MOUNT SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

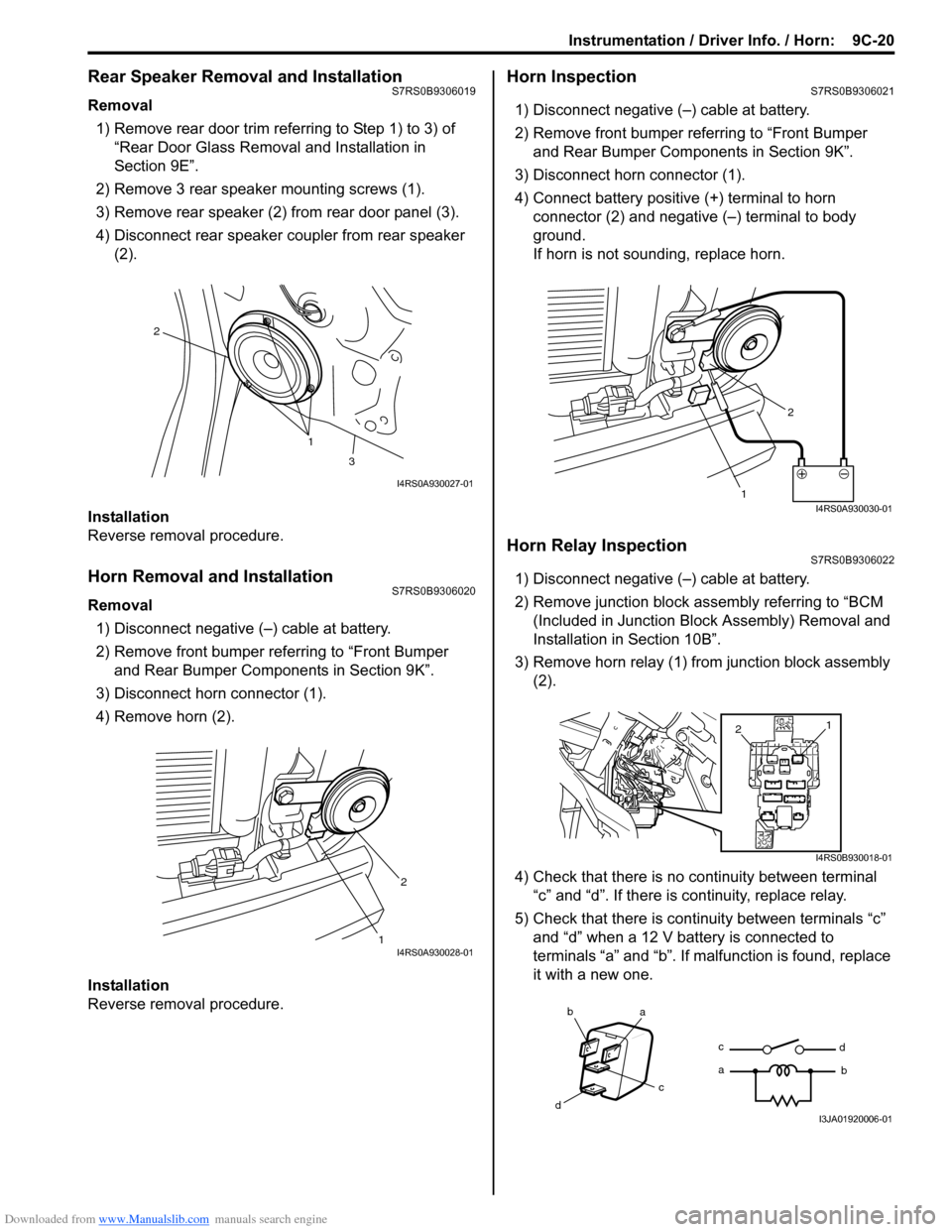

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

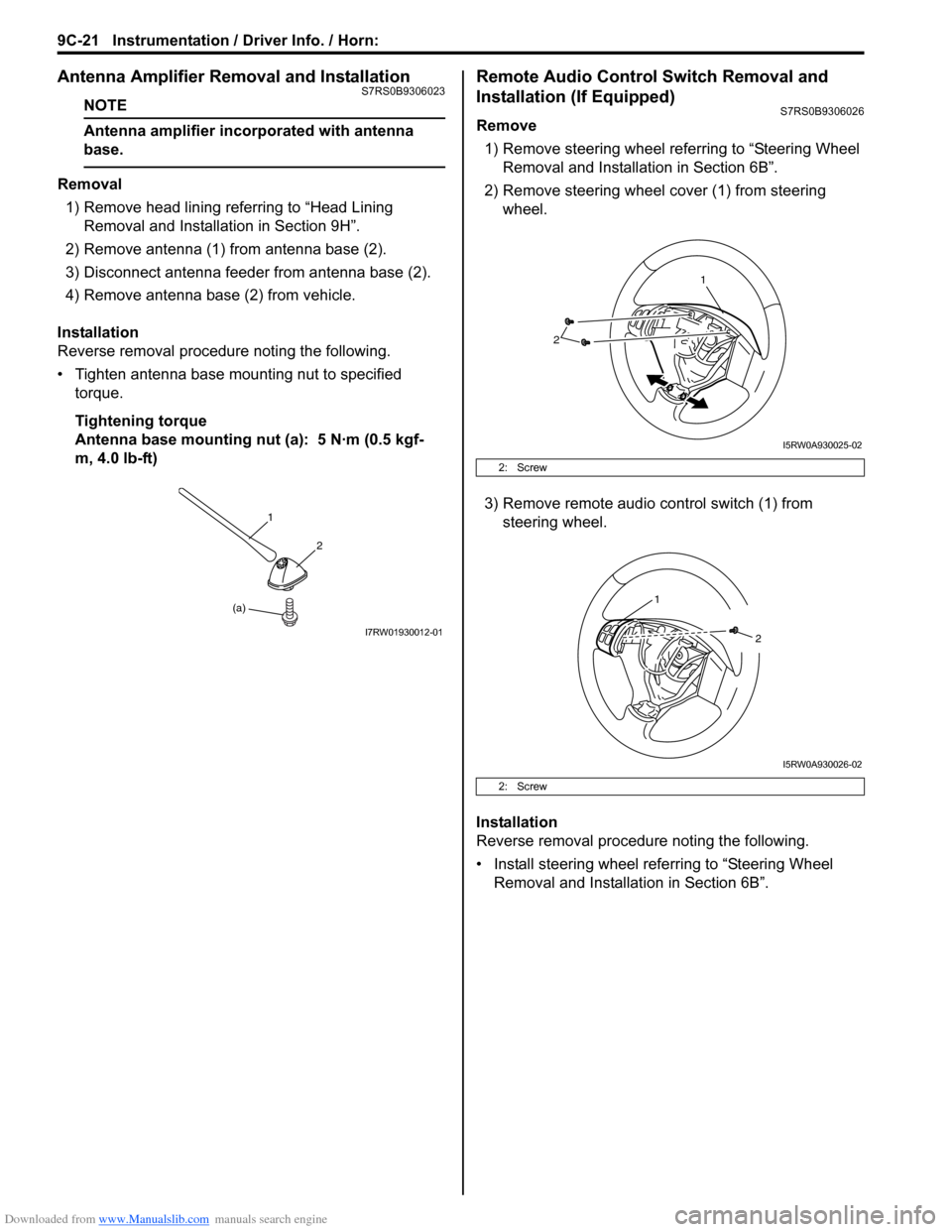

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01

Page 1316 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-21 Instrumentation / Driver Info. / Horn:

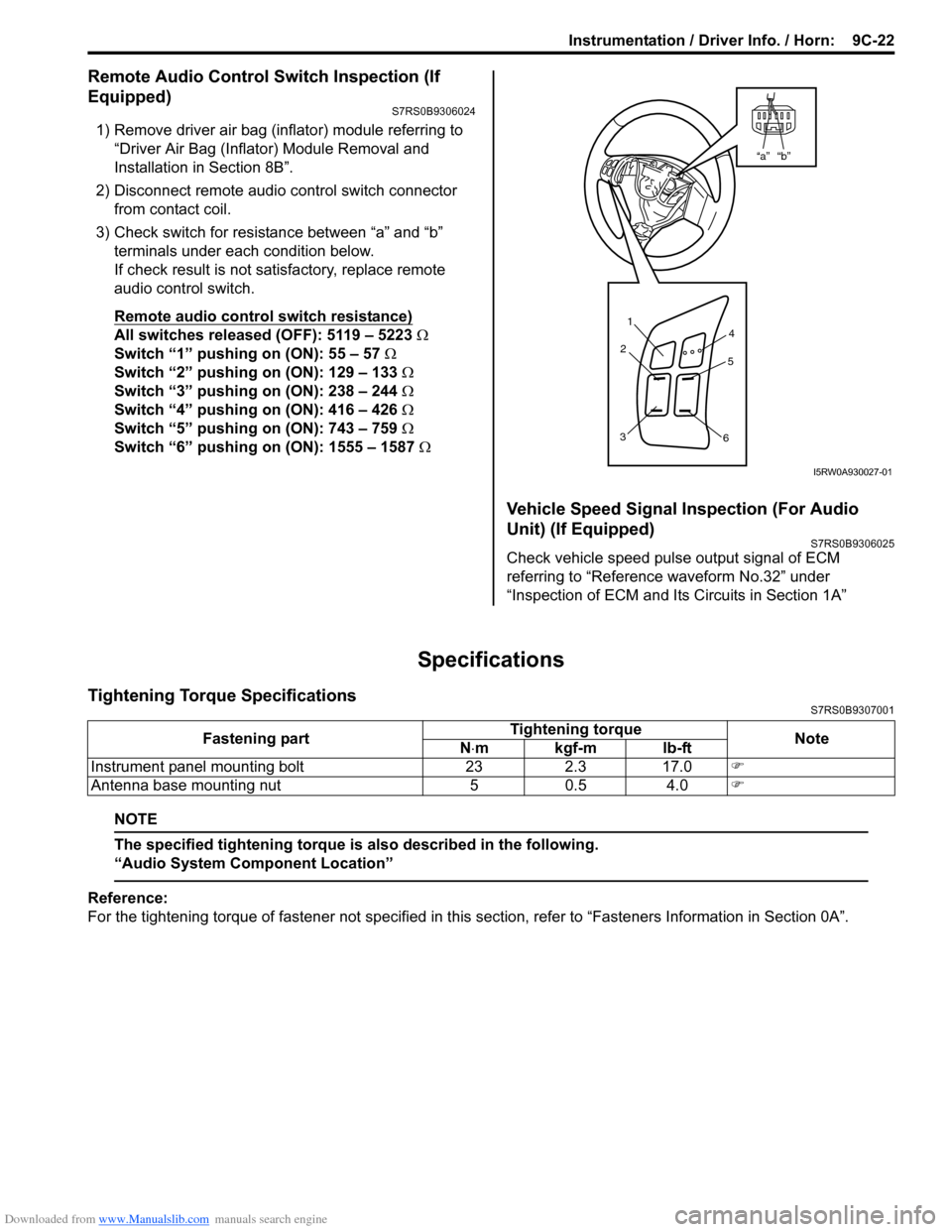

Antenna Amplifier Removal and InstallationS7RS0B9306023

NOTE

Antenna amplifier incorporated with antenna

base.

Removal1) Remove head lining referring to “Head Lining Removal and Installa tion in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting nut to specified torque.

Tightening torque

Antenna base mounting nut (a): 5 N·m (0.5 kgf-

m, 4.0 lb-ft)

Remote Audio Control Switch Removal and

Installation (If Equipped)

S7RS0B9306026

Remove

1) Remove steering wheel re ferring to “Steering Wheel

Removal and Installati on in Section 6B”.

2) Remove steering wheel cover (1) from steering wheel.

3) Remove remote audio control switch (1) from steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel Removal and Installati on in Section 6B”.

(a)1

2

I7RW01930012-01

2: Screw

2: Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1323 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-6

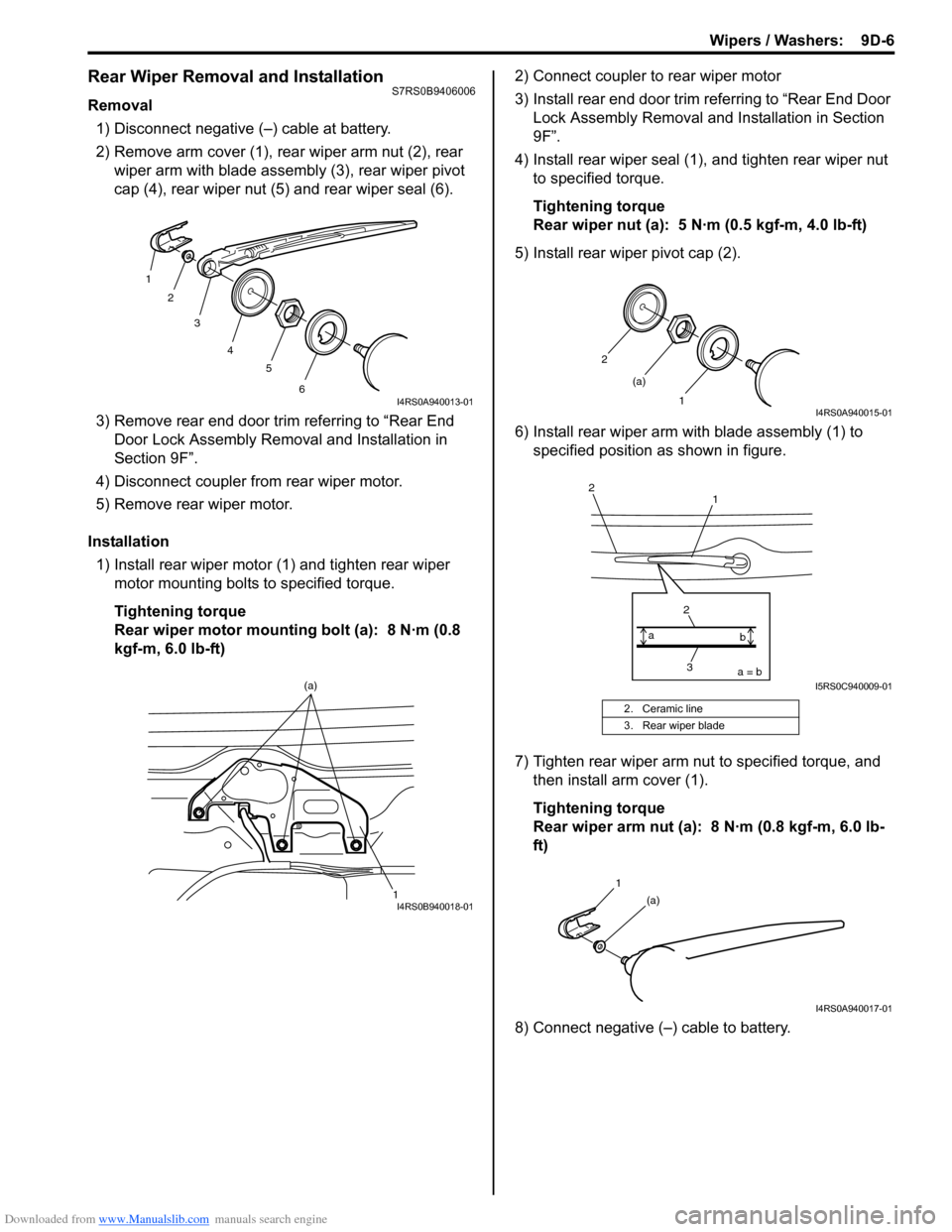

Rear Wiper Removal and InstallationS7RS0B9406006

Removal1) Disconnect negative (–) cable at battery.

2) Remove arm cover (1), rear wiper arm nut (2), rear wiper arm with blade assembly (3), rear wiper pivot

cap (4), rear wiper nut (5) and rear wiper seal (6).

3) Remove rear end door trim referring to “Rear End Door Lock Assembly Remo val and Installation in

Section 9F”.

4) Disconnect coupler from rear wiper motor.

5) Remove rear wiper motor.

Installation 1) Install rear wiper motor (1) and tighten rear wiper motor mounting bolts to specified torque.

Tightening torque

Rear wiper motor mounting bolt (a): 8 N·m (0.8

kgf-m, 6.0 lb-ft) 2) Connect coupler to rear wiper motor

3) Install rear end door trim referring to “Rear End Door

Lock Assembly Removal and Installation in Section

9F”.

4) Install rear wiper seal (1), and tighten rear wiper nut to specified torque.

Tightening torque

Rear wiper nut (a): 5 N·m (0.5 kgf-m, 4.0 lb-ft)

5) Install rear wiper pivot cap (2).

6) Install rear wiper arm with blade assembly (1) to specified position as shown in figure.

7) Tighten rear wiper arm nut to specified torque, and then install arm cover (1).

Tightening torque

Rear wiper arm nut (a): 8 N·m (0.8 kgf-m, 6.0 lb-

ft)

8) Connect negative (–) cable to battery.

1 2

3

4 5

6

I4RS0A940013-01

1

(a)I4RS0B940018-01

2. Ceramic line

3. Rear wiper blade

2

1

(a)

I4RS0A940015-01

1

2

3

2a = b

a

bI5RS0C940009-01

1

(a)

I4RS0A940017-01

Page 1327 of 1496

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-10

Rear Wiper Relay Removal and InstallationS7RS0B9406012

Removal1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

3) Remove rear wiper relay.

Installation

Reverse removal procedure for installation.

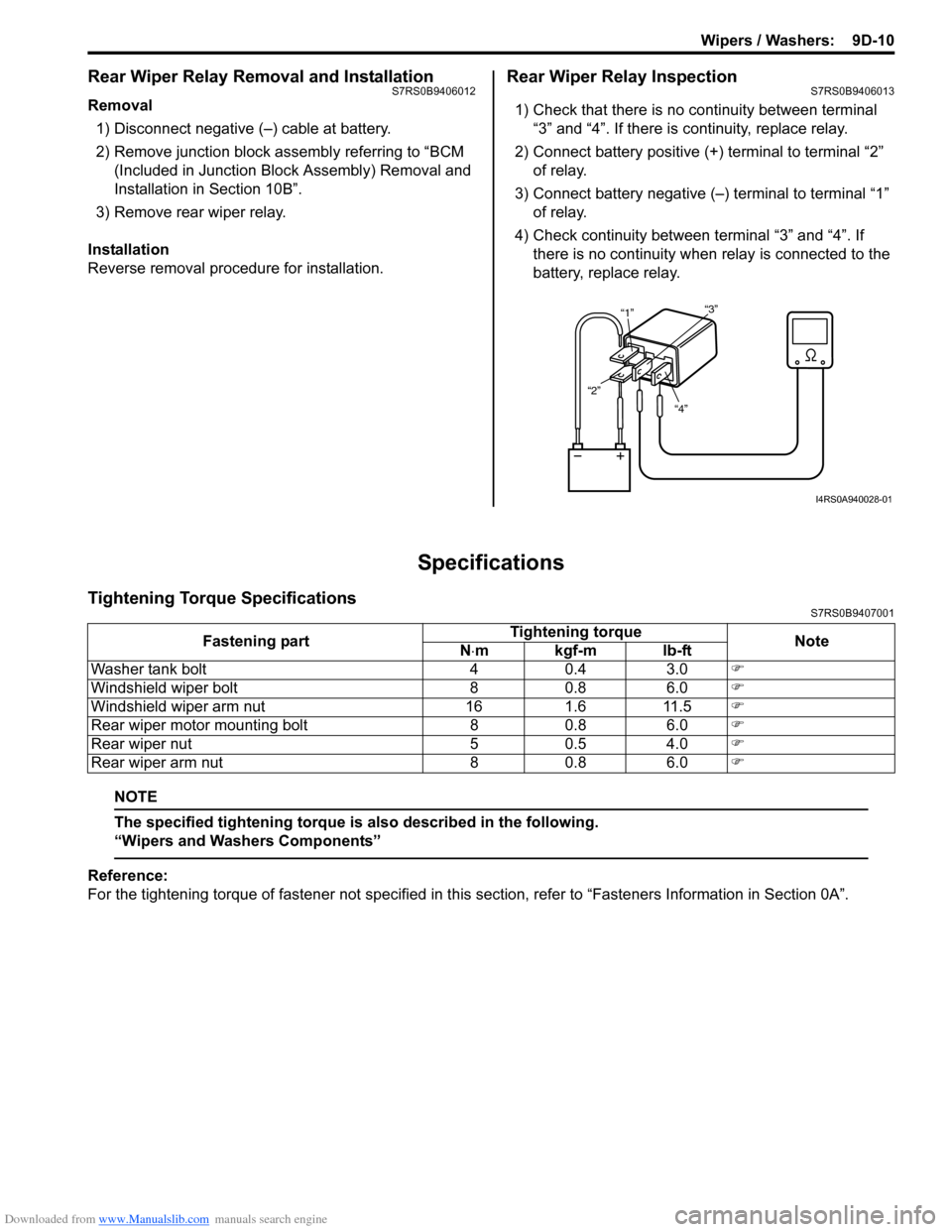

Rear Wiper Relay InspectionS7RS0B9406013

1) Check that there is no continuity between terminal “3” and “4”. If there is continuity, replace relay.

2) Connect battery positive (+ ) terminal to terminal “2”

of relay.

3) Connect battery negative (–) terminal to terminal “1” of relay.

4) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

Specifications

Tightening Torque SpecificationsS7RS0B9407001

NOTE

The specified tightening torque is also described in the following.

“Wipers and Washers Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“4”

“2” “1”

“3”

I4RS0A940028-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Washer tank bolt 4 0.4 3.0 �)

Windshield wiper bolt 8 0.8 6.0 �)

Windshield wiper arm nut 16 1.6 11.5 �)

Rear wiper motor mounting bolt 8 0.8 6.0 �)

Rear wiper nut 5 0.5 4.0 �)

Rear wiper arm nut 8 0.8 6.0 �)

Page 1333 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-6

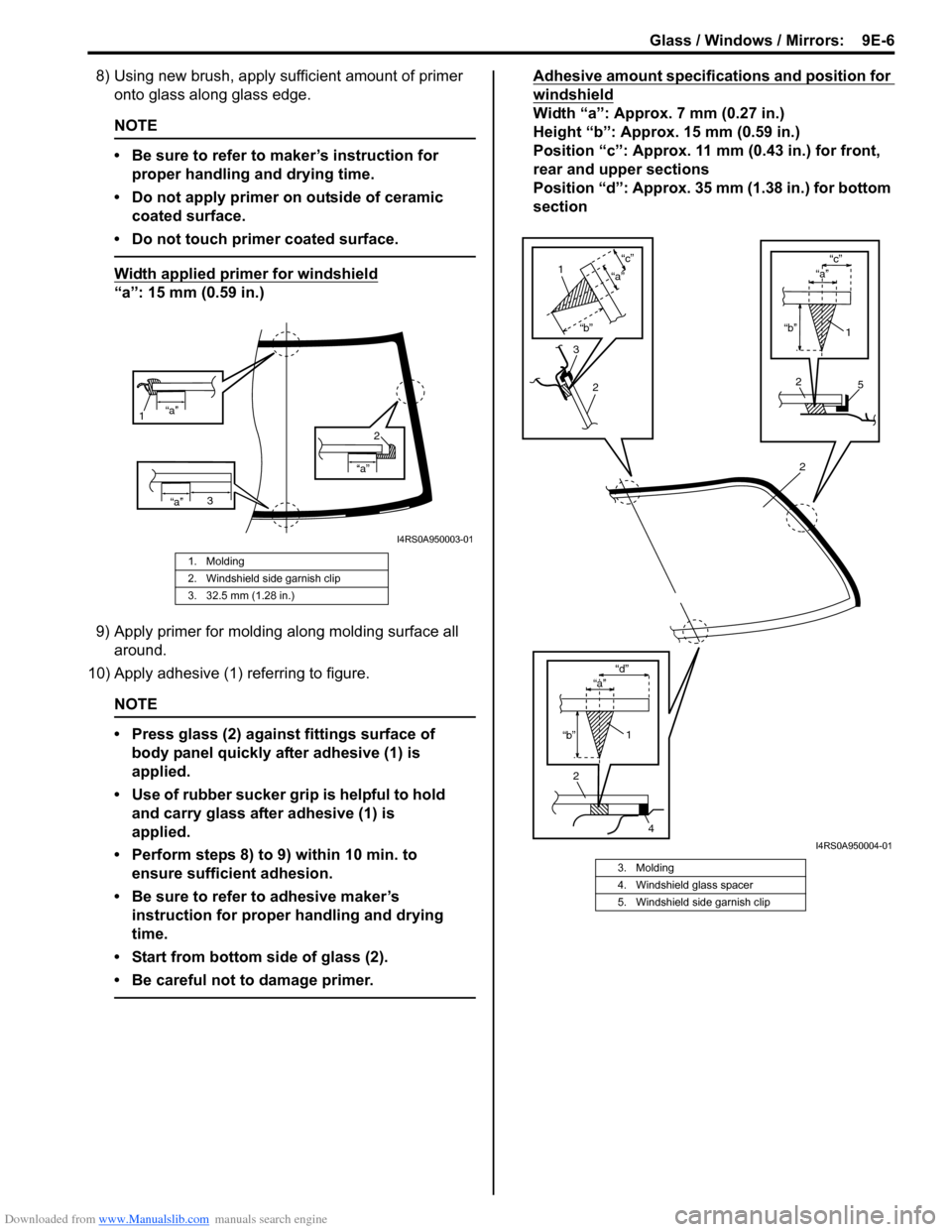

8) Using new brush, apply sufficient amount of primer onto glass along glass edge.

NOTE

• Be sure to refer to maker’s instruction for

proper handling and drying time.

• Do not apply primer on outside of ceramic coated surface.

• Do not touch primer coated surface.

Width applied primer for windshield

“a”: 15 mm (0.59 in.)

9) Apply primer for molding along molding surface all around.

10) Apply adhesive (1) referring to figure.

NOTE

• Press glass (2) against fittings surface of body panel quickly after adhesive (1) is

applied.

• Use of rubber sucker gr ip is helpful to hold

and carry glass after adhesive (1) is

applied.

• Perform steps 8) to 9) within 10 min. to ensure sufficient adhesion.

• Be sure to refer to adhesive maker’s instruction for proper handling and drying

time.

• Start from bottom side of glass (2).

• Be careful not to damage primer.

Adhesive amount specifications and position for

windshield

Width “a”: Approx. 7 mm (0.27 in.)

Height “b”: Approx. 15 mm (0.59 in.)

Position “c”: Approx. 11 mm (0.43 in.) for front,

rear and upper sections

Position “d”: Approx. 35 mm (1.38 in.) for bottom

section

1. Molding

2. Windshield side garnish clip

3. 32.5 mm (1.28 in.)

“a”

1

“a”

“a”

2

3

I4RS0A950003-01

3. Molding

4. Windshield glass spacer

5. Windshield side garnish clip

2

2

4

1

“b” “d”

“b”

“c”

2

1

“a”

3

2

1

“b”

“c”

5

“a”

“a”

I4RS0A950004-01

Page 1335 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-8

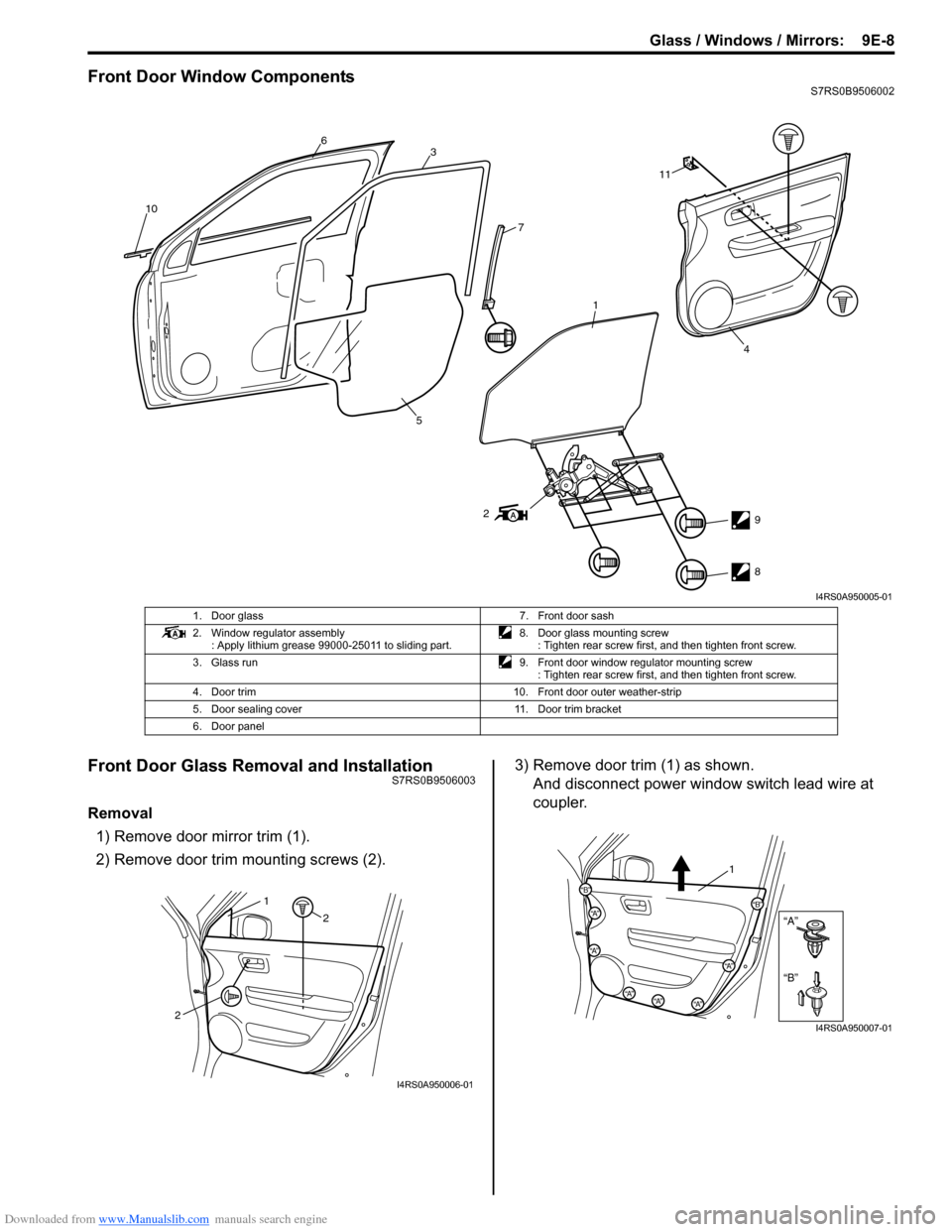

Front Door Window ComponentsS7RS0B9506002

Front Door Glass Removal and InstallationS7RS0B9506003

Removal1) Remove door mirror trim (1).

2) Remove door trim mounting screws (2). 3) Remove door trim (1) as shown.

And disconnect power window switch lead wire at

coupler.

10 6

3

1

7

11

5

2 9

8

4

I4RS0A950005-01

1. Door glass 7. Front door sash

2. Window regulator assembly : Apply lithium grease 99000-25011 to sliding part. 8. Door glass mounting screw

: Tighten rear screw first, and then tighten front screw.

3. Glass run 9. Front door window regulator mounting screw

: Tighten rear screw first, and then tighten front screw.

4. Door trim 10. Front door outer weather-strip

5. Door sealing cover 11. Door trim bracket

6. Door panel

2 2

1

I4RS0A950006-01

“B”

“A”

“B”

“A”

“B”“A”

“A”

“A”“A”“A”

1

I4RS0A950007-01

Page 1336 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-9 Glass / Windows / Mirrors:

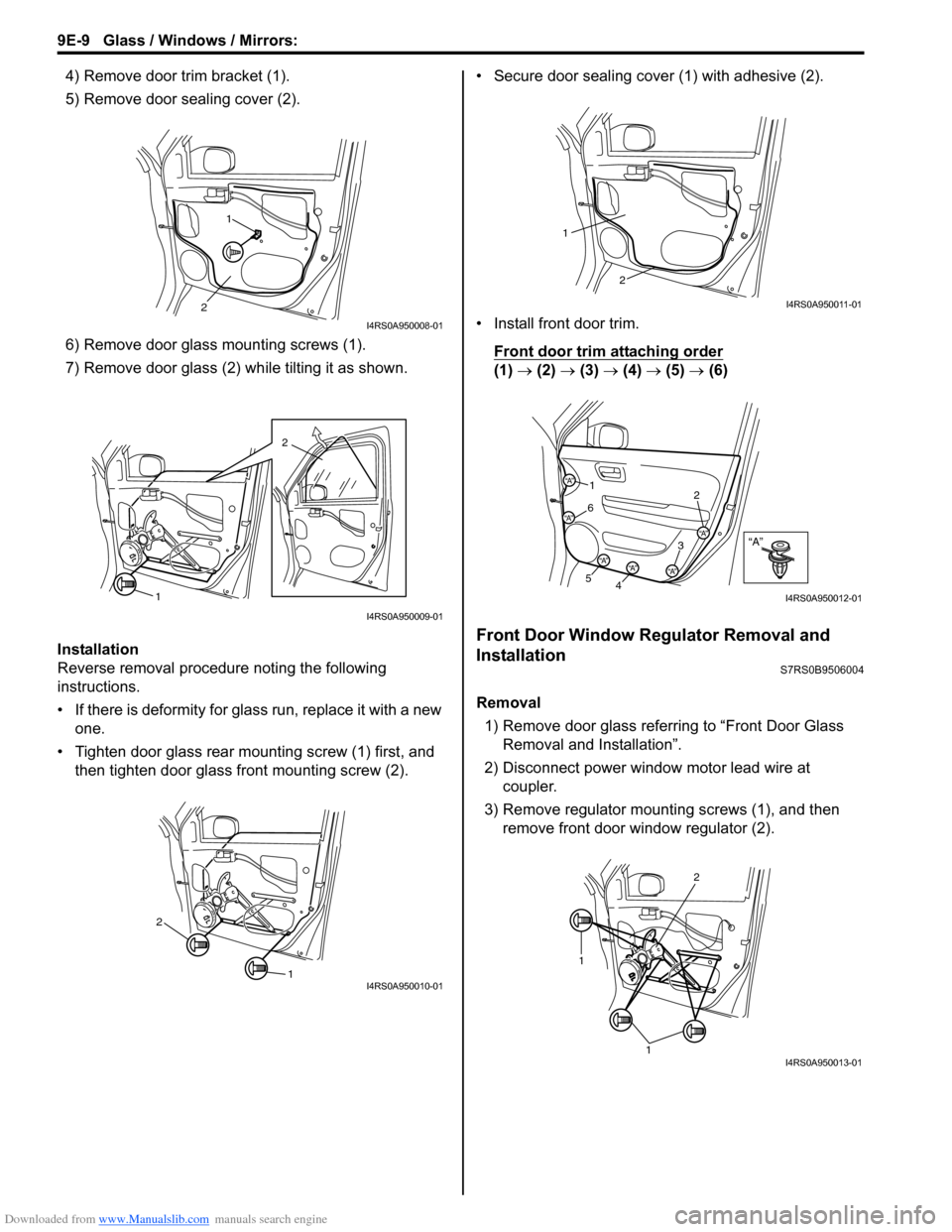

4) Remove door trim bracket (1).

5) Remove door sealing cover (2).

6) Remove door glass mounting screws (1).

7) Remove door glass (2) while tilting it as shown.

Installation

Reverse removal procedure noting the following

instructions.

• If there is deformity for glass run, replace it with a new one.

• Tighten door glass rear mounting screw (1) first, and then tighten door glass front mounting screw (2). • Secure door sealing cover (1) with adhesive (2).

• Install front door trim.

Front door trim attaching order

(1) → (2) → (3) → (4) → (5) → (6)

Front Door Window Regulator Removal and

Installation

S7RS0B9506004

Removal

1) Remove door glass referring to “Front Door Glass Removal and Installation”.

2) Disconnect power window motor lead wire at coupler.

3) Remove regulator mounting screws (1), and then remove front door window regulator (2).

1

2

I4RS0A950008-01

2

1

I4RS0A950009-01

1

2

I4RS0A950010-01

2

1

I4RS0A950011-01

“A”“A”

“A”

“A”

“A”“A”“A”

1 2

3

4

5 6

I4RS0A950012-01

1

1

2

I4RS0A950013-01

Page 1337 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-10

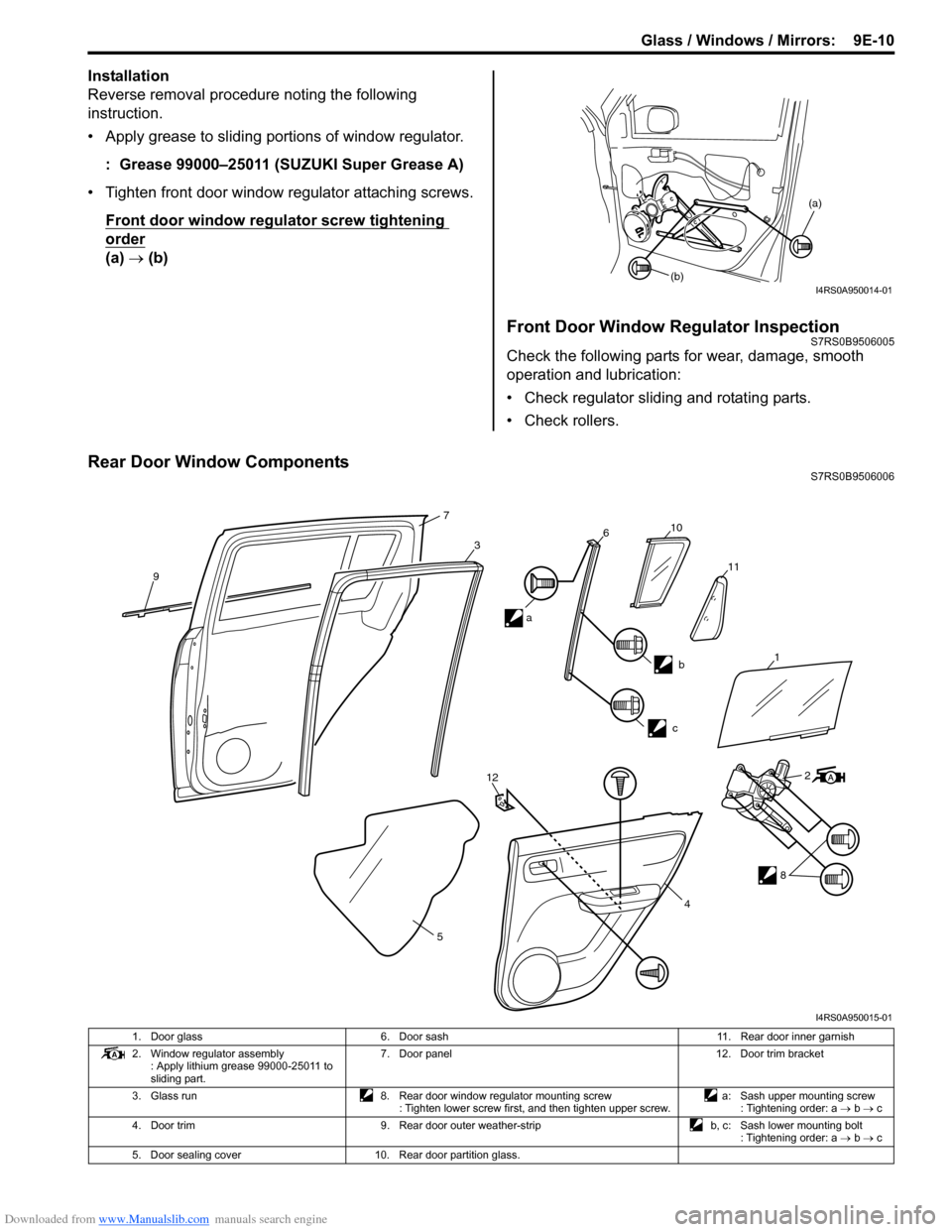

Installation

Reverse removal procedure noting the following

instruction.

• Apply grease to sliding portions of window regulator.: Grease 99000–25011 (SUZUKI Super Grease A)

• Tighten front door window regulator attaching screws. Front door window regulator screw tightening

order

(a) → (b)

Front Door Window Regulator InspectionS7RS0B9506005

Check the following parts for wear, dama ge, smooth

operation and lubrication:

• Check regulator sliding and rotating parts.

• Check rollers.

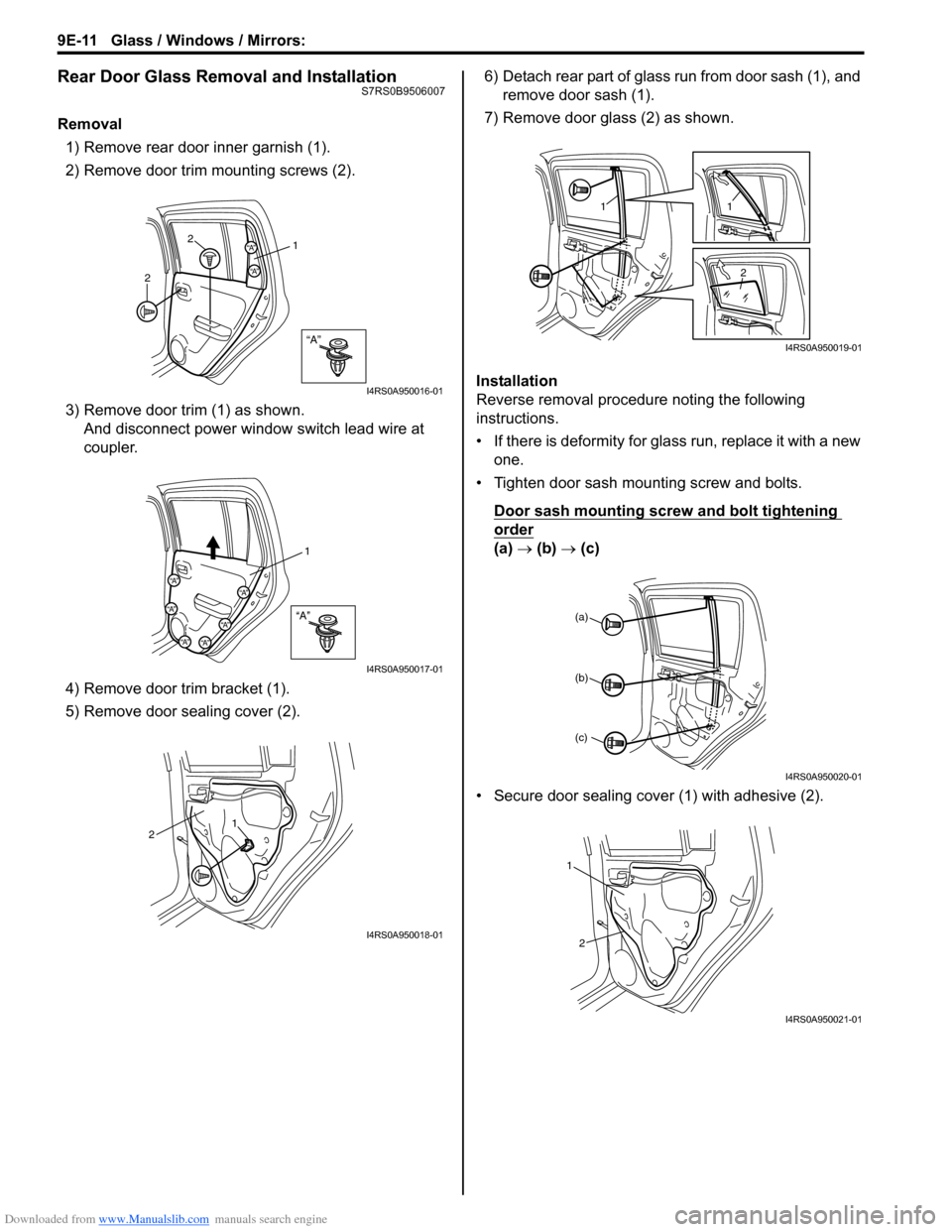

Rear Door Window ComponentsS7RS0B9506006

(a)

(b)

I4RS0A950014-01

9

7

3610

11

b

c

12

5 2

8

4

a

1

I4RS0A950015-01

1. Door glass

6. Door sash 11. Rear door inner garnish

2. Window regulator assembly : Apply lithium grease 99000-25011 to

sliding part. 7. Door panel

12. Door trim bracket

3. Glass run 8. Rear door window regulator mounting screw

: Tighten lower screw first, and then tighten upper screw. a: Sash upper mounting screw

: Tightening order: a → b → c

4. Door trim 9. Rear door outer weather-strip b, c: Sash lower mounting bolt

: Tightening order: a → b → c

5. Door sealing cover 10. Rear door partition glass.

Page 1338 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-11 Glass / Windows / Mirrors:

Rear Door Glass Removal and InstallationS7RS0B9506007

Removal1) Remove rear door inner garnish (1).

2) Remove door trim mounting screws (2).

3) Remove door trim (1) as shown. And disconnect power wi ndow switch lead wire at

coupler.

4) Remove door trim bracket (1).

5) Remove door sealing cover (2). 6) Detach rear part of glass run from door sash (1), and

remove door sash (1).

7) Remove door glass (2) as shown.

Installation

Reverse removal procedure noting the following

instructions.

• If there is deformity for glass run, replace it with a new one.

• Tighten door sash mounting screw and bolts.

Door sash mounting screw and bolt tightening

order

(a) → (b) → (c)

• Secure door sealing cover (1) with adhesive (2).

“A”

“A”

“A”

2

2 1

I4RS0A950016-01

“A”

“A”

“A”

“A”“A”

“A”

“A”

1

I4RS0A950017-01

1

2

I4RS0A950018-01

1

1

2

I4RS0A950019-01

(a)

(b)

(c)

I4RS0A950020-01

1

2

I4RS0A950021-01