Part SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 472 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-5 Wheels and Tires:

Radial Tire Lead / Pull DescriptionS7RS0B2401006

“Lead / Pull” is the deviation of the vehicle from a straight

path on a level road even with no pressure on the

steering wheel.

Lead is usually caused by the following conditions.

• Improper tire and wheel alignment.

• Uneven brake assemblies.

• Tire construction.

The way in which a tire is built can produce lead in a

vehicle. An example of this is placement of the belt. Off

center belts on radial tires can cause the tire to develop

a side force while rolling straight down the road. If one

side of the tire has a little larger diameter than the other,

the tire will tend to roll to one side. This will develop a

side force which can produce vehicle lead.

The procedure in the figure (Lead Diagnosis) should be

used to make sure that wheel alignment is not mistaken

for tire lead.

• Part of the lead diagnosis procedure is different from the proper tire rotation pattern currently in the owner

and service manuals. If a medium to high mileage tire

is moved to the other side of the vehicle, be sure to

check that ride roughness has not developed.

• Rear tires will not cause lead.

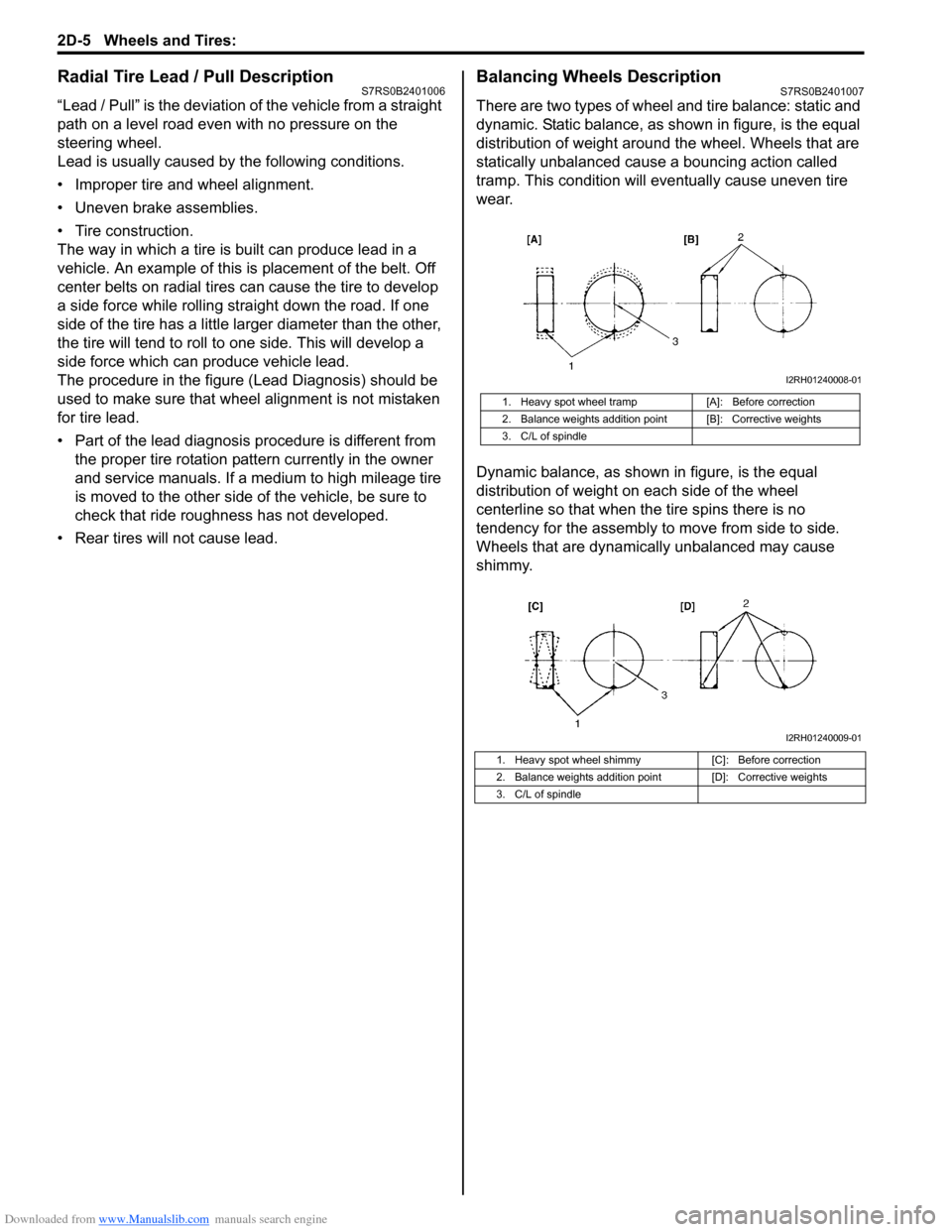

Balancing Wheels DescriptionS7RS0B2401007

There are two types of wheel an d tire balance: static and

dynamic. Static balance, as shown in figure, is the equal

distribution of weight around the wheel. Wheels that are

statically unbalanced cause a bouncing action called

tramp. This condition will eventually cause uneven tire

wear.

Dynamic balance, as shown in figure, is the equal

distribution of weight on each side of the wheel

centerline so that when the tire spins there is no

tendency for the assembly to move from side to side.

Wheels that are dynamically unbalanced may cause

shimmy.

1. Heavy spot wheel tramp [A]: Before correction

2. Balance weights addition point [B]: Corrective weights

3. C/L of spindle

1. Heavy spot wheel shimmy [C]: Before correction

2. Balance weights addition point [D]: Corrective weights

3. C/L of spindle

I2RH01240008-01

I2RH01240009-01

Page 476 of 1496

Downloaded from www.Manualslib.com manuals search engine 2D-9 Wheels and Tires:

2) Check tire if it can be repaired, referring to “Tire

Repair”. If it cannot be repaired, replace it with new

one.

3) Replace valve core of flat tire with new one if tire is reused after repairing.CAUTION!

Be sure to use new valve core. Otherwise, air

leak may occur due to sealant attached to

valve core.

4) Install tire to ri m of wheel, check that there is no air

leakage and adjust it to specified pressure shown on

tire placard.

Specifications

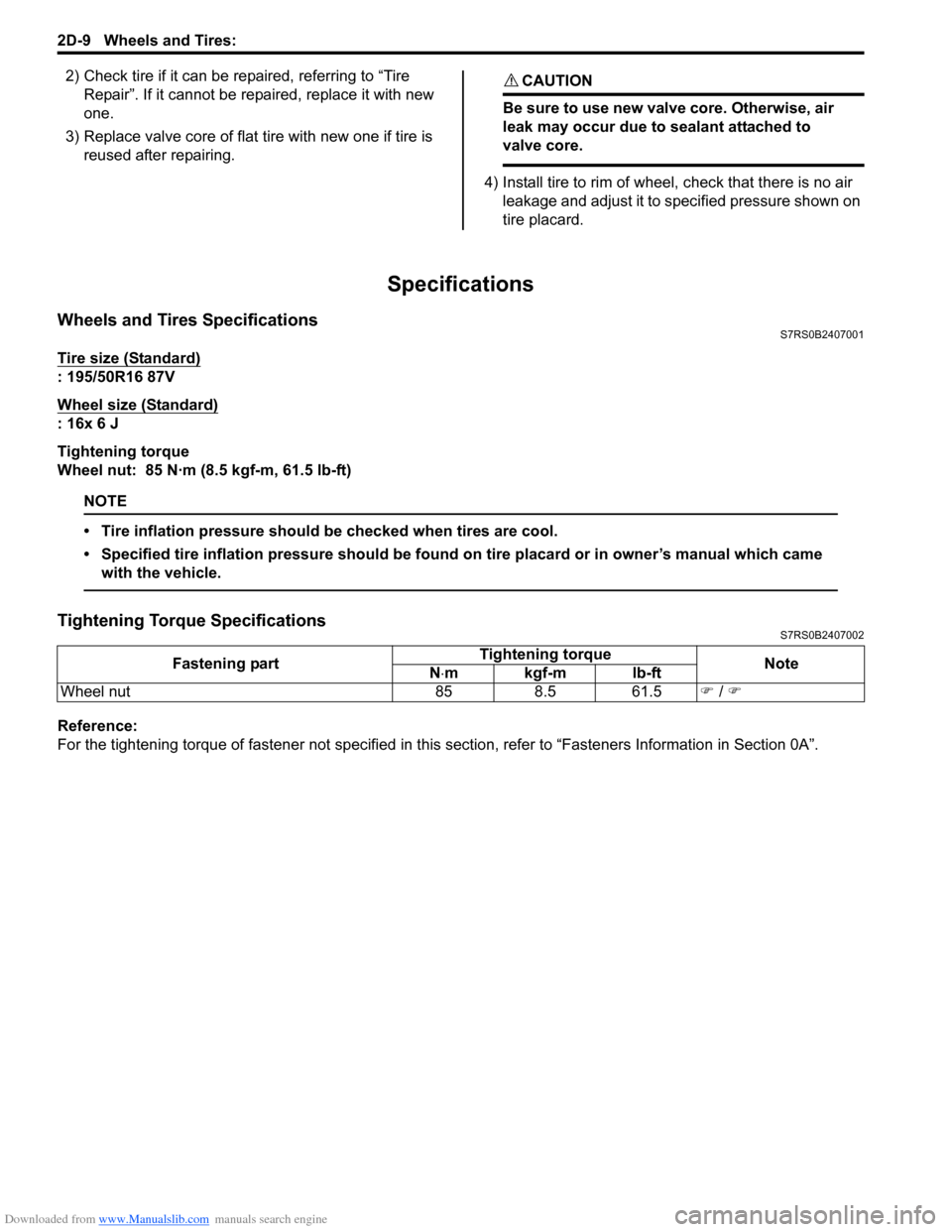

Wheels and Tires SpecificationsS7RS0B2407001

Tire size (Standard)

: 195/50R16 87V

Wheel size (Standard)

: 16x 6 J

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual which came

with the vehicle.

Tightening Torque SpecificationsS7RS0B2407002

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Wheel nut 858.5 61.5 �) / �)

Page 482 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-4 Drive Shaft / Axle:

Front Drive Shaft Assembly On-Vehicle

Inspection

S7RS0B3106002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for smooth rotation.

If any abnormality is found, replace.

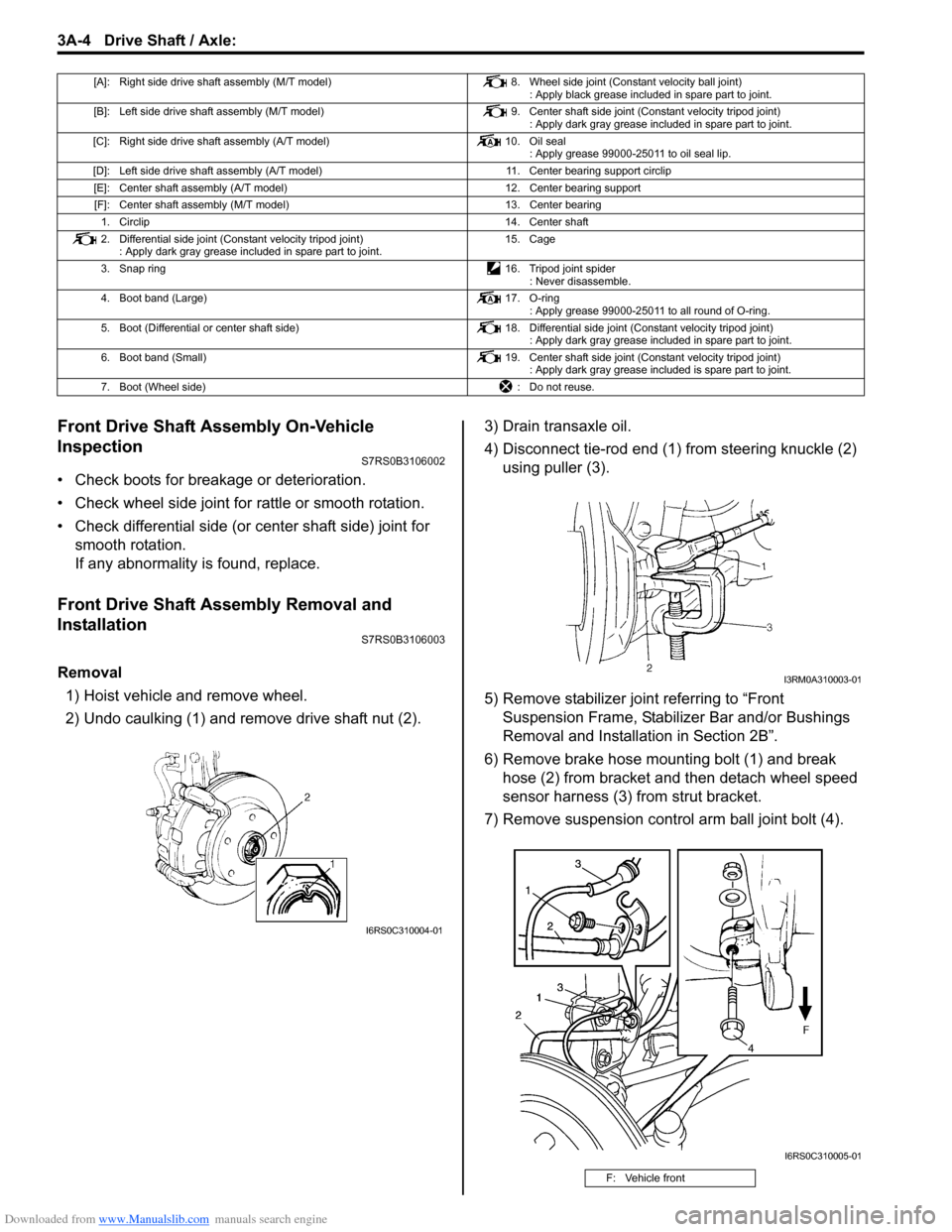

Front Drive Shaft Assembly Removal and

Installation

S7RS0B3106003

Removal

1) Hoist vehicle and remove wheel.

2) Undo caulking (1) and remove drive shaft nut (2). 3) Drain transaxle oil.

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).

5) Remove stabilizer join t referring to “Front

Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

6) Remove brake hose mounting bolt (1) and break hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

7) Remove suspension contro l arm ball joint bolt (4).

[A]: Right side drive shaft assembly (M/T model) 8. Wheel side joint (Constant velocity ball joint)

: Apply black grease included in spare part to joint.

[B]: Left side drive shaft assembly (M/T model) 9. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

[C]: Right side drive shaft assembly (A/T model) 10. Oil seal

: Apply grease 99000-25011 to oil seal lip.

[D]: Left side drive shaft assembly (A/T model) 11. Center bearing support circlip

[E]: Center shaft assembly (A/T model) 12. Center bearing support

[F]: Center shaft assembly (M/T model) 13. Center bearing

1. Circlip 14. Center shaft

2. Differential side joint (Constant velocity tripod joint) : Apply dark gray grease included in spare part to joint. 15. Cage

3. Snap ring 16. Tripod joint spider

: Never disassemble.

4. Boot band (Large) 17. O-ring

: Apply grease 99000-25011 to all round of O-ring.

5. Boot (Differential or center shaft side) 18. Differential side joint (Constant velocity tripod joint)

: Apply dark gray grease included in spare part to joint.

6. Boot band (Small) 19. Center shaft side joint (Constant velocity tripod joint)

: Apply dark gray grease included is spare part to joint.

7. Boot (Wheel side) : Do not reuse.

I6RS0C310004-01

F: Vehicle front

I3RM0A310003-01

I6RS0C310005-01

Page 486 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-8 Drive Shaft / Axle:

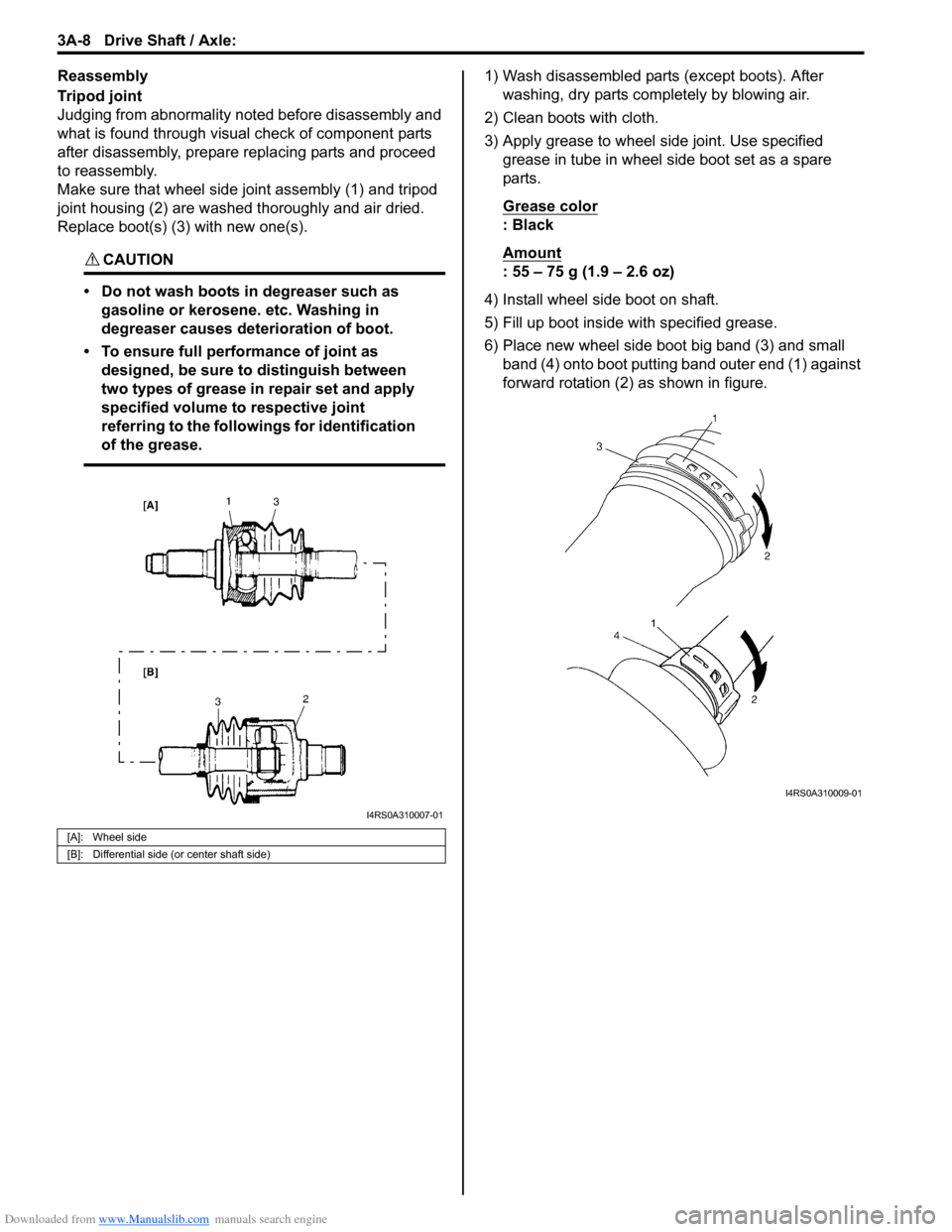

Reassembly

Tripod joint

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly (1) and tripod

joint housing (2) are washed thoroughly and air dried.

Replace boot(s) (3) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts comp letely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside with specified grease.

6) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure.

[A]: Wheel side

[B]: Differential side (or center shaft side)

I4RS0A310007-01

I4RS0A310009-01

Page 487 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-9

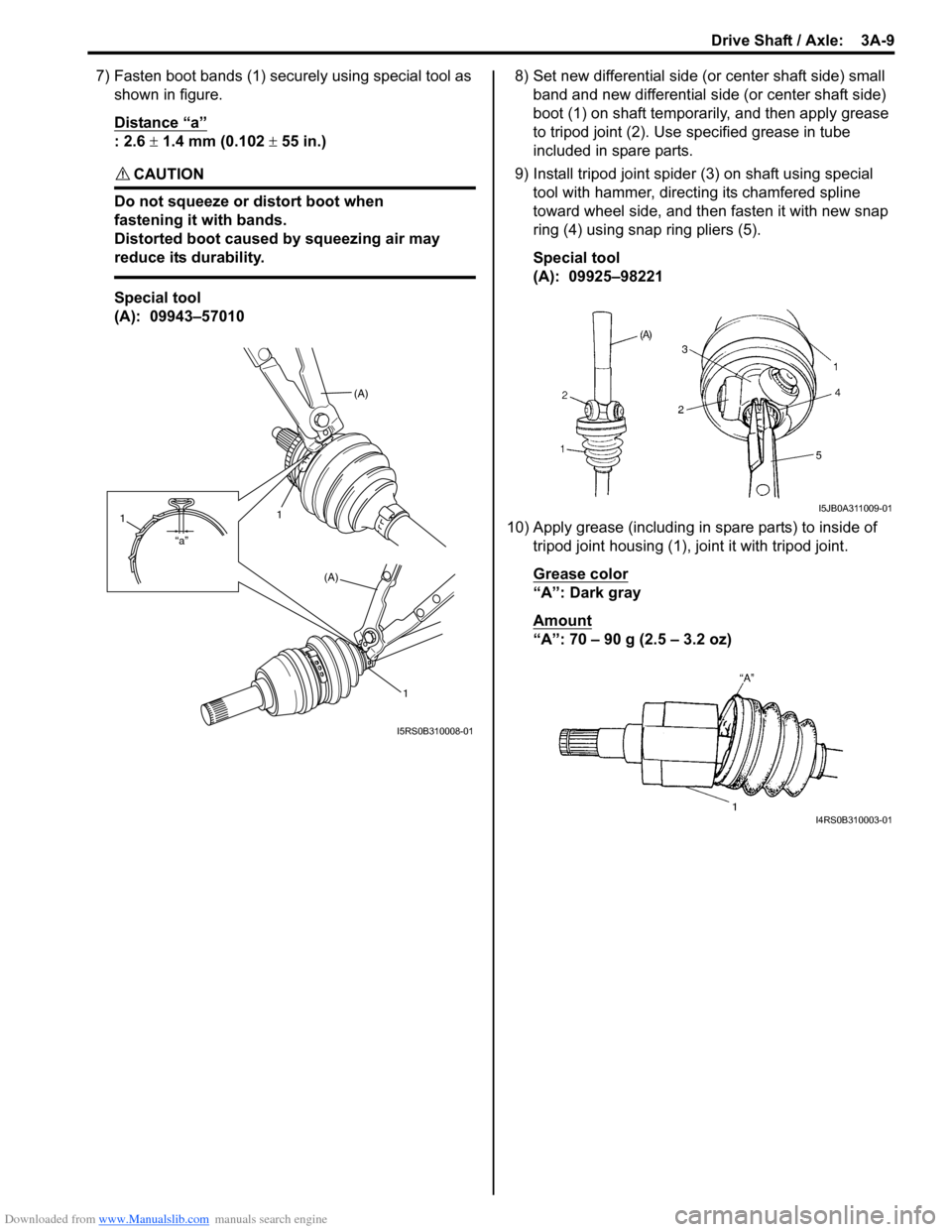

7) Fasten boot bands (1) securely using special tool as

shown in figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 55 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010 8) Set new differential side (or center shaft side) small

band and new differential side (or center shaft side)

boot (1) on shaft temporarily, and then apply grease

to tripod joint (2). Use specified grease in tube

included in spare parts.

9) Install tripod joint spider (3) on shaft using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (4) using snap ring pliers (5).

Special tool

(A): 09925–98221

10) Apply grease (including in spare parts) to inside of tripod joint housing (1), jo int it with tripod joint.

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz)

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

I5JB0A311009-01

I4RS0B310003-01

Page 489 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-11

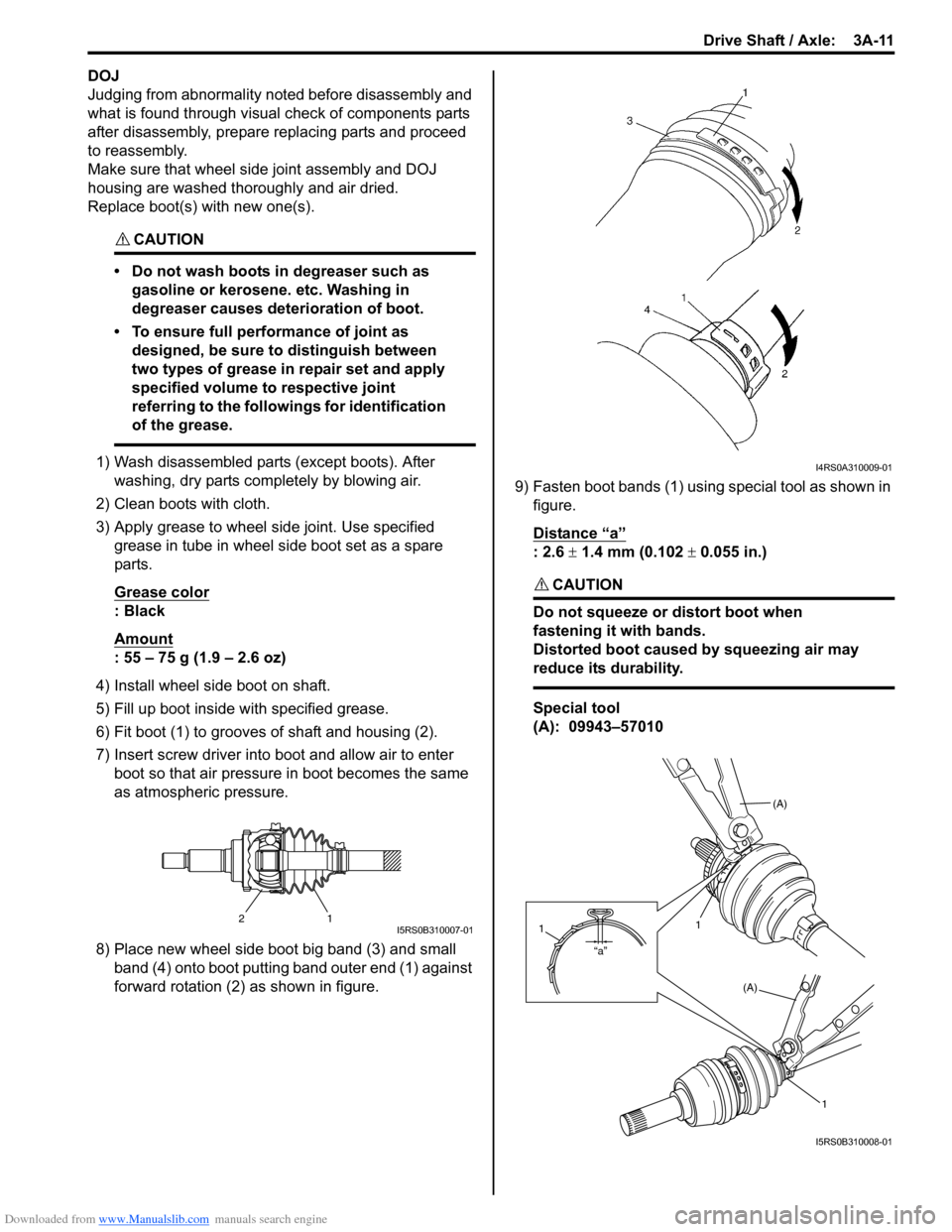

DOJ

Judging from abnormality noted before disassembly and

what is found through visual check of components parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly and DOJ

housing are washed thoroughly and air dried.

Replace boot(s) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts completely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified

grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside wi th specified grease.

6) Fit boot (1) to grooves of shaft and housing (2).

7) Insert screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

8) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure. 9) Fasten boot bands (1) using special tool as shown in

figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 0.055 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010

21I5RS0B310007-01

I4RS0A310009-01

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

Page 490 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-12 Drive Shaft / Axle:

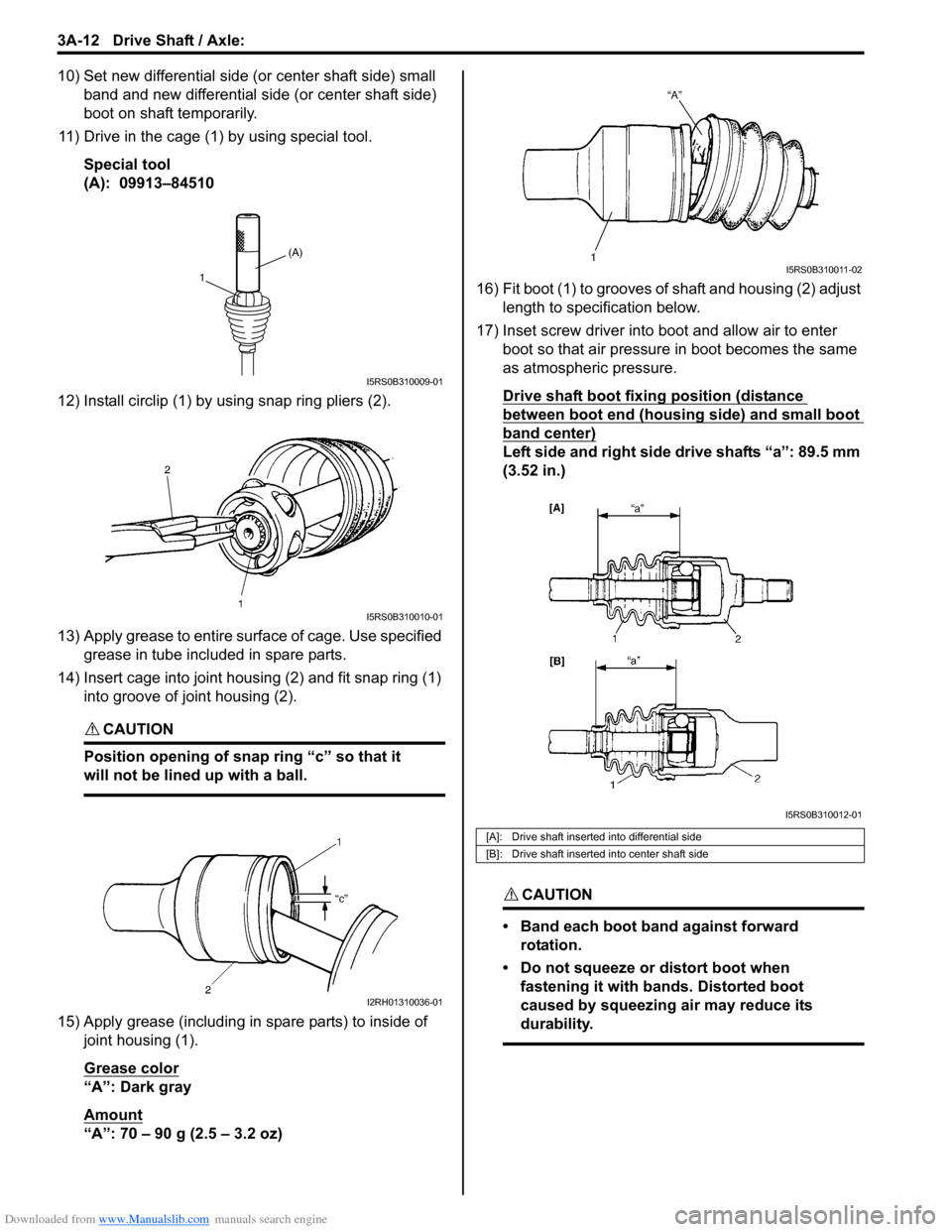

10) Set new differential side (or center shaft side) small band and new differential side (or center shaft side)

boot on shaft temporarily.

11) Drive in the cage (1) by using special tool.

Special tool

(A): 09913–84510

12) Install circlip (1) by using snap ring pliers (2).

13) Apply grease to entire su rface of cage. Use specified

grease in tube included in spare parts.

14) Insert cage into joint housing (2) and fit snap ring (1) into groove of joint housing (2).

CAUTION!

Position opening of snap ring “c” so that it

will not be lined up with a ball.

15) Apply grease (including in spare parts) to inside of joint housing (1).

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz) 16) Fit boot (1) to grooves of shaft and housing (2) adjust

length to specification below.

17) Inset screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

Drive shaft boot fixing position (distance

between boot end (housing side) and small boot

band center)

Left side and right side drive shafts “a”: 89.5 mm

(3.52 in.)

CAUTION!

• Band each boot band against forward rotation.

• Do not squeeze or distort boot when fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

(A)

1

I5RS0B310009-01

I5RS0B310010-01

I2RH01310036-01

[A]: Drive shaft inserted into differential side

[B]: Drive shaft inserted into center shaft side

I5RS0B310011-02

I5RS0B310012-01

Page 493 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-15

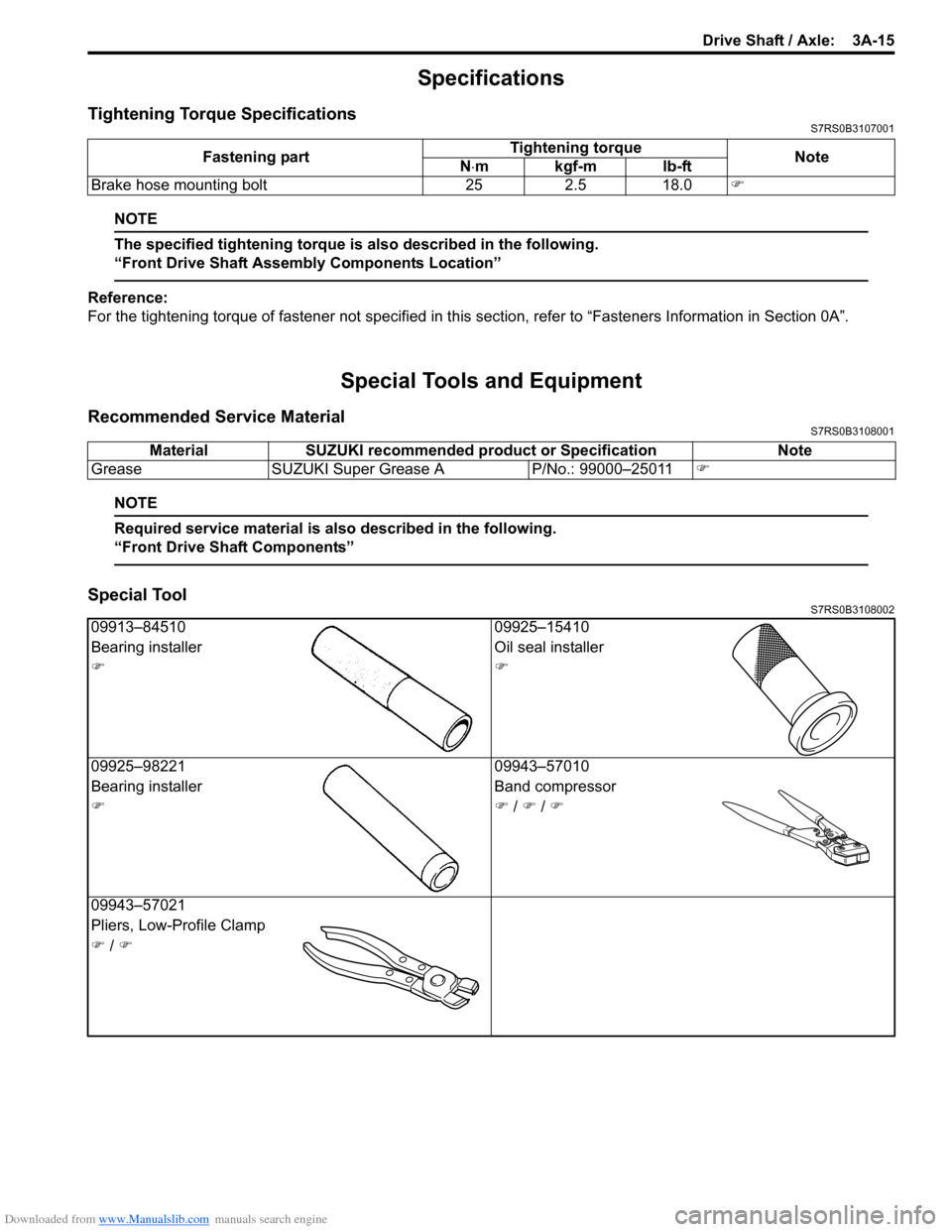

Specifications

Tightening Torque SpecificationsS7RS0B3107001

NOTE

The specified tightening torque is also described in the following.

“Front Drive Shaft Assembly Components Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B3108001

NOTE

Required service material is also described in the following.

“Front Drive Shaft Components”

Special ToolS7RS0B3108002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Brake hose mounting bolt 25 2.5 18.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25011�)

09913–84510 09925–15410

Bearing installer Oil seal installer

�)�)

09925–98221 09943–57010

Bearing installer Band compressor

�)�) / �) / �)

09943–57021

Pliers, Low-Profile Clamp

�) / �)

Page 502 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-4 Brake Control System and Diagnosis:

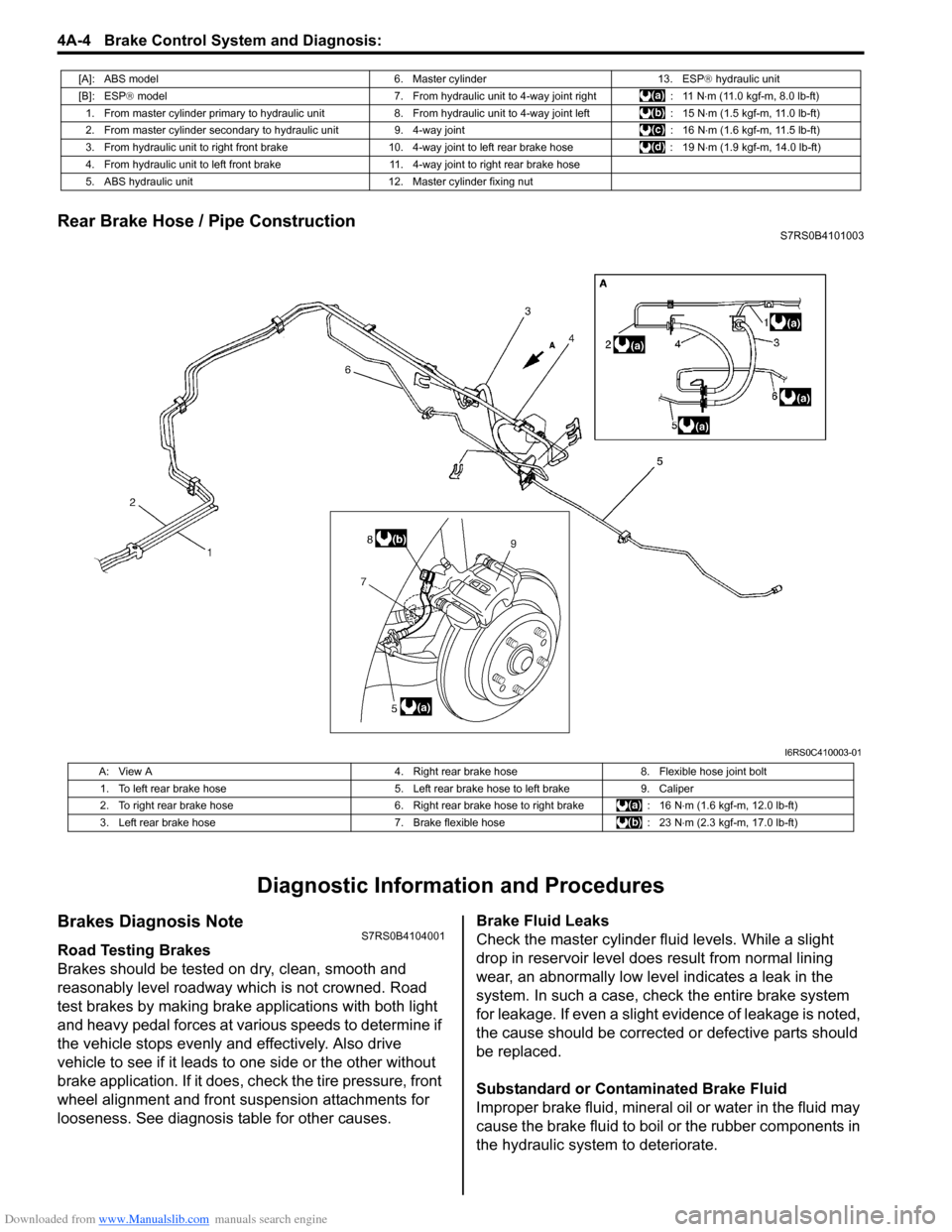

Rear Brake Hose / Pipe ConstructionS7RS0B4101003

Diagnostic Information and Procedures

Brakes Diagnosis NoteS7RS0B4104001

Road Testing Brakes

Brakes should be tested on dry, clean, smooth and

reasonably level roadway which is not crowned. Road

test brakes by making brake applications with both light

and heavy pedal forces at vari ous speeds to determine if

the vehicle stops evenly and effectively. Also drive

vehicle to see if it leads to one side or the other without

brake application. If it does, check the tire pressure, front

wheel alignment and front suspension attachments for

looseness. See diagnosis table for other causes. Brake Fluid Leaks

Check the master cylinder fl

uid levels. While a slight

drop in reservoir level does result from normal lining

wear, an abnormally low leve l indicates a leak in the

system. In such a case, chec k the entire brake system

for leakage. If even a slight ev idence of leakage is noted,

the cause should be corrected or defective parts should

be replaced.

Substandard or Contaminated Brake Fluid

Improper brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components in

the hydraulic system to deteriorate.

[A]: ABS model 6. Master cylinder13. ESP® hydraulic unit

[B]: ESP ® model 7. From hydraulic unit to 4-way joint right : 11 N⋅m (11.0 kgf-m, 8.0 lb-ft)

1. From master cylinder primary to hydraulic unit 8. From hydraulic unit to 4-way joint left: 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

2. From master cylinder secondary to hydraulic unit 9. 4-way joint: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. From hydraulic unit to right front brake 10.4-way joint to left rear brake hose : 19 N⋅m (1.9 kgf-m, 14.0 lb-ft)

4. From hydraulic unit to left front brake 11. 4-way joint to right rear brake hose

5. ABS hydraulic unit 12. Master cylinder fixing nut

I6RS0C410003-01

A: View A4. Right rear brake hose8. Flexible hose joint bolt

1. To left rear brake hose 5. Left rear brake hose to left brake9. Caliper

2. To right rear brake hose 6. Right rear brake hose to right brake: 16 N⋅m (1.6 kgf-m, 12.0 lb-ft)

3. Left rear brake hose 7. Brake flexible hose: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

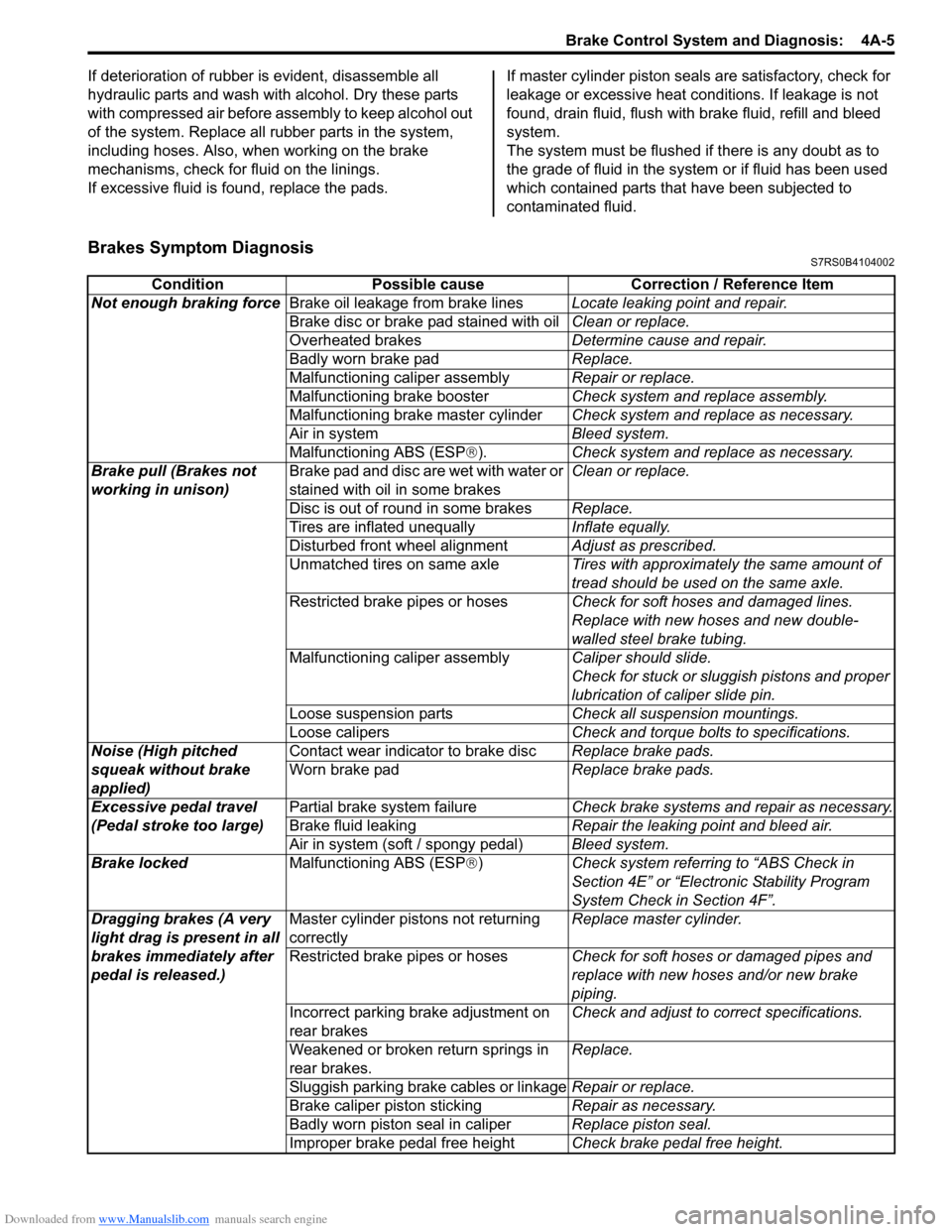

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.