manual gear SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 855 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-3

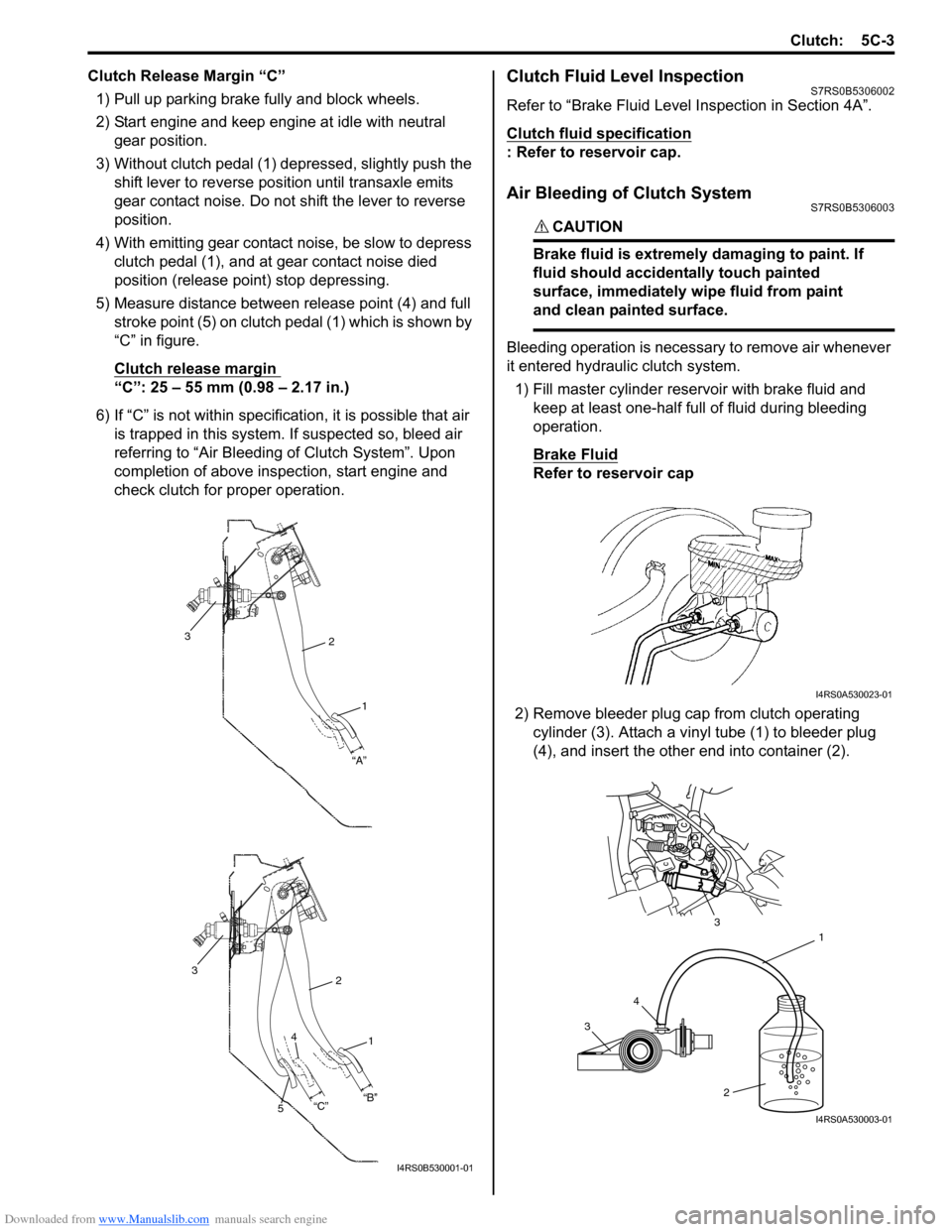

Clutch Release Margin “C”1) Pull up parking brake fully and block wheels.

2) Start engine and keep engine at idle with neutral gear position.

3) Without clutch pedal (1) dep ressed, slightly push the

shift lever to re verse position until transaxle emits

gear contact noise. Do not shift the lever to reverse

position.

4) With emitting gear contact noise, be slow to depress clutch pedal (1), and at gear contact noise died

position (release point) stop depressing.

5) Measure distance between release point (4) and full stroke point (5) on clutch pedal (1) which is shown by

“C” in figure.

Clutch release margin

“C”: 25 – 55 mm (0.98 – 2.17 in.)

6) If “C” is not within specificat ion, it is possible that air

is trapped in this system. If suspected so, bleed air

referring to “Air Bleeding of Clutch System”. Upon

completion of above inspection, start engine and

check clutch for proper operation.

Clutch Fluid Level InspectionS7RS0B5306002

Refer to “Brake Fluid Level Inspection in Section 4A”.

Clutch fluid specification

: Refer to reservoir cap.

Air Bleeding of Clutch SystemS7RS0B5306003

CAUTION!

Brake fluid is extremely damaging to paint. If

fluid should accidentally touch painted

surface, immediately wipe fluid from paint

and clean painted surface.

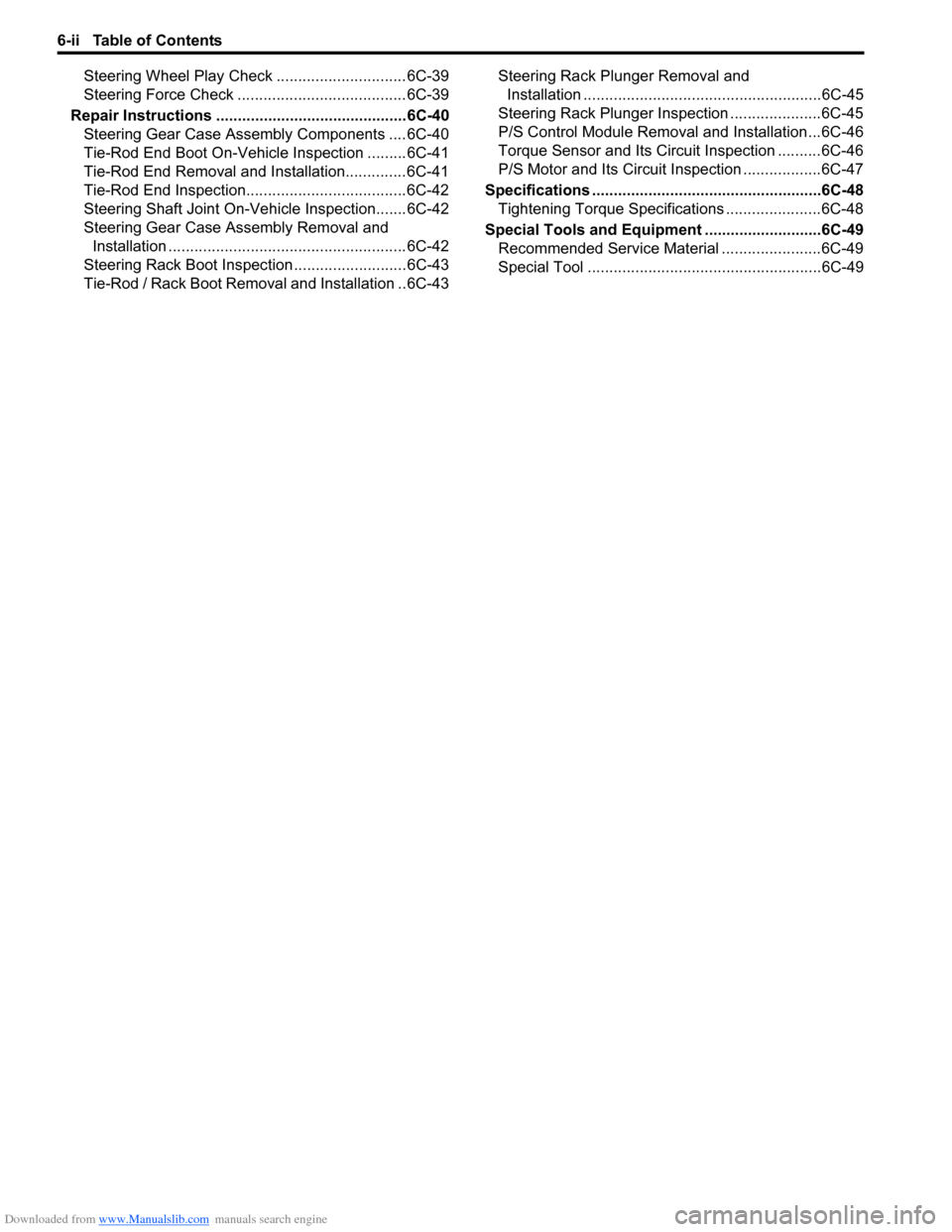

Bleeding operation is necessary to remove air whenever

it entered hydraulic clutch system.

1) Fill master cylinder reservoir with brake fluid and keep at least one-half full of fluid during bleeding

operation.

Brake Fluid

Refer to reservoir cap

2) Remove bleeder plug cap from clutch operating cylinder (3). Attach a vinyl tube (1) to bleeder plug

(4), and insert the other end into container (2).

2

1

“A”

3

2

1

3

“B”

“C”

4

5

I4RS0B530001-01

I4RS0A530023-01

3 4 1

2

3

I4RS0A530003-01

Page 868 of 1496

Downloaded from www.Manualslib.com manuals search engine 6-ii Table of Contents

Steering Wheel Play Check ..............................6C-39

Steering Force Check .......................................6C-39

Repair Instructions ........... .................................6C-40

Steering Gear Case Assembly Components ....6C-40

Tie-Rod End Boot On-Vehic le Inspection .........6C-41

Tie-Rod End Removal and Installation..............6C-41

Tie-Rod End Inspection.....................................6C-42

Steering Shaft Joint On-Vehicle Inspection.......6C-42

Steering Gear Case Assembly Removal and Installation .......................................................6C-42

Steering Rack Boot Inspec tion ..........................6C-43

Tie-Rod / Rack Boot Removal and Installation ..6C-43 Steering Rack Plunger Removal and

Installation .......................................................6C-45

Steering Rack Plunger Inspection .....................6C-45

P/S Control Module Removal and Installation...6C-46

Torque Sensor and Its Circuit Inspection ..........6C-46

P/S Motor and Its Circuit Inspection ..................6C-47

Specifications ..................... ................................6C-48

Tightening Torque Specifications ......................6C-48

Special Tools and Equipmen t ...........................6C-49

Recommended Service Material .......................6C-49

Special Tool ......................................................6C-49

Page 871 of 1496

Downloaded from www.Manualslib.com manuals search engine Steering General Diagnosis: 6A-2

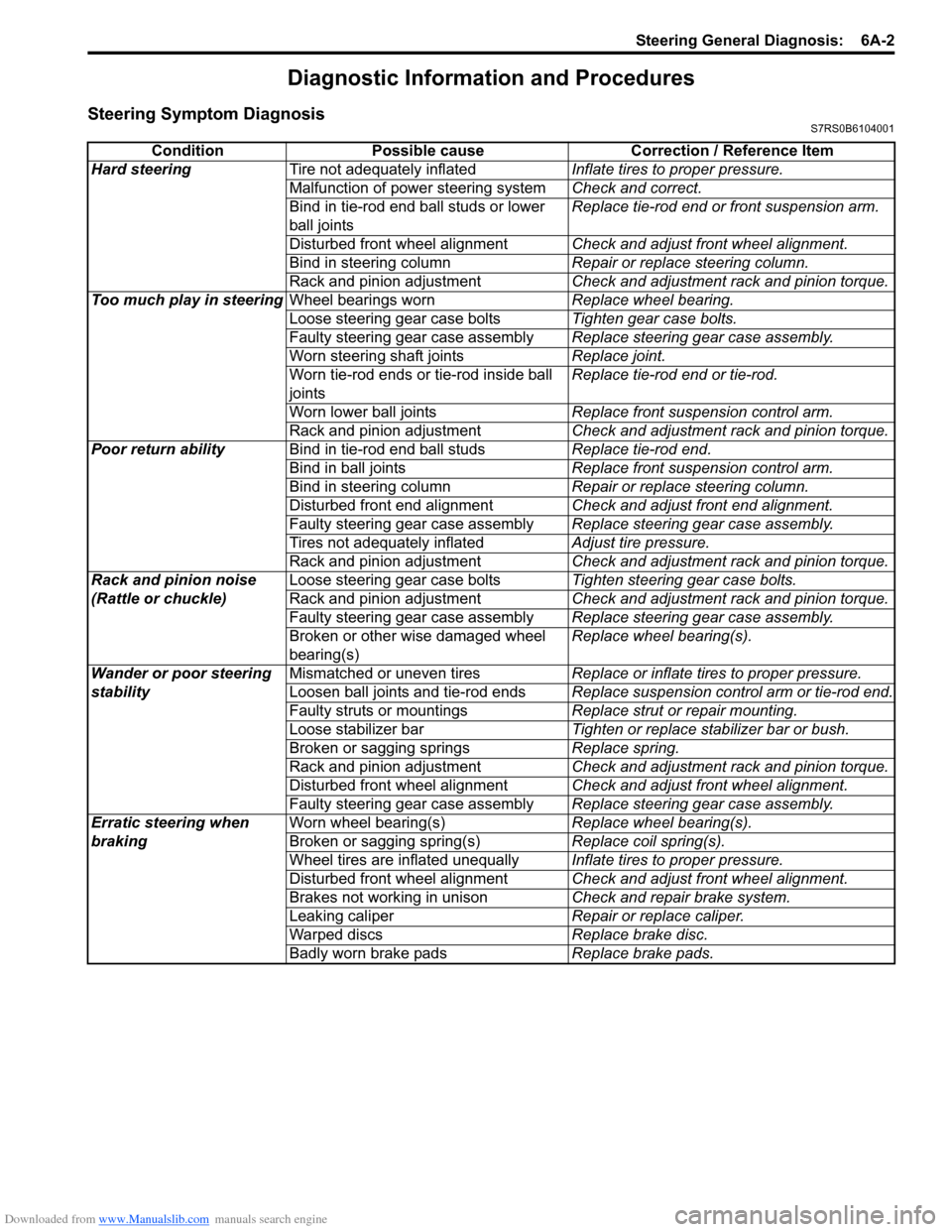

Diagnostic Information and Procedures

Steering Symptom DiagnosisS7RS0B6104001

ConditionPossible cause Correction / Reference Item

Hard steering Tire not adequately inflated Inflate tires to proper pressure.

Malfunction of power steering system Check and correct.

Bind in tie-rod end ball studs or lower

ball joints Replace tie-rod end or front suspension arm.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Bind in steering column Repair or replace steering column.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Too much play in steering Wheel bearings worn Replace wheel bearing.

Loose steering gear case bolts Tighten gear case bolts.

Faulty steering gear case assembly Replace steering gear case assembly.

Worn steering shaft joints Replace joint.

Worn tie-rod ends or tie-rod inside ball

joints Replace tie-rod end or tie-rod.

Worn lower ball joints Replace front suspension control arm.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Poor return ability Bind in tie-rod end ball studs Replace tie-rod end.

Bind in ball joints Replace front suspension control arm.

Bind in steering column Repair or replace steering column.

Disturbed front end alignment Check and adjust front end alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Tires not adequately inflated Adjust tire pressure.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Rack and pinion noise

(Rattle or chuckle) Loose steering gear case bolts

Tighten steering gear case bolts.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Faulty steering gear case assembly Replace steering gear case assembly.

Broken or other wise damaged wheel

bearing(s) Replace wheel bearing(s).

Wander or poor steering

stability Mismatched or uneven tires

Replace or inflate tires to proper pressure.

Loosen ball joints and tie-rod ends Replace suspension control arm or tie-rod end.

Faulty struts or mountings Replace strut or repair mounting.

Loose stabilizer bar Tighten or replace stabilizer bar or bush.

Broken or sagging springs Replace spring.

Rack and pinion adjustment Check and adjustment rack and pinion torque.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Faulty steering gear case assembly Replace steering gear case assembly.

Erratic steering when

braking Worn wheel bearing(s)

Replace wheel bearing(s).

Broken or sagging spring(s) Replace coil spring(s).

Wheel tires are inflated unequally Inflate tires to proper pressure.

Disturbed front wheel alignment Check and adjust front wheel alignment.

Brakes not working in unison Check and repair brake system.

Leaking caliper Repair or replace caliper.

Warped discs Replace brake disc.

Badly worn brake pads Replace brake pads.

Page 883 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-1

Steeri ng

Power Assisted Steering System

Precautions

Steering System NoteS7RS0B6300001

NOTE

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of these parts.

Precautions in Diagnosing TroublesS7RS0B6300002

• Take a note of DTC indicated on the SUZUKI scan tool.

• Before inspection, be sure to read “Pre cautions for Electrical Circuit Service in Section 00” and understand what is

written there.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON position and engine is not

running, but it means there is nothing abnormal if indica tion changes to a normal one when engine is started.

• As DTC is stored in memory of the P/S control module, be sure to clear memory after repair by performing the

procedure described in “DTC Clearance”.

Page 884 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-2 Power Assisted Steering System:

General Description

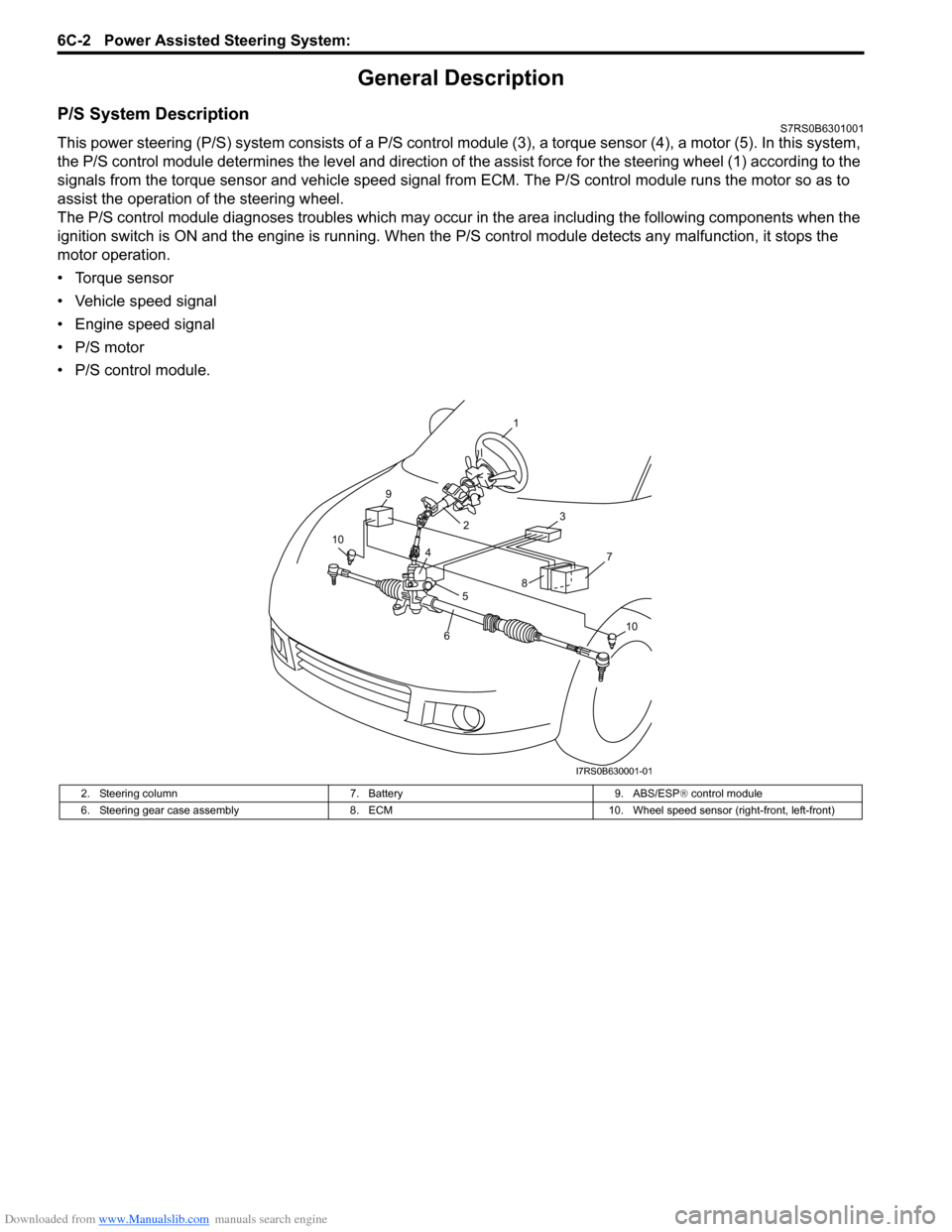

P/S System DescriptionS7RS0B6301001

This power steering (P/S) system consists of a P/S control module (3), a torque sensor (4), a motor (5). In this system,

the P/S control module determines the level and direction of the assist force for the steering wheel (1) according to the

signals from the torque sensor and vehicle speed signal from ECM. The P/S control module runs the motor so as to

assist the operation of the steering wheel.

The P/S control module diagnoses troubles which may occur in the area including the following components when the

ignition switch is ON and the engine is running. When the P/S control module detects any malfunction, it stops the

motor operation.

• Torque sensor

• Vehicle speed signal

• Engine speed signal

• P/S motor

• P/S control module.

2. Steering column 7. Battery9. ABS/ESP® control module

6. Steering gear case assembly 8. ECM10. Wheel speed sensor (right-front, left-front)

7

3

9

10

10

1

2

4

5

6

8

I7RS0B630001-01

Page 894 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-12 Power Assisted Steering System:

Scan Tool Data Definitions

Battery Voltage

This parameter indicates battery positive voltage.

TQS Power Supply (Torque Sensor Power Supply, V)

This parameter indicates the power supply voltage which

the P/S control module supplies to the torque sensor.

TQS Main Torque (Torque Sensor Main Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the main torque sensor is one of

these.

TQS Sub Torque (Torque Sensor Sub Torque, N ⋅m)

The torque sensor is installed to detect the steering force

and the steering directio n. It consists of two

potentiometers and the sub-torque sensor is one of

these. Its output characteristics are compared with those

of the main torque sensor.

Assist Torque (N ⋅m)

This parameter is an internal parameter of the P/S

control module. It is obtained by computing the torque

sensor input signal. Motor Control (Motor Control Current, A)

Based on the input signal, the P/S control module

determines the assist amount

and controls the current to

the motor suitable for that a ssist amount. This parameter

indicates that control value.

Motor Monitor (Motor Monitor Current, A)

This parameter indicates the actually measured value of

the current flowing to the motor. The motor circuit

condition is diagnosed by co mparing this parameter with

“Motor Control” parameter described previously.

Vehicle Speed (km/h, MPH)

Vehicle speed signal is fed from BCM. P/S control

module determines the amount of power assist based on

this vehicle speed signal and the torque sensor signal.

Engine Speed (rpm)

Engine speed signal is fed from the ECM so that it can

be used for trouble diagnos is of the electric power

steering system.

Motor Volt (V)

This parameter indicates the voltage between motor

terminals.

Ignition switch (ON, OFF)

This parameter indicates the condition of the power

supply through the ignition switch.

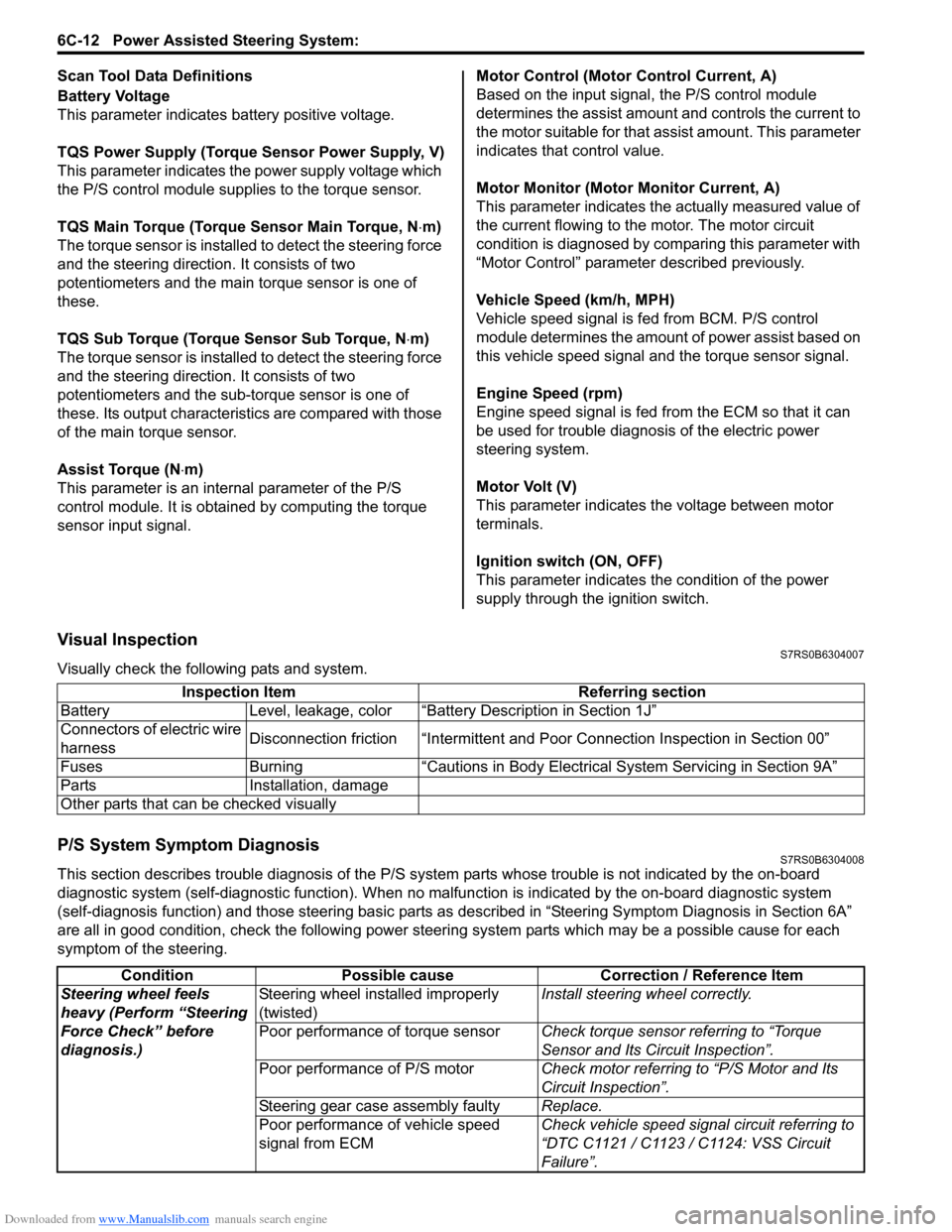

Visual InspectionS7RS0B6304007

Visually check the following pats and system.

P/S System Symptom DiagnosisS7RS0B6304008

This section describes trouble diagnosis of the P/S system parts whose trouble is not indicated by the on-board

diagnostic system (self-diagnostic functi on). When no malfunction is indicated by the on-board diagnostic system

(self-diagnosis function) and those stee ring basic parts as described in “Steering Symptom Diagnosis in Section 6A”

are all in good condition, check the following power steer ing system parts which may be a possible cause for each

symptom of the steering. Inspection Item Referring section

Battery Level, leakage, color “Batte ry Description in Section 1J”

Connectors of electric wire

harness Disconnection friction “Intermittent and Poor

Connection Inspection in Section 00”

Fuses Burning “Cautions in Body Electric al System Servicing in Section 9A”

Parts Installation, damage

Other parts that can be checked visually

Condition Possible cause Correction / Reference Item

Steering wheel feels

heavy (Perform “Steering

Force Check” before

diagnosis.) Steering wheel installed improperly

(twisted)

Install steering wheel correctly.

Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Poor performance of P/S motor Check motor referring to “P/S Motor and Its

Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor performance of vehicle speed

signal from ECM Check vehicle speed signal circuit referring to

“DTC C1121 / C1123 / C1124: VSS Circuit

Failure”.

Page 895 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-13

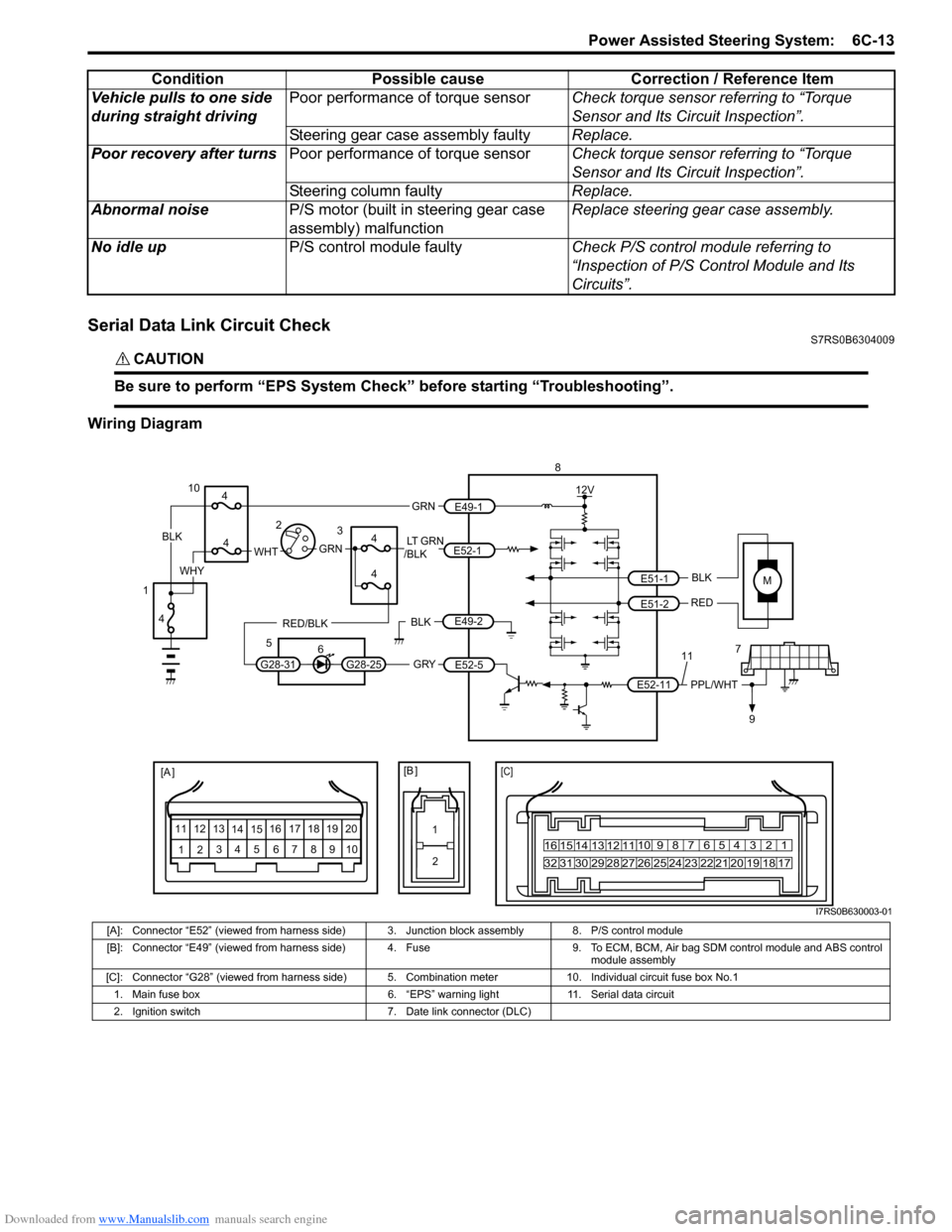

Serial Data Link Circuit CheckS7RS0B6304009

CAUTION!

Be sure to perform “EPS System Check” before starting “Troubleshooting”.

Wiring DiagramVehicle pulls to one side

during straight driving

Poor performance of torque sensor

Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering gear case assembly faulty Replace.

Poor recovery after turns Poor performance of torque sensor Check torque sensor referring to “Torque

Sensor and Its Circuit Inspection”.

Steering column faulty Replace.

Abnormal noise P/S motor (built in steering gear case

assembly) malfunction Replace steering gear case assembly.

No idle up P/S control module faulty Check P/S control module referring to

“Inspection of P/S Control Module and Its

Circuits”.

Condition Possible cause Correction / Reference Item

MBLK

RED

E52-11 E51-1

E51-2PPL/WHT

[A ]

12

3

4 5 67

89

11

10

12 13

141516

17 18 19 2010 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

8

79

12V

[B ]

11

12

GRY

LT GRN

/BLK

E52-1

E52-5

E49-1

GRNGRNWHTBLK

WHY

G28-25G28-31

RED/BLK

10

3

4

4

5 6

4

4

1 2

4

E49-2BLK

I7RS0B630003-01

[A]: Connector “E52” (viewed from harness side) 3. Junction block assembly 8. P/S control module

[B]: Connector “E49” (viewed from harness side) 4. Fuse 9. T o ECM, BCM, Air bag SDM control module and ABS control

module assembly

[C]: Connector “G28” (viewed from harness side) 5. Comb ination meter 10. Individual circuit fuse box No.1

1. Main fuse box 6. “EPS” warning light 11. Serial data circuit

2. Ignition switch 7. Date link connector (DLC)

Page 900 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-18 Power Assisted Steering System:

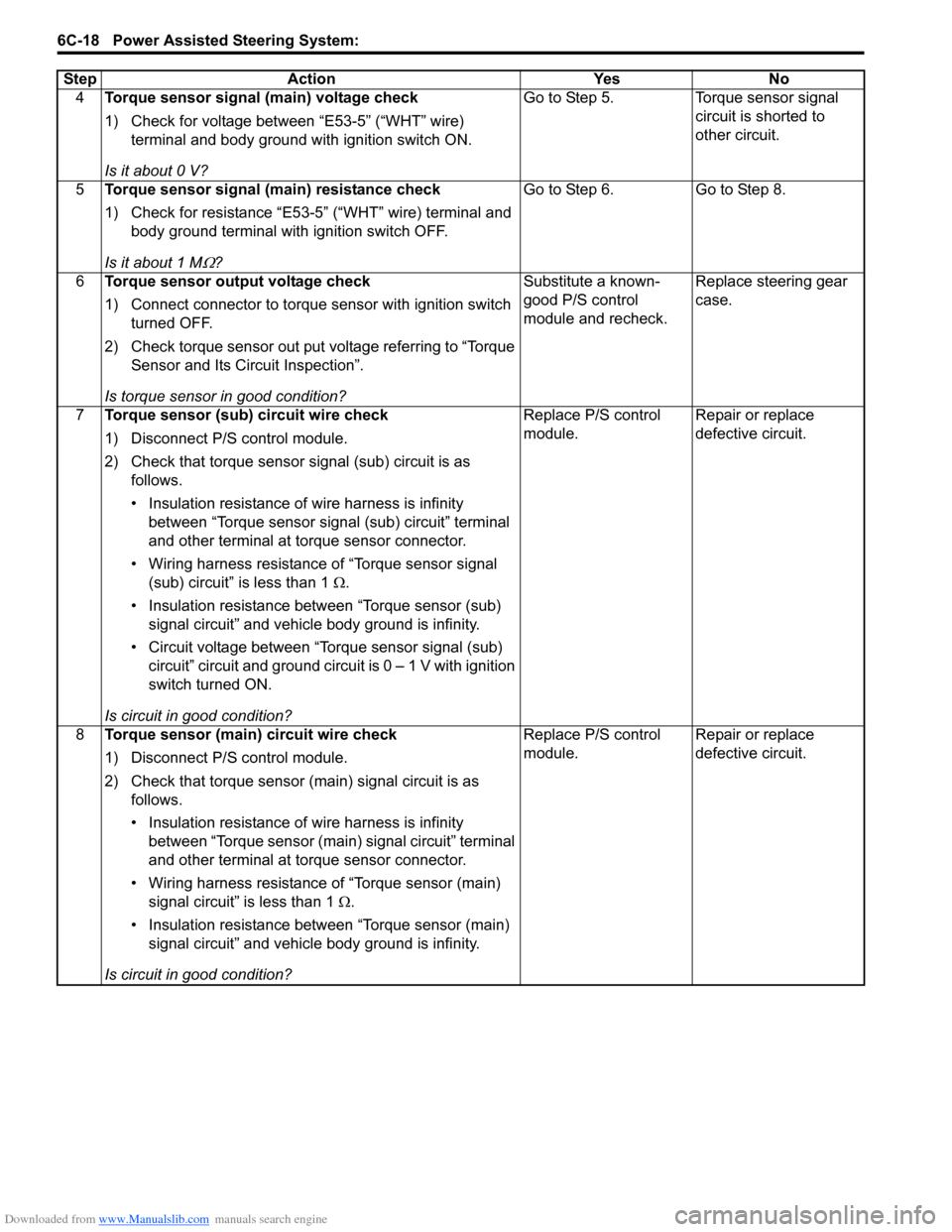

4Torque sensor signal (main) voltage check

1) Check for voltage between “E53-5” (“WHT” wire)

terminal and body ground with ignition switch ON.

Is it about 0 V? Go to Step 5. Torque sensor signal

circuit is shorted to

other circuit.

5 Torque sensor signal (main) resistance check

1) Check for resistance “E53-5” (“WHT” wire) terminal and

body ground terminal with ignition switch OFF.

Is it about 1 M

Ω? Go to Step 6. Go to Step 8.

6 Torque sensor output voltage check

1) Connect connector to torque sensor with ignition switch

turned OFF.

2) Check torque sensor out put voltage referring to “Torque Sensor and Its Circuit Inspection”.

Is torque sensor in good condition? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

7 Torque sensor (sub) circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor signal (sub) circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor signal (sub) circuit” terminal

and other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor signal (sub) circuit” is less than 1 Ω.

• Insulation resistance between “Torque sensor (sub) signal circuit” and vehicle body ground is infinity.

• Circuit voltage between “Torque sensor signal (sub) circuit” circuit and ground circuit is 0 – 1 V with ignition

switch turned ON.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

8 Torque sensor (main) circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor (main) signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor (main) signal circuit” terminal

and other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor (main) signal circuit” is less than 1 Ω.

• Insulation resistance between “Torque sensor (main) signal circuit” and vehicle body ground is infinity.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

Step Action Yes No

Page 902 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-20 Power Assisted Steering System:

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1153 and/or DTC C1155 indicated together? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Torque sensor 5 V reference power supply circuit

voltage check

1) With ignition switch turned OFF, disconnect torque

sensor connector and check for proper terminal

connection to torque sensor connector.

2) If connections are OK, check for voltage between “E53- 6” (“RED” wire) terminal and body ground with ignition

switch ON.

Is it approx. 5 V? Go to Step 4. Go to Step 5.

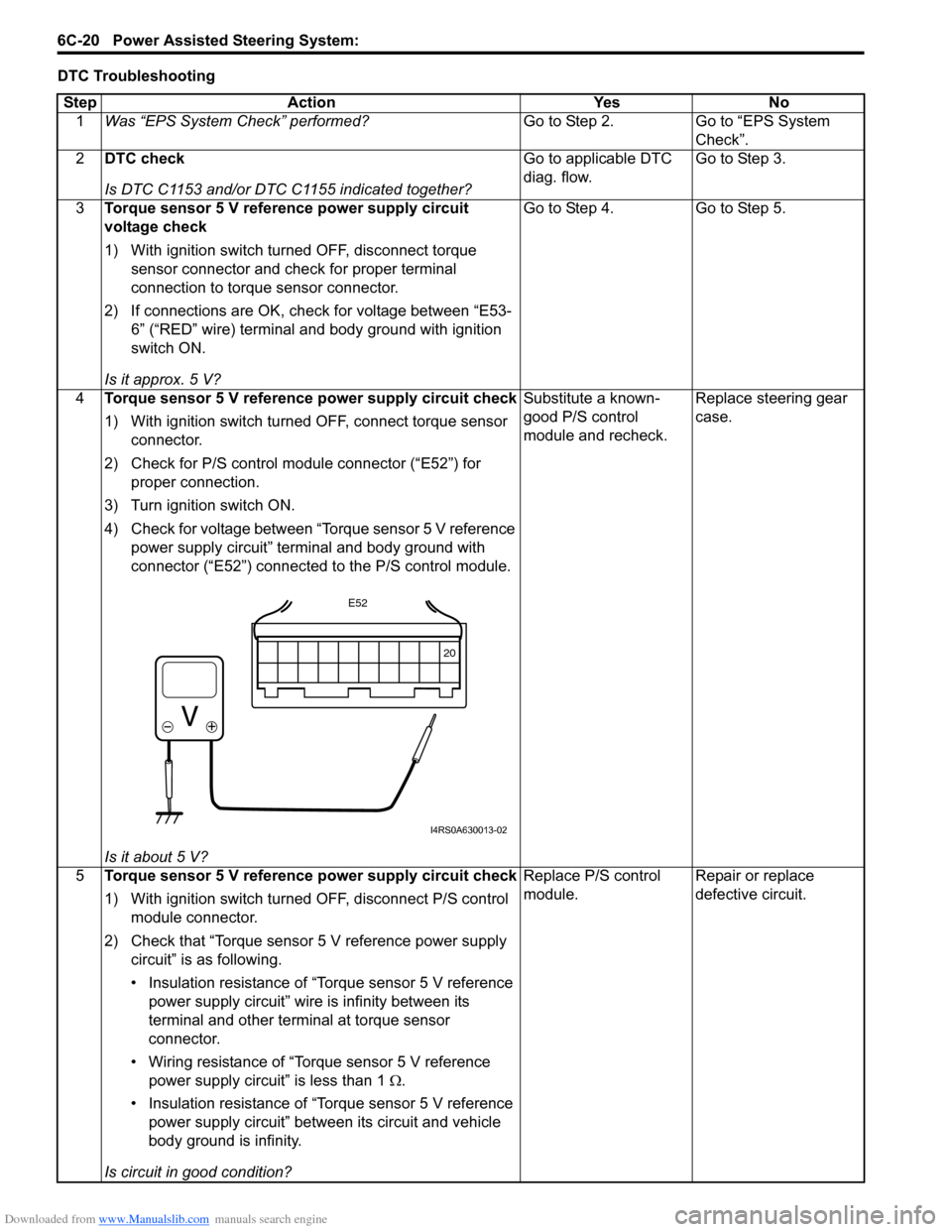

4 Torque sensor 5 V reference power supply circuit check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check for P/S control module connector (“E52”) for proper connection.

3) Turn ignition switch ON.

4) Check for voltage between “Torque sensor 5 V reference power supply circuit” terminal and body ground with

connector (“E52”) connected to the P/S control module.

Is it about 5 V? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

5 Torque sensor 5 V reference power supply circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check that “Torque sensor 5 V reference power supply circuit” is as following.

• Insulation resistance of “Torque sensor 5 V reference power supply circuit” wire is infinity between its

terminal and other terminal at torque sensor

connector.

• Wiring resistance of “Torque sensor 5 V reference power supply circuit” is less than 1 Ω.

• Insulation resistance of “Torque sensor 5 V reference power supply circuit” between its circuit and vehicle

body ground is infinity.

Is circuit in good condition? Replace P/S control

module.

Repair or replace

defective circuit.

20

E52

I4RS0A630013-02

Page 904 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

DTC Troubleshooting

DTC C1118: Steering Torque Sensor Failure Signal Circuit HighS7RS0B6304015

Wiring Diagram

Refer to “DTC C1117: Steering Torque Sensor Failure Signal Circuit Low”.

DTC Detecting Condition and Trouble AreaStep Action Yes No

1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

Is DTC C1113, C1114 and/or DTC C1119 indicated together? Go to applicable diag.

flow.

Go to Step 3.

3 Torque sensor internal failure signal circuit check

1) Check for P/S control module connector (“E52”) for

proper connection.

2) With ignition switch turned OFF, disconnect torque sensor connector.

3) Check for voltage between “E53-1” (“YEL” wire) terminal and body ground with ignition switch ON.

Is it about 5 V? Go to Step 4. Go to Step 5.

4 Torque sensor internal failure signal circuit check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check that voltage between “E52-16” (“YEL” wire) terminal and body ground is about 5V at the moment of

ignition switch turned ON.

Is it about 5 V? Substitute a known-

good P/S control

module and recheck.

Replace steering gear

case.

5 Torque sensor internal failure signal circuit wire check

1) Disconnect P/S control module.

2) Check that torque sensor failure signal circuit is as

follows.

• Insulation resistance of wire harness is infinity between “Torque sensor internal failure signal circuit”

terminal and other terminal at torque sensor

connector.

• Insulation resistance between “Torque sensor internal failure signal circuit” and vehicle body ground is

infinity.

Is circuit in good condition? Substitute a known-

good P/S control

module and recheck.

Repair or replace

defective circuit.

DTC detecting condition

Trouble area

Torque sensor internal failure signal circuit voltage is more

than 3.7 V for 1 second continuously

(1 driving cycle detection logic) • Torque sensor signal circuit

• Torque sensor internal failure signal circuit

• Torque sensor

• P/S control module