Hose SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1134 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-96 Air Bag System:

Repair and Inspection Required after AccidentS7RS0B8204049

CAUTION!

• All air bag system components, including the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from another vehicle.

• Do not attempt to service the parts below. Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator) modules

– Driver / Passenger side-air bag (inflator) modules

– Driver / Passenger side curtain-air bag (inflator) modules

– Driver / Passenger seat belt pretensioners

–Forward-sensor

– Driver / Passenger side-sensors

–SDM

– Contact coil and combination switch assembly

– Air bag wire harness in main harness, instrument panel harness and floor

harness.

• Proper operation of the sensors and air bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward-sensor

• Instrument panel When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faul

ty condition is found in the

following checks, replace faulty part.

Those components are:

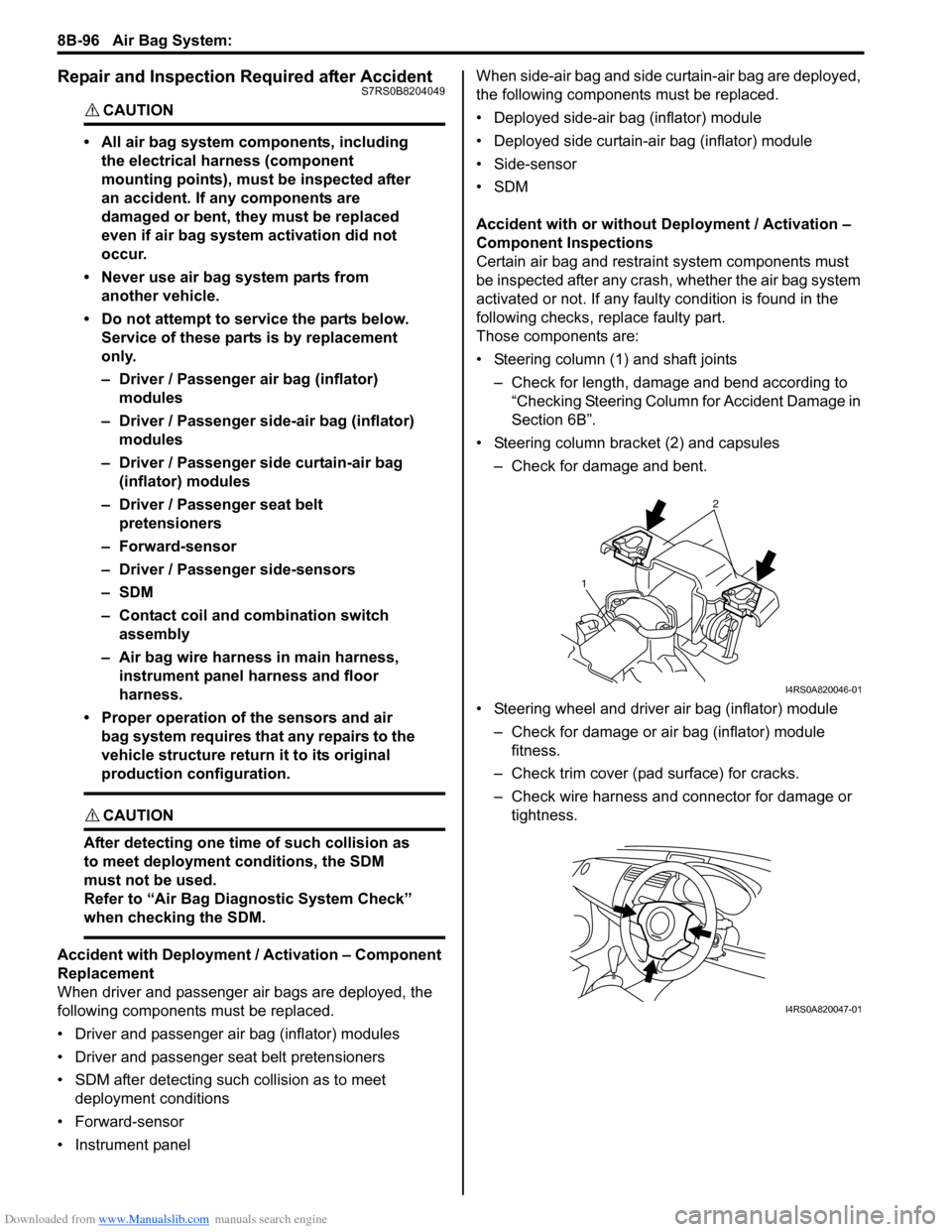

• Steering column (1) and shaft joints

– Check for length, damage and bend according to “Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules – Check for damage and bent.

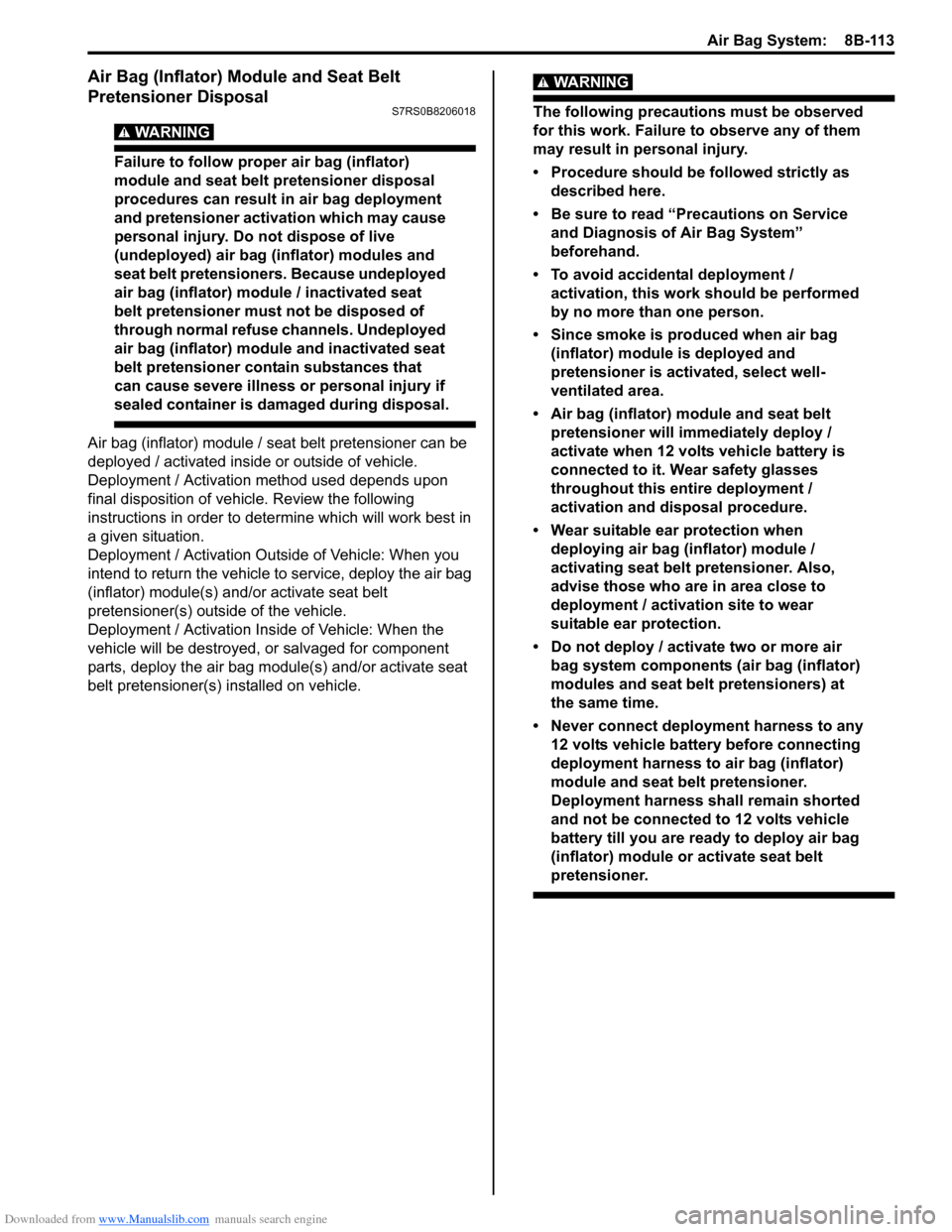

• Steering wheel and driver air bag (inflator) module – Check for damage or air bag (inflator) module fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or tightness.

2

1

I4RS0A820046-01

I4RS0A820047-01

Page 1151 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-113

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal

S7RS0B8206018

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. Do not dispose of live

(undeployed) air bag (inflator) modules and

seat belt pretensioners. Because undeployed

air bag (inflator) module / inactivated seat

belt pretensioner must not be disposed of

through normal refuse channels. Undeployed

air bag (inflator) module and inactivated seat

belt pretensioner contain substances that

can cause severe illness or personal injury if

sealed container is damaged during disposal.

Air bag (inflator) module / seat belt pretensioner can be

deployed / activated inside or outside of vehicle.

Deployment / Activation method used depends upon

final disposition of vehicle. Review the following

instructions in order to deter mine which will work best in

a given situation.

Deployment / Activation Ou tside of Vehicle: When you

intend to return the vehicle to service, deploy the air bag

(inflator) module(s) and/or activate seat belt

pretensioner(s) outside of the vehicle.

Deployment / Activation Insi de of Vehicle: When the

vehicle will be destroyed, or salvaged for component

parts, deploy the air bag module(s) and/or activate seat

belt pretensioner(s) installed on vehicle.

WARNING!

The following precautions must be observed

for this work. Failure to observe any of them

may result in personal injury.

• Procedure should be followed strictly as described here.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”

beforehand.

• To avoid accidental deployment / activation, this work should be performed

by no more than one person.

• Since smoke is produced when air bag (inflator) module is deployed and

pretensioner is activated, select well-

ventilated area.

• Air bag (inflator) module and seat belt pretensioner will immediately deploy /

activate when 12 volts vehicle battery is

connected to it. Wear safety glasses

throughout this entire deployment /

activation and disposal procedure.

• Wear suitable ear protection when deploying air bag (inflator) module /

activating seat belt pretensioner. Also,

advise those who are in area close to

deployment / activation site to wear

suitable ear protection.

• Do not deploy / activate two or more air bag system components (air bag (inflator)

modules and seat belt pretensioners) at

the same time.

• Never connect deployment harness to any 12 volts vehicle battery before connecting

deployment harness to air bag (inflator)

module and seat belt pretensioner.

Deployment harness sh all remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

Page 1156 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-118 Air Bag System:

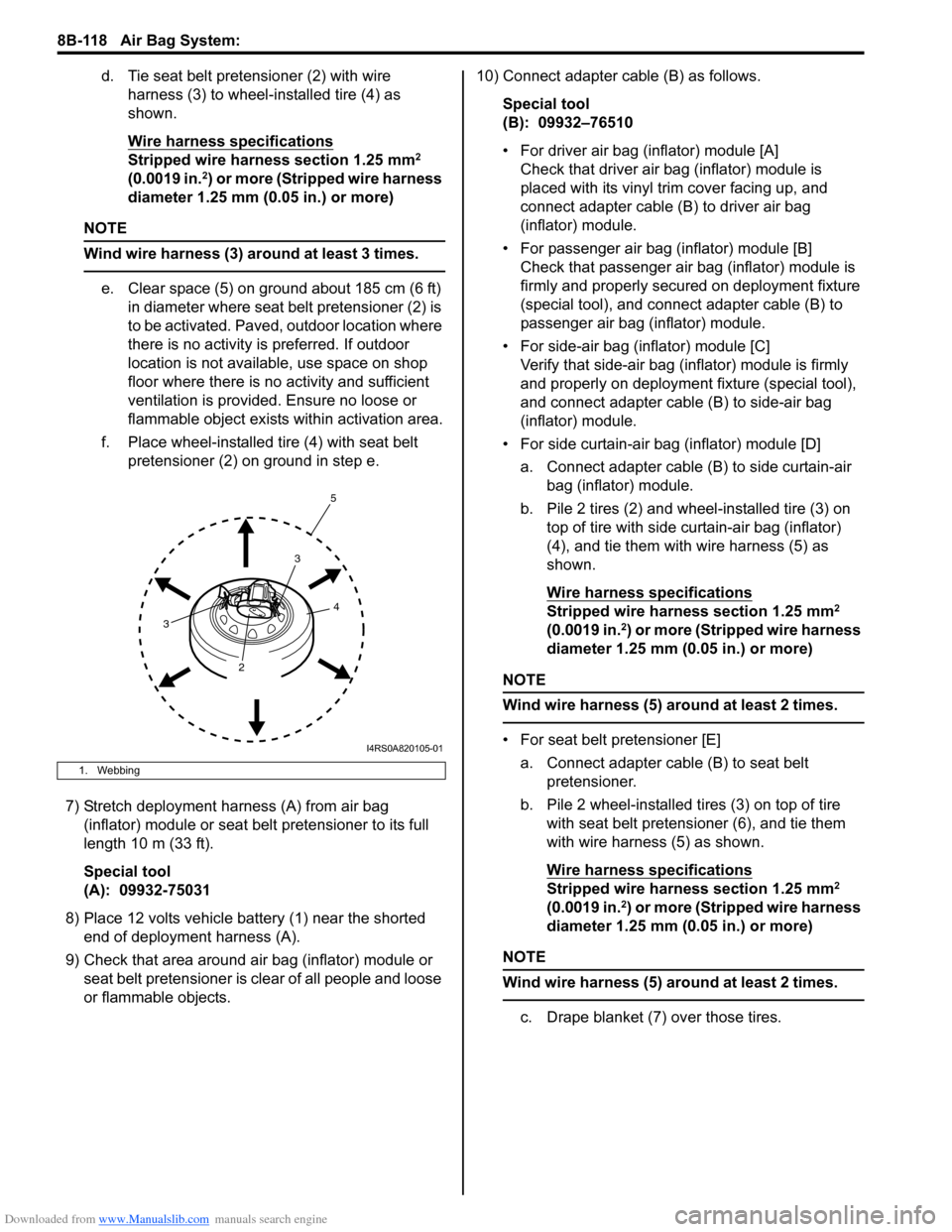

d. Tie seat belt pretensioner (2) with wire harness (3) to wheel-installed tire (4) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (3) around at least 3 times.

e. Clear space (5) on ground about 185 cm (6 ft) in diameter where seat belt pretensioner (2) is

to be activated. Paved, outdoor location where

there is no activity is preferred. If outdoor

location is not available, use space on shop

floor where there is no activity and sufficient

ventilation is provided. Ensure no loose or

flammable object exists within activation area.

f. Place wheel-installed tire (4) with seat belt pretensioner (2) on ground in step e.

7) Stretch deployment harness (A) from air bag (inflator) module or seat belt pretensioner to its full

length 10 m (33 ft).

Special tool

(A): 09932-75031

8) Place 12 volts vehicle battery (1) near the shorted end of deployment harness (A).

9) Check that area around air bag (inflator) module or seat belt pretensioner is clear of all people and loose

or flammable objects. 10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]Check that driver air bag (inflator) module is

placed with its vinyl trim cover facing up, and

connect adapter cable (B) to driver air bag

(inflator) module.

• For passenger air bag (inflator) module [B] Check that passenger air bag (inflator) module is

firmly and properly secured on deployment fixture

(special tool), and connect adapter cable (B) to

passenger air bag (inflator) module.

• For side-air bag (inflator) module [C] Verify that side-air bag (inflator) module is firmly

and properly on deployment fixture (special tool),

and connect adapter cable (B) to side-air bag

(inflator) module.

• For side curtain-air bag (inflator) module [D] a. Connect adapter cable (B) to side curtain-air bag (inflator) module.

b. Pile 2 tires (2) and wheel-installed tire (3) on top of tire with side curtain-air bag (inflator)

(4), and tie them with wire harness (5) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

• For seat belt pretensioner [E]

a. Connect adapter cable (B) to seat belt pretensioner.

b. Pile 2 wheel-installed tires (3) on top of tire with seat belt pretensioner (6), and tie them

with wire harness (5) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

c. Drape blanket (7) over those tires.

1. Webbing

4

3

3 2 5

I4RS0A820105-01

Page 1171 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 9-1

Body, Cab and Accessories

Precautions

Precautions

Precautions on Body, Cab and AccessoriesS7RS0B9000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Precautions for Body Service

Refer to “Precautions for Body Service”.

Fastener Caution for Body Service:

Refer to “Fastener Caution for Body Service”.

Cautions in Body Electrical System Servicing

Refer to “Cautions in Body Electrical System Servicing in Section 9A”.

Precautions for Body ServiceS7RS0B9000002

WARNING!

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

When servicing vehicle body, if shock may be applied to air bag system component parts, remove

those parts beforehand.

Fastener Caution for Body ServiceS7RS0B9000003

CAUTION!

• Fasteners are important attaching parts in that they could affect the performance of vital

components and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number of with an equivalent part if replacement become necessary.

• Do not use a replacement part of lesser quality or substitute a design. Torque values must be used as specified during reassembly to assure proper retention of these parts.

Page 1176 of 1496

Downloaded from www.Manualslib.com manuals search engine 9A-5 Wiring Systems:

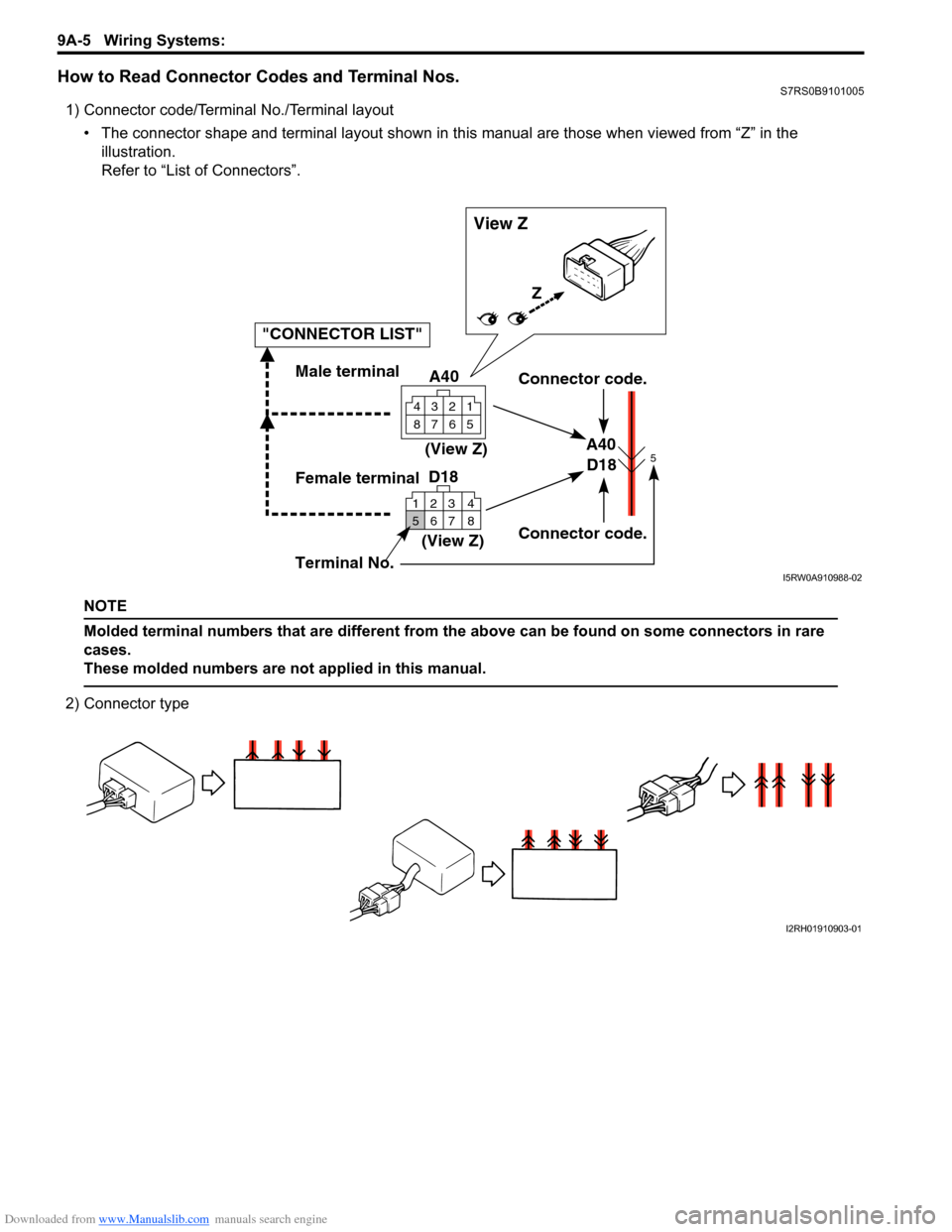

How to Read Connector Codes and Terminal Nos.S7RS0B9101005

1) Connector code/Terminal No./Terminal layout• The connector shape and terminal layout shown in th is manual are those when viewed from “Z” in the

illustration.

Refer to “List of Connectors”.

NOTE

Molded terminal numbers that are different from the above can be found on some connectors in rare

cases.

These molded numbers are not applied in this manual.

2) Connector type

A40

(View Z)

(View Z)

1

123 4

567 8 234

5678

D185

D18A40

Connector code.

Connector code.

Terminal No.

"CONNECTOR LIST"

Male terminal

Female terminal Z

View Z

I5RW0A910988-02

I2RH01910903-01

Page 1318 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-1 Wipers / Washers:

Body, Cab and Accessories

Wipers / Washers

Diagnostic Information and Procedures

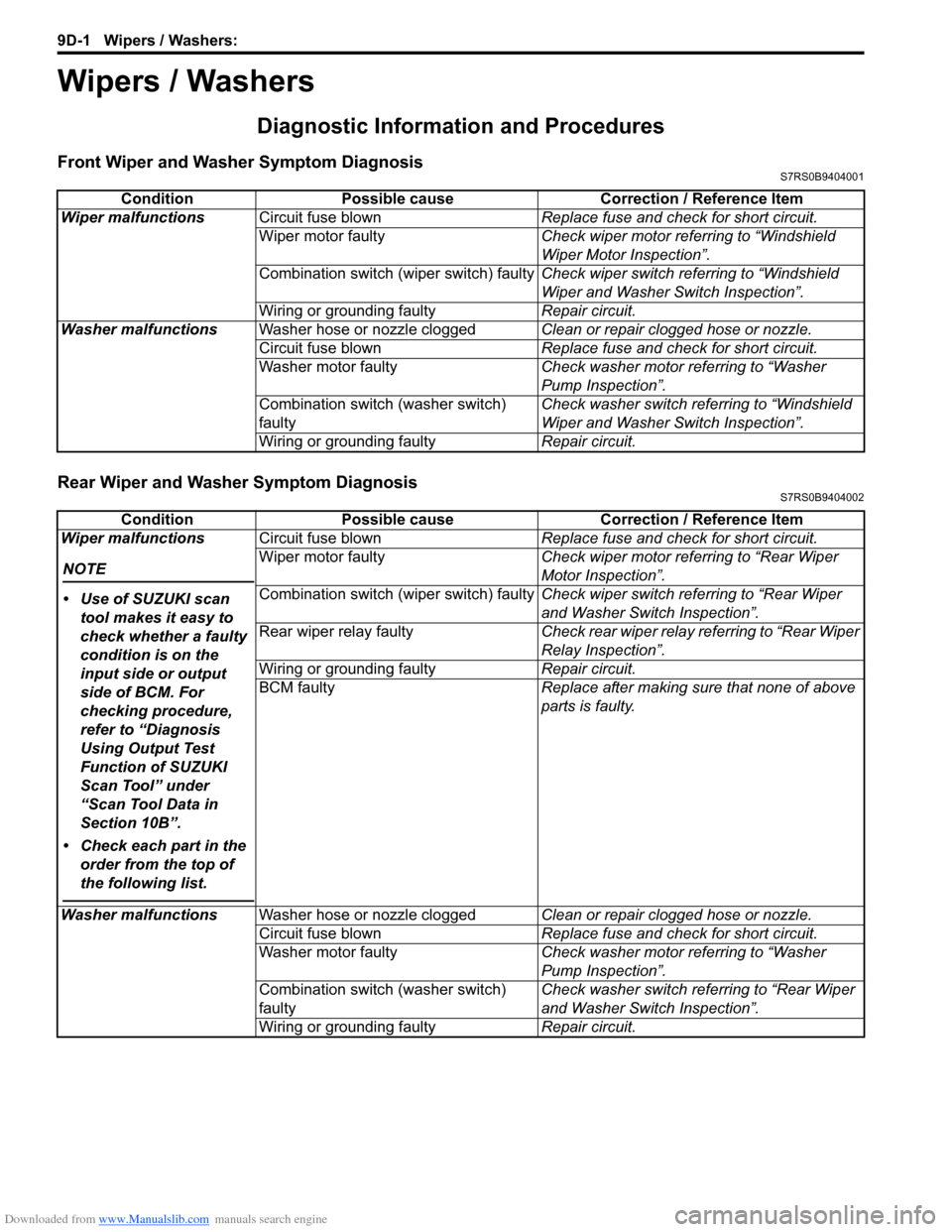

Front Wiper and Washer Symptom DiagnosisS7RS0B9404001

Rear Wiper and Washer Symptom DiagnosisS7RS0B9404002

ConditionPossible cause Correction / Reference Item

Wiper malfunctions Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Windshield

Wiper Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Windshield

Wiper and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

ConditionPossible cause Correction / Reference Item

Wiper malfunctions

NOTE

• Use of SUZUKI scan tool makes it easy to

check whether a faulty

condition is on the

input side or output

side of BCM. For

checking procedure,

refer to “Diagnosis

Using Output Test

Function of SUZUKI

Scan Tool” under

“Scan Tool Data in

Section 10B”.

• Check each part in the order from the top of

the following list.

Circuit fuse blown Replace fuse and check for short circuit.

Wiper motor faulty Check wiper motor referring to “Rear Wiper

Motor Inspection”.

Combination switch (wiper switch) faulty Check wiper switch referring to “Rear Wiper

and Washer Switch Inspection”.

Rear wiper relay faulty Check rear wiper relay referring to “Rear Wiper

Relay Inspection”.

Wiring or grounding faulty Repair circuit.

BCM faulty Replace after making sure that none of above

parts is faulty.

Washer malfunctions Washer hose or nozzle clogged Clean or repair clogged hose or nozzle.

Circuit fuse blown Replace fuse and check for short circuit.

Washer motor faulty Check washer motor referring to “Washer

Pump Inspection”.

Combination switch (washer switch)

faulty Check washer switch referring to “Rear Wiper

and Washer Switch Inspection”.

Wiring or grounding faulty Repair circuit.

Page 1320 of 1496

Downloaded from www.Manualslib.com manuals search engine 9D-3 Wipers / Washers:

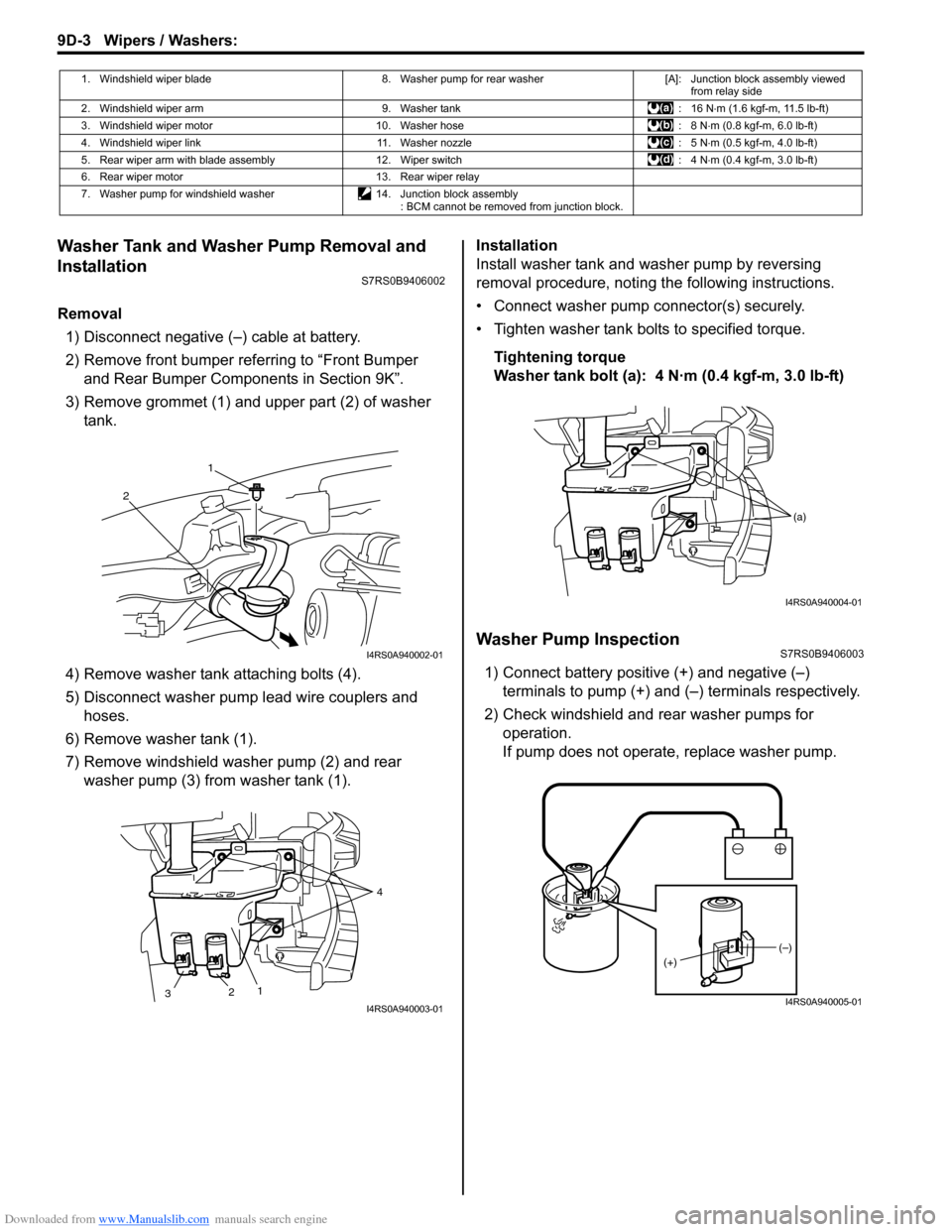

Washer Tank and Washer Pump Removal and

Installation

S7RS0B9406002

Removal1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Remove grommet (1) and upper part (2) of washer tank.

4) Remove washer tank attaching bolts (4).

5) Disconnect washer pump lead wire couplers and hoses.

6) Remove washer tank (1).

7) Remove windshield washer pump (2) and rear washer pump (3) from washer tank (1). Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) securely.

• Tighten washer tank bolts to specified torque.

Tightening torque

Washer tank bolt (a): 4 N·m (0.4 kgf-m, 3.0 lb-ft)

Washer Pump InspectionS7RS0B9406003

1) Connect battery positive (+) and negative (–) terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

1. Windshield wiper blade 8. Washer pump for rear washer[A]: Junction block assembly viewed

from relay side

2. Windshield wiper arm 9. Washer tank: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Windshield wiper motor 10. Washer hose : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

4. Windshield wiper link 11. Washer nozzle : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

5. Rear wiper arm with blade assembly 12. Wiper switch : 4 N⋅m (0.4 kgf-m, 3.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay

7. Washer pump for windshield washer 14. Junction block assembly

: BCM cannot be removed from junction block.

1

2

I4RS0A940002-01

2 1 4

3

I4RS0A940003-01

(a)

I4RS0A940004-01

(–)

(+)

I4RS0A940005-01

Page 1334 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-7 Glass / Windows / Mirrors:

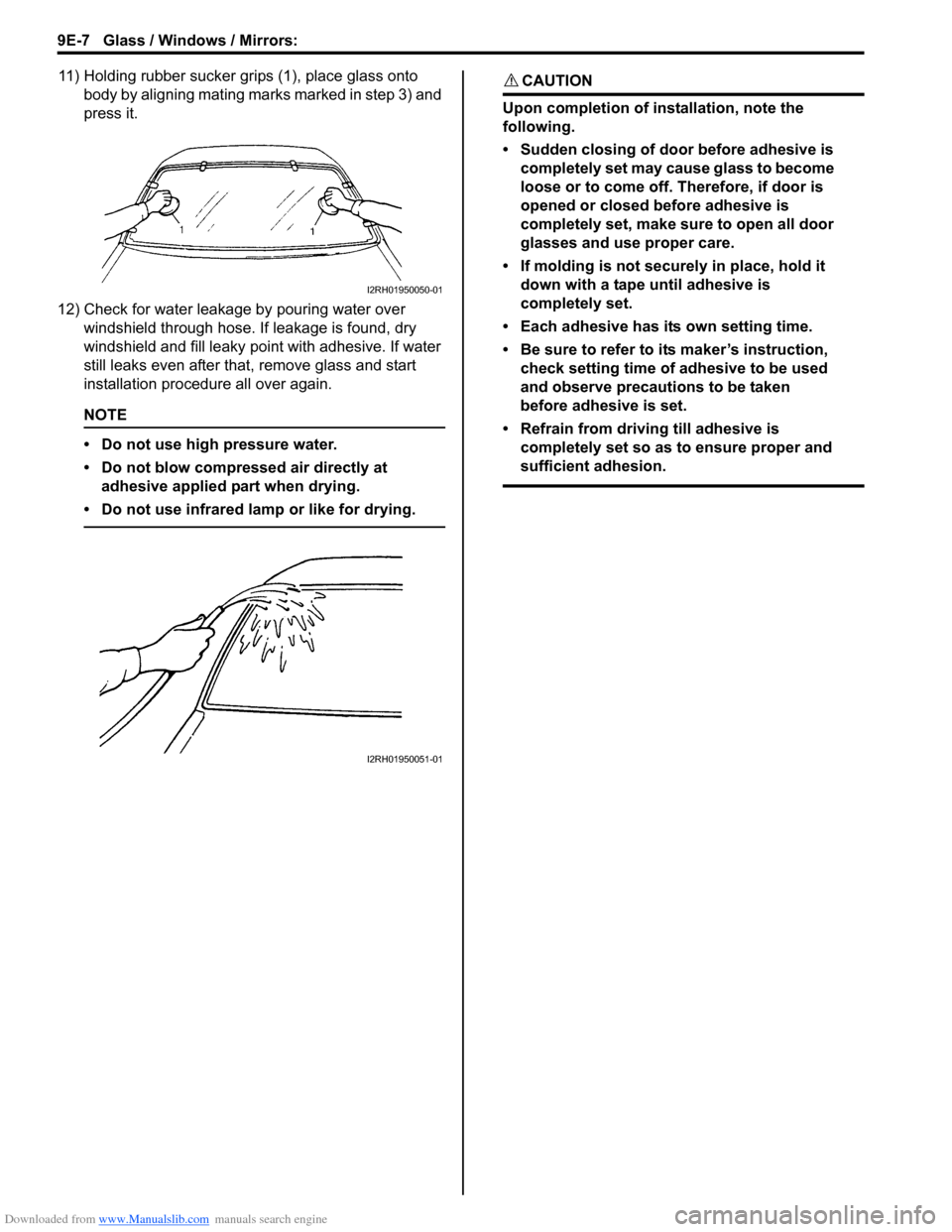

11) Holding rubber sucker grips (1), place glass onto body by aligning mating marks marked in step 3) and

press it.

12) Check for water leakage by pouring water over windshield through hose. If leakage is found, dry

windshield and fill leaky po int with adhesive. If water

still leaks even after that , remove glass and start

installation procedure all over again.

NOTE

• Do not use high pressure water.

• Do not blow compressed air directly at adhesive applied part when drying.

• Do not use infrared lamp or like for drying.

CAUTION!

Upon completion of installation, note the

following.

• Sudden closing of door before adhesive is completely set may cause glass to become

loose or to come off. Therefore, if door is

opened or closed before adhesive is

completely set, make sure to open all door

glasses and use proper care.

• If molding is not securely in place, hold it down with a tape until adhesive is

completely set.

• Each adhesive has its own setting time.

• Be sure to refer to its maker’s instruction, check setting time of adhesive to be used

and observe precautions to be taken

before adhesive is set.

• Refrain from driving till adhesive is completely set so as to ensure proper and

sufficient adhesion.

I2RH01950050-01

I2RH01950051-01

Page 1370 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-1 Hood / Fenders / Doors:

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

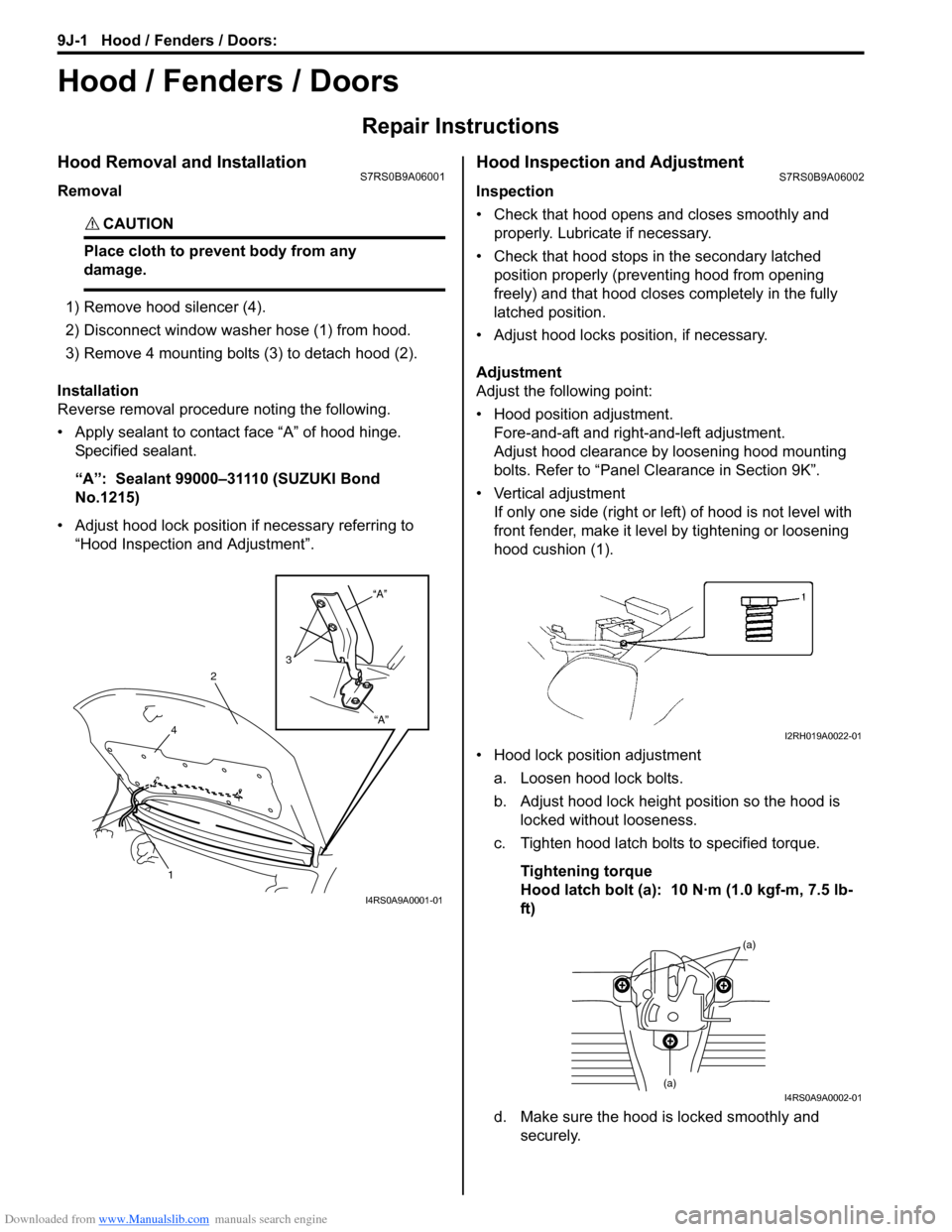

Hood Removal and InstallationS7RS0B9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge. Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to “Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS7RS0B9A06002

Inspection

• Check that hood opens and closes smoothly and properly. Lubricate if necessary.

• Check that hood stops in the secondary latched position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.

Adjustment

Adjust the following point:

• Hood position adjustment. Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and securely.

“A”

“A”

3

2

4

1

I4RS0A9A0001-01

I2RH019A0022-01

(a)

(a)I4RS0A9A0002-01

Page 1375 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-6

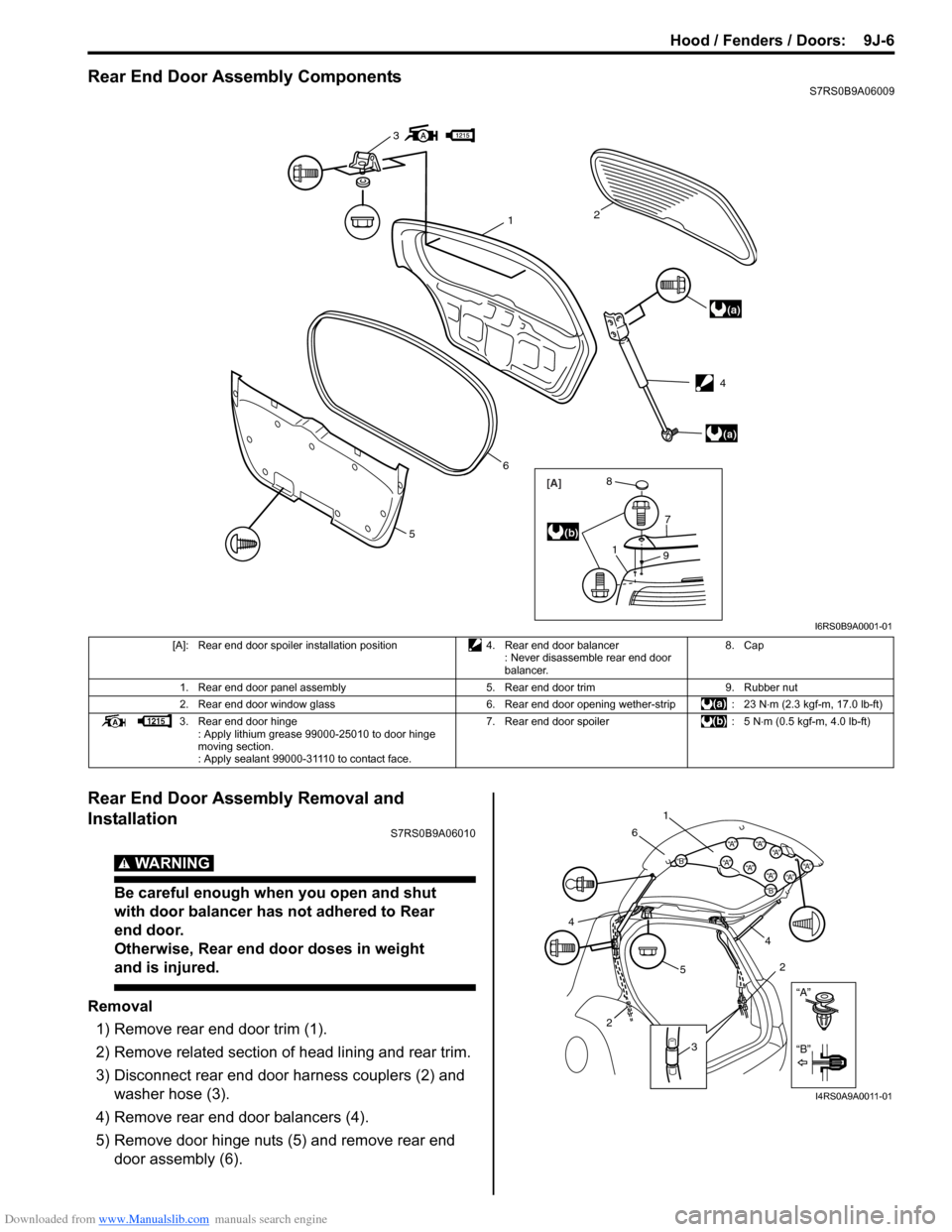

Rear End Door Assembly ComponentsS7RS0B9A06009

Rear End Door Assembly Removal and

Installation

S7RS0B9A06010

WARNING!

Be careful enough when you open and shut

with door balancer has not adhered to Rear

end door.

Otherwise, Rear end door doses in weight

and is injured.

Removal1) Remove rear end door trim (1).

2) Remove related section of head lining and rear trim.

3) Disconnect rear end door harness couplers (2) and washer hose (3).

4) Remove rear end door balancers (4).

5) Remove door hinge nuts (5) and remove rear end door assembly (6).

3

(a)

(a)

12

6

5

[A]

1

7

9

8

(b)

4

I6RS0B9A0001-01

[A]: Rear end door spoiler installation position 4. Rear end door balancer

: Never disassemble rear end door

balancer. 8. Cap

1. Rear end door panel assembly 5. Rear end door trim9. Rubber nut

2. Rear end door window glass 6. Rear end door opening wether-strip: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Rear end door hinge : Apply lithium grease 99000-25010 to door hinge

moving section.

: Apply sealant 99000-31110 to contact face. 7. Rear end door spoiler

: 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

“A”

“B”

“B”

“A”“B”“A”“A”“A”

“A”“A”“A”

“A”

1

6

5 4

2

3

2

4

I4RS0A9A0011-01