5b-1 SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 830 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-16 Manual Transmission/Transaxle:

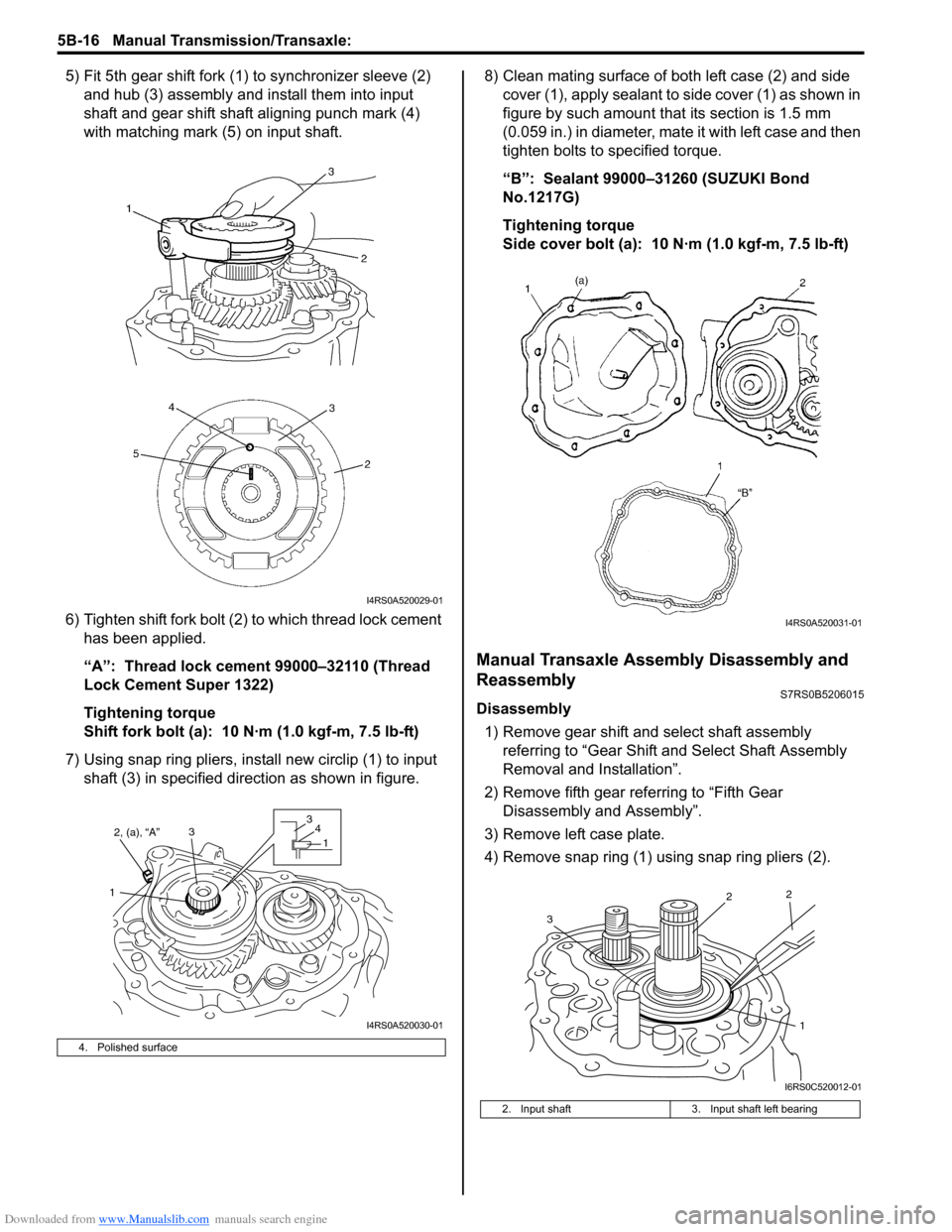

5) Fit 5th gear shift fork (1) to synchronizer sleeve (2) and hub (3) assembly and install them into input

shaft and gear shift shaft aligning punch mark (4)

with matching mark (5) on input shaft.

6) Tighten shift fork bolt (2) to which thread lock cement

has been applied.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Shift fork bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

7) Using snap ring pliers, inst all new circlip (1) to input

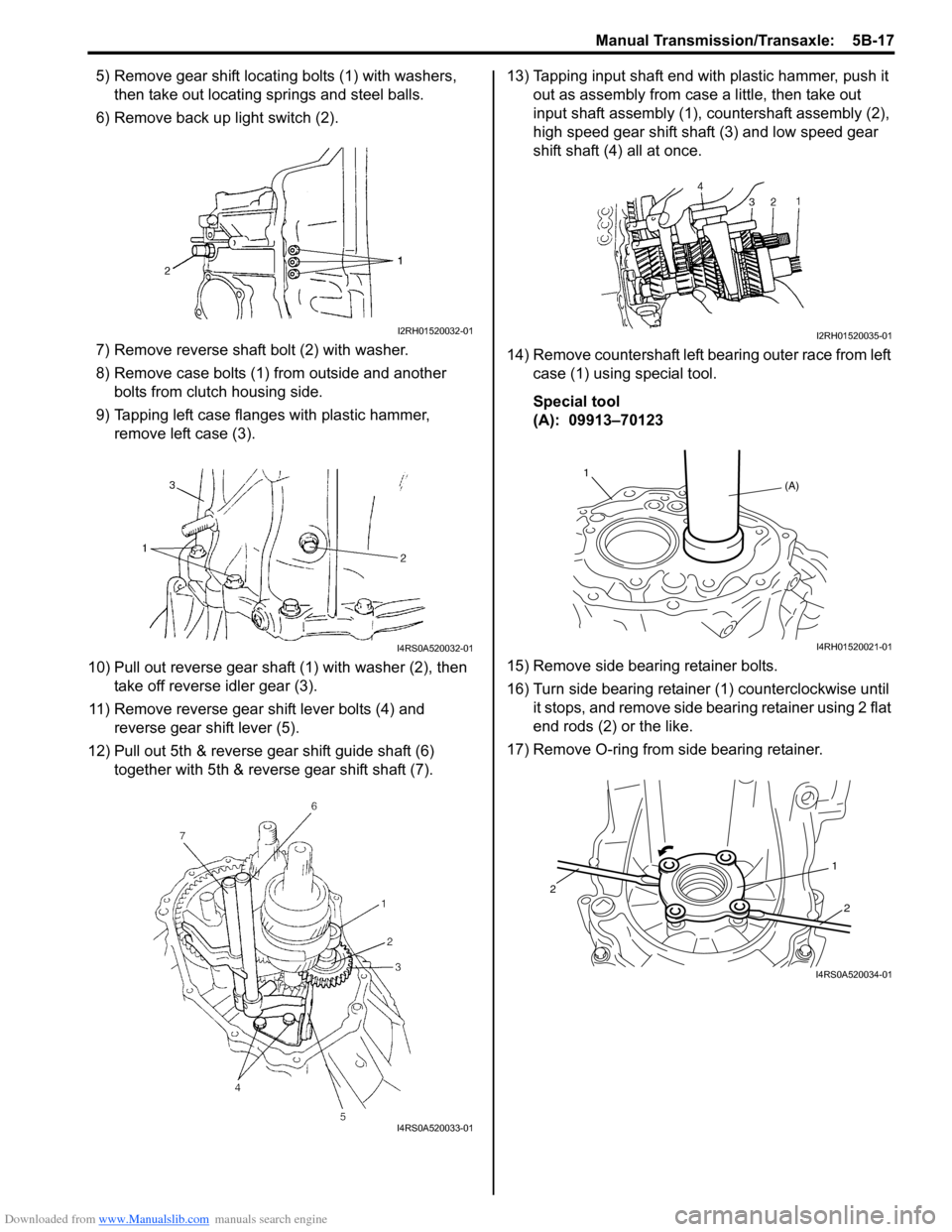

shaft (3) in specified direction as shown in figure. 8) Clean mating surface of both left case (2) and side

cover (1), apply sealant to side cover (1) as shown in

figure by such amount t hat its section is 1.5 mm

(0.059 in.) in diameter, mate it with left case and then

tighten bolts to specified torque.

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Side cover bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

Manual Transaxle Assembly Disassembly and

Reassembly

S7RS0B5206015

Disassembly

1) Remove gear shift and select shaft assembly referring to “Gear Shift an d Select Shaft Assembly

Removal and Installation”.

2) Remove fifth gear referring to “Fifth Gear Disassembly and Assembly”.

3) Remove left case plate.

4) Remove snap ring (1) using snap ring pliers (2).

4. Polished surface

I4RS0A520029-01

2, (a), “A”

1 33

4

1

I4RS0A520030-01

2. Input shaft 3. Input shaft left bearing

I4RS0A520031-01

1

2

2

3

I6RS0C520012-01

Page 831 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-17

5) Remove gear shift locating bolts (1) with washers,

then take out locating springs and steel balls.

6) Remove back up light switch (2).

7) Remove reverse shaft bolt (2) with washer.

8) Remove case bolts (1) from outside and another bolts from clutch housing side.

9) Tapping left case flanges with plastic hammer, remove left case (3).

10) Pull out reverse gear shaft (1) with washer (2), then take off reverse idler gear (3).

11) Remove reverse gear shift lever bolts (4) and reverse gear shift lever (5).

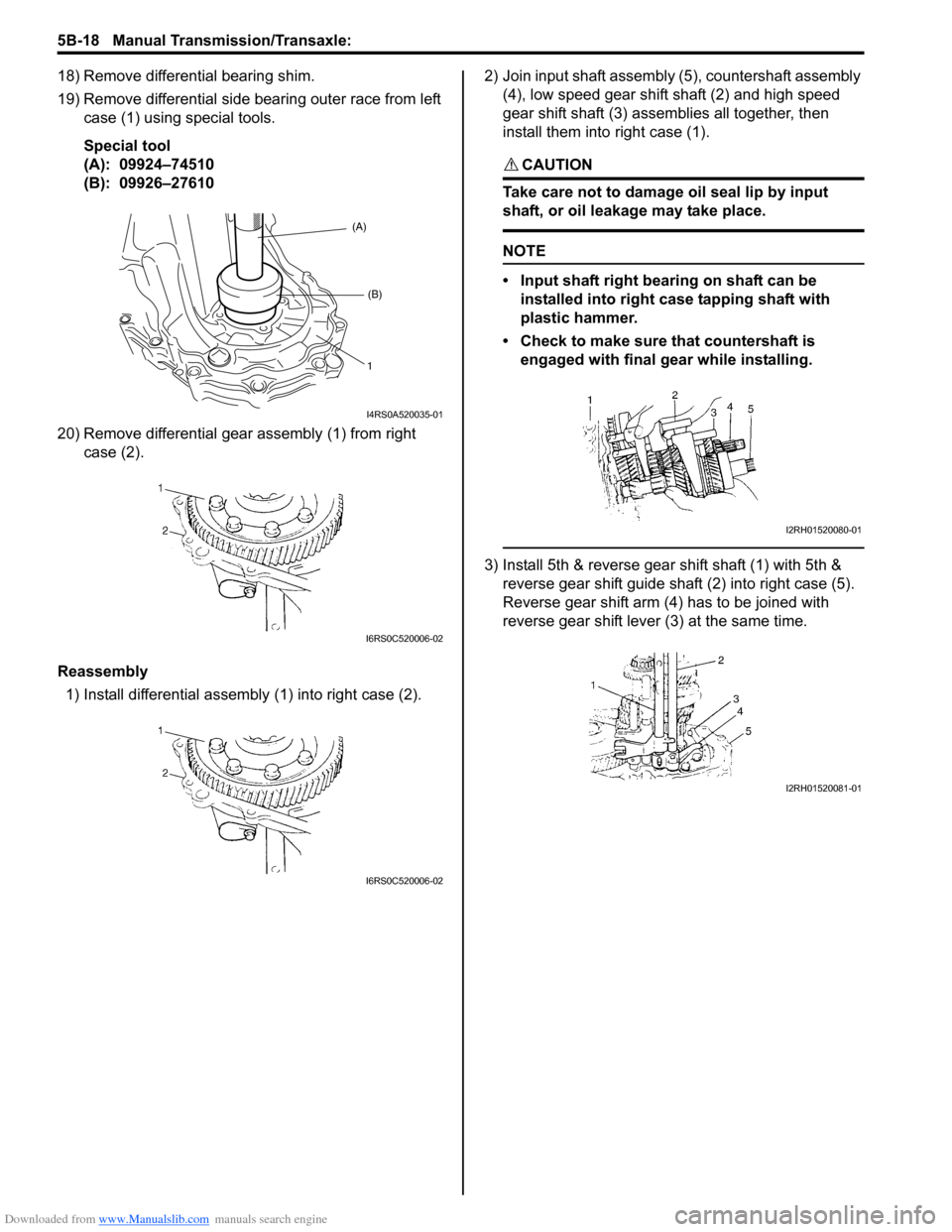

12) Pull out 5th & reverse gear shift guide shaft (6) together with 5th & reverse gear shift shaft (7). 13) Tapping input shaft end with plastic hammer, push it

out as assembly from case a little, then take out

input shaft assembly (1), countershaft assembly (2),

high speed gear shift shaft (3) and low speed gear

shift shaft (4) all at once.

14) Remove countershaft left bearing outer race from left case (1) using special tool.

Special tool

(A): 09913–70123

15) Remove side bearing retainer bolts.

16) Turn side bearing retainer (1) counterclockwise until it stops, and remove side bearing retainer using 2 flat

end rods (2) or the like.

17) Remove O-ring from side bearing retainer.

I2RH01520032-01

I4RS0A520032-01

I4RS0A520033-01

I2RH01520035-01

(A)

1

I4RH01520021-01

1

2

2

I4RS0A520034-01

Page 832 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-18 Manual Transmission/Transaxle:

18) Remove differential bearing shim.

19) Remove differential side bearing outer race from left case (1) using special tools.

Special tool

(A): 09924–74510

(B): 09926–27610

20) Remove differential gear assembly (1) from right case (2).

Reassembly 1) Install differential assembly (1) into right case (2). 2) Join input shaft assembly (5), countershaft assembly

(4), low speed gear shift shaft (2) and high speed

gear shift shaft (3) assemblies all together, then

install them into right case (1).

CAUTION!

Take care not to damage oil seal lip by input

shaft, or oil leakage may take place.

NOTE

• Input shaft right bearing on shaft can be

installed into right case tapping shaft with

plastic hammer.

• Check to make sure that countershaft is engaged with final g ear while installing.

3) Install 5th & reverse gear shift shaft (1) with 5th &

reverse gear shift guide shaft (2) into right case (5).

Reverse gear shift arm (4) has to be joined with

reverse gear shift lever (3) at the same time.

(A)

(B)

1

I4RS0A520035-01

I6RS0C520006-02

I6RS0C520006-02

I2RH01520080-01

I2RH01520081-01

Page 833 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-19

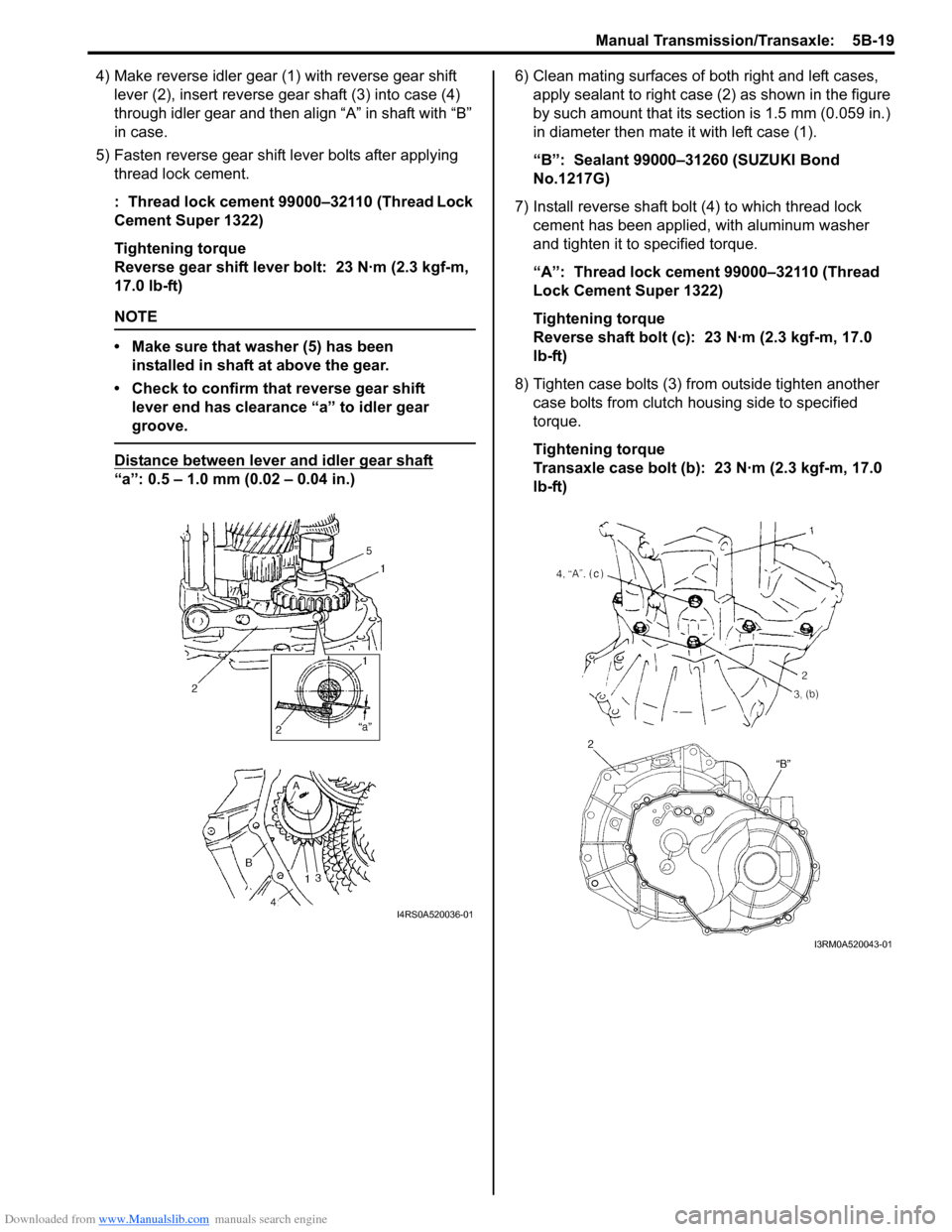

4) Make reverse idler gear (1) with reverse gear shift lever (2), insert reverse gear shaft (3) into case (4)

through idler gear and then align “A” in shaft with “B”

in case.

5) Fasten reverse gear shift lever bolts after applying thread lock cement.

: Thread lock cement 99000–32110 (Thread Lock

Cement Super 1322)

Tightening torque

Reverse gear shift lever bolt: 23 N·m (2.3 kgf-m,

17.0 lb-ft)

NOTE

• Make sure that washer (5) has been installed in shaft at above the gear.

• Check to confirm that reverse gear shift lever end has clearance “a” to idler gear

groove.

Distance between lever and idler gear shaft

“a”: 0.5 – 1.0 mm (0.02 – 0.04 in.) 6) Clean mating surfaces of both right and left cases,

apply sealant to right case (2) as shown in the figure

by such amount that its section is 1.5 mm (0.059 in.)

in diameter then mate it with left case (1).

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

7) Install reverse shaft bolt (4) to which thread lock cement has been applied, with aluminum washer

and tighten it to specified torque.

“A”: Thread lock cement 99000–32110 (Thread

Lock Cement Super 1322)

Tightening torque

Reverse shaft bolt (c): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

8) Tighten case bolts (3) from outside tighten another case bolts from clutch housing side to specified

torque.

Tightening torque

Transaxle case bolt (b): 23 N·m (2.3 kgf-m, 17.0

lb-ft)

I4RS0A520036-01

I3RM0A520043-01