engine speed sensor SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 682 of 1496

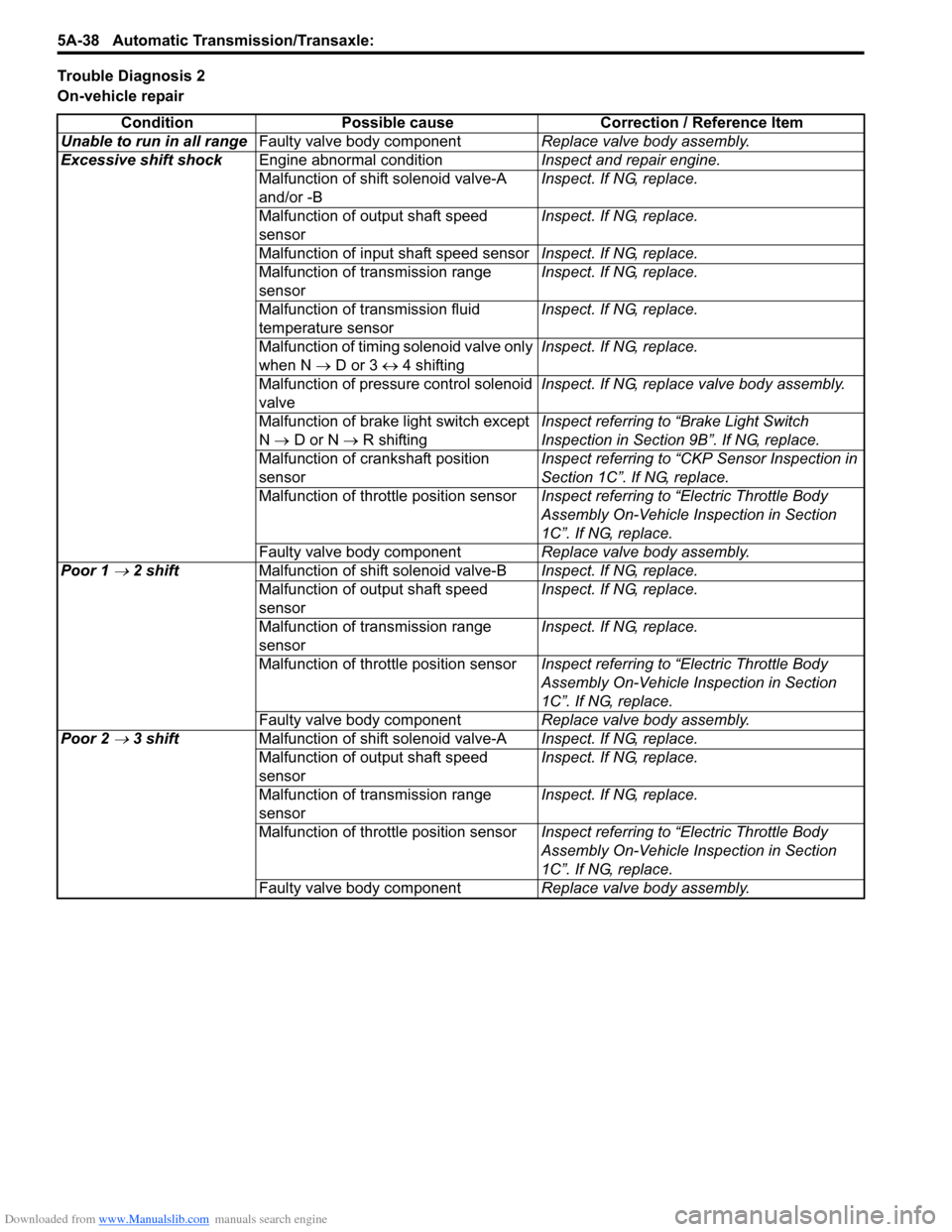

Downloaded from www.Manualslib.com manuals search engine 5A-38 Automatic Transmission/Transaxle:

Trouble Diagnosis 2

On-vehicle repair

Condition Possible cause Correction / Reference Item

Unable to run in all range Faulty valve body component Replace valve body assembly.

Excessive shift shock Engine abnormal condition Inspect and repair engine.

Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of timing solenoid valve only

when N → D or 3 ↔ 4 shifting Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Malfunction of brake light switch except

N → D or N → R shifting Inspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Malfunction of crankshaft position

sensor Inspect referring to “CKP Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Poor 1

→ 2 shift Malfunction of shift solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Poor 2

→ 3 shift Malfunction of shift solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Page 683 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-39

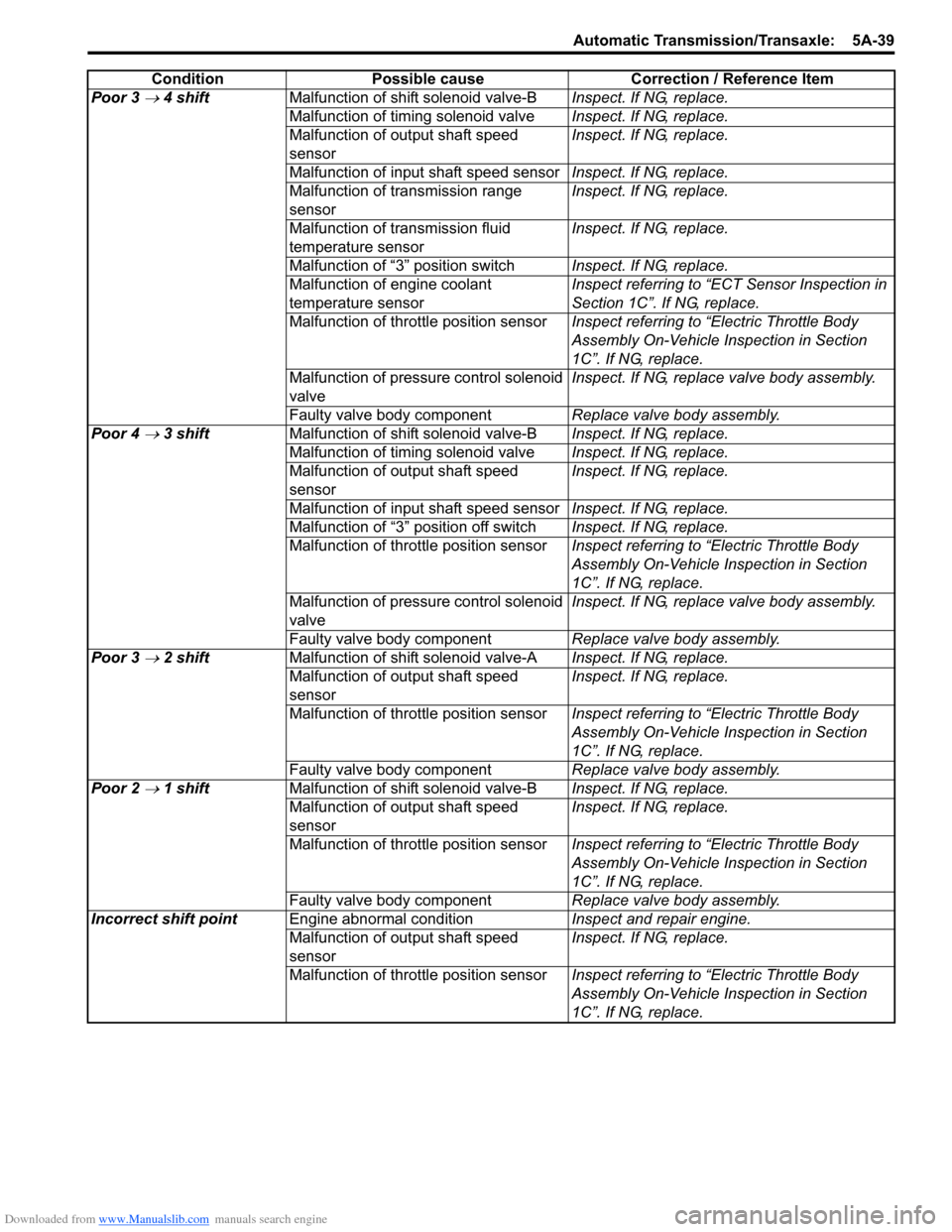

Poor 3 → 4 shiftMalfunction of shift solenoid valve-B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of “3” position switch Inspect. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect referring to “ECT Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Poor 4

→ 3 shift Malfunction of shift solenoid valve-B Inspect. If NG, replace.

Malfunction of timing solenoid valve Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of “3” position off switch Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Poor 3

→ 2 shift Malfunction of shift solenoid valve-A Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Poor 2

→ 1 shift Malfunction of shift solenoid valve-B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Incorrect shift point Engine abnormal condition Inspect and repair engine.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Condition Possible cause Correction / Reference Item

Page 684 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-40 Automatic Transmission/Transaxle:

Trouble Diagnosis 3

Off-vehicle repairNon operate TCC (lock-

up) system

Malfunction of TCC solenoid valve

Inspect. If NG, replace.

Malfunction of shift solenoid valve-A

and/or -B Inspect. If NG, replace.

Malfunction of output shaft speed

sensor Inspect. If NG, replace.

Malfunction of input shaft speed sensor Inspect. If NG, replace.

Malfunction of transmission range

sensor Inspect. If NG, replace.

Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve Inspect. If NG, replace valve body assembly.

Malfunction of throttle position sensor Inspect referring to “Electric Throttle Body

Assembly On-Vehicle Inspection in Section

1C”. If NG, replace.

Malfunction of engine coolant

temperature sensor Inspect referring to “ECT Sensor Inspection in

Section 1C”. If NG, replace.

Malfunction of brake light switch Inspect referring to “Brake Light Switch

Inspection in Section 9B”. If NG, replace.

Faulty valve body component Replace valve body assembly.

Excessive “N”

→ “D” or

“N”

→ “R” time lag Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Pressure control solenoid valve circuit

faulty Inspect. If NG, replace valve body assembly.

Clogged oil strainer Replace.

Faulty valve body component Replace valve body assembly.

Condition Possible cause Correction / Reference Item

Condition

Possible cause Correction / Reference Item

Unable to run in all range Faulty oil pump Inspect. If NG, replace.

Seized or broken planetary gear Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Damaged drive plate Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Faulty torque converter Replace.

Excessive “N”

→ “D” shift

shock Faulty forward clutch

Inspect. If NG, replace.

Excessive “N”

→ “R” shift

shock Faulty reverse clutch

Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Poor 1

→ 2 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 3 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Poor 3

↔ O/D shift,

excessive shock or

slippage Faulty forward clutch

Inspect. If NG, replace.

Faulty O/D and 2nd coast brake Inspect. If NG, replace.

Poor 3

→ 2 shift,

excessive shock or

slippage Faulty direct clutch

Inspect. If NG, replace.

Faulty one-way No.1 clutch Inspect. If NG, replace.

Poor 2

→ 1 shift,

excessive shock or

slippage Faulty 2nd brake

Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Page 689 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-45

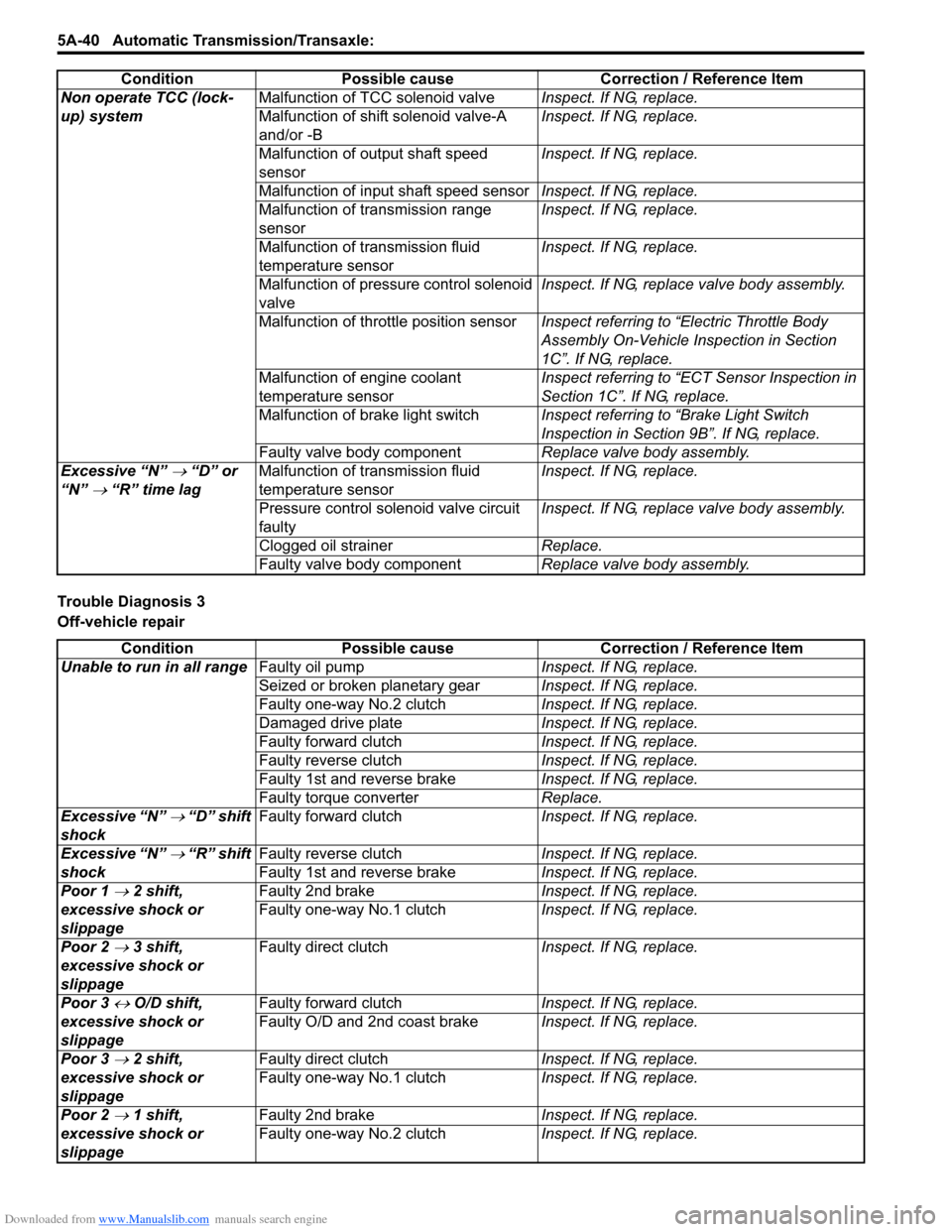

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Keep engine running at idle speed for 25 seconds or more.

5) Stop vehicle and check DTC.

DTC Troubleshooting DTC detecting condition Trouble area

Multiple or more signals are inputted simultaneously for 10

seconds. • Select cable maladjusted

• Transmission range sensor (switch) maladjusted

• Transmission range sensor (switch) or its circuit

malfunction

•TCM

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (“P”, “R”, “N”, “D”, “3”, “2” or “L”) on display when

shifting select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 690 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-46 Automatic Transmission/Transaxle:

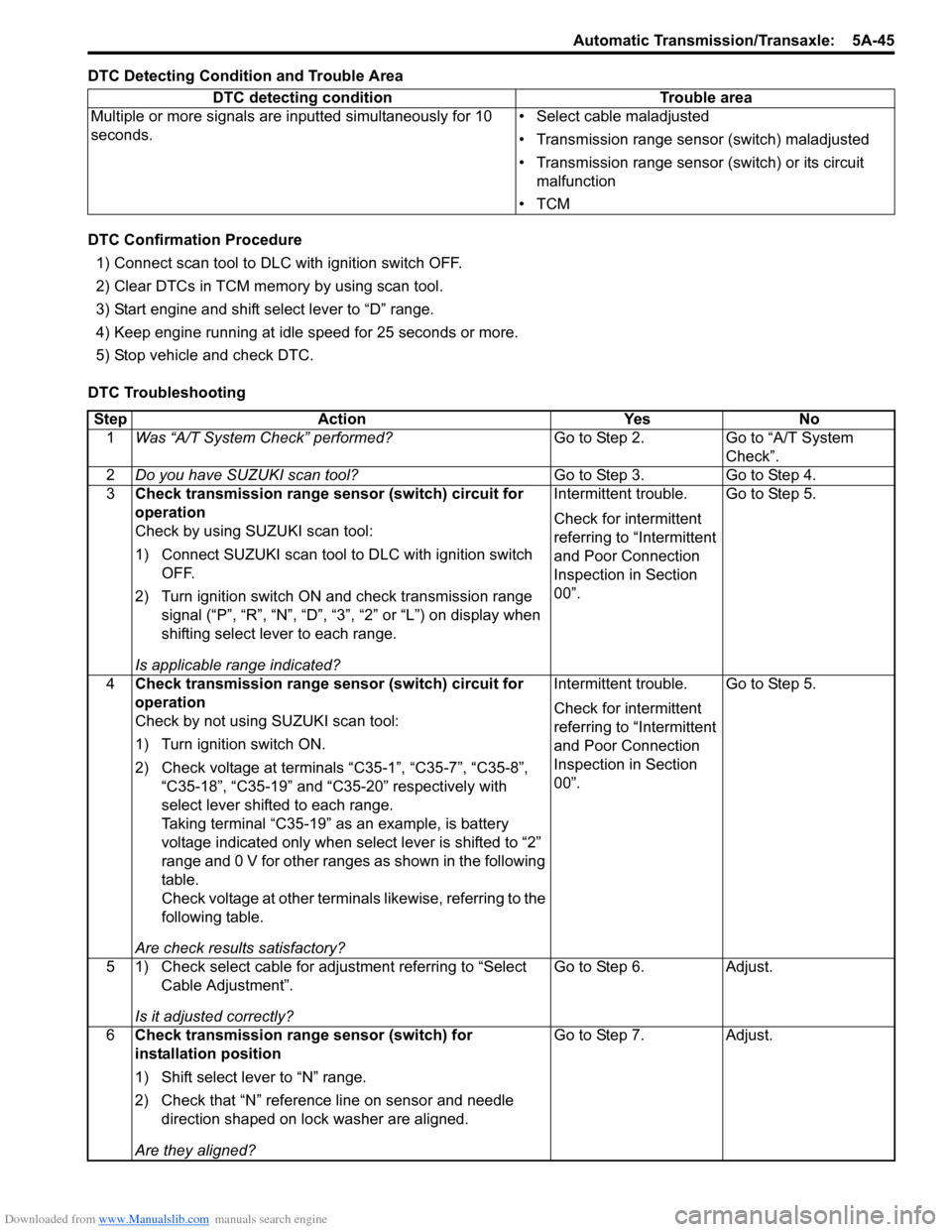

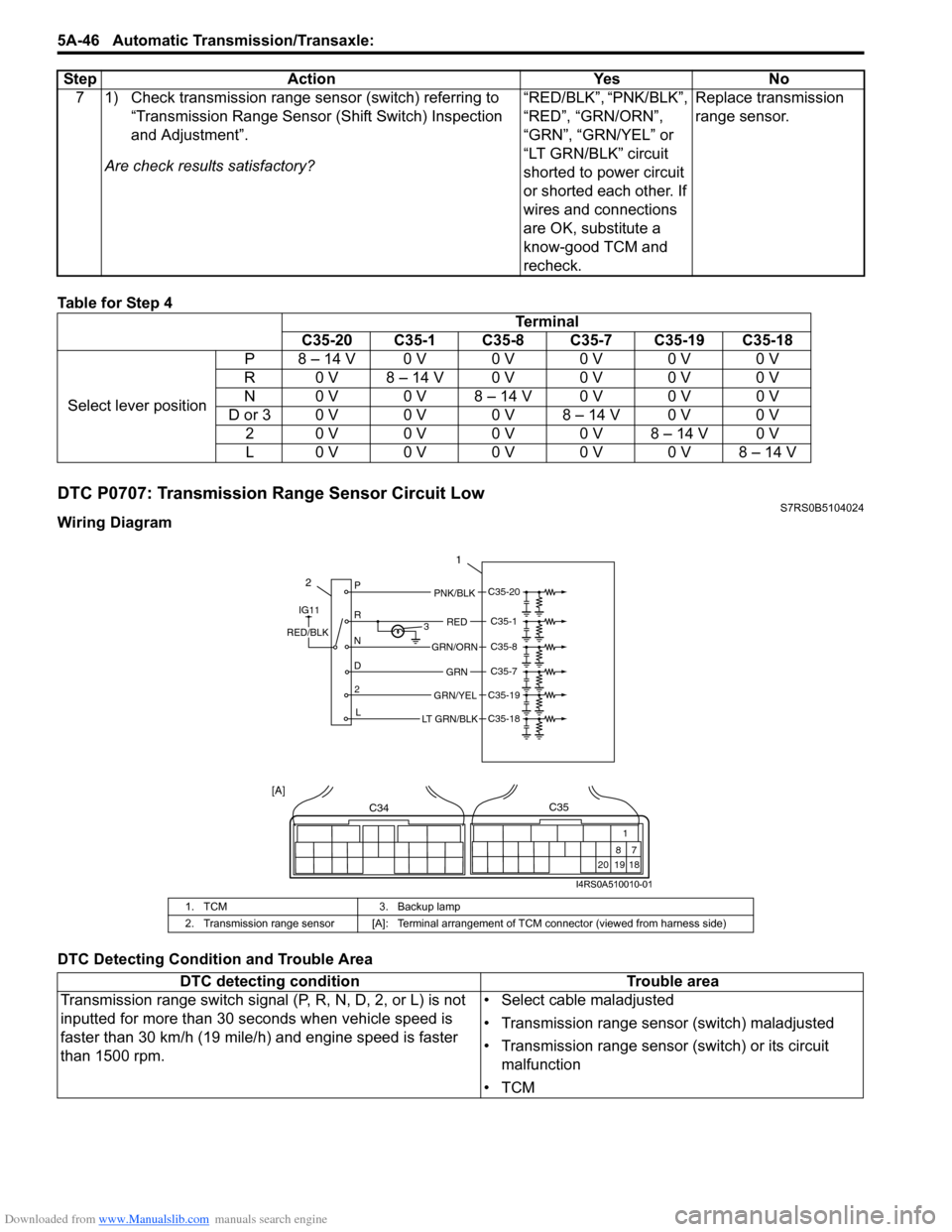

Table for Step 4

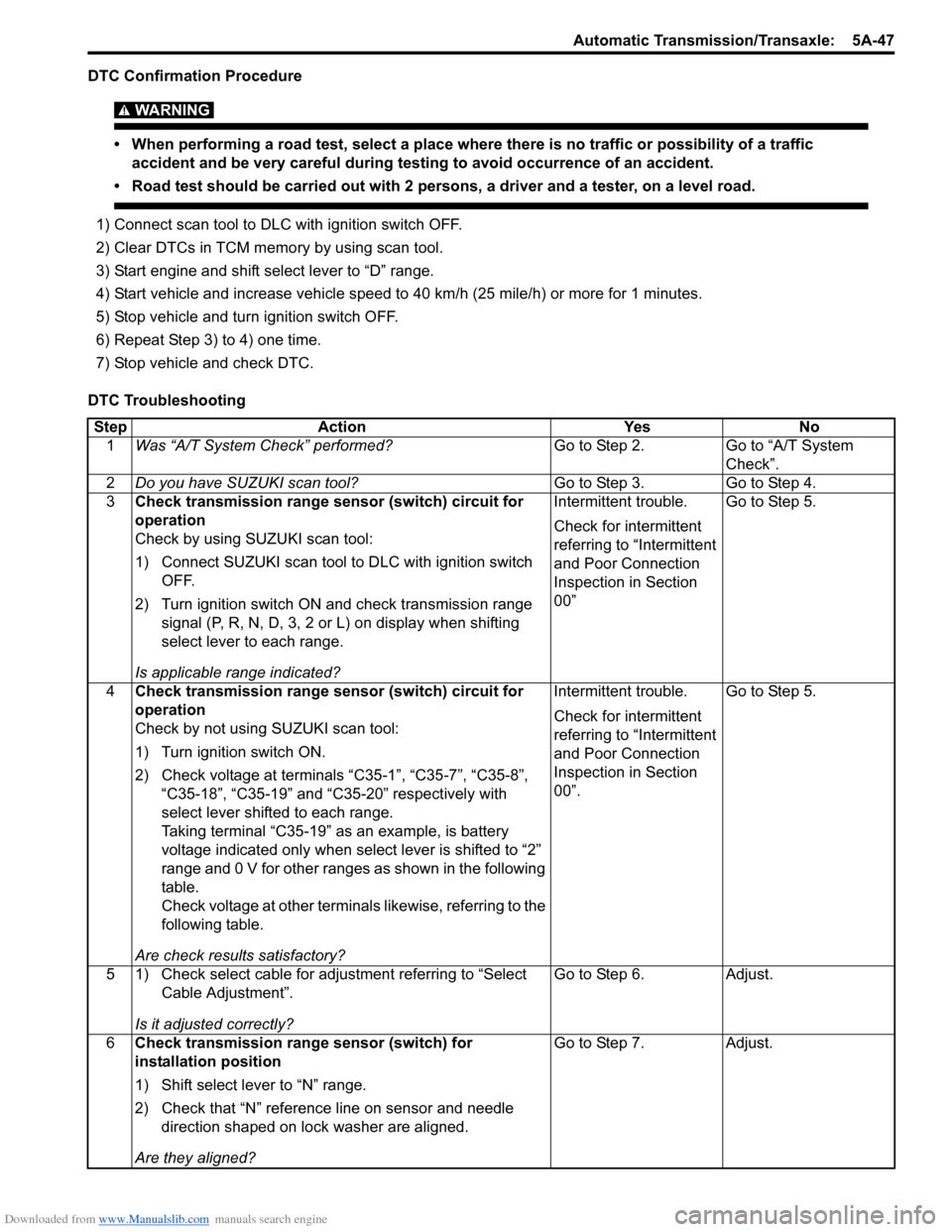

DTC P0707: Transmission Range Sensor Circuit LowS7RS0B5104024

Wiring Diagram

DTC Detecting Condition and Trouble Area7 1) Check transmission range sensor (switch) referring to

“Transmission Range Sensor (Shift Switch) Inspection

and Adjustment”.

Are check results satisfactory? “RED/BLK”, “PNK/BLK”,

“RED”, “GRN/ORN”,

“GRN”, “GRN/YEL” or

“LT GRN/BLK” circuit

shorted to power circuit

or shorted each other. If

wires and connections

are OK, substitute a

know-good TCM and

recheck.Replace transmission

range sensor.

Step Action Yes No

Terminal

C35-20 C35-1 C35-8 C35-7 C35-19 C35-18

Select lever position P 8 – 14 V 0 V 0 V 0 V 0 V 0 V

R 0 V 8 – 14 V 0 V 0 V 0 V 0 V

N 0 V 0 V 8 – 14 V 0 V 0 V 0 V

D or 3 0 V 0 V 0 V 8 – 14 V 0 V 0 V 2 0 V 0 V 0 V 0 V 8 – 14 V 0 V

L0 V0 V0 V0 V0 V8 – 14 V

1. TCM 3. Backup lamp

2. Transmission range sensor [A]: Terminal arrangem ent of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission range switch signal (P, R, N, D, 2, or L) is not

inputted for more than 30 seconds when vehicle speed is

faster than 30 km/h (19 mile/h) and engine speed is faster

than 1500 rpm. • Select cable maladjusted

• Transmission range sensor (switch) maladjusted

• Transmission range sensor (switch) or its circuit

malfunction

•TCM

2P

R

N

D 2 L 3

1

PNK/BLK

RED

GRN

GRN/ORN

GRN/YEL

IG11

RED/BLK

LT GRN/BLK

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18

C34

20 19

87

18

1

C35

[A]

I4RS0A510010-01

Page 691 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-47

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM memo ry by using scan tool.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed to 40 km/h (25 mile/h) or more for 1 minutes.

5) Stop vehicle and turn ignition switch OFF.

6) Repeat Step 3) to 4) one time.

7) Stop vehicle and check DTC.

DTC Troubleshooting Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 4.

3 Check transmission range sensor (switch) circuit for

operation

Check by using SUZUKI scan tool:

1) Connect SUZUKI scan tool to DLC with ignition switch

OFF.

2) Turn ignition switch ON and check transmission range signal (P, R, N, D, 3, 2 or L) on display when shifting

select lever to each range.

Is applicable range indicated? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”

Go to Step 5.

4 Check transmission range sensor (switch) circuit for

operation

Check by not using SUZUKI scan tool:

1) Turn ignition switch ON.

2) Check voltage at terminals “C35-1”, “C35-7”, “C35-8”,

“C35-18”, “C35-19” and “C35-20” respectively with

select lever shifted to each range.

Taking terminal “C35-19” as an example, is battery

voltage indicated only when se lect lever is shifted to “2”

range and 0 V for other ranges as shown in the following

table.

Check voltage at other terminals likewise, referring to the

following table.

Are check results satisfactory? Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 5.

5 1) Check select cable for adjustment referring to “Select Cable Adjustment”.

Is it adjusted correctly? Go to Step 6.

Adjust.

6 Check transmission range sensor (switch) for

installation position

1) Shift select lever to “N” range.

2) Check that “N” reference line on sensor and needle

direction shaped on lock washer are aligned.

Are they aligned? Go to Step 7.

Adjust.

Page 693 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Keep engine running at idle speed for 10 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting

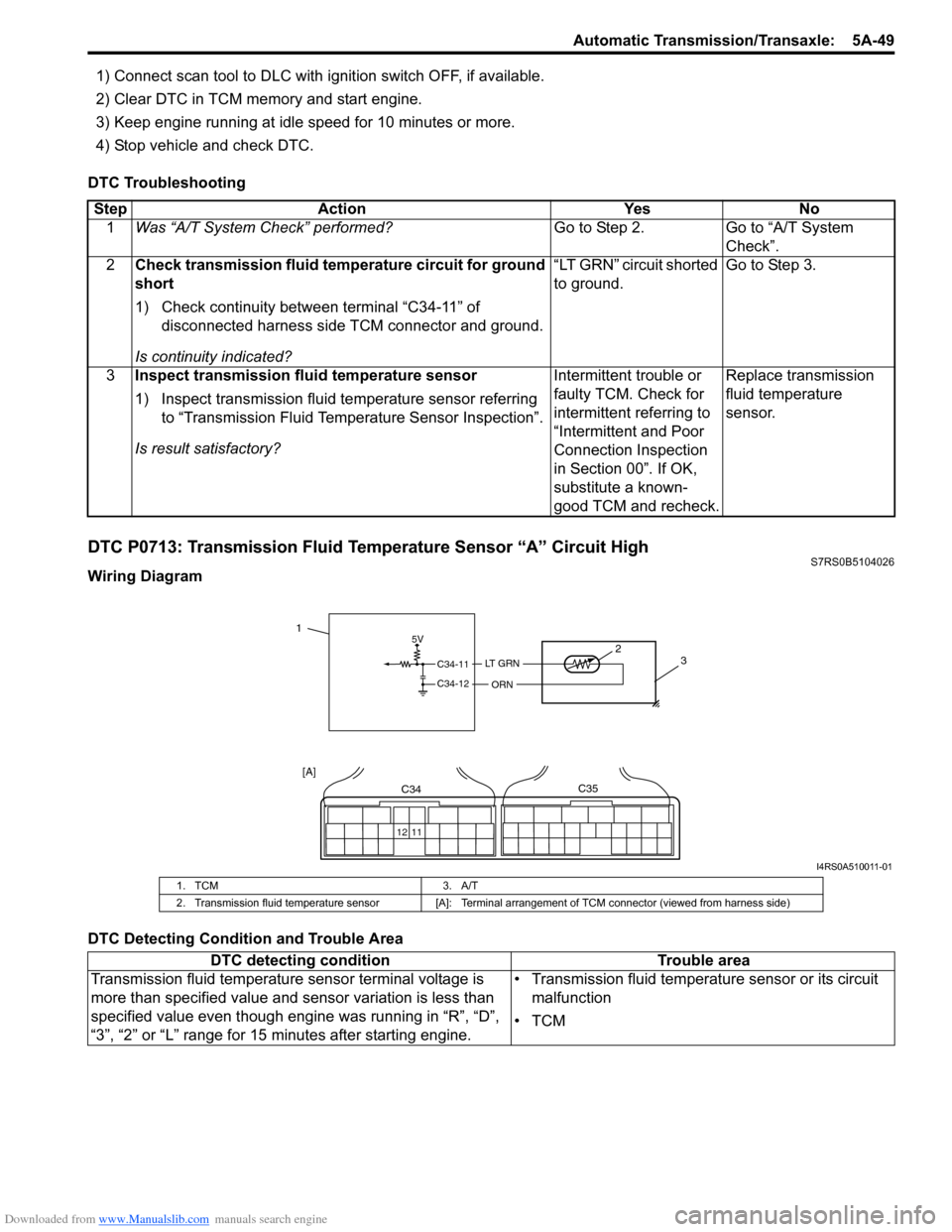

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit HighS7RS0B5104026

Wiring Diagram

DTC Detecting Condition and Trouble Area Step Action Yes No

1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for ground

short

1) Check continuity between terminal “C34-11” of

disconnected harness side TCM connector and ground.

Is continuity indicated? “LT GRN” circuit shorted

to ground.

Go to Step 3.

3 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM. Check for

intermittent referring to

“Intermittent and Poor

Connection Inspection

in Section 00”. If OK,

substitute a known-

good TCM and recheck.Replace transmission

fluid temperature

sensor.

5V

C34-11

C34-12

LT G R N

ORN

2

3

12 11

C34C35

[A]

1

I4RS0A510011-01

1. TCM 3. A/T

2. Transmission fluid temperature sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Transmission fluid temperature sensor terminal voltage is

more than specified value and sensor variation is less than

specified value even though engine was running in “R”, “D”,

“3”, “2” or “L” range for 15 minutes after starting engine. • Transmission fluid temperature sensor or its circuit

malfunction

•TCM

Page 694 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-50 Automatic Transmission/Transaxle:

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Start vehicle and increase vehicle speed to about 40 km/h (25 mile/h) for 20 minutes or more.

4) Stop vehicle and check DTC.

DTC Troubleshooting Step Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check transmission fluid temperature circuit for open

1) Turn ignition switch OFF.

2) Disconnect TCM connectors from TCM.

3) Check for proper connection to transmission fluid

temperature sensor at terminals “C34-11” and “C34-12”.

4) If OK, check continuity between terminals “C34-11” and “C34-12” of disconnected harness side TCM connector.

Is continuity indicated? Go to Step 3. “LT GRN” or “ORN”

circuit open.

3 Check transmission fluid temperature circuit for IG

short

1) Cool down A/T fluid te mperature under ambient

temperature.

2) Connect TCM connectors to TCM with ignition switch OFF.

3) Turn ignition switch ON.

4) Measure voltage between terminal “C34-11” of TCM connector and ground.

Is it 4.6 V or more? “LT GRN” circuit shorted

to power circuit.

If circuit is OK, go to

St ep 4 .

Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

4 Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace transmission

fluid temperature

sensor.

Page 695 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-51

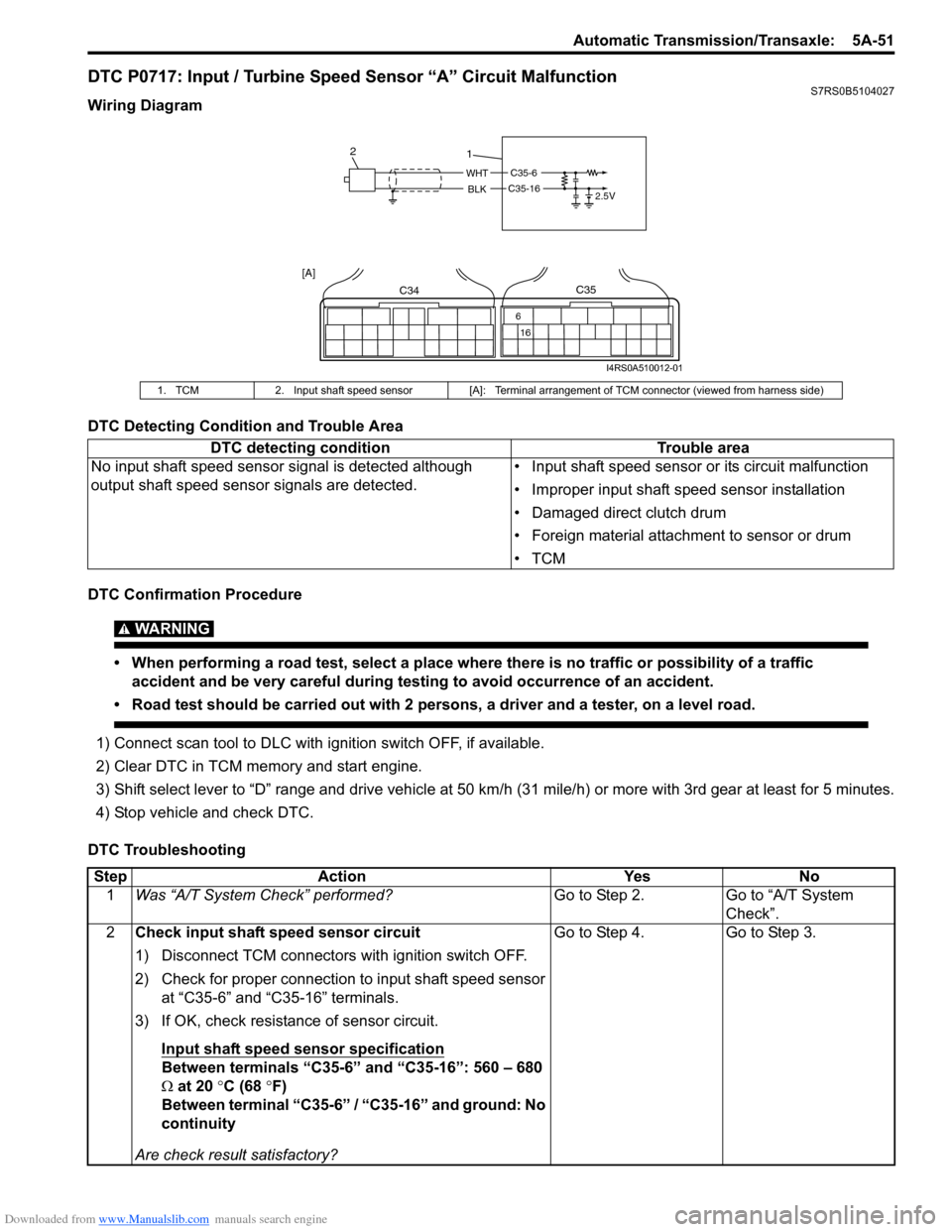

DTC P0717: Input / Turbine Speed Sensor “A” Circuit MalfunctionS7RS0B5104027

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 50 km /h (31 mile/h) or more with 3rd gear at least for 5 minutes.

4) Stop vehicle and check DTC.

DTC Troubleshooting

1. TCM 2. Input shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No input shaft speed sensor signal is detected although

output shaft speed sens or signals are detected. • Input shaft speed sensor or its circuit malfunction

• Improper input shaft speed sensor installation

• Damaged direct clutch drum

• Foreign material attachment to sensor or drum

•TCM

C35-6

2.5VWHT

BLKC35-16

1

2

C34

16

6

C35

[A]

I4RS0A510012-01

Step

Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check input shaft speed sensor circuit

1) Disconnect TCM connectors with ignition switch OFF.

2) Check for proper connection to input shaft speed sensor

at “C35-6” and “C35-16” terminals.

3) If OK, check resistance of sensor circuit.

Input shaft speed sensor specification

Between terminals “C35-6” and “C35-16”: 560 – 680

Ω at 20 °C (68 °F)

Between terminal “C35-6” / “C35-16” and ground: No

continuity

Are check result satisfactory? Go to Step 4. Go to Step 3.

Page 696 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-52 Automatic Transmission/Transaxle:

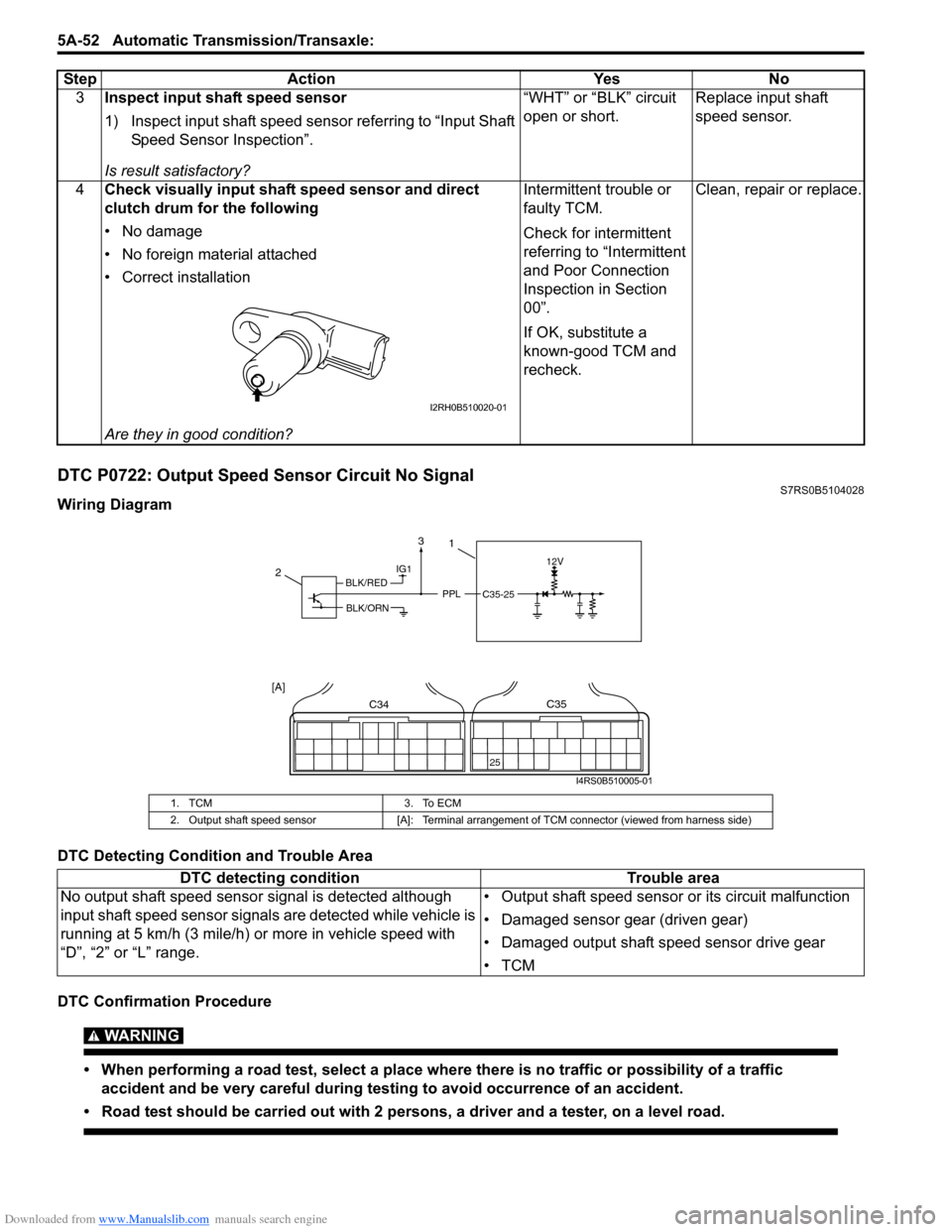

DTC P0722: Output Speed Sensor Circuit No SignalS7RS0B5104028

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

3 Inspect input shaft speed sensor

1) Inspect input shaft speed sensor referring to “Input Shaft

Speed Sensor Inspection”.

Is result satisfactory? “WHT” or “BLK” circuit

open or short.

Replace input shaft

speed sensor.

4 Check visually input shaft speed sensor and direct

clutch drum for the following

• No damage

• No foreign material attached

• Correct installation

Are they in good condition? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

Clean, repair or replace.

Step Action Yes No

I2RH0B510020-01

1. TCM

3. To ECM

2. Output shaft speed sensor [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

No output shaft speed sensor signal is detected although

input shaft speed sensor signal s are detected while vehicle is

running at 5 km/h (3 mile/h) or more in vehicle speed with

“D”, “2” or “L” range. • Output shaft speed sensor or its circuit malfunction

• Damaged sensor gear (driven gear)

• Damaged output shaft speed sensor drive gear

•TCM

IG112V

PPLC35-25

2

C34

25

C35

[A]

1

BLK/RED

BLK/ORN

3

I4RS0B510005-01