coolant level SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 145 of 1496

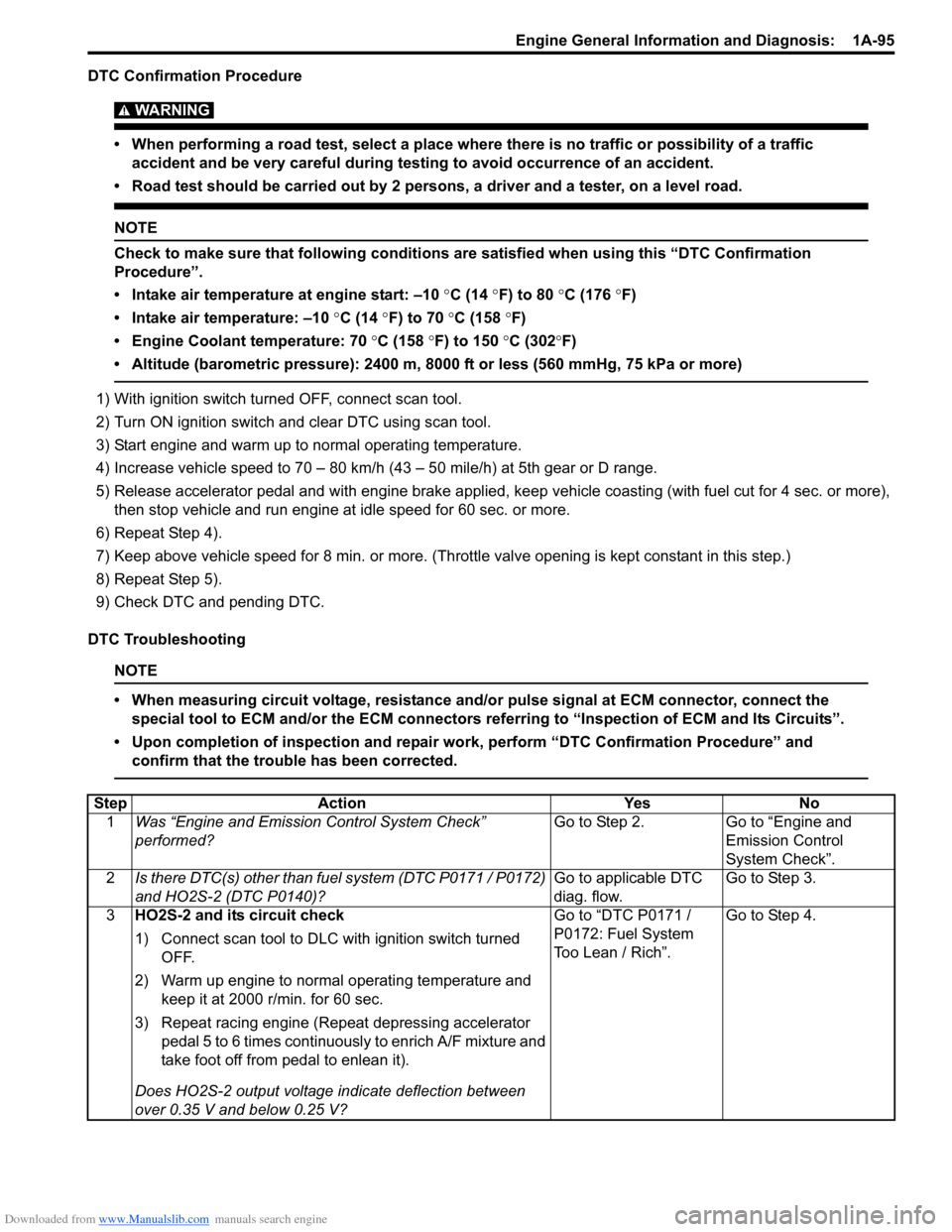

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-95

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine Coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Increase vehicle speed to 70 – 80 km/h (43 – 50 mile/h) at 5th gear or D range.

5) Release accelerator pedal and with engine brake applied, ke ep vehicle coasting (with fuel cut for 4 sec. or more),

then stop vehicle and run engine at idle speed for 60 sec. or more.

6) Repeat Step 4).

7) Keep above vehicle speed for 8 min. or more. (Throt tle valve opening is kept constant in this step.)

8) Repeat Step 5).

9) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Is there DTC(s) other than fuel system (DTC P0171 / P0172)

and HO2S-2 (DTC P0140)? Go to applicable DTC

diag. flow.Go to Step 3.

3 HO2S-2 and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Warm up engine to normal operating temperature and keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing accelerator pedal 5 to 6 times continuous ly to enrich A/F mixture and

take foot off from pedal to enlean it).

Does HO2S-2 output voltage indicate deflection between

over 0.35 V and below 0.25 V? Go to “DTC P0171 /

P0172: Fuel System

Too Lean / Rich”.

Go to Step 4.

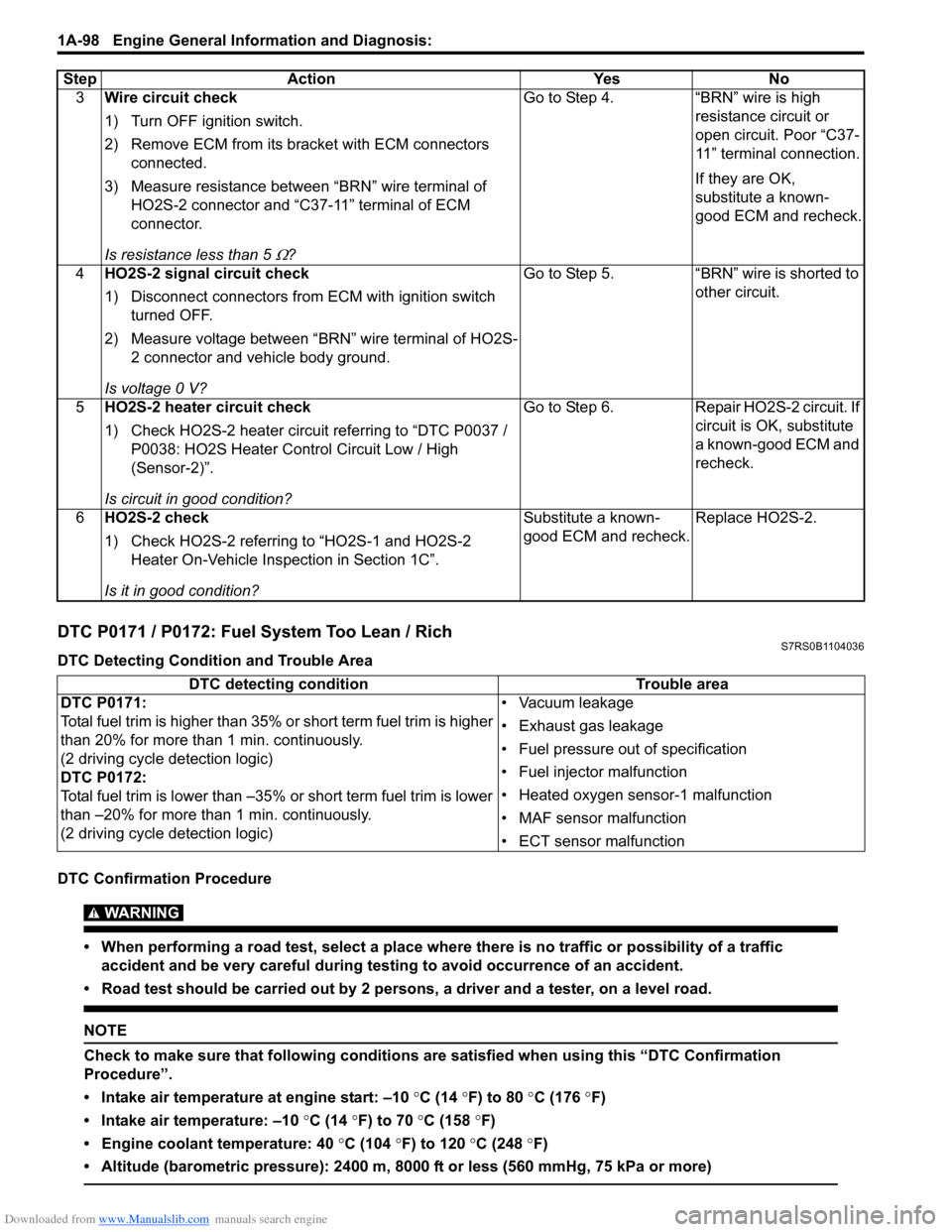

Page 148 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-98 Engine General Information and Diagnosis:

DTC P0171 / P0172: Fuel System Too Lean / RichS7RS0B1104036

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 40 °C (104 °F) to 120 °C (248 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

3 Wire circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its br acket with ECM connectors

connected.

3) Measure resistance between “BRN” wire terminal of HO2S-2 connector and “C37-11” terminal of ECM

connector.

Is resistance less than 5

Ω? Go to Step 4. “BRN” wire is high

resistance circuit or

open circuit. Poor “C37-

11” terminal connection.

If they are OK,

substitute a known-

good ECM and recheck.

4 HO2S-2 signal circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure voltage between “BRN” wire terminal of HO2S- 2 connector and vehicle body ground.

Is voltage 0 V? Go to Step 5. “BRN” wire is shorted to

other circuit.

5 HO2S-2 heater circuit check

1) Check HO2S-2 heater circuit referring to “DTC P0037 /

P0038: HO2S Heater Control Circuit Low / High

(Sensor-2)”.

Is circuit in good condition? Go to Step 6. Repair HO2S-2 circuit. If

circuit is OK, substitute

a known-good ECM and

recheck.

6 HO2S-2 check

1) Check HO2S-2 referring to “HO2S-1 and HO2S-2

Heater On-Vehicle Inspection in Section 1C”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Replace HO2S-2.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0171:

Total fuel trim is higher than 35% or short term fuel trim is higher

than 20% for more than 1 min. continuously.

(2 driving cycle detection logic)

DTC P0172:

Total fuel trim is lower than –35% or short term fuel trim is lower

than –20% for more than 1 min. continuously.

(2 driving cycle detection logic) • Vacuum leakage

• Exhaust gas leakage

• Fuel pressure out of specification

• Fuel injector malfunction

• Heated oxygen sensor-1 malfunction

• MAF sensor malfunction

• ECT sensor malfunction

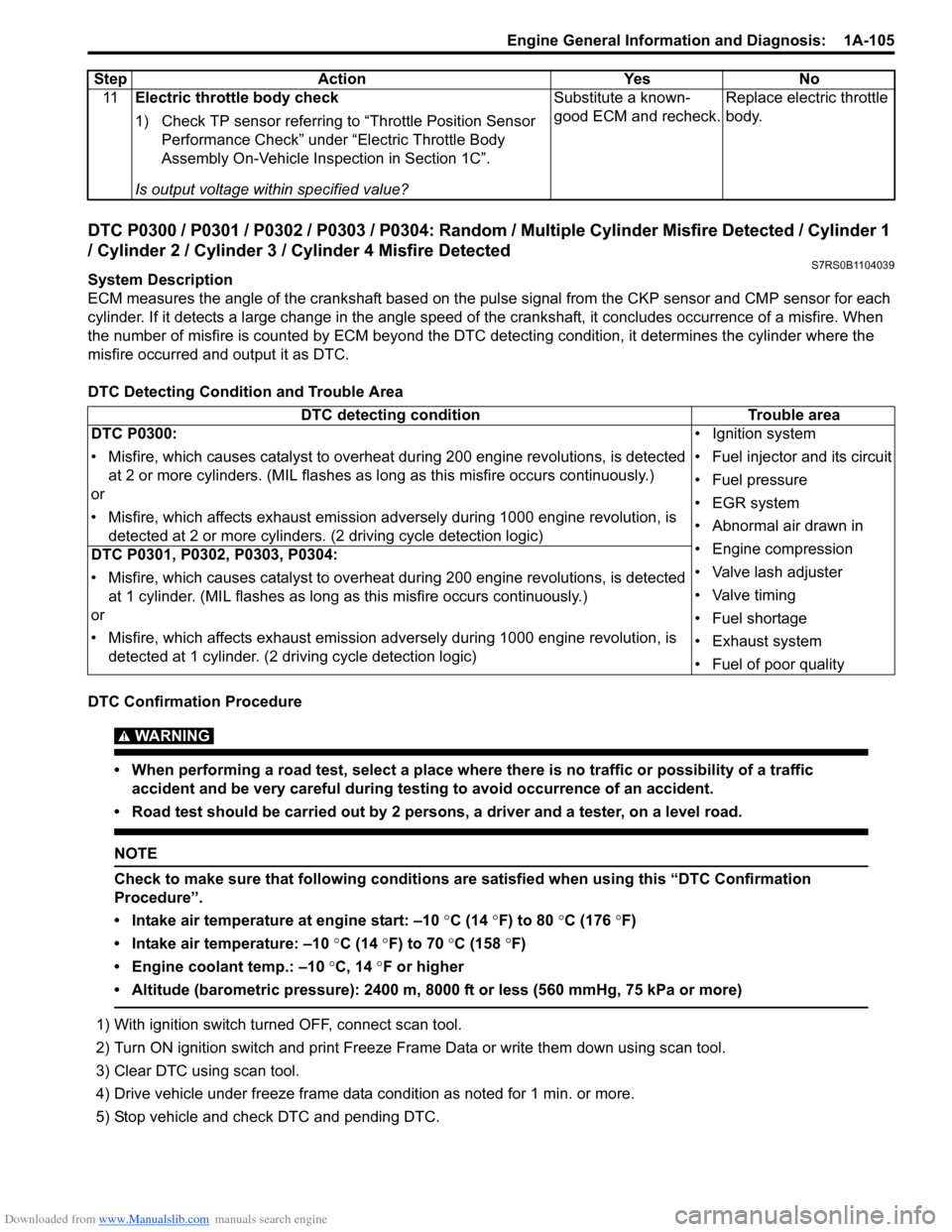

Page 155 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-105

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylinder Misfire Detected / Cylinder 1

/ Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected

S7RS0B1104039

System Description

ECM measures the angle of the crankshaft based on the pulse signal from the CKP sensor and CMP sensor for each

cylinder. If it detects a large change in the angle speed of the crankshaft, it concludes occurrence of a misfire. When

the number of misfire is counted by ECM beyond the DTC de tecting condition, it determines the cylinder where the

misfire occurred and output it as DTC.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: –10 °C, 14 °F or higher

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and print Freeze Frame Data or write them down using scan tool.

3) Clear DTC using scan tool.

4) Drive vehicle under freeze frame data condition as noted for 1 min. or more.

5) Stop vehicle and check DTC and pending DTC. 11

Electric throttle body check

1) Check TP sensor referring to “Throttle Position Sensor

Performance Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is output voltage within specified value? Substitute a known-

good ECM and recheck.

Replace electric throttle

body.

Step Action Yes No

DTC detecting condition

Trouble area

DTC P0300:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected at 2 or more cylinders. (MIL flashes as lo ng as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 2 or more cylinders. (2 driving cycle detection logic) • Ignition system

• Fuel injector and its circuit

• Fuel pressure

• EGR system

• Abnormal air drawn in

• Engine compression

• Valve lash adjuster

• Valve timing

• Fuel shortage

• Exhaust system

• Fuel of poor quality

DTC P0301, P0302, P0303, P0304:

• Misfire, which causes catalyst to overheat during 200 engine revolutions, is detected

at 1 cylinder. (MIL flashes as long as this misfire occurs continuously.)

or

• Misfire, which affects exhaust emission adv ersely during 1000 engine revolution, is

detected at 1 cylinder. (2 driving cycle detection logic)

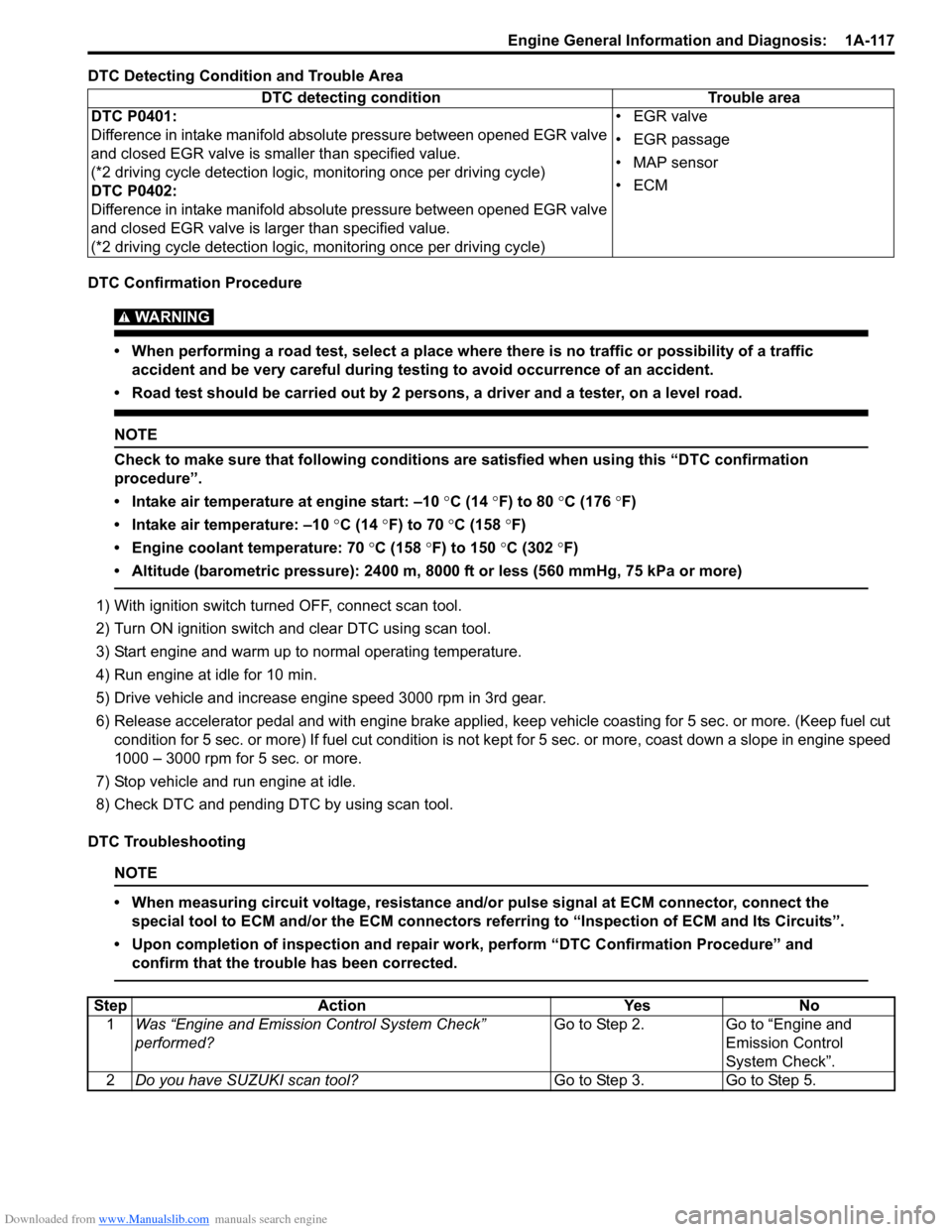

Page 167 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-117

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC confirmation

procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temperature: 70 °C (158 °F) to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up to normal operating temperature.

4) Run engine at idle for 10 min.

5) Drive vehicle and increase engine speed 3000 rpm in 3rd gear.

6) Release accelerator pedal and with engine brake applied, keep vehicle coasting for 5 sec. or more. (Keep fuel cut condition for 5 sec. or more) If fuel cut condition is not ke pt for 5 sec. or more, coast down a slope in engine speed

1000 – 3000 rpm for 5 sec. or more.

7) Stop vehicle and run engine at idle.

8) Check DTC and pending DTC by using scan tool.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

DTC P0401:

Difference in intake manifold absolute pressure between opened EGR valve

and closed EGR valve is smaller than specified value.

(*2 driving cycle detection logic, monitoring once per driving cycle)

DTC P0402:

Difference in intake manifold absolute pressure between opened EGR valve

and closed EGR valve is la rger than specified value.

(*2 driving cycle detection logic, monitoring once per driving cycle) •EGR valve

• EGR passage

• MAP sensor

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 5.

Page 171 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-121

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: 70 °C, 158 °F to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (500 mmHg, 75 kPa or more)

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Increase vehicle speed to 37 – 62 mph, 60 – 100 km/h. (engine speed: 2500 – 3000 r/min.)

4) Keep above vehicle speed for 10 min. or more (Thr ottle valve opening is kept constant in this step).

5) Stop vehicle and check if DTC / pending DTC exists using sc an tool. If not, check if catalyst monitoring test has

been completed using scan tool. If not in both of above checks (i.e., no DTC / pending DTC and catalyst

monitoring test not completed), check vehicle cond ition (environmental) and repeat Step 3) through 5).

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Response delay of HO2S-2 signal (shifting delay from rich to lean and

from lean to rich with threshold at 0.45 V) compared to switching cycle

(rich-lean) of A/F feed back is less than specified while vehicle is

running at constant speed and except with high engine load after

warmed up.

(*2 driving cycle detection logic, monitoring once per driving cycle) • Exhaust gas leak

• Warm up three way catalytic converter

malfunction

• HO2S-2 malfunction

• HO2S-1 malfunction

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Exhaust system visual check

1) Check exhaust system for leaks, damage and loose

connection.

Is it in good condition? Go to Step 3.

Repair or replace

defective part.

Page 291 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-6

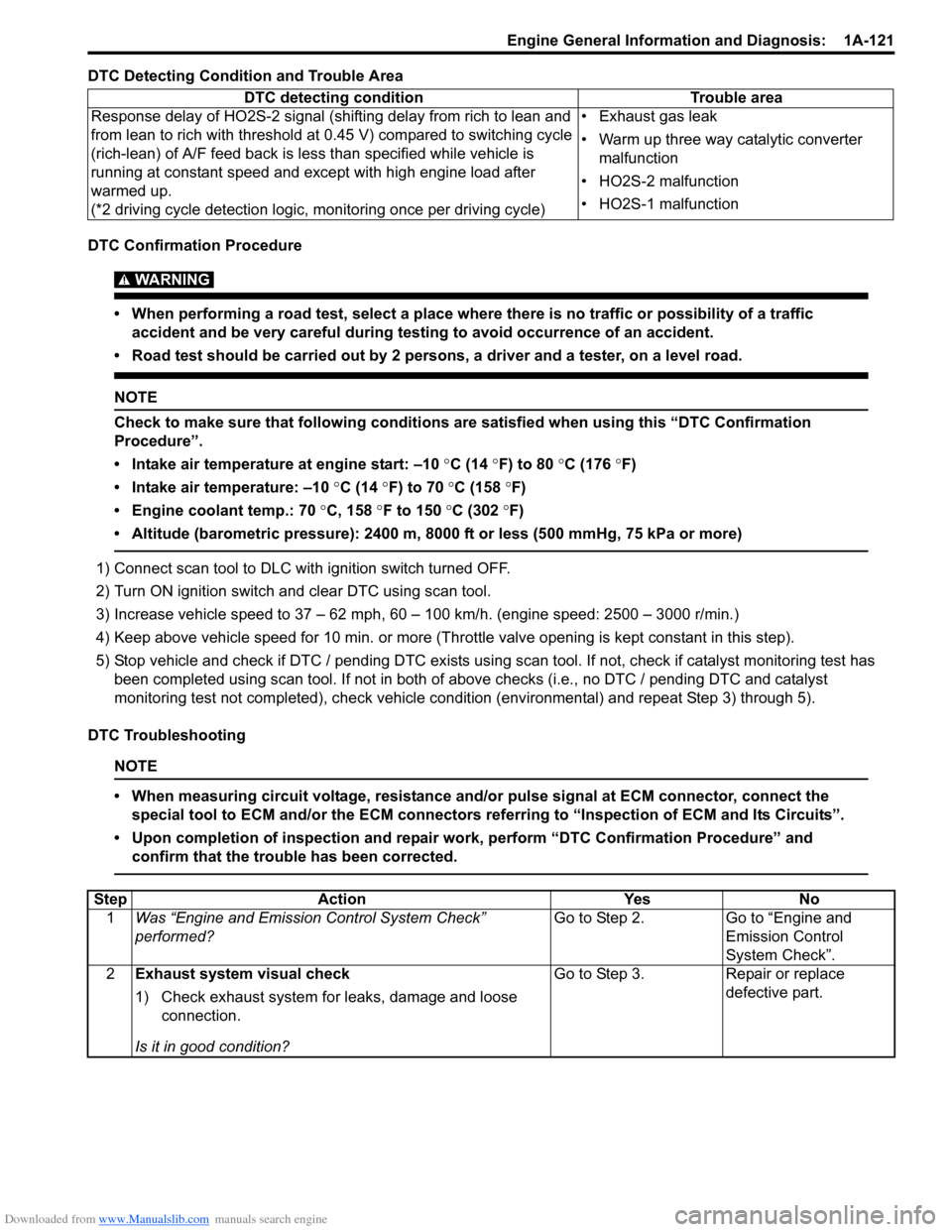

6) Connect special tool (Vacuum gauge) to PCV hose (1).

Special tool

(A): 09915–67311

7) Blind PCV valve (2) using tape (3) or the like.

8) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

9) Run engine at specified idle speed and read vacuum gauge. Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 in.Hg) at

specified idle speed

10) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

11) Disconnect special tool (vacuum gage) from PCV valve.

12) Detach blind cap from PCV valve, and connect PCV hose to PCV valve.

13) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

14) Install engine cover.

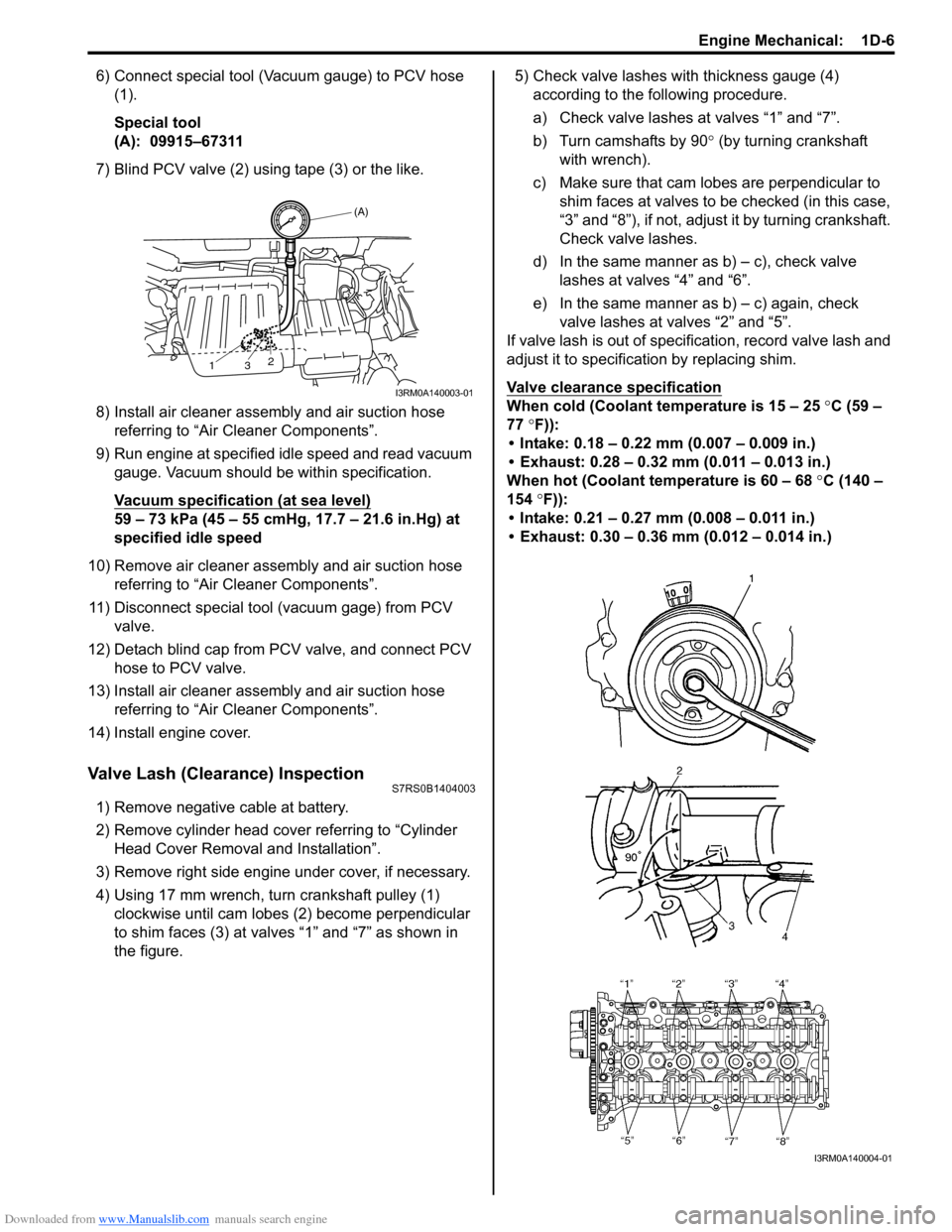

Valve Lash (Clearance) InspectionS7RS0B1404003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

3) Remove right side engine under cover, if necessary.

4) Using 17 mm wrench, turn crankshaft pulley (1) clockwise until cam lobes (2) become perpendicular

to shim faces (3) at valves “1” and “7” as shown in

the figure. 5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90 ° (by turning crankshaft

with wrench).

c) Make sure that cam lobes are perpendicular to shim faces at valves to be checked (in this case,

“3” and “8”), if not, adjust it by turning crankshaft.

Check valve lashes.

d) In the same manner as b) – c), check valve

lashes at valves “4” and “6”.

e) In the same manner as b) – c) again, check valve lashes at valves “2” and “5”.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant te mperature is 15 – 25 °C (59 –

77 °F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68 °C (140 –

154 °F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)

(A)

13 2

I3RM0A140003-01

I3RM0A140004-01

Page 364 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

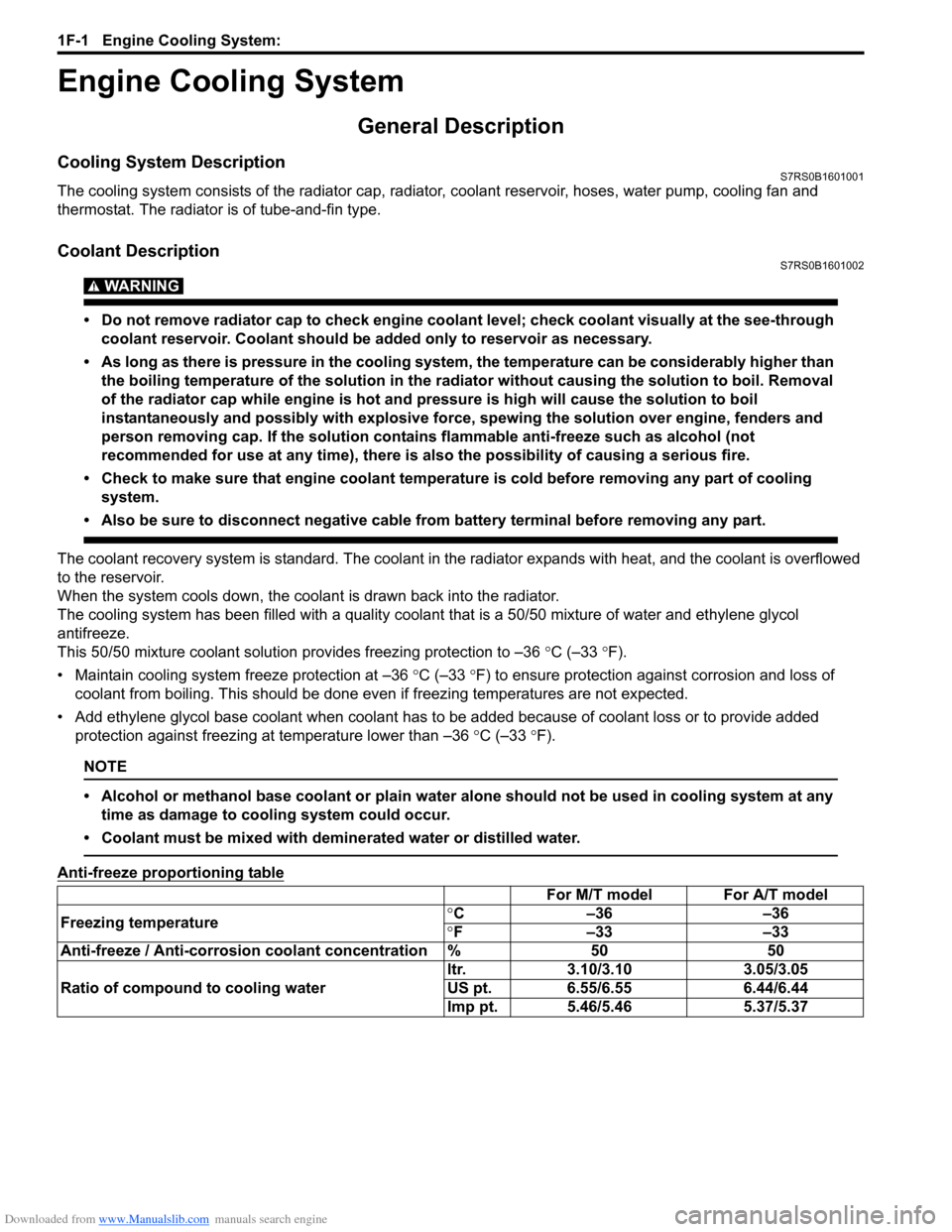

Cooling System DescriptionS7RS0B1601001

The cooling system consists of the radiator cap, radiator, coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS7RS0B1601002

WARNING!

• Do not remove radiator cap to check engine coolant level; check coolant visually at the see-through coolant reservoir. Coolant should be added only to reservoir as necessary.

• As long as there is pressure in the cooling system, the temperature can be considerably higher than the boiling temperature of the solution in the radiator without causing the solution to boil. Removal

of the radiator cap while engine is hot and pressure is high will cause the solution to boil

instantaneously and possibly with explosive force, spewing the solution over engine, fenders and

person removing cap. If the solution contains flammable anti-freeze such as alcohol (not

recommended for use at any time), there is also the possibility of causing a serious fire.

• Check to make sure that engine coolant temperature is cold before removing any part of cooling system.

• Also be sure to disconnect negative cable from battery terminal before removing any part.

The coolant recovery system is standard. The coolant in the radiator expands with heat, and the coolant is overflowed

to the reservoir.

When the system cools down, the coolant is drawn back into the radiator.

The cooling system has be en filled with a quality coolant that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–33 °F) to ensure protection against corrosion and loss of

coolant from boiling. This should be done even if freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to be added because of coolant loss or to provide added protection against freezing at temperature lower than –36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain water alone should not be used in cooling system at any

time as damage to cooling system could occur.

• Coolant must be mixed with deminerated water or distilled water.

Anti-freeze proportioning table

For M/T model For A/T model

Freezing temperature °

C –36 –36

° F –33 –33

Anti-freeze / Anti-corrosion coolant concentration % 50 50

Ratio of compound to cooling water ltr. 3.10/3.10 3.05/3.05

US pt. 6.55/6.55 6.44/6.44

Imp pt. 5.46/5.46 5.37/5.37

Page 367 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-4

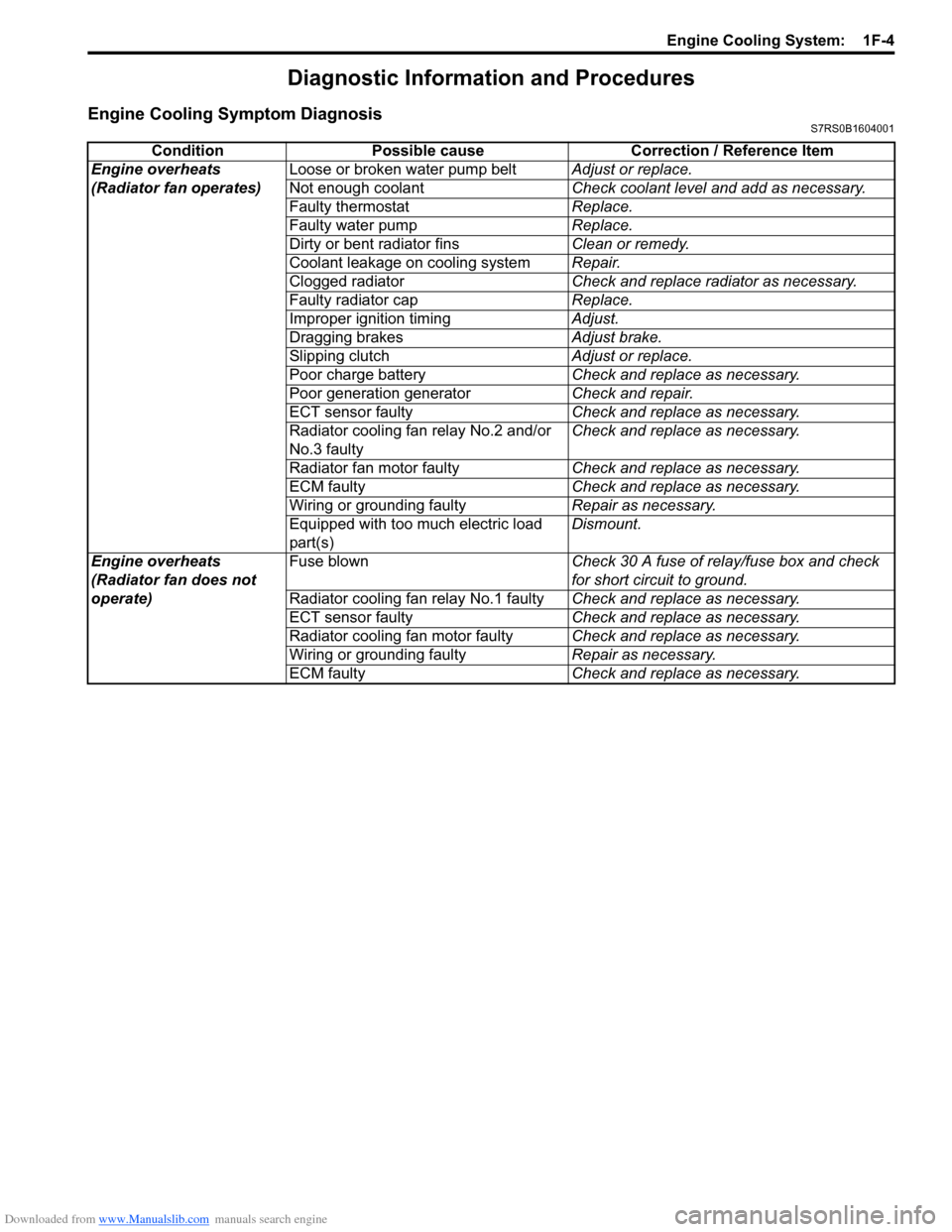

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS7RS0B1604001

ConditionPossible cause Correction / Reference Item

Engine overheats

(Radiator fan operates) Loose or broken water pump belt

Adjust or replace.

Not enough coolant Check coolant level and add as necessary.

Faulty thermostat Replace.

Faulty water pump Replace.

Dirty or bent radiator fins Clean or remedy.

Coolant leakage on cooling system Repair.

Clogged radiator Check and replace radiator as necessary.

Faulty radiator cap Replace.

Improper ignition timing Adjust.

Dragging brakes Adjust brake.

Slipping clutch Adjust or replace.

Poor charge battery Check and replace as necessary.

Poor generation generator Check and repair.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan relay No.2 and/or

No.3 faulty Check and replace as necessary.

Radiator fan motor faulty Check and replace as necessary.

ECM faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

Equipped with too much electric load

part(s) Dismount.

Engine overheats

(Radiator fan does not

operate) Fuse blown

Check 30 A fuse of relay/fuse box and check

for short circuit to ground.

Radiator cooling fan relay No.1 faulty Check and replace as necessary.

ECT sensor faulty Check and replace as necessary.

Radiator cooling fan motor faulty Check and replace as necessary.

Wiring or grounding faulty Repair as necessary.

ECM faulty Check and replace as necessary.

Page 369 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-6

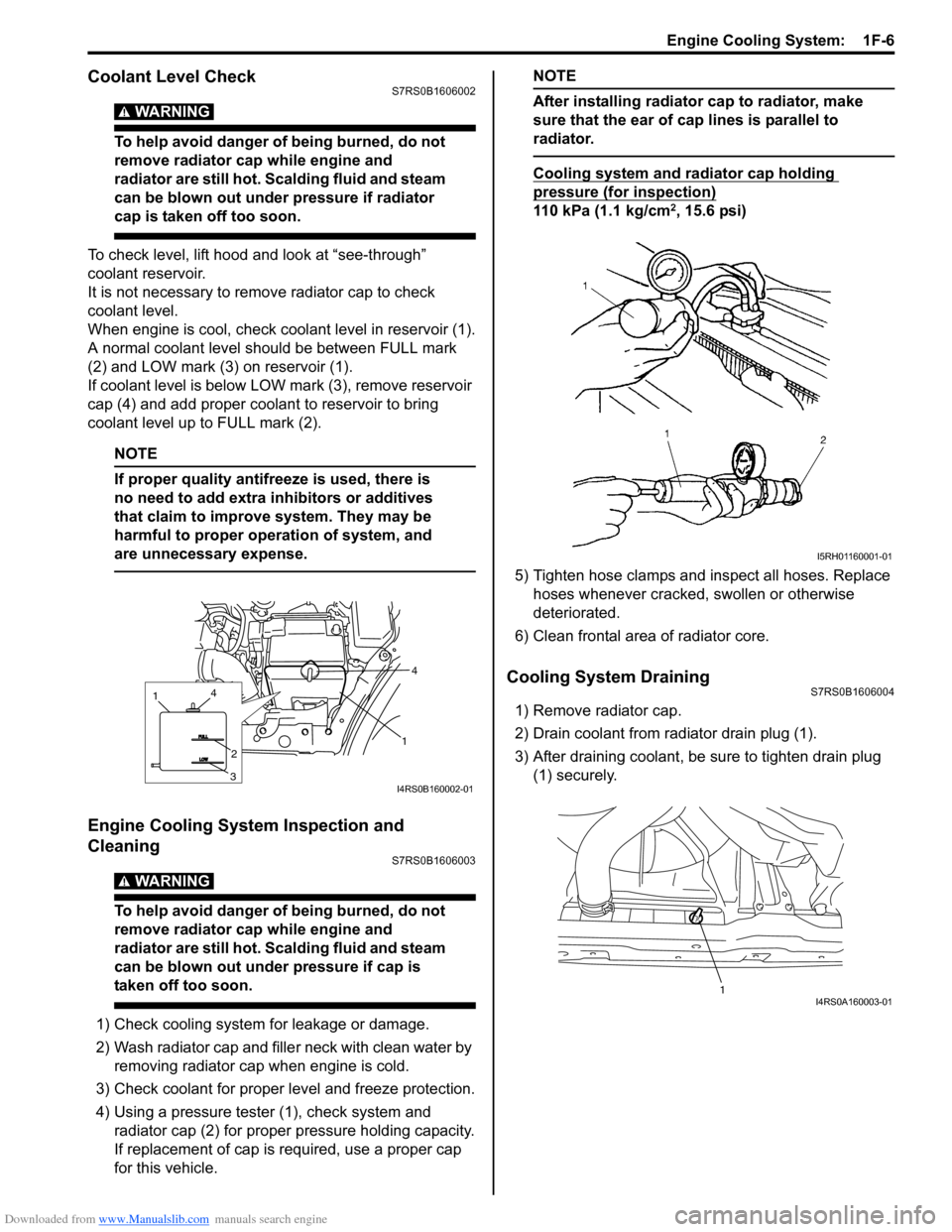

Coolant Level CheckS7RS0B1606002

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if radiator

cap is taken off too soon.

To check level, lift hood and look at “see-through”

coolant reservoir.

It is not necessary to remove radiator cap to check

coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between FULL mark

(2) and LOW mark (3) on reservoir (1).

If coolant level is below LOW mark (3), remove reservoir

cap (4) and add proper coolant to reservoir to bring

coolant level up to FULL mark (2).

NOTE

If proper quality antifreeze is used, there is

no need to add extra inhibitors or additives

that claim to improve system. They may be

harmful to proper operation of system, and

are unnecessary expense.

Engine Cooling System Inspection and

Cleaning

S7RS0B1606003

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

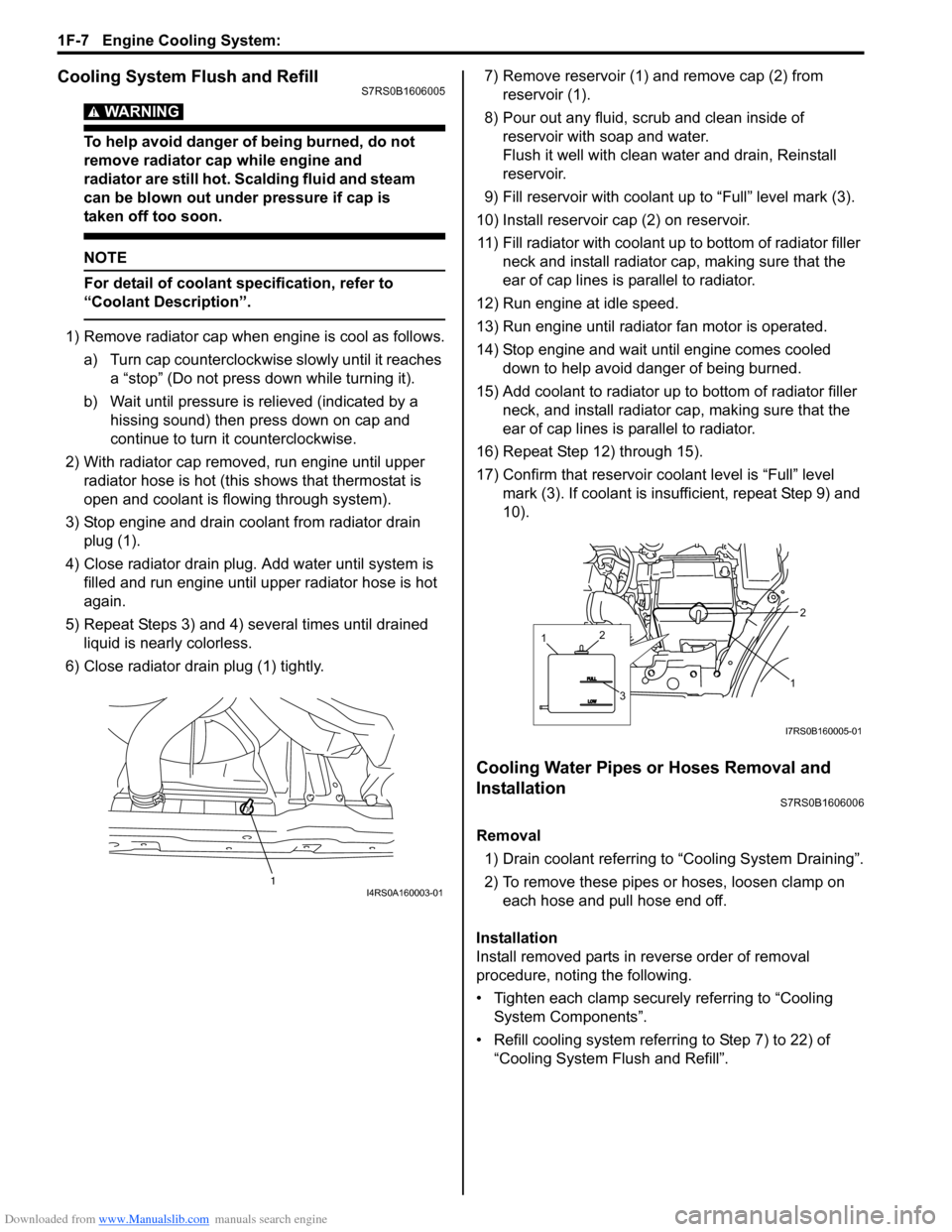

1) Check cooling system for leakage or damage.

2) Wash radiator cap and fille r neck with clean water by

removing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

4) Using a pressure tester (1), check system and radiator cap (2) for proper pressure holding capacity.

If replacement of cap is required, use a proper cap

for this vehicle.

NOTE

After installing radiator cap to radiator, make

sure that the ear of cap lines is parallel to

radiator.

Cooling system and radiator cap holding

pressure (for inspection)

110 kPa (1.1 kg/cm2, 15.6 psi)

5) Tighten hose clamps and inspect all hoses. Replace hoses whenever cracked, swollen or otherwise

deteriorated.

6) Clean frontal area of radiator core.

Cooling System DrainingS7RS0B1606004

1) Remove radiator cap.

2) Drain coolant from radiator drain plug (1).

3) After draining coolant, be sure to tighten drain plug (1) securely.

1

4

1

3

2

4

I4RS0B160002-01

I5RH01160001-01

1I4RS0A160003-01

Page 370 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-7 Engine Cooling System:

Cooling System Flush and RefillS7RS0B1606005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

NOTE

For detail of coolant specification, refer to

“Coolant Description”.

1) Remove radiator cap when engine is cool as follows.a) Turn cap counterclockwise slowly until it reaches a “stop” (Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a hissing sound) then press down on cap and

continue to turn it counterclockwise.

2) With radiator cap removed, run engine until upper radiator hose is hot (this shows that thermostat is

open and coolant is flowing through system).

3) Stop engine and drain coolant from radiator drain plug (1).

4) Close radiator drain plug. Add water until system is filled and run engine until up per radiator hose is hot

again.

5) Repeat Steps 3) and 4) several times until drained liquid is nearly colorless.

6) Close radiator drain plug (1) tightly. 7) Remove reservoir (1) and remove cap (2) from

reservoir (1).

8) Pour out any fluid, scrub and clean inside of reservoir with soap and water.

Flush it well with clean water and drain, Reinstall

reservoir.

9) Fill reservoir with coolant up to “Full” level mark (3).

10) Install reservoir cap (2) on reservoir. 11) Fill radiator with coolant up to bottom of radiator filler neck and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

12) Run engine at idle speed.

13) Run engine until radiator fan motor is operated.

14) Stop engine and wait until engine comes cooled down to help avoid danger of being burned.

15) Add coolant to radiator up to bottom of radiator filler

neck, and install radiator ca p, making sure that the

ear of cap lines is parallel to radiator.

16) Repeat Step 12) through 15).

17) Confirm that reservoir cool ant level is “Full” level

mark (3). If coolant is insu fficient, repeat Step 9) and

10).

Cooling Water Pipes or Hoses Removal and

Installation

S7RS0B1606006

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) To remove these pipes or hoses, loosen clamp on each hose and pull hose end off.

Installation

Install removed parts in reverse order of removal

procedure, noting the following.

• Tighten each clamp securely referring to “Cooling System Components”.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

1I4RS0A160003-01

1

2

1

3

2

I7RS0B160005-01