isc SUZUKI SWIFT 2008 2.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 215 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-165

4ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of APP sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 7. Go to Step 5.

5 ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “E23- 34” terminal.

4) If OK, measure voltage between “E23-34” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V? “RED” wire is open or

high resistance circuit.

Go to Step 6.

6 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “E23-34” terminal of ECM connector and engine ground.

Is resistance infinity? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

ground circuit.

7 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 36”, “E23-52” and “E23-51” terminals.

3) If OK, measure resistance between “YEL” wire terminal of APP sensor connector and vehicle body ground.

Is resistance infinity? Go to Step 8. “YEL” wire is shorted to

ground circuit.

8 Wire harness check

1) Measure resistance between “E23-36” and each “E23-

52”, “E23-51”, “E23-50” terminals of ECM connector with

ignition switch turned OFF.

Is each resistance infinity? Go to Step 9. “YEL” wire is shorted to

“BLU” wire and/or

“WHT” wire and/or

“E23-50” circuit.

9 Wire harness check

1) Measure resistance between “YEL” wire terminal of APP

sensor connector and “E23-36” terminal of ECM

connector with ignition switch turned OFF.

Is resistance below 5

Ω? Go to Step 10. “YEL” wire is open or

high resistance circuit.

Step Action Yes No

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 217 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-167

4ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of APP sensor connector and vehicle body ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6. Go to Step 5.

5 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 34” terminal.

3) If OK, measure voltage between “E23-34” terminal of ECM connector and engine ground with ignition switch

turned ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

power circuit.

6 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35”, “E23-36” and “E23-34” terminals.

3) If OK, measure resistance between “YEL” wire terminal and each “BRN”, “RED” wire terminals of APP sensor

connector.

Is each resistance infinity? Go to Step 7. “YEL” wire is shorted to

“BRN” wire and/or

“RED” wire.

7 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E23-36” terminal of ECM

connector and engine ground.

Is voltage 0 V? Go to Step 8. “YEL” wire is shorted to

power circuit.

8 Ground circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Measure resistance between “WHT” wire terminal of APP sensor connector and vehicle body ground.

Is resistance below 5

Ω? Go to Step 10. Go to Step 9.

Step Action Yes No

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 219 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-169

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Difference between the opening angle based on TP

sensor (main) and the opening angle based on TP sensor

(sub) is more than specif ication for specified time

continuously.

(1 driving detection logic) • Throttle position sensor (main) and (sub) circuit

• Electric throttle body

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

3 ECM voltage check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

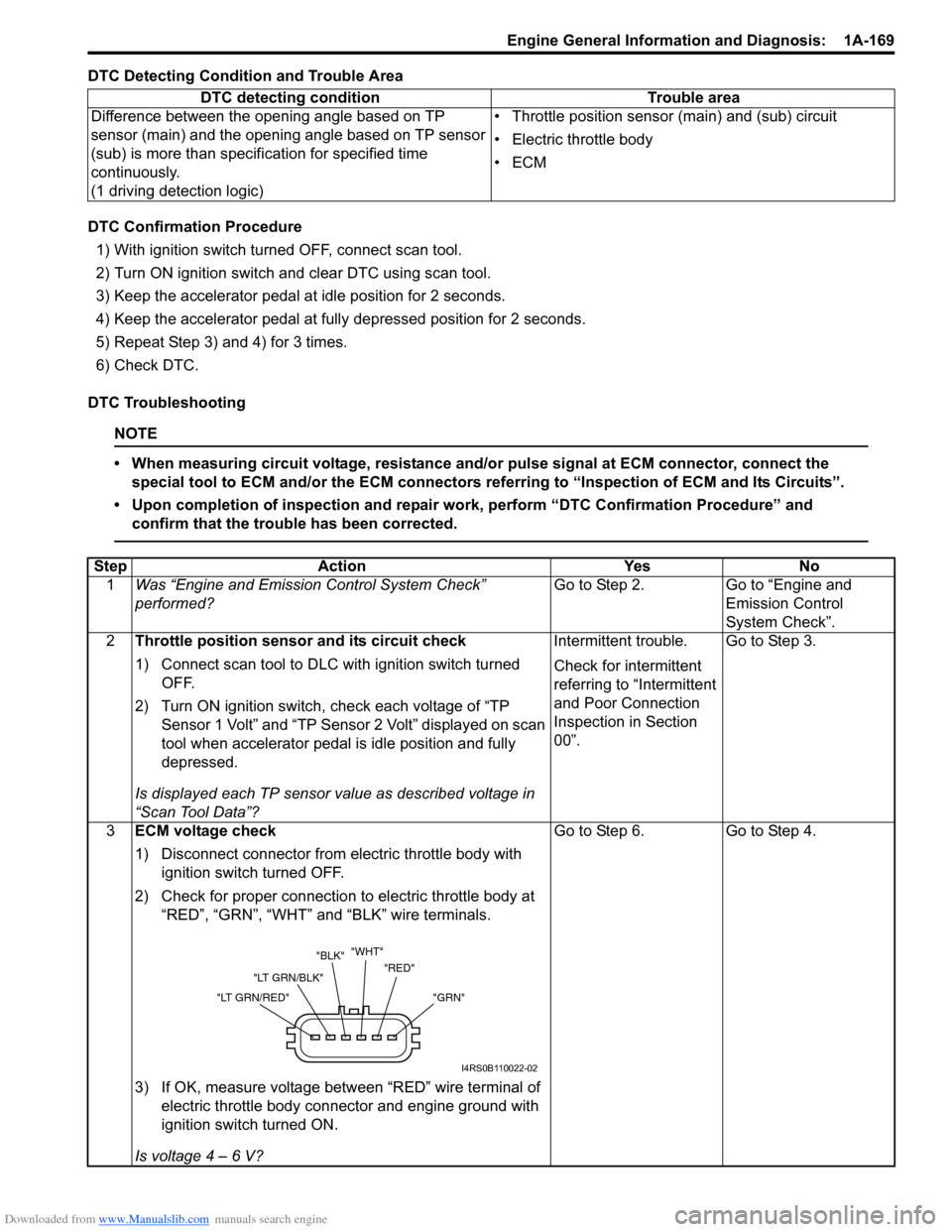

2) Check for proper connection to electric throttle body at “RED”, “GRN”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of electric throttle body connector and engine ground with

ignition switch turned ON.

Is voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 220 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-170 Engine General Information and Diagnosis:

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C37-43” terminal of ECM connector and engine ground.

Is resistance infinity? Go to Step 5. “RED” wire is shorted to

other circuit.

5 Wire harness check

1) Measure voltage between “C37-43” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V? Substitute a known-

good ECM and recheck.

“RED” wire is shorted to

other circuit.

6 Wire harness check

1) Measure voltage between “GRN” wire terminal of electric

throttle body connector and engine ground, between

“WHT” wire terminal of electric throttle body connector

and engine ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 9. Go to Step 7.

7 Wire harness check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Check for proper connection of ECM connector at “C37-

54” and “C37-40” terminals.

4) If OK, measure voltage between “C37-54” terminal of ECM connector and engine ground, between “C37-40”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “WHT”

wire is shorted to other

circuit.

8 Wire harness check

1) Measure resistance between “GRN” wire terminal of

electric throttle body connector and engine ground,

between “WHT” wire terminal of electric throttle body

connector and engine ground with ignition switch turned

OFF.

Is each resistance infinity? Substitute a known-

good ECM and recheck.

“GRN” wire or “WHT”

wire is shorted to other

circuit.

9 Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is each output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

Page 222 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-172 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 APP sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check each voltage of “APP Sensor 1 Volt” and “APP Sensor 2 Volt” displayed on scan tool when accelerator

pedal is idle position and fully depressed.

Is displayed each APP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

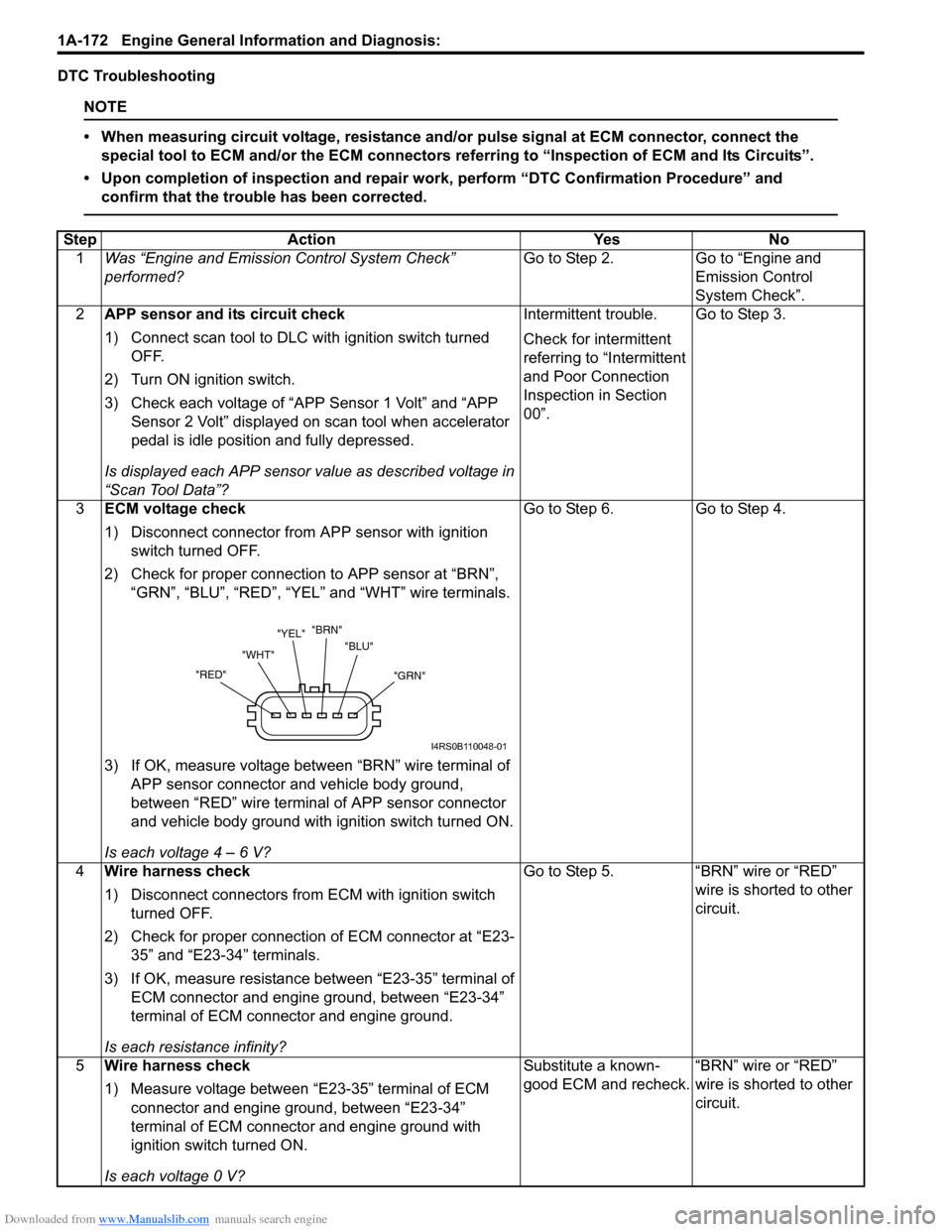

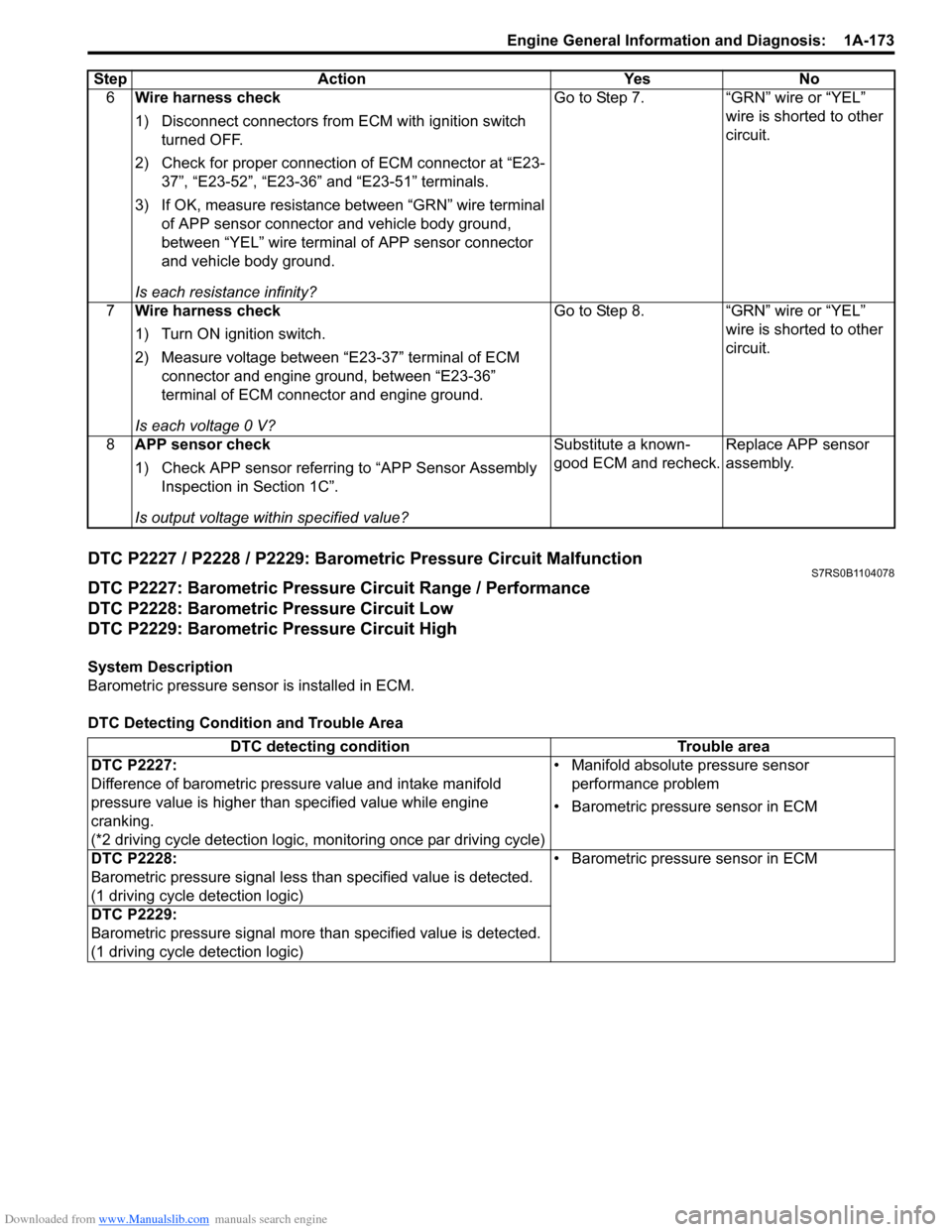

3 ECM voltage check

1) Disconnect connector from APP sensor with ignition

switch turned OFF.

2) Check for proper connection to APP sensor at “BRN”, “GRN”, “BLU”, “RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of APP sensor connector and vehicle body ground,

between “RED” wire terminal of APP sensor connector

and vehicle body ground with ignition switch turned ON.

Is each voltage 4 – 6 V? Go to Step 6.

Go to Step 4.

4 Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 35” and “E23-34” terminals.

3) If OK, measure resistance between “E23-35” terminal of ECM connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground.

Is each resistance infinity? Go to Step 5.

“BRN” wire or “RED”

wire is shorted to other

circuit.

5 Wire harness check

1) Measure voltage between “E23-35” terminal of ECM

connector and engine ground, between “E23-34”

terminal of ECM connector and engine ground with

ignition switch turned ON.

Is each voltage 0 V? Substitute a known-

good ECM and recheck.

“BRN” wire or “RED”

wire is shorted to other

circuit.

"GRN"

"BLU"

"BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 223 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-173

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit MalfunctionS7RS0B1104078

DTC P2227: Barometric Pressure Circuit Range / Performance

DTC P2228: Barometric Pressure Circuit Low

DTC P2229: Barometric Pressure Circuit High

System Description

Barometric pressure sensor is installed in ECM.

DTC Detecting Condition and Trouble Area6

Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E23- 37”, “E23-52”, “E23-36” and “E23-51” terminals.

3) If OK, measure resistance between “GRN” wire terminal of APP sensor connector and vehicle body ground,

between “YEL” wire terminal of APP sensor connector

and vehicle body ground.

Is each resistance infinity? Go to Step 7. “GRN” wire or “YEL”

wire is shorted to other

circuit.

7 Wire harness check

1) Turn ON ignition switch.

2) Measure voltage between “E23-37” terminal of ECM

connector and engine ground, between “E23-36”

terminal of ECM connector and engine ground.

Is each voltage 0 V? Go to Step 8. “GRN” wire or “YEL”

wire is shorted to other

circuit.

8 APP sensor check

1) Check APP sensor referring to “APP Sensor Assembly

Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace APP sensor

assembly.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P2227:

Difference of barometric pressure value and intake manifold

pressure value is higher than specified value while engine

cranking.

(*2 driving cycle detection logic, monitoring once par driving cycle) • Manifold absolute pressure sensor

performance problem

• Barometric pressure sensor in ECM

DTC P2228:

Barometric pressure signal less than specified value is detected.

(1 driving cycle detection logic) • Barometric pressure sensor in ECM

DTC P2229:

Barometric pressure signal more than specified value is detected.

(1 driving cycle detection logic)

Page 225 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-175

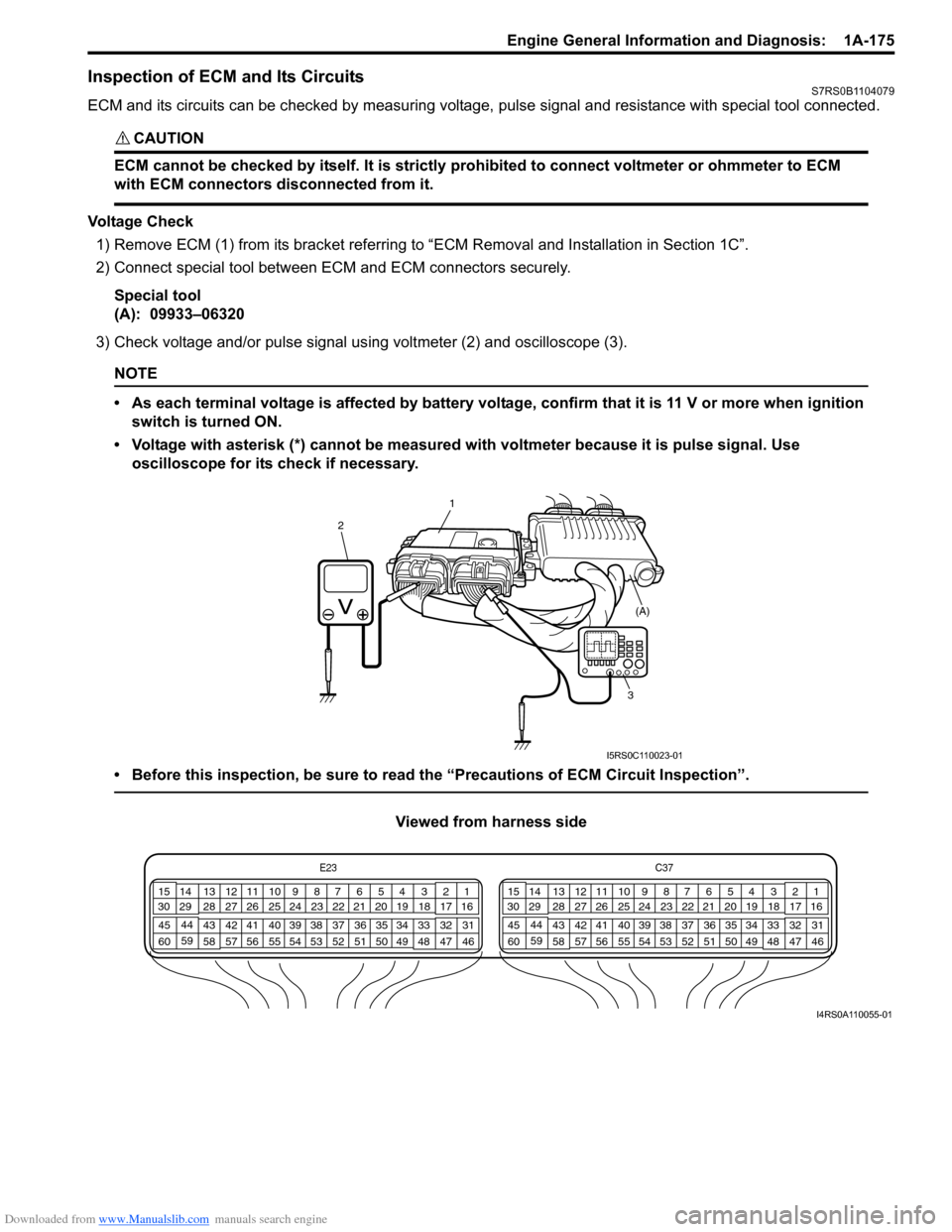

Inspection of ECM and Its CircuitsS7RS0B1104079

ECM and its circuits can be checked by measuring voltage, pulse signal and resistance with special tool connected.

CAUTION!

ECM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to ECM

with ECM connectors disconnected from it.

Voltage Check

1) Remove ECM (1) from its bracke t referring to “ECM Removal and Installation in Section 1C”.

2) Connect special tool between EC M and ECM connectors securely.

Special tool

(A): 09933–06320

3) Check voltage and/or pulse signal us ing voltmeter (2) and oscilloscope (3).

NOTE

• As each terminal voltage is affected by battery voltag e, confirm that it is 11 V or more when ignition

switch is turned ON.

• Voltage with asterisk (*) cannot be measured with voltmeter because it is pulse signal. Use oscilloscope for its check if necessary.

• Before this inspection, be sure to read the “Precautions of ECM Circuit Inspection”.

Viewed from harness side

1

2

3 (A)

I5RS0C110023-01

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110055-01

Page 228 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-178 Engine General Information and Diagnosis:

C37-20RED/

YEL CMP sensor signal 0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*0 – 0.6 V↑↓

4 – 5 V

(“Reference

waveform No.16: ” and “Reference

waveform No.17: ”) Engine running at idle

after warmed up engine.

Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(6 pulses are generated

per 1 camshaft revolution.)

C37-21 PNK CKP sensor signal 0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*4 – 5 V↑↓

0 – 0.6 V

(“Reference

waveform No.16: ” and “Reference

waveform No.17: ”) Engine running at idle

after warmed up engine. Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(30 (36 – 6) pulses are

generated per 1

crankshaft revolution.)

C37-22 — — — — —

C37-23 PNK/

BLU Electric load

current sensor

signal 3.8 – 4.2 V Ignition switch turned ON.

—

3.0 – 3.4 V

Ignition switch turned ON

and headlight switch

turned ON (HI beam).

2.3 – 2.7 V Ignition switch turned ON,

headlight switch turned

ON (HI beam) and blower

selector at HI position.

C37-24 LT GRN ECT sensor signal 3.3 – 3.8 V

Ignition switch turned ON,

ECT at 0

°C, 32 °F.

—

1.38 – 1.72 V Ignition switch turned ON,

ECT at 50

°C, 122 °F.

0.40 – 0.53 V Ignition switch turned ON,

ECT at 100

°C, 212 °F.

C37-25 BLK/

YEL IAT sensor signal 3.18 – 3.67 V

Ignition switch turned ON,

IAT at 0

°C, 32 °F.

—

1.32 – 1.65 V Ignition switch turned ON,

IAT at 40

°C, 104 °F.

0.46 – 0.60 V Ignition switch turned ON,

IAT at 80

°C, 176 °F.

C37-26 GRN/

BLK MAF sensor signal 0.5 – 1.5 V

Ignition switch turned ON

with engine at stop.

—

1.5 – 2.0 V

(“Reference

waveform No.18: ”) Wh

en engine running at

specified idle speed after

warmed up.

C37-27 GRY Ground for MAF

sensor Below 0.3 V Ignition switch turned ON.

—

C37-28 BLU/

YEL Generator control

signal output *0 – 0.6 V

↑↓

5 – 8 V

(“Reference

waveform No.19: ”) Engine running at idle

speed, headlight switch

turned ON.

Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C37-29 BLU/

BLK EVAP canister

purge valve output 10 – 14 V

Ignition switch turned ON

with engine at stop. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.20: ”) Set EVAP canister purge

valve at 52% by using

“Misc Test” of scan tool.

Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C37-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C37-31 — —— — —

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Page 239 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-189

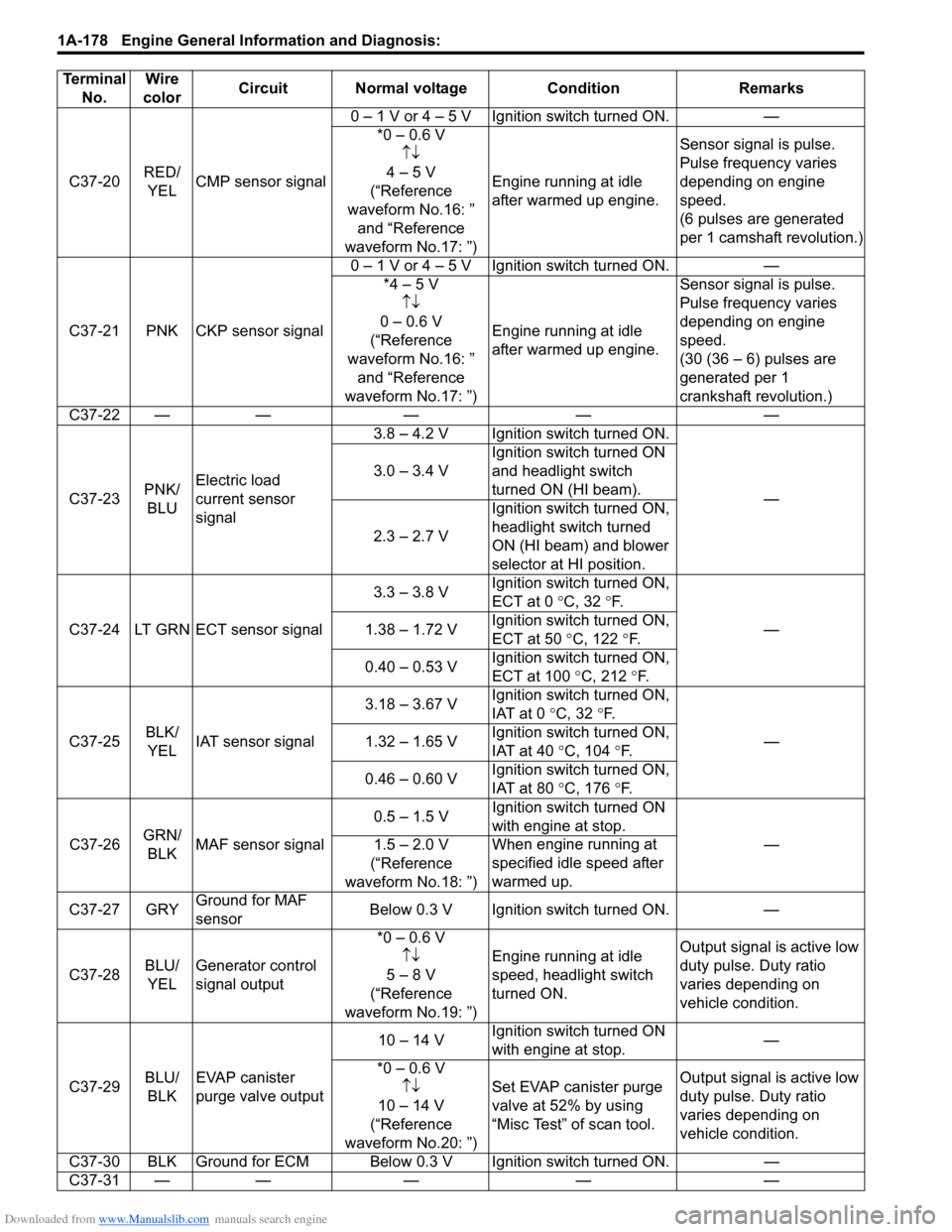

Reference waveform No.18

MAF sensor signal (1) with engine racing

Reference waveform No.19

Generator control signal (1) at engine idlingReference waveform No.20

EVAP canister purge valve signal

Measurement

terminal CH1: “C37-26” to “C37-27”

CH2: “C37-54” to “C37-55”

Oscilloscope

setting CH1: 1 V/DIV, CH2: 1 V/DIV

TIME: 200 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine racing

2. TP sensor signal

3. Racing

4. Idle

Measurement

terminal CH1: “C37-28” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV

TIME: 10 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Engine at specified idle speed

• For a few sec. from headlight switch turned ON

I4RS0B110066-01

I7RS0B110015-01

Measurement

terminal CH1: “C37-29” to “C37-58”

Oscilloscope

setting CH1: 10 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• EVAP canister purge valve setting at 52% by using “Misc Test” of

scan tool

1. ON signal

2. OFF signal

3. One duty cycle

4. 10 – 14 V

I4RS0B110067-01

Page 243 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

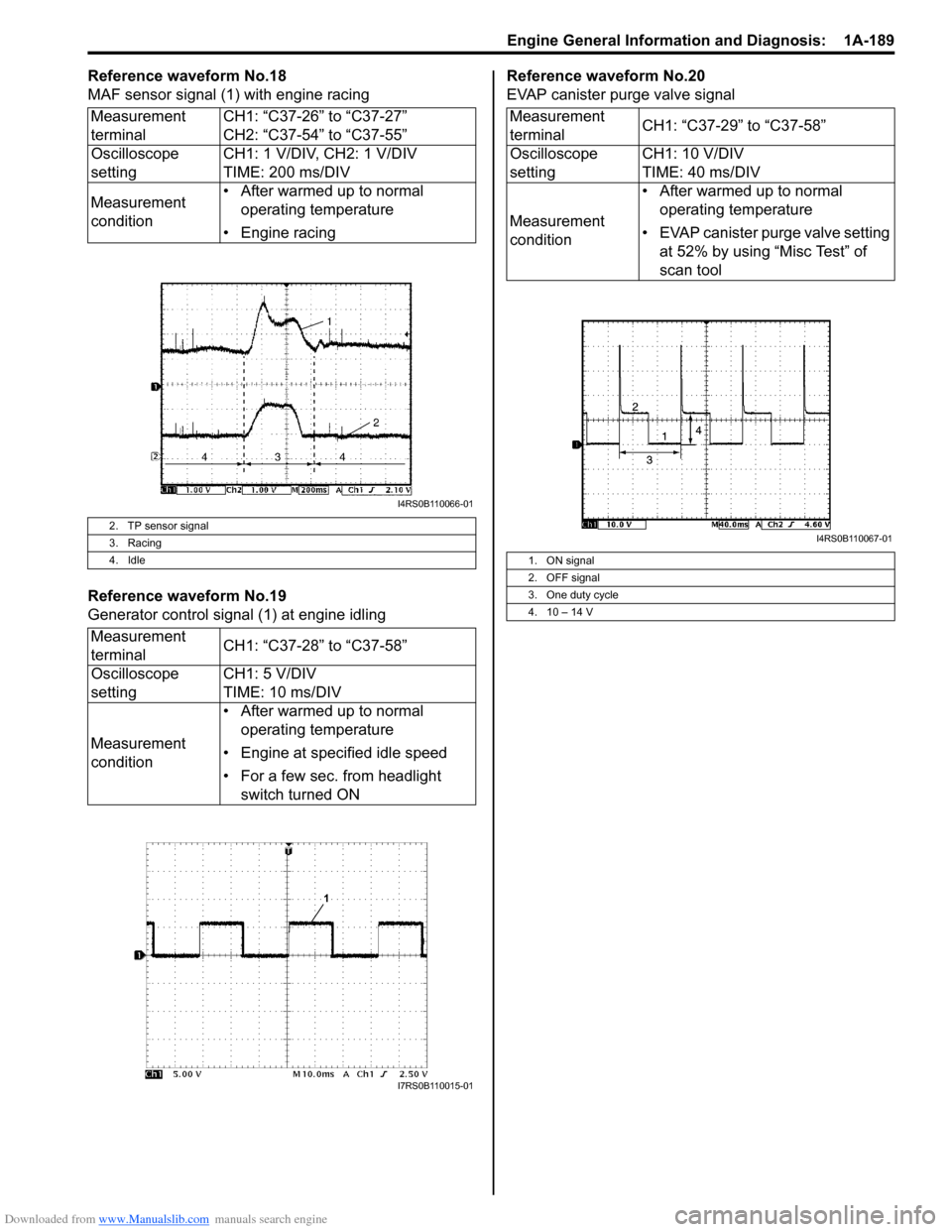

Reference waveform No.32

VSS signal at 30 km/h (19 mph)

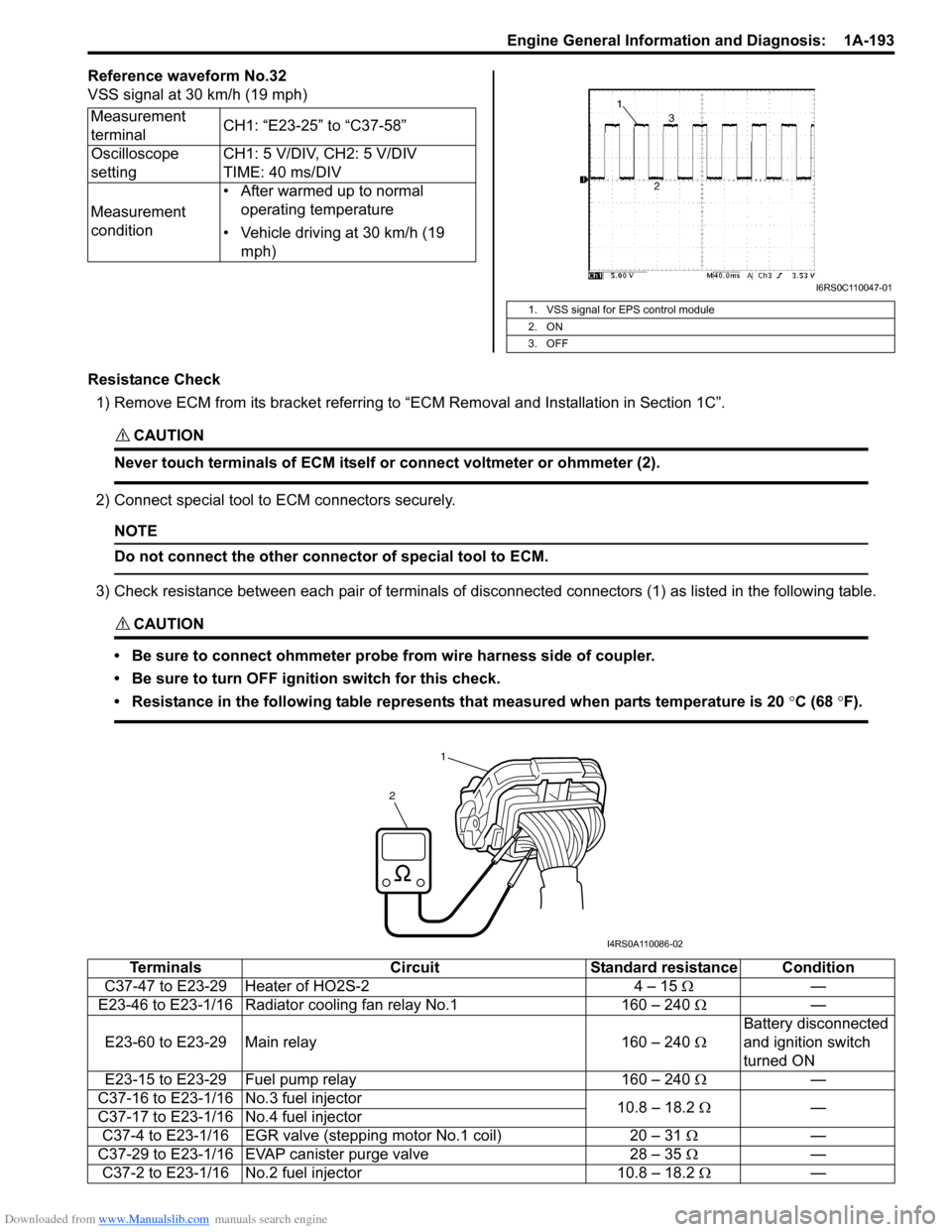

Resistance Check1) Remove ECM from its bracket referring to “ECM Removal and Installation in Section 1C”.

CAUTION!

Never touch terminals of ECM itself or connect voltmeter or ohmmeter (2).

2) Connect special tool to ECM connectors securely.

NOTE

Do not connect the other connector of special tool to ECM.

3) Check resistance between each pair of terminals of disconnected connectors (1) as listed in the following table.

CAUTION!

• Be sure to connect ohmmeter probe from wire harness side of coupler.

• Be sure to turn OFF ignition switch for this check.

• Resistance in the following table represents that measured when parts temperature is 20 °C (68 °F).

Measurement

terminal CH1: “E23-25” to “C37-58”

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 40 ms/DIV

Measurement

condition • After warmed up to normal

operating temperature

• Vehicle driving at 30 km/h (19 mph)

1. VSS signal for EPS control module

2. ON

3. OFF

I6RS0C110047-01

1

2

I4RS0A110086-02

Terminals CircuitStandard resistance Condition

C37-47 to E23-29 Heater of HO2S-2 4 – 15 Ω—

E23-46 to E23-1/16 Radiator cooling fan relay No.1 160 – 240 Ω —

E23-60 to E23-29 Main relay 160 – 240 ΩBattery disconnected

and ignition switch

turned ON

E23-15 to E23-29 Fuel pump relay 160 – 240 Ω —

C37-16 to E23-1/16 No.3 fuel injector 10.8 – 18.2 Ω —

C37-17 to E23-1/16 No.4 fuel injector

C37-4 to E23-1/16 EGR valve (st epping motor No.1 coil) 20 – 31 Ω —

C37-29 to E23-1/16 EVAP canister purge valve 28 – 35 Ω —

C37-2 to E23-1/16 No.2 fuel injector 10.8 – 18.2 Ω—