universal joint shaft SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

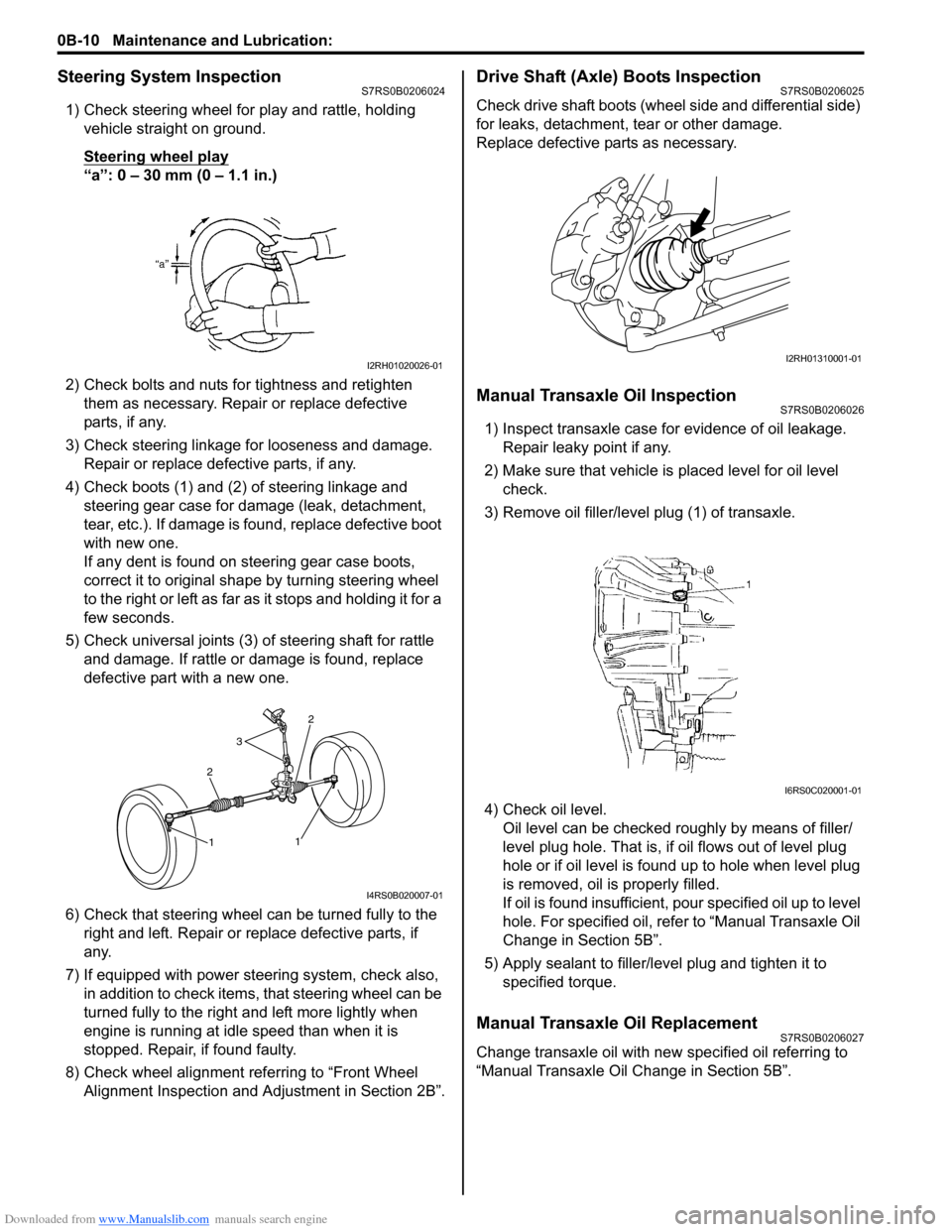

Steering System InspectionS7RS0B0206024

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01