Section 9 SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 198 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-148 Engine General Information and Diagnosis:

DTC P1676: CAN Communication (Reception Error for TCM)S7RS0B1104064

Wiring Diagram

Refer to “DTC P1674: CAN Communication (Bus Off Error)”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data for TCM is

detected for longer than specified time continuously.

(1 driving detection logic) •ECM

• TCM (for A/T model)

• CAN communication circuit

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Check CAN communication error for ECM

1) Check ECM for DTC.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error)”.

Go to Step 3.

3 ECM and TCM connector check

1) Check for proper connection at each ECM and TCM

connector terminals with ignition switch turned OFF.

2) If connections are OK, recheck ECM for DTC with engine running.

Is there DTC P1676? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 DTC check in TCM

1) Check DTC P1774 in TCM.

Is it indicated? Go to “DTC P1774:

CAN Communication

Bus Off in Section 5A”.

Go to Step 5.

5 CAN communication circuit check

1) Disconnect connectors of ECM and TCM.

2) Check CAN communication circuit between ECM and

TCM connectors for open, short and high resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check of ECM

1) Connect connectors to ECM and TCM with ignition

switch turned.

2) Check ECM for DTC.

Does ECM communicate with control module other than

TCM (i.e. DTC P1678 and/or P1685 are not detected)? Substitute a known-

good TCM and recheck.

Substitute a known-

good ECM and recheck.

Page 199 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-149

DTC P1678: CAN Communication (Reception Error for BCM)S7RS0B1104065

Wiring Diagram

Refer to “DTC P1674: CAN Communication (Bus Off Error)”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Reception error of communication data for BCM is

detected for longer than specified time continuously.

(1 driving detection logic but MIL does not light up) •ECM

• ABS/ESP®

control module

•BCM

• CAN communication circuit

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 CAN communication error check for ECM

1) Check ECM for DTC.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error)”.

Go to Step 3.

3 ECM, ABS control module and BCM connector check

1) Check for proper connecti on at each ECM, ABS/ESP®

control module and BCM connector terminals with

ignition switch turned OFF.

2) If connections are OK, recheck ECM for DTC with engine running.

Is there DTC P1678? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 DTC check in BCM

1) Check DTC U1073 in BCM.

Is it indicated? Go to “DTC U1073 (No.

1073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 5.

5 DTC check of ABS/ESP ® control module

1) Check DTC U1073 in ABS/ESP ® control module.

Is it indicated? Go to “DTC U1073:

Control Module

Communication Bus Off

in Section 4E”.Go to Step 6.

Page 201 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-151

TroubleshootingStep Action Yes No 1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 DTC check in ECM

1) Check ECM for DTC.

Is there DTC P1674? Go to “DTC P1674:

CAN Communication

(Bus Off Error)”.

Go to Step 3.

3 ECM and ABS/ESP ® control module connector check

1) Check for proper connection at each ECM and ABS/ ESP® control module connector terminals with ignition

switch turned OFF.

2) If connections are OK, recheck ECM for DTC with engine running.

Is there DTC P1685? Go to Step 4.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4 DTC check of ABS/ESP ® control module

1) Check DTC U1073 in ABS/ESP ® control module.

Is it indicated? Go to “DTC U1073:

Control Module

Communication Bus Off

in Section 4E” (Non-

ESP®

model) or “DTC

U1073: Control Module

Communication Bus Off

in Section 4F” (ESP ®

module). Go to Step 5.

5 CAN communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connector s form ECM and ABS/ESP ®

control module.

3) Check CAN communication circuit between ECM and ABS/ESP ® control module for open, short or high

resistance.

Is each CAN communication circuit in good condition? Go to Step 6.

Repair circuit.

6 DTC check in ECM

1) Connect connectors to ECM and ABS/ESP ® control

module with ignition switch turned.

2) Check ECM for DTC.

Does ECM communicate with control module other than

ABS/ESP

® control module (i.e. DTC P1676 and/or DTC

P1678 are not detected)? Substitute a known-

good ABS/ESP

®

control module and

recheck. Substitute a known-

good ECM and recheck.

Page 203 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-153

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

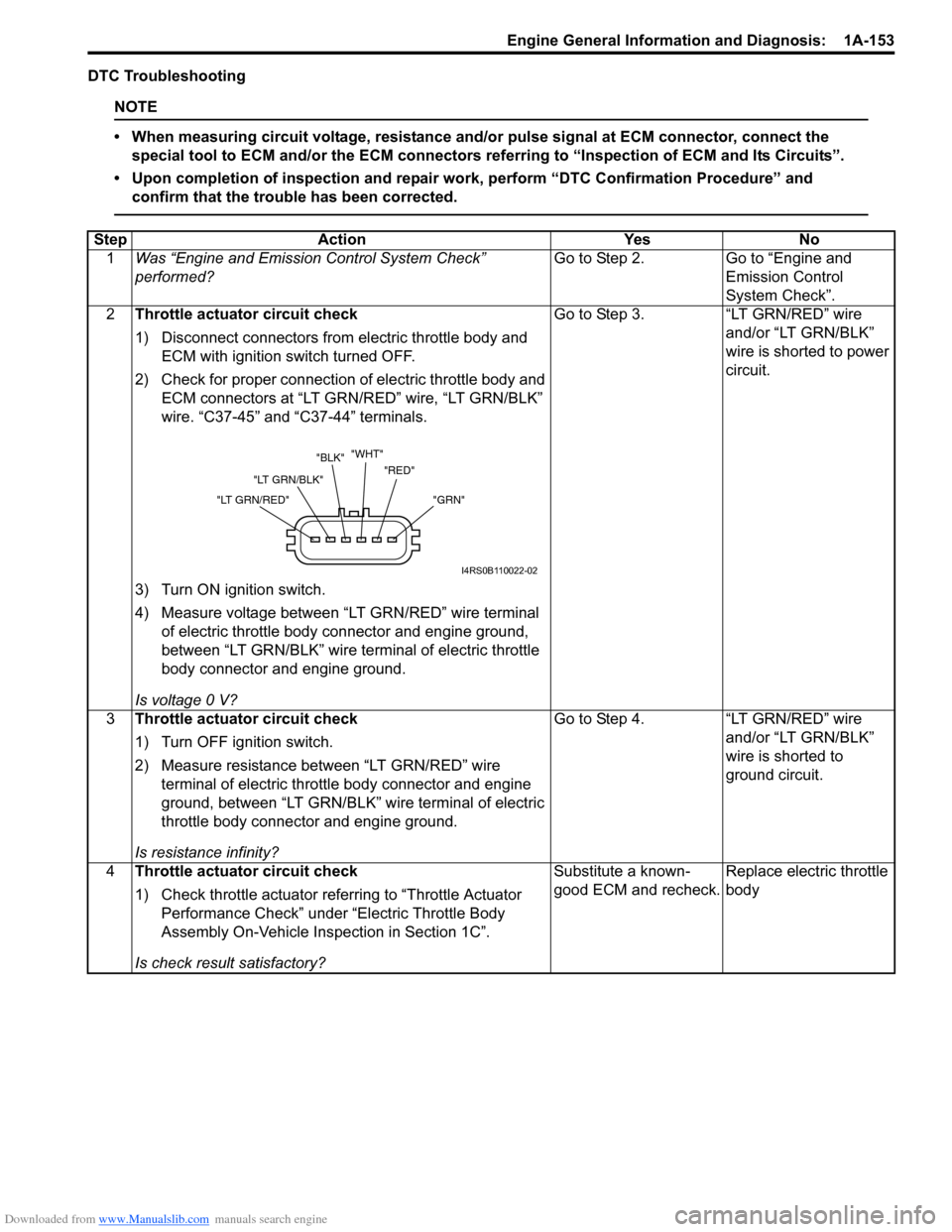

2 Throttle actuator circuit check

1) Disconnect connectors from electric throttle body and

ECM with ignition switch turned OFF.

2) Check for proper connection of electric throttle body and ECM connectors at “LT GRN/RED” wire, “LT GRN/BLK”

wire. “C37-45” and “C37-44” terminals.

3) Turn ON ignition switch.

4) Measure voltage between “LT GRN/RED” wire terminal of electric throttle body connector and engine ground,

between “LT GRN/BLK” wire terminal of electric throttle

body connector and engine ground.

Is voltage 0 V? Go to Step 3.

“LT GRN/RED” wire

and/or “LT GRN/BLK”

wire is shorted to power

circuit.

3 Throttle actuator circuit check

1) Turn OFF ignition switch.

2) Measure resistance between “LT GRN/RED” wire

terminal of electric throttle body connector and engine

ground, between “LT GRN/BLK” wire terminal of electric

throttle body connector and engine ground.

Is resistance infinity? Go to Step 4.

“LT GRN/RED” wire

and/or “LT GRN/BLK”

wire is shorted to

ground circuit.

4 Throttle actuator circuit check

1) Check throttle actuator refe rring to “Throttle Actuator

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric throttle

body

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 204 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-154 Engine General Information and Diagnosis:

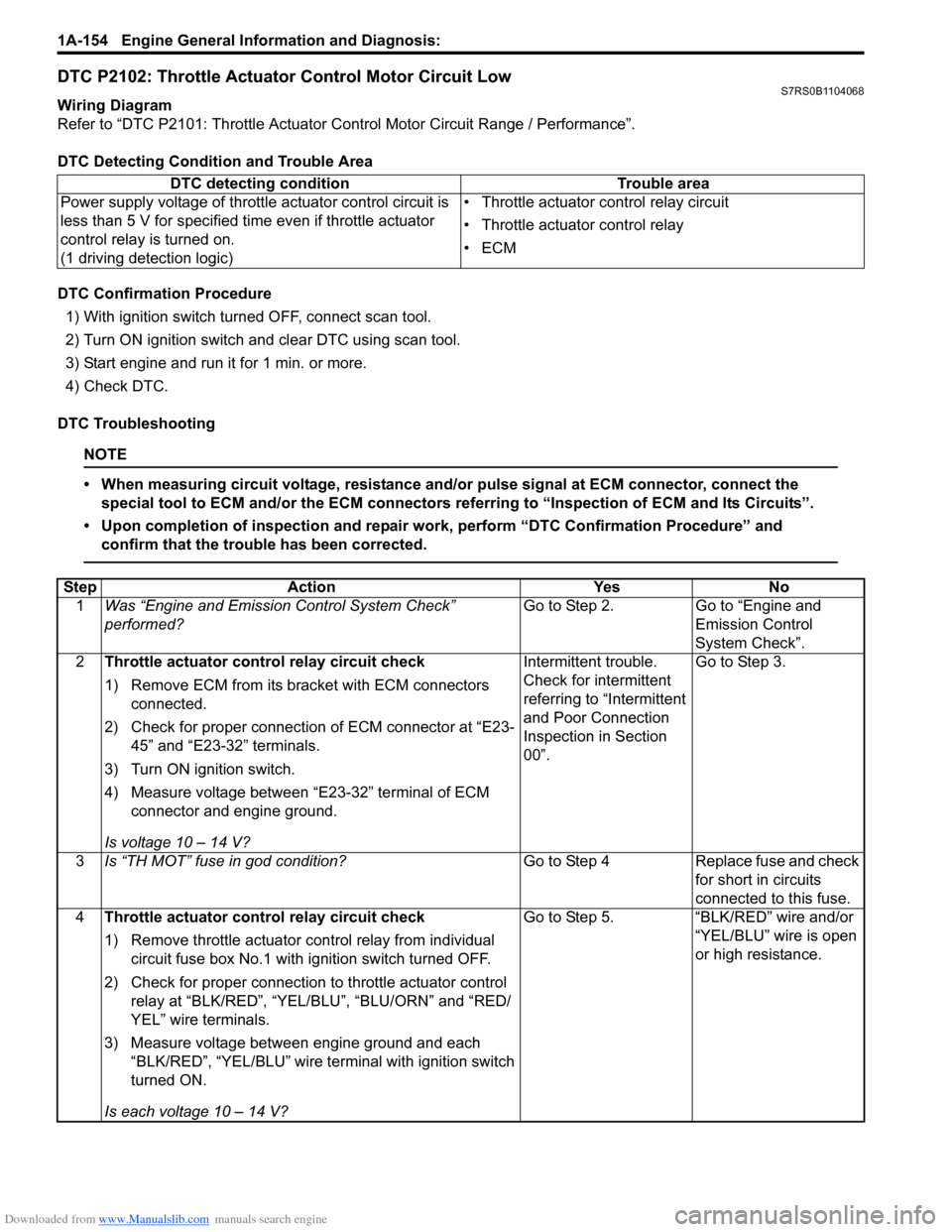

DTC P2102: Throttle Actuator Control Motor Circuit LowS7RS0B1104068

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and run it for 1 min. or more.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Power supply voltage of throttle actuator control circuit is

less than 5 V for specified time even if throttle actuator

control relay is turned on.

(1 driving detection logic) • Throttle actuator control relay circuit

• Throttle actuator control relay

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Throttle actuator cont rol relay circuit check

1) Remove ECM from its br acket with ECM connectors

connected.

2) Check for proper connection of ECM connector at “E23- 45” and “E23-32” terminals.

3) Turn ON ignition switch.

4) Measure voltage between “E23-32” terminal of ECM connector and engine ground.

Is voltage 10 – 14 V? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

3 Is “TH MOT” fuse in god condition? Go to Step 4Replace fuse and check

for short in circuits

connected to this fuse.

4 Throttle actuator cont rol relay circuit check

1) Remove throttle actuator co ntrol relay from individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to throttle actuator control relay at “BLK/RED”, “YEL/BLU”, “BLU/ORN” and “RED/

YEL” wire terminals.

3) Measure voltage between engine ground and each “BLK/RED”, “YEL/BLU” wire terminal with ignition switch

turned ON.

Is each voltage 10 – 14 V? Go to Step 5.

“BLK/RED” wire and/or

“YEL/BLU” wire is open

or high resistance.

Page 205 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-155

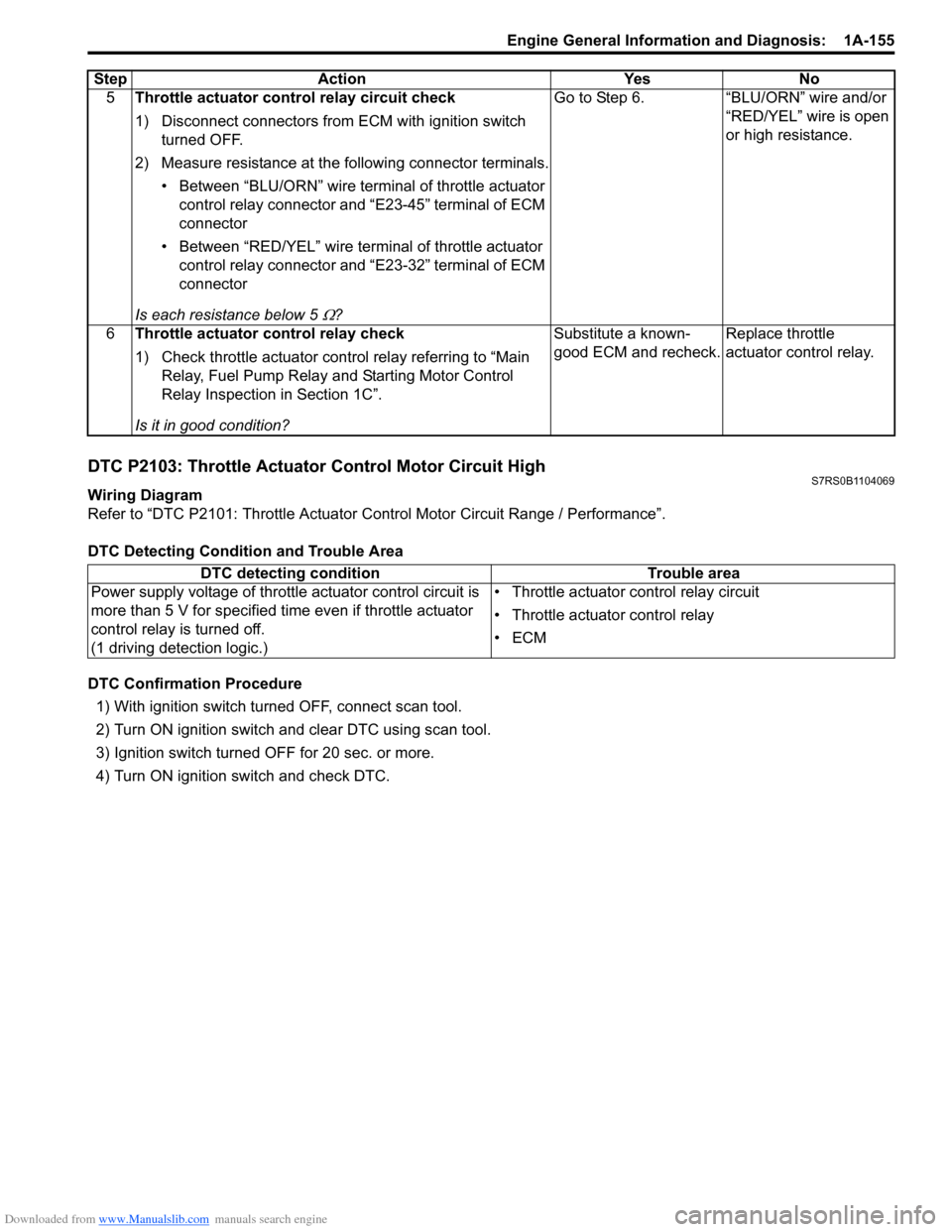

DTC P2103: Throttle Actuator Control Motor Circuit HighS7RS0B1104069

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC. 5

Throttle actuator cont rol relay circuit check

1) Disconnect connectors from ECM with ignition switch turned OFF.

2) Measure resistance at the following connector terminals. • Between “BLU/ORN” wire termin al of throttle actuator

control relay connector and “E23-45” terminal of ECM

connector

• Between “RED/YEL” wire terminal of throttle actuator control relay connector and “E23-32” terminal of ECM

connector

Is each resistance below 5

Ω? Go to Step 6. “BLU/ORN” wire and/or

“RED/YEL” wire is open

or high resistance.

6 Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main Relay, Fuel Pump Relay an d Starting Motor Control

Relay Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace throttle

actuator control relay.

Step

Action YesNo

DTC detecting condition Trouble area

Power supply voltage of throttle actuator control circuit is

more than 5 V for specified time even if throttle actuator

control relay is turned off.

(1 driving detection logic.) • Throttle actuator control relay circuit

• Throttle actuator control relay

•ECM

Page 206 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-156 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / ClosedS7RS0B1104070

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC.

Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2 Throttle actuator cont rol relay circuit check

1) Remove throttle actuator co ntrol relay from individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to throttle actuator control relay “BLK/RED”, “YEL/BLU”, “BLU/ORN” and “RED/

YEL” wire terminals.

3) Turn ON ignition switch.

4) Measure voltage between engine ground and “E23-32” terminal of ECM connector.

Is voltage 0 V? Go to Step 3. “RED/YEL” wire is

shorted to other circuit.

3 Throttle actuator cont rol relay circuit check

1) Disconnect connectors from ECM with ignition switch turned OFF.

2) Measure resistance between engine ground and “E23- 45” terminal of ECM connector.

Is resistance infinity? Go to Step 4. “BLU/ORN” wire is

shorted to ground

circuit.

4 Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main Relay, Fuel Pump Relay an d Starting Motor Control

Relay Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace throttle

actuator control relay.

DTC detecting condition

Trouble area

P2111:

Throttle valve default opening is greater than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic)

P2112:

Throttle valve default opening is smaller than 6 ° from

complementary closed position when diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic) • Electric throttle body

•ECM

Page 207 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-157

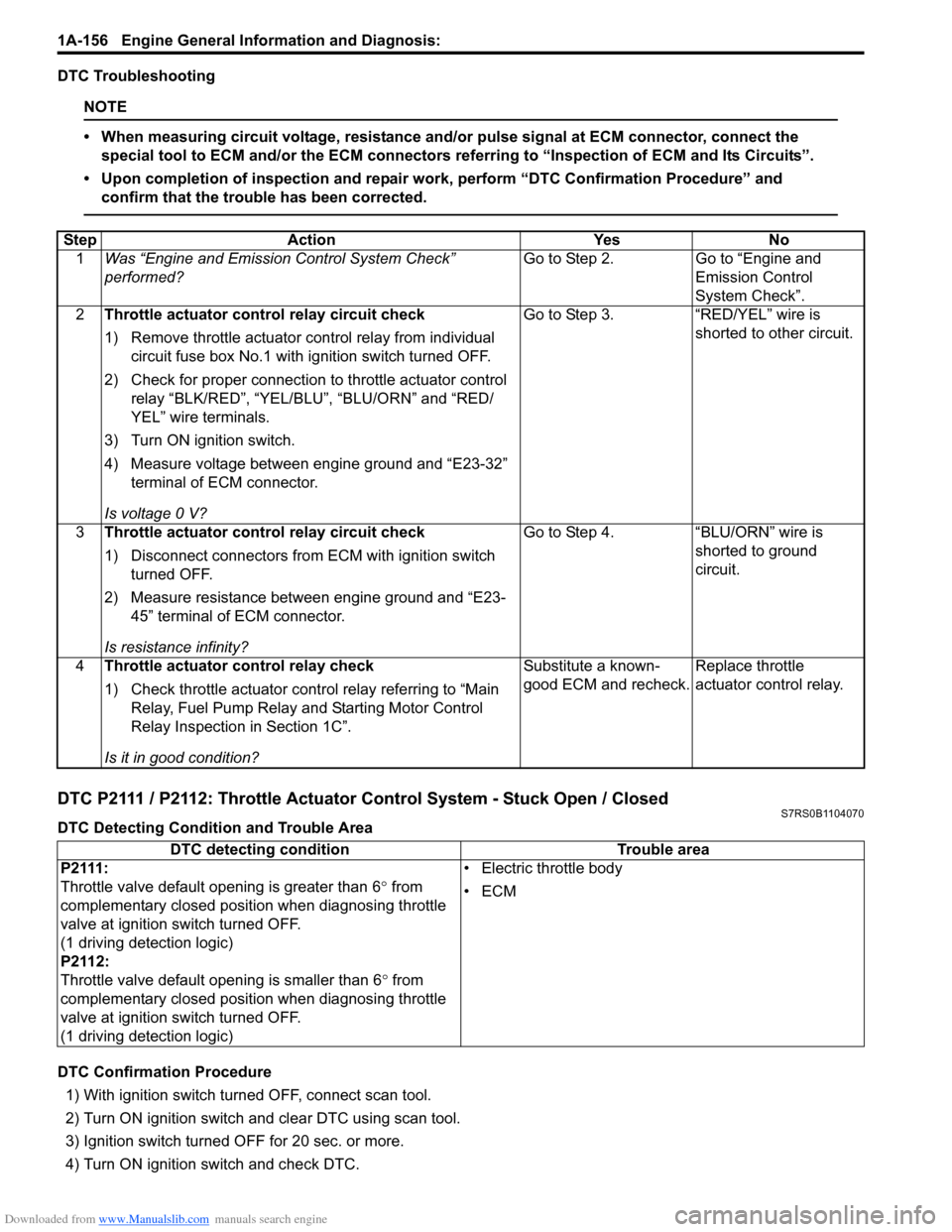

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC P2119: Throttle Actuator Control Throttle Body Range / PerformanceS7RS0B1104071

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to Step “Engine and

Emission Control

System Check”.

2 Throttle valve visual check

1) Check that there isn’t any foreign matter caught between

throttle valve and throttle body housing referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

Is it in good condition? Go to Step 3. Take it out after

removing throttle body

and clean inside of

throttle body thoroughly.

3 Throttle valve operation check

1) Check operation of throttle valve referring to “Throttle

Valve Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 4. Replace electric throttle

body.

4 Throttle actuator operation check

1) Check operation of throttle ac tuator referring to “Throttle

Actuator Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory? Go to Step 5. Replace electric throttle

body.

5 Throttle position sensor performance check

1) Check performance of throttle position sensor referring

to “Throttle Position Sensor Performance Check” under

“Electric Throttle Body Assembly On-Vehicle Inspection

in Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

DTC detecting condition

Trouble area

Difference between the measured (actual) throttle valve

opening angle and the target throttle valve opening angle

which is calculated based on accelerator pedal opening

angle and engine condition is more than specification for

specified time continuously.

(1 driving detection logic) • Throttle actuator circuit

• Electric throttle body

•ECM

Page 208 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-158 Engine General Information and Diagnosis:

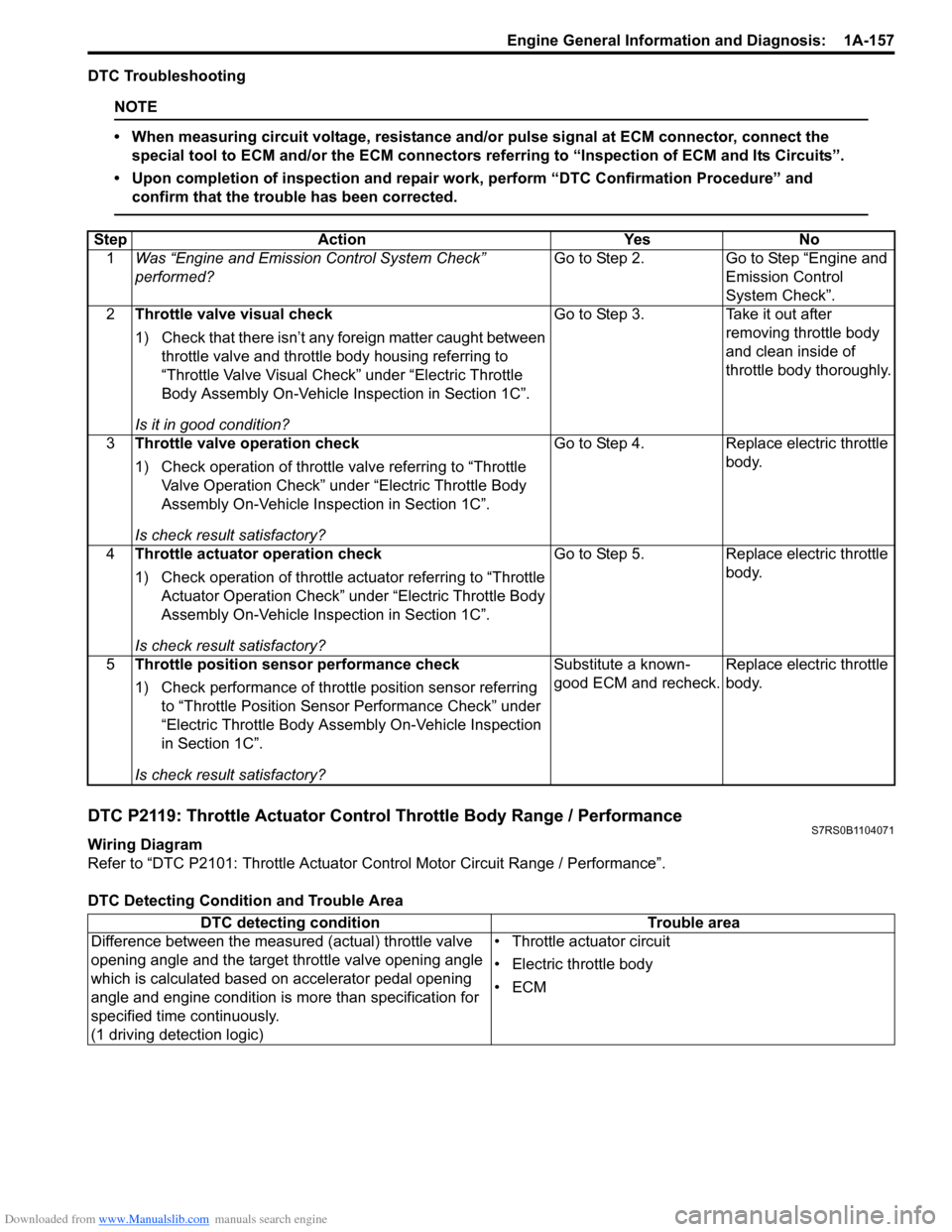

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Electric throttle body assembly system check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 3.

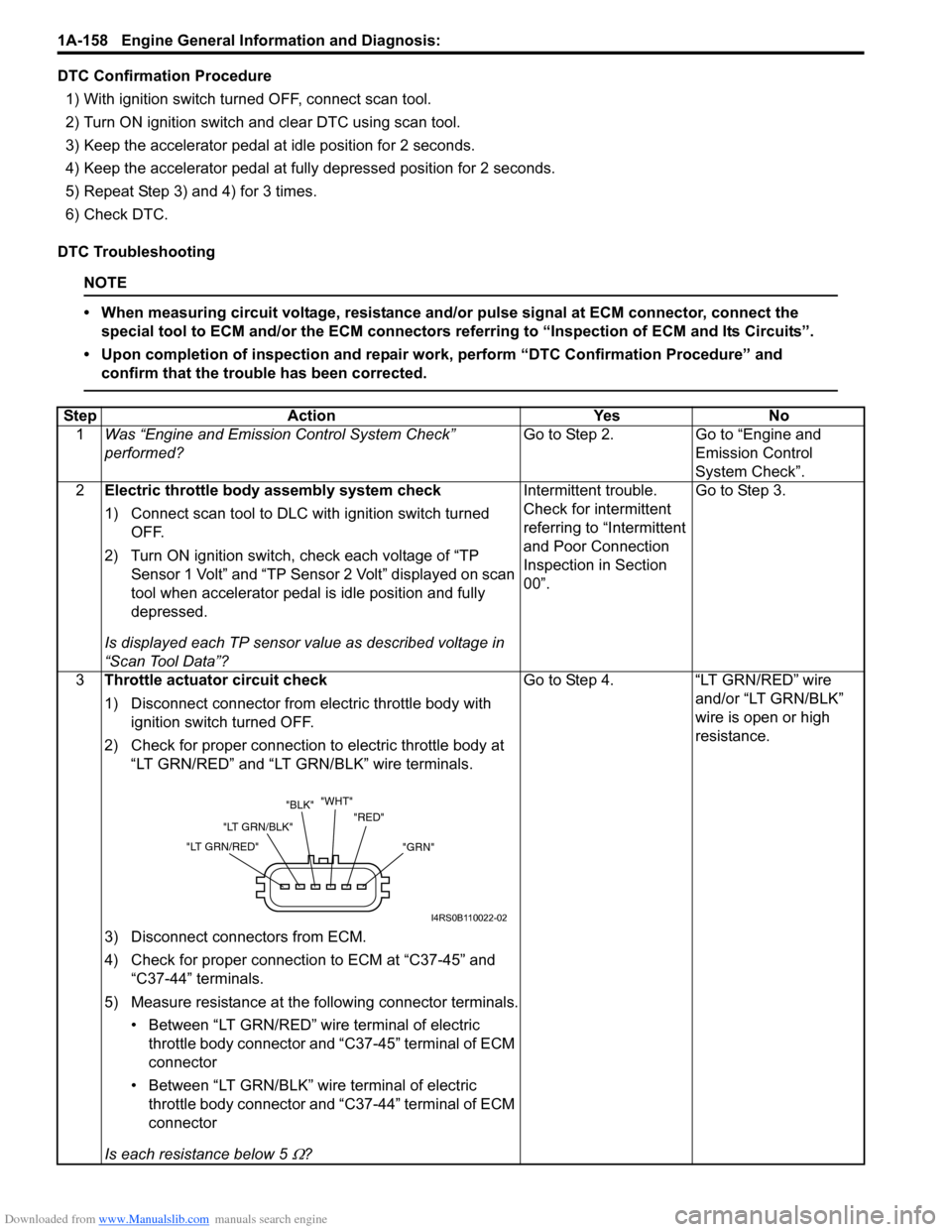

3 Throttle actuator circuit check

1) Disconnect connector from electric throttle body with

ignition switch turned OFF.

2) Check for proper connection to electric throttle body at “LT GRN/RED” and “LT G RN/BLK” wire terminals.

3) Disconnect connectors from ECM.

4) Check for proper connection to ECM at “C37-45” and “C37-44” terminals.

5) Measure resistance at the following connector terminals. • Between “LT GRN/RED” wire terminal of electric throttle body connector and “C37-45” terminal of ECM

connector

• Between “LT GRN/BLK” wire terminal of electric throttle body connector and “C37-44” terminal of ECM

connector

Is each resistance below 5

Ω? Go to Step 4. “LT GRN/RED” wire

and/or “LT GRN/BLK”

wire is open or high

resistance.

"GRN"

"RED"

"WHT"

"BLK"

"LT GRN/BLK"

"LT GRN/RED"

I4RS0B110022-02

Page 209 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-159

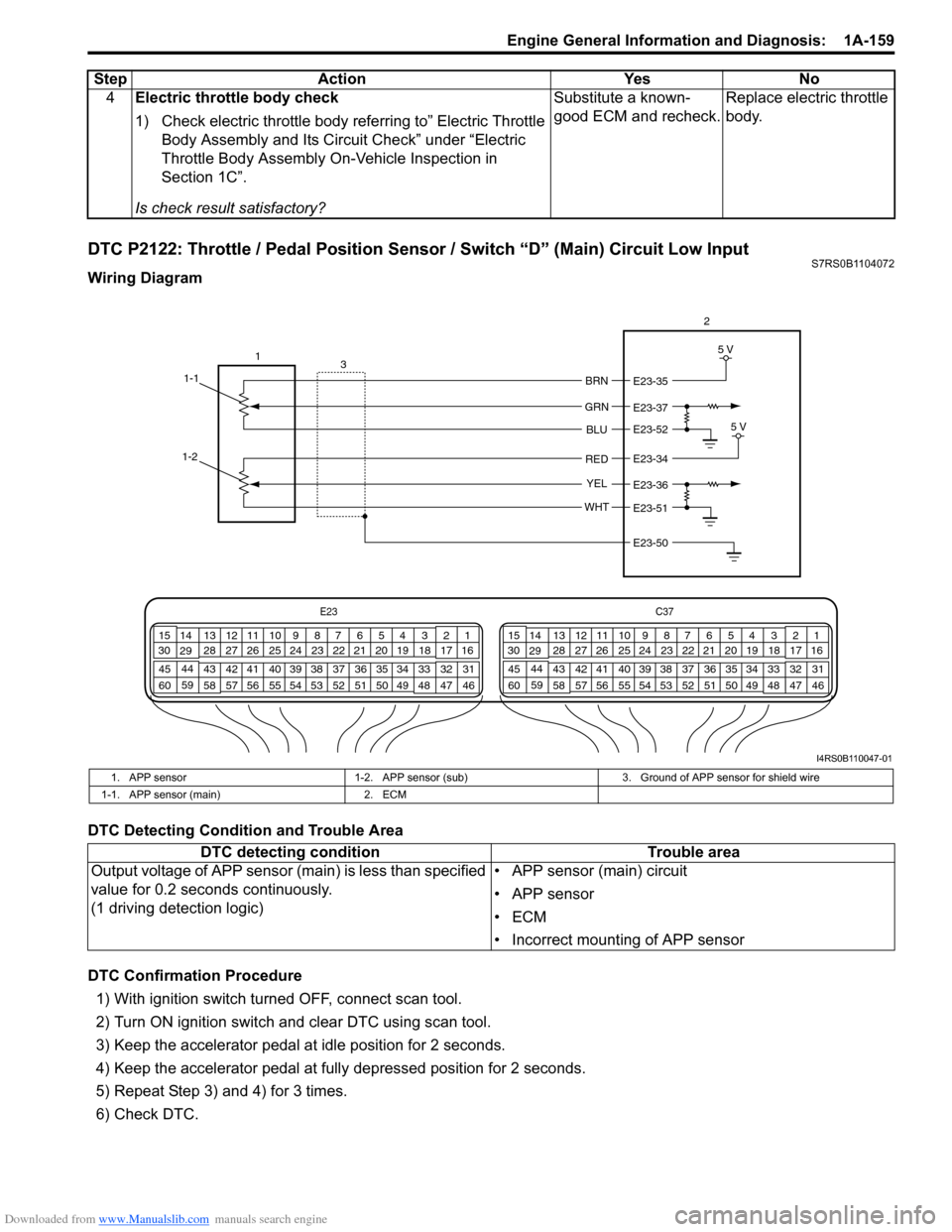

DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low InputS7RS0B1104072

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC. 4

Electric throttle body check

1) Check electric throttle body referring to” Electric Throttle

Body Assembly and Its Circuit Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Is check result satisfactory? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

E23

C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 48 32 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BRN

GRN

BLU

RED

YEL

WHT

E23-35

E23-37

E23-52

E23-34

E23-36

E23-51

E23-50 5 V

5 V

1

1-1 3 2

1-2

I4RS0B110047-01

1. APP sensor

1-2. APP sensor (sub) 3. Ground of APP sensor for shield wire

1-1. APP sensor (main) 2. ECM

DTC detecting condition Trouble area

Output voltage of APP sensor (main) is less than specified

value for 0.2 seconds continuously.

(1 driving detection logic) • APP sensor (main) circuit

• APP sensor

•ECM

• Incorrect mounting of APP sensor