Ecm SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 497 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 4-iii

ABS Warning Lamp Check ............................... 4F-14

EBD Warning Lamp (Brake Warning Lamp) Check .............................................................. 4F-15

DTC Check ....................................................... 4F-15

DTC Table ......................................................... 4F-15

DTC Clearance ................................................. 4F-18

Fail-Safe Table ................ .................................. 4F-19

Scan Tool Data ................................................. 4F-20

Visual Inspection ............................................... 4F-21

ESP ® Warning Lamp Does Not Come ON at

Ignition Switch ON .......................................... 4F-21

ESP ® Warning Lamp Comes ON Steady......... 4F-22

ABS Warning Lamp Does Not Come ON at Ignition Switch ON .......................................... 4F-23

ABS Warning Lamp Comes ON Steady............ 4F-24

EBD Warning Lamp (Brake Warning Lamp) Comes ON Steady .......................................... 4F-24

Serial Data Link Circuit Check .......................... 4F-26

DTC C1016: Stop Lamp Swit ch Circuit Failure .. 4F-28

DTC C1017 / C1023: Yaw Rate / G Sensor Assembly Failure ............................................ 4F-29

DTC C1018: Brake Fluid Le vel Switch Failure .. 4F-30

DTC 1020: Master Cylinder Pressure Sensor Power Supply Failure ...................................... 4F-31

DTC C1021, C1022 / C1025, C1026 / C1031, C1032 / C1035, C1036: Wheel Speed

Sensor Circuit or Encode r Failure ................... 4F-32

DTC C1024: Steering Angle Sensor Circuit

Failure ............................................................. 4F-34

DTC C1027: ESP ® OFF Switch Circuit

Failure ............................................................. 4F-34

DTC C1028: Master Cylinder Pressure Sensor Circuit Failure ....... .............................. 4F-35

DTC C1034: Yaw Rate / G Sensor Assembly Power Supply Failure ...................................... 4F-36

DTC C1037: Steering Angle Sensor Power Supply Failure ................................................. 4F-37

DTC C1038: Steering Angle Sensor Detect Rolling Counter Fa ilure from ESP® Control

Module ............................................................ 4F-38

DTC C1039: Yaw Rate / G Sensor Assembly Internal Failure .............. .................................. 4F-39

DTC C1040: Stability Control System Function Failure .............................................. 4F-39

DTC C1041 / C1042 / C1043 / C1044 / C1045 / C1046 / C1051 / C1052 / C1053 / C1054 /

C1055 / C1056: Solenoid Circuit Failure ......... 4F-40

DTC C1057: ESP ® Control Module Power

Supply Circuit Failure .... .................................. 4F-41

DTC C1061: Pump Motor and/or Motor Driver Circuit Failure .................................................. 4F-42

DTC C1063: Solenoid Valve Power Supply Driver Circuit Failure ....................................... 4F-43

DTC 1071: ESP ® Control Module Internal

Defect.............................................................. 4F-44 DTC C1073: Lost Communication With Yaw

Rate / G Sensor Assembly .............................. 4F-45

DTC C1075 / 1076 / 1078: Sensor Calibration Incomplete.......................... ............................. 4F-46

DTC C1090: Invalid Communication with

ECM ................................................................ 4F-47

DTC C1091 / C1094: ECM Data in CAN Line Failure / Invalid Torque Control

Communication with ECM .. ............................. 4F-48

DTC U1073: Control Module Communication Bus Off ............................................................ 4F-49

DTC U1100: Lost Communication with ECM (Reception Error)............................................. 4F-50

DTC U1126: Lost Communication with Steering Angle Sensor (Reception Error)........ 4F-51

DTC U1140: Lost Communication with BCM (Reception Error)............................................. 4F-52

Repair Instructions ........... ................................. 4F-54

ESP® Hydraulic Unit Operation Check ............. 4F-54

Sensor Calibration............................................. 4F-54

ESP® Hydraulic Unit / Control Module

Assembly On-Vehicle Inspection .................... 4F-55

ESP ® Hydraulic

Unit / Control Module

Assembly Removal and Inst allation ................ 4F-56

Front / Rear Wheel Speed Sensor On-Vehicle Inspection ........................................................ 4F-57

Front Wheel Speed Sensor Removal and Installation ....................................................... 4F-58

Front Wheel Speed Sensor Inspection ............. 4F-59

Rear Wheel Speed Sensor Removal and Installation ....................................................... 4F-59

Rear Wheel Speed Sensor Inspection .............. 4F-60

Front Wheel Encode r On-Vehicle Inspection .... 4F-61

Front Wheel Encoder Removal and Installation ....................................................... 4F-61

Rear Wheel Encoder On-Veh icle Inspection..... 4F-61

Rear Wheel Encoder Removal and Installation ....................................................... 4F-61

Master Cylinder Pressure Sensor On-Vehicle

Inspection ........................................................ 4F-61

Yaw Rate / G Sensor Assembly On-Vehicle Inspection ........................................................ 4F-62

Yaw Rate / G Sensor Assembly Removal and Installation ....................................................... 4F-63

Yaw Rate / G Sensor Inspection ....................... 4F-64

Steering Angle Sensor On-Vehicle Inspection .. 4F-64

Steering Angle Sensor Removal and Installation ....................................................... 4F-65

Steering Angle Sensor Inspection ..................... 4F-65

ESP® OFF Switch Removal an d Installation .... 4F-65

ESP® OFF Switch Inspection ........................... 4F-65

Specifications .................... ................................. 4F-66

Tightening Torque Specifications ...................... 4F-66

Special Tools and Equipmen t ........................... 4F-66

Special Tool ...................................................... 4F-66

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

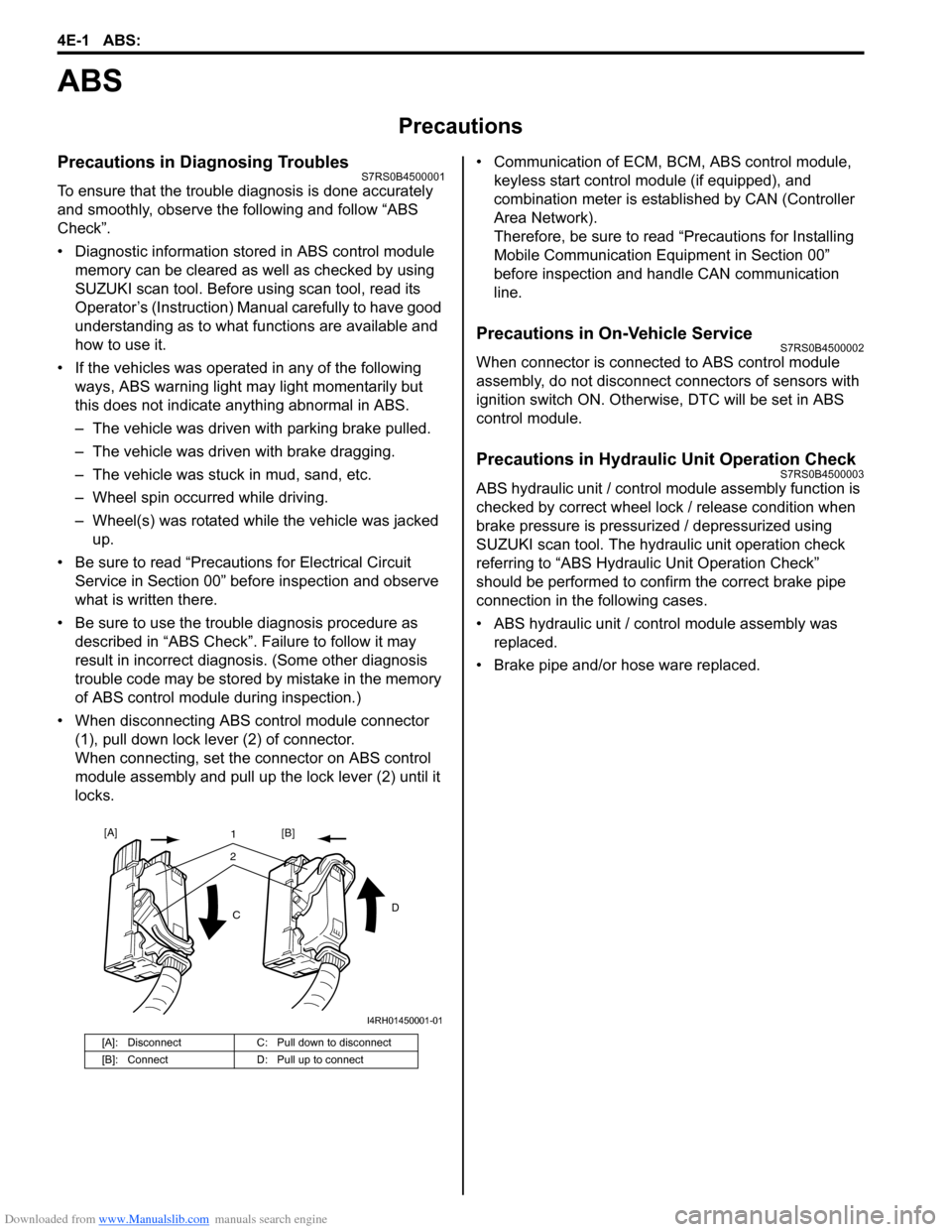

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 542 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-3 ABS:

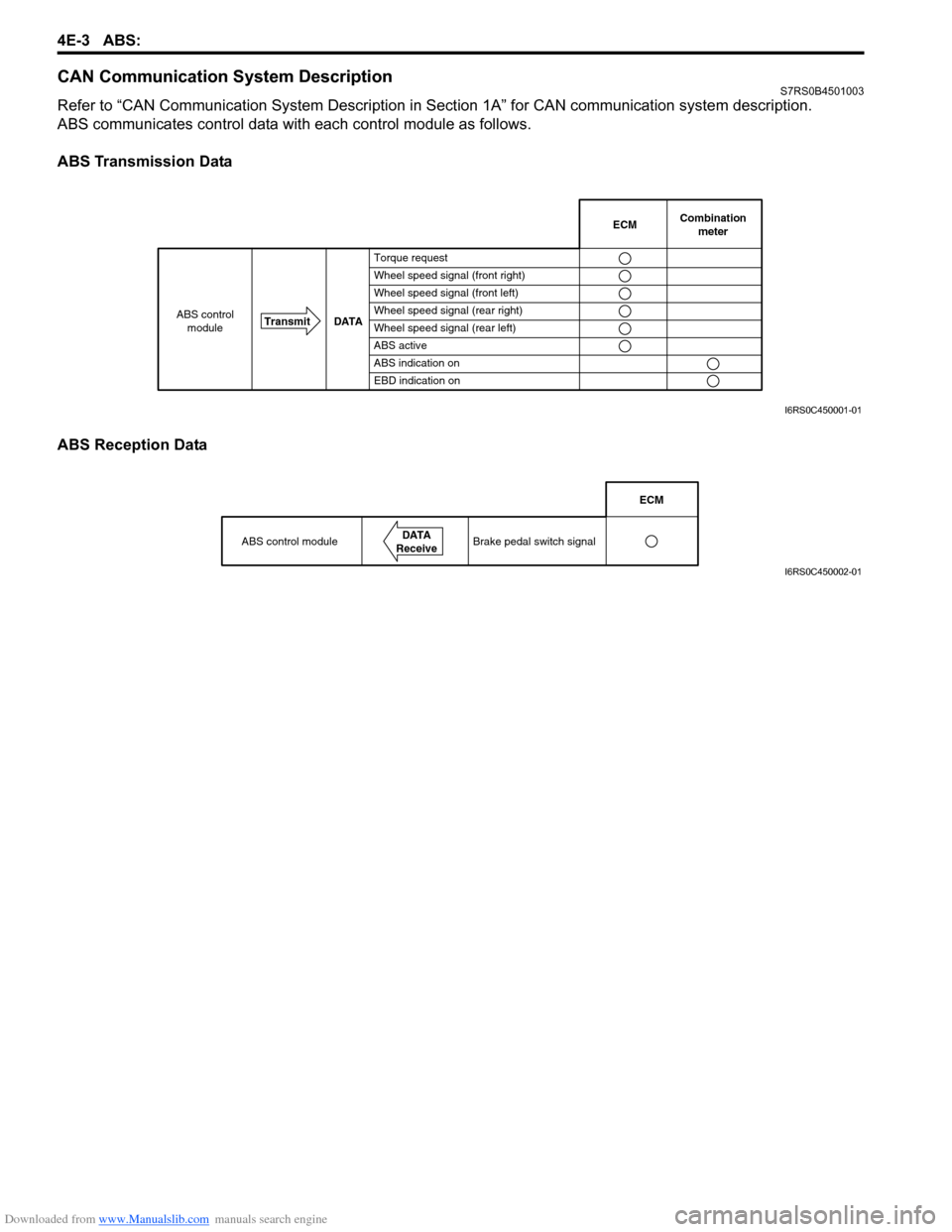

CAN Communication System DescriptionS7RS0B4501003

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

ABS communicates control data with each control module as follows.

ABS Transmission Data

ABS Reception Data

Combination

meter

Transmit DATA

ABS control

moduleECM

Torque request

Wheel speed signal (front right)

Wheel speed signal (front left)

Wheel speed signal (rear right)

Wheel speed signal (rear left)

ABS active

ABS indication on

EBD indication on

I6RS0C450001-01

ABS control moduleDATA

Receive

ECM

Brake pedal switch signal

I6RS0C450002-01

Page 543 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-4

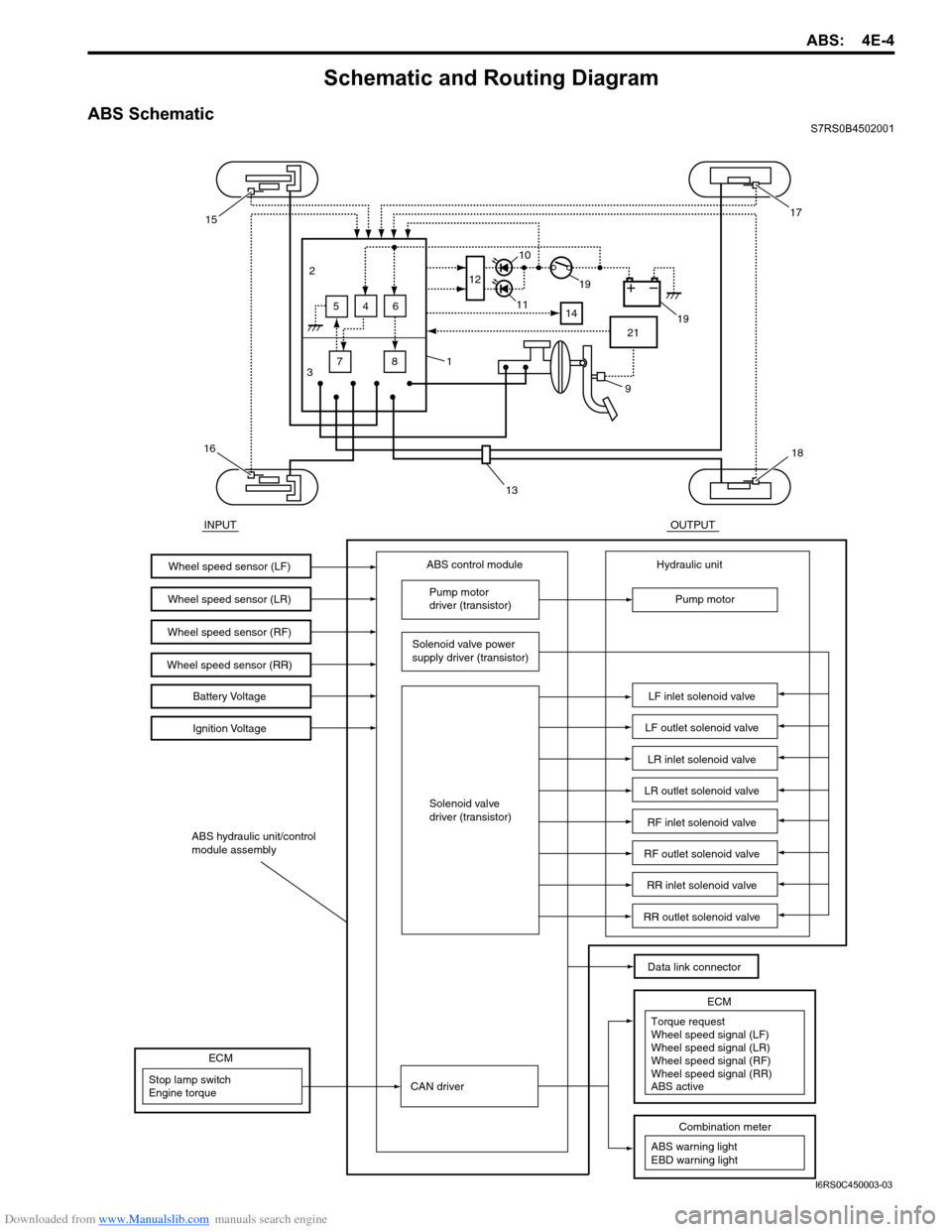

Schematic and Routing Diagram

ABS SchematicS7RS0B4502001

INPUTOUTPUT

ABS control moduleWheel speed sensor (LF)

Wheel speed sensor (LR)

Wheel speed sensor (RF)Battery Voltage

Ignition Voltage

Pump motor

driver (transistor)

Solenoid valve power

supply driver (transistor)

Solenoid valve

driver (transistor) Hydraulic unit

Pump motor

LF inlet solenoid valve

LF outlet solenoid valve

LR inlet solenoid valve

LR outlet solenoid valve

RF inlet solenoid valve

RF outlet solenoid valve

RR inlet solenoid valve

RR outlet solenoid valve

Data link connector

ABS hydraulic unit/control

module assembly

Wheel speed sensor (RR)

3 7

2

645

8 12

14

21

15

16

1

13

18

17

19

19

11

10

9

CAN driverStop lamp switch

Engine torque

ECM

ABS warning light

EBD warning light

Combination meter

Torque request

ECMWheel speed signal (LF)

Wheel speed signal (LR)

Wheel speed signal (RF)

Wheel speed signal (RR)

ABS active

I6RS0C450003-03

Page 544 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-5 ABS:

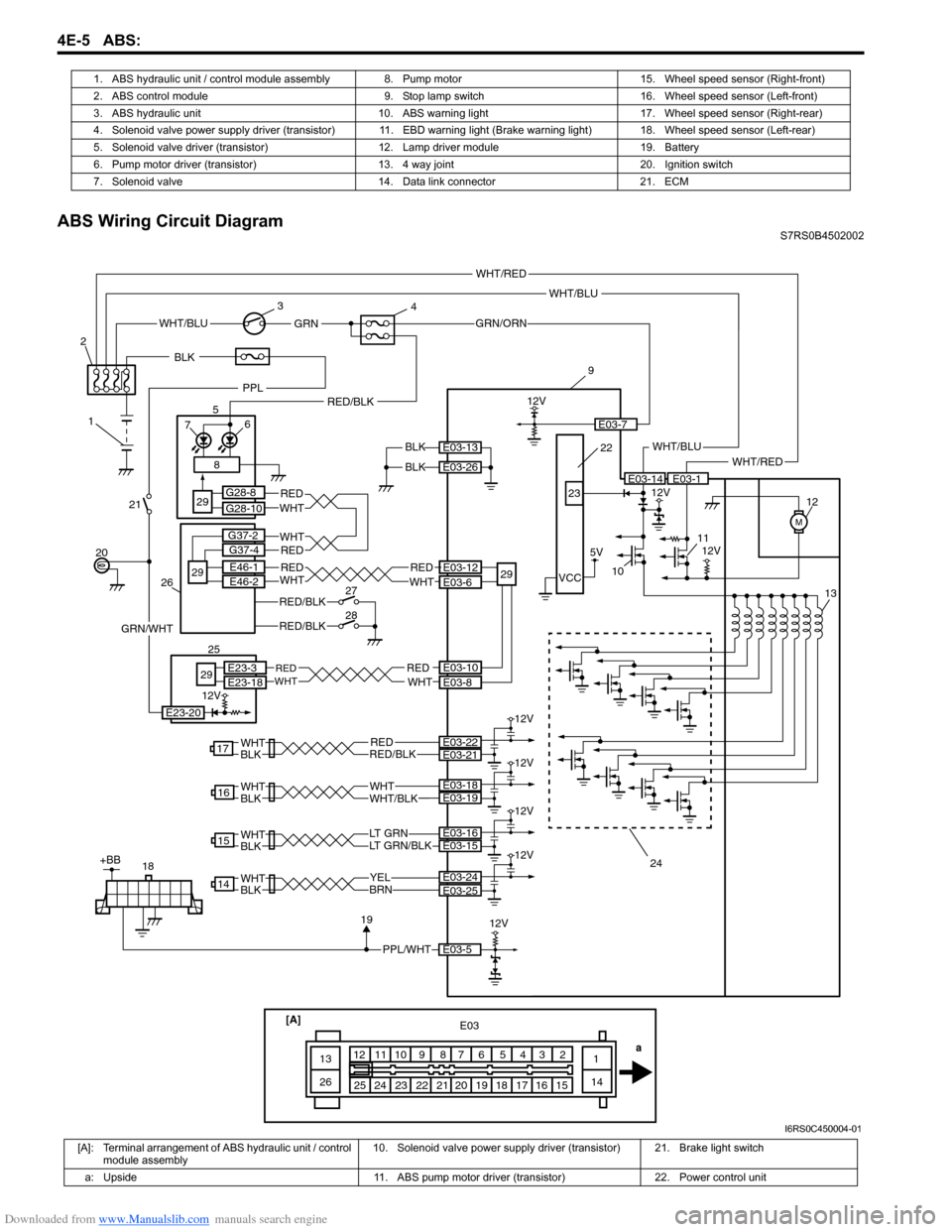

ABS Wiring Circuit DiagramS7RS0B4502002

1. ABS hydraulic unit / control module assembly 8.

Pump motor 15. Wheel speed sensor (Right-front)

2. ABS control module 9. Stop lamp switch 16. Wheel speed sensor (Left-front)

3. ABS hydraulic unit 10. ABS warning light 17. Wheel speed sensor (Right-rear)

4. Solenoid valve power supply driver (transistor) 11. EBD warnin g light (Brake warning light) 18. Wheel speed sensor (Left-rear)

5. Solenoid valve driver (transistor) 12. Lamp driver module 19. Battery

6. Pump motor driver (transistor) 13. 4 way joint 20. Ignition switch

7. Solenoid valve 14. Data link connector 21. ECM

[A]

14

1516171819202122232425 1

23456789101112

13

26 E03

a

WHT/BLU

BLKWHT/BLU

M

12V

9

10 11 12

13

BLKE03-14E03-1

E03-13

E03-26

YELBRN

14E03-24

LT GRN/BLKLT GRN

15

WHTWHT/BLK

16

RED

WHTBLK

WHTBLK

WHTBLK

WHTBLKRED/BLK

17

12V

PPL/WHT

18E03-5

1912V

5V

12V

23

24

VCC22

E03-25

E03-15E03-16

E03-19E03-18

E03-22E03-21

WHT/RED

WHT/RED

+BB

GRN/ORN

E03-7

WHT/BLUGRN

1

2

3

4

8

RED/BLK

E03-12

E03-6

RED

WHTE03-10E03-8

REDWHT

20 7

6

529

29

G28-8

G28-10

25

29

E23-3E23-18

GRN/WHT

21

PPL

12V

E23-20

12V

12V

12V

12V

REDWHTE46-1

E46-2

BLK

RED/BLK

RED/BLK

RED

RED

WHT

WHT

27

28

26

29

G37-2

G37-4

REDWHT

I6RS0C450004-01

[A]: Terminal arrangement of ABS hydraulic unit / control module assembly 10. Solenoid valve power supply driver

(transistor) 21. Brake light switch

a: Upside 11. ABS pump motor driver (transistor) 22. Power control unit

Page 545 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

1. Battery12. Pump motor23. Internal memory

2. Main fuse box 13. Solenoid valves24. Solenoid valve driver (transistor)

3. Ignition switch 14. Right-rear wheel speed sensor25. ECM

4. Circuit fuse box 15. Left-rear wheel speed sensor26. BCM

5. Combination meter 16. Right-front wheel speed sensor27. Brake fluid level switch

6. ABS warning light 17. Left-front wheel speed sensor28. Parking brake switch

7. EBD warning light (Brake warning light) 18. Data link connector29. CAN driver

8. Lamp driver module 19. To ECM, SDM and BCM

9. ABS hydraulic unit / control module assembly 20. Stop lamp

Terminal Wire color Circuit

E03 1

WHT/RED ABS pump motor driver (Transistor)

2— —

3— —

4— —

5 PPL/WHT Data link connector

6 WHT CAN communication line (low) for BCM

7 GRN/ORN Ignition switch

8 WHT CAN communication line (low) for ECM

9— —

10 RED CAN communication line (high) for ECM

11 — —

12 RED CAN communication line (high) for BCM

13 BLK Ground

14 WHT/BLU Solenoid valve power supply driver (Transistor)

15 LT GRN/BLK Left–rear wheel speed sensor (–)

16 LT GRN Left–rear wheel speed sensor (+)

17 — —

18 WHT Right–front wheel speed sensor (+)

19 WHT/BLK Right–front wheel speed sensor (–)

20 — —

21 RED/BLK Left–front wheel speed sensor (–)

22 RED Left–front wheel speed sensor (+)

23 — —

24 YEL Right–rear wheel speed sensor (+)

25 BRN Right–rear wheel speed sensor (–)

26 BLK Ground

Page 546 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-7 ABS:

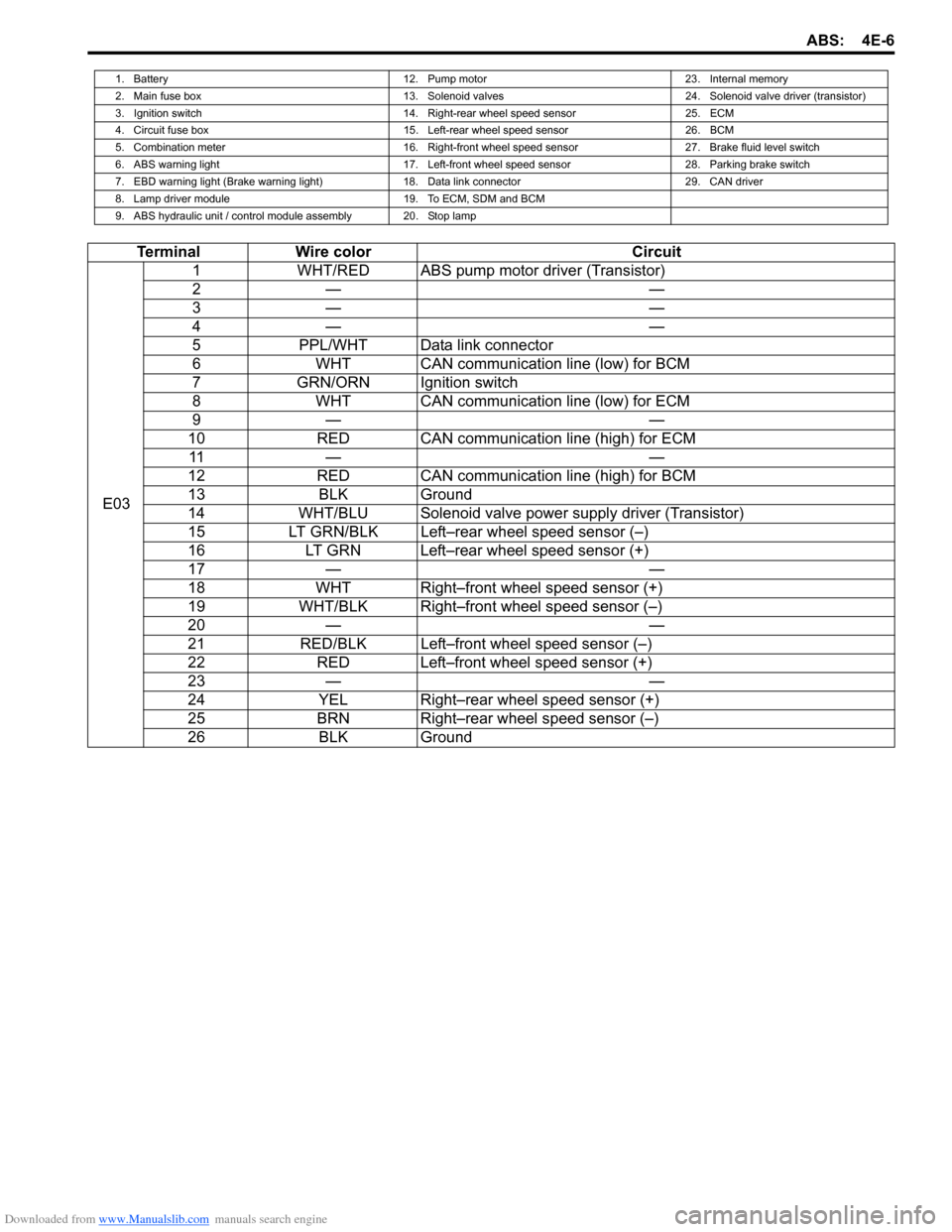

Component Location

ABS Components LocationS7RS0B4503001

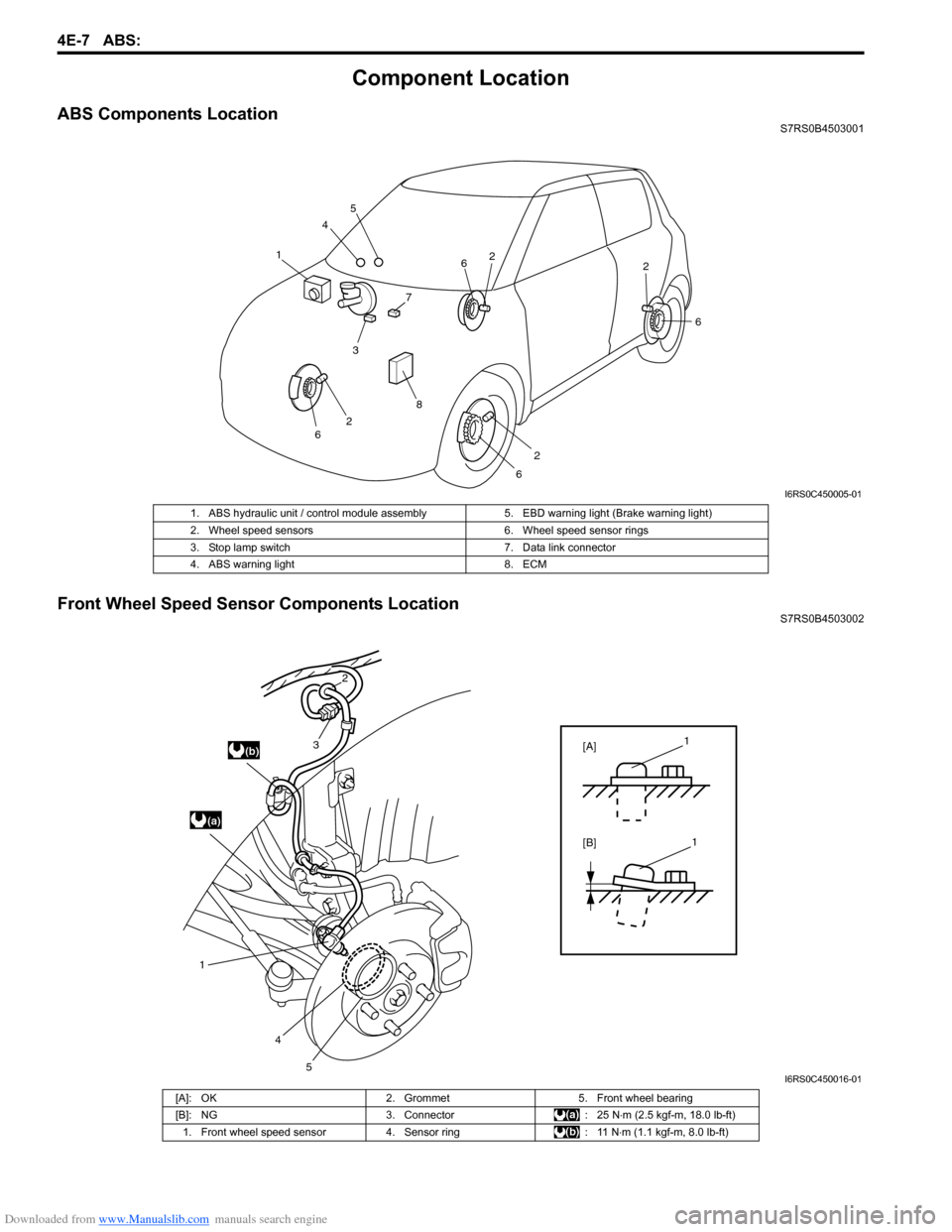

Front Wheel Speed Sensor Components LocationS7RS0B4503002

14

5

3

2 2

2

2

6

6

6

6

7

8

I6RS0C450005-01

1. ABS hydraulic unit / control module assembly

5. EBD warning light (Brake warning light)

2. Wheel speed sensors 6. Wheel speed sensor rings

3. Stop lamp switch 7. Data link connector

4. ABS warning light 8. ECM

[A]

[B]

1 1

2

3

4

1

(a)

(b)

5I6RS0C450016-01

[A]: OK 2. Grommet5. Front wheel bearing

[B]: NG 3. Connector: 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

1. Front wheel speed sensor 4. Sensor ring: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

Page 550 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-11 ABS:

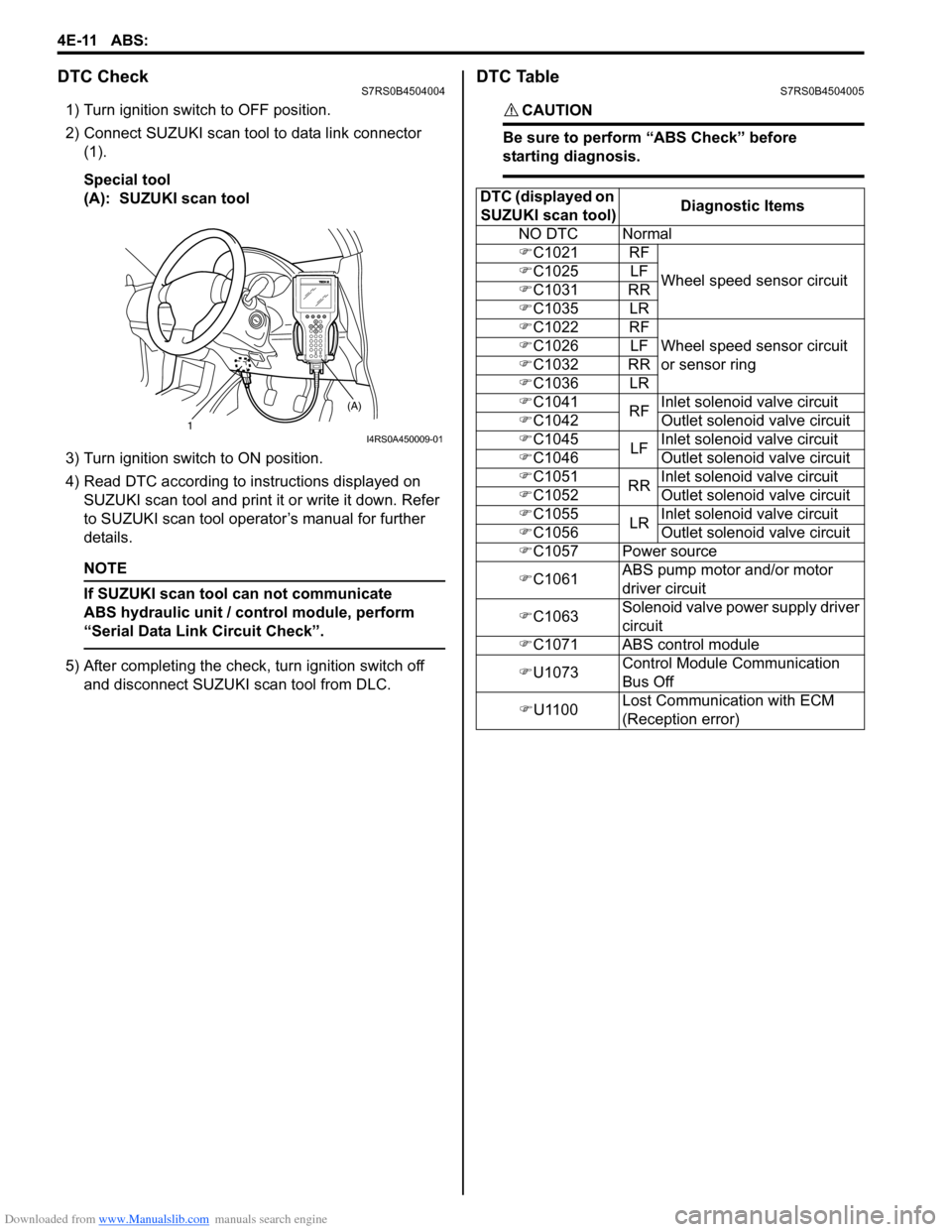

DTC CheckS7RS0B4504004

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (1).

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

NOTE

If SUZUKI scan tool can not communicate

ABS hydraulic unit / control module, perform

“Serial Data Link Circuit Check”.

5) After completing the check, turn ignition switch off and disconnect SUZUKI scan tool from DLC.

DTC TableS7RS0B4504005

CAUTION!

Be sure to perform “ABS Check” before

starting diagnosis.

1 (A)I4RS0A450009-01

DTC (displayed on

SUZUKI scan tool) Diagnostic Items

NO DTC Normal

�) C1021 RF

Wheel speed sensor circuit

�)

C1025 LF

�) C1031 RR

�) C1035 LR

�) C1022 RF

Wheel speed sensor circuit

or sensor ring

�)

C1026 LF

�) C1032 RR

�) C1036 LR

�) C1041

RFInlet solenoid valve circuit

�) C1042 Outlet solenoid valve circuit

�) C1045

LFInlet solenoid valve circuit

�) C1046 Outlet solenoid valve circuit

�) C1051

RRInlet solenoid valve circuit

�) C1052 Outlet solenoid valve circuit

�) C1055

LRInlet solenoid valve circuit

�) C1056 Outlet solenoid valve circuit

�) C1057 Power source

�) C1061 ABS pump motor and/or motor

driver circuit

�) C1063 Solenoid valve power supply driver

circuit

�) C1071 ABS control module

�) U1073 Control Module

Communication

Bus Off

�) U1100 Lost Communication with ECM

(Reception error)

Page 555 of 1496

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

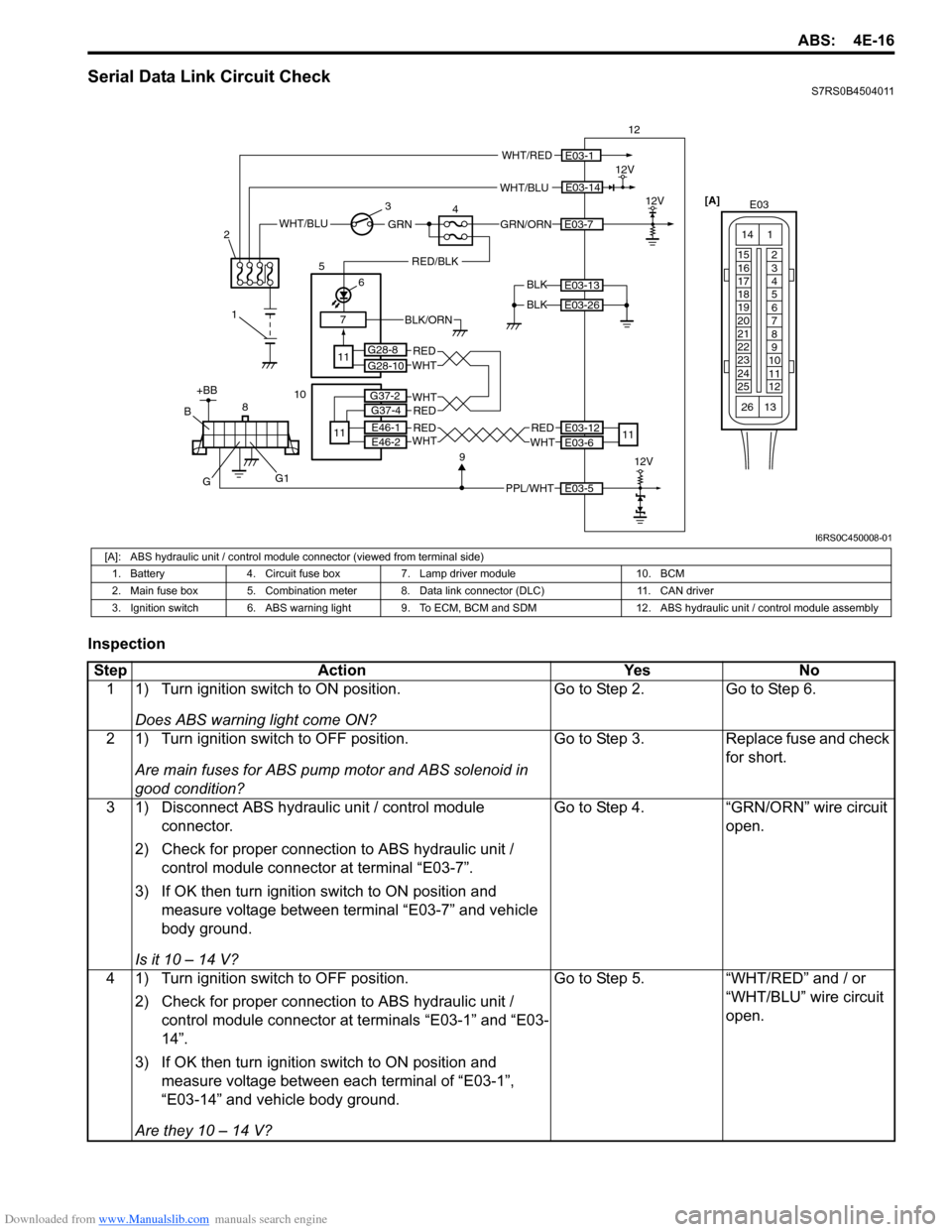

Serial Data Link Circuit CheckS7RS0B4504011

Inspection

WHT/BLU

BLK12V

12

BLK

E03-14

E03-13

E03-26

WHT/RED

GRN/ORNE03-7WHT/BLUGRN

1

2

3

47

RED/BLK

6

5

11

E03-112V

[A]

E03

15

16

17

18

19

20

21

22

23

24

25 2

3

4

5

6

7

8

9

10

11

12

1

13

14

26

BLK/ORN

PPL/WHT

8E03-5

912V

+BB

G

B

G1

E03-12

E03-6

REDWHT

11

G28-8

G28-10

REDWHTE46-1

E46-2RED

RED

WHT

WHT

10

11

G37-2

G37-4

I6RS0C450008-01

[A]: ABS hydraulic unit / control module connector (viewed from terminal side)

1. Battery 4. Circuit fuse box 7. Lamp driver module 10. BCM

2. Main fuse box 5. Combination meter 8. Data link connector (DLC) 11. CAN driver

3. Ignition switch 6. ABS warning light 9. To ECM, BCM and SDM 12. ABS hydraulic unit / control module assembly

Step Action YesNo

1 1) Turn ignition switch to ON position.

Does ABS warning light come ON? Go to Step 2.

Go to Step 6.

2 1) Turn ignition switch to OFF position. Are main fuses for ABS pump motor and ABS solenoid in

good condition? Go to Step 3.

Replace fuse and check

for short.

3 1) Disconnect ABS hydraulic unit / control module connector.

2) Check for proper connection to ABS hydraulic unit / control module connector at terminal “E03-7”.

3) If OK then turn ignition switch to ON position and measure voltage between terminal “E03-7” and vehicle

body ground.

Is it 10 – 14 V? Go to Step 4.

“GRN/ORN” wire circuit

open.

4 1) Turn ignition switch to OFF position. 2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-1” and “E03-

14”.

3) If OK then turn ignition switch to ON position and measure voltage between each terminal of “E03-1”,

“E03-14” and vehicle body ground.

Are they 10 – 14 V? Go to Step 5.

“WHT/RED” and / or

“WHT/BLU” wire circuit

open.

Page 556 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

5 1) Turn ignition switch to OFF position.2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK, measure resistance between each terminal of “E03-13”, “E03-26” and vehicle body ground.

Are resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 1) Check if communication is possible by trying communication with other controller (ECM, BCM or

SDM).

Is it possible to commun icate with other controller? Go to Step 7. Repair open in common

section of serial data

circuit (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

7 1) Turn ignition switch to ON position.

2) Measure voltage between terminal B of data link connector and vehicle body ground.

Is voltage 10 – 12 V? Go to step 8. Terminal B circuit open

or shorted to ground.

8 1) Turn ignition switch to OFF position. 2) Measure resistance between the following terminals;• Terminal G of data link connector and vehicle body ground.

• Terminal G1 of data link connector and vehicle body ground.

Is each resistance 1

Ω or less? Go to step 9. Terminal G and/or G1

circuit open or high

resistance.

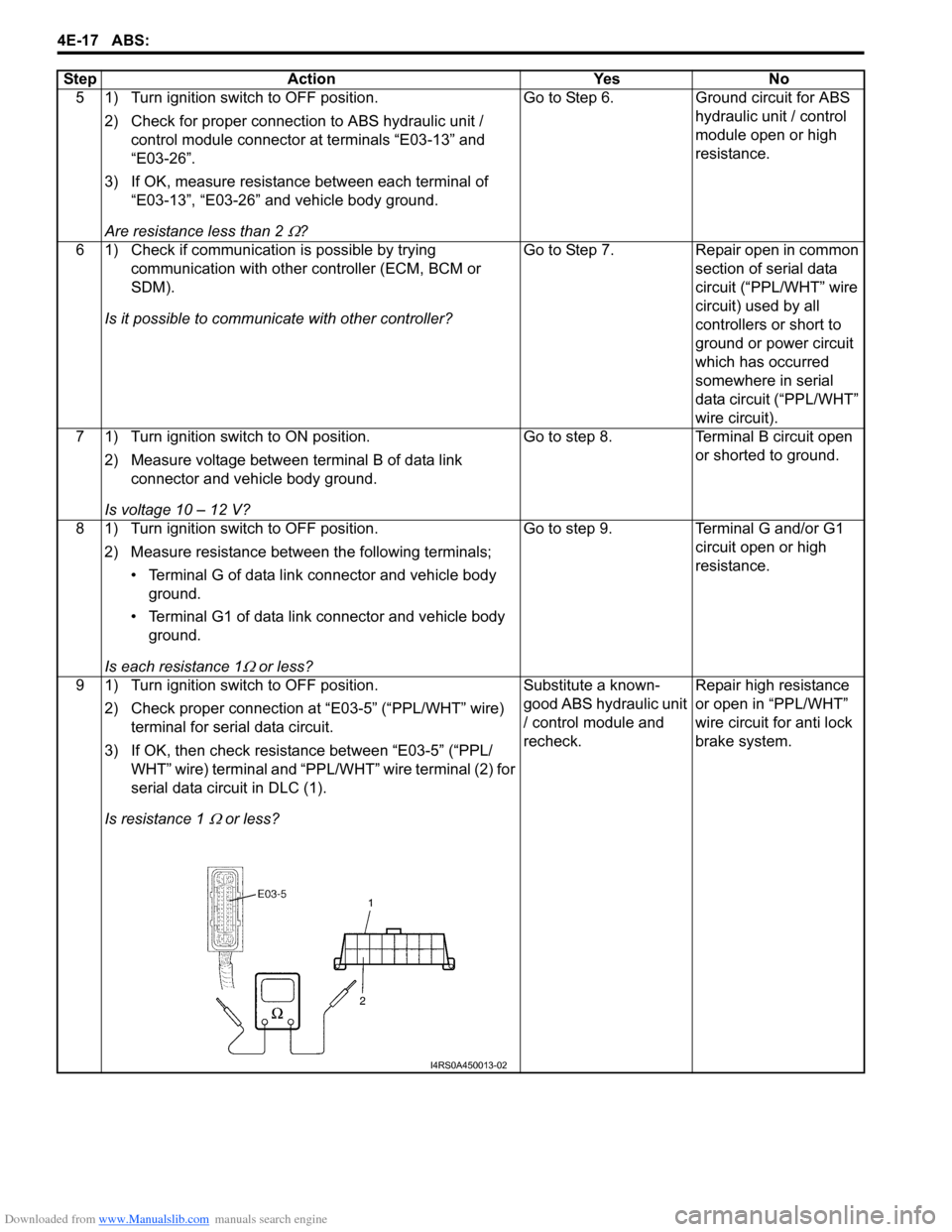

9 1) Turn ignition switch to OFF position. 2) Check proper connection at “E03-5” (“PPL/WHT” wire) terminal for serial data circuit.

3) If OK, then check resistance between “E03-5” (“PPL/ WHT” wire) terminal and “PPL/WHT” wire terminal (2) for

serial data circuit in DLC (1).

Is resistance 1

Ω or less? Substitute a known-

good ABS hydraulic unit

/ control module and

recheck.

Repair high resistance

or open in “PPL/WHT”

wire circuit for anti lock

brake system.

Step Action Yes No

I4RS0A450013-02