plugs SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 32 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-2 Maintenance and Lubrication:

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For spark plugs, replace every 50,000 km if the local law requires.

• Periodic replacement of fuel filter is not necessary if it is not instructed in “Periodic Maintenance Schedule” section of the Owner’s manual. The scheduled maintenance varies depending on the

vehicle specification.

Maintenance Recommended under Severe Driving ConditionsS7RS0B0205002

If the vehicle is usually used under the conditions corres ponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be per formed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – –

H: Towing a trailer (if admitted) Automatic transaxle fluid

Fluid level (I:

�)) —I—I—I

Fluid change (R: �)) Replace every 165,000 km (99,000

miles)

Fluid hose (I: �))———I——

All latches, hinges and locks (I: �)) —I—I—I

HVAC air filter (if equipped) (I: �) ) (R: �))— IR — IR

Interval

Km (x 1,000)

15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

– B C D – – – – Accessory drive belt �)

I Every 15,000 km

(9,000 miles) or 12 months

�) R Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter �) R Every 7,500 km

(4,500 miles) or 6 months

– – C – – – – – Air cleaner filter *1 �)

I Every 2,500 km

(1,500 miles)

�) R Every 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugs Iridium plug �) R Every 30,000 km (18,000 miles) or

24 months

– B C D – – – H Wheel bearings �) I Every 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shaft (axle) boots �) I Every 15,000 km

(9,000 miles) or 12 months

– B – – E – – H Manual transaxle oil �) R First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month

Page 36 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-6 Maintenance and Lubrication:

Exhaust System InspectionS7RS0B0206006

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When carrying out periodic maintenance, or the vehicle

is raised for other service, check exhaust system as

follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connections, dents and damages.

If bolts or nuts are loose, tighten them to specification.

• Check nearby body areas for damaged, missing or mispositioned parts, ope n seams, holes, loose

connections or other defects which could permit

exhaust fumes to seep into the vehicle.

• Make sure that exhaust system components have enough clearance from the underbody to avoid

overheating and possible damage to floor carpet.

• Any defects should be fixed at once.

Spark Plug ReplacementS7RS0B0206007

Replace spark plugs with new ones referring to “Spark

Plug Removal and Installation in Section 1H”.

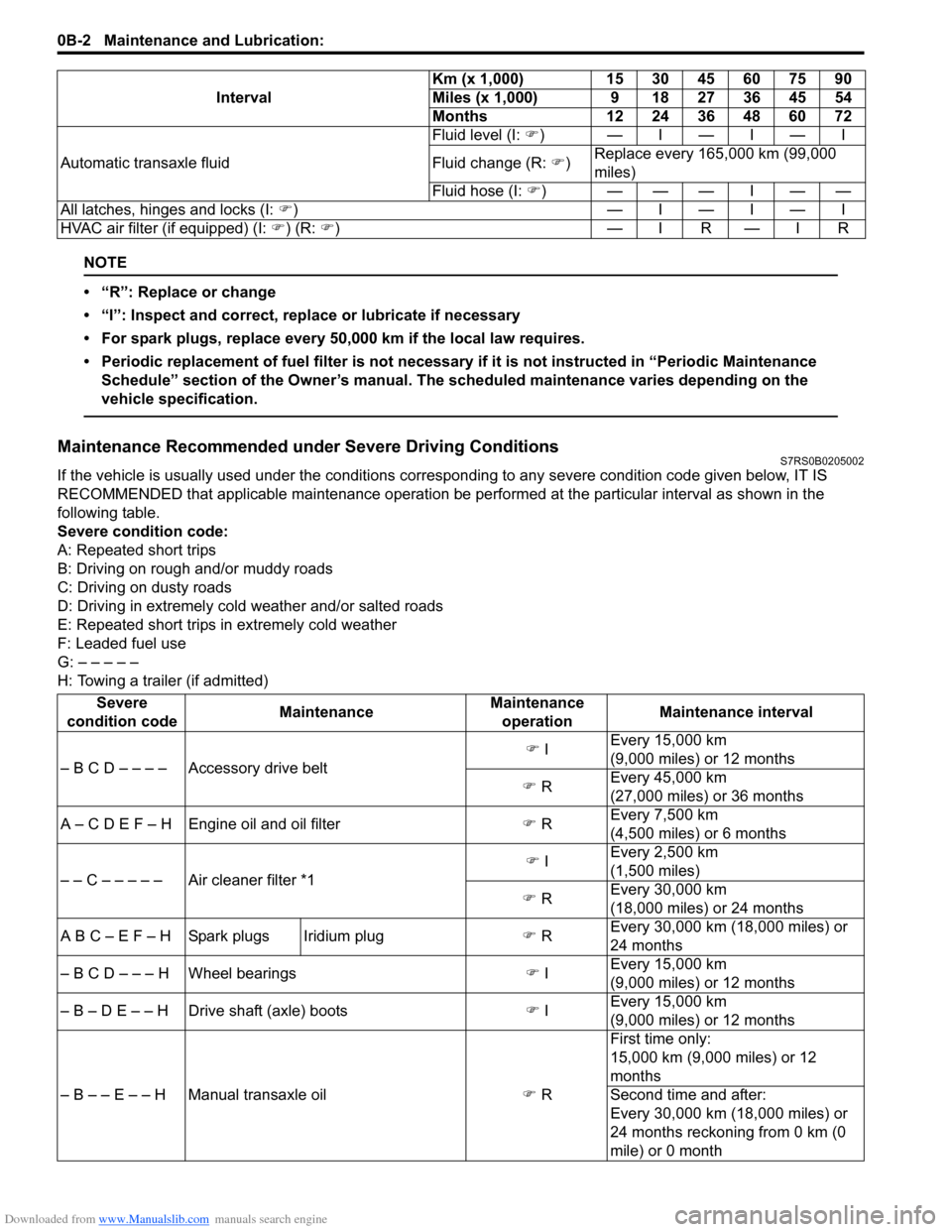

Air Cleaner Filter InspectionS7RS0B0206008

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily, clean filter with compressed air from air outlet

side of filter.

4) Install air cleaner filter and Clamp cap securely.

Air Cleaner Filter ReplacementS7RS0B0206009

Replace air cleaner filter with new one according to

Steps 1), 2) and 4) of “Air Cleaner Filter Inspection”.

Fuel Lines and Connections InspectionS7RS0B0206010

Visually inspect fuel lines and connections for evidence

of fuel leakage, hose cracking and damage. Make sure

all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

I4RS0A020003-01

I2RH01140007-01

I4RS0B020001-01

I4RS0A020005-01

Page 65 of 1496

![SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / SUZUKI SWIFT 2007 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS /](/img/20/7607/w960_7607-64.png)

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / ESP® control module 49. Radiator cooling fan motor

[B]: Auto A/C model 25. TCM 50. “RDTR FAN” fuse

1. ECM 26. To other control module connected CAN 51. A/C compressor relay

2. APP sensor assembly 27. Generator 52. Magnet clutch of compressor (A/C model)

3. Shield wire 28. Electric load current sensor (if equipped) 53. “A/C CPRSR” fuse

4. CMP sensor 29. Brake light 54. Ignition coil assembly (for No.1 and No.4 spark

plugs)

5. CKP sensor 30. Brake light switch 55. Ignition coil assembly (for No.2 and No.3 spark

plugs)

6. MAF and IAT sensor 31. Diagnosis connector (Hong Kong model) 56. P/S control module

7. MAP sensor 32. Throttle actuator control relay 57. “RADIO” fuse

8. ECT sensor 33. “THR MOT” fuse 58. Main relay

9. A/C refrigerant pressure sensor 34. Throttle throttle body assembly 59. “IG COIL” fuse

10. A/C evaporator outlet air temp. sensor (Manual A/C model) 35. Throttle actuator

60. Ignition switch

11. HO2S-1 36. TP sensor 61. “IG ACC” fuse

12. HO2S-2 37. Injector No.1 62. “FI” fuse

13. Knock sensor 38. Injector No.2 63. Starting motor control relay

14. Blower motor relay 39. Injector No.3 64. “ST SIG” fuse

15. Blower motor 40. Injector No.4 65. “ST MOT” fuse

16. Blower motor resistor 41. EVAP canister purge valve66. Transmission range switch (A/T model) or CPP

switch (Hong Kong model with M/T)

17. Blower speed selector 42. EGR valve 67. Starting motor

18. A/C switch 43. Oil control valve (Camshaft position

control) (VVT model) 68. Immobilizer coil antenna

19. Blower motor controller 44. Fuel pump relay 69. Main fuse box

20. HVAC control module 45. Fuel pump 70. Battery

21. Data link connector (DLC) 46. Radiator cooling fan motor relay No.1 71. Barometric pressure sensor

22. To other control module connected with DLC 47. Radiator cooling fan motor relay No.2

72. Engine ground

23. BCM 48. Radiator cooling fan motor relay No.3 73. Body ground

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110008-01

Page 90 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-40 Engine General Information and Diagnosis:

11Check fuel pump for operation

Was fuel pump operating sou nd heard from fuel filler for

about 2 seconds after ignition switch ON and stop? Go to “Fuel Pressure

Check”.

Go to “Fuel Pump and

Its Circuit Check”.

12 Check ignition spark

1) Disconnect injector couplers.

2) Remove spark plugs and connect them to high-tension

cords or ignition coil assemblies.

3) Ground spark plugs.

4) Crank engine and check if each spark plug sparks.

Is it in good condition? Go to Step 13. Go to “Ignition Spark

Test in Section 1H”.

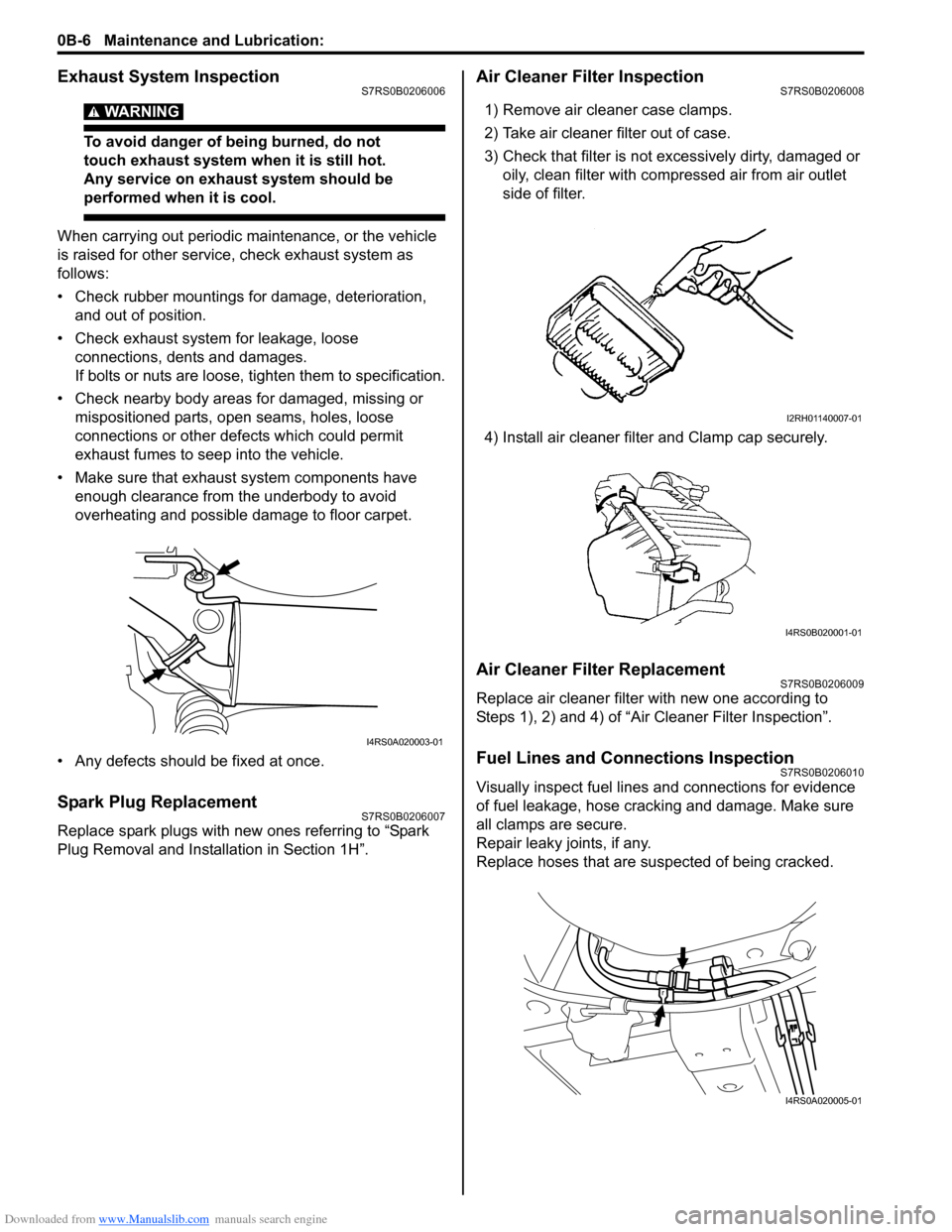

13 Check fuel injector for operation

1) Install spark plugs and connect injector connectors.

2) Using sound scope (1), check operating sound of each

injector (2) when cranking engine.

Was injector operating sound heard from all injectors? Go to “Engine Symptom

Diagnosis”.

Go to “Fuel Injector

Circuit Check”.

Step Action Yes No

I3RM0A110015-01

Page 164 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-114 Engine General Information and Diagnosis:

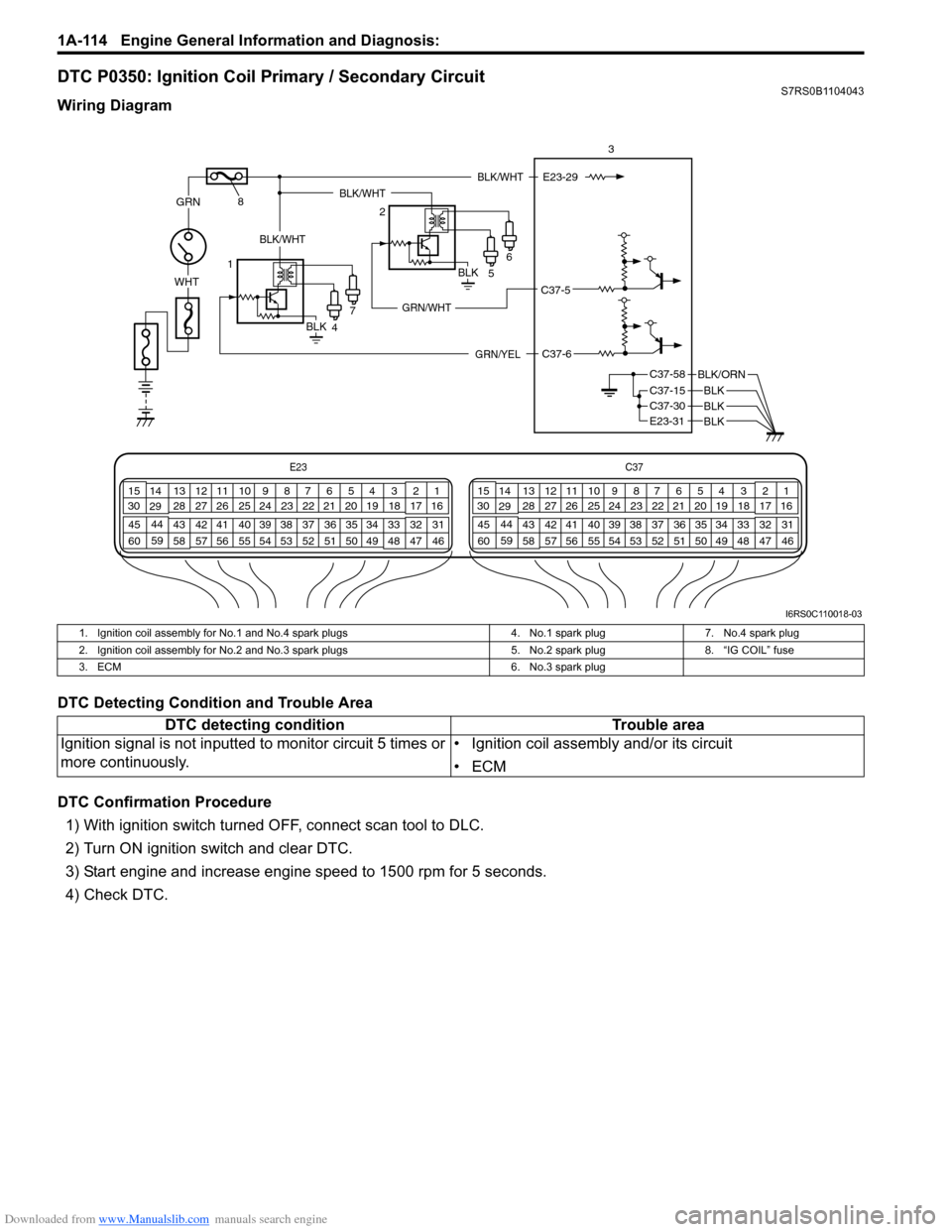

DTC P0350: Ignition Coil Primary / Secondary CircuitS7RS0B1104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC.

3) Start engine and increase engine speed to 1500 rpm for 5 seconds.

4) Check DTC.

BLK/WHT

GRN

WHT

BLK/ORN

BLKBLK

BLK/WHT

4 3

1 7

GRN/YEL

GRN/WHT

C37-6

C37-5

C37-58

C37-15C37-30

BLKE23-31

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

8BLK/WHT

E23-29

BLK

5 6BLK

2

I6RS0C110018-03

1. Ignition coil assembly for No.1 and No.4 spark plugs

4. No.1 spark plug7. No.4 spark plug

2. Ignition coil assembly for No.2 and No.3 spark plugs 5. No.2 spark plug8. “IG COIL” fuse

3. ECM 6. No.3 spark plug

DTC detecting conditionTrouble area

Ignition signal is not inputted to monitor circuit 5 times or

more continuously. • Ignition coil assembly and/or its circuit

•ECM

Page 165 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-115

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Ignition spark check

1) Check that each spark plug sparks referring to “Ignition

Spark Test in Section 1H”.

Is check result satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3 Ignition coil power, output and ground circuit check

1) Disconnect ignition coil connector of the cylinder found

as faulty in Step 2.

2) Check ignition coil circuit of the cylinder found as faulty in Step 2 for the following.

• Voltage between power circuit wire terminal of ignition coil connector and vehicle body ground is 10 – 14 V

with ignition switch turned ON.

• Voltage between output circuit wire terminal of ignition coil connector and vehicle body ground is 4 – 6 V with

ignition switch turned ON.

• Resistance between ground circuit wire terminal of ignition coil connector and vehicle body ground is less

than 2 Ω.

Are they in good condition? Go to Step 4.

Repair or replace

defective wire.

4 Ignition coil check

1) Replace ignition coil for No.1 and No.4 spark plugs with

ignition coil for No.2 and No.3 spark plugs.

Is the cylinder found as faulty in good condition now? Faulty ignition coil. Go to Step 5.

5 Ignition coil output circuit check

1) Disconnect connectors from ECM.

2) Check ignition coil circuit of the cylinder found as faulty

in Step 2 for the following.

• Resistance of output wire circuit between ignition coil

connector and ECM connector is less than 2 Ω.

• Resistance of output wire circuit between ignition coil connector and vehicle b ody ground is infinity.

Are they in good condition? Substitute a known-

good ECM and recheck.

Repair or replace

defective wire.

Page 289 of 1496

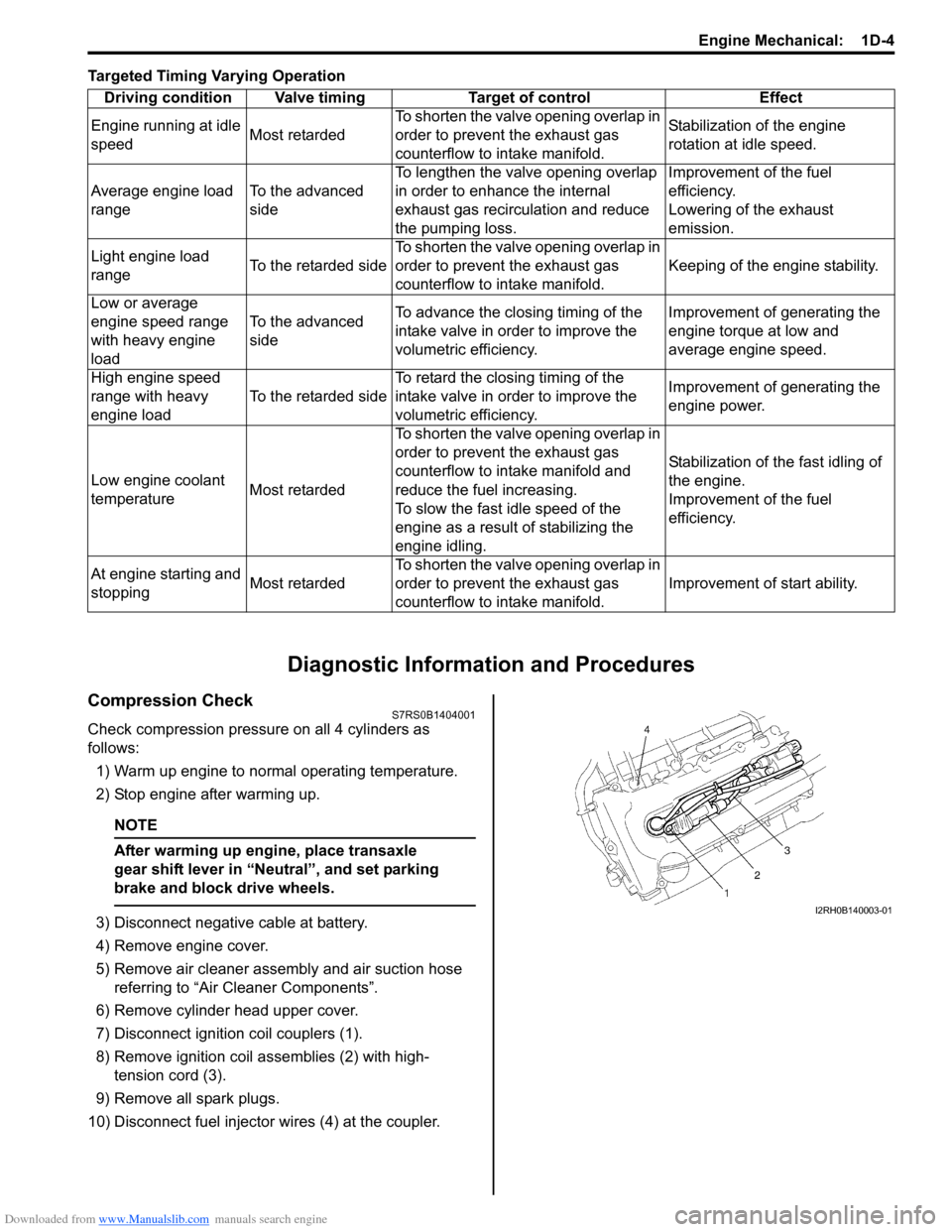

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-4

Targeted Timing Varying Operation

Diagnostic Information and Procedures

Compression CheckS7RS0B1404001

Check compression pressure on all 4 cylinders as

follows:

1) Warm up engine to normal operating temperature.

2) Stop engine after warming up.

NOTE

After warming up engine, place transaxle

gear shift lever in “Neutral”, and set parking

brake and block drive wheels.

3) Disconnect negative cable at battery.

4) Remove engine cover.

5) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

6) Remove cylinder head upper cover.

7) Disconnect ignition coil couplers (1).

8) Remove ignition coil assemblies (2) with high- tension cord (3).

9) Remove all spark plugs.

10) Disconnect fuel injector wires (4) at the coupler. Driving condition Valve timing Target of control Effect

Engine running at idle

speed Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Stabilization of the engine

rotation at idle speed.

Average engine load

range To the advanced

sideTo lengthen the valve opening overlap

in order to enhance the internal

exhaust gas recirculation and reduce

the pumping loss. Improvement of the fuel

efficiency.

Lowering of the exhaust

emission.

Light engine load

range To the retarded sideTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Keeping of the engine stability.

Low or average

engine speed range

with heavy engine

load To the advanced

side

To advance the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine torque at low and

average engine speed.

High engine speed

range with heavy

engine load To the retarded sideTo retard the closing timing of the

intake valve in order to improve the

volumetric efficiency. Improvement of generating the

engine power.

Low engine coolant

temperature Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to intake manifold and

reduce the fuel increasing.

To slow the fast idle speed of the

engine as a result of stabilizing the

engine idling. Stabilization of the fast idling of

the engine.

Improvement of the fuel

efficiency.

At engine starting and

stopping Most retardedTo shorten the valve opening overlap in

order to prevent the exhaust gas

counterflow to in

take manifold. Improvement of start ability.I2RH0B140003-01

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

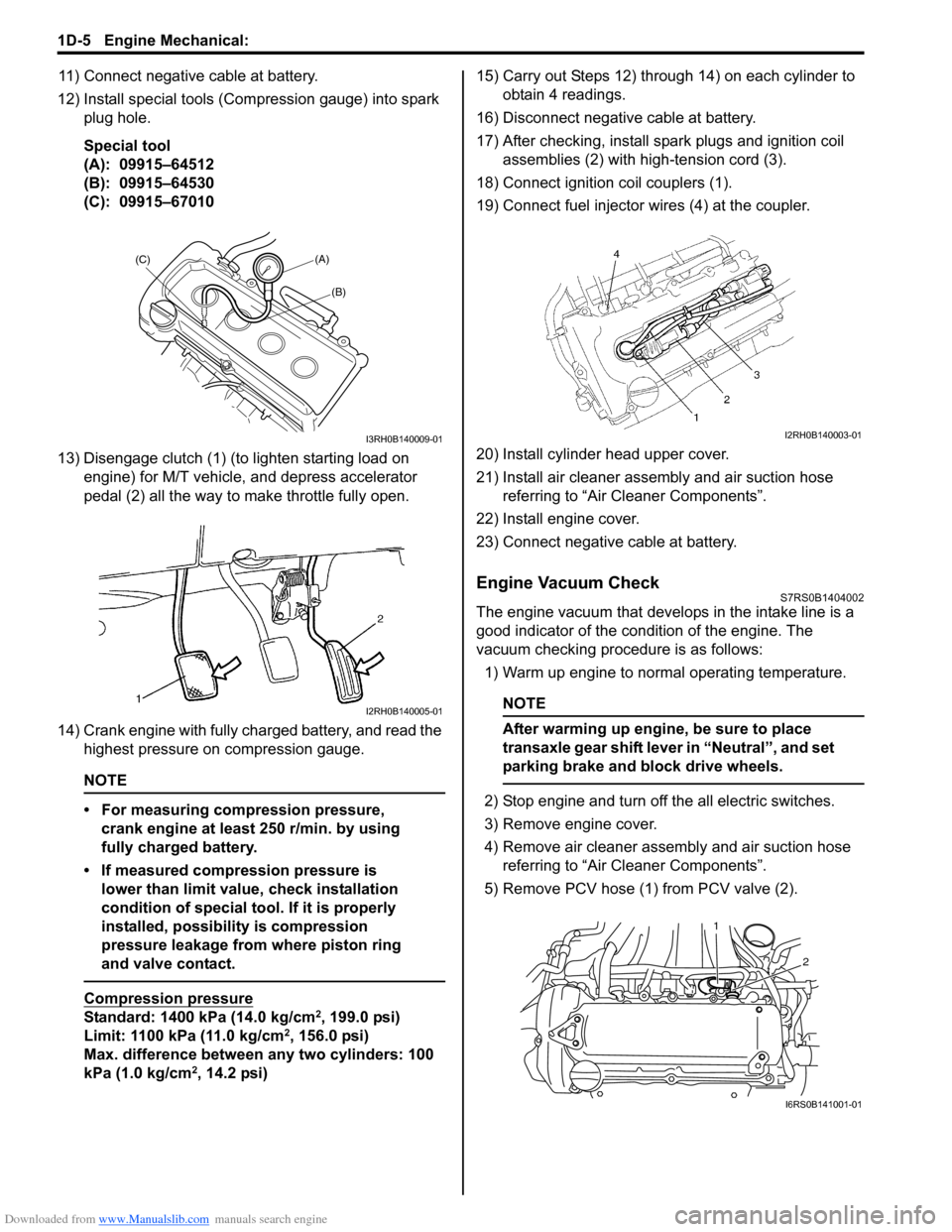

11) Connect negative cable at battery.

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 393 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-1

Engine

Ignition System

General Description

Ignition System ConstructionS7RS0B1801001

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below.

• ECM

It detects the engine and vehicle conditions through the si gnals from the sensors, determines the most suitable

ignition timing and time for electricity to flow to the primar y coil and sends a signal to the ignitor (power unit) in the

ignition coil assembly.

• Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built -in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is induced

in the secondary coil.

• High-tension cords and spark plugs

• CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression stroke,

detects the crank angle and adjusts in itial ignition timing automatically.

• TP sensor, ECT sensor, MAP sensor, MAF sensor, IAT sensor, knock sensor and other sensors / switches

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and No.4

spark plugs and the other is for No.2 and No.3 spark plugs). W hen an ignition signal is sent from ECM to the ignitor in

the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary coil and that

passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simultaneously. Likewise,

when an ignition signal is sent to the ignitor in the ot her ignition coil assembly, No.2 and No.3 spark plugs spark

simultaneously.