circuit SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 5 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions ............................................... 00-1

Precautions........................................................... 00-1

Precautions for Vehicles Equipped with a Supplemental Restraint (A ir Bag) System ........ 00-1

General Precautions ........... ................................ 00-4

Warning for Wheel (with tire) Removal ............... 00-7

Warning for Handling Emergency Flat Tire Repair Kit .......................................................... 00-7

Precautions for Catalytic Converter .................... 00-7

Precautions for Installing Mobile Communication Equipment ............................... 00-7

Precaution for CAN Communication System ...... 00-7 Precautions for Electrical Circuit Service ............ 00-8

Air Bag Warning ................................................ 00-10

Air Bag System Service Warning ...................... 00-10

Fastener Caution............................................... 00-10

Suspension Caution .......................................... 00-10

Wheels and Tires Caution ................................. 00-10

Precaution for Vehicle Equipped with ESP

®

System ............................................................ 00-11

Brake Caution ................................................... 00-11

Repair Instructions ........ .................................... 00-11

Electrical Circuit Inspection Procedure ............. 00-11

Intermittent and Poor Co nnection Inspection .... 00-13

Page 7 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-2

Servicing and Handling

WARNING!

Many of service procedures require

disconnection of “A/BAG” fuse and all air

bag (inflator) module(s) from initiator circuit

to avoid an accidental deployment.

Driver, Passenger, Side and Curtain Air Bag

(Inflator) Modules

• For handling and storage of a live air bag (inflator) module, select a place where the

ambient temperature below 65 °C (150 ° F),

without high humidity and away from

electric noise.

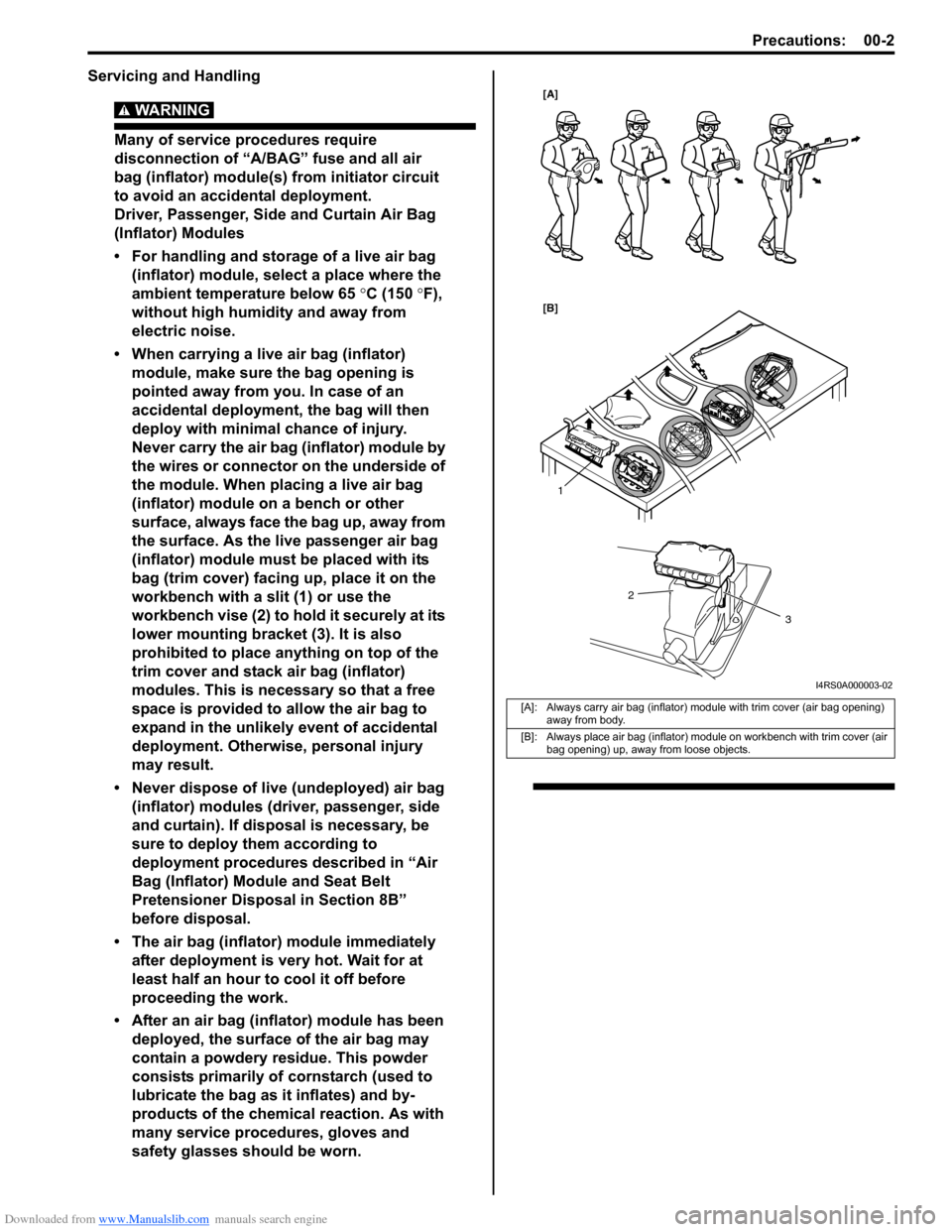

• When carrying a live air bag (inflator) module, make sure the bag opening is

pointed away from you. In case of an

accidental deployment, the bag will then

deploy with minimal chance of injury.

Never carry the air bag (inflator) module by

the wires or connector on the underside of

the module. When placing a live air bag

(inflator) module on a bench or other

surface, always face the bag up, away from

the surface. As the live passenger air bag

(inflator) module must be placed with its

bag (trim cover) facing up, place it on the

workbench with a slit (1) or use the

workbench vise (2) to hold it securely at its

lower mounting bracket (3). It is also

prohibited to place anything on top of the

trim cover and stack air bag (inflator)

modules. This is necessary so that a free

space is provided to allow the air bag to

expand in the unlikely event of accidental

deployment. Otherwise, personal injury

may result.

• Never dispose of live (undeployed) air bag (inflator) modules (driver, passenger, side

and curtain). If disposal is necessary, be

sure to deploy them according to

deployment procedures described in “Air

Bag (Inflator) Module and Seat Belt

Pretensioner Disposal in Section 8B”

before disposal.

• The air bag (inflator) module immediately

after deployment is very hot. Wait for at

least half an hour to cool it off before

proceeding the work.

• After an air bag (inflator) module has been deployed, the surface of the air bag may

contain a powdery residue. This powder

consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-

products of the chemical reaction. As with

many service procedures, gloves and

safety glasses should be worn.

[A]: Always carry air bag (inflator) module with trim cover (air bag opening) away from body.

[B]: Always place air bag (inflator) module on workbench with trim cover (air bag opening) up, away from loose objects.

1

2

3

[A]

[B]

I4RS0A000003-02

Page 13 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-8

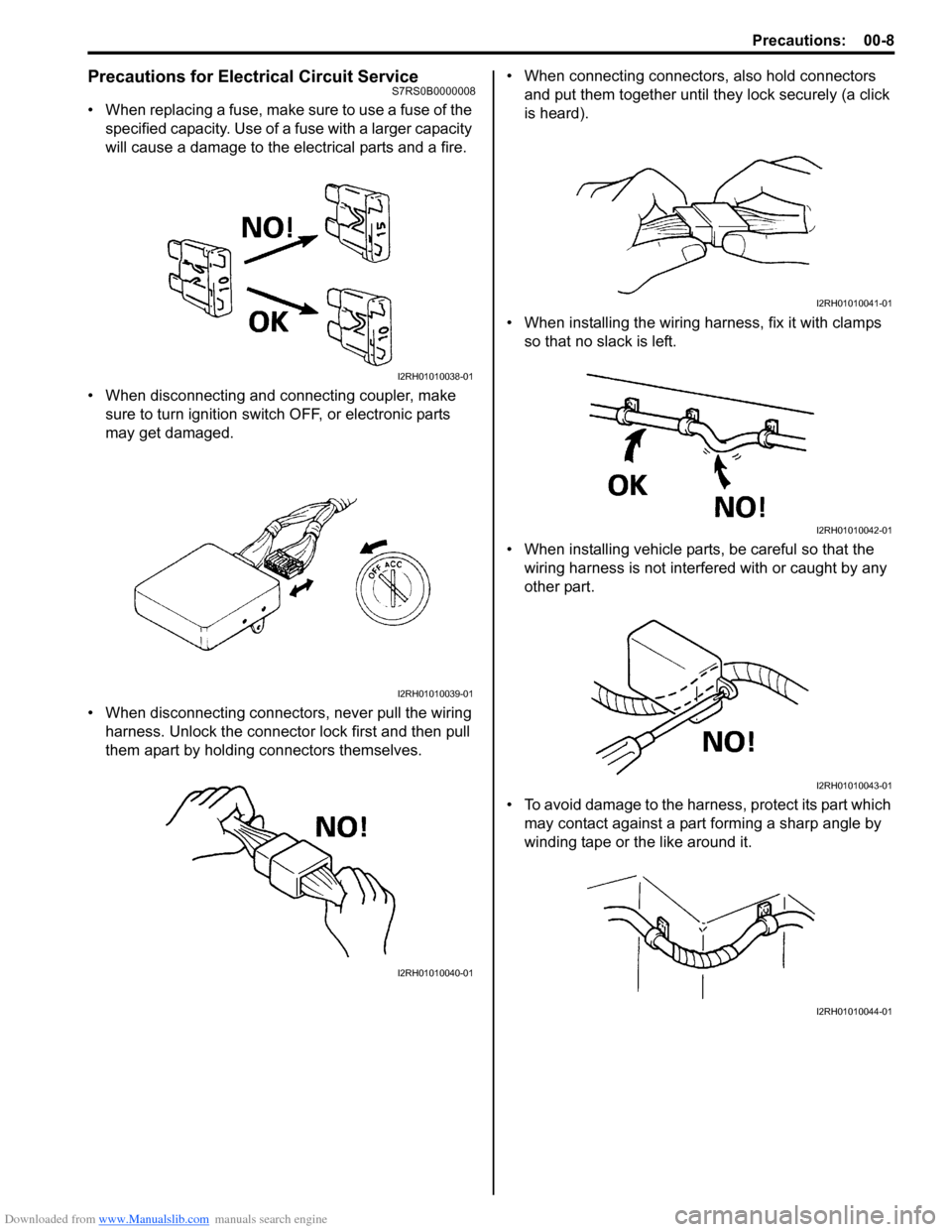

Precautions for Electrical Circuit ServiceS7RS0B0000008

• When replacing a fuse, make sure to use a fuse of the specified capacity. Use of a fuse with a larger capacity

will cause a damage to the electrical parts and a fire.

• When disconnecting and connecting coupler, make sure to turn ignition switch OFF, or electronic parts

may get damaged.

• When disconnecting connectors, never pull the wiring harness. Unlock the connecto r lock first and then pull

them apart by holding connectors themselves. • When connecting connectors, also hold connectors

and put them together until th ey lock securely (a click

is heard).

• When installing the wiring harness, fix it with clamps so that no slack is left.

• When installing vehicle parts, be careful so that the wiring harness is not interfered with or caught by any

other part.

• To avoid damage to the harnes s, protect its part which

may contact against a part forming a sharp angle by

winding tape or the like around it.

I2RH01010038-01

I2RH01010039-01

I2RH01010040-01

I2RH01010041-01

I2RH01010042-01

I2RH01010043-01

I2RH01010044-01

Page 16 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-11 Precautions:

Precaution for Vehicle Equipped with ESP®

System

S7RS0B0000015

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP ®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP ® control module

• When ESP ® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP ® control

module.

• When any of the following operation is done, calibrate steering angle sensor referring to “Sensor Calibration

in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

Brake CautionS7RS0B0000014

CAUTION!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

Repair Instructions

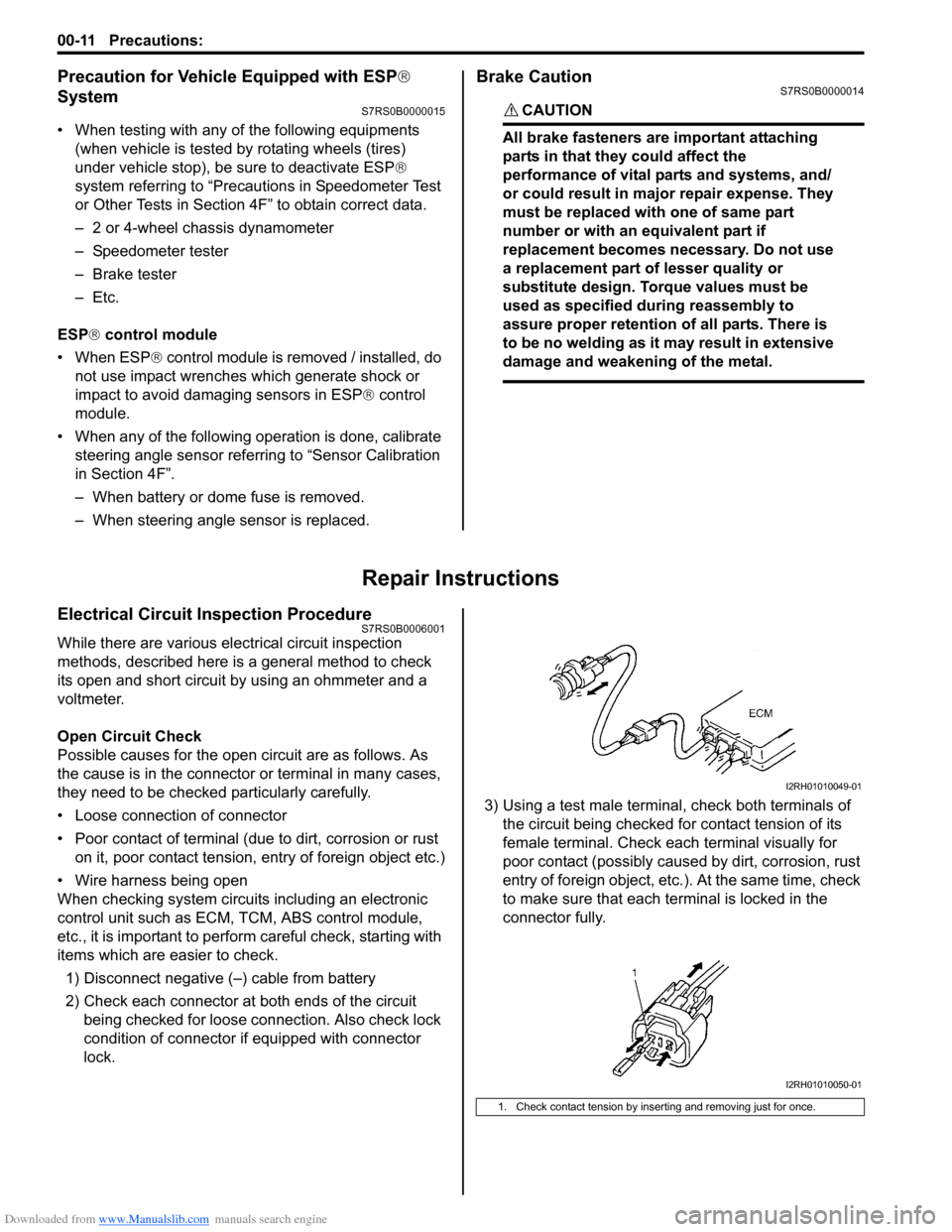

Electrical Circuit Inspection ProcedureS7RS0B0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perfor m careful check, starting with

items which are easier to check.

1) Disconnect negative (–) cable from battery

2) Check each connector at both ends of the circuit being checked for loose connection. Also check lock

condition of connector if equipped with connector

lock. 3) Using a test male terminal

, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each te rminal is locked in the

connector fully.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

Page 17 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-12

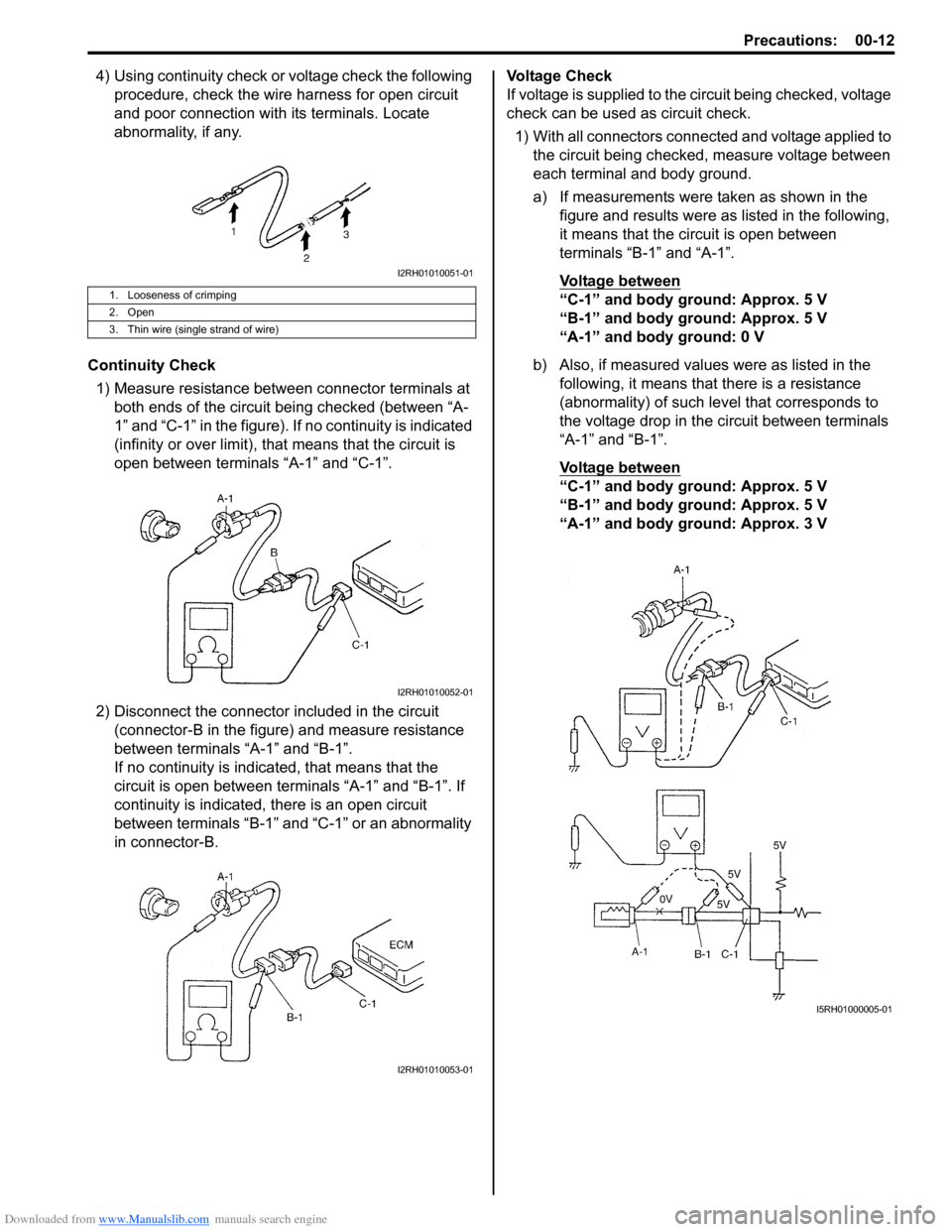

4) Using continuity check or voltage check the following procedure, check the wire harness for open circuit

and poor connection with its terminals. Locate

abnormality, if any.

Continuity Check 1) Measure resistance between connector terminals at both ends of the circuit being checked (between “A-

1” and “C-1” in the figure). If no continuity is indicated

(infinity or over limit), that means that the circuit is

open between terminals “A-1” and “C-1”.

2) Disconnect the connector included in the circuit (connector-B in the figure) and measure resistance

between terminals “A-1” and “B-1”.

If no continuity is indica ted, that means that the

circuit is open between terminals “A-1” and “B-1”. If

continuity is indicated, there is an open circuit

between terminals “B-1” and “C-1” or an abnormality

in connector-B. Voltage Check

If voltage is supplied to the circuit being checked, voltage

check can be used as circuit check.

1) With all connectors connected and voltage applied to the circuit being checked, measure voltage between

each terminal and body ground.

a) If measurements were taken as shown in the figure and results were as listed in the following,

it means that the circuit is open between

terminals “B-1” and “A-1”.

Voltage between

“C-1” and body ground: Approx. 5 V

“B-1” and body ground: Approx. 5 V

“A-1” and body ground: 0 V

b) Also, if measured values were as listed in the following, it means that there is a resistance

(abnormality) of such le vel that corresponds to

the voltage drop in the circuit between terminals

“A-1” and “B-1”.

Voltage between

“C-1” and body ground: Approx. 5 V

“B-1” and body ground: Approx. 5 V

“A-1” and body ground: Approx. 3 V

1. Looseness of crimping

2. Open

3. Thin wire (single strand of wire)

I2RH01010051-01

I2RH01010052-01

I2RH01010053-01

I5RH01000005-01

Page 18 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-13 Precautions:

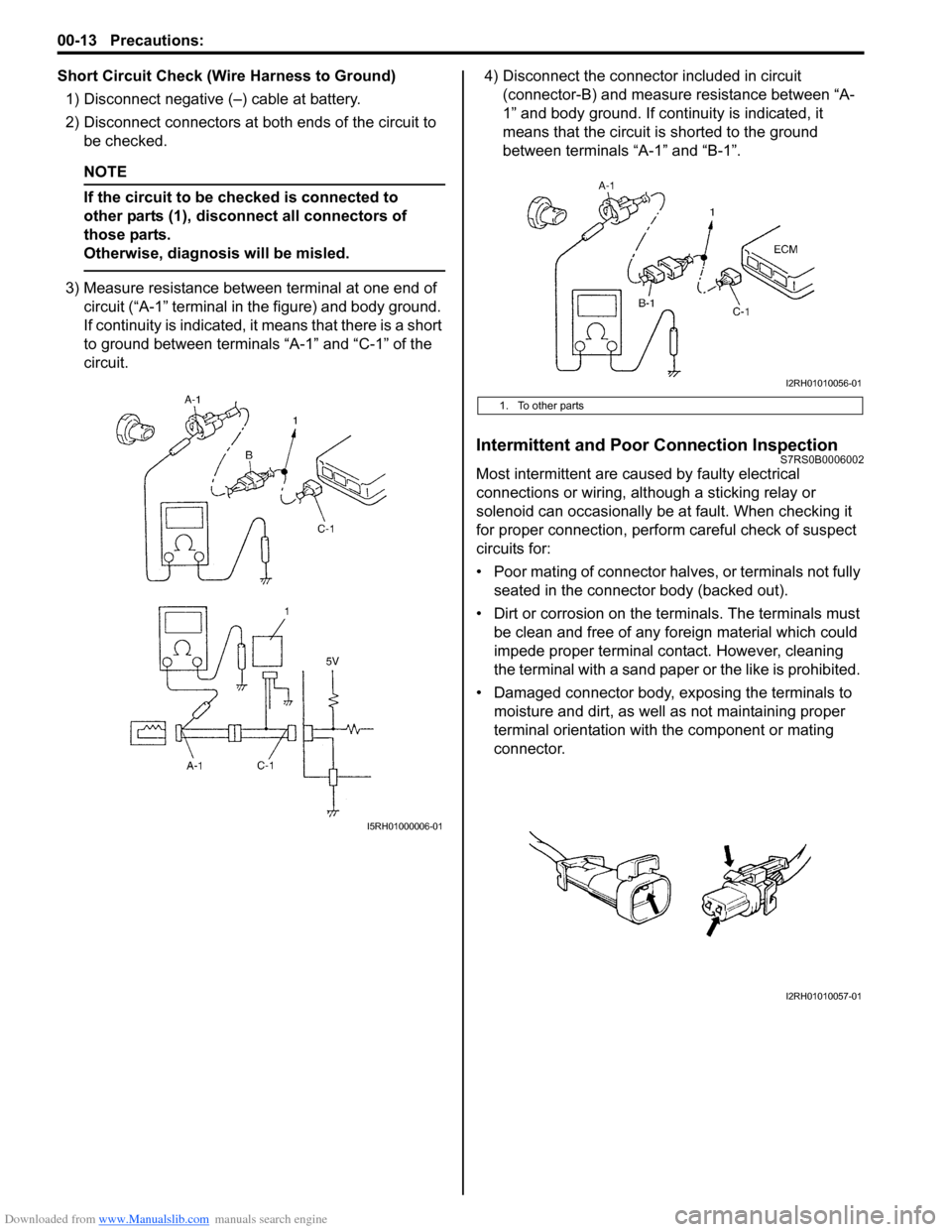

Short Circuit Check (Wire Harness to Ground)1) Disconnect negative (–) cable at battery.

2) Disconnect connectors at bot h ends of the circuit to

be checked.

NOTE

If the circuit to be checked is connected to

other parts (1), disconnect all connectors of

those parts.

Otherwise, diagnosis will be misled.

3) Measure resistance between terminal at one end of circuit (“A-1” terminal in the figure) and body ground.

If continuity is indicated, it means that there is a short

to ground between terminals “A-1” and “C-1” of the

circuit. 4) Disconnect the connector included in circuit

(connector-B) and measure resistance between “A-

1” and body ground. If continuity is indicated, it

means that the circuit is shorted to the ground

between terminals “A-1” and “B-1”.

Intermittent and Poor Connection InspectionS7RS0B0006002

Most intermittent are caused by faulty electrical

connections or wiring, although a sticking relay or

solenoid can occasionally be at fault. When checking it

for proper connection, perfor m careful check of suspect

circuits for:

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact. However, cleaning

the terminal with a sand paper or the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

I5RH01000006-01

1. To other parts

I2RH01010056-01

I2RH01010057-01

Page 19 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-14

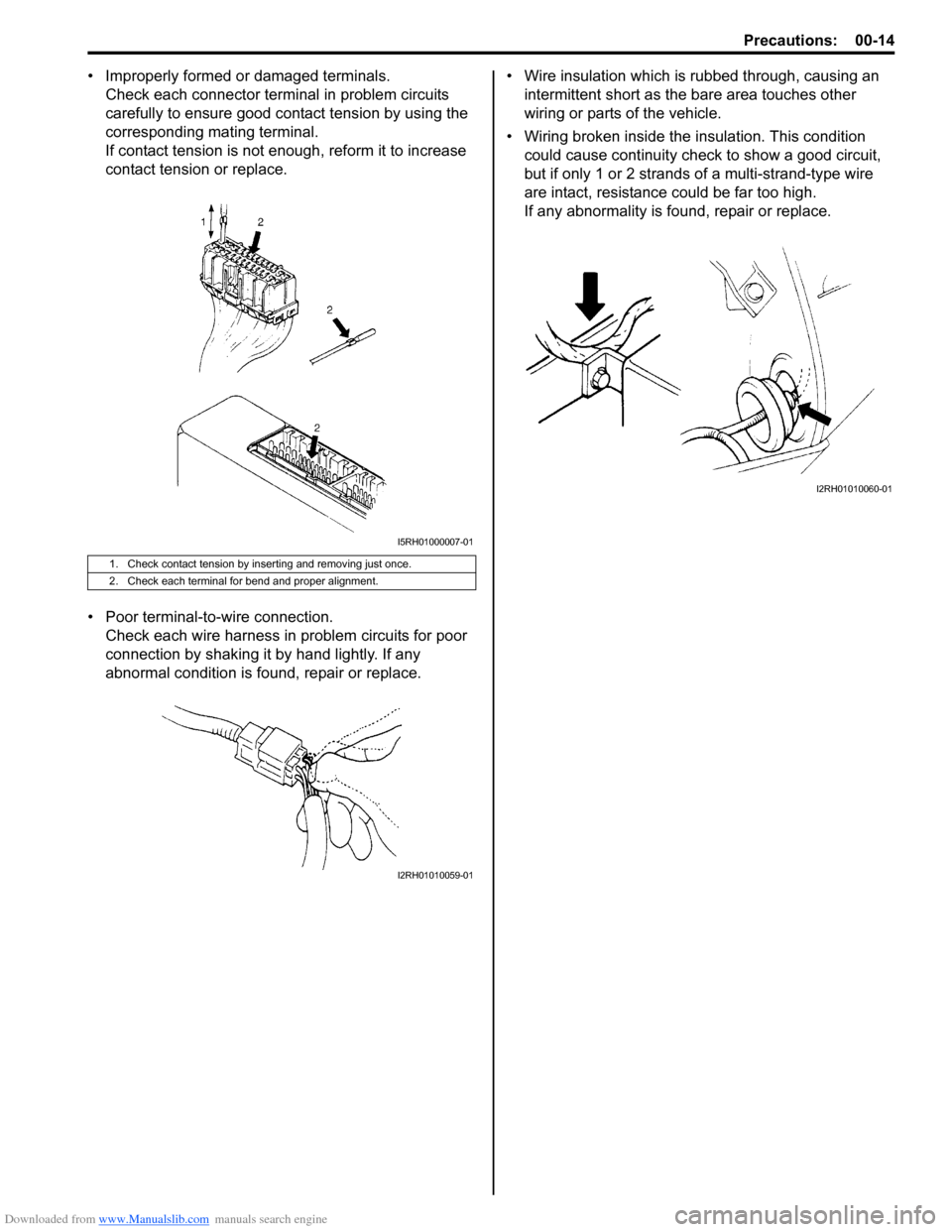

• Improperly formed or damaged terminals.Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal.

If contact tension is not enough, reform it to increase

contact tension or replace.

• Poor terminal-to -wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace. • Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wiring broken inside the insulation. This condition

could cause continuity check to show a good circuit,

but if only 1 or 2 strands of a multi-strand-type wire

are intact, resistance could be far too high.

If any abnormality is found, repair or replace.

1. Check contact tension by inserting and removing just once.

2. Check each terminal for bend and proper alignment.

I5RH01000007-01

I2RH01010059-01

I2RH01010060-01

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 45 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1- i

1

Section 1

CONTENTS

Engine

Precautions ................................................. 1-1

Precautions............................................................. 1-1

Precautions for Engine .......................................... 1-1

Engine General Information and

Diagnosis ............. .................................... 1A-1

Precautions........................................................... 1A-1

Precautions on Engine Service ........................... 1A-1

Precaution on On-Board Diagnostic (OBD) System .............................................................. 1A-1

Precautions in Diagnosing Trouble ..................... 1A-1

Precautions of ECM Circuit Inspection................ 1A-2

Precautions of Electric Throttle Body System

Calibration ......................................................... 1A-2

General Description ............................................. 1A-2 Statement on Cleanliness and Care ................... 1A-2

Engine Diagnosis General Description ............... 1A-3

On-Board Diagnostic System Description ........... 1A-3

Data Link Connector (DLC) ................................. 1A-6

Engine and Emission Control System Description ........................................................ 1A-6

CAN Communication System Description........... 1A-7

Air Intake System Description ............................. 1A-9

Description of Electric Throttle Body System ...... 1A-9

Description of Electric Throttle Body System Calibration ....................................................... 1A-10

Fuel Cut Control Description ............................. 1A-10

Generator Control System Description ............. 1A-11

Electronic Control System Description .............. 1A-12

Engine and Emission Control Input / Output Table ............................................................... 1A-18

Schematic and Routing Diagram ...................... 1A-19 Engine and Emission Control System Diagram .......................................................... 1A-19

Component Locatio n ......................................... 1A-21

Electronic Control System Components Location .......................................................... 1A-21

Diagnostic Information and Procedures .......... 1A-22 Engine and Emission Control System Check.... 1A-22

Malfunction Indicator Lamp (MIL) Check .......... 1A-25

DTC Check ....................................................... 1A-26

DTC Clearance ................................................. 1A-27

DTC Table ......................................................... 1A-27

Fail-Safe Table ................ .................................. 1A-31 Scan Tool Data ................................................. 1A-33

Visual Inspection ............................................... 1A-37

Engine Basic Inspection .................................... 1A-38

Engine Symptom Diagnosis .............................. 1A-41

MIL Does Not Come ON with Ignition Switch

ON and Engine Stop (but Engine Can Be

Started) ........................................................... 1A-47

Malfunction Indicator Lamp Remains ON after Engine Starts................................................... 1A-48

DTC P0010: “A” Camshaft Position Actuator Circuit .............................................................. 1A-49

DTC P0011 / P0012: “A” Camshaft Position - Timing Over-Advanced or System

Performance / -Retarded................................. 1A-52

DTC P0031 / P0032: HO2S Heater Control Circuit Low / High (Sensor-1) .......................... 1A-54

DTC P0037 / P0038: HO2S Heater Control Circuit Low / High (Sensor-2) .......................... 1A-56

DTC P0101: Mass or Volume Air Flow Circuit Range / Performance ...................................... 1A-58

DTC P0102: Mass or Volume Air Flow Circuit Low Input......................................................... 1A-61

DTC P0103: Mass or Volume Air Flow Circuit High Input ........................................................ 1A-63

DTC P0106: Manifold Absolute Pressure /

Barometric Pressure Circuit Range /

Performance.................................................... 1A-64

DTC P0107: Manifold Absolute Pressure /

Barometric Pressure Circ uit Low Input............ 1A-66

DTC P0108: Manifold Absolute Pressure /

Barometric Pressure Circ uit High Input ........... 1A-67

DTC P0111: Intake Air Temperature Sensor 1 Circuit Range / Performance ........................... 1A-69

DTC P0112: Intake Air Temperature Sensor 1 Circuit Low ...................................................... 1A-72

DTC P0113: Intake Air Temperature 1 Sensor Circuit High...................................................... 1A-74

DTC P0116: Engine Coolant Temperature Circuit Range / Performance ........................... 1A-76

DTC P0117: Engine Coolant Temperature Circuit Low ...................................................... 1A-79

DTC P0118: Engine Coolant Temperature Circuit High...................................................... 1A-81

DTC P0122: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit Low ........................ 1A-83

Page 46 of 1496

Downloaded from www.Manualslib.com manuals search engine 1-ii Table of Contents

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit High ....................... 1A-85

DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

1) ..................................................................... 1A-88

DTC P0133: O2 Sensor (HO2S) Circuit Slow

Response (Sensor- 1) ...................................... 1A-91

DTC P0134: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -1) ........................... 1A-92

DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

2) ..................................................................... 1A-94

DTC P0140: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -2) ........................... 1A-97

DTC P0171 / P0172: Fuel System Too Lean / Rich ................................................................. 1A-98

DTC P0222: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit Low ....................... 1A-100

DTC P0223: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit High ...................... 1A-102

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylin der Misfire Detected

/ Cylinder 1 / Cylinder 2 / Cylinder 3 /

Cylinder 4 Misfire Detected ........................... 1A-105

DTC P0327 / P0328: Knoc k Sensor 1 Circuit

Low / High ..................................................... 1A-107

DTC P0335: Crankshaft Position (CKP) Sensor “A” Circuit .......................................... 1A-109

DTC P0340: Camshaft Position (CMP) Sensor “A” Circuit .......................................... 1A-111

DTC P0350: Ignition Coil Primary / Secondary Circuit ............................................................ 1A-114

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected /

Excessive Detected ...................................... 1A-116

DTC P0403: Exhaust Gas Recirculation Control Circuit ................... ............................ 1A-118

DTC P0420: Catalyst System Efficiency

below Threshold ................ ............................ 1A-120

DTC P0443: Evaporativ e Emission System

Purge Control Valve Circuit ........................... 1A-122

DTC P0480: Fan 1 (Radiator Cooling Fan) Control Circuit ................... ............................ 1A-124

DTC P0500: Vehicle Speed Sensor “A” Malfunction .................................................... 1A-128

DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low ... ............................... 1A-130

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit High ................................. 1A-132

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control

Module Programming Error / Control Module

Performance ................................................. 1A-134

DTC P0616: Starter Relay Circuit Low............ 1A-135

DTC P0617: Starter Relay Circuit High ........... 1A-136

DTC P0620: Generator Control Circuit ........... 1A-137

DTC P0625 / P0626: Generator Field Terminal Circuit Low / High . .......................... 1A-139

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / High . ............................ 1A-141 DTC P1510: ECM Back-Up Power Supply

Malfunction .................................................... 1A-143

DTC P1603: TCM Trouble Code Detected ..... 1A-144

DTC P1674: CAN Communication (Bus Off Error) ............................................................. 1A-145

DTC P1676: CAN Communication (Reception Error for TCM) ............................................... 1A-148

DTC P1678: CAN Communication (Reception Error for BCM) ............................................... 1A-149

DTC P1685: CAN Communication (Reception Error for ABS/ESP ® Control Module) ........... 1A-150

DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance ......................... 1A-152

DTC P2102: Throttle Actuator Control Motor Circuit Low .................................................... 1A-154

DTC P2103: Throttle Actuator Control Motor Circuit High.................................................... 1A-155

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / Closed ...................... 1A-156

DTC P2119: Throttle Actu ator Control Throttle

Body Range / Performance ........................... 1A-157

DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input............. 1A-159

DTC P2123: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit High Input ............ 1A-161

DTC P2127: Throttle Pedal Position Sensor / Switch “E” (Sub) Circuit Low Input ................ 1A-164

DTC P2128: Throttle / Pedal Position Sensor

/ Switc

h “E” (Sub) Circuit High Input ............. 1A-166

DTC P2135: Throttle / Pedal Position Sensor / Switch “A”/“B” (Main / Sub) Voltage

Correlation..................................................... 1A-168

DTC P2138: Throttle / Pedal Position Sensor / Switch “D”/“E” (Main / Sub) Voltage

Correlation..................................................... 1A-171

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit Malfunction ......................... 1A-173

Inspection of ECM and Its Circuits .................. 1A-175

ECM Power and Ground Circuit Check........... 1A-194

Fuel Injector Circuit Check .............................. 1A-198

Fuel Pump and Its Circuit Check..................... 1A-200

Fuel Pressure Check....................................... 1A-203

A/C System Circuits Check ............................. 1A-205

Electric Load Signal Circuit Check .................. 1A-209

Radiator Cooling Fan Low Speed Control System Check ............................................... 1A-211

Radiator Cooling Fan High Speed Control System Check ............................................... 1A-213

Repair Instructions ......... .................................1A-216

Idle Speed and IAC Throttle Valve Opening Inspection ...................................................... 1A-216

Special Tools and Equipmen t .........................1A-217

Special Tool .................................................... 1A-217

Aux. Emission Control Devices ............. 1B-1

Diagnostic Information and Procedures ............1B-1

EGR System Inspection ...................................... 1B-1

Repair Instructions ............ ..................................1B-1

EVAP Canister Purge Inspec tion ........................ 1B-1