intermittent SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1125 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-87

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The combined resistance of the side curtain-air bag (inflator) module (driver or passenger), harness wiring and

connector terminal contact is below a specified value for specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

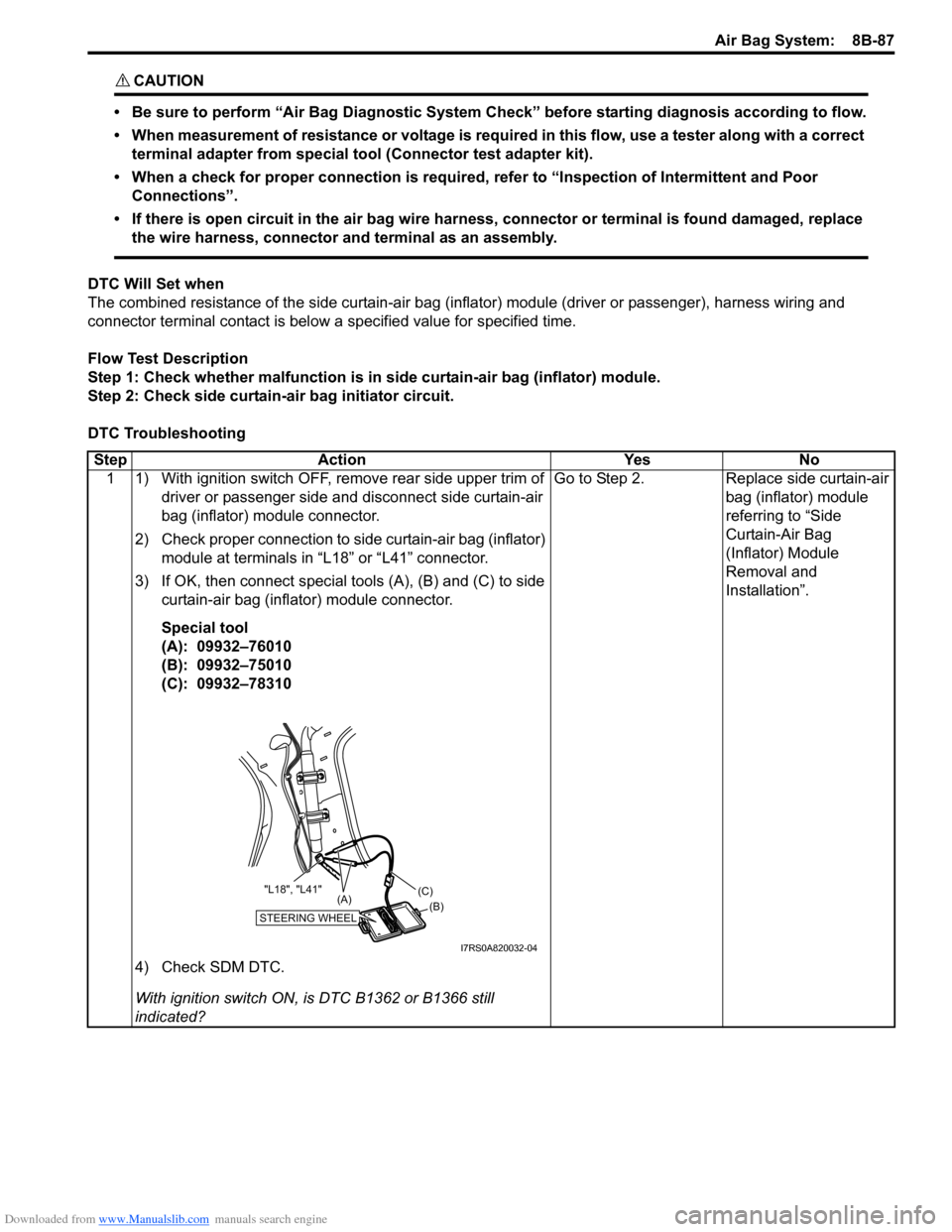

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1362 or B1366 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1127 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-89

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

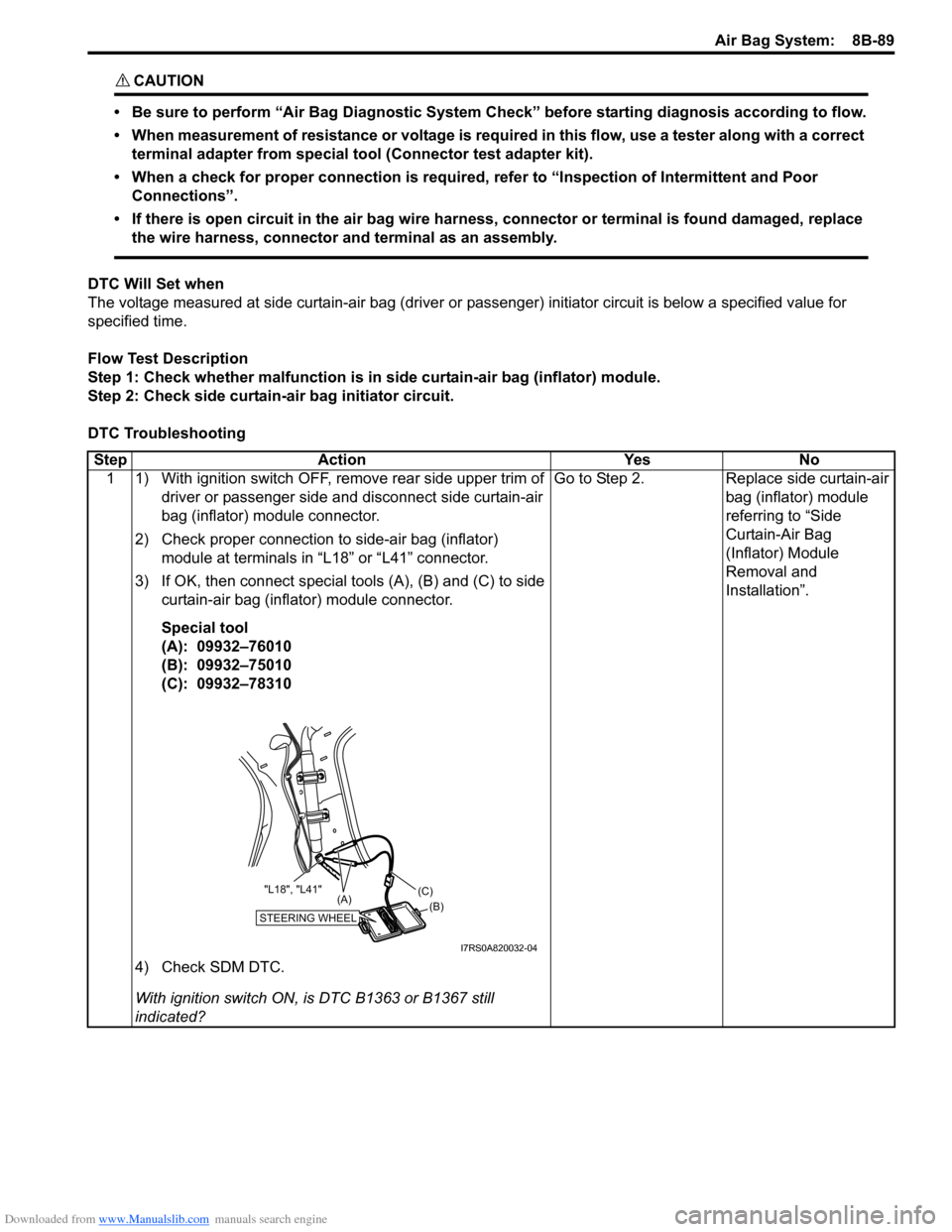

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1363 or B1367 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

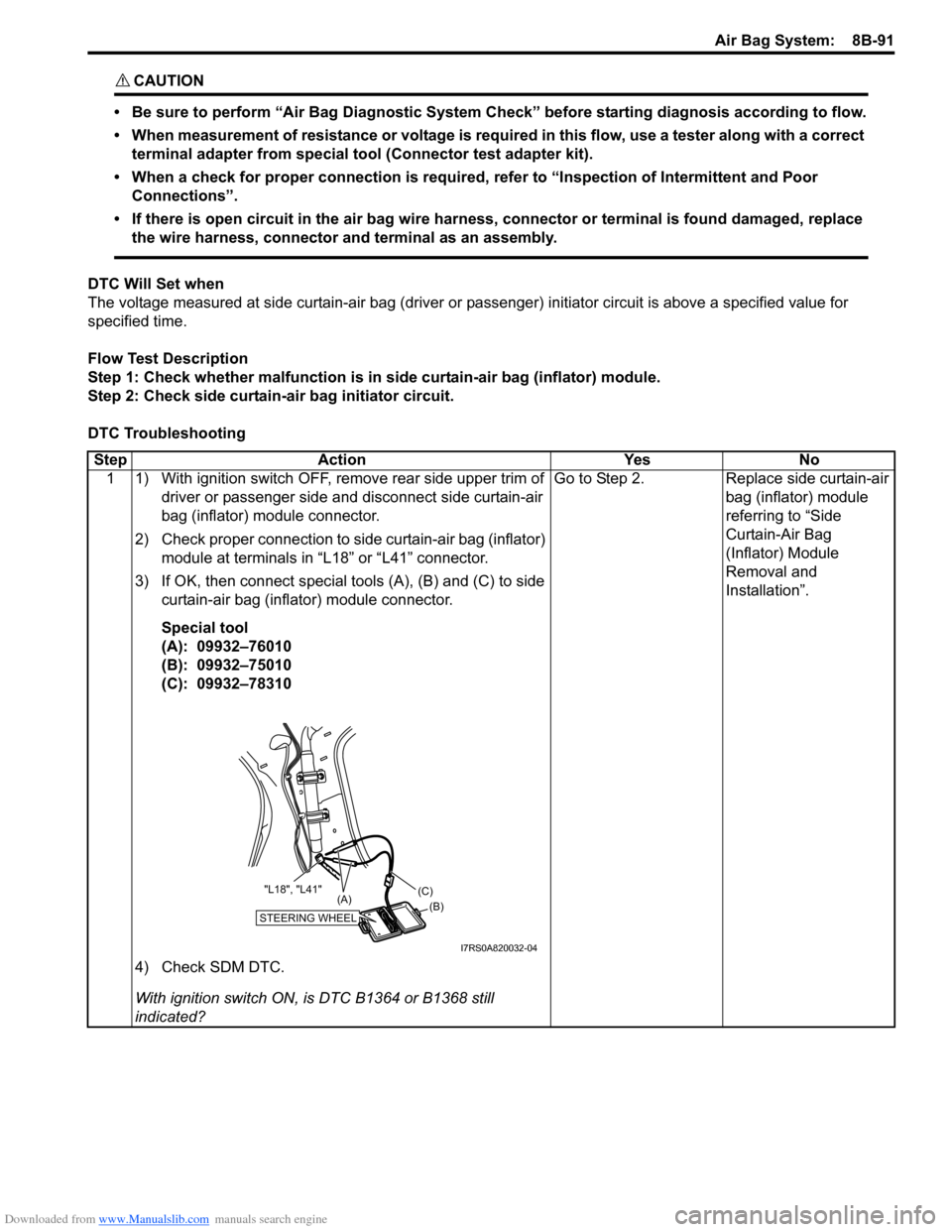

Step Action YesNo

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1133 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-95

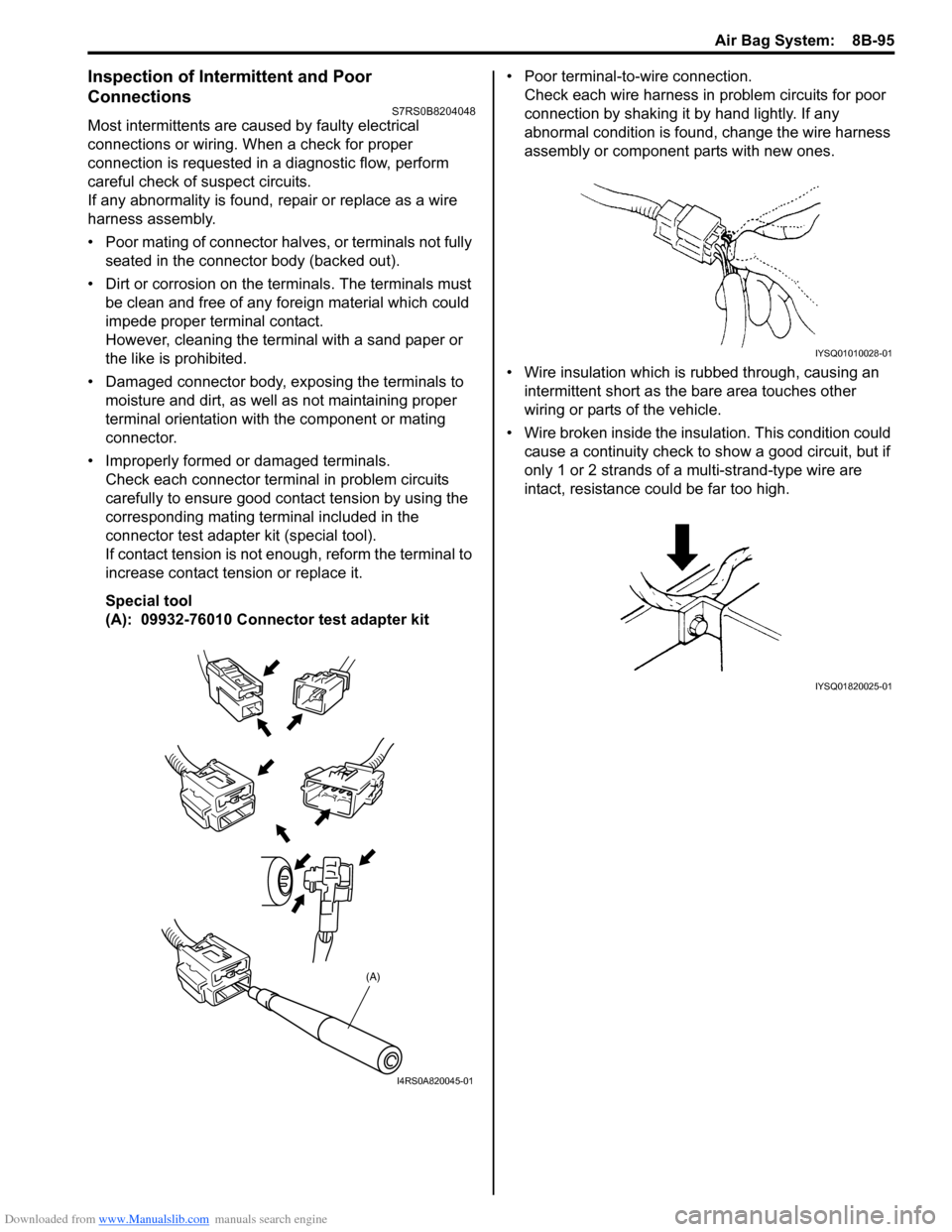

Inspection of Intermittent and Poor

Connections

S7RS0B8204048

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

• Improperly formed or damaged terminals. Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not e nough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932-76010 Connector test adapter kit • Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

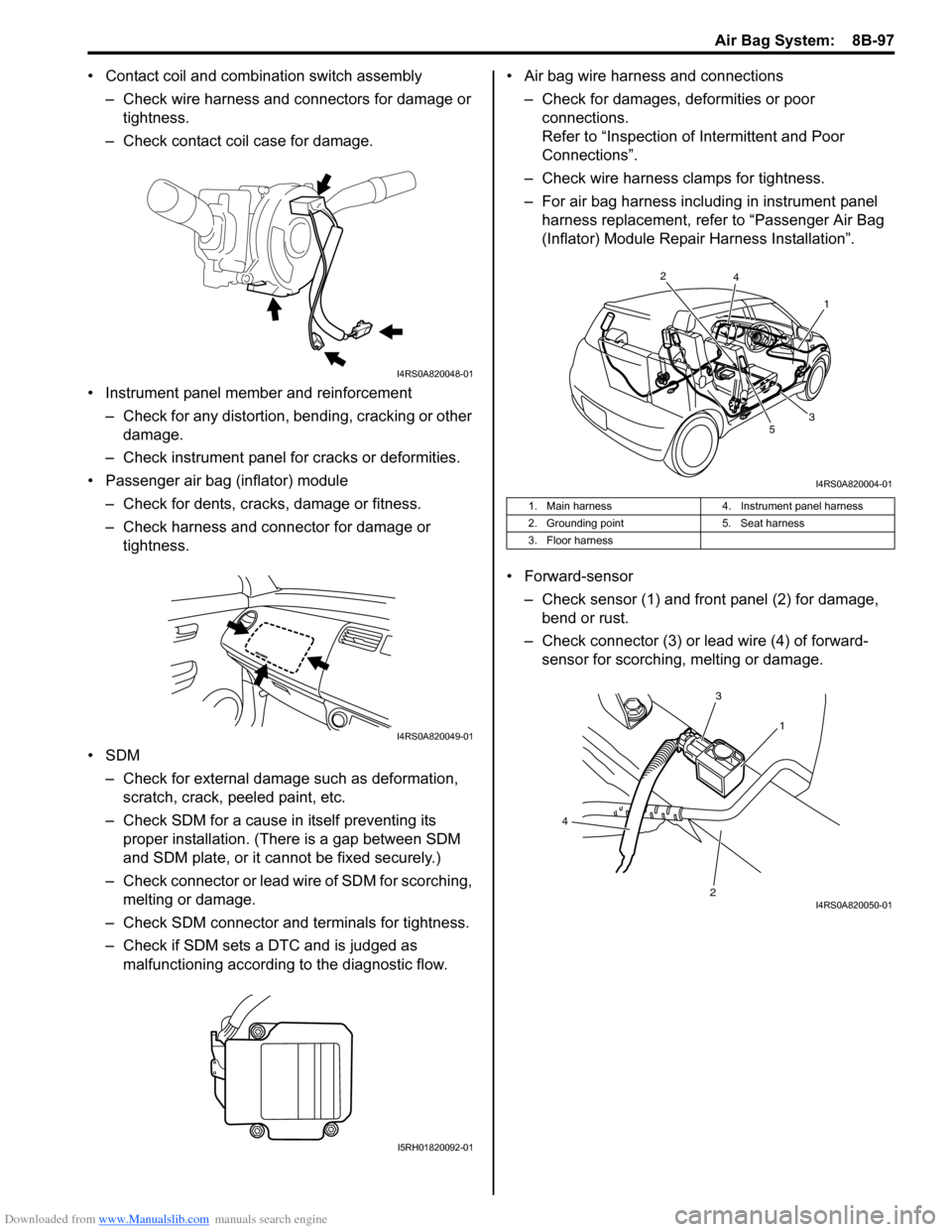

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1164 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-126 Air Bag System:

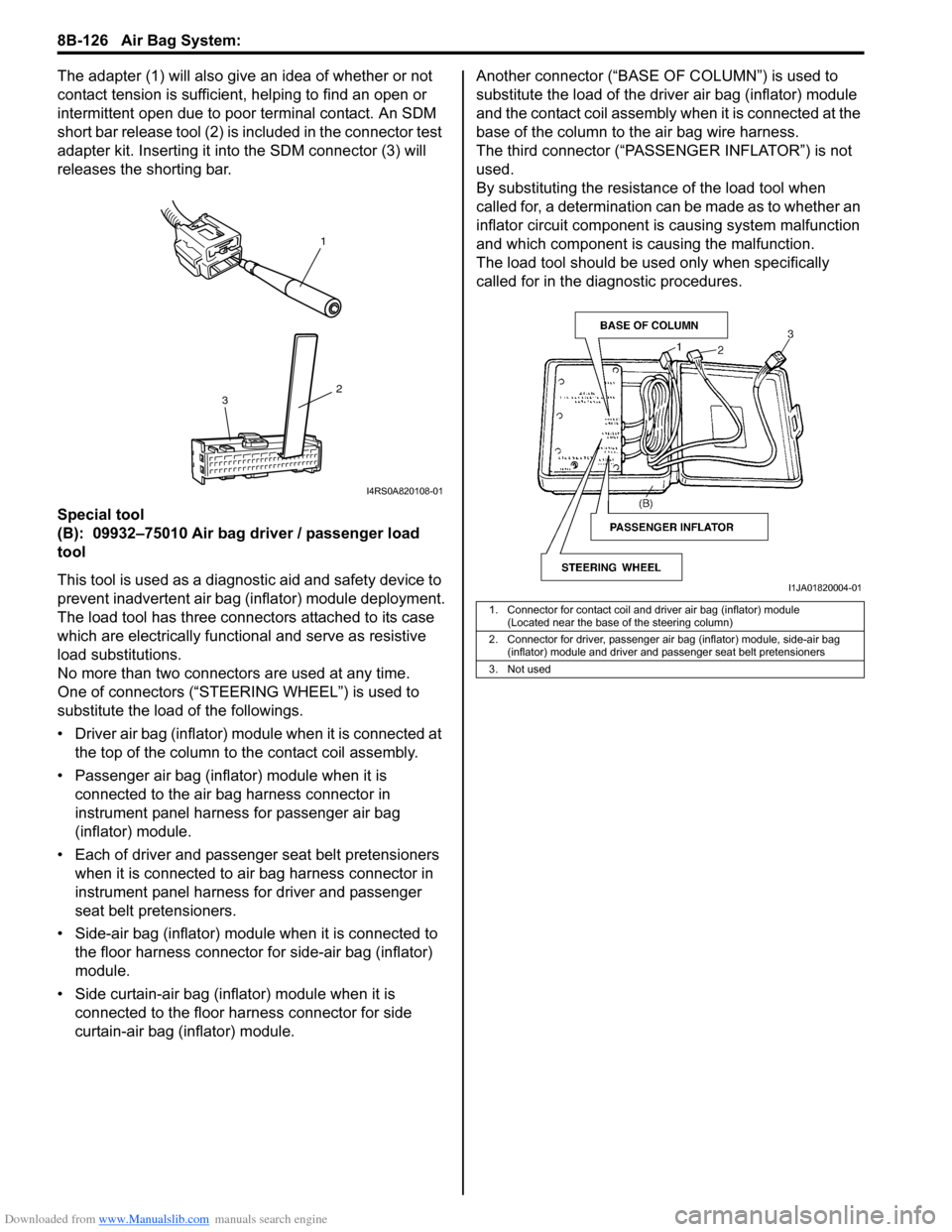

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it in to the SDM connector (3) will

releases the shorting bar.

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagno stic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEER ING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passen ger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is connected to the floor harness connector for side

curtain-air bag (inflator) module. Another connec

tor (“BASE OF COLUMN ”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistan ce of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag (inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01

Page 1172 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-1 Wiring Systems:

Body, Cab and Accessories

Wiring Systems

Precautions

Cautions in Body Electrical System ServicingS7RS0B9100001

When servicing the electric systems, observe the cautions described in “Precautions for Electrical Circuit Service in

Section 00” to protect electrical parts and to prevent a fire.

General Description

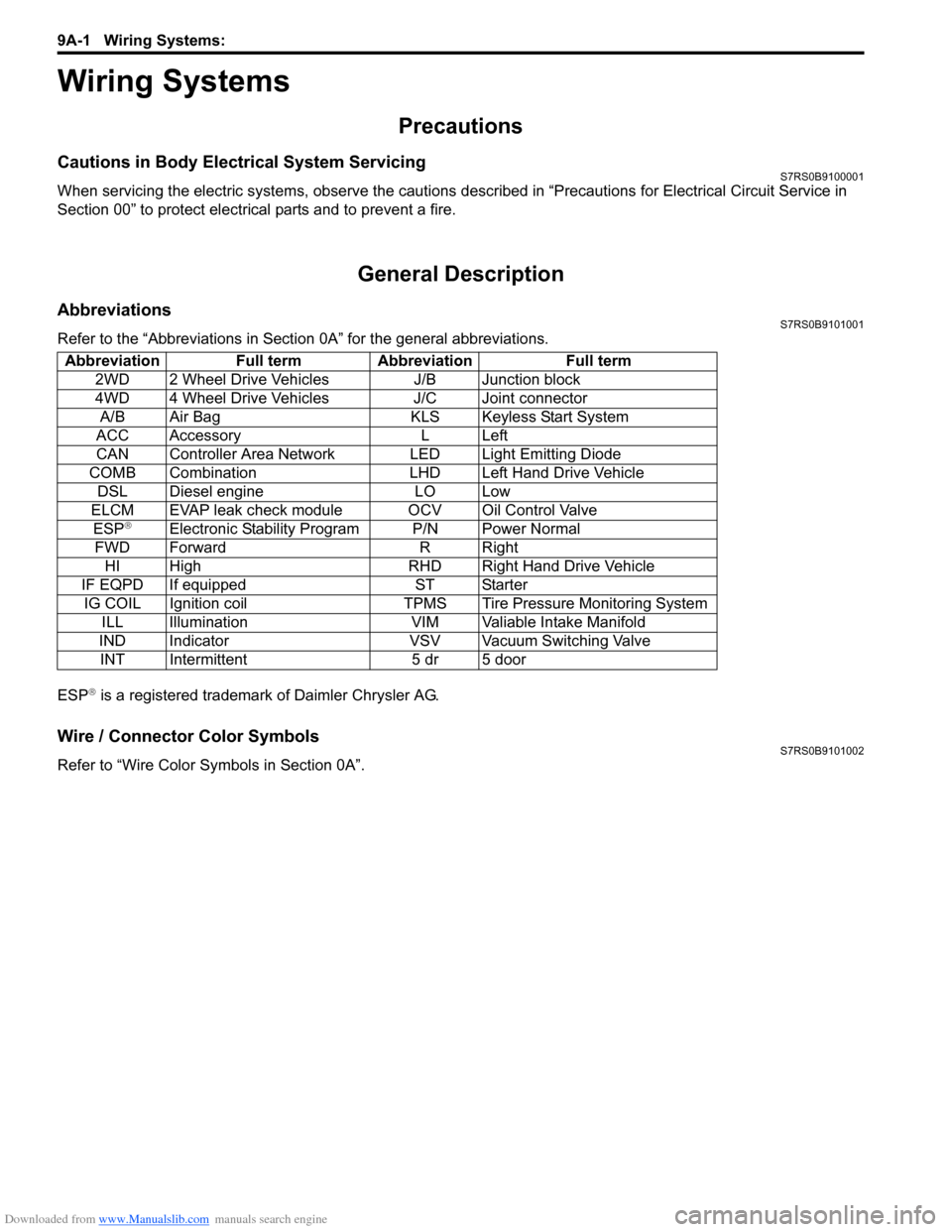

AbbreviationsS7RS0B9101001

Refer to the “Abbreviations in Sect ion 0A” for the general abbreviations.

ESP

® is a registered trademark of Daimler Chrysler AG.

Wire / Connector Color SymbolsS7RS0B9101002

Refer to “Wire Color Sy mbols in Section 0A”.

Abbreviation Full term Abbreviation Full term

2WD 2 Wheel Drive Vehicles J/B Junction block

4WD 4 Wheel Drive Vehicles J/C Joint connectorA/B Air Bag KLS Keyless Start System

ACC Accessory L Left

CAN Controller Area Network LED Light Emitting Diode

COMB Combination LHD Left Hand Drive Vehicle DSL Diesel engine LO Low

ELCM EVAP leak check module OCV Oil Control Valve ESP

®Electronic Stability Program P/N Power Normal

FWD Forward R Right HI High RHD Right Hand Drive Vehicle

IF EQPD If equipped ST Starter IG COIL Ignition coil TPMS Tire Pressure Monitoring System ILL Illumination VIM Valiable Intake Manifold

IND Indicator VSV Vacuum Switching Valve INT Intermittent 5 dr 5 door

Page 1325 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-8

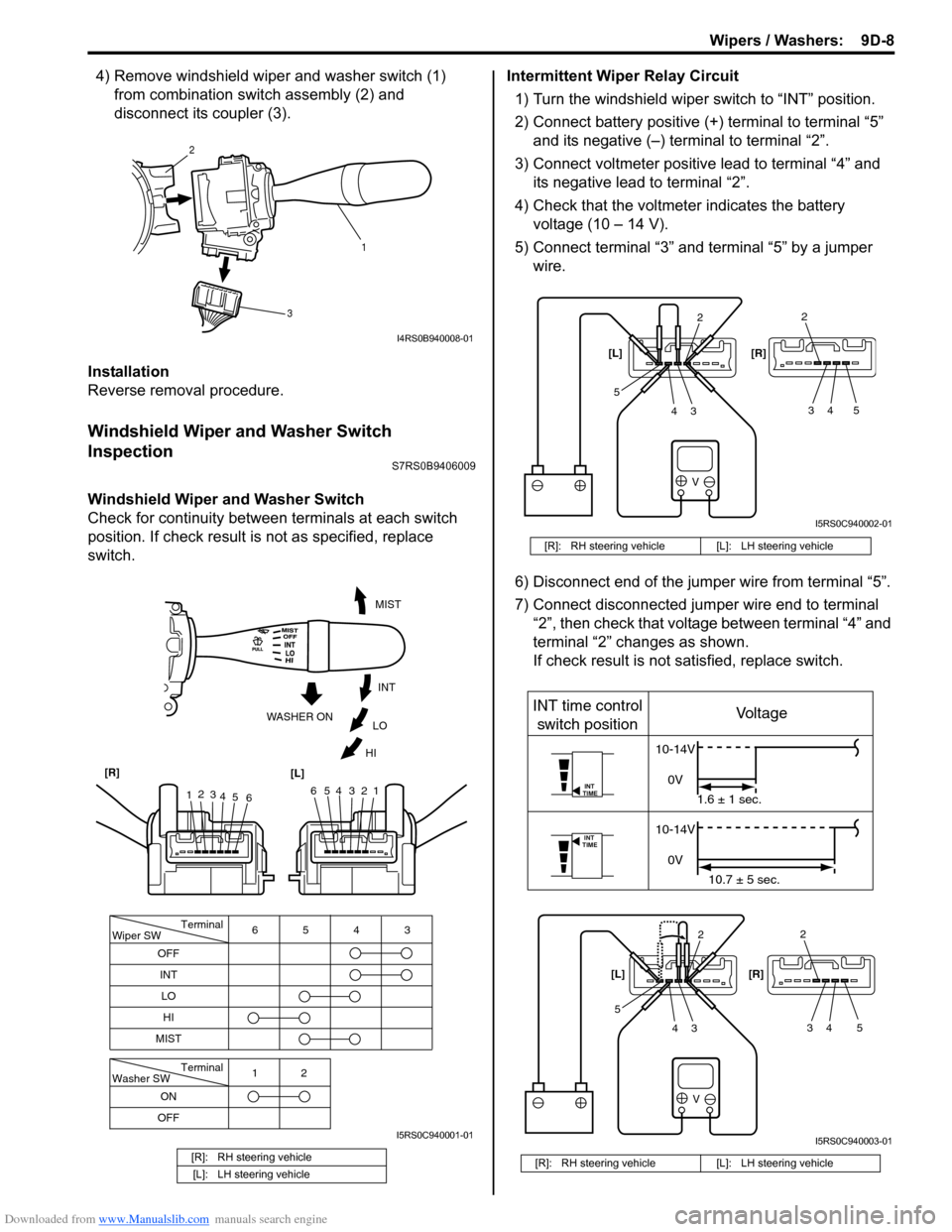

4) Remove windshield wiper and washer switch (1) from combination swit ch assembly (2) and

disconnect its coupler (3).

Installation

Reverse removal procedure.

Windshield Wiper and Washer Switch

Inspection

S7RS0B9406009

Windshield Wiper and Washer Switch

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch. Intermittent Wiper Relay Circuit

1) Turn the windshield wiper switch to “INT” position.

2) Connect battery positive (+ ) terminal to terminal “5”

and its negative (–) terminal to terminal “2”.

3) Connect voltmeter positive lead to terminal “4” and its negative lead to terminal “2”.

4) Check that the voltmeter indicates the battery voltage (10 – 14 V).

5) Connect terminal “3” and terminal “5” by a jumper wire.

6) Disconnect end of the jumper wire from terminal “5”.

7) Connect disconnected jumper wire end to terminal “2”, then check that voltage between terminal “4” and

terminal “2” changes as shown.

If check result is not satisfied, replace switch.

[R]: RH steering vehicle

[L]: LH steering vehicle

1

2

3

I4RS0B940008-01

Terminal

Wiper SW

OFF

INT 6543

MIST

Terminal

Washer SW

OFF 12

ONLO

HI

654321

MIST

INT

LO

HI

WASHER ON

1

2

3

4 5 6

[R]

[L]

I5RS0C940001-01

[R]: RH steering vehicle [L]: LH steering vehicle

[R]: RH steering vehicle [L]: LH steering vehicle

V

2

34

52

34 5

[L] [R]

I5RS0C940002-01

V

INT

TIME

INT

TIME

INT time control

switch position Voltage

10-14V

0V 1.6 ± 1 sec.

10-14V

0V 10.7 ± 5 sec.

2

34

52

34 5

[L]

[R]

I5RS0C940003-01

Page 1413 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-10

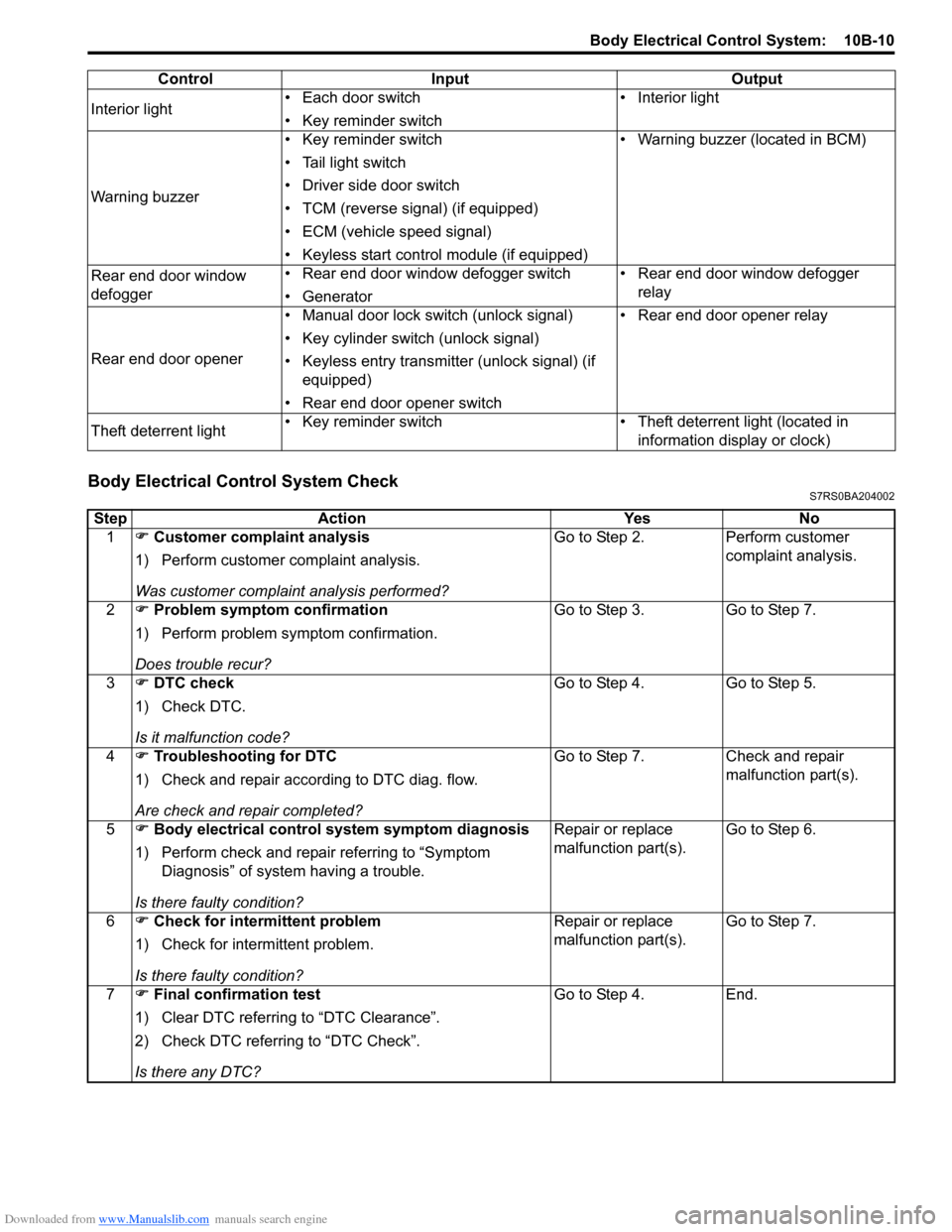

Body Electrical Control System CheckS7RS0BA204002

Interior light• Each door switch

• Key reminder switch • Interior light

Warning buzzer • Key reminder switch

• Tail light switch

• Driver side door switch

• TCM (reverse signal) (if equipped)

• ECM (vehicle speed signal)

• Keyless start control module (if equipped) • Warning buzzer (located in BCM)

Rear end door window

defogger • Rear end door window defogger switch

• Generator • Rear end door window defogger

relay

Rear end door opener • Manual door lock switch (unlock signal)

• Key cylinder switch (unlock signal)

• Keyless entry transmitter (unlock signal) (if

equipped)

• Rear end door opener switch • Rear end door opener relay

Theft deterrent light • Key reminder switch • Theft deterrent light (located in

information display or clock)

Control Input Output

Step

Action YesNo

1 �) Customer complaint analysis

1) Perform customer complaint analysis.

Was customer complaint analysis performed? Go to Step 2.

Perform customer

complaint analysis.

2 �) Problem symptom confirmation

1) Perform problem symptom confirmation.

Does trouble recur? Go to Step 3.

Go to Step 7.

3 �) DTC check

1) Check DTC.

Is it malfunction code? Go to Step 4.

Go to Step 5.

4 �) Troubleshooting for DTC

1) Check and repair according to DTC diag. flow.

Are check and repair completed? Go to Step 7.

Check and repair

malfunction part(s).

5 �) Body electrical control system symptom diagnosis

1) Perform check and repair referring to “Symptom Diagnosis” of system having a trouble.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 6.

6 �) Check for intermittent problem

1) Check for interm ittent problem.

Is there faulty condition? Repair or replace

malfunction part(s).

Go to Step 7.

7 �) Final confirmation test

1) Clear DTC referring to “DTC Clearance”.

2) Check DTC referring to “DTC Check”.

Is there any DTC? Go to Step 4.

End.

Page 1414 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-11 Body Electrical Control System:

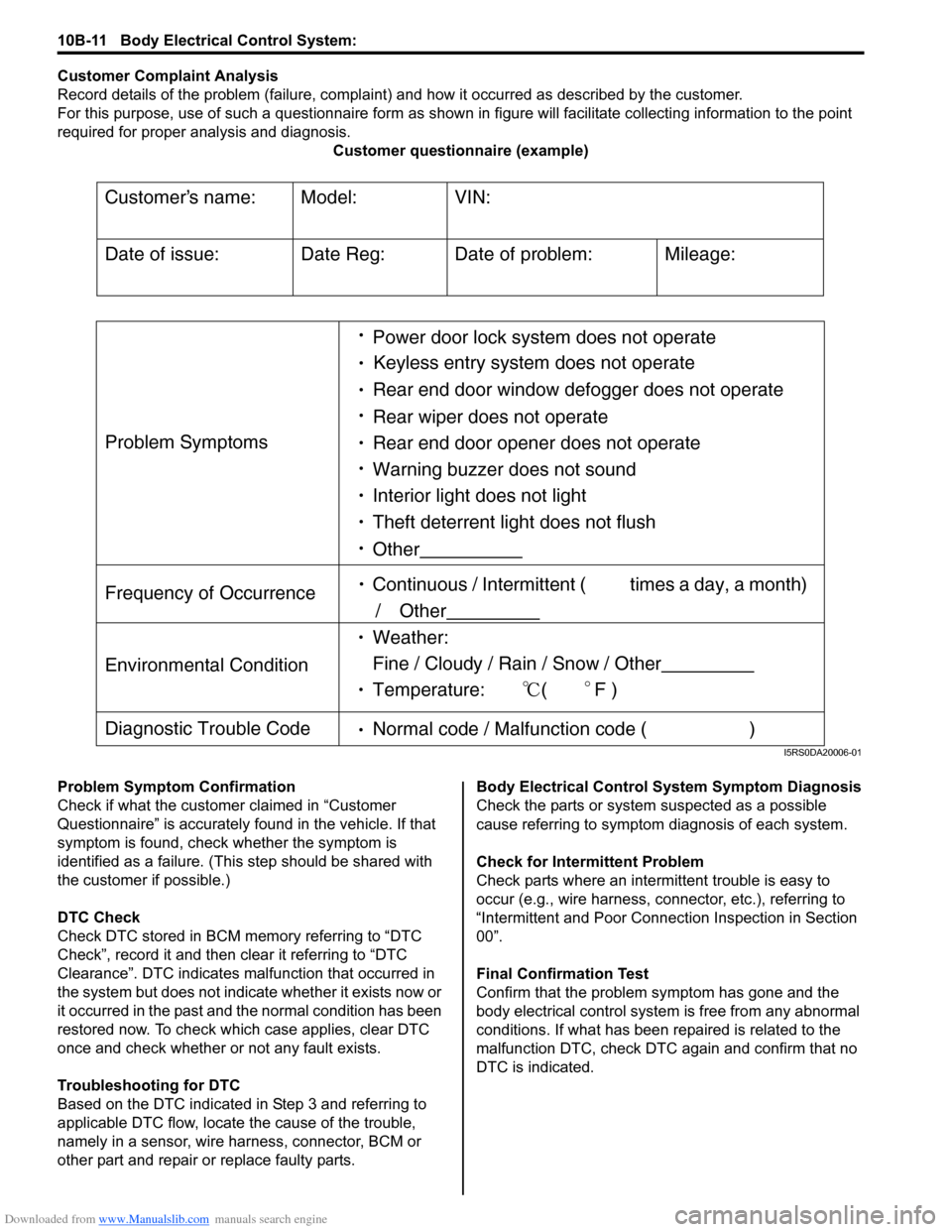

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in figure will facilitate collectin g information to the point

required for proper analysis and diagnosis. Customer questionnaire (example)

Problem Symptom Confirmation

Check if what the custom er claimed in “Customer

Questionnaire” is accurately f ound in the vehicle. If that

symptom is found, check whether the symptom is

identified as a failure. (This step should be shared with

the customer if possible.)

DTC Check

Check DTC stored in BCM me mory referring to “DTC

Check”, record it and then clear it referring to “DTC

Clearance”. DTC indicates malfunction that occurred in

the system but does not indicate whether it exists now or

it occurred in the past and the normal condition has been

restored now. To check which case applies, clear DTC

once and check whether or not any fault exists.

Troubleshooting for DTC

Based on the DTC indicated in Step 3 and referring to

applicable DTC flow, locate the cause of the trouble,

namely in a sensor, wire harness, connector, BCM or

other part and repair or replace faulty parts. Body Electrical Control System Symptom Diagnosis

Check the parts or system

suspected as a possible

cause referring to symptom diagnosis of each system.

Check for Intermi ttent Problem

Check parts where an intermit tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00”.

Final Confirmation Test

Confirm that the problem symptom has gone and the

body electrical control system is free from any abnormal

conditions. If what has been repaired is related to the

malfunction DTC, check DTC again and confirm that no

DTC is indicated.

Customers name:

Model:

VIN:

Date of issue:

Date Reg:

Date of problem:

Mileage:

Problem Symptoms

Power door lock system does not operate

Keyless entry system does not operate

Rear end door window defogger does not operate

Rear wiper does not operate

Rear end door opener does not operate

Other

Frequency of Occurrence

Continuous / Intermittent ( times a day, a month)

/ Other

Environmental Condition

Weather:

Fine / Cloudy / Rain / Snow / Other

Temperature: (F )

Diagnostic Trouble Code Normal code / Malfunction code ( )

Warning buzzer does not sound

Interior light does not light

Theft deterrent light does not flush

I5RS0DA20006-01