AIR CON SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 15 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-10

Air Bag WarningS7RS0B0000009

WARNING!

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer. Refer

to “Air Bag System Components, Wiring

and Connectors Location in Section 8B” in

order to confirm whether you are

performing service on or near the air bag

system components or wiring. Please

observe all WARNINGS in Air Bag System

section and “Precautions on Service and

Diagnosis of Air Bag System in Section

8B” before performing service on or

around the air bag system components or

wiring. Failure to follow WARNINGS could

result in unintentional activation of the

system or could render the system

inoperative. Either of these two conditions

may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is

turned to the LOCK position and the

negative cable is disconnected from the

battery. Otherwise, the system may be

activated by reserve energy in the Sensing

and Diagnostic Module (SDM).

Air Bag System Service WarningS7RS0B0000010

WARNING!

• Service on or around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer.

Please observe all WARNINGS in Air Bag

System section and “Precautions on

Service and Diagnosis of Air Bag System

in Section 8B” before performing service

on or around the air bag system

components or wiring. Failure to follow

WARNINGS could result in unintended

activation of the system or could render

the system inoperative. Either of these two

conditions may result in severe injury.

• The procedures in the air bag system section must be followed in the order

listed to disable the air bag system

temporarily and prevent false DTCs from

setting. Failure to follow procedures could

result in possible activation of the air bag

system, personal injury or otherwise

unneeded air bag system repairs.

Fastener CautionS7RS0B0000011

CAUTION!

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number

fastener for that application. If the correct

part number fastener is not available, a

fastener of equal size and strength (or

stronger) may be used. Fasteners that are not

reused, and those requiring thread-locking

compound, will be called out. The correct

torque value must be used when installing

fasteners that require it. If the conditions are

not followed, parts or system damage could

result.

Suspension CautionS7RS0B0000012

CAUTION!

• All suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems,

and/or could result in major repair

expense. They must be replaced with one

of the same part number or with an

equivalent part if replacement becomes

necessary. Do not use a replacement part

of lesser quality or substitute design.

Torque values must be used as specified

during reassembly to assure proper

retention of this part.

• Never attempt to heat, quench or straighten any suspension part. Replace it

with a new part or damage to the part may

result.

Wheels and Tires CautionS7RS0B0000013

CAUTION!

All wheel fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of the same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts.

There is to be no welding as it may result in

extensive damage and weakening of the

metal.

Page 16 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-11 Precautions:

Precaution for Vehicle Equipped with ESP®

System

S7RS0B0000015

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP ®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP ® control module

• When ESP ® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP ® control

module.

• When any of the following operation is done, calibrate steering angle sensor referring to “Sensor Calibration

in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

Brake CautionS7RS0B0000014

CAUTION!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

Repair Instructions

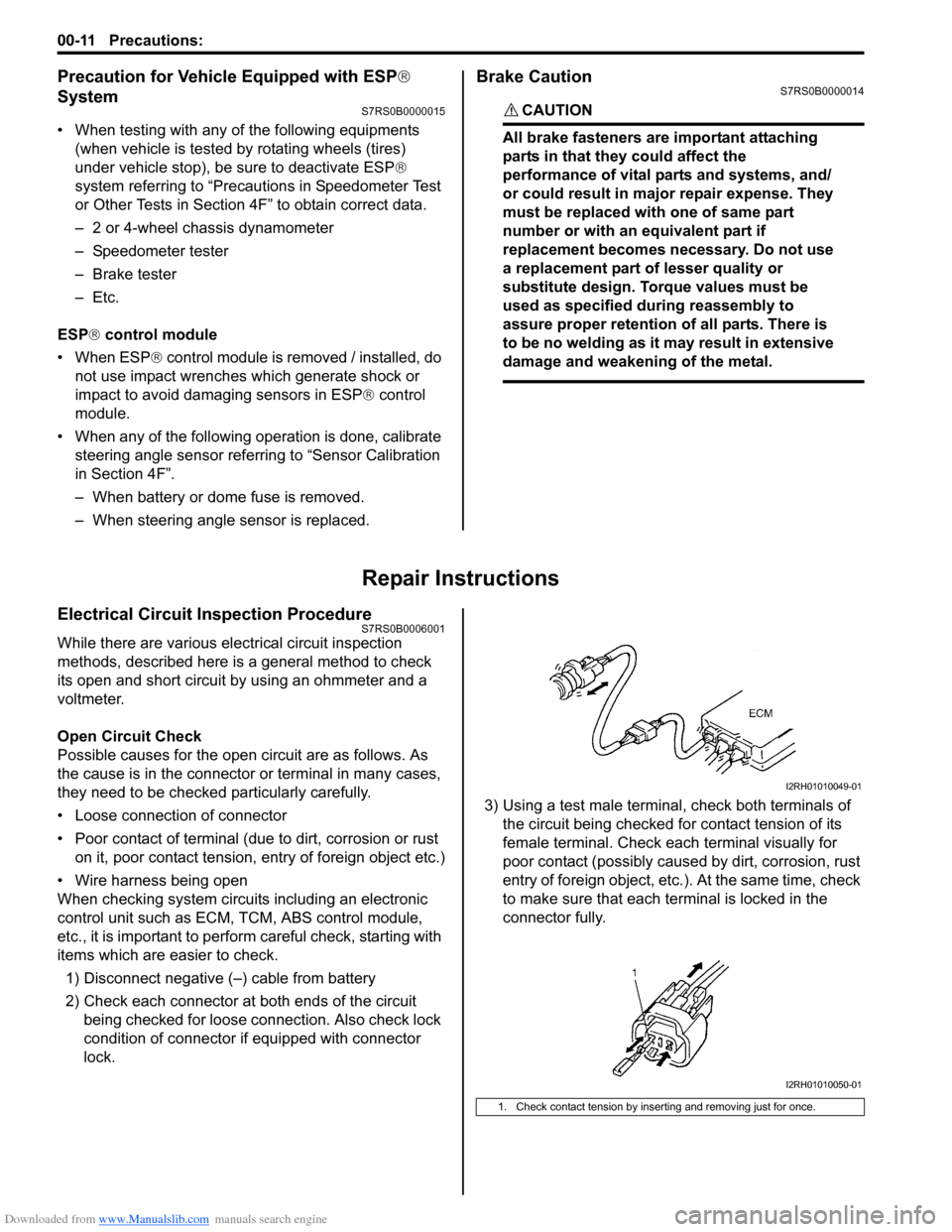

Electrical Circuit Inspection ProcedureS7RS0B0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perfor m careful check, starting with

items which are easier to check.

1) Disconnect negative (–) cable from battery

2) Check each connector at both ends of the circuit being checked for loose connection. Also check lock

condition of connector if equipped with connector

lock. 3) Using a test male terminal

, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each te rminal is locked in the

connector fully.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

Page 19 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-14

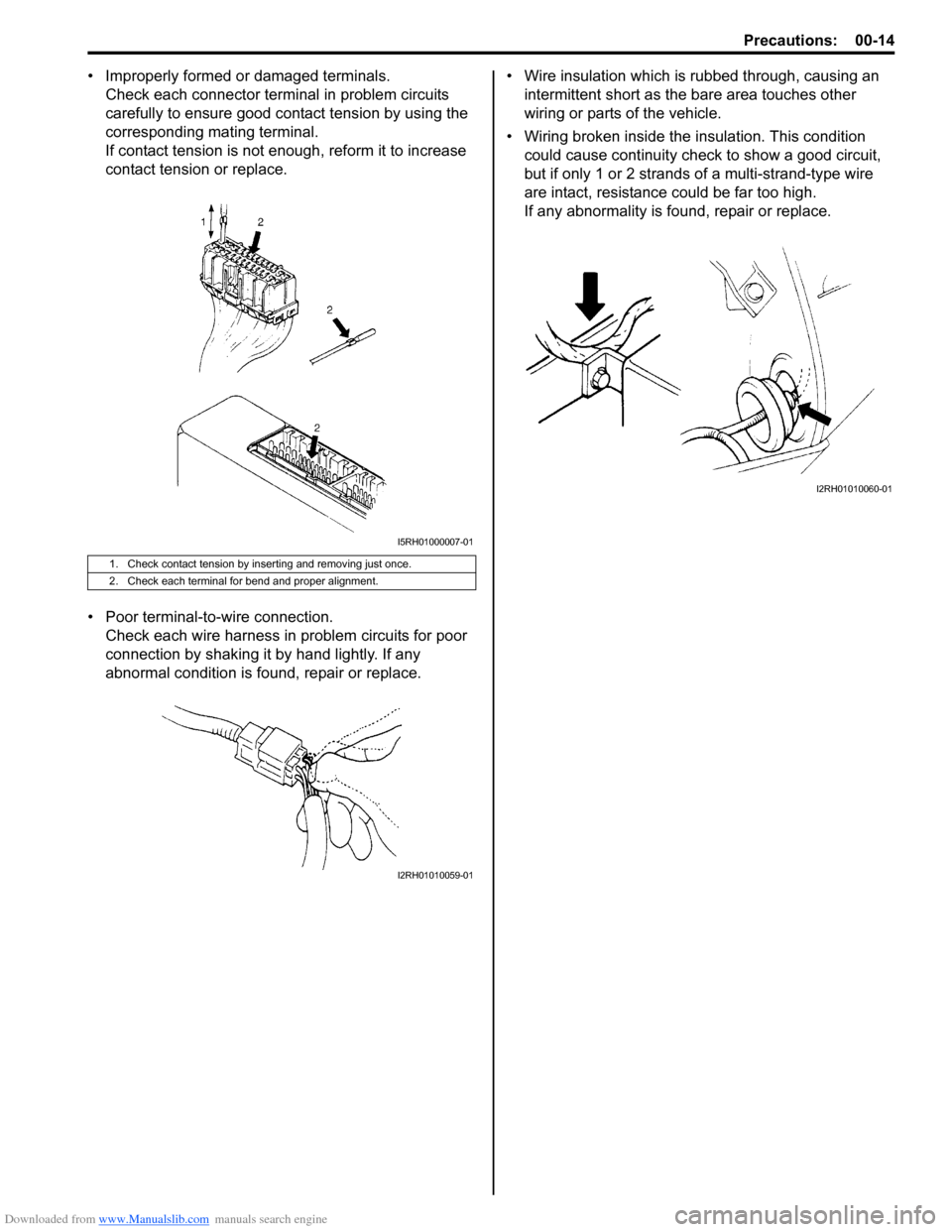

• Improperly formed or damaged terminals.Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal.

If contact tension is not enough, reform it to increase

contact tension or replace.

• Poor terminal-to -wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace. • Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wiring broken inside the insulation. This condition

could cause continuity check to show a good circuit,

but if only 1 or 2 strands of a multi-strand-type wire

are intact, resistance could be far too high.

If any abnormality is found, repair or replace.

1. Check contact tension by inserting and removing just once.

2. Check each terminal for bend and proper alignment.

I5RH01000007-01

I2RH01010059-01

I2RH01010060-01

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

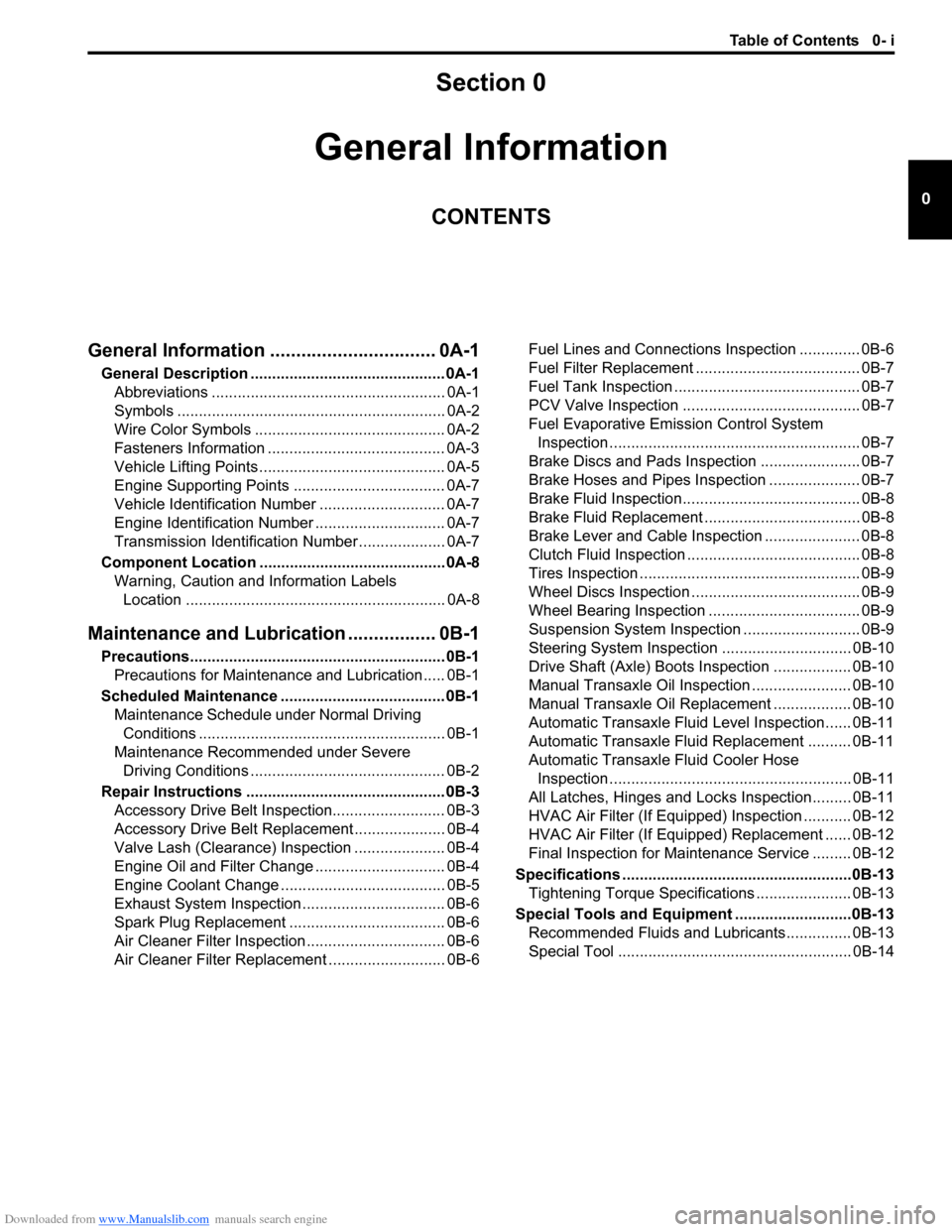

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

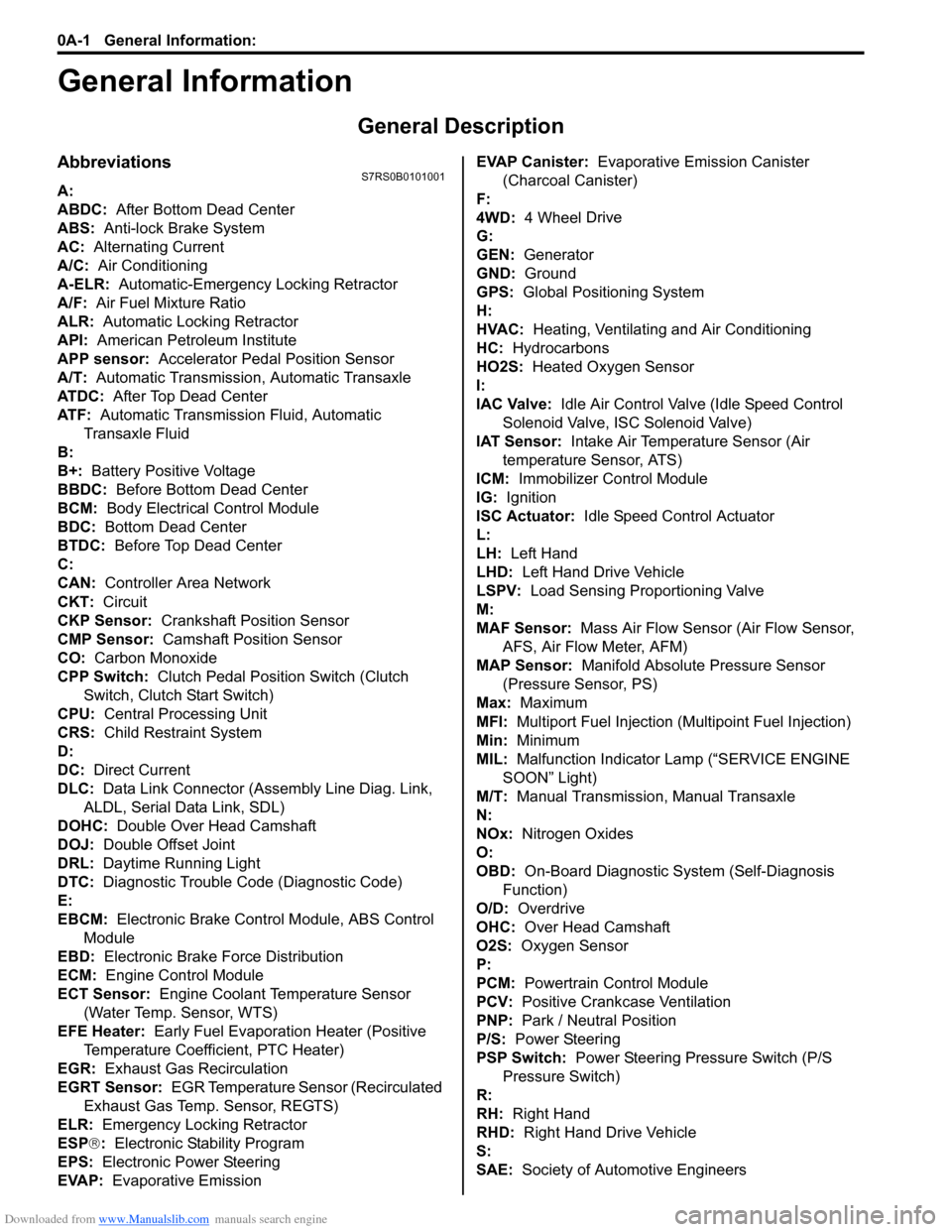

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 23 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

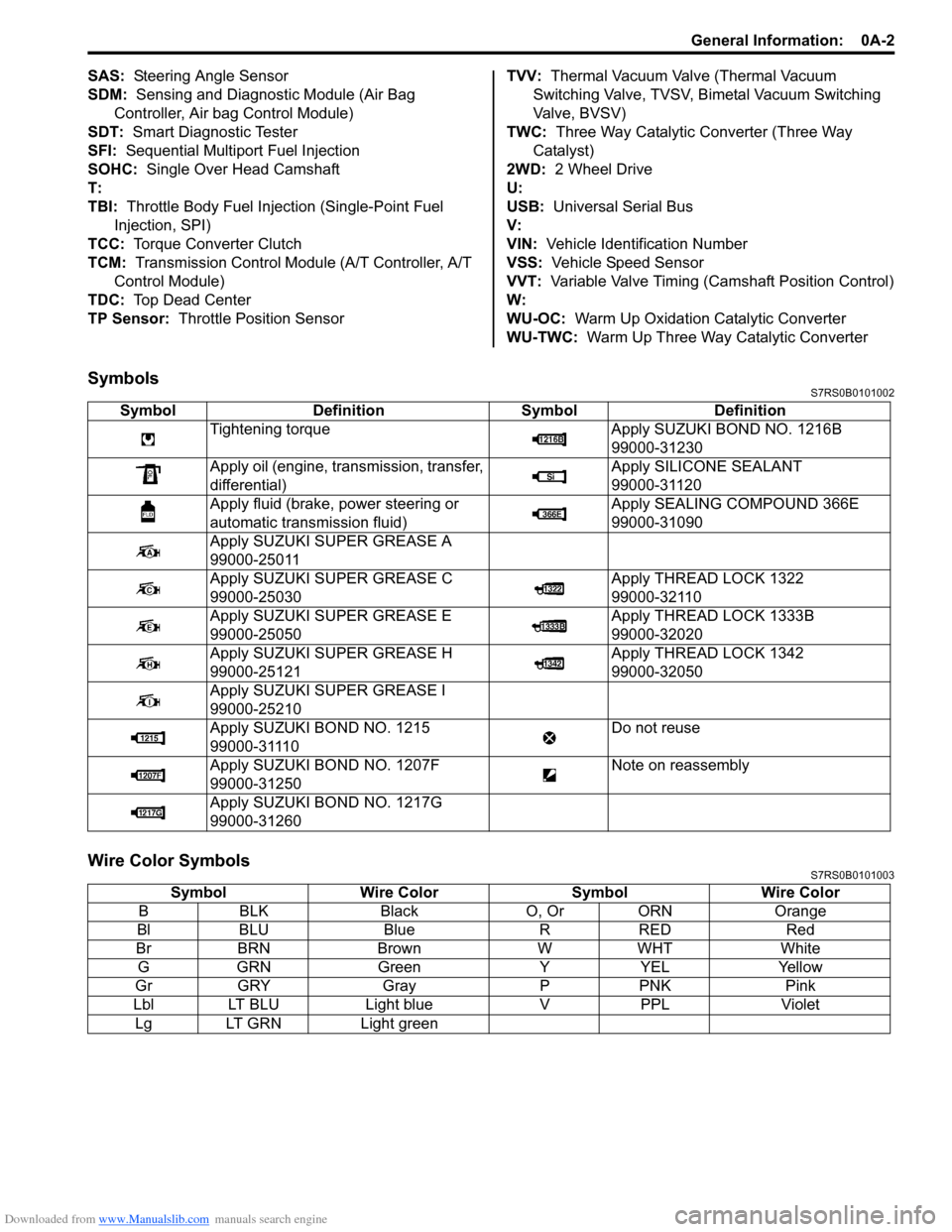

SAS: Steering Angle Sensor

SDM: Sensing and Diagnostic Module (Air Bag Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multipor t Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position Sensor TVV:

Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bi metal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

SymbolsS7RS0B0101002

Wire Color SymbolsS7RS0B0101003

Symbol Definition SymbolDefinition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential) Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid) Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030 Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050 Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25121 Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110 Do not reuse

Apply SUZUKI BO ND NO. 1207F

99000-31250 Note on reassembly

Apply SUZUKI BO ND NO. 1217G

99000-31260

Symbol Wire Color SymbolWire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue RRED Red

Br BRN Brown WWHT White

G GRN Green YYEL Yellow

Gr GRY Gray PPNK Pink

Lbl LT BLU Light blueVPPL Violet

Lg LT GRN Light green

Page 30 of 1496

![SUZUKI SWIFT 2008 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 0A-9 General Information:

[A]

12

4 5

6

7 8

9

3

I4RS0B010002-03

1. Air bag label on driver air bag (inflator) module 6. Air bag label on SDM

2 SUZUKI SWIFT 2008 2.G Service User Guide Downloaded from www.Manualslib.com manuals search engine 0A-9 General Information:

[A]

12

4 5

6

7 8

9

3

I4RS0B010002-03

1. Air bag label on driver air bag (inflator) module 6. Air bag label on SDM

2](/img/20/7607/w960_7607-29.png)

Downloaded from www.Manualslib.com manuals search engine 0A-9 General Information:

[A]

12

4 5

6

7 8

9

3

I4RS0B010002-03

1. Air bag label on driver air bag (inflator) module 6. Air bag label on SDM

2. Air bag label on combination switch and contact coil assembly7. Pretensioner label on seat belt retractor

3. Air bag label on passenger air bag (inflator) module 8. Child seat label (if equipped)

4. Air bag label on side air bag (inflator) module (if equipped) 9. Side/Curtain air bag label on pillar (both right and left sides) (if equipped)

5. Air bag label on curtain air bag (inflator) module (if equipped) [A]: These labels are attached on vehicle equipped with air ba g system only.

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

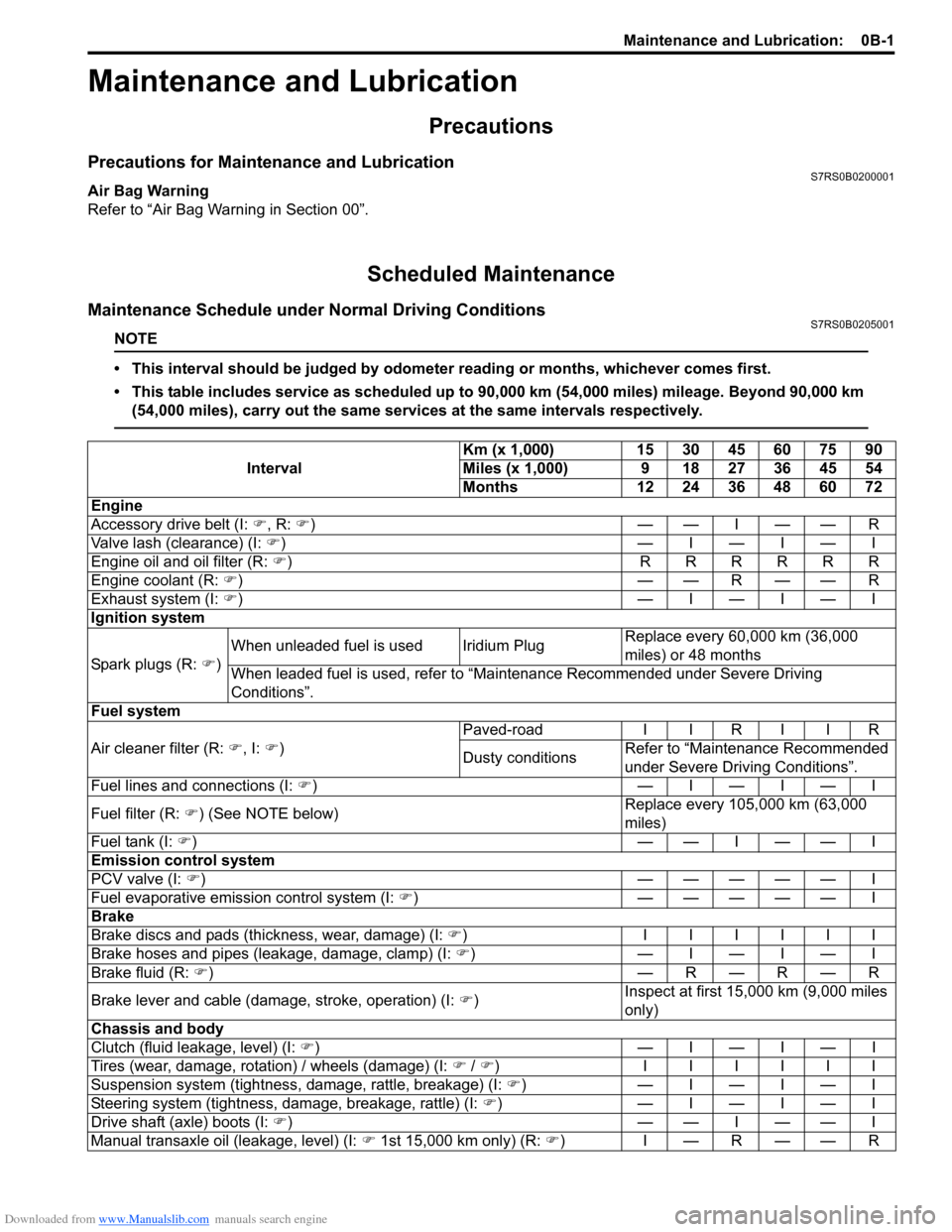

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 32 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-2 Maintenance and Lubrication:

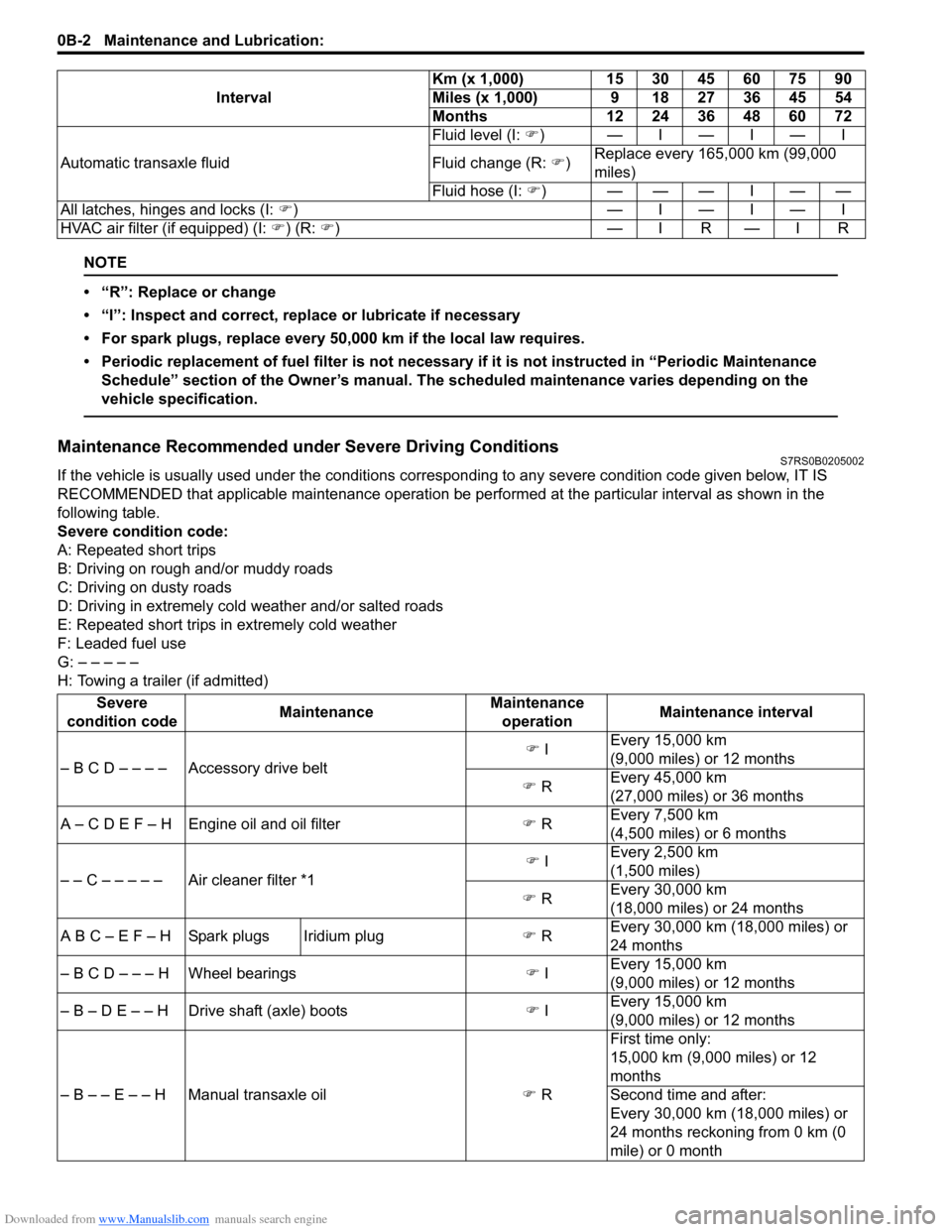

NOTE

• “R”: Replace or change

• “I”: Inspect and correct, replace or lubricate if necessary

• For spark plugs, replace every 50,000 km if the local law requires.

• Periodic replacement of fuel filter is not necessary if it is not instructed in “Periodic Maintenance Schedule” section of the Owner’s manual. The scheduled maintenance varies depending on the

vehicle specification.

Maintenance Recommended under Severe Driving ConditionsS7RS0B0205002

If the vehicle is usually used under the conditions corres ponding to any severe condition code given below, IT IS

RECOMMENDED that applicable maintenance operation be per formed at the particular interval as shown in the

following table.

Severe condition code:

A: Repeated short trips

B: Driving on rough and/or muddy roads

C: Driving on dusty roads

D: Driving in extremely cold weather and/or salted roads

E: Repeated short trips in extremely cold weather

F: Leaded fuel use

G: – – – – –

H: Towing a trailer (if admitted) Automatic transaxle fluid

Fluid level (I:

�)) —I—I—I

Fluid change (R: �)) Replace every 165,000 km (99,000

miles)

Fluid hose (I: �))———I——

All latches, hinges and locks (I: �)) —I—I—I

HVAC air filter (if equipped) (I: �) ) (R: �))— IR — IR

Interval

Km (x 1,000)

15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

– B C D – – – – Accessory drive belt �)

I Every 15,000 km

(9,000 miles) or 12 months

�) R Every 45,000 km

(27,000 miles) or 36 months

A – C D E F – H Engine oil and oil filter �) R Every 7,500 km

(4,500 miles) or 6 months

– – C – – – – – Air cleaner filter *1 �)

I Every 2,500 km

(1,500 miles)

�) R Every 30,000 km

(18,000 miles) or 24 months

A B C – E F – H Spark plugs Iridium plug �) R Every 30,000 km (18,000 miles) or

24 months

– B C D – – – H Wheel bearings �) I Every 15,000 km

(9,000 miles) or 12 months

– B – D E – – H Drive shaft (axle) boots �) I Every 15,000 km

(9,000 miles) or 12 months

– B – – E – – H Manual transaxle oil �) R First time only:

15,000 km (9,000 miles) or 12

months

Second time and after:

Every 30,000 km (18,000 miles) or

24 months reckoning from 0 km (0

mile) or 0 month

Page 33 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-3

NOTE

• “I”: Inspect and correct or replace if necessary

• “R”: Replace or change

• *1: Inspect or replace more frequently if the vehicle is used under dusty conditions.

• *2: Clean or replace more frequently if the air from the air conditioning decreases.

Repair Instructions

Accessory Drive Belt InspectionS7RS0B0206001

WARNING!

All inspection and replacement are to be

performed with ENGINE NOT RUNNING.

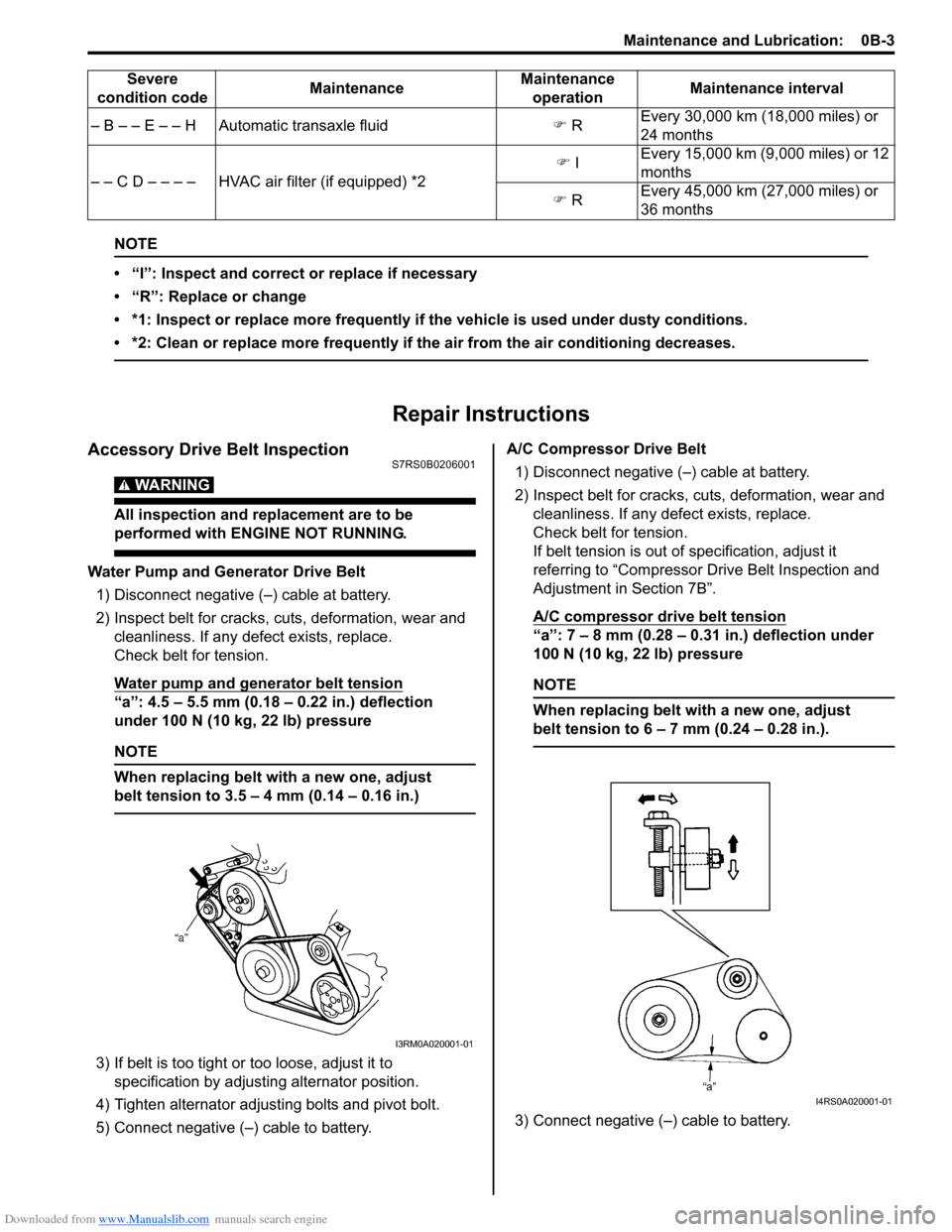

Water Pump and Generator Drive Belt1) Disconnect negative (–) cable at battery.

2) Inspect belt for cracks, cu ts, deformation, wear and

cleanliness. If any defect exists, replace.

Check belt for tension.

Water pump and generator belt tension

“a”: 4.5 – 5.5 mm (0.18 – 0.22 in.) deflection

under 100 N (10 kg, 22 lb) pressure

NOTE

When replacing belt with a new one, adjust

belt tension to 3.5 – 4 mm (0.14 – 0.16 in.)

3) If belt is too tight or too loose, adjust it to

specification by adjusting alternator position.

4) Tighten alternator adjusting bolts and pivot bolt.

5) Connect negative (–) cable to battery. A/C Compressor Drive Belt

1) Disconnect negative (–) cable at battery.

2) Inspect belt for cracks, cuts, deformation, wear and cleanliness. If any defect exists, replace.

Check belt for tension.

If belt tension is out of specification, adjust it

referring to “Compressor Dr ive Belt Inspection and

Adjustment in Section 7B”.

A/C compressor drive belt tension

“a”: 7 – 8 mm (0.28 – 0.31 in.) deflection under

100 N (10 kg, 22 lb) pressure

NOTE

When replacing belt with a new one, adjust

belt tension to 6 – 7 mm (0.24 – 0.28 in.).

3) Connect negative (–) cable to battery.

– B – – E – – H Automatic transaxle fluid

�) R Every 30,000 km (18,000 miles) or

24 months

– – C D – – – – HVAC air filter (if equipped) *2 �)

I Every 15,000 km (9,000 miles) or 12

months

�) R Every 45,000 km (27,000 miles) or

36 months

Severe

condition code MaintenanceMaintenance

operation Maintenance interval

I3RM0A020001-01

I4RS0A020001-01