Parking SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 355 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

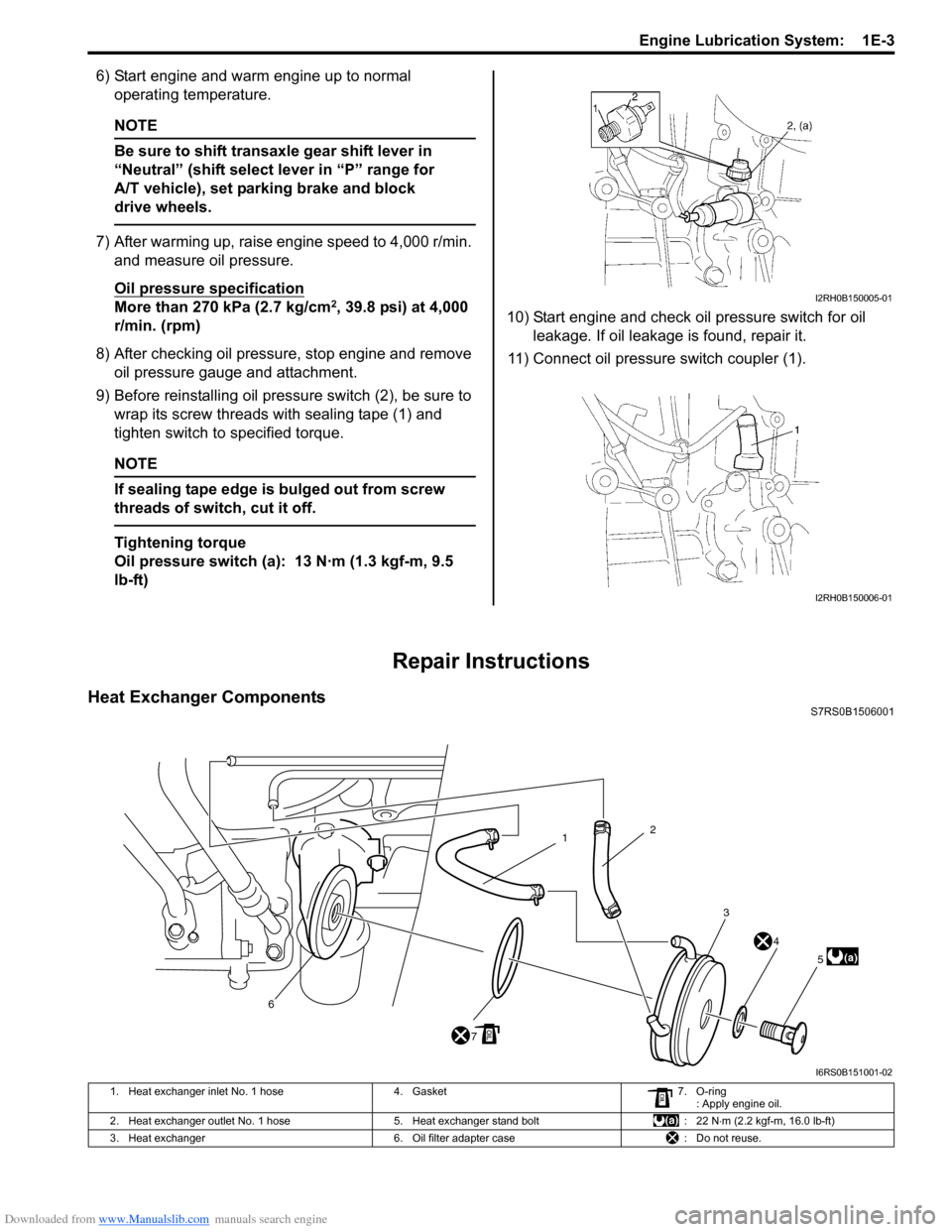

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

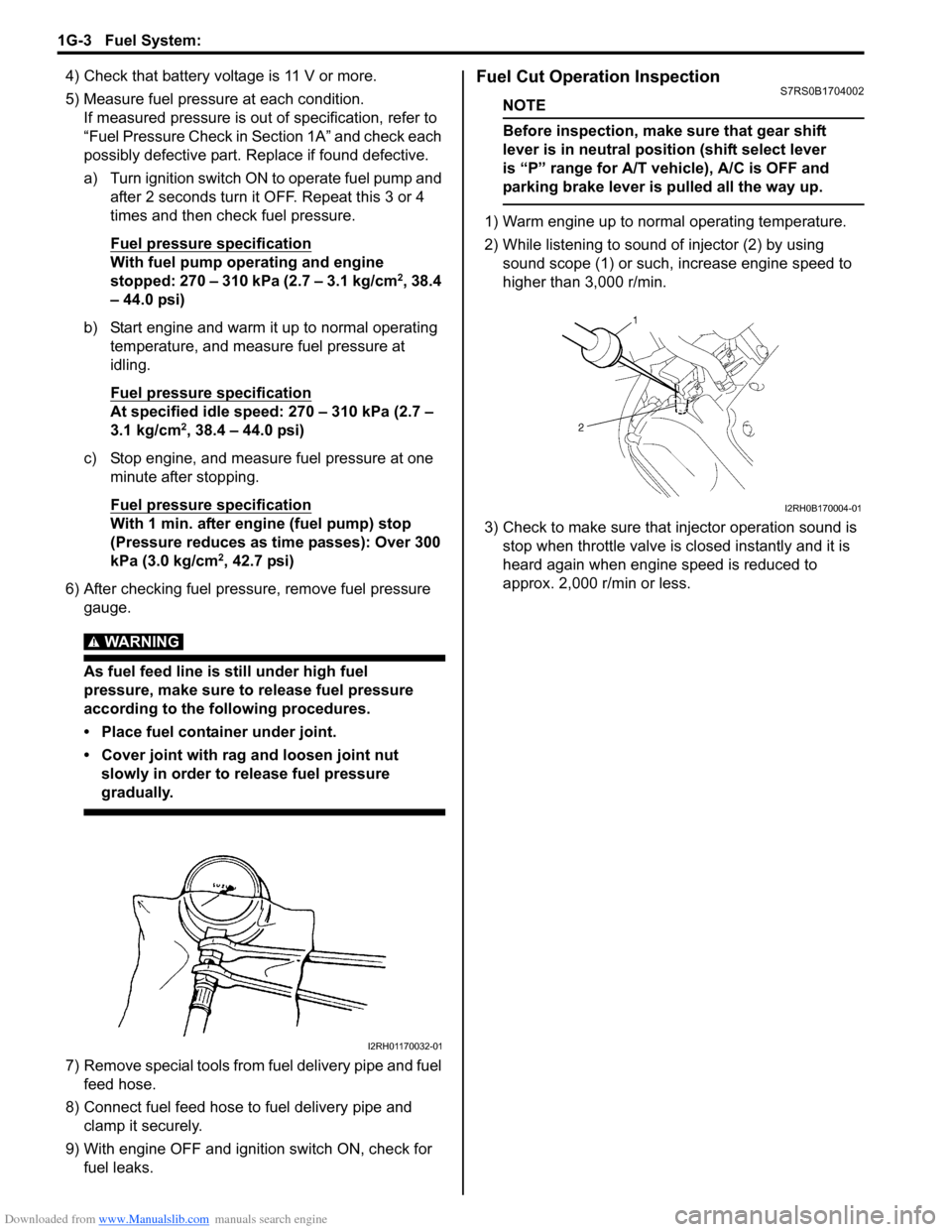

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 378 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-3 Fuel System:

4) Check that battery voltage is 11 V or more.

5) Measure fuel pressure at each condition.If measured pressure is out of specification, refer to

“Fuel Pressure Check in Section 1A” and check each

possibly defective part. Replace if found defective.

a) Turn ignition switch ON to operate fuel pump and after 2 seconds turn it OFF. Repeat this 3 or 4

times and then check fuel pressure.

Fuel pressure specification

With fuel pump operating and engine

stopped: 270 – 310 kPa (2.7 – 3.1 kg/cm2, 38.4

– 44.0 psi)

b) Start engine and warm it up to normal operating temperature, and measure fuel pressure at

idling.

Fuel pressure specification

At specified idle speed: 270 – 310 kPa (2.7 –

3.1 kg/cm2, 38.4 – 44.0 psi)

c) Stop engine, and measure fuel pressure at one minute after stopping.

Fuel pressure specification

With 1 min. after engine (fuel pump) stop

(Pressure reduces as time passes): Over 300

kPa (3.0 kg/cm

2, 42.7 psi)

6) After checking fuel pressure, remove fuel pressure gauge.

WARNING!

As fuel feed line is still under high fuel

pressure, make sure to release fuel pressure

according to the following procedures.

• Place fuel container under joint.

• Cover joint with rag and loosen joint nut slowly in order to release fuel pressure

gradually.

7) Remove special tools from fuel delivery pipe and fuel feed hose.

8) Connect fuel feed hose to fuel delivery pipe and clamp it securely.

9) With engine OFF and ignition switch ON, check for fuel leaks.

Fuel Cut Operation InspectionS7RS0B1704002

NOTE

Before inspection, make sure that gear shift

lever is in neutral positi on (shift select lever

is “P” range for A/T vehicle), A/C is OFF and

parking brake lever is pulled all the way up.

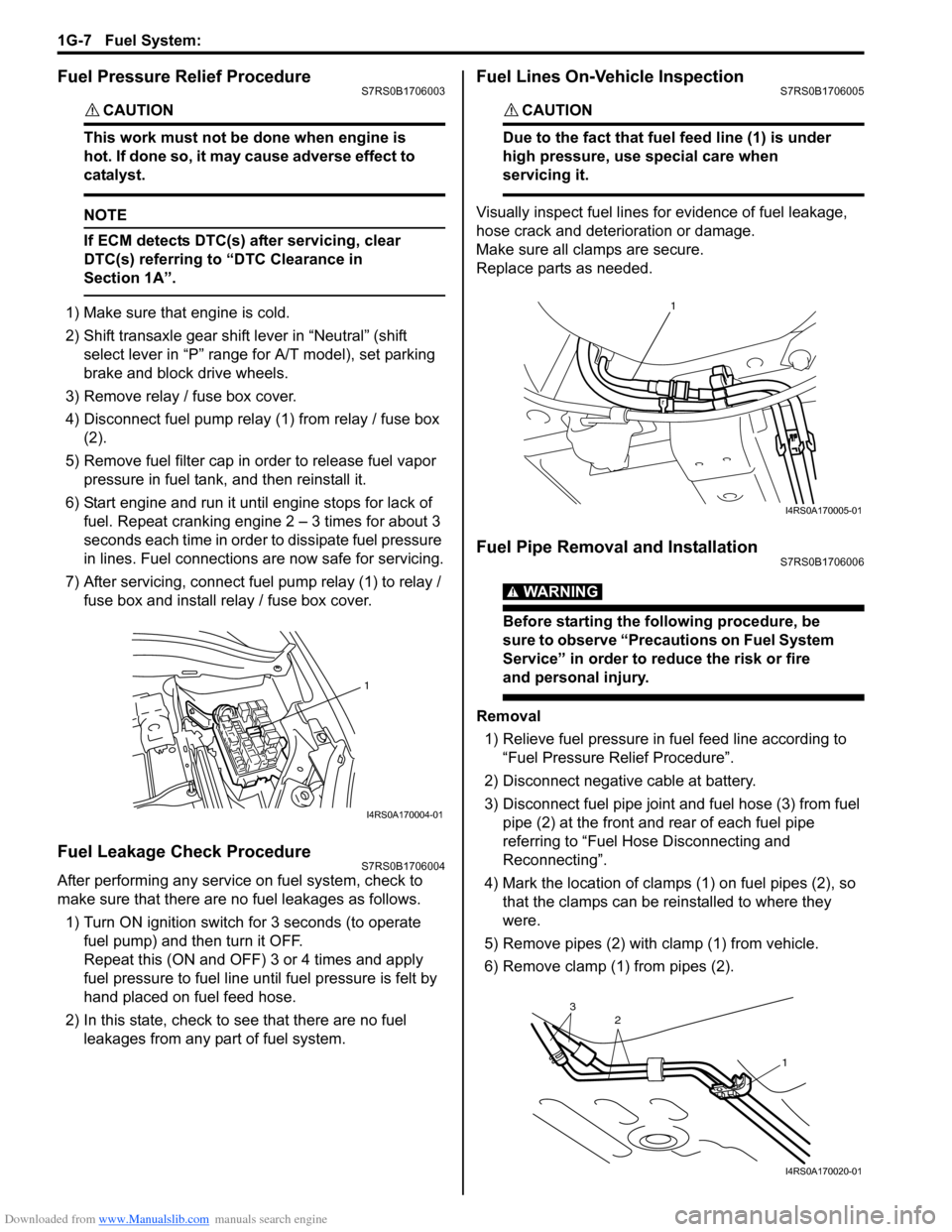

1) Warm engine up to normal operating temperature.

2) While listening to sound of injector (2) by using sound scope (1) or such, increase engine speed to

higher than 3,000 r/min.

3) Check to make sure that injector operation sound is stop when throttle valve is closed instantly and it is

heard again when engine speed is reduced to

approx. 2,000 r/min or less.

I2RH01170032-01

I2RH0B170004-01

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 400 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-8 Ignition System:

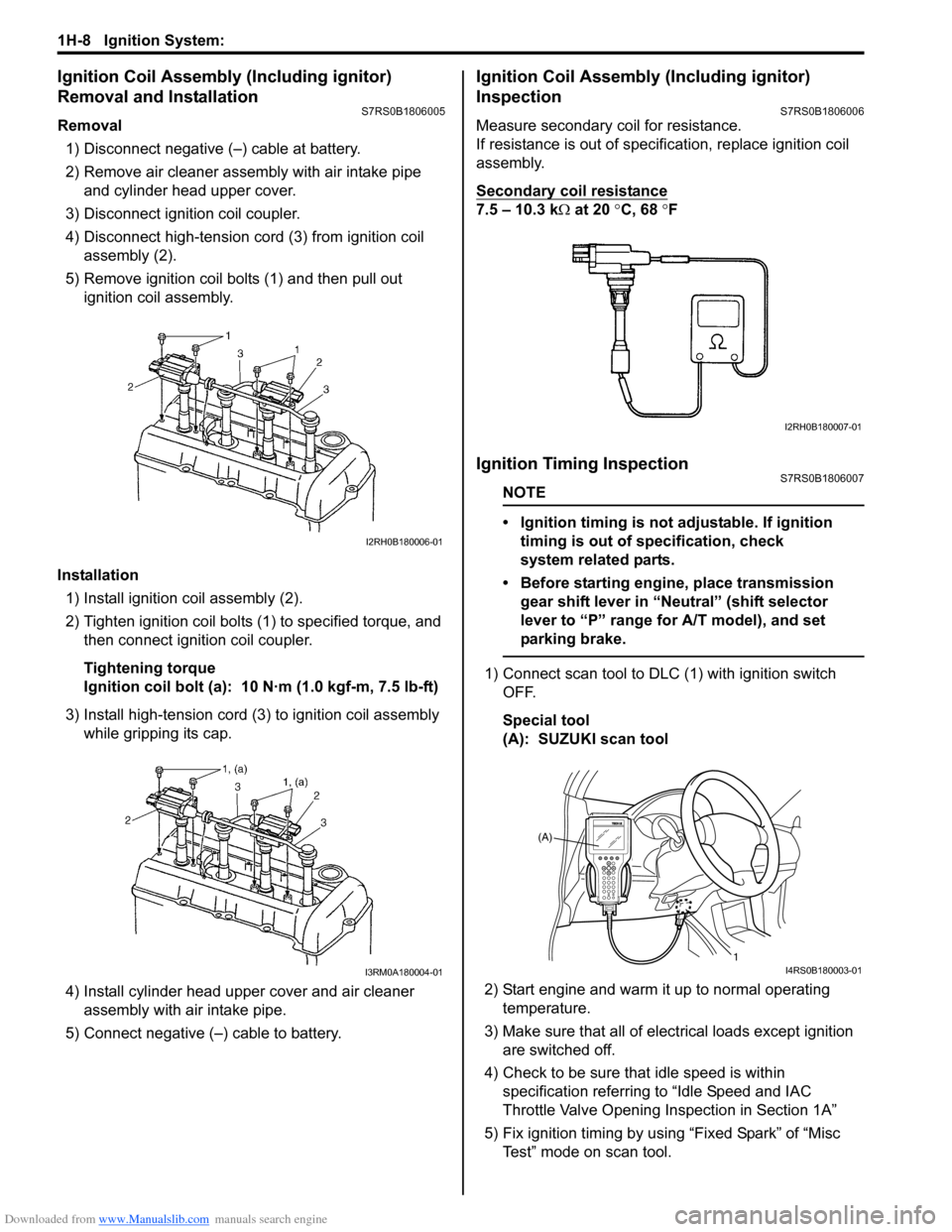

Ignition Coil Assembly (Including ignitor)

Removal and Installation

S7RS0B1806005

Removal1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly (2).

5) Remove ignition coil bolts (1) and then pull out ignition coil assembly.

Installation 1) Install ignition coil assembly (2).

2) Tighten ignition coil bolts (1) to specified torque, and then connect igni tion coil coupler.

Tightening torque

Ignition coil bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

3) Install high-tension cord (3) to ignition coil assembly while gripping its cap.

4) Install cylinder head upper cover and air cleaner assembly with air intake pipe.

5) Connect negative (–) cable to battery.

Ignition Coil Assembly (Including ignitor)

Inspection

S7RS0B1806006

Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

7.5 – 10.3 k Ω at 20 °C, 68 ° F

Ignition Timing InspectionS7RS0B1806007

NOTE

• Ignition timing is not adjustable. If ignition

timing is out of specification, check

system related parts.

• Before starting engine, place transmission gear shift lever in “Neutral” (shift selector

lever to “P” range for A/T model), and set

parking brake.

1) Connect scan tool to DLC (1) with ignition switch OFF.

Special tool

(A): SUZUKI scan tool

2) Start engine and warm it up to normal operating temperature.

3) Make sure that all of electrical loads except ignition are switched off.

4) Check to be sure that idle speed is within specification referring to “Idle Speed and IAC

Throttle Valve Opening Inspection in Section 1A”

5) Fix ignition timing by using “Fixed Spark” of “Misc Test” mode on scan tool.

I2RH0B180006-01

I3RM0A180004-01

I2RH0B180007-01

(A)

1

I4RS0B180003-01

Page 416 of 1496

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

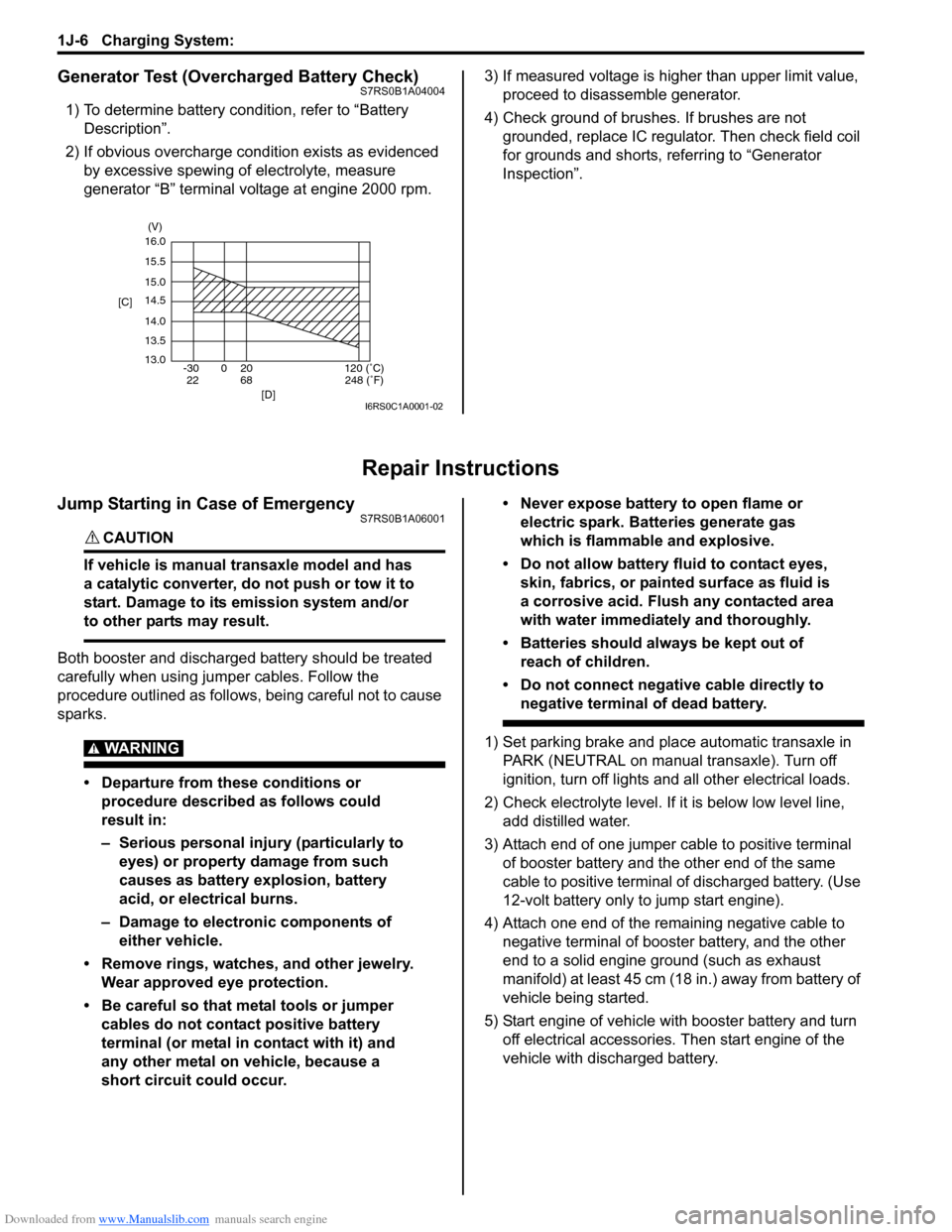

Generator Test (Overcharged Battery Check)S7RS0B1A04004

1) To determine battery condition, refer to “Battery Description”.

2) If obvious overcharge condition exists as evidenced by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm. 3) If measured voltage is higher than upper limit value,

proceed to disassemble generator.

4) Check ground of brushes. If brushes are not grounded, replace IC regulator. Then check field coil

for grounds and shorts, referring to “Generator

Inspection”.

Repair Instructions

Jump Starting in Case of EmergencyS7RS0B1A06001

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using ju mper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or procedure described as follows could

result in:

– Serious personal injury (particularly to eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of either vehicle.

• Remove rings, watches, and other jewelry. Wear approved eye protection.

• Be careful so that metal tools or jumper cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur. • Never expose battery to open flame or

electric spark. Batteries generate gas

which is flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surface as fluid is

a corrosive acid. Flush any contacted area

with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

• Do not connect negative cable directly to negative terminal of dead battery.

1) Set parking brake and place automatic transaxle in PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then start engine of the

vehicle with discharged battery.

16.0

15.5

15.0

14.5

14.0

13.5

13.0 -30 0 20

[C]

[D]

68

22120 (˚C)

248 (˚F)

(V)

I6RS0C1A0001-02

Page 458 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-4 Rear Suspension:

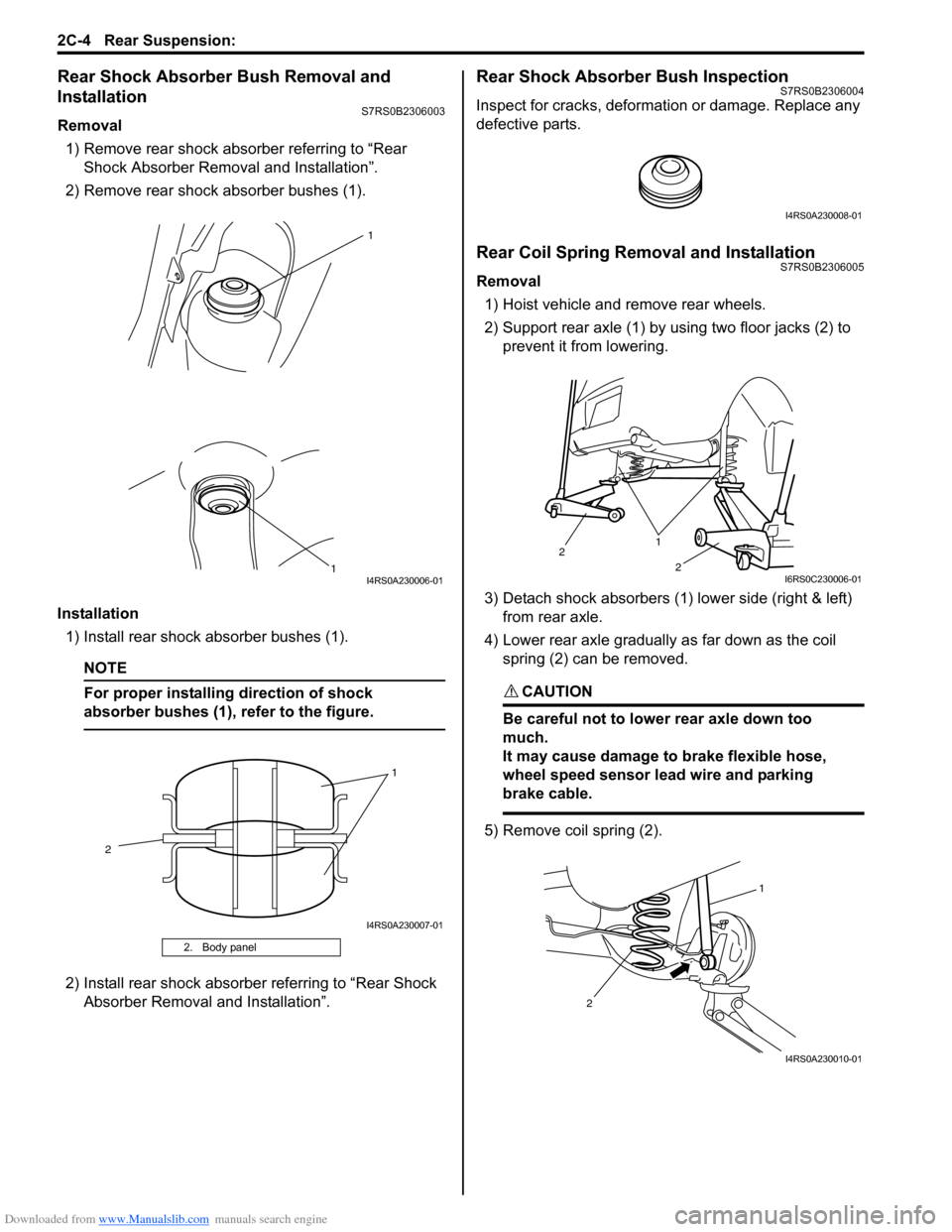

Rear Shock Absorber Bush Removal and

Installation

S7RS0B2306003

Removal1) Remove rear shock absorber referring to “Rear Shock Absorber Remova l and Installation”.

2) Remove rear shock absorber bushes (1).

Installation 1) Install rear shock absorber bushes (1).

NOTE

For proper installing direction of shock

absorber bushes (1), refer to the figure.

2) Install rear shock absorber referring to “Rear Shock Absorber Removal and Installation”.

Rear Shock Absorber Bush InspectionS7RS0B2306004

Inspect for cracks, deformation or damage. Replace any

defective parts.

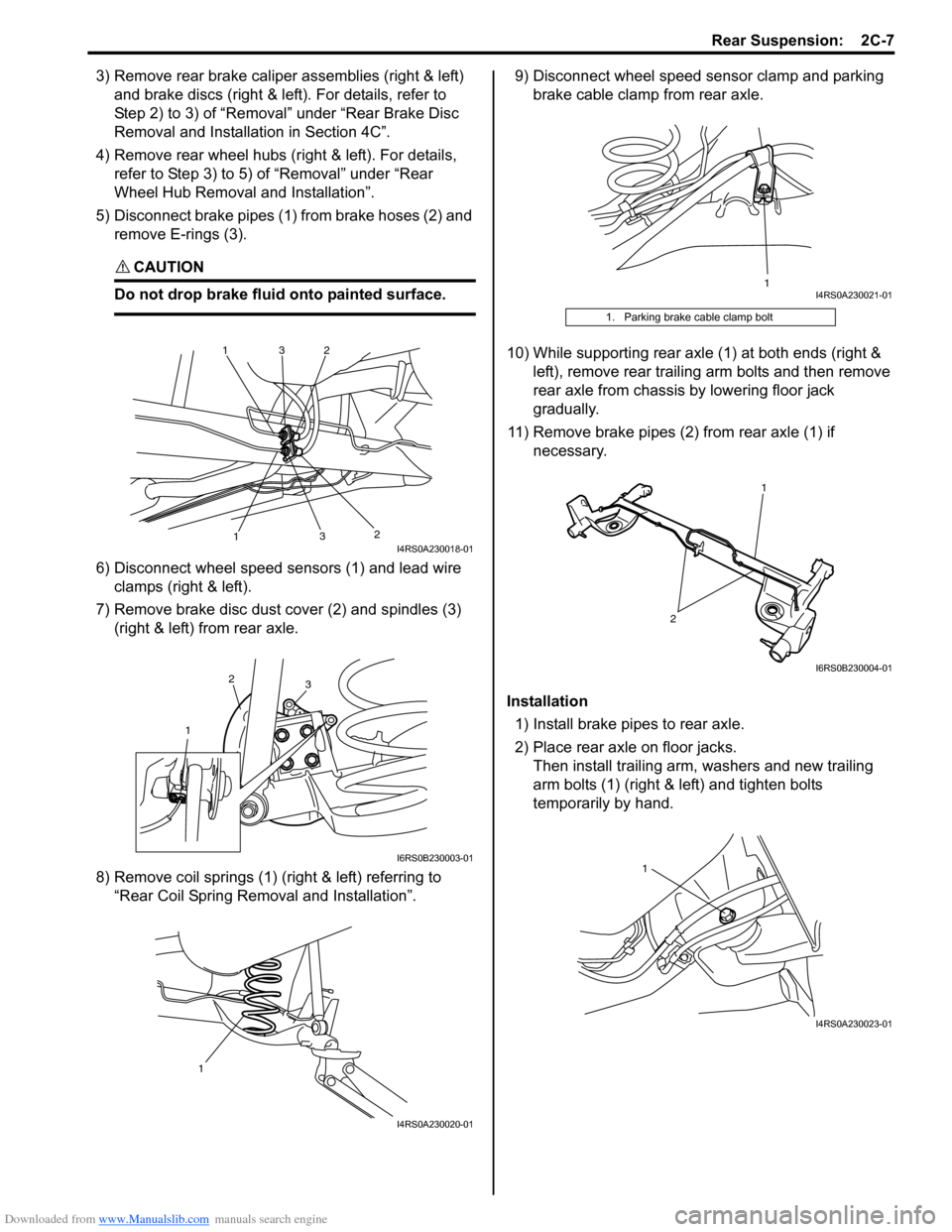

Rear Coil Spring Removal and InstallationS7RS0B2306005

Removal

1) Hoist vehicle and remove rear wheels.

2) Support rear axle (1) by using two floor jacks (2) to prevent it from lowering.

3) Detach shock absorbers (1) lower side (right & left) from rear axle.

4) Lower rear axle gradually as far down as the coil spring (2) can be removed.

CAUTION!

Be careful not to lowe r rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

5) Remove coil spring (2).

2. Body panel

1

1

I4RS0A230006-01

1

2

I4RS0A230007-01

I4RS0A230008-01

1

2

2

I6RS0C230006-01

1

2

I4RS0A230010-01

Page 461 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-7

3) Remove rear brake caliper assemblies (right & left)

and brake discs (right & left ). For details, refer to

Step 2) to 3) of “Removal” under “Rear Brake Disc

Removal and Installa tion in Section 4C”.

4) Remove rear wheel hubs (r ight & left). For details,

refer to Step 3) to 5) of “Removal” under “Rear

Wheel Hub Removal and Installation”.

5) Disconnect brake pipes (1) from brake hoses (2) and remove E-rings (3).

CAUTION!

Do not drop brake fluid onto painted surface.

6) Disconnect wheel speed sensors (1) and lead wire clamps (right & left).

7) Remove brake disc dust cover (2) and spindles (3) (right & left) from rear axle.

8) Remove coil springs (1) (right & left) referring to “Rear Coil Spring Removal and Installation”. 9) Disconnect wheel speed sensor clamp and parking

brake cable clamp from rear axle.

10) While supporting rear axle (1) at both ends (right & left), remove rear trailing arm bolts and then remove

rear axle from chassis by lowering floor jack

gradually.

11) Remove brake pipes (2) from rear axle (1) if necessary.

Installation 1) Install brake pipes to rear axle.

2) Place rear axle on floor jacks. Then install trailing arm, washers and new trailing

arm bolts (1) (right & left) and tighten bolts

temporarily by hand.

1

1

2

2

3

3I4RS0A230018-01

1

2

3

I6RS0B230003-01

1

I4RS0A230020-01

1. Parking brake cable clamp bolt

1I4RS0A230021-01

2

1

I6RS0B230004-01

1

I4RS0A230023-01

Page 462 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-8 Rear Suspension:

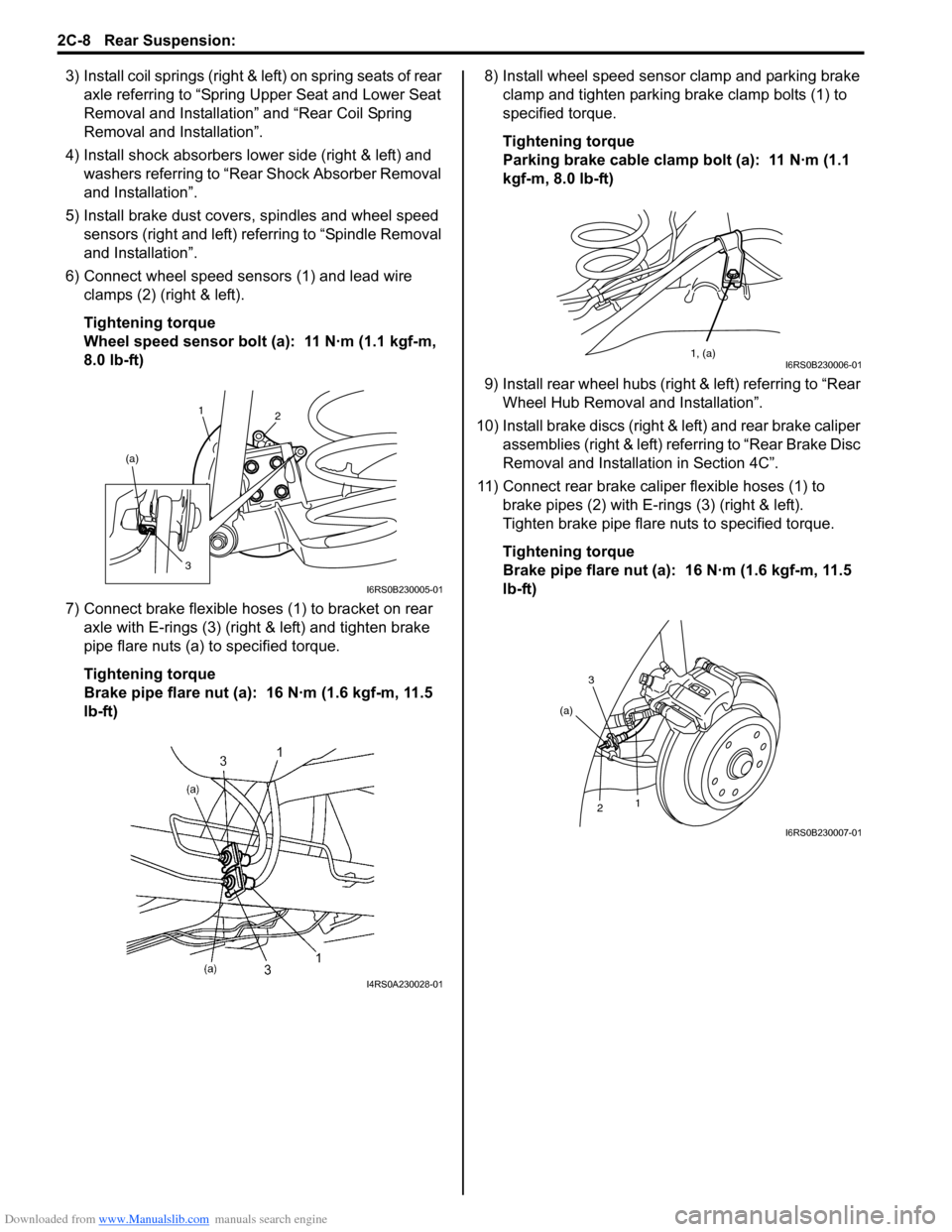

3) Install coil springs (right & left) on spring seats of rear

axle referring to “Spring Upper Seat and Lower Seat

Removal and Installation” and “Rear Coil Spring

Removal and Installation”.

4) Install shock absorbers lower side (right & left) and washers referring to “Rear Shock Absorber Removal

and Installation”.

5) Install brake dust covers, spindles and wheel speed sensors (right and left) referring to “Spindle Removal

and Installation”.

6) Connect wheel speed sensors (1) and lead wire clamps (2) (right & left).

Tightening torque

Wheel speed sensor bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Connect brake flexible hoses (1) to bracket on rear axle with E-rings (3) (right & left) and tighten brake

pipe flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft) 8) Install wheel speed sensor clamp and parking brake

clamp and tighten parking brake clamp bolts (1) to

specified torque.

Tightening torque

Parking brake cable clamp bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

9) Install rear wheel hubs (right & left) referring to “Rear Wheel Hub Removal and Installation”.

10) Install brake discs (right & left) and rear brake caliper assemblies (right & left) referring to “Rear Brake Disc

Removal and Installati on in Section 4C”.

11) Connect rear brake caliper flexible hoses (1) to brake pipes (2) with E-rings (3) (right & left).

Tighten brake pipe flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

1 2

(a)

3

I6RS0B230005-01

I4RS0A230028-01

1, (a)I6RS0B230006-01

3

2 1

(a)

I6RS0B230007-01

Page 463 of 1496

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-9

12) Fill reservoir with brake fluid and bleed brake system. For bleeding operation, see “Air Bleeding of

Brake System in Section 4A”.

13) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Adjust parking brake cable. For adjustment, refer to “Parking Brake Inspection and Adjustment in Section

4D”.

15) Lower hoist and bounce vehicle up and down several times to stabilize suspension.

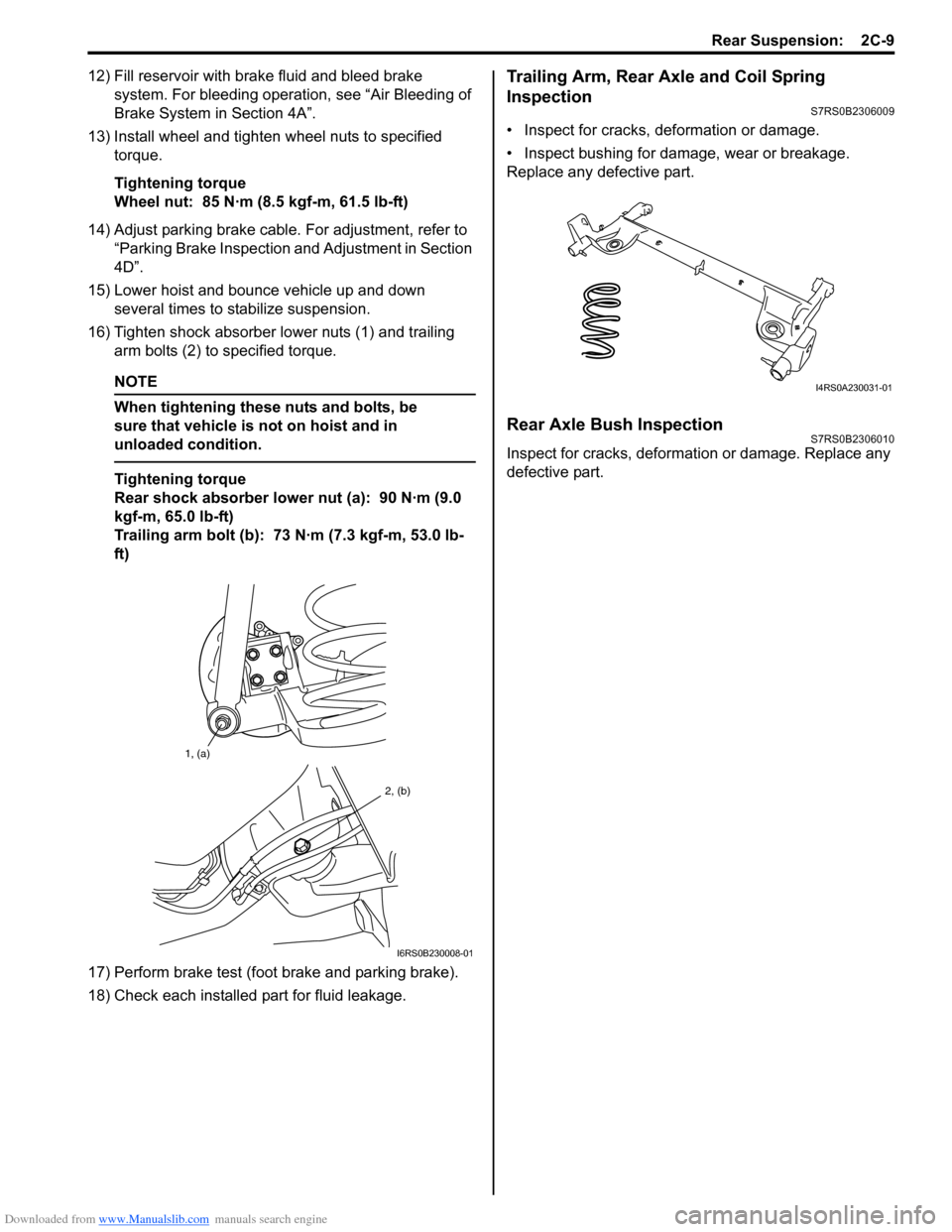

16) Tighten shock ab sorber lower nuts (1) and trailing

arm bolts (2) to specified torque.

NOTE

When tightening these nuts and bolts, be

sure that vehicle is not on hoist and in

unloaded condition.

Tightening torque

Rear shock absorber lower nut (a): 90 N·m (9.0

kgf-m, 65.0 lb-ft)

Trailing arm bolt (b): 73 N·m (7.3 kgf-m, 53.0 lb-

ft)

17) Perform brake test (foot brake and parking brake).

18) Check each installed part for fluid leakage.

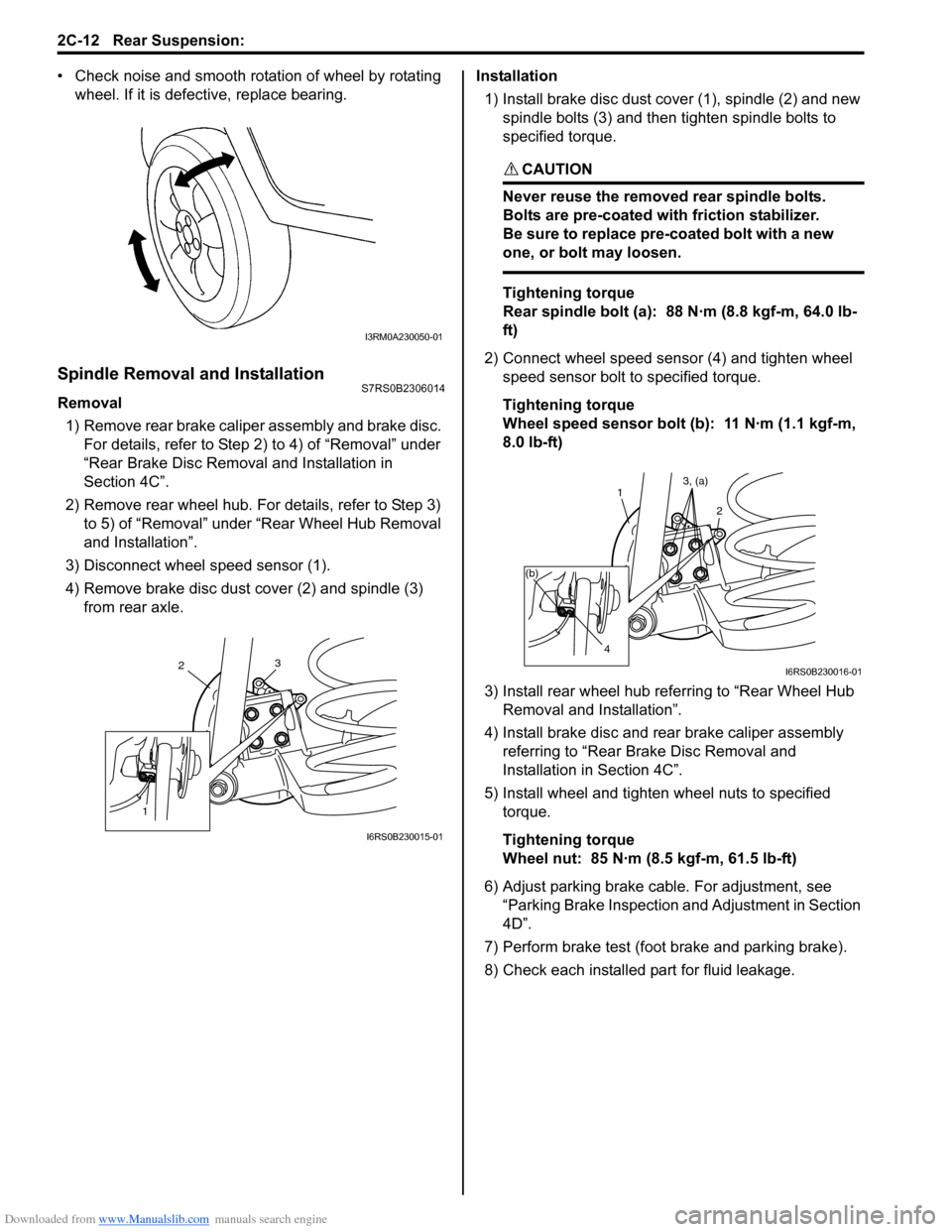

Trailing Arm, Rear Axle and Coil Spring

Inspection

S7RS0B2306009

• Inspect for cracks, deformation or damage.

• Inspect bushing for damage, wear or breakage.

Replace any defective part.

Rear Axle Bush InspectionS7RS0B2306010

Inspect for cracks, deformation or damage. Replace any

defective part.

1, (a)

2, (b)

I6RS0B230008-01

I4RS0A230031-01

Page 466 of 1496

Downloaded from www.Manualslib.com manuals search engine 2C-12 Rear Suspension:

• Check noise and smooth rotation of wheel by rotating wheel. If it is defect ive, replace bearing.

Spindle Removal and InstallationS7RS0B2306014

Removal

1) Remove rear brake caliper assembly and brake disc. For details, refer to Step 2) to 4) of “Removal” under

“Rear Brake Disc Removal and Installation in

Section 4C”.

2) Remove rear wheel hub. For details, refer to Step 3) to 5) of “Removal” under “Rear Wheel Hub Removal

and Installation”.

3) Disconnect wheel speed sensor (1).

4) Remove brake disc dust cover (2) and spindle (3) from rear axle. Installation

1) Install brake disc dust cover (1), spindle (2) and new spindle bolts (3) and then tighten spindle bolts to

specified torque.

CAUTION!

Never reuse the removed rear spindle bolts.

Bolts are pre-coated wi th friction stabilizer.

Be sure to replace pre-coated bolt with a new

one, or bolt may loosen.

Tightening torque

Rear spindle bolt (a): 88 N·m (8.8 kgf-m, 64.0 lb-

ft)

2) Connect wheel speed sensor (4) and tighten wheel speed sensor bolt to specified torque.

Tightening torque

Wheel speed sensor bolt (b): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

3) Install rear wheel hub re ferring to “Rear Wheel Hub

Removal and Installation”.

4) Install brake disc and rear brake caliper assembly referring to “Rear Brake Disc Removal and

Installation in Section 4C”.

5) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) Adjust parking brake cable. For adjustment, see “Parking Brake Inspection and Adjustment in Section

4D”.

7) Perform brake test (foot brake and parking brake).

8) Check each installed part for fluid leakage.

I3RM0A230050-01

2

1 3

I6RS0B230015-01

1

(b)

4

2

3, (a)

I6RS0B230016-01