joint nut 505.0 36.5 �) / �)

Strut nut 505.0 36.5 �)

Wheel nut 858.5 61.5 �) / �) / �)

Strut support lower nut 505.0 36.5 �)

Suspension control arm ball joint nut 606.0 43.5 �) / �)

Wheel speed sensor mounting bolt 111.1 8.0 �)

Caliper carrier bolt 858.5 61.5 �)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm front bolt 959.5 68.0 �)

Suspension control arm rear bolt 959.5 68.0 �)

Stabilizer bar mounting bracket bolt 232.3 17.0 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Front suspension frame mounting bolt 150 15.0 108.5�)

Engine rear mounting bolt 555.5 40.0 �)

Steering shaft joint bolt 252.5 18.5 �)

Wheel bolt 858.5 61.5 �)

Page 462 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-8 Rear Suspension:

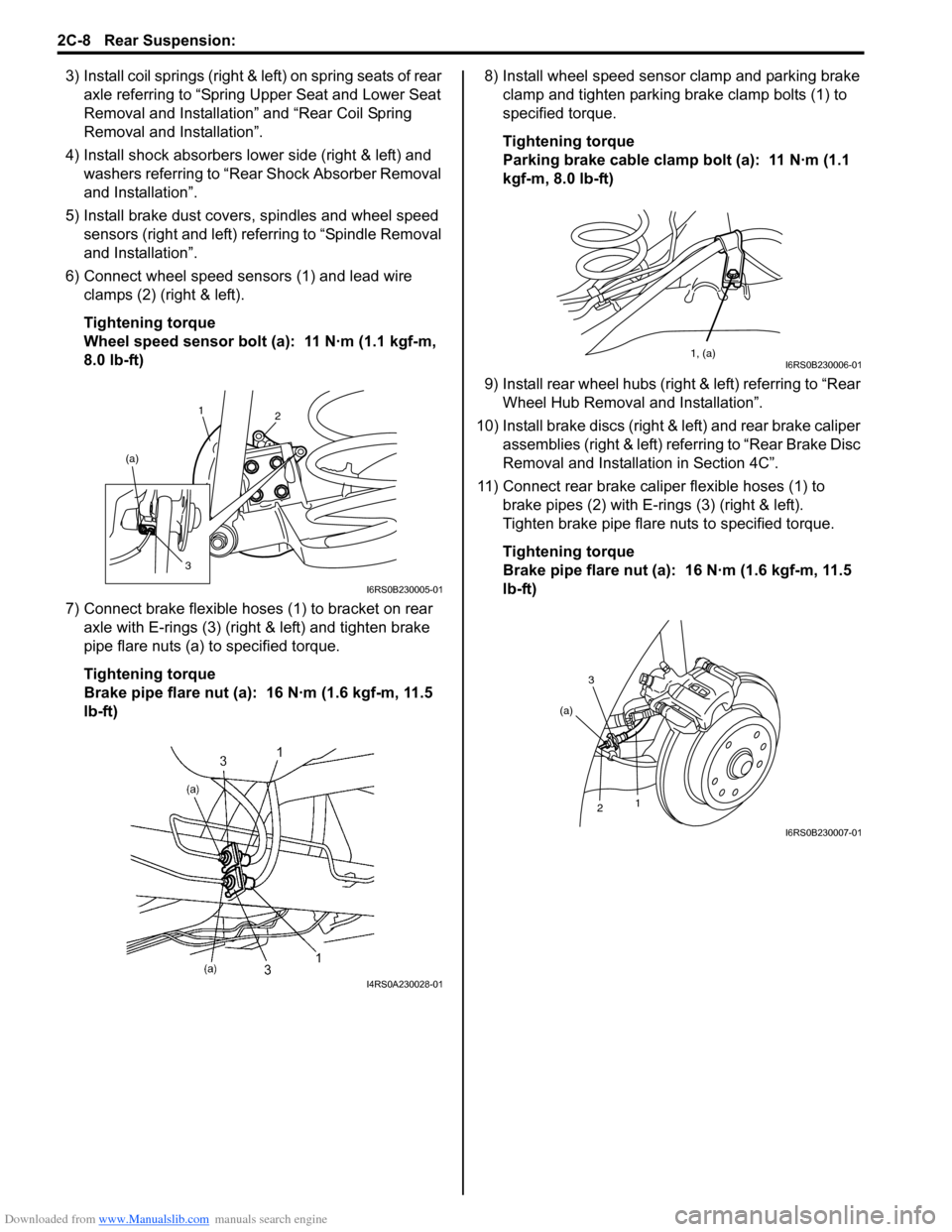

3) Install coil springs (right & left) on spring seats of rear

axle referring to “Spring Upper Seat and Lower Seat

Removal and Installation” and “Rear Coil Spring

Removal and Installation”.

4) Install shock absorbers lower side (right & left) and washers referring to “Rear Shock Absorber Removal

and Installation”.

5) Install brake dust covers, spindles and wheel speed sensors (right and left) referring to “Spindle Removal

and Installation”.

6) Connect wheel speed sensors (1) and lead wire clamps (2) (right & left).

Tightening torque

Wheel speed sensor bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Connect brake flexible hoses (1) to bracket on rear axle with E-rings (3) (right & left) and tighten brake

pipe flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft) 8) Install wheel speed sensor clamp and parking brake

clamp and tighten parking brake clamp bolts (1) to

specified torque.

Tightening torque

Parking brake cable clamp bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

9) Install rear wheel hubs (right & left) referring to “Rear Wheel Hub Removal and Installation”.

10) Install brake discs (right & left) and rear brake caliper assemblies (right & left) referring to “Rear Brake Disc

Removal and Installati on in Section 4C”.

11) Connect rear brake caliper flexible hoses (1) to brake pipes (2) with E-rings (3) (right & left).

Tighten brake pipe flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

1 2

(a)

3

I6RS0B230005-01

I4RS0A230028-01

1, (a)I6RS0B230006-01

3

2 1

(a)

I6RS0B230007-01

Page 465 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-11

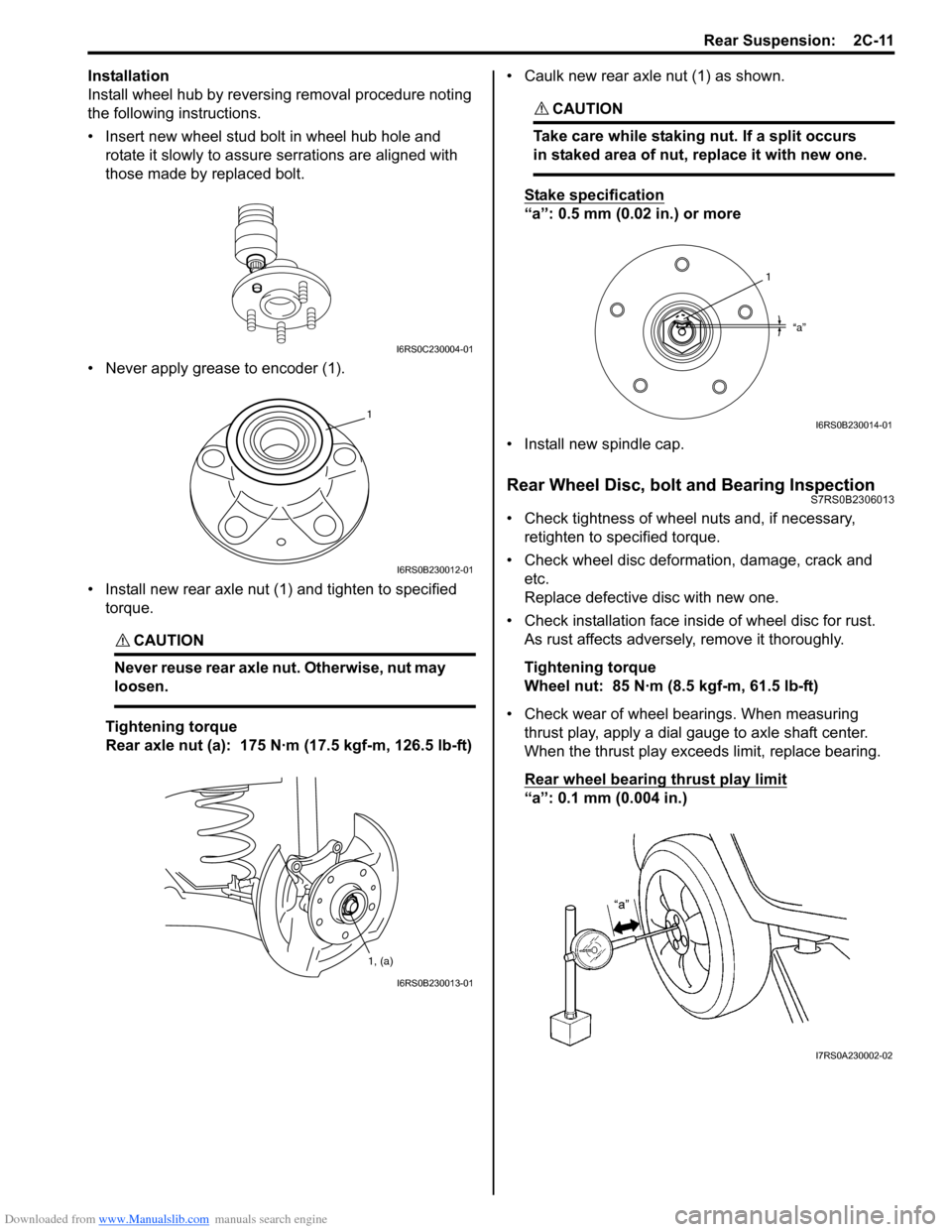

Installation

Install wheel hub by reversing removal procedure noting

the following instructions.

• Insert new wheel stud bolt in wheel hub hole and rotate it slowly to assure serrations are aligned with

those made by replaced bolt.

• Never apply grease to encoder (1).

• Install new rear axle nut (1) and tighten to specified torque.

CAUTION!

Never reuse rear axle nut. Otherwise, nut may

loosen.

Tightening torque

Rear axle nut (a): 175 N·m (17.5 kgf-m, 126.5 lb-ft) • Caulk new rear axle nut (1) as shown.

CAUTION!

Take care while staking nut. If a split occurs

in staked area of nut,

replace it with new one.

Stake specification

“a”: 0.5 mm (0.02 in.) or more

• Install new spindle cap.

Rear Wheel Disc, bolt and Bearing InspectionS7RS0B2306013

• Check tightness of wheel nuts and, if necessary, retighten to specified torque.

• Check wheel disc deformation, damage, crack and etc.

Replace defective disc with new one.

• Check installation face insi de of wheel disc for rust.

As rust affects adversely, remove it thoroughly.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

• Check wear of wheel bearings. When measuring thrust play, apply a dial gauge to axle shaft center.

When the thrust play exce eds limit, replace bearing.

Rear wheel bearing thrust play

limit

“a”: 0.1 mm (0.004 in.)

I6RS0C230004-01

1

I6RS0B230012-01

1, (a)

I6RS0B230013-01

1

“a”

I6RS0B230014-01

I7RS0A230002-02

Page 466 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-12 Rear Suspension:

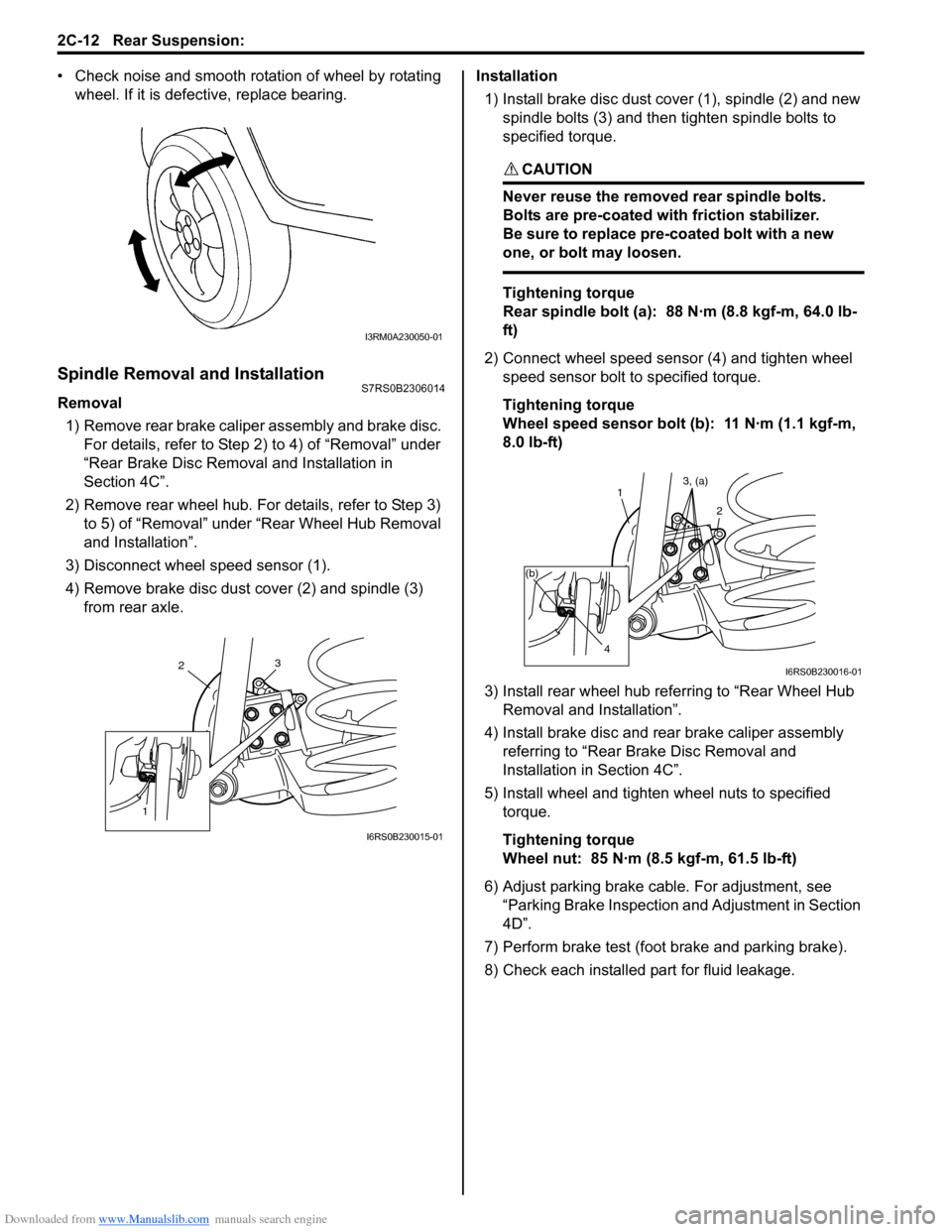

• Check noise and smooth rotation of wheel by rotating wheel. If it is defect ive, replace bearing.

Spindle Removal and InstallationS7RS0B2306014

Removal

1) Remove rear brake caliper assembly and brake disc. For details, refer to Step 2) to 4) of “Removal” under

“Rear Brake Disc Removal and Installation in

Section 4C”.

2) Remove rear wheel hub. For details, refer to Step 3) to 5) of “Removal” under “Rear Wheel Hub Removal

and Installation”.

3) Disconnect wheel speed sensor (1).

4) Remove brake disc dust cover (2) and spindle (3) from rear axle. Installation

1) Install brake disc dust cover (1), spindle (2) and new spindle bolts (3) and then tighten spindle bolts to

specified torque.

CAUTION!

Never reuse the removed rear spindle bolts.

Bolts are pre-coated wi th friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Rear spindle bolt (a): 88 N·m (8.8 kgf-m, 64.0 lb-

ft)

2) Connect wheel speed sensor (4) and tighten wheel speed sensor bolt to specified torque.

Tightening torque

Wheel speed sensor bolt (b): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

3) Install rear wheel hub re ferring to “Rear Wheel Hub

Removal and Installation”.

4) Install brake disc and rear brake caliper assembly referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) Adjust parking brake cable. For adjustment, see “Parking Brake Inspection and Adjustment in Section

4D”.

7) Perform brake test (foot brake and parking brake).

8) Check each installed part for fluid leakage.

I3RM0A230050-01

2

1 3

I6RS0B230015-01

1

(b)

4

2

3, (a)

I6RS0B230016-01

Page 467 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-13

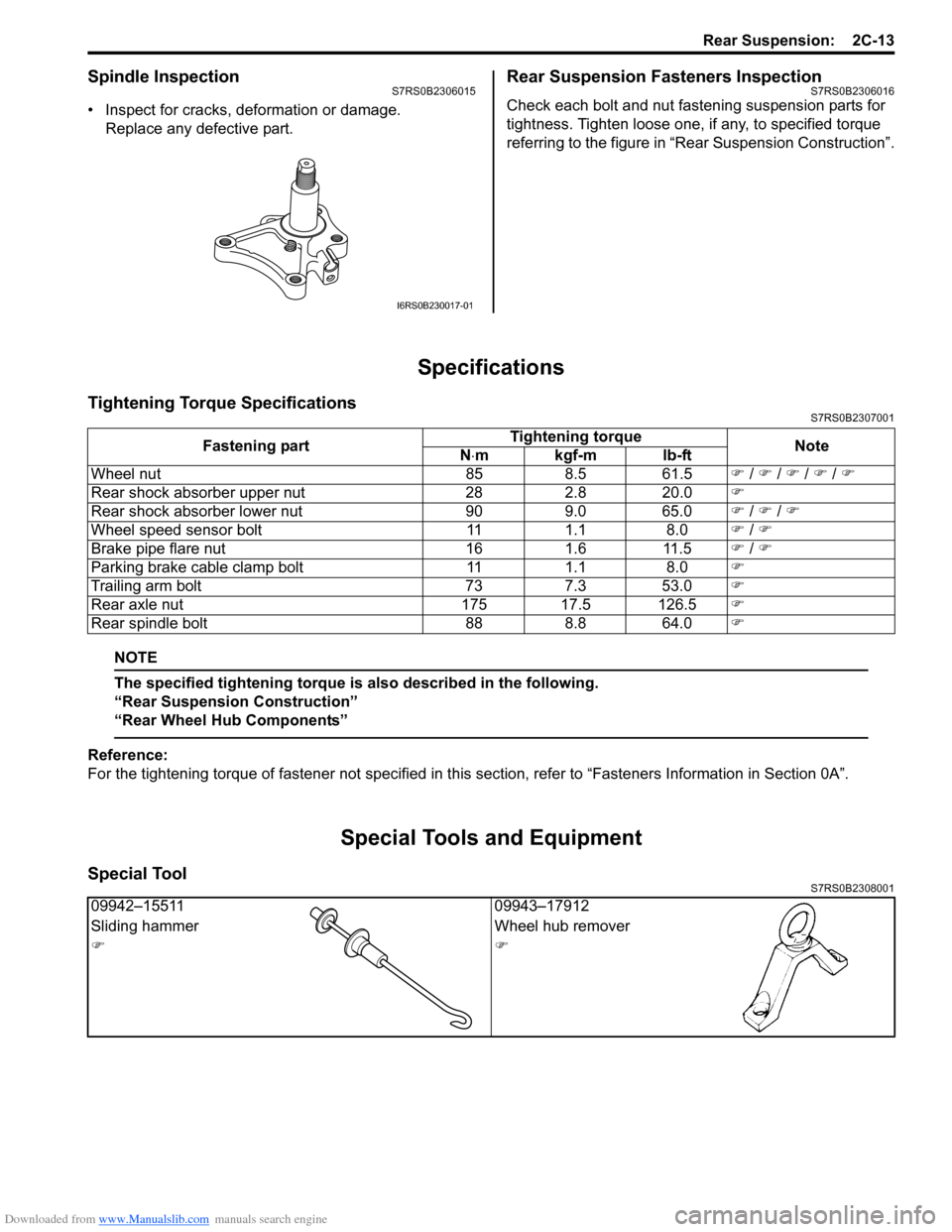

Spindle InspectionS7RS0B2306015

• Inspect for cracks, deformation or damage.Replace any defective part.

Rear Suspension Fasteners InspectionS7RS0B2306016

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque

referring to the figure in “Rear Suspension Construction”.

Specifications

Tightening Torque SpecificationsS7RS0B2307001

NOTE

The specified tightening torque is also described in the following.

“Rear Suspension Construction”

“Rear Wheel Hub Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B2308001

I6RS0B230017-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 85 8.5 61.5 �) / �) / �) / �) / �)

Rear shock absorber upper nut 28 2.8 20.0 �)

Rear shock absorber lower nut 90 9.0 65.0 �) / �) / �)

Wheel speed sensor bolt 11 1.1 8.0 �) / �)

Brake pipe flare nut 16 1.6 11.5 �) / �)

Parking brake cable clamp bolt 11 1.1 8.0 �)

Trailing arm bolt 73 7.3 53.0 �)

Rear axle nut 175 17.5 126.5 �)

Rear spindle bolt 88 8.8 64.0 �)

09942–1551109943–17912

Sliding hammer Wheel hub remover

�)�)

Page 607 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-33

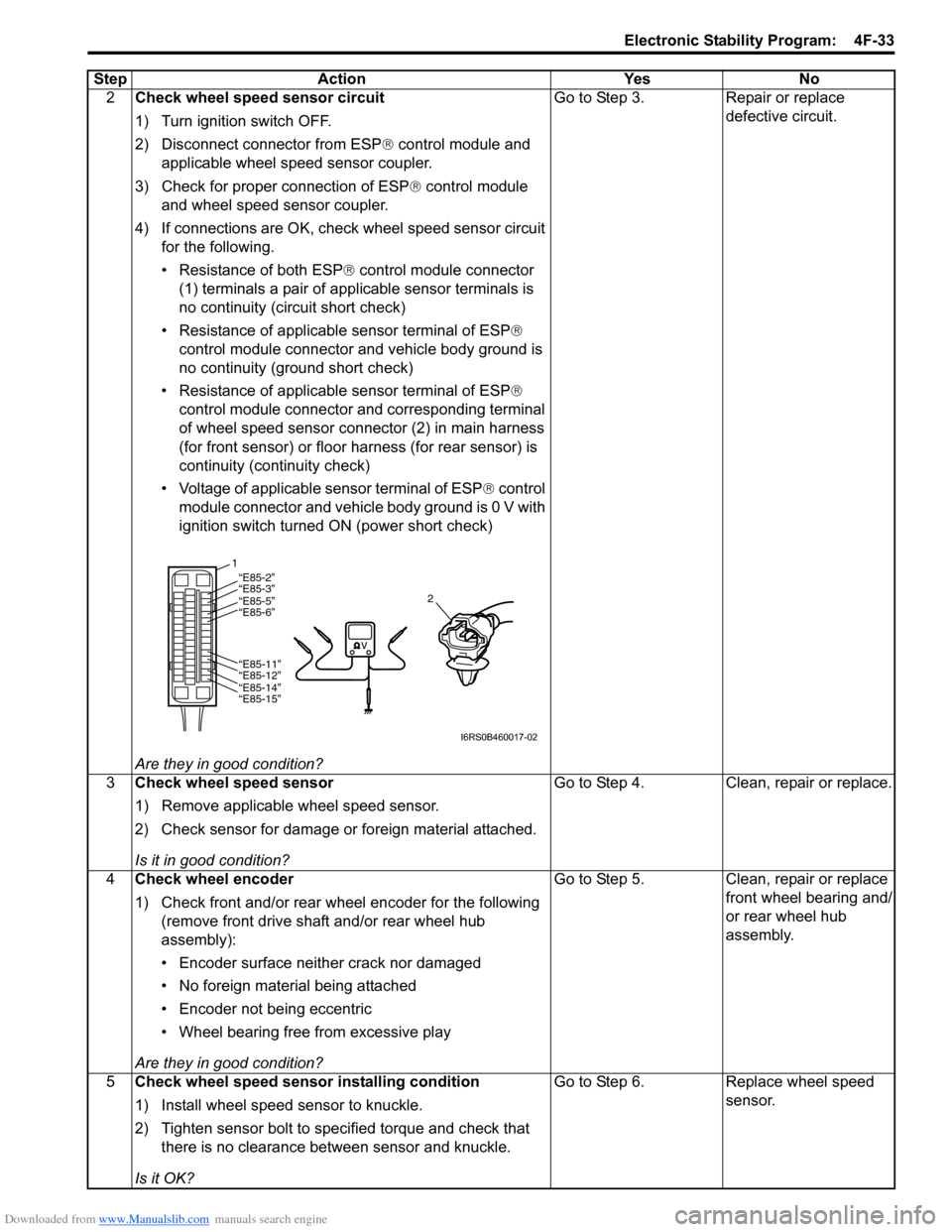

2Check wheel speed sensor circuit

1) Turn ignition switch OFF.

2) Disconnect connector from ESP ® control module and

applicable wheel speed sensor coupler.

3) Check for proper connection of ESP ® control module

and wheel speed sensor coupler.

4) If connections are OK, che ck wheel speed sensor circuit

for the following.

• Resistance of both ESP ® control module connector

(1) terminals a pair of app licable sensor terminals is

no continuity (circuit short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and vehicle body ground is

no continuity (ground short check)

• Resistance of applicable sensor terminal of ESP ®

control module connector and corresponding terminal

of wheel speed sensor connector (2) in main harness

(for front sensor) or floor harness (for rear sensor) is

continuity (continuity check)

• Voltage of applicable sensor terminal of ESP ® control

module connector and vehicle body ground is 0 V with

ignition switch turned ON (power short check)

Are they in good condition? Go to Step 3. Repair or replace

defective circuit.

3 Check wheel speed sensor

1) Remove applicable wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition? Go to Step 4. Clean, repair or replace.

4 Check wheel encoder

1) Check front and/or rear wheel encoder for the following

(remove front drive shaft and/or rear wheel hub

assembly):

• Encoder surface neither crack nor damaged

• No foreign material being attached

• Encoder not being eccentric

• Wheel bearing free from excessive play

Are they in good condition? Go to Step 5. Clean, repair or replace

front wheel bearing and/

or rear wheel hub

assembly.

5 Check wheel speed sensor installing condition

1) Install wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK? Go to Step 6. Replace wheel speed

sensor.

Step Action Yes No

1

2“E85-2”“E85-3”“E85-5”

“E85-6”

“E85-11”

“E85-12”

“E85-14”

“E85-15”

I6RS0B460017-02