cylinder bore SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 513 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-15

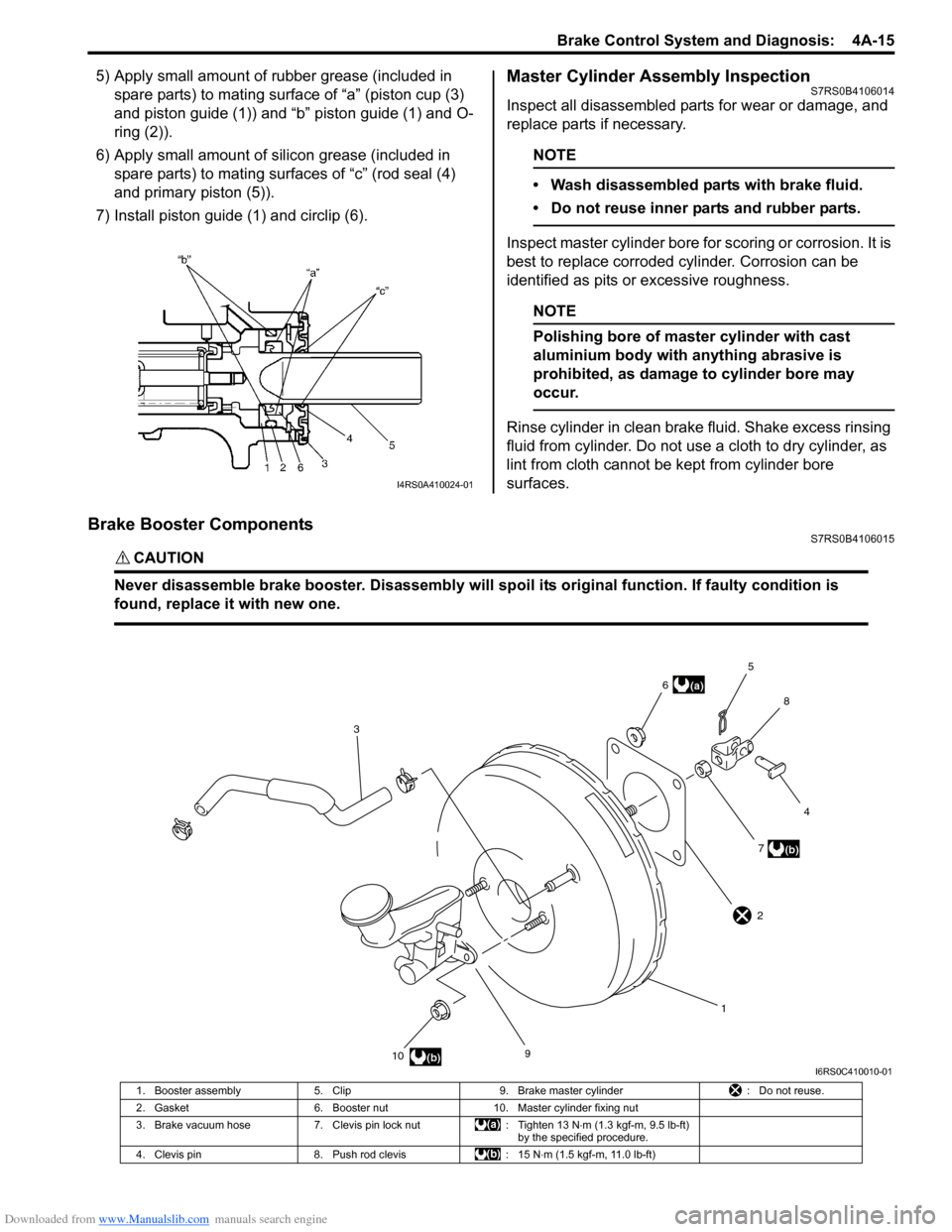

5) Apply small amount of rubber grease (included in spare parts) to mating surface of “a” (piston cup (3)

and piston guide (1)) and “b” piston guide (1) and O-

ring (2)).

6) Apply small amount of s ilicon grease (included in

spare parts) to mating surfaces of “c” (rod seal (4)

and primary piston (5)).

7) Install piston guide (1) and circlip (6).Master Cylinder Assembly InspectionS7RS0B4106014

Inspect all disassembled parts for wear or damage, and

replace parts if necessary.

NOTE

• Wash disassembled parts with brake fluid.

• Do not reuse inner parts and rubber parts.

Inspect master cylinder bore for scoring or corrosion. It is

best to replace corroded cylinder. Corrosion can be

identified as pits or excessive roughness.

NOTE

Polishing bore of master cylinder with cast

aluminium body with anything abrasive is

prohibited, as damage to cylinder bore may

occur.

Rinse cylinder in clean brake fluid. Shake excess rinsing

fluid from cylinder. Do not use a cloth to dry cylinder, as

lint from cloth cannot be kept from cylinder bore

surfaces.

Brake Booster ComponentsS7RS0B4106015

CAUTION!

Never disassemble brake booster. Disassembly will spoi l its original function. If faulty condition is

found, replace it with new one.

I4RS0A410024-01

9

10 17

4

8

5

6

3

(b)

(a)

(b)

2

I6RS0C410010-01

1. Booster assembly 5. Clip 9. Brake master cylinder : Do not reuse.

2. Gasket 6. Booster nut 10. Master cylinder fixing nut

3. Brake vacuum hose 7. Clevis pin lock nut : Tighten 13 N⋅m (1.3 kgf-m, 9.5 lb-ft)

by the specified procedure.

4. Clevis pin 8. Push rod clevis : 15 N⋅m (1.5 kgf-m, 11.0 lb-ft)

Page 520 of 1496

Downloaded from www.Manualslib.com manuals search engine 4B-4 Front Brakes:

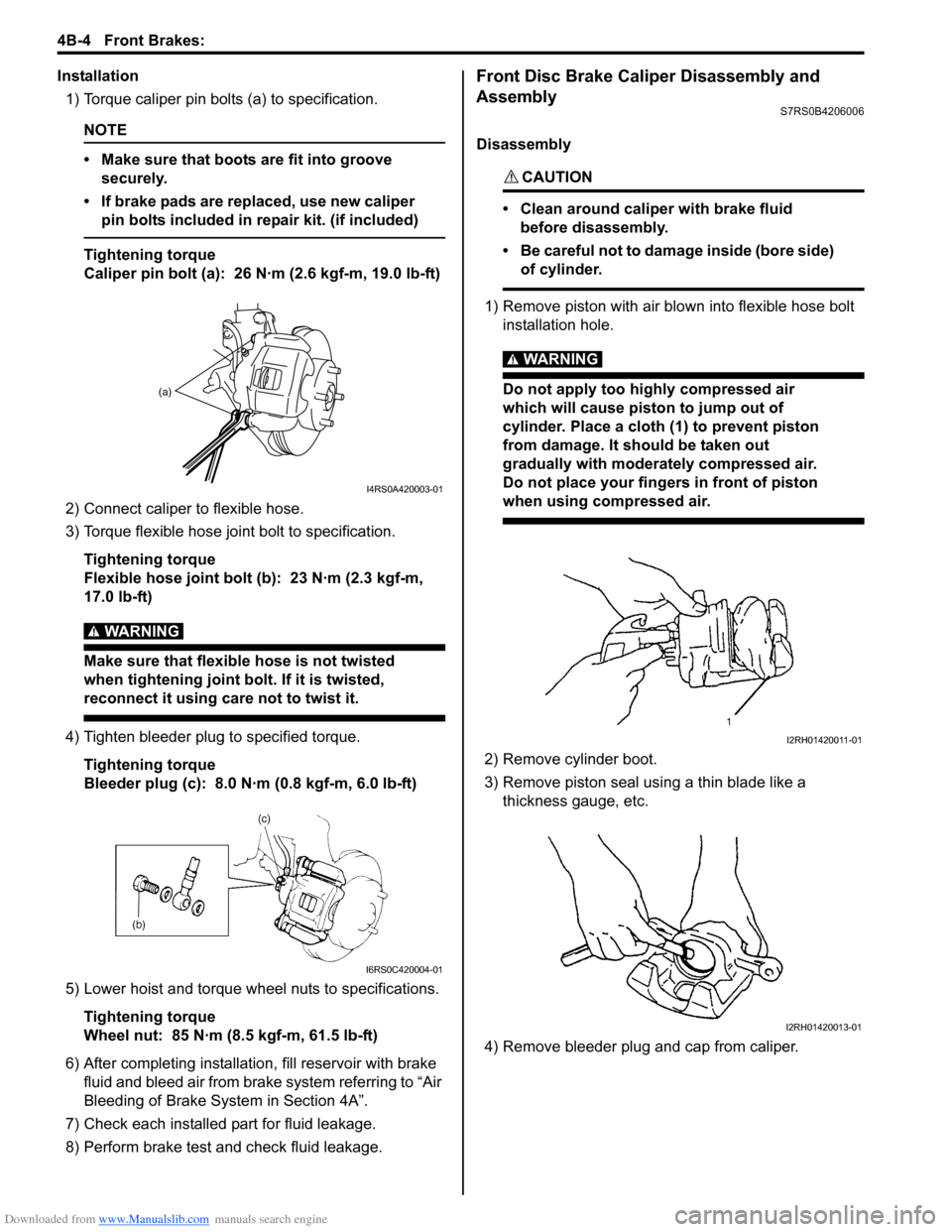

Installation1) Torque caliper pin bolts (a) to specification.

NOTE

• Make sure that boots are fit into groove securely.

• If brake pads are replaced, use new caliper pin bolts included in repair kit. (if included)

Tightening torque

Caliper pin bolt (a): 26 N·m (2.6 kgf-m, 19.0 lb-ft)

2) Connect caliper to flexible hose.

3) Torque flexible hose jo int bolt to specification.

Tightening torque

Flexible hose joint bolt (b): 23 N·m (2.3 kgf-m,

17.0 lb-ft)

WARNING!

Make sure that flexible hose is not twisted

when tightening joint bolt. If it is twisted,

reconnect it using care not to twist it.

4) Tighten bleeder plug to specified torque. Tightening torque

Bleeder plug (c): 8.0 N·m (0.8 kgf-m, 6.0 lb-ft)

5) Lower hoist and torque wheel nuts to specifications. Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

6) After completing installation, fill reservoir with brake

fluid and bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

7) Check each installed part for fluid leakage.

8) Perform brake test and check fluid leakage.

Front Disc Brake Caliper Disassembly and

Assembly

S7RS0B4206006

Disassembly

CAUTION!

• Clean around caliper with brake fluid before disassembly.

• Be careful not to damage inside (bore side) of cylinder.

1) Remove piston with air blown into flexible hose bolt installation hole.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth (1) to prevent piston

from damage. It should be taken out

gradually with moderately compressed air.

Do not place your fingers in front of piston

when using compressed air.

2) Remove cylinder boot.

3) Remove piston seal using a thin blade like a thickness gauge, etc.

4) Remove bleeder plug and cap from caliper.

(a)

I4RS0A420003-01

I6RS0C420004-01

I2RH01420011-01

I2RH01420013-01

Page 530 of 1496

Downloaded from www.Manualslib.com manuals search engine 4C-6 Rear Brakes:

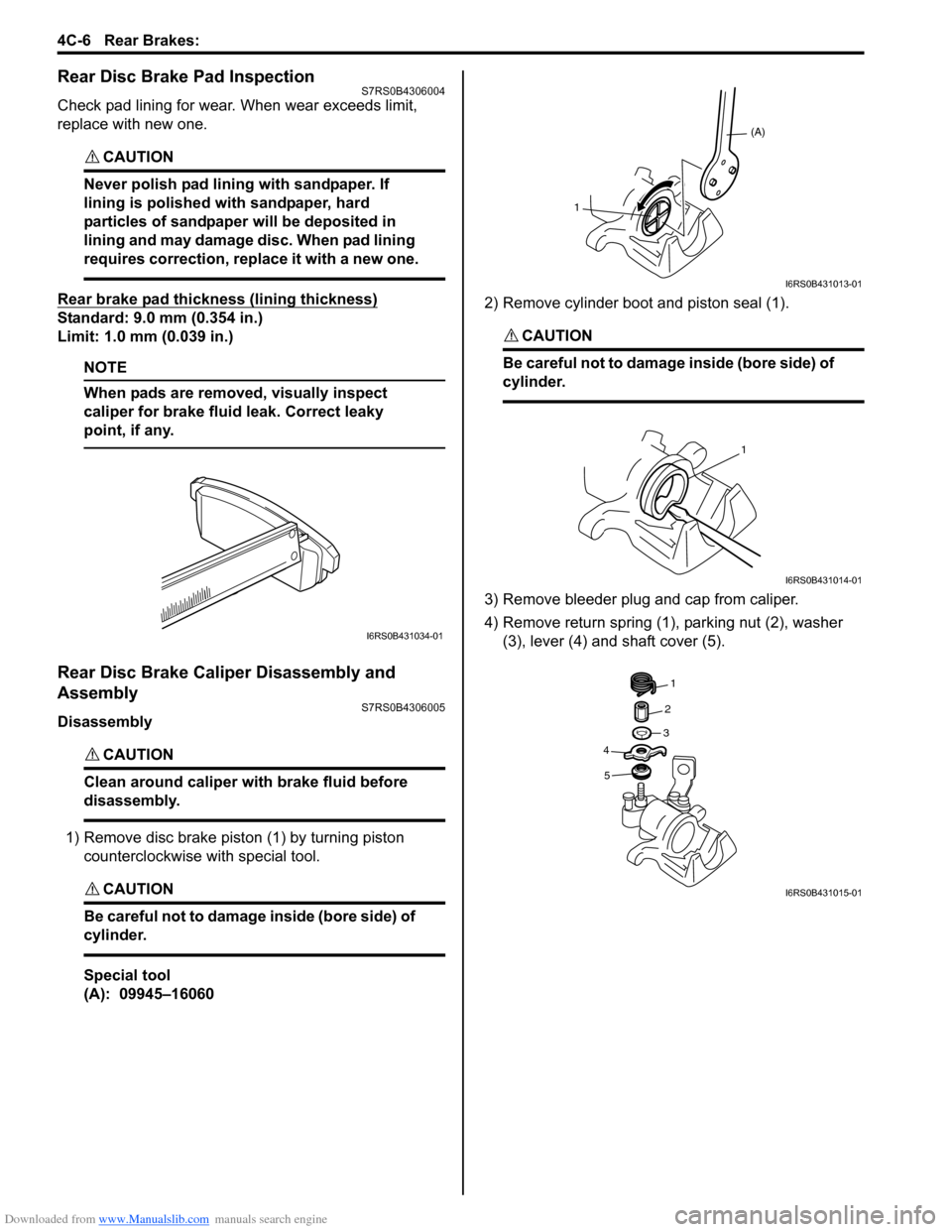

Rear Disc Brake Pad InspectionS7RS0B4306004

Check pad lining for wear. When wear exceeds limit,

replace with new one.

CAUTION!

Never polish pad lining with sandpaper. If

lining is polished with sandpaper, hard

particles of sandpaper will be deposited in

lining and may damage disc. When pad lining

requires correction, replace it with a new one.

Rear brake pad thickness (lining thickness)

Standard: 9.0 mm (0.354 in.)

Limit: 1.0 mm (0.039 in.)

NOTE

When pads are removed, visually inspect

caliper for brake fluid leak. Correct leaky

point, if any.

Rear Disc Brake Caliper Disassembly and

Assembly

S7RS0B4306005

Disassembly

CAUTION!

Clean around caliper with brake fluid before

disassembly.

1) Remove disc brake piston (1) by turning piston counterclockwise with special tool.

CAUTION!

Be careful not to damage inside (bore side) of

cylinder.

Special tool

(A): 09945–16060 2) Remove cylinder boot and piston seal (1).

CAUTION!

Be careful not to damage inside (bore side) of

cylinder.

3) Remove bleeder plug and cap from caliper.

4) Remove return spring (1), parking nut (2), washer

(3), lever (4) and shaft cover (5).

I6RS0B431034-01

(A)

1

I6RS0B431013-01

1

I6RS0B431014-01

1

2

3

4

5

I6RS0B431015-01