Connection SUZUKI SWIFT 2008 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 220 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-170 Engine General Information and Diagnosis:

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-43” terminal of ECM connector and engine ground.

Is resistance infinity? Go to Step 5. “RED” wire is shorted to

other circuit.

5 Wire harness check

1) Measure voltage between “C37-43” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

other circuit.

6 Wire harness check

1) Measure voltage between “GRN” wire terminal of electric

throttle body connector and engine ground, between

“WHT” wire terminal of electric throttle body connector

and engine ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 9. Go to Step 7.

7 Wire harness check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Check for proper connection of ECM connector at “C37-

54” and “C37-40” terminals.

4) If OK, measure voltage between “C37-54” terminal of ECM connector and engine ground, between “C37-40”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “WHT”

wire is shorted to other

circuit.

8 Wire harness check

1) Measure resistance between “GRN” wire terminal of

electric throttle body connector and engine ground,

between “WHT” wire terminal of electric throttle body

connector and engine ground with ignition switch turned

OFF.

Is each resistance infinity? Substitute a known-

good ECM and recheck.

“GRN” wire or “WHT”

wire is shorted to other

circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is each output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

Page 222 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-172 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is displayed each APP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

3 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

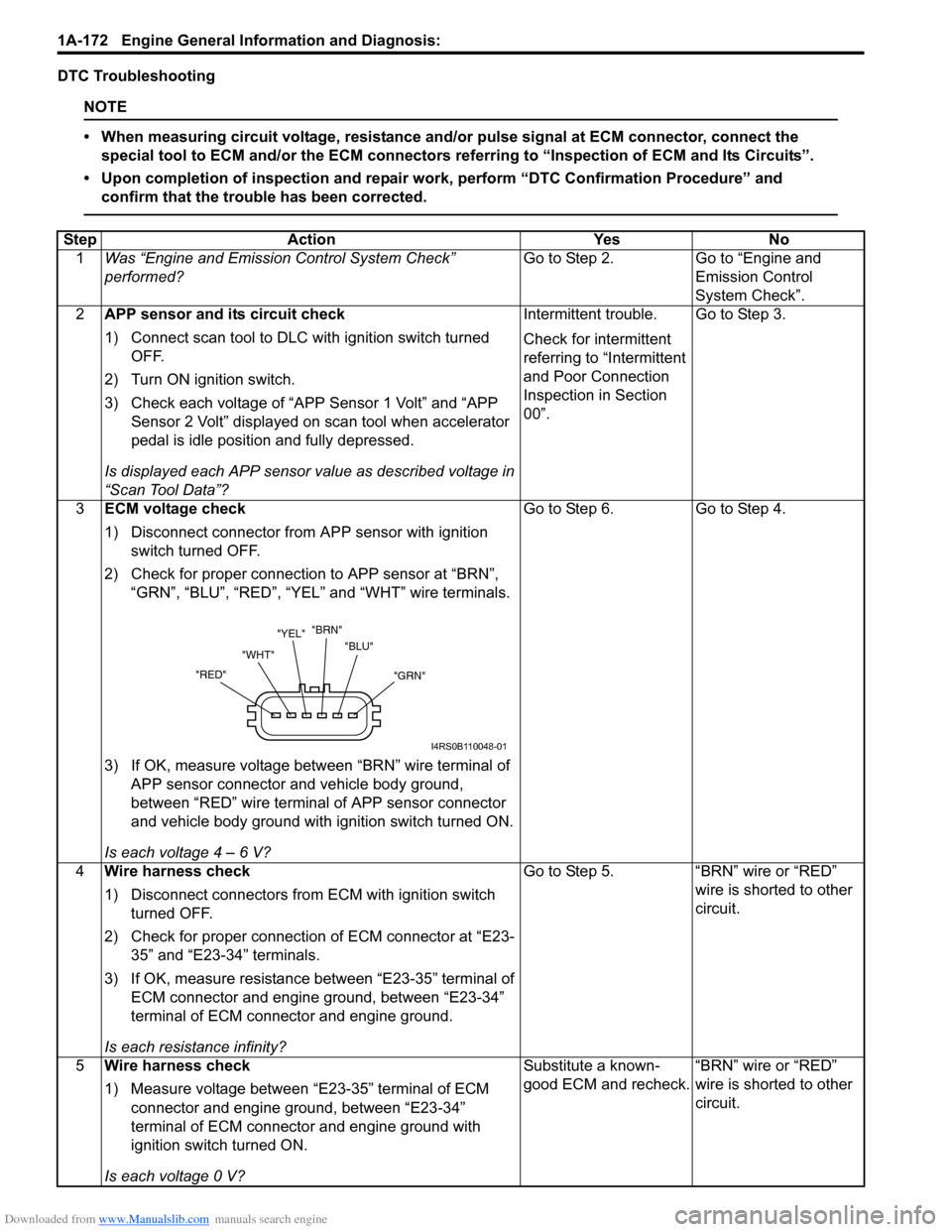

2) Check for proper connection to APP sensor at “BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground,

between “RED” wire terminal of APP sensor connector

and vehicle body ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” and “E23-34” terminals.

3) If OK, measure resistance between “E23-35” terminal of ECM connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground.

Is each resistance infinity? Go to Step 5.

“BRN” wire or “RED”

wire is shorted to other

circuit.

5 Wire harness check

1) Measure voltage between “E23-35” terminal of ECM

connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 223 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-173

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit MalfunctionS7RS0B1104078

DTC P2227: Barometric Pressure Circuit Range / Performance

DTC P2228: Barometric Pressure Circuit Low

DTC P2229: Barometric Pressure Circuit High

System Description

Barometric pressure sensor is installed in ECM.

DTC Detecting Condition and Trouble Area6

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 37”, “E23-52”, “E23-36” and “E23-51” terminals.

3) If OK, measure resistance between “GRN” wire terminal of APP sensor connector and vehicle body ground,

between “YEL” wire terminal of APP sensor connector

and vehicle body ground.

Is each resistance infinity? Go to Step 7. “GRN” wire or “YEL”

wire is shorted to other

circuit.

7 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E23-37” terminal of ECM

connector and engine ground, between “E23-36”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “YEL”

wire is shorted to other

circuit.

8 APP sensor check

1) Check APP sensor referring to “APP Sensor Assembly

Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace APP sensor

assembly.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P2227:

Difference of barometric pressure value and intake manifold

pressure value is higher than specified value while engine

cranking.

(*2 driving cycle detection logic, monitoring once par driving cycle) • Manifold absolute pressure sensor

performance problem

• Barometric pressure sensor in ECM

DTC P2228:

Barometric pressure signal less than specified value is detected.

(1 driving cycle detection logic) • Barometric pressure sensor in ECM

DTC P2229:

Barometric pressure signal more than specified value is detected.

(1 driving cycle detection logic)

Page 245 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-195

Circuit Description

When the ignition switch is turned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Circuit fuse check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to ECM connector at “E23- 2”, “E23-29”, “E23-60”, “E23-1”, “E23-16”, “E23-31”,

“C37-58”, “C37-15” and “C37-30” terminals.

3) If OK, check “RADIO” fuse and “IG COIL” fuse for blowing.

Are “RADIO” fuse and “IG COIL” fuse in good condition? Go to Step 2.

Replace fuse (s) and

check for short in

circuits connected to

fuse(s).

2 Power supply circuit check

1) Measure voltage between “E23-2” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 3.

“WHT/RED” or “WHT”

wire is open circuit.

3 Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between “E23-29” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/WHT” or “GRN”

wire is open circuit.

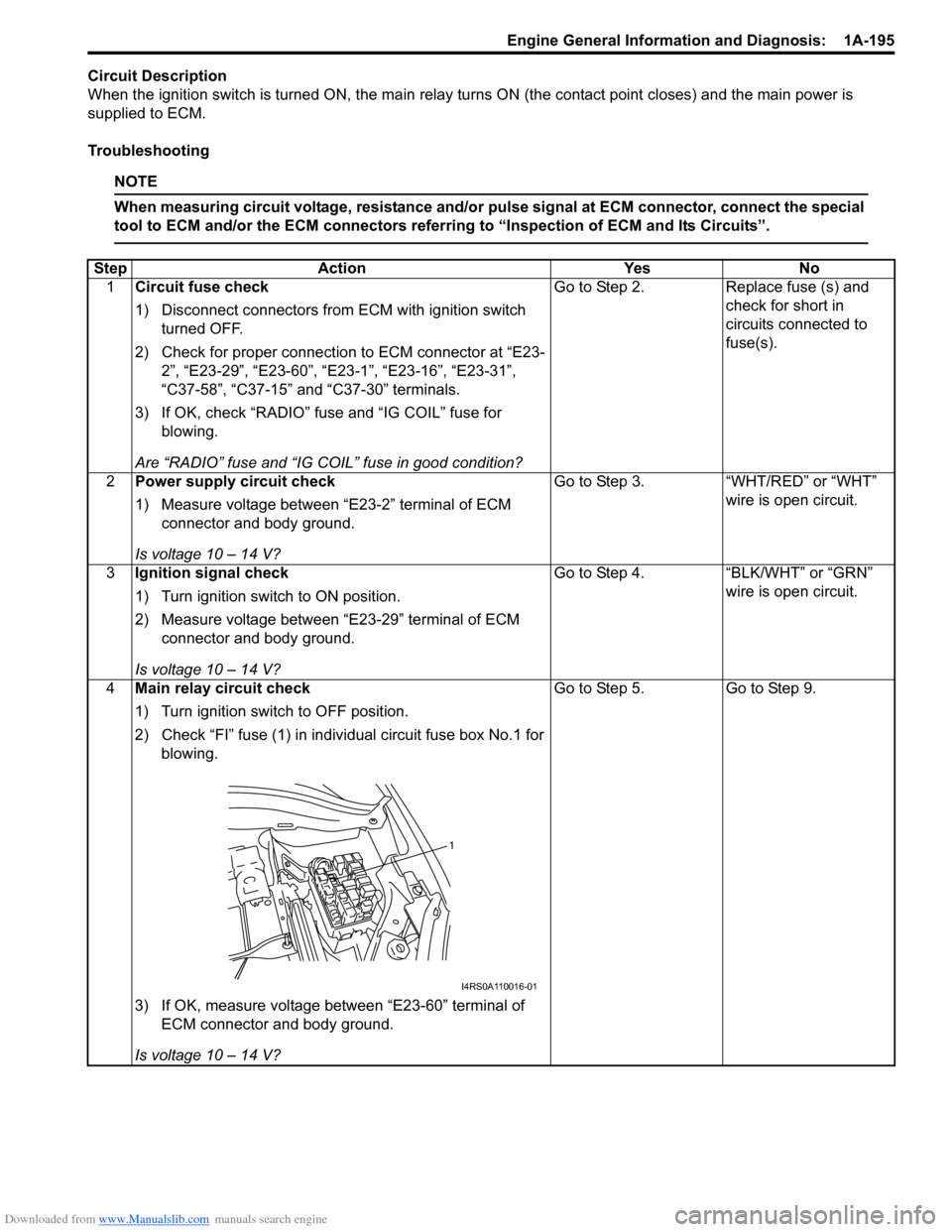

4 Main relay circuit check

1) Turn ignition switch to OFF position.

2) Check “FI” fuse (1) in indivi dual circuit fuse box No.1 for

blowing.

3) If OK, measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 10 – 14 V? Go to Step 5.

Go to Step 9.

1

I4RS0A110016-01

Page 246 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-196 Engine General Information and Diagnosis:

5Main relay circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between “E23-60” terminal of ECM connector and body ground.

Is voltage 0 – 1 V? Go to Step 7. Go to Step 6.

6 ECM ground circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from ECM.

3) Measure resistance between each “E23-31”, “C37-58”,

“C37-15” and “C37-30” terminals of ECM connector and

body ground.

Is resistance 1

Ω or less? Substitute a known-

good ECM and recheck.

“BLK/ORN” or “BLK”

wire is open or high

resistance circuit.

7 Main relay circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Using service wire, ground “E23-60” terminal of ECM connector and measure voltage between each “E23-1”

and “E23-16” terminals of ECM connector and body

ground.

Is voltage 10 – 14 V? Go to Step 11. Go to Step 8.

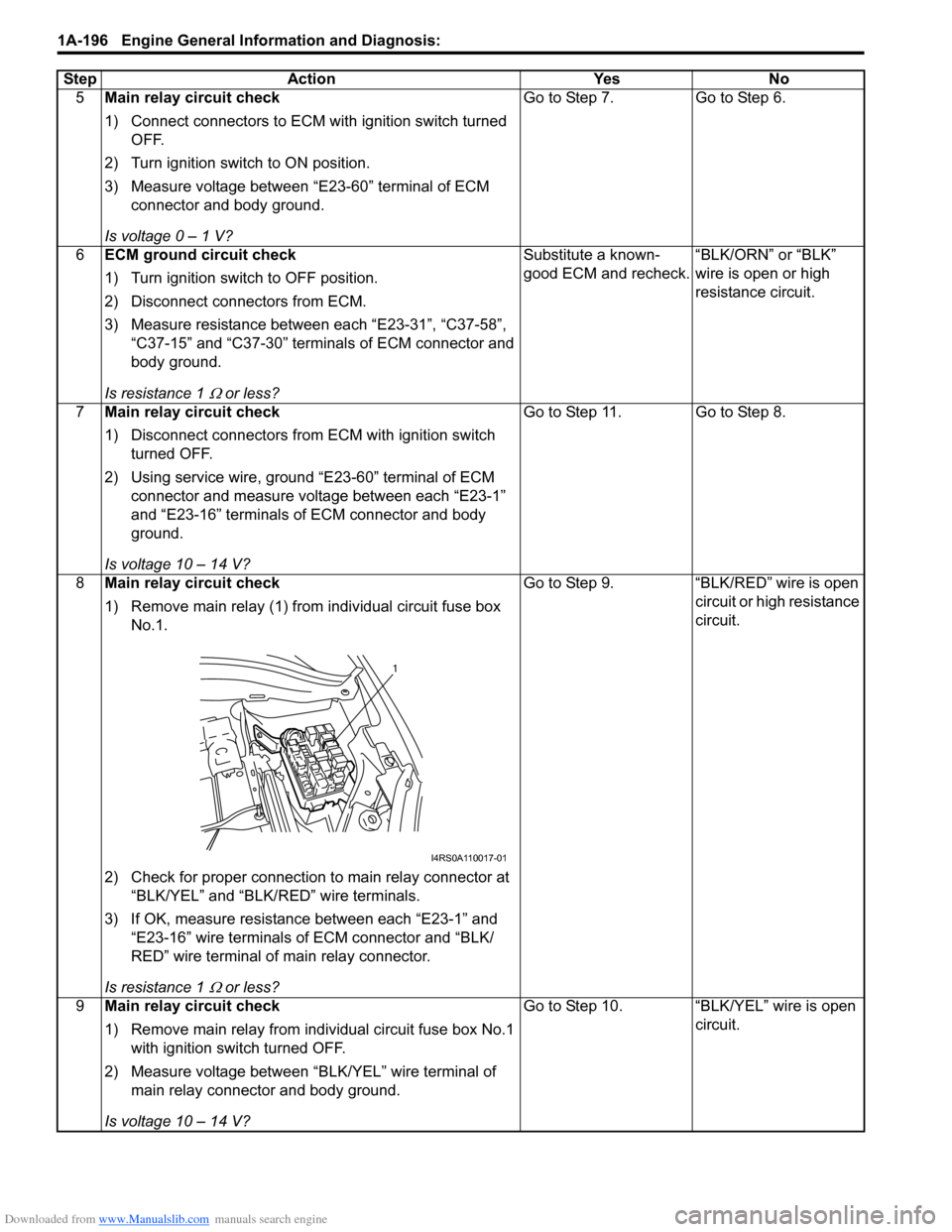

8 Main relay circuit check

1) Remove main relay (1) from individual circuit fuse box

No.1.

2) Check for proper connection to main relay connector at “BLK/YEL” and “BLK/RED” wire terminals.

3) If OK, measure resistance between each “E23-1” and “E23-16” wire terminals of ECM connector and “BLK/

RED” wire terminal of main relay connector.

Is resistance 1

Ω or less? Go to Step 9. “BLK/RED” wire is open

circuit or high resistance

circuit.

9 Main relay circuit check

1) Remove main relay from individual circuit fuse box No.1

with ignition swit ch turned OFF.

2) Measure voltage between “BLK/YEL” wire terminal of main relay connector and body ground.

Is voltage 10 – 14 V? Go to Step 10. “BLK/YEL” wire is open

circuit.

Step Action Yes No

1

I4RS0A110017-01

Page 249 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector ma ke operating sound? Fuel injectors circuit is

in good condition.

Go to Step 2.

2 Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each terminals.

3) If OK, check all 4 fuel inject ors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition? Go to Step 3.

Faulty fuel injector.

3 Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation? Go to Step 4.

Faulty fuel injector.

4 Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V? Go to Step 5.

“BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5 Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity? Go to Step 6.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6 Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V? Go to Step 7.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7 Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C37-1”, “C37-2”, “C37- 16”, “C37-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V? Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.

“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 251 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-201

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

StepAction YesNo

1 Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON? Fuel pump circuit is in

good condition.

Go to Step 2.

2 Fuel pump relay po wer supply check

1) Disconnect fuel pump relay from individual circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each terminal.

3) If OK, turn ON ignition switch, measure voltage between “BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V? Go to Step 3.

“BLK/WHT” wire is open

or shorted to ground

circuit.

3 Fuel pump relay po wer supply check

1) Turn ON ignition switch, measure voltage between “BLK/ RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V? Go to Step 4.

“BLK/RED” wire is open

circuit.

4 Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay and Starting Moto r Control Relay Inspection

in Section 1C”.

Is relay in good condition? Go to Step 5.

Faulty relay.

5 Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E23-15” terminal of ECM connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned ON.

Is voltage 10 – 14 V? Go to Step 6.

“GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 254 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-204 Engine General Information and Diagnosis:

Troubleshooting

NOTE

Before using following flow, check to make sure that battery voltage is higher than 11 V. If battery

voltage is low, pressure becomes lower than specification even if fuel pump and line are in good

condition.

StepAction YesNo

1 Fuel pressure check

1) Check fuel pressure referring to “Fuel Pressure

Inspection in Section 1G”.

Is check result satisfactory? Go to Step 2.

Go to Step 5.

2 Fuel pressure check

1) Start engine and warm it up to normal operating

temperature.

2) Keep engine speed at 4000 rpm.

Does fuel pressure show about the same value as Step 1? Go to Step 3.

Go to Step 8.

3 Fuel line check

1) Check fuel pipe, fuel hose and joint for fuel leakage.

Are they in good condition? Go to Step 4.

Repair or replace

defective part.

4 Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition? Faulty fuel pressure

regulator.

Repair or replace

damaged or damaged

part.

5 Was fuel pressure higher than specification in Step 1? Go to Step 6.Go to Step 7.

6 Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition? Faulty fuel pressure

regulator.

Repair or replace

damaged or damaged

part.

7 Fuel pump operating sound check

1) Remove fuel filler cap and th en turn ON ignition switch.

Can you hear operating sound? Go to Step 8.

Faulty fuel pump.

8 Fuel line check

1) Check fuel pipe, fuel hose and joint for damage or

deform.

Are they in good condition? Clogged fuel filter, faulty

fuel pump, faulty fuel

pressure regulator or

fuel leakage from hose

connection in fuel tank.Repair or replace

defective part.

Page 257 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-207

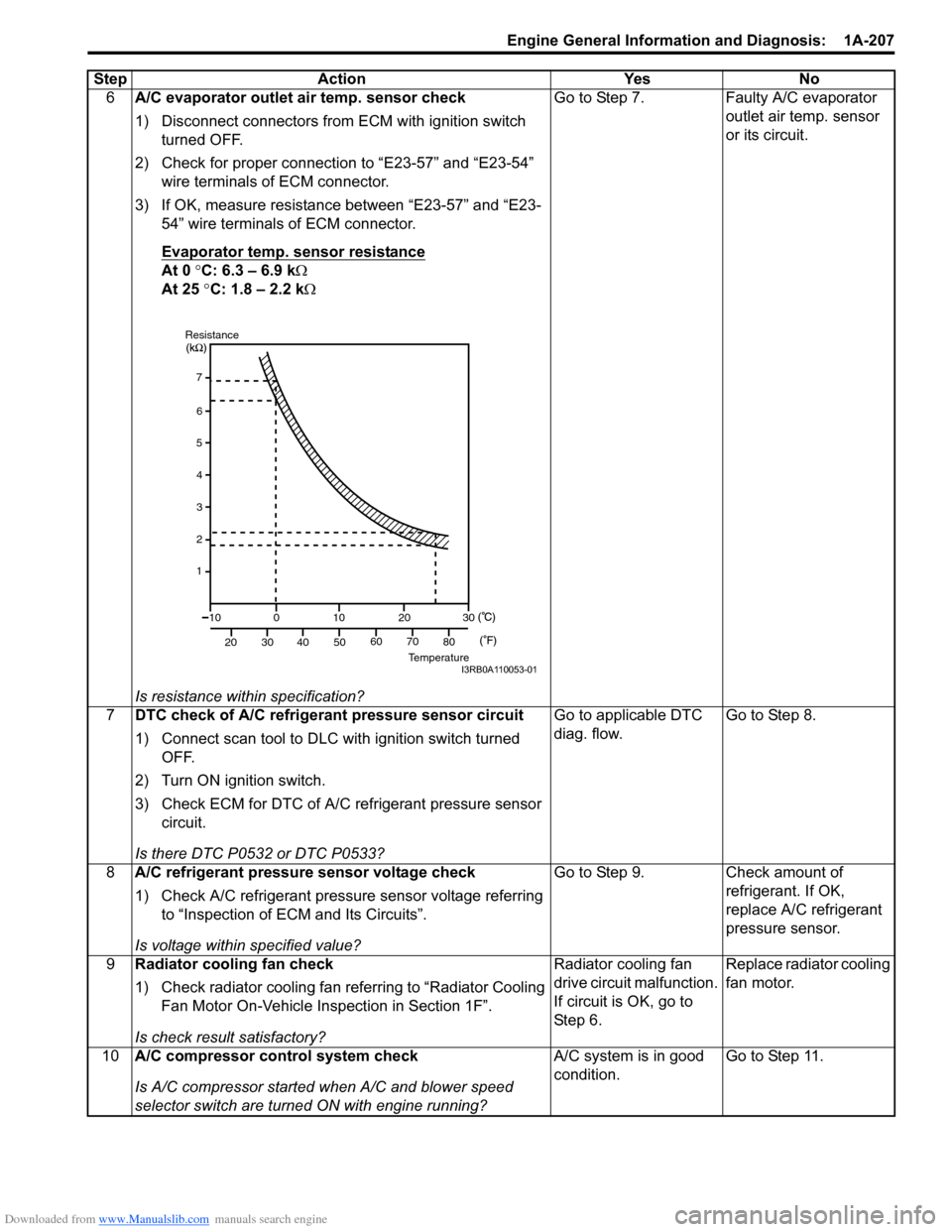

6A/C evaporator outlet air temp. sensor check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to “E23-57” and “E23-54” wire terminals of ECM connector.

3) If OK, measure resistance between “E23-57” and “E23- 54” wire terminals of ECM connector.

Evaporator temp. sensor resistance

At 0 °C: 6.3 – 6.9 k Ω

At 25 °C: 1.8 – 2.2 k Ω

Is resistance within specification? Go to Step 7. Faulty A/C evaporator

outlet air temp. sensor

or its circuit.

7 DTC check of A/C refrigerant pressure sensor circuit

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check ECM for DTC of A/C refrigerant pressure sensor circuit.

Is there DTC P0532 or DTC P0533? Go to applicable DTC

diag. flow.

Go to Step 8.

8 A/C refrigerant pressure sensor voltage check

1) Check A/C refrigerant pressure sensor voltage referring

to “Inspection of ECM and Its Circuits”.

Is voltage within specified value? Go to Step 9. Check amount of

refrigerant. If OK,

replace A/C refrigerant

pressure sensor.

9 Radiator cooling fan check

1) Check radiator cooling fan referring to “Radiator Cooling

Fan Motor On-Vehicle Inspection in Section 1F”.

Is check result satisfactory? Radiator cooling fan

drive circuit malfunction.

If circuit is OK, go to

St ep 6 .

Replace radiator cooling

fan motor.

10 A/C compressor control system check

Is A/C compressor started when A/C and blower speed

selector switch are turned ON with engine running? A/C system is in good

condition.

Go to Step 11.

Step Action Yes No

7

6

5

4

3

2

1

10

20 30

40 50

0

10

2030

60 70 80

ResistanceTemperatureI3RB0A110053-01

Page 269 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-2

EVAP Canister Purge Valve and Its Circuit

Inspection

S7RS0B1206002

WARNING!

Do not apply vacuum by mouth; otherwise

harmful fuel vapor can be breathed in.

CAUTION!

Do not apply vacuum more than –86 kPa (–

12.47 psi); otherwise EVAP canister purge

valve could be damaged.

1) Prepare to operate EVAP canister purge valve as follows.

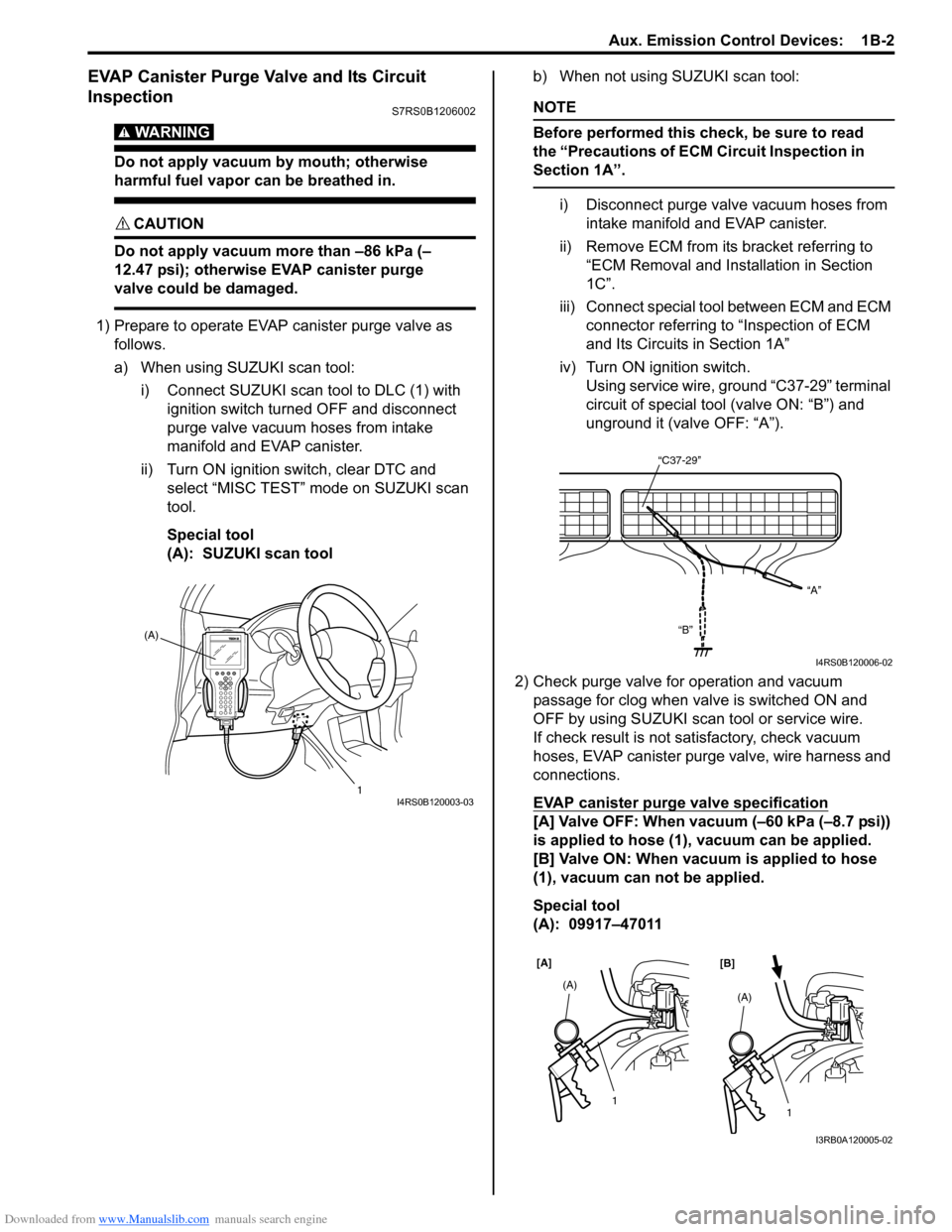

a) When using SUZUKI scan tool:

i) Connect SUZUKI scan tool to DLC (1) with ignition switch turned OFF and disconnect

purge valve vacuum hoses from intake

manifold and EVAP canister.

ii) Turn ON ignition switch, clear DTC and select “MISC TEST” mode on SUZUKI scan

tool.

Special tool

(A): SUZUKI scan tool b) When not using SUZUKI scan tool:

NOTE

Before performed this check, be sure to read

the “Precautions of ECM Circuit Inspection in

Section 1A”.

i) Disconnect purge valve vacuum hoses from

intake manifold and EVAP canister.

ii) Remove ECM from it s bracket referring to

“ECM Removal and Inst allation in Section

1C”.

iii) Connect special tool between ECM and ECM connector referring to “Inspection of ECM

and Its Circuits in Section 1A”

iv) Turn ON ignition switch. Using service wire, ground “C37-29” terminal

circuit of special tool (valve ON: “B”) and

unground it (valve OFF: “A”).

2) Check purge valve for operation and vacuum passage for clog when valve is switched ON and

OFF by using SUZUKI scan tool or service wire.

If check result is not satisfactory, check vacuum

hoses, EVAP canister purge valve, wire harness and

connections.

EVAP canister purge valve specification

[A] Valve OFF: When vacuum (–60 kPa (–8.7 psi))

is applied to hose (1), vacuum can be applied.

[B] Valve ON: When vacuum is applied to hose

(1), vacuum can not be applied.

Special tool

(A): 09917–47011

(A)

1

I4RS0B120003-03

“C37-29”“A”

“B”

I4RS0B120006-02

[A] [B]

1

(A)1

(A)

I3RB0A120005-02