crankshaft cover SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

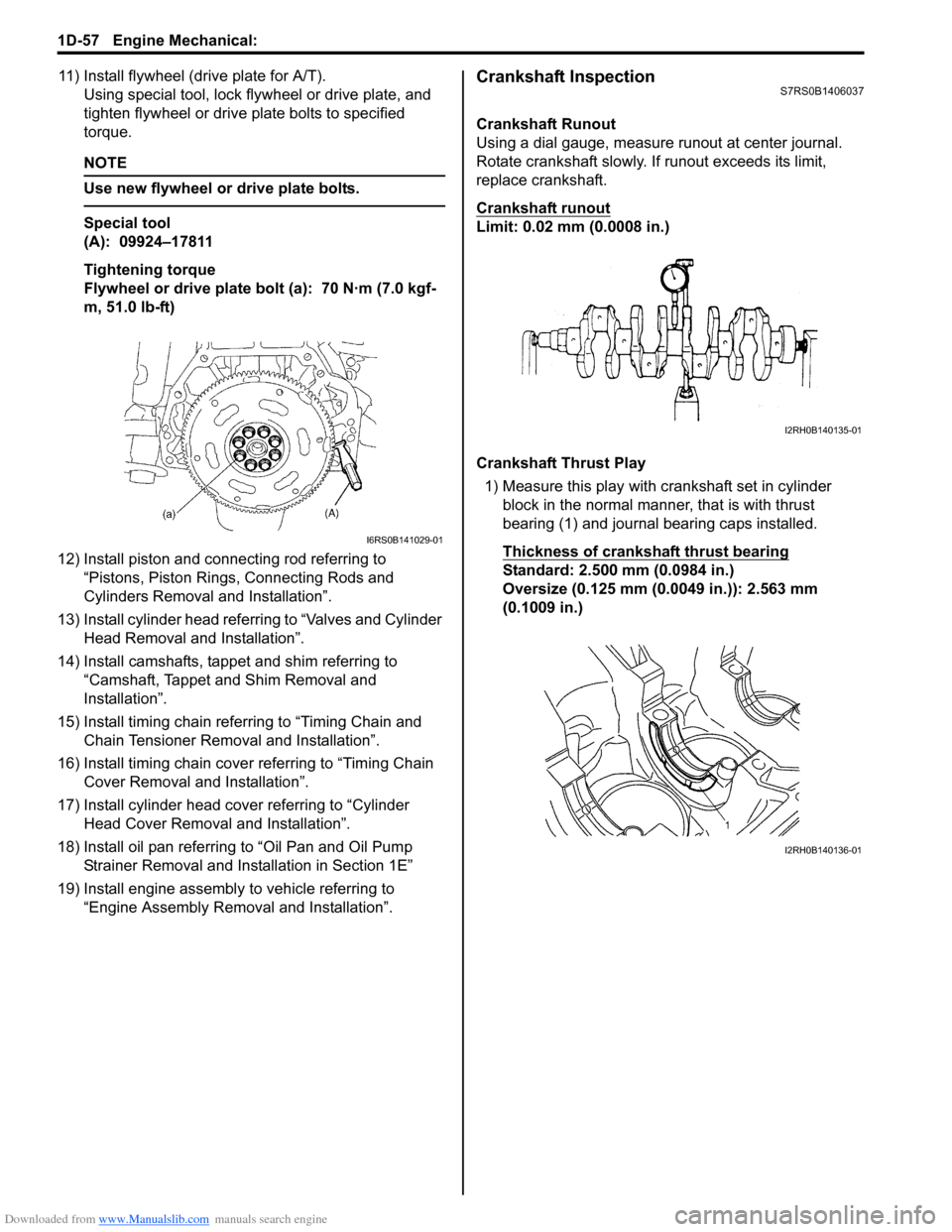

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

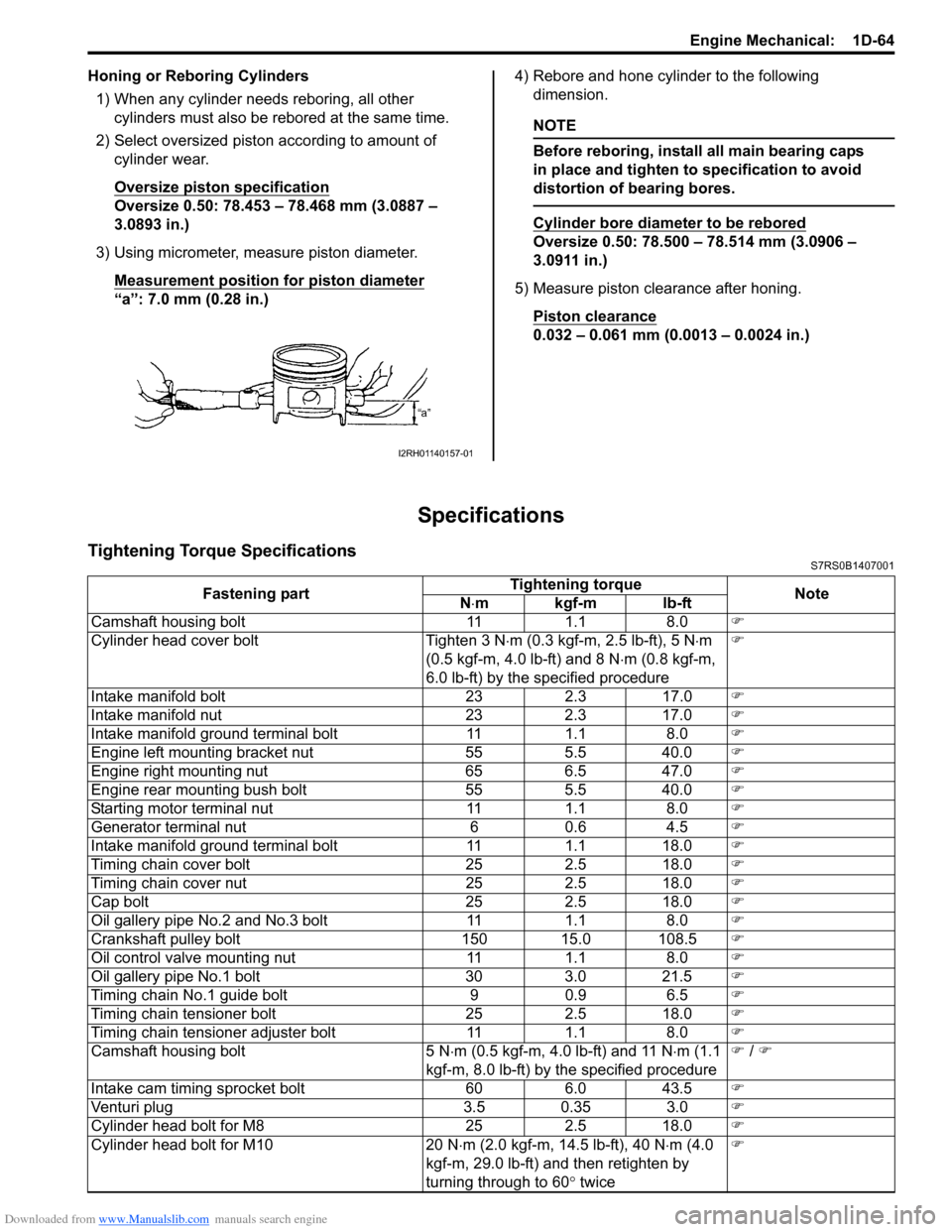

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 349 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-64

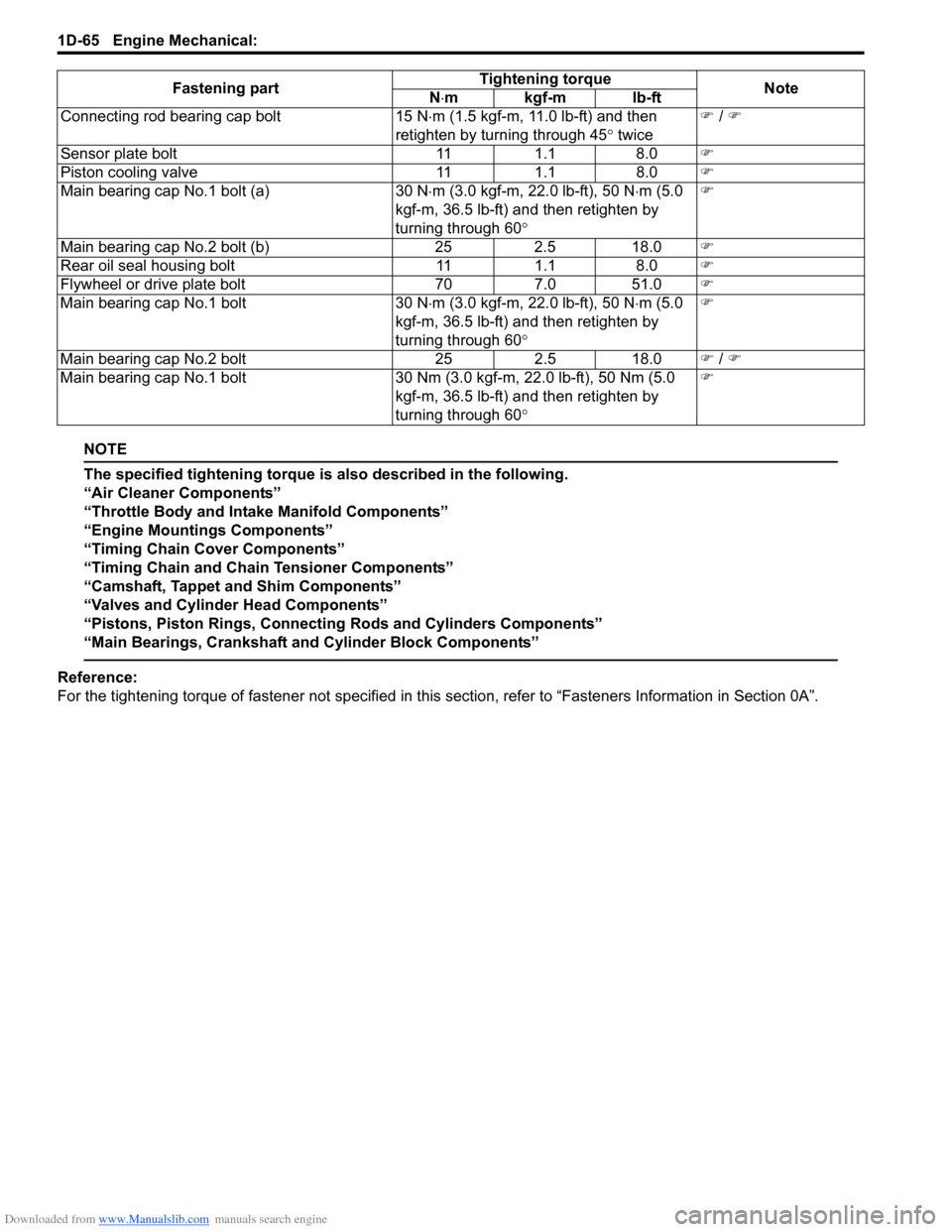

Honing or Reboring Cylinders1) When any cylinder needs reboring, all other cylinders must also be rebored at the same time.

2) Select oversized piston according to amount of cylinder wear.

Oversize piston specification

Oversize 0.50: 78.453 – 78.468 mm (3.0887 –

3.0893 in.)

3) Using micrometer, measure piston diameter. Measurement position for piston diameter

“a”: 7.0 mm (0.28 in.) 4) Rebore and hone cylinder to the following

dimension.

NOTE

Before reboring, install all main bearing caps

in place and tighten to specification to avoid

distortion of bearing bores.

Cylinder bore diameter to be rebored

Oversize 0.50: 78.500 – 78.514 mm (3.0906 –

3.0911 in.)

5) Measure piston clearance after honing. Piston clearance

0.032 – 0.061 mm (0.0013 – 0.0024 in.)

Specifications

Tightening Torque SpecificationsS7RS0B1407001

I2RH01140157-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Camshaft housing bolt 11 1.1 8.0 �)

Cylinder head cover bolt Tighten 3 N ⋅m (0.3 kgf-m, 2.5 lb-ft), 5 N ⋅m

(0.5 kgf-m, 4.0 lb-ft) and 8 N ⋅m (0.8 kgf-m,

6.0 lb-ft) by the specified procedure �)

Intake manifold bolt 23 2.3 17.0 �)

Intake manifold nut 23 2.3 17.0 �)

Intake manifold ground terminal bolt 11 1.1 8.0 �)

Engine left mounting bracket nut 55 5.5 40.0 �)

Engine right mounting nut 65 6.5 47.0 �)

Engine rear mounting bush bolt 55 5.5 40.0 �)

Starting motor terminal nut 11 1.1 8.0 �)

Generator terminal nut 6 0.6 4.5 �)

Intake manifold ground terminal bolt 11 1.1 18.0 �)

Timing chain cover bolt 25 2.5 18.0 �)

Timing chain cover nut 25 2.5 18.0 �)

Cap bolt 25 2.5 18.0 �)

Oil gallery pipe No.2 and No.3 bolt 11 1.1 8.0 �)

Crankshaft pulley bolt 150 15.0 108.5 �)

Oil control valve mounting nut 11 1.1 8.0 �)

Oil gallery pipe No.1 bolt 30 3.0 21.5 �)

Timing chain No.1 guide bolt 9 0.9 6.5 �)

Timing chain tensioner bolt 25 2.5 18.0 �)

Timing chain tensioner adjuster bolt 11 1.1 8.0 �)

Camshaft housing bolt 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft) and 11 N ⋅m (1.1

kgf-m, 8.0 lb-ft) by the specified procedure �)

/ �)

Intake cam timing sprocket bolt 60 6.0 43.5 �)

Venturi plug 3.5 0.35 3.0 �)

Cylinder head bolt for M8 25 2.5 18.0 �)

Cylinder head bolt for M10 20 N ⋅m (2.0 kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0

kgf-m, 29.0 lb-ft) and then retighten by

turning through to 60 ° twice �)

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 351 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-66

Special Tools and Equipment

Recommended Service MaterialS7RS0B1408001

NOTE

Required service material is also described in the following.

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

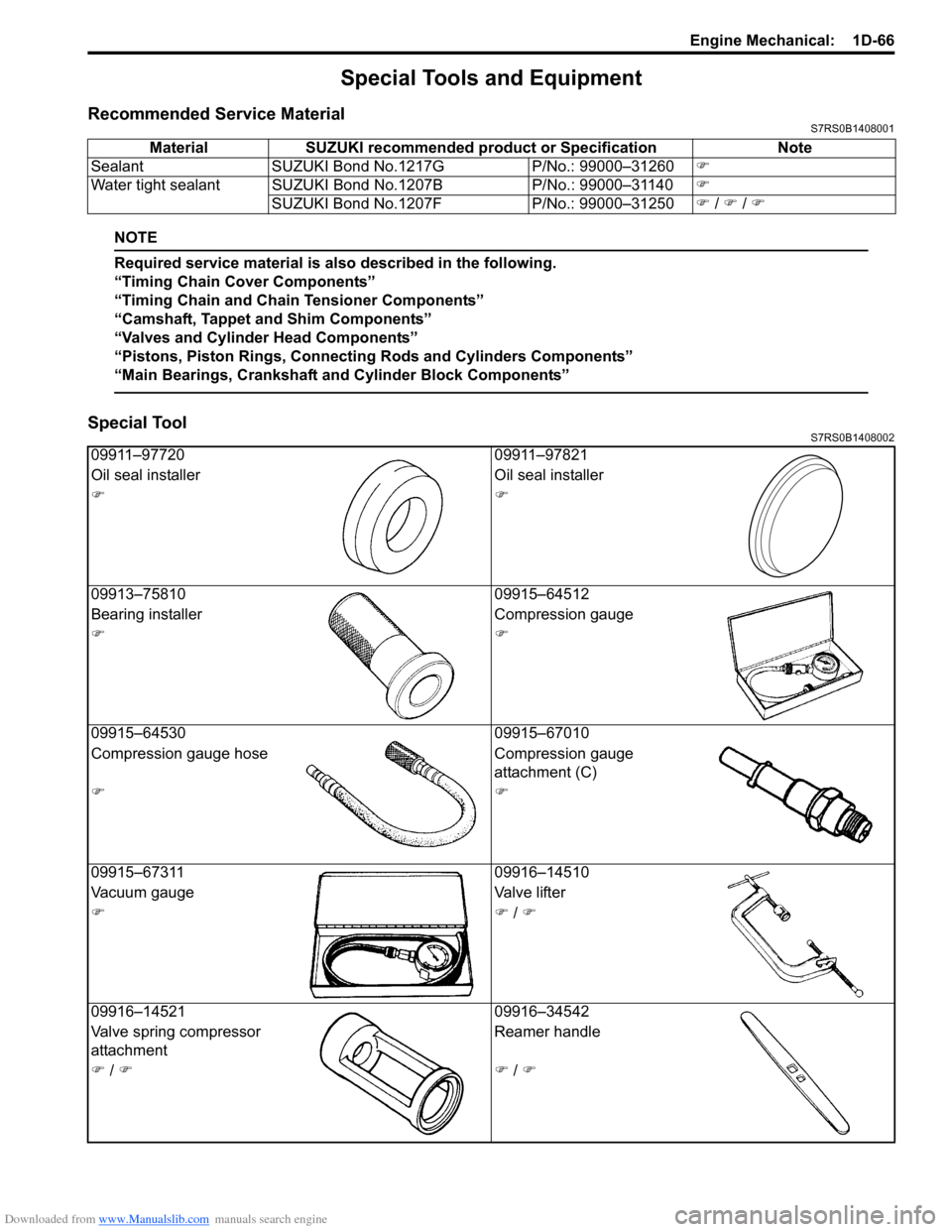

Special ToolS7RS0B1408002

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

Water tight sealant SUZUKI Bond No.1207B P/No.: 99000–31140�)

SUZUKI Bond No.1207F P/No.: 99000–31250�) / �) / �)

09911–97720 09911–97821

Oil seal installer Oil seal installer

�)�)

09913–75810 09915–64512

Bearing installer Compression gauge

�)�)

09915–64530 09915–67010

Compression gauge hose Compression gauge

attachment (C)

�)�)

09915–67311 09916–14510

Vacuum gauge Valve lifter

�)�) / �)

09916–14521 09916–34542

Valve spring compressor

attachment Reamer handle

�) / �)�) / �)

Page 853 of 1496

Downloaded from www.Manualslib.com manuals search engine Clutch: 5C-1

Transmission / Transaxle

Clutch

General Description

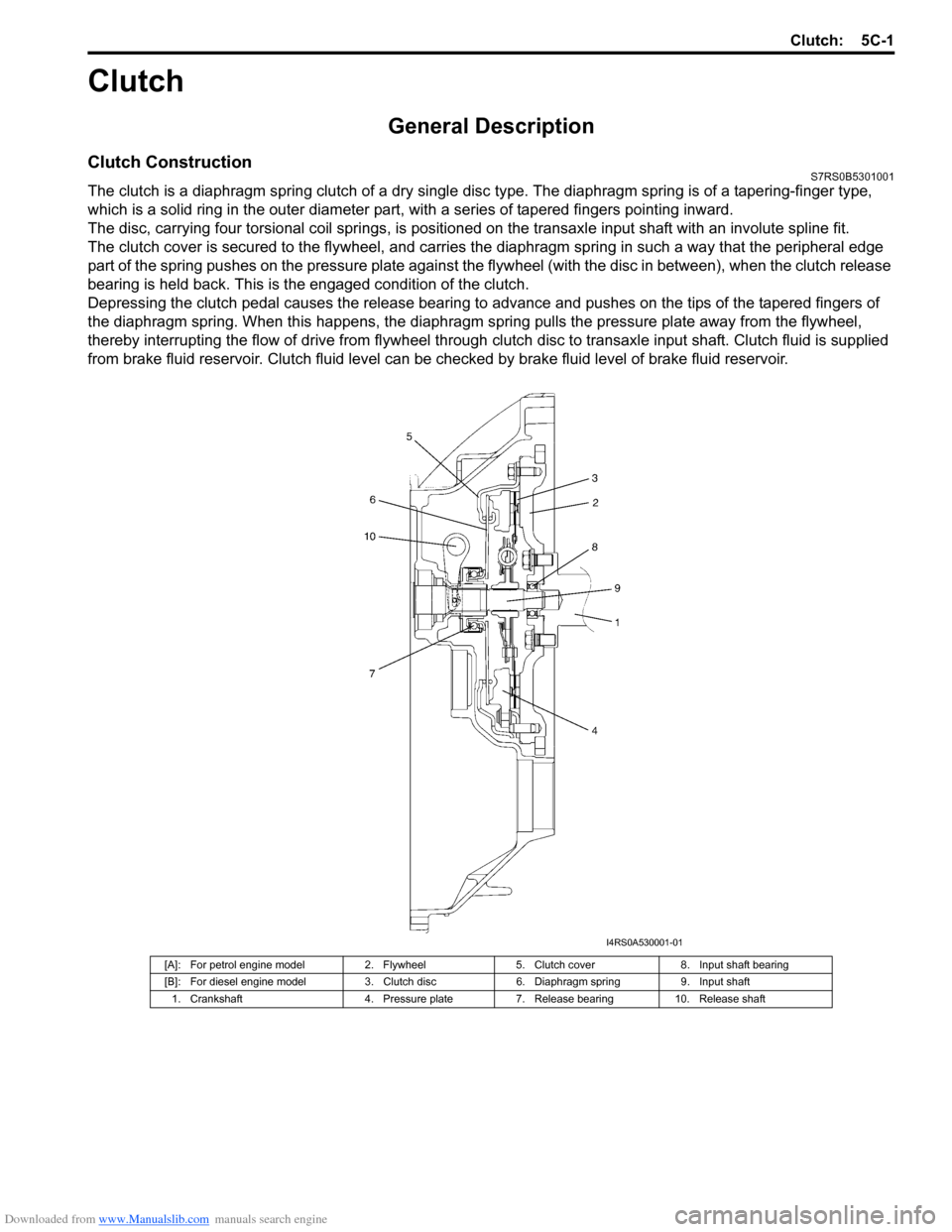

Clutch ConstructionS7RS0B5301001

The clutch is a diaphragm spring clutch of a dry single disc type. The diaphragm spring is of a tapering-finger type,

which is a solid ring in the outer diameter part, with a series of tapered fingers pointing inward.

The disc, carrying four torsional coil springs, is positione d on the transaxle input shaft with an involute spline fit.

The clutch cover is secured to the flywheel, and carries the diaphragm spring in such a way that the peripheral edge

part of the spring pushes on the pressure plate against the flywheel (with the disc in between), when the clutch release

bearing is held back. This is the engaged condition of the clutch.

Depressing the clutch pedal c auses the release bearing to advance and pushes on the tips of the tapered fingers of

the diaphragm spring. When this happens, the diaphragm sp ring pulls the pressure plate away from the flywheel,

thereby interrupting the flow of drive from flywheel through clutch disc to transaxle input shaft. Clutch fluid is supplied

from brake fluid reservoir. Clutch fluid level can be checked by brake fluid level of brake fluid reservoir.

[A]: For petrol engine model2. Flywheel5. Clutch cover 8. Input shaft bearing

[B]: For diesel engine model 3. Clutch disc6. Diaphragm spring 9. Input shaft

1. Crankshaft 4. Pressure plate7. Release bearing 10. Release shaft

I4RS0A530001-01

Page 862 of 1496

Downloaded from www.Manualslib.com manuals search engine 5C-10 Clutch:

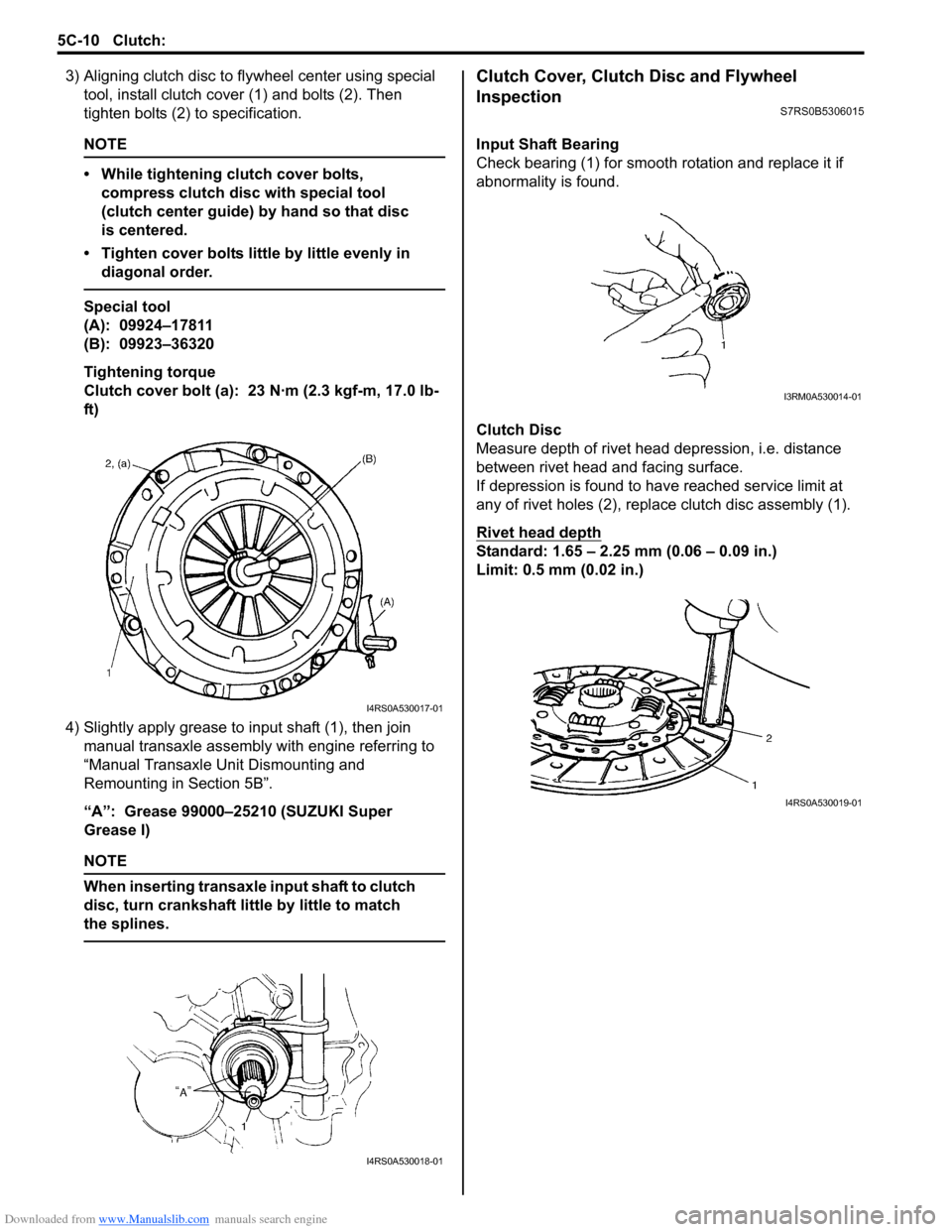

3) Aligning clutch disc to flywheel center using special

tool, install clutch cover (1) and bolts (2). Then

tighten bolts (2) to specification.

NOTE

• While tightening clutch cover bolts, compress clutch disc with special tool

(clutch center guide) by hand so that disc

is centered.

• Tighten cover bolts little by little evenly in diagonal order.

Special tool

(A): 09924–17811

(B): 09923–36320

Tightening torque

Clutch cover bolt (a): 23 N·m (2.3 kgf-m, 17.0 lb-

ft)

4) Slightly apply grease to input shaft (1), then join manual transaxle assembly with engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B”.

“A”: Grease 99000–25210 (SUZUKI Super

Grease I)

NOTE

When inserting transaxle input shaft to clutch

disc, turn crankshaft li ttle by little to match

the splines.

Clutch Cover, Clutch Disc and Flywheel

Inspection

S7RS0B5306015

Input Shaft Bearing

Check bearing (1) for smooth ro tation and replace it if

abnormality is found.

Clutch Disc

Measure depth of rivet head depression, i.e. distance

between rivet head and facing surface.

If depression is found to hav e reached service limit at

any of rivet holes (2), repl ace clutch disc assembly (1).

Rivet head depth

Standard: 1.65 – 2.25 mm (0.06 – 0.09 in.)

Limit: 0.5 mm (0.02 in.)

I4RS0A530017-01

I4RS0A530018-01

I3RM0A530014-01

I4RS0A530019-01